Académique Documents

Professionnel Documents

Culture Documents

Montaza Sarki

Transféré par

CaneTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Montaza Sarki

Transféré par

CaneDroits d'auteur :

Formats disponibles

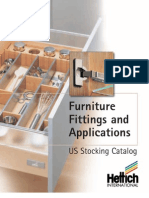

Programme overview Group 2 2.0.

1

Programme overview

Group 2

2.1 Design principle System 32

2.1.0 - 2.1.3

2.2 Automatic drilling and insertion machines Blue Max

Range summary 2.2.4 i

2.3 Assembly aids, drilling jigs and hole-marking templates

Range summary 2.3.0 - 2.3.1 i

2.4 Drills and bits

Range summary 2.4.1 i

Design principle

System 32

Design principle System 32 www.hettich.com 2.1.0

32

32

32

32

32

32

5

37

32

32

32

32

32

32

N x 32

The international standard for furniture construction

Allows for hole line and fitting and assembles

these to create a constructional unit

Saves time and money in work preparation, production

and assembly

Ideal for production processes involving CNC, automatic drilling

machines and drilling jigs

Design principle System 32

Hole distance : 32 mm

Drilling diameter: 5 mm

Hole-centre distance from hole line to front edge of side: 37 mm

(sealing lips, bumper etc. belong to the front edge of the side, are

included in the 37 mm dimension and must be taken into account

when cutting to size and drilling)

Hole-centre distance in vertical hole lines:

divisible by 32

Beneficial:

- The first and last drill hole in a hole line is equidistant from the

upper and lower edge of the side

- The distance between the rear edge of the side and rear hole line

is also 37 mm

Units 0 1 2 3 4 5 6 7 8 9

Tens

0 0 32 64 96 128 160 192 224 256 288

1 320 352 384 416 448 480 512 544 576 608

2 640 672 704 736 768 800 832 864 896 928

3 960 992 1024 1056 1088 1120 1152 1184 1216 1248

4 1280 1312 1344 1376 1408 1440 1472 1504 1536 1568

5 1600 1632 1664 1696 1728 1760 1792 1824 1856 1888

6 1920 1952 1984 2016 2048 2080 2112 2144 2176 2208

7 2240 2272 2304 2336 2368 2400 2432 2464 2496 2528

8 2560 2592 2624 2656 2688 2720 2752 2784 2816 2848

9 2880 2912 2944 2976 3008 3040 3072 3104 3136 3168

Design principle System 32 2.1.1

Design principle

System 32

Cam fittings

Rastex

Cam fittings

VB

Quadro runner systems

Roller runner systems

A wide range of different

fittings are mounted in

System 32 hole lines:

Connecting screws Back panel connectors Connecting angle

Fittings for office organisation Hinge systems Intermat / Ecomat,

Slide-on and Minimat

Flap stays

Leveller Shelf support Wardrobe tube bearing Even handles are mounted within

the 32 mm hole pattern

!

Design principle

System 32

Example application

Design principle System 32 www.hettich.com 2.1.2

Door stop

A = distance from upper edge of door to

centre of hinge cup

B = distance from upper edge of side to centre of dowel

F = door overhang or door reveal

X = multiple of 32 mm

Formula for calculation of hinge distance:

A = B + X - 16

9,5 + 96 - 16 = 89,5 mm

A desired door reveal F is to be subtracted.

A desired door overhang F is to be added.

19

10 30

9,5

32 10

9,5

9,5

32 37

5

9,5

5

B

8

X

F

A

F

16

32

37

Hole line and connecting fitting

When processing panels ensure that:

The position of the dowel drilling in the edge of

the top and bottom panels corresponds with

the data given in the catalogue!

Example of connecting fitting VB 20:

distance = 9,5 mm

Design principle System 32 2.1.3

Design principle

System 32

Example application

Advantage to the cabinet maker:

There is no longer any need to

differentiate between a left and

right unit side, since the upper and

lower hole positions are identical.

Constructing a cabinet side

X/Y = multiple of 32 mm

B = hole distance from side upper or

lower edge to centre of dowel

E.g., for 19 mm shelf thickness :

B = 9,5 mm

Calculation of cabinet side:

Height= X + (2 x B)

Width = Y + (2 x 37 mm)

Y

B

X

B

B

37 37

19

9,5

9,5

19

9,5

22,5

32

9,5

Height

Plinth

Plinth

Depth

For dimension X, 1984 is

selected from the table.

The cabinet height is therefore

1984 + (2 x 9,5) = 2003 mm.

For dimension Y (600 - 2 x 37),

512 mm is selected from the pattern

table. The cabinet depth is therefore

512 + (2 x 37) = 586 mm.

Example:

Desired height approx. 2000 mm

Desired depth approx. 600 mm

Connecting fitting VB

20 - 19 mm shelves

Units 0 1 2 3 4 5 6 7 8 9

Tens

0 0 32 64 96 128 160 192 224 256 288

1 320 352 384 416 448 480 512 544 576 608

2 640 672 704 736 768 800 832 864 896 928

3 960 992 1024 1056 1088 1120 1152 1184 1216 1248

4 1280 1312 1344 1376 1408 1440 1472 1504 1536 1568

5 1600 1632 1664 1696 1728 1760 1792 1824 1856 1888

6 1920 1952 1984 2016 2048 2080 2112 2144 2176 2208

7 2240 2272 2304 2336 2368 2400 2432 2464 2496 2528

8 2560 2592 2624 2656 2688 2720 2752 2784 2816 2848

9 2880 2912 2944 2976 3008 3040 3072 3104 3136 3168

X = 1984 + (2 x 9,5) = 2003 mm Y = 512 + (2 x 37) = 586 mm

Automatic drilling and insertion machines

Blue Max

Automatic drilling and insertion machines Blue Max www.hettich.com 2.2.0

Blue Max mini

Elementary functions

For stationary use in the workshop

and for mobile use

on the construction site

Blue Max provides the right

solution to any requirement

Blue Max Modular

Functions in 5 configurations

For precision results

in the workshop

For details on equipment, see page 2.2.2

Automatic drilling and insertion machines Blue Max 2.2.1

Automatic drilling and insertion machines

Blue Max on the Internet

Would you like further

details on Blue Max?

www.hettich.com/bluemax

On the Internet, you will find:

Operating instructions

Videos on using Blue Max

Tips, tricks and answers to FAQs

Instructions on constructing practical base units, with

component drawings and part lists in PDF format for

downloading and as data packages for importing into

Selection Professional (for individually tailored adjustments)

Training opportunities available

and more ...

Summary of functions

Modular drilling and insertion machine Blue Max

Automatic drilling and insertion machines Blue Max www.hettich.com 2.2.2

Depth adjustment of up to 550 mm

facilitates the machining of large workpieces

Caterpillar drive for hole lines with individually adjustable cam

actuation for variable hole line patterns

2250 mm side adjustment is

used exactly and quickly

simply by repositioning the

handle and turning the

spindle. There is no need to

move the workpiece!

Interchangeable drilling units provide the capability

of adapting hole patterns and save resetting time.

Workpieces are machined quickly and in full.

Hinges: Drill holes/press-in type

Mounting plates: Drill holes/press-in type

Connecting fittings: Drill holes/press-in type

Runners: Drill holes

System 32 hole lines: Drill holes

Blue Max Modular

always the right solution

Automatic drilling and insertion machines Blue Max 2.2.3

Summary of functions

Modular drilling and insertion machine Blue Max

Fast and

straightforward

setting of the

drilling depth

Straightforward machine

setting for quickly optimising

various work operations

Optimum travel

for drilling and inserting

Shorter distances

for hole-line drillings with

continuation stop

Digital display of hole pattern

to the accuracy of one tenth of

a millimetre

The 5-spindle horizontal drilling unit allows

you to drill holes for connecting fittings and

wooden dowels at one and the same time

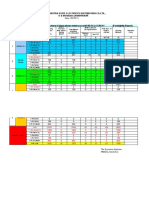

Range summary/Technical comparison

Automatic drilling and insertion machines Blue Max

Automatic drilling and insertion machines Blue Max www.hettich.com 2.2.4

Professional

2.2.5

Advanced Plus

2.2.6

Advanced

2.2.7

Basic Plus

2.2.8

Basic

2.2.9

i

Blue Max Modular

Page number

Vertical drilling

Motor power rating 1,6 kW (2,1 HP)

400 V/50 Hz/3 -phase

Connection for chip extractor,

diameter mm

Mechanism for interchangeable drilling units,

for using different drilling units

Use of drilling units for hole lines,

up to 19 spindles

Use of drilling units for hole lines,

up to 19 spindles,

90 rotation

Use of drilling units for hinges,

connecting fittings and hole lines,

up to 3 spindles,

90 rotation

560 x 3000

Work bench

Dimensions mm 560 x 3000 300 x 3000 560 x 800 300 x 800

Pneumatic

device for holding workpiece down

Depth adjustment

Depth adjustment 90 mm

Depth adjustment 550 mm

LCD depth position display

Side adjustment

2250 mm side adjustment

using sliding carriage

LCD side position display

Pneumatic caterpillar drive for

automatic lateral traversal

Aluminium fence

with indexing in mm and inch

Horizontal drilling

Horizontal drilling unit

for end-face dowel holes,

5 spindles, with quick-change chuck,

motor power 0,75 kW (1 HP)

Can be

retrofitted

Can be

retrofitted

Can be

retrofitted

Can be

retrofitted

Connection for chip extractor,

diameter 100 mm

Can be

retrofitted

Can be

retrofitted

Can be

retrofitted

Can be

retrofitted

= included

= not possible

Blue Max mini

Practical, small and suitable even for mobile use

2.2.16 - 2.2.21

!

100 100 100 100 80

Automatic drilling and insertion machines Blue Max 2.2.5

Automatic drilling and insertion machine

Blue Max Modular Professional

with caterpillar drive and horizontal drilling unit

Needs to be ordered separately

For drilling units and optional accessories,

see pages 2.2.10 - 2.2.15

Pneumatic caterpillar drive Horizontal boring unit

Special features of this equipment option

For interchangeable drilling unit

Straightforward machine setting

Pneumatic hold-down clamp

550 mm depth adjustment with LCD display

2250 mm side adjustment with LCD display

Pneumatic caterpillar drive for automatic

lateral traversal = for even greater work efficiency

5-spindle horizontal drilling unit

for end-face dowel holes

Article Order no. PU

with horizontal boring unit 9 079 441 1

without horizontal boring unit 9 083 833 1 !

Automatic drilling and insertion machine

Blue Max Modular Advanced Plus

with side and depth adjustment

Automatic drilling and insertion machines Blue Max www.hettich.com 2.2.6

Special features of this equipment option

For interchangeable drilling unit

Straightforward machine setting

Pneumatic hold-down clamp

2250 mm side adjustment with LCD display

Plus 550 mm depth adjustment

with LCD display for exact positioning

Wide range of adjustment options

for complete workpiece machining

Order no. PU

9079440 1

Needs to be ordered separately

For drilling units and optional accessories,

see pages 2.2.10 - 2.2.15

Depth adjustment

Automatic drilling and insertion machines Blue Max 2.2.7

Automatic drilling and insertion machine

Blue Max Modular Advanced

with side adjustment

Special features of this equipment option

For interchangeable drilling unit

Straightforward machine setting

Pneumatic hold-down clamp

Large work bench and 2250 mm lateral adjustment range

for drilling and insertion unit:

Hardly any need to move workpieces

Rotatable, individually adjustable latch-lever profile

for four different basic settings

LCD display for exact positioning of hole pattern

Needs to be ordered separately

For drilling units and optional accessories,

see pages 2.2.10 - 2.2.15

Order no. PU

9079439 1

Side adjustment

Automatic drilling and insertion machine

Blue Max Modular Basic Plus

for interchangeable drilling unit with depth adjustment

Automatic drilling and insertion machines Blue Max www.hettich.com 2.2.8

Special features of this equipment option

For interchangeable drilling unit

Straightforward machine setting

Pneumatic hold-down clamp

Plus 550 mm depth adjustment

with LCD display for exact positioning

Additional adjustment capabilities

for machining workpieces

Needs to be ordered separately

For drilling units and optional accessories,

see pages 2.2.10 - 2.2.15

Order no. PU

9079438 1

Depth adjustment

Automatic drilling and insertion machines Blue Max 2.2.9

Automatic drilling and insertion machine

Blue Max Modular Basic

for interchangeable drilling unit

Interchangeable drilling units save resetting time:

Simply change the drilling unit instead of the inconvenience

and time-consuming process of changing drill bits

Straightforward machine setting for optimising

various work operations

Pneumatic hold-down clamp

Needs to be ordered separately

For drilling units and optional accessories,

see pages 2.2.10 - 2.2.15

Order no. PU

9079436 1

Interchangeable drilling unit

Interchangeable drilling unit

for Blue Max Modular

Automatic drilling and insertion machines Blue Max www.hettich.com 2.2.10

Interchangeable drilling unit for System 32 hole line

For depthwise hole-line drillings and hardware drillings

Suitable for equipping with continuation stops

Continuation stop

For Blue Max Modular interchangeable

drilling unit with 9 or 19 spindles

Order no. PU

9 079 480 1 set

Needs to be ordered separately

For drilling pins, see page 2.2.15

9 spindles

19 spindles

Number of spindles Order no. PU

9 without quick-change chuck 9 079 506 1

19 without quick-change chuck 9 079 508 1

9 with quick-change chuck 9 083 835 1

19 with quick-change chuck 9 083 836 1

32

R L R L R R L R L

18 x 32 = 576

32

R L R L R R L R L

8 x 32 = 256

!

!

!

Automatic drilling and insertion machines Blue Max 2.2.11

Interchangeable drilling unit

for Blue Max Modular Professional with caterpillar drive

Interchangeable drilling unit for System 32 hole line

with 5 spindles

For automatic hole lines drillings

Adapted for working with

pneumatic caterpillar drive

for automatic lateral traversal

Horizontal boring unit

with 5-spindle boring head

With quick release chucks

For frontal drilling, e.g. dowel holes

Order no. PU

9 079 478 1

Article Order no. PU

without quick-change chuck 9 079 482 1

with quick-change chuck 9 084 003 1

R

32

4 x 32 = 128

R L R L

R

32

4 x 32 = 128

R L R L

!

!

!

Interchangeable drilling unit

for Blue Max Modular

Automatic drilling and insertion machines Blue Max www.hettich.com 2.2.12

52

5,5

C

L

R

L

Interchangeable drilling unit for hinges

For hinge hole pattern T43,

e.g.Intermat, Ecomat and Slide-on hinge ranges

(interchangeable drilling unit for other hinge drilling

patterns on request)

Prepared for press-in mounting frame

Order no. PU

9 079 477 1

Order no. PU

0 061 256 1

Interchangeable drilling unit for System 32 hole line

with 4 spindles

With quick-change chuck for fast changeover

E.g. for mounting VB connecting fittings, InLine

mounting plates for hinges,

MultiTech drawer-front connectors etc.

Prepared for press-in mounting frame

Spare quick-change chuck

Order no. PU

0 040 657 1

Chuck plug

For quick-change chuck

Plastic red

R L L

32 32

32

Article Order no. PU

without quick-change chuck 9 079 509 1

with quick-change chuck 9 083 837 1

2.2.12

!

Automatic drilling and insertion machines Blue Max 2.2.13

Press-in frame and dies

for Blue Max Modular

Order no. PU

9079479 1

Blue Max Modular press-in frame

Can be used with Blue Max Modular interchangeable drilling units,

hinge and System 32 hole line with 4 spindles

For fitting with Blue Max insertion dies

Insertion die for

Intermat, Ecomat and

Slide-on hinge ranges

with T 43 cup

Insertion dies

Insertion die for Order no. PU

Hinges from Intermat,

Ecomat and Slide-on

range with T 43 cup 0061355 1

Hinges from

Selekta Pro 2000 range

with T 23 cup 0010079 1

Knock-in System 9000

InLine mounting plate 0046626 1

Connecting fittings VB 18/19/20/21 0061289 1

Connecting fittings VB 36 0068637 1

Front connectors MultiTech 0040129 1

Insertion die for InLine

mounting plate

Insertion die for

VB 36 connecting fittings

Work top extension and stops

for Blue Max Modular

Automatic drilling and insertion machines Blue Max www.hettich.com 2.2.14

Work top extension

Two metres

Can be used for left and right

Centre stop Blue Max Modular

Left and right-hand stop with independent

threads for individual positioning

Article Order no. PU

Fence with scale 0061268 1

Fence without scale 0061831 1

Plastic profile, red 0061832 1

Pendulum stop for fence

Right-hand/left-hand

Tilt stop for fence

Article Order no. PU

Right 0061351 1

Left 0061353 1

Order no. PU

9079481 1

Blue Max Modular laser

For exact positioning of workpieces

with marked hole pattern

Easy to install, battery-operated

(1 x AA, 1,5V or storage battery 1,2V)

Order no. PU

9079513 1

Order no. PU

0061285 1

Automatic drilling and insertion machines Blue Max 2.2.15

Drilling pins with shaft mount

for Blue Max Modular

Dummy plug 0076497 1

Dummy plug for quick-change chuck 0040657 1

Turning clockwise and anticlockwise = can be used on both sides!

Outstanding service life, similar to diamond-tipped drill bits

Long resharpening zone

Length 57,5 mm

Shaft diameter 10 mm

Diameter mm Order no. PU

8,0 9079424 1

6,0 9079422 1

5,0 9079420 1

3,0 9079417 1

2,5 9079414 1

Turning clockwise and anticlockwise

Drilling direction marked in colour

right = black, left = orange

Length 57 mm

Shaft diameter 10 mm

For socket drill holes

Diameter 8 mm

Length 50 mm

Turning clockwise

Shaft diameter 10 mm

Diameter Order no. PU

mm right left

40,0 0069250 1

35,0 0053955 0074438 1

35,0 (without centring pin) 0072404 1

30,0 0069251 0053954 1

26,0 0061650 0058962 1

25,0 0053945 1

24,0 0078963 0052987 1

20,0 0053944 0053953 1

19,0 0078042 0052986 1

18,0 0073099 0073143 1

15,0 0053943 0061651 1

14,0 0053941 0053942 1

12,0 0053819 0053820 1

10,0 0053952 0053951 1

8,0 0053817 0053818 1

7,5 0061652 0061653 1

7,0 0071722 0071721 1

6,0 0072039 0072040 1

5,0 0053950 0053949 1

4,0 0072163 0071723 1

3,0 0070025 0070026 1

2,0 0071897 0071896 1

Order no. PU

0058961 1

For horizontal boring unit

Diameter 8 mm

Length 70 mm

Turning clockwise or anticlockwise

Drilling direction marked in colour

right = black, left = orange

Shaft diameter 10 mm

Order no. PU

right left

0065561 0065562 1

Set of drill bits for VB 36, containing:

1x 20 mm right, 1x 10 mm left 0070034 1 set

Set of drill bits for VB 18/19/20/21, containing:

1x 30 mm right, 1x 10 mm left 0070035 1 set

Automatic drilling and insertion machine

Blue Max mini

Automatic drilling and insertion machines Blue Max www.hettich.com 2.2.16

Blue Max mini

Practical, small and suitable even for mobile use

5,5

52

32

L L

R

L

20

L L

32

Suitable for installing:

Hinges

Cross mounting plates

Knock-in mounting plates

Connecting fittings

Dowels

Optional equipment:

Hold-down clamp, press-in

frame and foot switch

Motor power rating 0.75 kW (1 HP)

Pneumatic stroke movement

(or alternatively with hand lever)

Fence

with two pendulum stops

6-spindle boring head

Work bench

400 x 800 mm

Automatic drilling and insertion machines Blue Max 2.2.17

Automatic drilling and insertion machine

Blue Max mini

Blue Max mini Type 3

Pneumatic stroke movement

Connection Order no. PU

400 V/50 Hz/3-phase 0077566 1

230 V/50 Hz/3-phase 0077567 1

230 V/50 Hz/1-phase 0078987 1

Blue Max mini Type 3

Pneumatic stroke movement

Hold-down

Insertion unit

Foot pedal

Connection Order no. PU

400 V/50 Hz/3-phase 0077610 1

Blue Max mini Type 2/6

Hand lever

Set contains:

1 Blue Max mini type 2/6

1 set of drill bits

1 x 35 mm right

2 x 10 mm left

Connection Order no. PU

230 V/50 Hz/1-phase 0047222 1 set

Needs to be ordered separately

For drilling pins and optional accessories,

see pages 2.2.18 - 2.2.21

Accessories

for drilling and insertion machine Blue Max mini

Automatic drilling and insertion machines Blue Max www.hettich.com 2.2.18

Fence extension

With scale

Right-hand/left-hand

2 quick clamping levers for adjusting fence

Order no. PU

0072152 1 set

Pneumatic hold-down clamp complete

Order no. PU

0072146 1

Length mm Order no. PU

1500 0061266 1

2000 0061268 1

Automatic drilling and insertion machines Blue Max 2.2.19

Accessories

for drilling and insertion machine Blue Max mini

Set of fixed stops

For fence fixed positions

Order no. PU

0 072 151 1 set

Pendulum stop for fence

Right-hand/left-hand

Tilt stop for fence

Article Order no. PU

Right 0 061 351 1

Left 0 061 353 1

Order no. PU

0 061 285 1

Pendulum-stop system Maxi Stop

Versatile

Order no. PU

0 051 502 1

Blue stop

MultiTech height 86

Green stop:

MultiTech height 118

Yellow stop:

MultiTech height 150

Red stop:

MultiTech height 214

Working with Maxi Stop using the example of a MultiTech drawer-front connector

!

Accessories

for drilling and insertion machine Blue Max mini

Automatic drilling and insertion machines Blue Max www.hettich.com 2.2.20

Blue Max mini press-in frame

Can be used with Blue Max mini, type 3

Insertion die for

Intermat, Ecomat and

Slide-on hinge ranges

with T 43 cup

Insertion dies

Insertion die for Order no. PU

Hinges from Intermat,

Ecomat and Slide-on range

with T 43 cup 0061355 1

Hinges from

Selekta Pro 2000 range

with T 23 cup 0010079 1

Knock-in System 9000

InLine mounting plate 0046626 1

Connecting fittings VB 18/19/20/21 0072147 1

Connecting fittings VB 36 0072148 1

Article Order no. PU

Press-in frame for Blue Max mini,

type 3 0070032 1

Insertion die for

InLine mounting plate

Automatic drilling and insertion machines Blue Max 2.2.21

Accessories

for drilling and insertion machine Blue Max mini

Turning clockwise and anticlockwise = can be used on both sides!

Outstanding service life, similar to diamond-tipped drill bits

Long resharpening zone

Length 57,5 mm

Shaft diameter 10 mm

Diameter mm Order no. PU

8,0 9079424 1

6,0 9079422 1

5,0 9079420 1

3,0 9079417 1

2,5 9079414 1

Turning clockwise and anticlockwise

Drilling direction marked in colour

right = black, left = orange

Length 57 mm

Shaft diameter 10 mm

For socket drill holes

Diameter 8 mm

Length 50 mm

Turning clockwise

Shaft diameter 10 mm

Dummy plug

Diameter Order no. PU

mm right left

40,0 0069250 1

35,0 0053955 0074438 1

35,0 (without centring pin) 0072404 1

30,0 0069251 0053954 1

26,0 0061650 0058962 1

25,0 0053945 1

24,0 0078963 0052987 1

20,0 0053944 0053953 1

19,0 0078042 0052986 1

18,0 0073099 0073143 1

15,0 0053943 0061651 1

14,0 0053941 0053942 1

12,0 0053819 0053820 1

10,0 0053952 0053951 1

8,0 0053817 0053818 1

7,5 0061652 0061653 1

7,0 0071722 0071721 1

6,0 0072039 0072040 1

5,0 0053950 0053949 1

4,0 0072163 0071723 1

3,0 0070025 0070026 1

2,0 0071897 0071896 1

Order no. PU

0058961 1

Order no. PU

0076497 1

Set of drill bits for Blue Max mini

with 6-spindle boring head, containing:

1x 35 mm right, 2 x 10 mm left, 2 x 5 mm 0070033 1 set

Set of drill bits for VB 36, containing:

1x 20 mm right, 1x 10 mm left 0070034 1 set

Set of drill bits for VB 18/19/20/21, containing:

1x 30 mm right, 1x 10 mm left 0070035 1 set

Range summary/Technical comparison

Drilling jigs and assembly aids

Drilling jigs and assembly aids www.hettich.com 2.3.0

Page number

InnoFit Start

2.3.5

Brief

description Transportable

assembly aid

Stationary

assembly aid

Stationary

assembly aid

InnoFit Pro

2.3.2 - 2.3.3

InnoFit N

2.3.4

MultiFit Pro

2.3.6 - 2.3.7

Suitable for

mounting InnoTech

drawers

InnoTech

drawers and

pot-and-pan drawers

Stationary

assembly aid

InnoTech

drawers and

pot-and-pan drawers

MultiTech

drawers and

pot-and-pan drawers

Efficiency approx. 53 drawers/hour approx. 82 drawers/hour approx. 85 drawers/hour approx. 60 drawers/hour

Page number

Accura

2.3.8 - 2.3.16

Brief

description Ruler drilling jig

with versatile

modular-system drilling

templates and sleeve drills

Ruler drilling jig

with versatile drilling

template

Small, versatile

marking jig

Exakta

2.3.17 - 2.3.23

MultiBlue

2.3.24 - 2.3.35

Suitable for

mounting Fittings in System 32

Runners

Hinges and mounting

plates

Handles and knobs

Fittings in System 32

Connecting fittings

Rastex and VB

Runners

Hinges and mounting

plates

Handles and knobs

Connecting fittings

Rastex and VB

Runners

Hinges and mounting

plates

Assembly aids for drawers

Versatile drilling jigs

i

Drilling jigs and assembly aids 2.3.1

Range summary/Technical comparison

Drilling jigs and assembly aids

Page number

BlueJig for handles

2.3.42 - 2.3.43

Suitable for mounting Handles and knobs

BlueJig FR/MultiTech

2.3.46

FR cabinet runners

MultiTech cabinet runners

Quadro runners

to wooden drawers

BlueJig Quadro EB 20

2.3.44 - 2.3.45

Page number

DrillJig VB

2.3.38 - 2.3.39

Suitable for mounting Connecting fittings VB

Steel dowels for

Rastex connecting fittings

Wooden dowels

BlueJig Dowel

2.3.40 - 2.3.41

Page number

Practica

2.3.26 - 2.3.29

Suitable for mounting Front panels/fronts of

InnoTech drawers

MultiTech drawers

Systema Top 2000

file frames and wide

drawers

BlueJig FB

2.3.32

Drawer front connectors

and railing tubes for

InnoTech drawers

MultiTech drawers

Systema Top 2000

pencil trays

Accura

2.3.30 - 2.3.31

Page number

Positioning aid

2.3.33

Suitable for mounting Hinges with

DrillJig hinge

Hinge gauge

BlueJig hinge

2.3.36 - 2.3.37

Hinges

Cross mounting plates

Hinges

Cross mounting plates

DrillJig hinge

2.3.34 - 2.3.35

Drilling jigs and assembly aids for fitting front panels

Drilling jigs and assembly aids for mounting hinges

Drilling jigs and assembly aids for mounting connecting fittings

Drilling jigs and assembly aids for mounting handles and runners

i

Drilling jigs and assembly aids www.hettich.com 2.3.2

Assembly aid for InnoTech drawers

InnoFit Pro

For assembling InnoTech drawers and pot-and-pan drawers

Quickly set using latch levers for

- Drawer widths of 275 mm and 300 to 1200 mm

in 50 mm increments

- Drawer depths of 260, 300, 350, 420, 470, 520 and 620 mm

- Rear-panel heights of 70, 144 and 176 mm

Also for customised drawer widths

Sturdy aluminium frame

Assembly

Order no. PU

0 041 777 1

Setting customised

drawer width

Setting on ruler using cut

width of base

Setting standard

drawer width

With latch levers for cabinet

widths of 275 mm and 300 to

1200 mm in 50 mm increments

Setting rear-panel height

With latch levers for rear-panel

heights of 70, 144 and 176 mm

!

Setting drawer depth

With latch levers for nominal

lengths of 260, 300, 350, 420, 470,

520 and 620 mm

Drilling jigs and assembly aids 2.3.3

Assembly aid for InnoTech drawers

InnoFit Pro

2. Insert profile into assembly aid

5. Clamp profiles

4. Pull profiles and rear panel down in one piece

6. Screw components in place or knock in pins. Done!

Assembly

1. Insert base into assembly aid, inside

facing down

3. Clip rear panel into receiver on profiles

Tool for knocking in pins

For assembling InnoTech

Order no. PU

0078091 1

Drilling jigs and assembly aids www.hettich.com 2.3.4

InnoFit N assembly aid

For assembling InnoTech drawers and pot-and-pan drawers

Pneumatic profile assembly, with compressed air at 6 - 8 bar/100 psi

Quickly set using latch levers for

- Drawer widths of 275 mm and 300 to 1200 mm

in 50 mm increments

- Drawer depths of 260, 300, 350, 420, 470, 520 and 620 mm

- Rear-panel heights of 70, 144 and 176 mm

Also for customised drawer widths

Sturdy aluminium frame

Order no. PU

9019743 1

Assembly aid for InnoTech drawers

InnoFit N

2. Insert profile into assembly aid

5. Remove finished drawer

4. Pneumatically press pins of side profiles into base

1. Insert base into assembly aid, inside

facing down

3. Clip rear panel into receiver on profiles

Assembly

Drilling jigs and assembly aids 2.3.5

Assembly aid for InnoTech drawers

InnoFit Start

For assembling InnoTech drawers

For all drawers widths from 275 to 1200 mm

and depths of 260, 300, 350, 420, 470, 520 and 620 mm

Lightweight polystyrene elements protect the

drawer components from damage

Quickly set up and dismantled,

easily transported for assembly on site

Setting up

Order no. PU

0045555 1

Tool for knocking in pins

For assembling InnoTech

Order no. PU

0078091 1

Position assembly aid on work

bench with stops against bench

edge and fix in place on left hand

side.

The right-hand profile mount can

be re-positioned. The ruler marks

cabinet nominal dimensions.

1. Insert profile into assembly aid 2. Insert base between profiles 3. Position profiles so that outer

sides rest against stop

5. Screw components in place or knock in

pins. Done!

4. Insert rear panel and slide base

up against rear panel

Assembly

Assembly aid for MultiTech drawers

MultiFit Pro

Drilling jigs and assembly aids www.hettich.com 2.3.6

For assembling MultiTech drawers and pot-and-pan drawers

Quickly set using latch levers for

- Drawer widths of 275 mm and 300 to 900 mm

in 50 mm increments

- Drawer depths of 250, 275, 350, 400, 450, 500 and 550 mm

- Rear-panel heights of 86, 118, 150 and 214 mm

Also for customised drawer widths

Sturdy aluminium frame

Order no. PU

9079392 1

Setting rear-panel height

With latch levers for rear-panel

heights of 86, 118, 150 and

214 mm

Assembly

Setting standard

drawer width

With latch levers for carcase

widths of 275 mm and 300 to

900 mm in 50 mm increments

Setting customised

drawer width

Setting on ruler using cut

width of base

Setting drawer depth

With latch levers for nominal

lengths of 250, 275, 400, 450,

500 and 550 mm

Drilling jigs and assembly aids 2.3.7

Assembly aid for MultiTech drawers

MultiFit Pro

1. Insert rear panel into receiver 2. Insert base into assembly aid, inside

facing down

3. Insert profile into assembly aid

5. Screw profiles to rear panel and base

4. Clamp profiles

Assembly

Drilling jig Accura

Drilling jigs and assembly aids www.hettich.com 2.3.8

mm Inch

Accura rail with

measurement scale

Bolt

Viewing window for

measurement scale

Accura drilling template

for handle collection

ProDecor

Accura drilling template

for runner systems

Adjustable stop

for individual (un-assembled)

cabinet sides

Adjustable stop for

assembled cabinet

Accura drilling

template for hinges/

mounting plates

Guide for sleeve drill

Centre punch

Sleeve drill

Marking pin

for cup drillings

Marking pin

for hole lines

Drilling jig Accura

for System 32

Drilling jigs and assembly aids 2.3.9

Drilling jig Accura

for hinges, mounting plates,

handles/knobs and runner systems

Modular-system drilling jig

Versatile

Efficient, economical and professional

Accura drilling templates for hinges/mounting plates

are suitable for:

The Intermat, Ecomat, Minimat and Slide-on series of

hinges

Mounting plates System 9000 Intermat, Ecomat

Mounting plates System 2006 Slide-on

System 32, hole line drillings

For overlaid and inset doors

The Accura drilling template for hinges and knobs

plates can be used with:

Handles with two or three bases with hole spacing

64 mm or greater

Furniture knobs

The drilling template for runner systems is used for

mounting:

Roller runner systems FR (302/402/602/6142 )

Ball-bearing slides KA

Quadro slide-on technology

partial and full extension

Quadro plug-on technology

partial and over-extension

Quadro runner systems and ball bearing slides for the

Systema Top 2000 product ranges

Further functional advantages:

Drilling template and rail made of aluminium

Sleeve drill minimal bit wear, because the bit is not

in direct contact with the jig

Stops can be used on left and right

Easy adjustment of the drilling template and stops by

means of clamping screws

Rail with measurement scale

Simple measurement determination via viewing

window in drilling template

Article Order no. PU

Accura rail with measurement scale, Aluminium

Length 500 mm 0044764 1

Length 1000 mm 0070263 1

Length 1500 mm 0070264 1

Length 2000 mm 0020014 1

Accura drilling template for hinges/mounting plates

with centre punch and cup pattern, aluminium/plastic 0013841 1 set

Accura drilling template for handles and knobs, aluminium/plastic 0044765 1

Replacement slide rail with drilling bushes

for Accura drilling templates for handles and knobs 0044767 1

Accura drilling template for runner systems

aluminium/plastic 0070265 1

Additional centre punch 0023680 1

Adjustable stop for assembled cabinet, plastic 0070267 1

Adjustable stop for individual (un-assembled) cabinet sides, plastic 0070266 1

Sleeve drill 3 mm 0078095 1

Spare drill 3 mm without sleeve 0079004 1

Sleeve drill 5 mm 0070268 1

Spare drill 5 mm without sleeve 0070269 1

Sleeve drill 8 mm 0046084 1

Spare drill 8 mm without sleeve 0046628 1

Sleeve drill 10 mm 0078096 1

Spare drill 10 mm without sleeve 0079005 1

High-powered high-speed steel twist drill (HSS) 5 mm 0044766 1

Measuring pin for Accura drilling template

for guide components 0046629 1

Accura drilling template 1000 mm, aluminium

with 3 stop pins/marking pins 0010573 1

Drilling jig Accura

for hinges/mounting plates

Drilling jigs and assembly aids www.hettich.com 2.3.10

22

52

5,5

5

34

16,5

38

8

5

25

32

37

16

32

32

16

57

32

37

32

52

3

5

22 5,5

4,5

38

8 16,5

2

6

3,5

Hole pattern for System 2006/9000

cross-mounting plates for

Intermat, Ecomat

and Slide-On hinge series

(overlay doors)

Drilling position for hinge arm Minimat

(overlay doors)

Hole pattern for System 2006/9000

cross-mounting plates for

Intermat, Ecomat

and Slide-On hinge series

(inset doors)

Punching positions for automatic hinges of

the Intermat, Ecomat and Slide-on product

series, for cup diameter 35 mm and cup

distance C = 4,5 mm

Punching positions for automatic

hinges of the Minimat product

range, for cup diameter 26 mm

and cup distance C = 3,5 mm

Drilling positions for

System 32 hole lines

Cabinet front edge

Fixing point for cup pattern

Drilling jigs and assembly aids 2.3.11

Drilling jig Accura

for hinges/mounting plates

2

2

3

3

1

Remove cup pattern and position the drilling

template as required in the cabinet. Directly drill the holes

for the mounting plates with the sleeve drills.

Door rear edge

Door lower edge

Sleeve drill

Align the drilling template and adjustable stop.

Using the centre punch, mark and start the holes for the

relevant hinge type. Drill the cup holes for the hinges.

Determine the hinge spacing using the cup pattern.

The desired reveal can be set by sliding the adjustable stops

with reference to the scale on the rail.

Drilling jig Accura

for handles/knobs

Drilling jigs and assembly aids www.hettich.com 2.3.12

2

1

3

4

5

6

7

180

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170

2

1

3

4

5

6

7 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

1

2

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170

2

1

3

4

5

6

7

180

180

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170

2

1

3

4

5

6

7

3

Accura drilling template set for handles with hole spacing

64 mm or greater and knobs

Set contains:

2 Accura drilling templates for handles with hole spacing 64 mm

or greater and knobs

2 drill plates with guide sleeve for 5 mm high-powered

high-speed steel twist drill (HSS)

1 Accura slide rail with measuring scale in mm and inch,

length 500 mm

1 adjustable stop for front edge alignment

Handles with two bases

centred or positioned as desired

Set up drilling template

Adjust hole spacing

Adjust handle to front distance

Check hole spacing using feeler gauge

Drill holes Screw on handle

Article Order no. PU

Accura drilling template set for handles and knobs 0044763 1 set

Replacement slide with drilling bush for Accura drilling jig for handles and knobs 0044767 1

High-powered high-speed steel twist drill (HSS) 5 mm 0044766 1

Drilling jigs and assembly aids 2.3.13

Drilling jig Accura

for handles/knobs

2

1

3

4

5

6

7

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

2

1

3

4

5

6

7

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

2

1

3

4

5

6

7

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

Set up drilling template

Adjust hole spacing

Adjust handle to front

distance

Use measuring components

to check hole spacing

2

1

3

4

5

6

7

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

2

1

3

4

5

6

7

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

2

1

3

4

5

6

7

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

3

1

2

Handles with three bases

centred or positioned as desired

Drill holes

Screw on handle

2

1

3

4

5

6

7

2

1

3

4

5

6

7

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

1

2

3

2

1

3

4

5

6

7

2

1

3

4

5

6

7

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

3

2

1

Two handles

aligned symmetrically

Drill holes for first handle

Turn drilling jig over

Drill holes for second handle

Screw on handles

Set up drilling template

Adjust hole spacing

Adjust handle to front

distance

Use measuring

components to check

hole spacing

Drilling jig Accura

for runner systems

Drilling jigs and assembly aids www.hettich.com 2.3.14

16

20

16

13

64

352

320

16

37

96

128

160

192

224

256

288

320

352

32

Cabinet front edge

Drilling positions for

Quadro slide-on/plug-on technology

Quadro Duplex 60/70 Systema Top 2000 cabinet

Roller runner systems FR

Ball-bearing slides KA

Drilling position for

KA 270, Quadro 12 and Quadro Duplex 45

Systema Top 2000 pedestal, narrow pedestal

Drilling jigs and assembly aids 2.3.15

Drilling jig Accura

for runner systems

36 36

The adjustable stop is fixed "flush" with the rail:

using the inspection window, you can read off the exact

screw-on positions for the individual runner systems

from the rail scale.

Position of universal drilling template system

on individual, un-assembled cabinet sides.

Extremely useful e.g. for application with

Systema Top 2000

The drilling template and adjustable stop are placed on the

bottom panel, thereby permitting interchangeability between the

Quadro 30 partial extension and Quadro V6 full extension runner

whilst maintaining the same position for the drawer/front panel.

Drilling template Accura

for System 32 hole line

Drilling jigs and assembly aids www.hettich.com 2.3.16

Enables you to drill a hole line

in System 32 rationally,

economically and expertly.

Applications

Hole line spaced 37 mm

from front edge

Hole line at a distance of

13 mm from the front edge

(office applications: Top 2000 pedestal)

Drilling the first hole line

for connecting fittings

(for 16 mm and 19 mm panel thickness)

Stop for continuing hole line

Stop for rear hole line

in assembled cabinet

Practical advantages:

Drilling template in aluminium

Sleeve drill minimum bit wear,

because the bit does not come

into contact with the jig

Can be used for left and right

Functions easily set

using stop/rig pins

5

1000

37

97

32 32

8,5

10

32

13

37

32

32

37

10

13

8,5

20

37

20

13

37

32 32

29 holes in 32 mm spacing

0,1

Stop for front edge of cabinet side

Hole line at distance of 37 mm from

the front edge

Stop for bottom edge of cabinet side

first hole line drilling at 8 mm

for 16 mm panel with connecting fittings

Stop for bottom edge of the cabinet side

first hole line drilling at 10 mm

for 19 mm panel with connecting fittings

Stop for continuing the hole line.

The pin is inserted in the last hole in the line.

Stop for front edge of cabinet side

hole line at distance of 13 mm from

the front edge

(office furniture: Systema Top 2000

work station pedestal)

Rear edge of drilling template for drilling the

rear hole line in a ready assembled cabinet

the distance to the back panel is 37 mm.

Article Order no. PU

Accura drilling template 1000 mm,

aluminium with 3 stop pins/marking pins 0010573 1 set

Sleeve drill 3 mm 0078095 1

Spare drill 3 mm without sleeve 0079004 1

Sleeve drill 5 mm 0070268 1

Spare drill 5 mm without sleeve 0070269 1

Sleeve drill 8 mm 0046084 1

Spare drill 8 mm without sleeve 0046628 1

Sleeve drill 10 mm 0078096 1

Spare drill 10 mm without sleeve 0079005 1

Drilling jigs and assembly aids 2.3.17

Drilling jig Exakta

Rail

Adjustable stop

Fixed stop

Centre punch

Locating point

Hardened

drilling bushes

5 mm

Drilling hole

5 mm

Pin

Cup pattern

Locating point

Drilling hole 5 mm

Drilling template

Practical for small furniture batches, constructing samples

and contract furnishing

For greater accuracy and rational production

Can be used for mounting:

- Hinges

- Mounting plates

- Connecting fittings

- Shelf supports

- Flap supports

- And other fittings in System 32

The Exakta drilling template

can be employed also without the rail:

simply fit to the workpiece with a clamp!

Article Order no. PU

Rail with 2 stops

1000 mm 0014825 1

1500 mm 0015328 1

2000 mm 0014826 1

2500 mm 0014827 1

Drilling template 0022617 1

Centre punch 0023680 1

Adjustable stop 0073788 1

High-powered high-speed steel twist

drill (HSS) 5 mm 0044766 1

Drilling jig Exakta

System 32 hole line boring

Drilling jigs and assembly aids www.hettich.com 2.3.18

37

32

32

32

32

32

With Exakta, hole lines at a distance of 37 mm from the

side front edge can be drilled directly.

For this purpose, several drilling templates can be pushed closely together and

drilling can be performed directly through the hardened bushes.

Hole distances are 32 mm, drilling diameter 5 mm.

All fittings denoted with can be mounted in the hole lines.

For transfer from right to left, the Exakta can be placed in the same position

on the opposite side.

... e.g. for the shelf support range

32

37

32

32

Drilling jigs and assembly aids 2.3.19

Drilling jig Exakta

Drilling pattern/Connecting fittings

32 10

9,5

32 9,5

VB 36/36 M

See pages 8.2.20 - 8.2.21

VB 35/35 M

See pages 8.2.18 - 8.2.19

9,5

20

+0,5

10 32

10 10

30

15

+0,5

+0,5

+0,5

10 20

32

9,5

VB 18/19/ 20/21

See pages 8.2.14 - 8.2.15

34

Rastex 15

See pages 8.2.2 - 8.2.3

15

34

When using dowels with a dowel

length of 30 mm (drilling dimension =

dowel length + 4 mm)

Drilling jig Exakta

Cabinet assembly with cam fittings

Drilling jigs and assembly aids www.hettich.com 2.3.20

Drilling cabinet sides

Mark constructional dimensions

for panels on the cabinet side

The dimensions depend

on the fitting and panel

thickness

Several drilling templates

can be used for marking all

drilling dimensions for

height construction on the

cabinet side in one operation

Place Exakta against front edge

of side, with fixed stop on lower

edge of side

Position drilling template with

the locating points on the

markings

Insert drill into hardened bushes

and drill directly

Drill holes:

- Drilling distance from front of

side edge is 37 mm

- Drilling diameter 5 mm

- Drilling depth according to

dowel dimensions

For drilling front and rear

holes. The drilling templates

remain in the same position:

simply position Exakta the

opposite way round.

37

5

Shelf

Dowel centre

Side

front edge

Dowel centre

Shelf

Dowel centre

Side

rear edge

Drilling jigs and assembly aids 2.3.21

Drilling jig Exakta

Cabinet assembly with cam fittings

Side front

edge

Drilling the top/bottom panels

Align fixed stop flush with

adjustable stop

Position Exakta with the adjustable

stop against the front edge of the

side

Set drilling template with pins on

dowel holes and fix in place

Transfer distances to the top and

bottom panels

For transfer from right to left, simply

position Exakta the other way round!

5

Shelf LH

side edge

Shelf

front edge

Shelf RH

side edge

Shelf

front edge

!

Position Exakta against the panel

side edge on the right or left and

place the fixed or adjustable stop

(for VB 35/36 and Rastex 15)

on the panel front edge

Using the centre punch, mark the

drill holes for the connecting fittings

through the appropriate

centring holes

Drill holes according to specified

dimensions

Drilling jig Exakta

Hole marking positions for hinges from the

Intermat, Ecomat, Minimat and Slide-on ranges

Drilling jigs and assembly aids www.hettich.com 2.3.22

for 35 mm cup diameter

and cup distance C = 4,5 mm

Hole marking and drilling positions of the cross mounting plate systems 2006/9000

from the Intermat, Ecomat, Minimat and Slide-on hinge ranges

5,5

52

22

8

38

16,5

26 35

52

3

5

22 5,5

4,5

38

8 16,5

2

6

3,5

for 26 mm cup diameter

and cup distance C = 3,5 mm

28

32

37

32

55

32

55 32

32

28/37

Hole marking position

for inset doors

Cup diameters 35 and 26 mm can also be

measured with the Exakta drilling template.

... e.g. for hinge versions

Intermat 9943

Ecomat 9843

Intermat 9924

Slide-on 2333

Minimat 2225

... for the mounting plate versions

System 9000 Intermat and Ecomat hinges

System 2006 Slide-on hinges

Minimat 2225

Hole marking position

for overlaid doors

Drilling jigs and assembly aids 2.3.23

Drilling jig Exakta

Marking/drilling holes for hinges and mounting plates

Position Exakta against rear edge of

door, with the fixed stop against the

door's lower edge

Using the centre punch, mark drill

holes for relevant hinge type

Drill cup holes for the hinges. Exakta

always guarantees that hinges are

mounted perfectly horizontally.

If the doors are drilled first, the

hinge distances can be

measured by inserting the cup

patterns on the drill templates

into the cup holes. These can

then be transferred to the

cabinet side.

Set clearance with the

adjustable stop

Position Exakta against front

edge of side, with the fixed stop

against the side's lower edge

For cross mounting plates to be

fixed directly (with 5 mm pins

or euroscrews), insert drill into

hardened bushes and drill

directly

Mark screw holes with centre

punch for all other cross

mounting plates

Door rear edge

Door lower edge

Reveal

Door

Hole marking gauge Multi Blue

Drilling jigs and assembly aids www.hettich.com 2.3.24

5

37

Marking position

for holes 32 mm apart

e.g. for different mounting plate versions

System 9000 (Intermat- and Ecomat-hinges)

System 2006 (Slide-on hinges)

Minimat 2225 and Hettich Direkt Top

e.g. for

Screw-in dowel

End and double dowel for Rastex

Shelf support

32

32

32

32

32

32

5

37

32

32

32

32

32

32

N x 32

5

32

37

Order no. PU

0000351 1

Hole marking gauge Multi Blue

Small and easy to use, yet multifunctional

Simple hole-marking template: the perfect aid for on-site

assembly whenever a fitting has to be mounted professionally

without the use of large machinery.

The Multi Blue double-sided hole marking

gauge can be used for marking out:

System 32 hole lines for

- Mounting plates

- Dowels

- Shelf supports

Cup drillings dia. 35 and 26 with dimension C 4 mm for hinges

Holes dia. 25 and 20 for connecting fittings

Drilling jigs and assembly aids 2.3.25

Hole marking gauge Multi Blue

35

21,5

Hole marking positions

for cup diameter 35 mm

and cup distance C = 4 mm

. . . e.g. for hinge versions

Intermat

Ecomat

Slide-on

... e.g. for hinge versions

Intermat 9924

Minimat

... e.g. for connecting fittings

Rastex 25

... e.g. for connecting fittings

VB 35

VB 135

Hole marking positions

for cup diameter 26 mm

and cup distance C = 4 mm

Hole marking positions

for hole 25 mm

Hole marking positions

for hole 20 mm

3

5

21,5

4

2

6

4

17

33,5

25

9,5

+0,5

20

3

7

21,5

2

8

17

26

17

2

8

33,5

25

33,5

3

7

9,5

20

9,5

Drawer front template Practica

Drilling jigs and assembly aids www.hettich.com 2.3.26

The Practica drawer front template

provides a safe and simple method of

installing front panel fixings

The side overlay and height of the front

panel are adjustable.

The system contains three elements:

- Practica angle stopper

- Practica drilling template

- Sleeve drill

Seven different drilling templates can be

combined with the angle stopper:

- For InnoTech drawer system

- For MultiTech drawer system

- For Systema Top 2000, pedestals, EB 292/392

- For Systema Top 2000, hanging file frame,

cranking 13 mm and 22 mm

- For Systema Top 2000, wide drawer,

cranking 13 mm and 22 mm

2

1

3

!

Drilling jigs and assembly aids 2.3.27

Drawer front template Practica

Practica angle stopper

for combining with Practica drilling templates for

InnoTech drawer System

MultiTech drawer system

Systema Top 2000, Pedestals, EB 292/392

Systema Top 2000, hanging file frame,

cranking 13 mm and 22 mm

For Systema Top 2000,

wide drawer, cranking 13 mm and 22 mm

Aluminium

Practica drilling template

InnoTech drawer system

For installing the front panel fixings for

InnoTech drawer

InnoTech pot-and-pan drawer

InnoTech pot-and-pan drawer with

2nd railing level

Range of adjustment

Side overlay of front panel:

up to 6 mm to +20 mm

Front panel height:

from bottom edge of bottom panel

up to +35 mm

Aluminium

up to +20

up to +35

up to 6

2

1

3

Order no. PU

0 078 093 1

Order no. PU

0 013 392 1

Article Order no. PU

Sleeve drill 3 mm 0 078 095 1

Spare drill 3 mm, without sleeve 0 079 004 1

Sleeve drill 5 mm 0 070 268 1

Spare drill 5 mm, without sleeve 0 070 269 1

Sleeve drill 8 mm 0 046 084 1

Spare drill 8 mm, without sleeve 0 046 628 1

Sleeve drill 10 mm 0 078 096 1

Spare drill 10 mm, without sleeve 0 079 005 1

Sleeve drill

Bit wear is minimised,

as the bits do not come into

contact with the template

Sleeve for precise drill guidance

Adjustable drilling depth stop

!

Drawer front template Practica

Drilling jigs and assembly aids www.hettich.com 2.3.28

Practica drilling template

MultiTech drawer system

For installing the front panel fixings for

MultiTech drawer

Height 54, 86, 118, 150 and 214 mm

MultiTech pot-and-pan drawer

Range of adjustment

Side overlay of front panel: up to +20 mm

Front panel height:

from bottom edge of bottom panel

up to +35 mm

Aluminium

Order no. PU

0079637 1

Order no. PU

0010794 1

up to +20

up to +35

Practica drilling template for Systema Top 2000

pedestal, installation width EB 292/392 in System 32

For installing the front panel fixings for

Systema Top 2000 steel drawer

Installation width 292 mm,

installation depth 530 and 730 mm

Systema Top 2000 steel drawer

Installation width 392 mm,

installation depth 530 and 730 mm

Systema Top 2000 steel drawers with front stay

Range of adjustment

Side overlay of front panel:

up to +20 mm

Front panel height:

from bottom edge of bottom panel

up to +35 mm

Aluminium

up to +20

up to +35

Drilling jigs and assembly aids 2.3.29

Drawer front template Practica

Practica drilling template for Systema Top 2000,

wide drawer,

cranking 13 mm and 22 mm

in System 32

For installing the front panel fixings for

Systema Top 2000, wide drawer

Cabinet depth 400 mm and 600 mm

Systema Top 2000, wide drawer with front stay

Range of adjustment

Side overlay of front panel:

up to +20 mm

Front panel height:

from bottom edge of bottom panel

+10 mm to +45 mm

Aluminium

Practica drilling template for Systema Top 2000

hanging file frame,

cranking 13 mm and 22 mm

in System 32

For installing the front panel fixings for

Systema Top 2000, hanging file frame

Cabinet depth 400 mm and 600 mm

Systema Top 2000, hanging file frames with front stay

Range of adjustment

Side overlay of front panel:

up to +20 mm

Front panel height:

from top edge of frame: +52 to +87 mm

Front panel height with lock installation:

from top edge of frame +84 to +119 mm

Aluminium

up to +20

up to +35

min. 52

without lock

min. 84

with lock

+10 up to +45

up to +20

Cranking Order no. PU

X = 13 0010796 1

X = 22 0010798 1

Cranking Order no. PU

X = 13 0010795 1

X = 22 0010797 1

Drawer front template Accura

for Systema Top 2000 pencil tray

Drilling jigs and assembly aids www.hettich.com 2.3.30

For drilling dowel holes for connecting the front panel of

Systema Top 2000 pencil trays

Practical advantages:

Drilling jig in aluminium

For internal widths of 392 mm (standard pedestal)

and 292 mm (narrow pedestal)

Side front panel overlay can be varied from 13 to 19 mm

Additional stop position for inset front panels

(Reveal 2,5 mm)

Hole marking position for cylinder cam lock

Hole marking position

for cylinder cam lock fixing screw

Sleeve drill minimum drill wear as the

drill bit does not come into contact with the jig

Relocatable stop pins for fast

and accurate front panel positioning

392

13

14

15

16

17

18

19

392

392

292

292 292

392 392

-2,5

451

80,5

392

292

23

20,3

Stop for side front panel overlay, 13 to 19 mm

Stop for inset front panel, reveal 2,5 mm

Stop for front panel bottom edge

Hole marking position for cylinder cam lock

Hole marking position for cylinder cam lock fixing screw

Inside edge of cabinet side

Centre of pencil tray

Drill holes for sleeve drill

Article Order no. PU

Accura drawer-front jig

for Systema Top 2000 pencil tray

with 3 stops 0022555 1

Sleeve drill 8 mm 0046084 1

Spare drill 8 mm without sleeve 0046628 1

Hole marking punch 0023680 1

Drilling jigs and assembly aids 2.3.31

Drawer front template Accura

for Systema Top 2000 pencil tray

13

14

15

16

17

18

19

-2,5

392

13

14

15

16

17

18

19

-2,5

292

Hole patterns

for installation width 392 mm

Front panel

Drawer front panel drilling jig Accura

Front panel connector for pencil tray

Systema Top 2000

Hole patterns

for installation width 292 mm

Front panel

Drawer front panel drilling jig Accura

Front panel connector for pencil tray

Systema Top 2000

3

9

2 13

14

15

16

17

18

19

3

9

2 3

9

2 2

9

2

2

9

2

2

9

2

3

9

2

3

9

2

-2,5

13 - 19

392

3

9

2 13

14

15

16

17

18

19

3

9

2 3

9

2 2

9

2

2

9

2

2

9

2

3

9

2

3

9

2

-2,5

2,5

392

Overlay door

Inset

Drilling and hole-marking

positions for overlaid front panel,

Installation width 392 mm,

overlay adjustable from 13 - 19 mm

Drilling and hole marking

positions for inset front panel,

Installation width 392 mm,

reveal 2,5 mm

3

9

2 13

14

15

16

17

18

19

3

9

2 3

9

2 2

9

2

2

9

2

2

9

2

3

9

2

3

9

2

-2,5

13 - 19

292

3

9

2 13

14

15

16

17

18

19

3

9

2 3

9

2 2

9

2

2

9

2

2

9

2

3

9

2

3

9

2

-2,5

292

2,5

Overlay door Inset

Drilling and hole-marking

positions for overlaid front panel,

Installation width 292 mm,

overlay adjustable from 13 - 19 mm

Drilling and hole marking

positions for inset front panel,

Installation width 292 mm,

reveal 2,5 mm

Drilling jigs and assembly aids BlueJig FB

for drawer-front connectors

Drilling jigs and assembly aids www.hettich.com 2.3.32

64

32

InnoTech MultiTech

Insert marking

gauge in

drawer profile

Align front panel

and mark drilling

positions

R

L

Order no. PU

0048437 1 set

Order no. PU

0078097 1 set

Order no. PU

0051425 1 set

Mounting tool

For knock-in assembly of front connectors

Drilling template BlueJig MT

For MultiTech front panels

Plastic/steel

Drilling template BlueJig IT

For InnoTech front panels

Plastic/steel

Drilling template BlueJig

For InnoTech/MultiTech railing

Aluminium/steel

Article Order no. PU

For front connector

MultiTech 54 0079564 1

Suitable for all front connectors

MultiTech 86/118/150/214 0040133 1

Drilling jigs and assembly aids 2.3.33

Positioning aid

for DrillJig hinge drilling jig

and BlueJig hinge hole-marking template

Order no. PU

9078866 1

For inserting into mounting-plate drill holes

or System 32 hole lines

Facilitates the positioning of hinge cup holes,

also in conjunction with retrofitting doors

DrillJig hinge drilling jig and BlueJig hinge hole-marking templates

are simply positioned against the line marker for drilling the cup hole

32

5

!

Drilling jig DrillJig hinge

Drilling jigs and assembly aids www.hettich.com 2.3.34

DrillJig hinge

Hinge installation made easy: with a standard commercially

available power drill and the DrillJig hinge, Hettich hole

patterns can be made everywhere simply, rationally and

precisely.

Regardless whether you are retrofitting doors on pre-installed

shelves or blind panels, for individual or special applications,

the DrillJig hinge eliminates the need for unprofitable and

time-consuming machine adjustment simply drill and fit,

and that's it.

Precise and clean hole drilling

for hinges and mounting plates

Angled, precise drilling with

tungsten carbide tipped drill bits

No "runaway" of the drill bit

when cut-drilling half-moon holes

Commercially available power drills, 230 V/min. 350 W

or cordless screwdriver, min. 9,6 V

The following hinge and mounting plate ranges can be

processed with the Hettich DrillJig hinge:

Intermat

Ecomat

Slide-on

Selekta Pro 2000

Mounting plate series System 9000

Mounting plate series System 2006

Mounting

plate drilling jig

Hinge drilling pattern

The DrillJig hinge set contains:

1 drilling template for hinges

1 drilling template for mounting plates

1 hexagonal driver

1 drill bit, 35 mm installed

2 drill bit, 10/2,5 mm installed

5

2

34

5

6

7

8

F

E

D

Accessories/Replacement parts

Drill bits Order no. PU

35/2x10 0 020 165 1 set

35/2x2,5 0 046 413 1 set

/ 2a

/ 2a

2a

Article Order no. PU

Drilling template for mounting plates 0 020 130 1

Drill bits 35 mm 0020 688 1

Drill bits 10 mm 0020 687 1

Drill bits 2,5 mm 0 046 085 1

Hexagonal follower 0020 695 1

Allen screw M8 x 16 DIN 912 0020 689 1

Washer 8,4 DIN 125

Sleeve

Spring

Washer 12x18x 0,5 DIN 988

Drilling jigs and assembly aids 2.3.35

Drilling jig DrillJig hinge

32 52

5

5,5/9

C

37

E

E

70

70

70

Overlay

Top panel Overlay

Side Door

Hinge and mounting plate fixing holes

The door overlay on the top or bottom panel can

be precisely marked on the scale:

Overlay for "overlay door": up to +24 mm

Reveal for "inset door": up to 3 mm

Side

Door

11

13

10x11

9

52

12,5 35

9

52

12,5 35

13

11

13

10x11

5,5

52

12,5 35

13

5,5

52

12,5 35

Hole dimensions T23

Selekta Pro 2000

Hole dimensions T23/9

Selekta Pro 2000

Hole dimensions T42

Intermat, Ecomat, Slide-on

Hole dimensions T22

Selekta Pro 2000

Hole dimensions T22/9

Selekta Pro 2000

52

C > C < 2 8

E E

E E 12,5 12,5

12,5 12,5

Variable "C" setting: from min. 2 to max. 8

Scale point E

12,5

: template setting for Selekta Pro 2000.

52

35

C

5,5

13

11 13

35

C

5,5

10

52

Hole dimensions

T43/Flash/THFix

Intermat, Ecomat, Slide-on

Hole-marking template BlueJig hinge

for hinges and cross mounting plates

Drilling jigs and assembly aids www.hettich.com 2.3.36

5,5

22

52

Ideal for use on site

For concealed hinges

- Intermat

- Ecomat

- Slide-on

For mounting-plate options

- System 9000 (Intermat- and Ecomat-hinges)

- System 2006 (Slide-on hinges)

Also for half-overlay applications

Separate hole-marking positions additionally provide the

possibility of mounting the Hettich Top cross mounting plate for

half-overlay applications with pre-mounted self-tapping screws

Hole marking position for Hettich

concealed hinges

(Intermat, Ecomat, Slide-on)

with cup version T 42

(cup diameter 35 mm,

cup distance C 4,5 mm)

Hole marking position:

Overlay mounting position

for Hettich mounting plate systems

9000 (Intermat, Ecomat) and 2006 (Slide-on)

C

=

4,5

52

22

5,5

37

32

37

32

m

i

n

. 1

5

Order no. PU

0045150 1

Drilling jigs and assembly aids 2.3.37

Hole-marking template BlueJig hinge

for hinges and cross mounting plates

Hole marking position:

Inset mounting position for

Hettich mounting plate systems 9000

(Intermat, Ecomat) and 2006 (Slide-on)

Hole marking position:

Overlaid centre panel door

for screw-on cross mounting plate

Hettich Top with pre-mounted

chipboard screws

Hole marking position:

Inset centre panel door for

screw-on cross mounting plate

Hettich Top with pre-mounted

chipboard screws

57

32

37

2,5

2,5

32

37

2,5

32

2,5

m

i

n

. 1

5

2,5

57

2,5

32

57

2,5

32 2,5

m

i

n

. 1

5

57

32

m

i

n

. 1

5

!

Drilling jig DrillJig VB

Drilling jigs and assembly aids www.hettich.com 2.3.38

DrillJig VB

All you need for rapid, rational, simple and at the same time precise

installation of Hettich connecting fittings is the DrillJig VB drilling

jig and a standard commercially available power drill.

For retrofitting structural shelves and panels

Single or special production

Precise, clean and also angled holes

Tungsten carbide tipped bits

No "runaway" of the drill bit when cut-drilling half-moon holes

Holes spaced at regular 32 mm intervals

Fixed end stop at 37 mm (= distance between hole line and

front side edge)

Drilling diameter 5 mm

For wood thickness of 16/19 and 22 mm

Commercially available power drills, 230 V / min. 350 W or

cordless screwdriver, min. 9,6 V

Drill-Jig VB can be used with:

Connecting fittings

VB 18/ 19/ 20/ 21/ 35/ 35M/ 36/ 36M

Connecting fitting VB 135

Shelf connecting fittings Toolex VB 54 16/ 19/ 23E

Drilling template

dowel

Connector drilling jig

The DrillJig VB contains:

1 drilling template for VB connecting fittings

1 drilling template for dowels

1 drill bit 10 mm, fitted

1 drill bit 20 mm, fitted for VB 35/35M/36/36M and VB135

1 hexagonal driver

17

15

13 16 14

12

17

15

1 3

16

1 4

1 2

8 9,5

8,5 9

10

1 1 , 5

1 0 , 5

1 1

8

9 , 5

8,5

9

1 0

11,5

1 0 , 5

1 1

17

15

1 3

16

1 4

1 2

Accessories/Replacement parts

Article Order no. PU

DrillJig VB 0 020 166 1 set

30 mm dia. drill bit for VB18, VB19, VB20, VB21 0 020 167 1

Drill bit 18 mm for shelf connecting fitting Toolex VB54 16/ 19/ 23E 0 020 168 1

Article Order no. PU

Drilling template dowel 0 020 131 1

30 mm dia. drill bit for

VB18, VB19, VB20, VB21 0 020 167 1

Drill bit 18 mm for shelf connecting fitting

Toolex VB54 16/ 19/ 23E 0 020 168 1

20 mm dia. drill bit for

VB35/35M, VB36/36M, VB135 0 020 686 1

Drill bit 10 mm 0020 687 1

Hexagonal follower 0020 695 1

Allen screw

M8 x 16 DIN 912 0 020 689 1

Washer 8,4 DIN 125

Sleeve

Spring

Washer 12x18x 1,2 DIN 988

Washer 12x18x 0,5 DIN 988

Drilling jigs and assembly aids 2.3.39

Drilling jig DrillJig VB

Holes for connecting fittings and associated steel dowels

1 9 / 2 21 9 / 2 2

1 61 6

37 32 32

5

17

15

13

16

14

1 2

17

15

13

16

14

1 2

17

15

13

16

14

1 2

8

9,5

8,5

9

1 0

1 1 , 5 1 0 , 5

1 1

8

9,5

8,5

9

1 0

1 1 , 51 0 , 5

1 1

Hole centre spacing setting: 8-11,5 mm in increments of 0,5 mm

8

1 7

1 5

13

1 6

1 4

12

1 7

1 5

13

1 6

1 4

12

1 7

1 5

13

1 6

1 4

12

8

9,5

8 , 5

9

10

11,5 10,5

11

8

9,5

8 , 5

9

10

11,5 10,5

11

1 7

1 5

13

1 6

1 4

12

1 7

1 5

13

1 6

1 4

12

1 7

1 5

13

1 6

1 4

12

8

9,5

8 , 5

9

10

11,5 10,5

11

8

9,5

8 , 5

9

10

11,5 10,5

11

11,5

17

15

13 16 14

12

17

15

1 3

16

1 4

1 2

8 9,5

8,5 9

10

1 1 , 5

1 0 , 5

1 1

8

9 , 5

8,5

9

1 0

11,5

1 0 , 5

1 1

17

15

1 3

16

1 4

1 2

2 1

Drill depth setting:

12-17 mm in increments of 1 mm

Hole centre spacing

Front/rear edge Bottom

Top/bottom edge

Side

Side

Bottom

Drill depth scale

Centre

Side stop,

right

Side stop left

Side marking

right

Side marking left

Drill depth scale Drill depth

scale

Hexagonal follower

Adjustable stop for drilling position Adjustable stop

for drilling position

Drive

for 20 mm drill

Drive

for 10 mm drill