Académique Documents

Professionnel Documents

Culture Documents

Passive vs Active Vibration Isolation Comparison

Transféré par

Madan YadavDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Passive vs Active Vibration Isolation Comparison

Transféré par

Madan YadavDroits d'auteur :

Formats disponibles

Comparison of Passive and Active Vibration Isolation

Systems

By AZoM.com Staff Writers

Topics Covered

Introduction

Low Frequency Resonance

Performance Comparison

Sensitivity to the Instrument Size

Multiple Axis Isolation

Stiffness

Cost

Isolation at the Instrument Level

Site and Maintenance Requirements

Comparison Table

About Herzan

Introduction

In some applications, active isolation systems like the Table Stable systems available

from Herzan can deliver the required performance, while passive isolation systems are

adequate for applications which are not so sensitive.

Low Frequency Resonance

Low frequency resonance problems are common in all passive vibration isolation

systems. Hence, a passive isolation system will often increase the low frequency noise

instead of damping it, creating problem for instruments such as SEMs and AFMs that are

susceptible to low frequency vibration.

Conversely, the Table Stable active isolation systems eliminate the low frequency

resonance by means of an internal feedback loop which allows them to cancel vibrations

at sub-hertz frequencies.

Moreover, the feedback loop ensures effective isolation at all frequencies, thanks to its

ability to do housekeeping in higher frequencies. Figures 1 and 2 illustrate a resonant

system and a non-resonant system.

Figure 1. Resonant System

Figure 2. Non-Resonant System

Performance Comparison

The performance of passive isolation systems increases rapidly once they start damping,

substantially reducing vibration within a few hertz. Additionally, the level of damping is

further decreased by other mechanical resonances present in a passive system.

Since the resonances in a Table Stable active isolation system are removed by its

feedback loop, it has a smooth roll-off moving into the higher frequencies. This means

that active systems maintain high level of attenuation in higher frequencies once they

reach their peak performance at 10Hz.

Nevertheless, both active and passive systems provide 98% to 99% reduction at

frequencies above 30Hz.

Sensitivity to the Instrument Size

Since passive isolation systems are simple mechanical structures, their performance

relies on the weight, size, and center of gravity of the equipment loaded on top of the

isolation system. The equipment affects the performance of the isolation system by

changing the mechanical structure and resonances of the system.

Also, the mounting platform size has to be in proportion to the location of the center of

gravity of the equipment.

Mechanical variations are offset by the feedback loop on the Table Stable systems,

enabling the systems to deliver superior performance as long as the equipment is within

their footprint and load capacity.

Multiple Axis Isolation

Most passive isolation systems cancel out only Z axis vibrations and are incapable of

isolating horizontal vibrations. Different isolation mechanisms need to be used to allow a

passive system to isolate horizontal vibrations.

However, the system cannot handle vibrations which are not purely X, Y, or Z. Table

Stable active systems isolate vibrations in six degrees of freedom using the same

sensing and damping mechanism used in passive systems. There is communication

between the sensors, thus allowing the Table Stable system to provide the isolation at

the same level across all axes.

Stiffness

Passive systems are made very soft, in order to push their low frequency resonance to

the lowest level possible.

When soft systems are exposed to a major disturbance, they take more time to settle,

typically on the order of seconds. Some systems take minutes before they are isolating

again, increasing measurement times and demanding the restart of long scans.

Moreover, soft systems are more sensitive to load changes, air currents, user bumping

compared to stiffer systems.

Since low frequency resonance is removed in the Table Stable systems, they can use

very stiff springs. Hence, they are less prone to be unsettled and their settling time is on

the order of milliseconds (Figure 3).

Figure 3. Settling Time - TS vs. Passive

Cost

Passive systems are significantly less expensive than active systems. Rubber mounts

and pads can offer adequate level of isolation for applications that are not so sensitive at

a cost of few dollars.

Very high levels of vibration isolation can be achieved using bungee systems with

appropriate geometry and tuning at a cost of less than hundred dollars. Air-based

isolation systems can provide adequate vibration cancellation for a variety of research

instruments at a cost of few thousand dollars.

The cost of active systems is typically more than five thousand dollars. Hence, they are

not an economical option for less expensive instruments.

Isolation at the Instrument Level

Passive systems can only isolate ground-borne vibrations, whereas Table Stable

systems sense and isolate vibrations at the instrument level.

Hence, they can damp certain noises originating from the equipment, including parasitic

noise from cabling, air movements, acoustic noise coupled into the casing, and even

certain noises generated by the equipment itself.

Site and Maintenance Requirements

An air compressor or clean air supply in the installation area is often required for passive

systems. Air diaphragms of air-based isolation systems need to be replaced after several

years of service.

Air is not required for Table Stable systems, but 110 240V AC power is required. Table

Stable systems run maintenance free for years and require ventilation if in a confined

space where heat dissipation is a problem.

Table Stable active vibration control systems are designed to run continuously for years

with no maintenance. These systems do not require air; their only requirement is 110

240V AC power. If the system is being used in a confined space and heat dissipation is a

concern, then ventilation should be used.

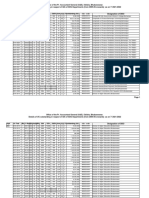

Comparison Table

The following table compares passive and active vibration control systems:

PASSIVE VS. ACTIVE - Comparison Table

FEATURE PASSIVE ACTIVE

Isolation Range >5Hz >.7Hz

Low Frequency Resonance 2 - 5 Hz None

Amplification at Resonance 4-9 times N/A

Load Sensitive Yes No

High Center of Gravity Decreases Efficiency Yes No

Stiffness Soft 500x Stiffer than Passive

Isolation in All Six Degrees of Freedom No Yes

Air Supply Requirements Hand Pump or Air Supply None

AC Power None 110-240 VAC

Settling Time 2 - 10 seconds 10-20 milliseconds

Automatic Load Adjustment

-M No

-A - Yes

AVI No

TS - Yes

Noise Isolated Ground-borne vibrations Ground, instrument, and acoustic noise

Price Low to Moderate Moderate to High

About Herzan

Herzan provides high performance environmental solutions for precision research

instruments. They include acoustic enclosures, vibration isolation systems, Faraday

cages, and site survey tools. Herzan specializes in supporting nanotechnology research,

but also offers solutions for product testing, in-vitro fertilization, and many other

applications.

Herzan understands that every application and environment is different, so it

collaborates with customers to create comprehensive integrated solutions that satisfy

their unique demands.

Herzan was founded in 1992 by Ann Scanlan in Orange County, California. Originally,

Herzan was established as an American subsidiary of Herz Company Ltd., a Japanese

company specializing in vibration control.

Vous aimerez peut-être aussi

- Design For Quiet WHT PperDocument8 pagesDesign For Quiet WHT PperAdrian DavidescuPas encore d'évaluation

- Vibration Isolation Products: Creating The Best Environment For Your LaboratoryDocument16 pagesVibration Isolation Products: Creating The Best Environment For Your LaboratoryMuhammad HammadPas encore d'évaluation

- MEBS6008 Environmental Services II Acoustic Treatment and Vibration ControlDocument26 pagesMEBS6008 Environmental Services II Acoustic Treatment and Vibration ControlSandeep BhatiaPas encore d'évaluation

- Aeroflex Wire Rope Isolators Protect Equipment in All EnvironmentsDocument28 pagesAeroflex Wire Rope Isolators Protect Equipment in All Environmentsraju3685Pas encore d'évaluation

- Industrial Products Division: Kurashiki Kako Co., Ltd. Kurashiki Kako Co., LTDDocument32 pagesIndustrial Products Division: Kurashiki Kako Co., Ltd. Kurashiki Kako Co., LTDWilliam Ronald Ochoa PaucarPas encore d'évaluation

- Vibration Isolation Francis Andrews ReadingDocument11 pagesVibration Isolation Francis Andrews Readingcrustybubbles100% (1)

- Reduce Structure Vibrations to Protect EquipmentDocument7 pagesReduce Structure Vibrations to Protect EquipmentadbPas encore d'évaluation

- Vibration Isolation TheoryDocument4 pagesVibration Isolation TheoryRa BalamuruganPas encore d'évaluation

- VibrationIsolation by Simmons PDFDocument10 pagesVibrationIsolation by Simmons PDFaruatscribdPas encore d'évaluation

- EliminatorSub EdsDocument4 pagesEliminatorSub EdsdddsPas encore d'évaluation

- Frequently Asked Questions About Vibration: What Does It Mean To Isolate Vibration?Document8 pagesFrequently Asked Questions About Vibration: What Does It Mean To Isolate Vibration?joeeoj189189Pas encore d'évaluation

- DESPL CatalogDocument24 pagesDESPL Cataloggurudev001Pas encore d'évaluation

- Bilz - Vibration Isolation of Foundations & FrameworksDocument12 pagesBilz - Vibration Isolation of Foundations & FrameworksmikelotingaPas encore d'évaluation

- Fabr Pneumatic 033009Document28 pagesFabr Pneumatic 033009daniper89Pas encore d'évaluation

- A Primer For Vibration IsolationDocument9 pagesA Primer For Vibration IsolationFadooollPas encore d'évaluation

- Vibration Isolation - SimmonsDocument12 pagesVibration Isolation - SimmonsJoão Cavalcanti100% (1)

- DS1032 ADocument4 pagesDS1032 Areading4chPas encore d'évaluation

- Deicon: Active, Feedback-Controlled Induction Noise AbatementDocument1 pageDeicon: Active, Feedback-Controlled Induction Noise AbatementdvarsastryPas encore d'évaluation

- The Basic Principles of Effective Ceiling Loudspeaker InstallationDocument3 pagesThe Basic Principles of Effective Ceiling Loudspeaker Installationjanaisha_bai7170Pas encore d'évaluation

- Essay in VibrationDocument7 pagesEssay in VibrationReynalene PanaliganPas encore d'évaluation

- Closed Box Loudspeaker Systems Part II SynthesisDocument8 pagesClosed Box Loudspeaker Systems Part II SynthesisyodifoyorPas encore d'évaluation

- Basics of Vibration IsolationDocument8 pagesBasics of Vibration IsolationSAiTejaPas encore d'évaluation

- Basics of Vibration IsolationDocument8 pagesBasics of Vibration IsolationRajaSekarsajjaPas encore d'évaluation

- Lowfreq Preceng PDFDocument4 pagesLowfreq Preceng PDFho-faPas encore d'évaluation

- Noise Exposure Control Offshore Oil and GasDocument16 pagesNoise Exposure Control Offshore Oil and Gashpham2005Pas encore d'évaluation

- Biamp Design Guide Desono EntasysDocument56 pagesBiamp Design Guide Desono EntasysDaniel AndoziaPas encore d'évaluation

- Vibration Control: R.Narasimha Swamy Senior ConsultantDocument23 pagesVibration Control: R.Narasimha Swamy Senior ConsultantbiniePas encore d'évaluation

- Closed-Box Loudspeaker Systems - 2Document8 pagesClosed-Box Loudspeaker Systems - 2Alexis AndrésPas encore d'évaluation

- CAT407 Isolated FoundationsDocument9 pagesCAT407 Isolated FoundationsKim Patrick GonzalesPas encore d'évaluation

- Cat 407 Foundations StructuresDocument16 pagesCat 407 Foundations StructuresNielss88100% (1)

- Audible Noise ReductionDocument4 pagesAudible Noise ReductionManzoor A. ShaikhPas encore d'évaluation

- Vibration Isolation Group ProjectDocument14 pagesVibration Isolation Group ProjectChrispen MapapaPas encore d'évaluation

- SimmonsDocument12 pagesSimmonsGürelBaltalıPas encore d'évaluation

- Isolating Components Uav VibrationDocument12 pagesIsolating Components Uav VibrationAhmad BasPas encore d'évaluation

- vr900 SonidoDocument16 pagesvr900 SonidoLarumba PortalPas encore d'évaluation

- Engineered Elastomer - E-A-r Engineering Design GuideDocument20 pagesEngineered Elastomer - E-A-r Engineering Design GuidebPas encore d'évaluation

- Technical Seminar-Vibration IsolatorsDocument14 pagesTechnical Seminar-Vibration Isolatorsvivek338Pas encore d'évaluation

- VAV BrochureDocument28 pagesVAV BrochureMuralidharan SudhakarPas encore d'évaluation

- Small - Closed Box System part-IIDocument8 pagesSmall - Closed Box System part-IIKichiro CarvajalPas encore d'évaluation

- Korfund Spring Mounts PDFDocument50 pagesKorfund Spring Mounts PDFBaher SalehPas encore d'évaluation

- Noise Control EngineeringDocument12 pagesNoise Control EngineeringArindam BhowmickPas encore d'évaluation

- Audible Noise ReductionDocument4 pagesAudible Noise ReductionGaurav SharmaPas encore d'évaluation

- Generator Set RoomsDocument7 pagesGenerator Set RoomsAnonymous TvOpvXPas encore d'évaluation

- Advantages of GroundingDocument3 pagesAdvantages of GroundingNabarunSarma100% (1)

- Lecture 5Document52 pagesLecture 5Wbamlak AshebrPas encore d'évaluation

- Insulation Coordination in Power SystemsDocument5 pagesInsulation Coordination in Power SystemsAndrewcaesarPas encore d'évaluation

- Korfund Spring MountsDocument50 pagesKorfund Spring Mountsuamiranda3518Pas encore d'évaluation

- Tutorial: Enclosure-Type Performance Comparision: Sub-30Hz BehaviorDocument3 pagesTutorial: Enclosure-Type Performance Comparision: Sub-30Hz BehaviortinguibluePas encore d'évaluation

- Vibration Isolation TechniquesDocument7 pagesVibration Isolation TechniquesSyed AkramPas encore d'évaluation

- 250ex Specs 4Document2 pages250ex Specs 4liquid_statePas encore d'évaluation

- Carrier 38mhrc18a - 3 Article 1490986726820 en SsDocument24 pagesCarrier 38mhrc18a - 3 Article 1490986726820 en SsCvijic DejanPas encore d'évaluation

- Adaptive Moving Sliding Mode Control For SISO Systems Application To An Electropneumatic SystemDocument5 pagesAdaptive Moving Sliding Mode Control For SISO Systems Application To An Electropneumatic SystemCesar VillamizarPas encore d'évaluation

- Afils Design GuideDocument29 pagesAfils Design Guideperoperic101Pas encore d'évaluation

- Washing Machine - Vibration Control & Noise ReductionDocument6 pagesWashing Machine - Vibration Control & Noise ReductionAshley WellsPas encore d'évaluation

- Front Flow Type: VRF Multi-Split Air Conditioning SystemDocument14 pagesFront Flow Type: VRF Multi-Split Air Conditioning SystemDemo OnlyPas encore d'évaluation

- Ultrasonic Atomizing Nozzle SystemsDocument40 pagesUltrasonic Atomizing Nozzle SystemsAnonymous H8hysGxA100% (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentD'EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Pass Ultrasound Physics Exam Study Guide ReviewD'EverandPass Ultrasound Physics Exam Study Guide ReviewÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Equipment StandardsDocument30 pagesEquipment StandardsMadan YadavPas encore d'évaluation

- Sa 515Document2 pagesSa 515Madan YadavPas encore d'évaluation

- C-FORCE Classroom GuideDocument1 pageC-FORCE Classroom GuideMadan YadavPas encore d'évaluation

- 06 CompressorsDocument16 pages06 CompressorsmunatsiPas encore d'évaluation

- How Scrubber WorksDocument2 pagesHow Scrubber WorksMadan YadavPas encore d'évaluation

- SA516Document2 pagesSA516Madan YadavPas encore d'évaluation

- How Scrubber WorksDocument2 pagesHow Scrubber WorksMadan YadavPas encore d'évaluation

- 516 Vs 515Document2 pages516 Vs 515Madan YadavPas encore d'évaluation

- Essential HVAC Calculations Spreadsheet for Load Estimation, Psychrometrics, Duct DesignDocument52 pagesEssential HVAC Calculations Spreadsheet for Load Estimation, Psychrometrics, Duct DesignSyed ShahbazPas encore d'évaluation

- Grade 310 Stainless Steel Properties and Applications GuideDocument4 pagesGrade 310 Stainless Steel Properties and Applications GuideMadan YadavPas encore d'évaluation

- Bag FilterDocument3 pagesBag FilterMadan YadavPas encore d'évaluation

- Fan BasicsDocument72 pagesFan BasicsMadan Yadav80% (5)

- Hastelloy C-276 Alloy Composition Properties ApplicationsDocument2 pagesHastelloy C-276 Alloy Composition Properties ApplicationsMadan YadavPas encore d'évaluation

- Fabric Filter DesignDocument16 pagesFabric Filter DesignDragan GasicPas encore d'évaluation

- SS 904LDocument3 pagesSS 904LMadan YadavPas encore d'évaluation

- Alloy 20Document3 pagesAlloy 20Madan YadavPas encore d'évaluation

- Benitez Cap10Document36 pagesBenitez Cap10Madan YadavPas encore d'évaluation

- Mega Mex Guide to Super Duplex Stainless Steels S32760 and S32750Document5 pagesMega Mex Guide to Super Duplex Stainless Steels S32760 and S32750Madan YadavPas encore d'évaluation

- SS Grade SelectionDocument4 pagesSS Grade SelectionMadan YadavPas encore d'évaluation

- Duplex SS2507Document3 pagesDuplex SS2507Madan YadavPas encore d'évaluation

- Placement Consultant in UdaipurDocument2 pagesPlacement Consultant in UdaipurMadan YadavPas encore d'évaluation

- Grade 304 Stainless Steel Properties and ApplicationsDocument4 pagesGrade 304 Stainless Steel Properties and ApplicationssupermannonPas encore d'évaluation

- SS 410Document3 pagesSS 410Madan YadavPas encore d'évaluation

- SS 410Document3 pagesSS 410Madan YadavPas encore d'évaluation

- SS 2304Document2 pagesSS 2304Madan YadavPas encore d'évaluation

- SS 321Document4 pagesSS 321Madan YadavPas encore d'évaluation

- Ss 2507Document5 pagesSs 2507Madan YadavPas encore d'évaluation

- SS 347Document1 pageSS 347Madan YadavPas encore d'évaluation

- Stainless Steel GradesDocument6 pagesStainless Steel GradesMadan YadavPas encore d'évaluation

- Piksi Schematics v2.3.1Document7 pagesPiksi Schematics v2.3.1Danut StanciuPas encore d'évaluation

- Bangalisan V Ca G.R. No. 124678 July 31, 1997 Regalado, J.: FactsDocument1 pageBangalisan V Ca G.R. No. 124678 July 31, 1997 Regalado, J.: FactsKate GaroPas encore d'évaluation

- Division 8 Doors and Windows: Group 3Document22 pagesDivision 8 Doors and Windows: Group 3Alen Ybanez100% (2)

- How to Clear a TableDocument20 pagesHow to Clear a TableRochell CapellanPas encore d'évaluation

- Procedural Due Process - Refers To The Mode of Procedure Which GovernmentDocument13 pagesProcedural Due Process - Refers To The Mode of Procedure Which GovernmentCharlene M. GalenzogaPas encore d'évaluation

- Autoclave SOP for Sterilization and DecontaminationDocument10 pagesAutoclave SOP for Sterilization and Decontaminationrijulesh karmelPas encore d'évaluation

- The Risk Management of Medical Device-Related Pressure Ulcers Based On The Australian/ New Zealand StandardDocument11 pagesThe Risk Management of Medical Device-Related Pressure Ulcers Based On The Australian/ New Zealand StandardJugurtha BoutlikhetPas encore d'évaluation

- Items in The Classroom: Words)Document2 pagesItems in The Classroom: Words)Alan MartínezPas encore d'évaluation

- Edu Uc Ddo 05 06 Onwards 7-21Document20 pagesEdu Uc Ddo 05 06 Onwards 7-21biplabsahoo10Pas encore d'évaluation

- FACTORS Affecting The Entrepreneurial DynamicsDocument4 pagesFACTORS Affecting The Entrepreneurial DynamicsAzraPas encore d'évaluation

- AWS ServicesDocument25 pagesAWS ServicesShaik Mahammad AlthafPas encore d'évaluation

- Eco System and Green Logistics BasicsDocument32 pagesEco System and Green Logistics BasicsBudmed GanbaatarPas encore d'évaluation

- 2019 - 2020 Skills Gap Report FINAL PDFDocument12 pages2019 - 2020 Skills Gap Report FINAL PDFPradyumna DangewarPas encore d'évaluation

- Capacity Building Programme Methods Template Signed1Document14 pagesCapacity Building Programme Methods Template Signed1REXPas encore d'évaluation

- Huawei IPCC SolutionDocument12 pagesHuawei IPCC Solutionsimonpeter02Pas encore d'évaluation

- Configure IP Tunnels GuideDocument12 pagesConfigure IP Tunnels GuideAril Muhammad Fauzan MuslimPas encore d'évaluation

- Probationary DigestsDocument22 pagesProbationary DigestsMatt ManlapidPas encore d'évaluation

- UAE HealthcareDocument15 pagesUAE HealthcareUmaira UsmanPas encore d'évaluation

- Citizen PTR Receipt (2023-2024)Document1 pageCitizen PTR Receipt (2023-2024)AnmolBansalPas encore d'évaluation

- Synopsis NDocument9 pagesSynopsis NAnonymous g7uPednIPas encore d'évaluation

- Michael Haid Four Key HR Practices That Drive RetentionDocument6 pagesMichael Haid Four Key HR Practices That Drive RetentionBiswajit SikdarPas encore d'évaluation

- Tumkur University Pre PHD Course Work Syllabus ManagementDocument6 pagesTumkur University Pre PHD Course Work Syllabus Managementafjwftijfbwmen100% (1)

- Drying of FVF - Volume 2Document220 pagesDrying of FVF - Volume 2JoelBerkaPas encore d'évaluation

- Jiang Et Al - 2009 - Total Reward Strategy - A Human Resources Management Strategy Going With The Trend of The TimesDocument7 pagesJiang Et Al - 2009 - Total Reward Strategy - A Human Resources Management Strategy Going With The Trend of The TimesJoaquínMartínezMiño100% (1)

- Cummins 6cta8.3 Engine Spare Parts CatalogDocument11 pagesCummins 6cta8.3 Engine Spare Parts CatalogChen CarolinePas encore d'évaluation

- Retail Design: Prepared by Dilbar IqbalDocument16 pagesRetail Design: Prepared by Dilbar IqbalDILBAR SHAKIRPas encore d'évaluation

- (Labour Law-1) - 1Document4 pages(Labour Law-1) - 1Arghyadeep NagPas encore d'évaluation

- Stiffness Method BeamDocument8 pagesStiffness Method BeamTaha GargoumPas encore d'évaluation

- Quadcopter Project Presentation Using KK 2.1.5 ControllerDocument13 pagesQuadcopter Project Presentation Using KK 2.1.5 ControllerAkshay SinghalPas encore d'évaluation

- Practice SetclozetestDocument48 pagesPractice SetclozetestLia TouskaPas encore d'évaluation