Académique Documents

Professionnel Documents

Culture Documents

Report - Butting Bracket

Transféré par

Sukanth KannanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Report - Butting Bracket

Transféré par

Sukanth KannanDroits d'auteur :

Formats disponibles

1 | P a g e

CHAPTER 1

COMPANY PROFILE

ASHOK LEYLAND

1.1 OVERVIEW OF COMPANY:

For over six decades, Ashok Leyland has been moving people and goods,

touching millions across 50 countries worldwide. Today, Ashok Leyland the

flagship of the Hinduja Group, one of the largest commercial vehicle

manufacturers in India with a turnover of US $ 2.5 billion in 2010-11 having

consistently delivered profits to our stake-holders since inception.

Ashok Leyland buses safely carry 70 million passengers to their destinations

every day. Close to 700,000 of their vehicles keep the wheels of economies turning

and, as the largest supplier of logistics vehicles to the Indian Army. The company

is committed to provide transport solutions that offer the best operating economics

while for users of the vehicles, comfort and safety. This has driven the company to

pioneer concepts that have become industry norms fueled both by our robust

inherent R&D capabilities and the strength of strategic alliances forged with global

technology leaders.

Early products included the Leyland Comet bus which was a passenger body

built on a truck chassis, sold in large numbers to many operators, including

Hyderabad road transport, Ahmedabad municipality, Travancore state transport,

and Bombay state transport and Delhi road transport authority. By 1963, the Comet

was operated by every State Transport Undertaking in India, and over 8,000 were

in service. Ashok Leyland had collaboration with the Japanese company Hino

Motors from whom the technology for the H-series engines was bought. Many

indigenous versions of H-series engine were developed with 4 and 6 cylinder and

also conforming to BS2 and BS3 emission norms in India.

2 | P a g e

The companys future product is the U Truck range which will comprise the

complete range of trucks from 16 to 49 tonne, which includes haulage trucks,

tippers and tractors. The new range will eventually replace the existing range of

trucks offered by Ashok Leyland.

Ashok Leyland has developed a completely new series of engines to power

the U Truck. The new Neptune series of engines will set benchmarks offering

superior levels of performance, power and fuel efficiency. In the Neptune series,

there are 11 different power ratings starting from 160 to 360 hp, which will be

Euro 3, Euro 4-compliant and the Neptune series can be upgraded to Euro 5. The

Neptune engines are both SCR and EGR ready. The company has worked with

AVL of Austria in developing the new series of engines.

Headquartered in Chennai, India, Ashok Leyland manufacturing footprint is

pan-India with two facilities in Prague (Czech Republic) and Ras Al Khaimah

(UAE). Ashok Leyland have inked 50:50 Joint Ventures (JV) with Nissan Motor

Company (Japan) for Light Commercial Vehicles and John Deere (USA) for

construction equipment. Also JV with Continental AG (Germany) for developing

automotive infotronics while the one with the Alteams Group for producing high

press die casting extruded aluminum components for both the automotive and

telecommunication sectors.

3 | P a g e

CHAPTER 2

INTRODUCTION

2.1 CAMSHAFT:

In internal combustion engines with pistons, the camshaft is used to operate

poppet valves. It then consists of a cylindrical rod running the length of the

cylinder bank with a number of lobes protruding from it, one for each valve. The

cams force the valves open by pressing on the valve, or on some intermediate

mechanism as they rotate.

Ashok Leyland manufactures inline, 6 & 4 cylinder engines. So the

Camshaft consists of 12 & 8 cams through the length depending on the number of

cylinders. These cams are placed at regular intervals and at specific angles.

Fig. 2.1 Camshaft model of AL 6 cylinder engine.

4 | P a g e

2.2 FUNCTIONS OF CAMSHAFT:

A camshaft is commonly used to operate poppet valves in the engine.

It is situated in the cylinder block or cylinder head and has oblong lobes called

cams which push the intake and exhaust valves. The force is applied on the valve

directly or through push rod and rocker arm assembly.

The camshaft receives its motion from the crankshaft, from which all of the

accessories also must be driven. The camshaft provides a means of actuating the

opening & controlling the period before closing, both inlet as well as exhaust

valves. It provides a drive for the ignition distributor and the fuel pump through

gear train. It also drives the oil pump with the help of a gear provided in the middle

of the camshaft.

Fig. 2.2 Cam and follower arrangement

5 | P a g e

2.2.1 Camshaft Timing:

The relationship between the rotation of the camshaft and the rotation of the

crankshaft is of critical importance. Since the valves control the flow of the air/fuel

mixture intake and exhaust gases, they must be opened and closed at the

appropriate time during the stroke of the piston. For this reason, the camshaft is

connected to the crankshaft either directly, via a gear mechanism, or indirectly via

a belt or chain called a timing belt or timing chain. In some designs the camshaft

also drives the distributor and the oil and fuel pumps. Some vehicles may have the

power steering pump driven by the camshaft. With some early fuel injection

systems, cams on the camshaft would operate the fuel injectors.

Fig. 2.3 Cam and follower timing

2.2.2 Duration:

Duration is the number of crankshaft degrees of engine rotation during

which the valve is off the seat. As a generality, greater duration results in more

6 | P a g e

horsepower. The RPM at which peak horsepower occurs is typically increased as

duration increases at the expense of lower rpm efficiency (torque).

[citation needed]

Duration can often be confusing because manufacturers may select any lift

point to advertise a camshaft's duration and sometimes will manipulate these

numbers. The power and idle characteristics of a camshaft rated at .006" will be

much different than one rated the same at .002".

Many performance engine builders gauge a race profile's aggressiveness by

looking at the duration at .020", .050" and .200". The .020" number determines

how responsive the motor will be and how much low end torque the motor will

make. The .050" number is used to estimate where peak power will occur, and the

.200" number gives an estimate of the power potential.

2.3 TERMINOLOGIES OF CAM:

Terminology for angles and lift

Lobe terminology

Lift curves

2.3.1 Angle and Lift Terminology

There are several terms and abbreviations which are used when discussing

camshafts. The following abbreviations have to do with the location of the piston

in the cycle.

TC or TDC Top Center or Top Dead Center (piston at the highest point)

BC or BDC Bottom Center (piston at lowest point)

BTC or BTDC Before Top Center (piston rising)

7 | P a g e

ATC or ATDC After Top Center (piston lowering)

BBC or BBDC Before Bottom Center (piston lowering)

ABC or ABDC After Bottom Center (piston risinng)

Some of the other terms used are illustrated in the drawing and are explained

below.

Fig. 2.4 Angle and lift terminology

Valve Opening and Closing Angles:

The angles are usually measured in crankshaft degrees when the valves first

leave and then return to their seats. The opening and closing angles may also refer

to a specified nominal lift, e.g. at 0.050 in cam lift. For example, a cam's timing

8 | P a g e

may be stated as 25-65-65-25. These numbers are (1) intake opening BTDC,

intake closing ABDC, (3) exhaust opening BBDC and (4) exhaust closing ATDC.

For these numbers to have meaning, the lift at which the numbers are taken must

be specified.

Duration:

It is the difference between the closing and opening angles. This is the

number of degrees the valves are "off their seats". Duration is usually expressed in

crankshaft degrees. Duration may also refer to the number of degrees that the lift is

greater than a specified value, e.g. duration at 0.050 lift. For a cam with timing 25-

65-65-25, the intake and exhaust duration are both (25 + 65 + 180) = 270 degrees.

Cam Lift:

The lift measured at the tappet or lifter. Gross lift is measured with no valve

clearance; Net lift is the actual lift with valve clearance.

Valve Lift:

The cam lift (gross or net) multiplied by the rocker ratio.

Valve Clearance (Tappet Gap) or Valve Lash:

It is the maximum space between the end valve stem and the adjacent rocker

end or lifter.

Overlap:

This is the number of degrees that the intake and exhaust valves are open at

the same time. A cam with timing of 25-65-65-25 has (25 + 25) = 50 degrees of

overlap. Overlap is the most important parameter effecting idle and off idle quality.

9 | P a g e

Increasing the duration or decreasing the lobe separation cause an increase in

overlap

Lobe Centerline:

The highest lift point of a cam lobe, expressed in crankshaft degrees. For a

symmetric lobe, the centerline is the average of the opening and closing angles. A

symmetric cam with timing 25-65-65-25 has intake and exhaust centers of

(65+180-25)/2 = 110 ATDC and 110 BTDC, respectively.

Lobe Separation Angle or Lobe Displacement Angle:

The angle between the centerline of intake and exhaust lobes. For timing 25-

65-65-25, the lobe separation is 110 cam degrees (220 crank degrees).

Cam Advance:

The position of the midpoint between intake and exhaust lobes relative to

TDC. A cam with timing 25-65-65-25 has no advance and is said to be "straight

up". If the same cam is advanced 4 degrees, its timing becomes 29-61-69-21. The

intake and exhaust centerlines are now at 106 ATDC and 114 BTDC respectively.

Dual Pattern Cam:

If the intake and exhaust lobes have a different grind, the cam is called a

dual pattern cam or dual pattern grind. From the earliest days of cam design, it has

been common to use an exhaust lobe with 10 to 20 degrees more duration than the

intake lobe.

10 | P a g e

2.3.2 Lobe Terminology:

Some of the terminology, which describes a single lobe, is illustrated in

the drawing below.

Fig. 2.5 Cam lobe terminology

Heel or Base Circle:

It is the portion of the cam which is concentric with the bearings and has no

lift.

Ramps:

Immediately adjacent to the base circle, the cam has a portion with low

velocity so there is not a major collision as slack is removed from the valve train at

11 | P a g e

the start of the lift event. Similarly, a closing ramp is used so the valve will seat

gently and not bounce off the seat.

Flanks:

The portion of the cam with large acceleration and velocity to get the valve

moving as quickly as possible

Nose or Toe:

The portion of the cam with the smallest radius of curvature, opposite the

heel. This part has the greatest lift.

Asymmetric Lobe:

The opening and closing side of the cam are different

Core:

The rough part of the camshaft between the lobes, bearings and gears

2.3.3 Lift Curves:

The purpose of the cam lobe is to raise the lifter and open the valve.

One can look at the lobe, but it doesn't tell you exactly how it is going to do its

job. The lift curve is a more precise way to look at the cam lift. It is a graph of

the lifter (or valve) motion as the cam rotates.

Below is an example for a cam with 251 degrees of duration at 0.050 lift.

The lift curve can be measured using a degree wheel and dial indicator or more

accurately using a computer driven cam profiling system. The opening intake

12 | P a g e

ramp and flank and the intake nose are indicated on the graph. The ramp does not

extend much beyond the valve opening, usually less than 0.015 in (0.4 mm) lift.

After the ramp, the large upward curvature indicates the start of the flank. The nose

portion is the large central area with negative curvature.

Fig. 2.6 Lift curves

2.4 MATERIAL COMPOSITION OF CAMSHAFT:

EN-8D & BS-970:

0.42% to 0.45% of Carbon,

0.35% Maximum of Silicon,

0.7% to 0.9% of Manganese,

0.06% Maximum of Sulphur & Phosphorous

13 | P a g e

2.5 CAMSHAFT POSITION:

Depending on the location of the camshaft, the cams operate the valves either

directly or through a linkage of pushrods and rocker arms.

In the past, when engines were not as reliable as today this was seen as too

much bother, but in modern gasoline engines the overhead cam system,

where the camshaft is on top of the cylinder head, is quite common.

Some engines use two camshafts each for the intake and exhaust valves;

such an arrangement is known as a double or dual overhead cam (DOHC).

14 | P a g e

CHAPTER 3

MACHING OPERATIONS OF CAMSHAFT

3.1 CAMSHAFT MACHINING SEQUENCE:

The rough material from the Casting area in the foundry goes through the

following process as represented in sequence.

3.1.1 FACING AND CENTERING:

Machine: Endomatic (or) Facing and Centering

In this process the total length of the camshaft is maintained by milling on

both the faces and the work center is produced by drilling operation on the centre.

Further the collar position is maintained for the purpose of doing the operation in

the CNC machine as the program is developed based on the length of the camshaft.

Gauges used

Dimension of length gauge:

Go: 821.18 mm No Go: 820.928 mm

Centre Depth Gauge

Go: 10.87 mm No Go: 10.72 mm

3.1.2 STRAIGHTENING:

Machine: Hydraulic Press

As the camshaft is so lengthy it may get bend during transportation. So

before turning operation the straightening of the component is to be carried out.

3.1.3 ROUGH TURNING:

Machine: CNC turning machine (Warner & Swashey Turning center)

In this process all the journals, stem diameter, cam width, collar width is

turned to rough size.

15 | P a g e

3.1.4 FINISH TURNING:

Machine: CNC Turning machine (Warner & Swashey turning center)

In this process all the journals, stem diameter, cam width, collar width is

turned to the required size here. The journals and gear diameter is maintained with

0.050mm tolerance.

Dimension of gauge used:

Collar width

Go: 7.82mm No Go: 7.77mm

Camshaft

Go: 17.065mm No Go: 16.815mm

Journals

Go: 53.683mm No Go: 53.632mm

Gear

Go: 50.825mm No Go: 50.775mm

Stem (between gears)

Go: 33.25mm No Go: 32.75mm

Stem (between cams)

Go: 29.45mm No Go: 28.95mm

3.1.5 STRAIGHTENING:

Machine: Hydraulic press

Straightening is the process by which the bend in the component is

eliminated by the application of the pressure by the timed provision. The reason for

the application of the straightening is the length of the camshaft the job may get

bend due to the turning operation and hence the straightening process is carried out

and tolerance is maintained by 0.050mm.

16 | P a g e

3.1.6 KEYWAY MILLING:

Machine: BFW VMC

Keyway is the vital requirement of a camshaft carried out after the

straightening process. Keyway is machined in the front end of the camshaft and its

due to the reason that the cam gear that can be fitted in the engine assembly

process which is driven by crank shaft gear. Another need of the keyway is that it

acts as locating reference point for cam milling/grinding.

In the process of cam grinding/milling the keyway which acts as the basis for

holding the chuck so the keyway is of great importance. Following shows the

specifications of a keyway.

Specifications:

Key width Go: 4.813mm No Go: 4.839mm

Length Go: 14.402mm No Go: 14.529mm

Depth Go: 2.607mm No Go: 2.632mm

3.1.7 CAM MILLING:

Machine: CNC milling machine (KOPP) Germany

The keyway milling has two purposes i.e. for the cam gear positioning in the

engine and also to act as a reference point for the cam milling process. Cam

milling process is carried out in the camshaft due to the reason that the cam noses

are placed by the different angles for valve operation. So the cam is being milled

with the help of CNC using the mill cutter. In this machine, there is X and Z axis

in addition to this it has C and W axis. The C axis is called as Chuck axis. The W

axis is called work piece axis. The chuck has a key on which the job is placed by

17 | P a g e

keyway. The C axis determines the position of the nose of the cam and according

to that the milling is done.

3.1.8 GEAR HOBBING:

Machine: Hobbing Machine (Cooper)

Gear hobbing mechanism is discussed in depth ,in gear manufacturing

process and in the camshaft the hobbing is carried out using hobbing machine

named as cooper The camshaft that has to be hobbed is placed vertically with the

help of the carrier and the other end is held with the help on pneumatic chuck. In

the middle of the camshaft, one spiral gear with 15 teeth and 45

0

angle is produced.

The purpose of the gear is to drive the oil pump gear.

3.1.9 GUN DRILLING:

Machine: Gun Drilling Machine (or) Deep hole drilling

It is a special purpose machine to make an 11mm hole through the entire

length of the camshaft through which the oil passes for lubrication purpose.

Oil hole diameter after drilling = 11mm

3.1.10 COUNTER BORING AND TAPPING:

Machine: Esskay machine tools

Counter boring is the operation of enlarging the end of a hole cylindrically.

The enlarged hole forms a square shoulder with the original hole. This is necessary

in some cases to accommodate the heads of bolts, studs and pins. The tool used for

counter boring is called a coulter bore. The counter bores are made with straight or

tapered shank to fit in the drill spindle. The cutting edges may have straight or

spiral teeth. The tool is guided by a pilot which extends beyond the end of the

cutting edges. The pilot fits into the small diameter hole having running clearance

and maintains the alignment of the tool

18 | P a g e

In the assembly, the camshaft is placed and the cam gear with locking nut is

to be placed on the front end and the plug with hole has to be placed (to drain the

lubricating oil) on the rear end of the camshaft. For inserting the locking nut and

plug, thread is needed on both ends. Further as the work centre is removed during

the gun drilling operation, a new work centre has to be created for the further

process which is done between centres of the job. So, we need a tap and bore on

both ends.

For BSF thread, the tap is needed and the required drill size for the tap is

16.7mm diameter and length of 45mm.

To determine the start of the thread and to get the required length of the thread,

step reaming is done. The step reaming is done for 19.8mm diameter and 12.7mm

length. To produce the new work center counter boring for 25.4mm diameter and

counter sink for an angle of 60

0

is done. Finally the threading is done in the job. So

all this 4 process are done in this single stage.

3.1.11 OIL HOLE DRILLING:

Machine: Small Radial Drilling Machine

For the purpose of lubrication two holes (through hole for the entry and exit

of the oil) are put perpendicularly on the collar. In addition to this single hole is

machined on other two journals.

3.1.12 DRESSING:

To remove the burr in the inner surface of the camshaft a deburring tool is

inserted and removed in the through hole, so that if there is any bur it will get

removed. The gear is dressed using file.

19 | P a g e

3.1.13 WASHING:

As the job passed through the above mentioned process, some oil particles

may stick on the job. Before hardening, the oil particles have to be removed

otherwise it may lead to unwanted burning. So the oil particles are removed in the

Washing Machine using heated Soda Water.

3.1.14 NUMBER PUNCHING:

Each and every camshaft has a unique serial number and it is punched on the

job for the purpose of identification.

E.g., xx x xx

The first two variables represent the model code, third variable represent the place

it is manufactured ie Ennore (E), and the last two variables represent the year code.

3.1.15 INDUCTION HARDENING:

Machine: CNC Hardening Machine (EMA)

Induction hardening is a form of heat treatment in which a metal part is

heated by induction heating and then quenched. Induction hardening is used to

selectively harden areas of a part or assembly without affecting the properties of

the part as a whole. . The temperature is raised to about 840 degree Celsius and

cooled rapidly using water.

During the operation of engine, the journals, cams and the gear (oil pump

drive) have to overcome very high stress. So it has to be strengthened. For this, the

hardening is done. Instead of hardening the whole length of the job, the required

parts alone is hardened in this process. If the whole length of the camshaft is

hardened, then there may be chances to get broken because of the high stress. In

this process according to the required hardness the program is developed in the

CNC and further hardness testing is done.

20 | P a g e

3.1.16 TEMPERING:

After the hardening treatment is applied, job is often harder than needed and

is too brittle for most practical uses. Also, severe internal stresses are set up during

the rapid cooling from the hardening temperature. To relieve the internal stresses

and reduce brittleness, you should temper the steel after it is hardened. Tempering

consists of heating the steel to a specific temperature about 260 degrees Celsius,

holding it at that temperature for the required length of time, and then cooling it,

usually instill air.

During the hardening process, the hardening is done only on the journals,

cam and gear but not on the stem diameter. This will create temper (an uneven

hardness) on the job and may lead to breakage of the job during the operation of

the engine. So to avoid this tempering is done.

In this process, the job is heated up to a particular temperature and hot air is

blown on the whole length of the job for 3 hrs and then kept at room temperature

for 1 hr. Thus the temper is neutralized thereby unwanted stress is relieved.

3.1.17 STRAIGHTERNING:

Machine: Hydraulic Press

In the hardening process, there may be a chance for the job to get bend. So the

straightening is done and maintained by 0.050mm tolerance.

3.1.18 GRINDING:

For the camshaft, the grinding is done in three stages. It is an important

process as it determines the accuracy of the job. The finishing is done very

accurately so that the efficiency of the engine will be increased.

The four stages are:

Camshaft Gear Diameter grinding

Steady diameter grinding

21 | P a g e

Journal diameter grinding

Cam grinding

3.1.19 CAMSHAFT GEAR DIAMETER GRINDING:

At the front end of the camshaft, a gear has to be placed. This gear is driven

by crank shaft gear during the engine operation so that the camshaft is rotated and

the valves will be operated. Thus the front end of the camshaft is grinded in this

stage. The grinding is done accurately.

In this grinding, the thickness of the collar is also maintained. The

dimension of the collar is: Go: 7.44mm No Go: 7.42mm

3.1.20 STEADY DIAMETER GRINDING:

In the camshaft, there are four journals- one at the front end, one at the rear

end and two in the middle. As the job is placed in between centre in the machine,

the front end and the rear end of the job will be supported by headstock and

tailstock respectively. So there will be no vibration during the grinding process.

For placing the pin on the stem, the diameter is maintained according to the

need in this steady diameter grinding process. There is no need for the specific

dimension for the diameter of the stem. But the grinding should be done accurately

without any ovality. If there is any ovality in the stem diameter, it will be reflected

in the journal diameter.

3.1.21 JOURNAL DIAMETER GRINDING

In this process, the four journals are grinded to the required diameter and

maintained by 0.025mm tolerance. The collar width is also maintained by

0.025mm tolerance.

22 | P a g e

3.1.22 CAM GRINDING:

Machine: CNC grinding machine (SCHOUD German made)

In this process the 12 cams are ground to the required dimension. As the cam

plays the vital role in the value operation, higher finish is required in this process.

Tolerance of 0.25mm is maintained for cam height

3.1.23 HARDNESS CHECKING:

During the operation of engine, large stress is developed in the camshaft. So

the hardness of the camshaft should be maintained up to a particular depth. Hence

the hardness of the camshaft is checked using Rockwell hardness test and the range

is about 55 RC on the cam lobe and 45 RC on other sides of the lobe.

3.1.24 CRACK DETECTION:

There is possibility of cracks and blow holes in the camshaft; hence the

camshaft to be tested is magnetized by passing a heavy current through it or by

making it the core of a coil through which a heavy current is passed. Cracks or

inclusions cause the magnetic flux to break the surface forming free magnetic

poles. When the finely divided magnetic particle mixed with kerosene (8:100) is

sprayed, they collect at the free poles to visibly show the presence of defects.

The presence of a surface or sub surface flaw (void or crack) in the material can be

easily viewed by looking the camshaft in ultra violet light through this method.

3.1.25 DEMAGNETIZATION:

In this process, the component is made to pass through a current carrying

coil and thus the component is demagnetized.

23 | P a g e

CHAPTER 4

COST MANAGAMENT INITIATIVES

4.1 COST MANAGEMENT:

Cost management is the process by which companies control and plan the

costs of doing business. Individual projects should have customized cost

management plans, and companies as a whole also integrate cost management into

their overall business model. There is no single accepted definition for this term,

because it has such broad applications and possible strategies. When properly

implemented, cost management will translate into reduced costs of production for

products and services, as well as increased value being delivered to the customer.

For a company's management to be effective overall, cost management must

be an integral feature of it. It is easiest to understand this concept if it is explained

in the context of a single project. For instance, before a project is started, the

anticipated costs should be identified and measured. These expenses should then

be approved before any purchasing occurs. During the process of completing a

project, all incurred costs should be noted and kept in a record of some kind, to

help ensure that the costs are controlled and kept in line with initial expectations, to

the extent that this is possible.

4.2 Cost Management in an organization:

Taking this approach to cost management will help a company determine

whether they accurately estimated expenses at first, and will help them more

closely predict expenses in the future. Any overspending can also be monitored in

this way, and either eliminated in future projects or specifically approved if the

expense was necessary. Cost management cannot be used in isolation; projects

must be organized and tailored with this strategy in mind.

24 | P a g e

Starting a project with cost management in mind will help to avoid certain

pitfalls that may be present otherwise. If the objectives of the project are not

clearly defined at first, or are changed during the course of the project, cost over-

runs will be more likely. If costs are not fully researched before the project, they

may be underestimated, thereby inflating the expectation of the project's success

unrealistically. Construction projects are subject to their own particular challenges;

these can include constraints in the form of laws and regulations that must be

planned around.

25 | P a g e

CHAPTER 5

PROBLEM IDENTIFICATION

After studying the entire camshaft section, we decided to do our project on

cost reduction in Camshaft manufacturing process.

In camshaft process, there were few areas which had scope of cost reduction they

were

Tool cost reduction

Scrap Reduction

Consumable reduction

Electricity

In these four areas, tool cost reduction was already carried out by few of the

employees and they achieved half the initial cost in tool. Scrap Reduction was the

area which still needed improvement and we chose to do it in Scrap Reduction.

Considering the present market scenario and need for war on cost, we decided to

focus on scrap reduction.

5.1 TYPES OF SCRAP IN CAMSHAFT MACHINING:

The various types of scrap in camshaft manufacturing process are

material scrap and operational scrap.

5.1.1 Material Scrap:

These are the scraps that occur due to the defects in the material itself.

Following are the examples of material scrap:

a.) Cam width less

b.) Collar width less

c.) Journal width less

26 | P a g e

d.) Gear width less

e.) Total length less

f.) Cam unwashed

g.) Insufficient material in stem and journal

h.) Crack in forging.

5.1.2 Operation Scrap:

These scrap occur due to the improper machining operation. These might

occur due the worker negligence or some problem in the machine. Following are

the examples of the operational scrap:

a.) Overall length undersize

b.) Collar width undersize

c.) Journal diameter under size

d.) Gear diameter undersize

e.) Cam gear diameter undersize

f.) Keyway oversize

g.) Cam height undersize

h.) Gear teeth overlap

i.) Run out in counter boring.

We collected the material scrap details from the company and studied it.

The plant requirement for manufacturing cam per month is 2697 Nos. We took the

data sheet for scrap for past 4 months from July to October and studied it.

The table below shows the percentage of the material and operational scrap

produced. The total number of components produces in the company for 4 months

is 10785 nos.

27 | P a g e

Table 5.1 Scrap data July to October 2011

The graph describes the percentage of the material scrap and operational

scrap.

Fig. 5.1 Scrap data in graph

The material scrap was found to be 45000PPM (486 NOS OUT OF 10785)

during period of JUL-OCT2011 in camshaft machining process. Since material

scrap is the highest, preventing the material cost would increase the profit and

improve the production.

2.15 4.51

O/S M/S

%

A

G

E

SCRAP

CAMSHAFT SCRAP JUL-OCT 11

Scrap analysis of Camshaft JULY - OCTOBER 2011

Type of

Engine

E0/E1 E2

TOTAL

%

Total

Production

5163 5622 10785

O/S Scrap 99 133 232 2.15

M/S Scrap 228 258 486 4.51

28 | P a g e

CHAPTER 6

PROBLEM ANALYSIS

6.1 OBJECTIVE:

To reduce the material scrap in camshaft manufacturing process from

45000ppm to 1000ppm within a period of 3 weeks [From 3/12/2011 to

28/12/2011].

6.2 PROBLEM SCRUTINY:

The reason for material scrap is found out that is because of the turning

operation in the machining process and then we started to inspect all the turning

operation in the production of the camshaft.

The focus is now on the turning operation which causes high amount of

material scrap. We analyzed the turning operation which causes material scrap and

plotted a pareto chart and also a cause & effect diagram.

6.3 PARETO ANALYSIS:

Pareto analysis is a statistical technique in decision making that is used for

selection of a limited number of tasks that produce significant overall effect. It uses

the Pareto principle the idea that by doing 20% of work, 80% of the advantage of

doing the entire job can be generated. Or in terms of quality improvement, a large

majority of problems (80%) are produced by a few key causes (20%).

In quality control concentrating in particular on the most troublesome causes

follows the principle. In management control, the principle is used by top

management looking continually at certain key figures. Thus it is clear that the

Pareto concept the vital few and the trivial many is of utmost importance to

management.

29 | P a g e

6.4 PARETO ANALYSIS OF CAMSHAFT MATERIAL SCRAP:

Fig. 6.1 Pareto analysis

The above pareto analysis clearly shows that the cam width less, cam lobe

unwashed, journal width less, cam crack and gear width less are the main reasons

for the material scrap.

Also from the pareto diagram, we came to know that the cam width, journal

& gear unwashed contribute to 71.6 % of material scrap.

The above said material scrap occurred in turning process. The component

which is scraped cannot be reworked again, hence it is a huge loss for the company

and productivity is decreased. So all the turning machining process is to be

analyzed to reduce the material scrap.

251

81 80

57

19

0

10

20

30

40

50

60

70

80

90

100

0

50

100

150

200

250

300

350

400

450

Cam

width less

Cam lobe

unwash

Jl width

less

Cam

crack

Gear

width less

C

U

M

%

Q

T

Y

DEFECTS

PARETO ANALYSIS OF CAMSHAFT MATERIAL SCRAP

NOV-DEC 11

30 | P a g e

6.5 CAUSE AND EFFECT DIAGRAM:

Level 1:

Fig. 6.2 Level 1 - All possible causes

Level 2:

The tool offset, machining allowance in pre machining, overall length and

hydraulic pressure in machine is found to be perfect so eliminated

Fig. 6.3 Level 2 Causes eliminated

31 | P a g e

Level 3:

On analyzing the causes due to the working personnel, they all found to be alright

Fig. 6.4 Level 3 - Analyzing the cause - MEN

Level 4:

Fig. 6.5 level 4 Analyzing the cause - MATERIAL

6.5.1 Bend in component:

If the component is having bent, it will lead to unwashed cam and journals.

After checking it is found that bend in component is found within the tolerance and

also there is straightening process before turning

32 | P a g e

6.5.2 Machining allowance:

In the rough material we checked the machining allowance for 50 nos. and

found to be 2.5 mm both side in journal, cam & gear

6.5.3 Positional variation:

We found out that the positional variation in the rough material will lead to

unwashed in journal, cam and gear width in turning process.

Fig.6.6 Turning process

Level 5:

Fig. 6.7 Level 5 - Analyzing the cause - METHOD

33 | P a g e

6.5.4 Work Holding Devices:

When chuck pressure and centre spring tension is checked, it is found ok.

When tail stock and steady pressure is checked it is found to be 20bar and 14bar

respectively and the working condition of the chuck is found to be ok.

6.5.5 Malfunction:

There was no malfunction problem in encoders, as the mechatronics

department found it ok, also the same is ensured through quality check of

dimension after turning.

6.6 ROOT CAUSE:

It has been found that the main reason for cam, journal and gear width

unwashed in turning process is due to the positional variation of the tool during the

turning process, which is shown in the root cause diagram.

Fig. 6.8 Root Cause Diagram

34 | P a g e

CHAPTER 7

BRAINSTORMING FOR SOLUTIONS

7.1 EVALUATION:

The rough material is bought from Shardlow India Ltd in pre machined

condition. To avoid tool breakage and control tools consumption and cycle time,

pre-machining is being done at supplier end with a machining allowance of 2.5

mm per side in length and diameter. When 100 numbers of camshaft rough

materials is checked using the template provided and found the cam and journal

position is ok.

Hence we concluded that positional variation occurred after facing and

centering, so we analyzed the facing and centering process. We checked the

position of the work piece and any error in material loading.

Fig. 7.1 Facing and centering machine

35 | P a g e

7.2 PRESENT METHOD:

The butting pad locates the camshaft over the clamping jaws in correct

position.

As the front end of camshaft hits the butting plate, it is released &seated in

position.

Now the facing operation begins.

Fig. 7.2 Cam shaft loaded into position

Fig. 7.3 Butting bracket rubbing the front end of camshaft

36 | P a g e

CHAPTER 8

PROBLEM DEFINITION

8.1 LENGTH VARIATION:

The required length of cam gear dia is 20.4 mm in the pre machined

material.

But there is a variation of more than 2 mm, barring the overall length which

remains constant.

Fig. 8.1 Required length of cam gear dia.

Fig. 8.2 Variation in length

37 | P a g e

8.2 UNEVEN SURFACE

In some work pieces there was a pip and uneven surface at the butting face

of the component.

Pip and uneven surface will lead to positional variation in turning process.

So we segregated 100 Numbers of uneven surface/pip components and

removed the same in a centre lathe without affecting the length.

Then we proceeded with facing and centering and turning operation.

We found that 3 NOS having unwashed cam width (ie 3%).

The problem is not fully eliminated.

8.3 COLLAR LENGTH:

By using the L gauge collar centre position is checked visually and length

is also checked using the gauge and centre depth is also checked at both ends after

facing and centering. It is found that the length, centre drill depth is ok but the

collar length varies in 5 numbers out of 100 numbers (50000 ppm)

Fig. 8.3 Collar center position is checked using L gauge

38 | P a g e

CHAPTER 9

INFERENCE

9.1 DEVELOPMENT OF SOLUTION:

We checked cam gear diameter length in 100 numbers and found that 5

numbers have excess length of 3mm.

But in the facing and centering process cam gear diameter face is the butting

surface.

Hence length variation of camshaft gear diameter will lead to positional

variation.

The length variation in the camshaft gear diameter will advance the

component to the rear side in facing and centering process.

Due to this the length of rear end journal will be less.

The rear end journal is the butting surface in turning process as shown.

Length variation leading to unwashed cam, journal and gear area in turning.

Hence these length variations in the front end of the component lead to

positional variation in turning.

The cam position is maintained from collar face in pre-machining operation

at supplier end.

They do the pre machining with allowance of 4 mm, & face the end portions

to maintain the overall length.

So any variation in the camshaft length is compensated by adding or

reducing the cam gear dia.

39 | P a g e

Fig 9.1 Template for checking raw material

On next step through the help of the template (as shown in fig above) we

checked the linear position of the cam, collar and the journals.

9.2 ALTERNATIVE SOLUTION:

The template checking implied the result, the position is maintained from the

collar surface and cam gear diameter has not been taken into consideration.

We finalized this result, the position of butting should be changed to collar position

in order to avoid scrap and following design process is carried out.

40 | P a g e

CHAPTER 10

PROPOSED METHOD

As through the alternative solution the butting position is changed from

camshaft face to collar. The positional variation in the camshaft facing & centering

can be overcome by shifting the reference position.

Fig 10.1 Proposed collar butting

The old butting bracket used to position with the front face of the camshaft

cannot be used to transfer the position to collar. Because the collar is situated at a

higher position to the face of camshaft also it will cause damage to the machine

due to space constraints. Hence we designed the new butting bracket for

positioning with the collar.

41 | P a g e

CHAPTER 11

DESIGN OF COLLAR BUTTING BRACKET

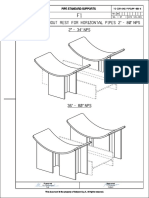

11.1 EVOLUTION OF DESIGN:

The design of the butting plate is divided into four major sections A, B, C.

A is the head portion consisting the provision for mounting the bracket in the

machine.

B is the central extension providing the required length to reach the cam collar

surface.

C section holds the pin assembly.

Fig. 11.1 Sections of butting bracket

42 | P a g e

Due to the shift from cam front end surface to the collar, the displacement

required:

i. Reduce the overall height of the bracket from 160mm to 110mm.

ii. Extend the length from 70mm to 90mm.

11.2 DESIGN:

The butting pin needs to be raised by a distance of 25mm from its present

position.

To achieve this, the height of section B and C is reduced.

The height of the section A is maintained as same in old bracket as it should

hold the bracket in the machine, rigidly in position.

Section C height is brought down from 60mm to 30mm.

Section B is reduced by 20mm.

The nose length of the new bracket needs to be stretched to make the pin

reach front side of the cam collar.

The length of section A is extended by 5mm.

The section B & C are also stretched.

The position of the pin assembly section D is shifted left from centre axis of

the bracket by 10mm to prevent the bracket from striking against the

machine during operation.

The section C is sliced by 10mm to make the pin fit inside the dimension of

the bracket.

43 | P a g e

Fig. 11.2 Design of collar butting bracket.

Fig. 11.3 New butting bracket assembly

44 | P a g e

11.3 IMPLEMENTATION:

We implemented the butting bracket in the facing and centering process.

After absorbing the components for 5 days, we came to know that there is

0% failure in those absorbed components.

Then we checked those components with L gauge and length is also

checked with reference to collar. Then we implemented this project to run in

the centering and facing machine.

So, as the result of our work, where we found it to be the successful, we

further confirmed it to the Unit Planning and we standardized our new

modified budding pad in the Facing and Centering process.

45 | P a g e

CHAPTER 12

RESULT

12.1 GOALS ACHIEVED:

After the implementation of the project the material scrap due to positional

variation in turning process reduced from 3.28% to zero%. Camshaft material

scrap reduced from 4.51% to 1.23%.

12.2 PROJECTED SAVINGS:

The cost saved due to elimination of scrap in camshaft production is

given below

Component produced /Annum =18,000 NOS

Component cost (Rough Material) - Rs 1300

We have calculated the cost per component of camshaft for the facing and

centering operation taking a period of 12 months. The calculation is been done in

comparison with cost before and after modification and the projected cost saving

per annum is given.

12.2.1 MATERIAL COST:

BEFORE IMPLEMENTATION:

Material scrap before project 3.28%

Projected material scrap /Annum = 18000*3.28 = 590 NOS

AFTER IMPLEMENTATION:

Material scrap after project - Nil

Cost of saving (50/50% Production basis of models) =590*1300

Projected cost saving/Annum =Rs 7, 67,000/Annum

46 | P a g e

12.2.2 PROCESS COST:

Up to turning process, process cost per work piece = Rs 36.60

Components saved by the project -590 numbers (3.28% of total production)

Cost saving =590* 36.60 = Rs. 21,594/Annum

Total cost = Rough Material cost + Process cost

= 7, 67,000 + 21,594

= 7, 88,594/Annum.

47 | P a g e

CHAPTER 13

BENEFITS

13.1 BENEFITS OF COLLAR BUTTING BRACKET:

TANGIBLE BENEFITS:

Material scrap reduced from 4.51 % to 1.23%

Operation scrap in grinding reduced from 0.97% to zero

Tool cost / component reduced by 10% in turning process

INTANGIBLE BENEFITS:

Reduction in the material scrap will increase the bargaining capability of

rough material cost.

Timely delivery to engine assembly

Internal customer satisfaction

13.2 FUTURE SCOPE OF THE PROJECT:

This project created greater awareness and this approach can be

implemented to other group of operations. This project provides valuable

suggestions in machining area to reduce manufacturing cost, scrap reduction,

rework reduction etc.

48 | P a g e

CHAPTER 14

CONCLUSIONS

Our main intent of this project is to condense the scrap rate in cam shaft

production. To accomplish our objective, first we chosen to remove the pip on the

front end surface of the camshaft but we could not reach the appropriate results. So

we secondly shifted the butting point to collar of the camshaft and then there was a

diminution in the scrap rate.

By means of this collar butting bracket, when 50 numbers of camshafts is

machined in facing and centering process, we found that there was no unwashed

cam and journal width by implementation of new pad. Also the time taken to

analyze the scrap part is radically reduced. Thus material scrap was reduced

drastically and productivity is increased.

49 | P a g e

CHAPTER 15

REFERENCES

1. K. Venkataraman, Design of Jigs Fixtures & Press Tools, Tata McGraw Hill,

New Delhi, 2005.

2. Kempster, Jigs and Fixture Design, Hoddes and Stoughton Third Edition

1974.

3. Joshi, P.H. Press Tools Design and Construction, Wheels publishing, 1996.

4. Hoffman Jigs and Fixture Design Thomson Delmar Learning, Singapore,

2004.

5. ASTME Fundamentals of Tool Design Prentice Hall of India.

6. Donaldson, Lecain and Goold Tool Design, III rd Edition Tata McGraw Hill,

2000.

7. www. wikipedia.org.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- FMRI - Working PaperDocument4 pagesFMRI - Working PaperSukanth KannanPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Indian Emission Regulation BookletDocument33 pagesIndian Emission Regulation BookletSukanth KannanPas encore d'évaluation

- Feed DrivesDocument13 pagesFeed DrivesSukanth Kannan100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Non-Destructive Testing 03Document111 pagesNon-Destructive Testing 03MahmoudRaafatPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- TQM Unit - 5Document11 pagesTQM Unit - 5Sukanth KannanPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Rapid PrototypingDocument12 pagesRapid PrototypingSukanth KannanPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Nokia C500 UG enDocument95 pagesNokia C500 UG enGurumurty JvsPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Sruakg - Monthly Budget: S.no Particulars Projected AmountDocument12 pagesSruakg - Monthly Budget: S.no Particulars Projected AmountSukanth KannanPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Anna University Non Autonomus College University Holers ListDocument409 pagesAnna University Non Autonomus College University Holers ListSenthatty Ganesh Kumar SethuramalingamPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Medical CertificateDocument1 pageMedical CertificateSukanth KannanPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- T R C P: HE Esearch Onference ResentationDocument13 pagesT R C P: HE Esearch Onference ResentationSukanth KannanPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Tancet MESUBSECDocument51 pagesTancet MESUBSECSukanth KannanPas encore d'évaluation

- FMEA - A Guide For Continuous ImprovementDocument36 pagesFMEA - A Guide For Continuous Improvementvipin_chaudhary100% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Unit 1 QBDocument2 pagesUnit 1 QBSukanth KannanPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grms CalcDocument6 pagesGrms CalcSukanth KannanPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Center DuctDocument1 pageCenter DuctSukanth KannanPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Butting BracketDocument60 pagesButting BracketSukanth KannanPas encore d'évaluation

- Data Base 2013Document24 pagesData Base 2013Sukanth KannanPas encore d'évaluation

- ME (CIM) - PART TIME-Curriculam and SyllabusDocument44 pagesME (CIM) - PART TIME-Curriculam and SyllabusSukanth KannanPas encore d'évaluation

- Computer-Integrated Manufacturing (CIM)Document46 pagesComputer-Integrated Manufacturing (CIM)Sukanth KannanPas encore d'évaluation

- Kim Walter LeeDocument31 pagesKim Walter LeeSukanth KannanPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Chengalpattu - Tambaram Up - Week Days Chengalpattu - Tambaram Up - Week DaysDocument3 pagesChengalpattu - Tambaram Up - Week Days Chengalpattu - Tambaram Up - Week Daysrsrinisha215Pas encore d'évaluation

- CNC 2013Document22 pagesCNC 2013Sukanth KannanPas encore d'évaluation

- How To Get The Target Id of Your MachineDocument2 pagesHow To Get The Target Id of Your Machinesaputro123Pas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- SerialDocument1 pageSerialSukanth KannanPas encore d'évaluation

- CookbookDocument11 pagesCookbookAnand BabuPas encore d'évaluation

- Car SpecificationsDocument7 pagesCar SpecificationsSukanth KannanPas encore d'évaluation

- Airport Guide enDocument14 pagesAirport Guide enmarped82Pas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Section I 2015Document33 pagesSection I 2015ferds2599Pas encore d'évaluation

- Cat ArielDocument107 pagesCat Arieljorge velasquezPas encore d'évaluation

- SEMIKRON Technical Explanation SEMITOP® Classic EN 2021-07-30 Rev-06Document20 pagesSEMIKRON Technical Explanation SEMITOP® Classic EN 2021-07-30 Rev-06carlosmitecPas encore d'évaluation

- Epofine 107 1:finehard 107 1Document2 pagesEpofine 107 1:finehard 107 1Karishma PrabhuPas encore d'évaluation

- Rocket Lab ReportDocument4 pagesRocket Lab Reportbishopclark98Pas encore d'évaluation

- Blower Air Room HeaterDocument18 pagesBlower Air Room HeaterPrashant SrivastavaPas encore d'évaluation

- Laboratory Manual For HardnesstestDocument12 pagesLaboratory Manual For Hardnesstest15 Saad HassanPas encore d'évaluation

- Is-10810 - 5 Methods of Test For Cables ResistanceDocument3 pagesIs-10810 - 5 Methods of Test For Cables ResistancepankajnbiPas encore d'évaluation

- Control of Decarburization of Steel PDFDocument5 pagesControl of Decarburization of Steel PDFBhushan VermaPas encore d'évaluation

- Flat Rack Loading Guidelines 5-28 (NCB Revised Mod 2)Document25 pagesFlat Rack Loading Guidelines 5-28 (NCB Revised Mod 2)Shane Anderson100% (1)

- Company Profile CBP-2019Document17 pagesCompany Profile CBP-2019sunanPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Department of Mechanical Engineering: List of Experiments Hvac LabDocument3 pagesDepartment of Mechanical Engineering: List of Experiments Hvac LabHamid MasoodPas encore d'évaluation

- Curing 4Document588 pagesCuring 4santoruno lupinottiPas encore d'évaluation

- Attachment 2 Color Codes Table of ContentsDocument18 pagesAttachment 2 Color Codes Table of ContentsLy Thanh HaPas encore d'évaluation

- falchemspecFALCOOL2k PDFDocument2 pagesfalchemspecFALCOOL2k PDFandhito yanaPas encore d'évaluation

- Axial Stop Without Rest For Horizontal Pipes 2" - 80" NPS: Pipe Standard SupportsDocument4 pagesAxial Stop Without Rest For Horizontal Pipes 2" - 80" NPS: Pipe Standard SupportsMainuddin AliPas encore d'évaluation

- Wind Turbine Installation-ManualDocument23 pagesWind Turbine Installation-Manualויליאם סן מרמיגיוסPas encore d'évaluation

- FIR and APPENDICES PHMSA WUTC Williams Plymouth 2016 04 28 REDACTEDDocument39 pagesFIR and APPENDICES PHMSA WUTC Williams Plymouth 2016 04 28 REDACTEDrty2Pas encore d'évaluation

- Vultac-5: Mixture of Poly-Tert-Amylphenoldisulfide and Silica GelDocument1 pageVultac-5: Mixture of Poly-Tert-Amylphenoldisulfide and Silica Geljulius hasan33Pas encore d'évaluation

- Valvula Asiento Inclinado Buschjost 84510Document2 pagesValvula Asiento Inclinado Buschjost 84510Base SistemasPas encore d'évaluation

- Design Engineering and Selection of MaterialsDocument58 pagesDesign Engineering and Selection of MaterialsYusuf SahinPas encore d'évaluation

- District ScheduleDocument407 pagesDistrict ScheduleHAZRAT NABI XI JINPINGPas encore d'évaluation

- Hyundai Steel Products GuideDocument40 pagesHyundai Steel Products GuidecarloPas encore d'évaluation

- Gear RatiosDocument10 pagesGear RatiosYouMinePas encore d'évaluation

- MAAGGear OpenGearingDocument4 pagesMAAGGear OpenGearingMuhammadPas encore d'évaluation

- Oi-Andritz Centrifugal Pumps Portfolio enDocument8 pagesOi-Andritz Centrifugal Pumps Portfolio enRangwane MallexPas encore d'évaluation

- 20d-Stepped Masonry Retaining Wall-Stability CheckDocument6 pages20d-Stepped Masonry Retaining Wall-Stability CheckParthiban Arivazhagan100% (1)

- DSMTS-0095.3 NiCrAlMo CompositeDocument3 pagesDSMTS-0095.3 NiCrAlMo Compositeivanis_davorPas encore d'évaluation

- CO2 FloodingDocument15 pagesCO2 FloodingUzumaki28Pas encore d'évaluation

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsD'EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsPas encore d'évaluation

- Advanced Modelling Techniques in Structural DesignD'EverandAdvanced Modelling Techniques in Structural DesignÉvaluation : 5 sur 5 étoiles5/5 (3)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresD'EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresÉvaluation : 1 sur 5 étoiles1/5 (2)

- Marine Structural Design CalculationsD'EverandMarine Structural Design CalculationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (13)

- To Engineer Is Human: The Role of Failure in Successful DesignD'EverandTo Engineer Is Human: The Role of Failure in Successful DesignÉvaluation : 4 sur 5 étoiles4/5 (137)

- Pile Design and Construction Rules of ThumbD'EverandPile Design and Construction Rules of ThumbÉvaluation : 4.5 sur 5 étoiles4.5/5 (15)

- Structural Cross Sections: Analysis and DesignD'EverandStructural Cross Sections: Analysis and DesignÉvaluation : 4.5 sur 5 étoiles4.5/5 (19)