Académique Documents

Professionnel Documents

Culture Documents

Thermodynamic Analysis of An Electrochemical Refrigeration Cycle

Transféré par

Mawaz Khan Mirza0 évaluation0% ont trouvé ce document utile (0 vote)

17 vues15 pagesThe coupling

of a water-based electrochemical cell and fuel cell are discussed as a means to

form a refrigeration cycle. In the proposed configuration, the process fluids can be passively

driven through the flow circuits. The cycle requires low direct current voltages for driving

the

cycle. Current densities must be maintained sufficiently low in the electrochemical cell in order to

operate below neutral voltage levels. Overall, the cycle's operational limit for the configuration

described is close to Carnot efficiency.

Titre original

Thermodynamic Analysis of an Electrochemical Refrigeration Cycle

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe coupling

of a water-based electrochemical cell and fuel cell are discussed as a means to

form a refrigeration cycle. In the proposed configuration, the process fluids can be passively

driven through the flow circuits. The cycle requires low direct current voltages for driving

the

cycle. Current densities must be maintained sufficiently low in the electrochemical cell in order to

operate below neutral voltage levels. Overall, the cycle's operational limit for the configuration

described is close to Carnot efficiency.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

17 vues15 pagesThermodynamic Analysis of An Electrochemical Refrigeration Cycle

Transféré par

Mawaz Khan MirzaThe coupling

of a water-based electrochemical cell and fuel cell are discussed as a means to

form a refrigeration cycle. In the proposed configuration, the process fluids can be passively

driven through the flow circuits. The cycle requires low direct current voltages for driving

the

cycle. Current densities must be maintained sufficiently low in the electrochemical cell in order to

operate below neutral voltage levels. Overall, the cycle's operational limit for the configuration

described is close to Carnot efficiency.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 15

Thermodynamic Analysis of an

Electrochemical Refrigeration Cycle

ACRCTR-1l2

For additional information:

Air Conditioning and Refrigeration Center

University of Illinois

Mechanical & Industrial Engineering Dept.

1206 West Green Street

Urbana,IL 61801

(217) 333-3115

T. A. Newell

February 1997

The Air Conditioning and Refrigeration Center

was founded in 1988 with a grant from the estate

of Richard W. Kritzer, the founder of Peerless of

America Inc. A State of Illinois Technology

Challenge Grant helped build the laboratory

facilities. The ACRC receives continuing

supportfrom the Richard W. Kritzer Endowment

and the National Science Foundation. The

following organizations have also become

sponsors of the Center.

Amana Refrigeration, mc.

Brazeway, Inc.

Carrier Corporation

Caterpillar, Inc.

Copeland Corporation

Dayton Thennal Products

Delphi Harrison Thennal Systems

Eaton Corporation

Ford Motor Company

Frigidaire Company

General Electric Company

Hydro Aluminum Adrian, mc.

Lennox mtemational, mc.

Modine Manufacturing Co.

Peerless of America, mc.

Redwood Microsystems, mc.

The Trane Company

Whirlpool Corporation

For additional information:

Air Conditioning & Refrigeration Center

Mechanical & Industrial Engineering Dept.

University of Illinois

1206 West Green Street

Urbana IL 61801

2173333115

ABSTRACT

Thermodynamic Analysis of an

Electrochemical Refrigeration Cycle

Ty A. Newell

The coupling of a water-based electrochemical cell and fuel cell are discussed as a means to

form a refrigeration cycle. In the proposed configuration, the process fluids can be passively

driven through the flow circuits. The cycle requires low direct current voltages for driving the

cycle. Current densities must be maintained sufficiently low in the electrochemical cell in order to

operate below neutral voltage levels. Overall, the cycle's operational limit for the configuration

described is close to Carnot efficiency.

INTRODUCTION

A fuel cell and its reversible analog, the electrochemical cell, can be coupled in a manner that

forms some interesting thermodynamic cycles. A simple thermodynamic analysis of a

configuration for a refrigeration cycle is described in this paper. Alternative configurations can

also be developed for achieving refrigeration effects and for forming thermally driven power

cycles.

Fuel cells and electrochemical cells have a long history in science and in application (Soo

(1968)). Industrial electrochemical processes are responsible for the production of many materials.

Research in the fuel cell area continues to grow with significant demonstrations of the technology

showing its future potential (Appleby and Foulkes (1989)). Thermodynamic processes are

understood and basic fuel cell analyses commonly appear in thermodynamic textbooks (e.g.,

Moran and Shapiro(1995), Howell and Buckius (1992)). Several areas of difficulties related to

materials, transport processes and cost must be addressed in order to determine whether a practical

system of the type described could be developed. Ohta (1979) and Casper (1978) discuss many

fuel cell and electrochemical performance issues.

CYCLE DESCRIPTION

Figure 1 is a schematic of the proposed cycle. Four primary components make up the

system. An electrochemical cell is the heat absorber, equivalent to an evaporator in a conventional

vapor compression refrigeration system. A fuel cell rejects heat in a manner similar to a condenser

in a common vapor compression refrigeration cycle. The third component is a heat exchanger

between gas streams and water flow stream. The fourth component is a current pump for elevating

the fuel cell's voltage output to a level sufficient for driving the electrochemical cell. The voltage

required is sufficiently low such that the cycle may be one that is conveniently matched for solar

1

photo voltaic cells or other direct current electric energy conversion systems. It should be noted

that the system shown in Figure 1 can be used as a thennally driven power cycle by operating the

fuel cell at a temperature lower than the electrochemical cell. In this case, the voltage supply

becomes a load driven by the electric circuit.

The system is assumed to be based on a water/hydrogenloxygen fuel cell and electrochemical

cell combination. Other combinations may also be considered. For example, sodium chloride

highly concentrated in water would produce chlorine and oxygen in the electrochemical cell. An

aqueous solution of sodium chloride and sodium hydroxide would be passed to the fuel cell for the

reversed chlorine/oxygen reaction. Possible advantages or disadvantages of this or other

alternative working fluids are not considered in this work.

The configuration envisioned for the system shown in Figure 1 operates near atmospheric

pressure. The components could be operated at nearly uniform pressures with gravitation andlor

surface tension used for transporting the working fluids within and between components. Water

may be moved from the electrochemical cell and fuel cell to external heat exchange surfaces, or, the

cells could be configured for direct heat exchange with their surroundings.

,

Heat and

Work IN

H2

Heat Exchanger

... I I I I I

02 II III IIII III

H20

,

--

Electrochemical

Cell

""'"-

Fuel

Cell

I

current flow

~ - - - - - - J -----I: /1 I ~ ~

~

..... 1 - - & V added ~

current flow ,

~ V electrochemical

cell

&V fuel cell

Heat and

Work OUT

Figure 1 Schematic of an electrochemical absorption refrigeration cycle. The electrochemical cell

is the heat absorber and the fuel cell the heat rejector.

2

CYCLE ANALYSIS

Basic forms of the 1 st and 2nd Laws of thermodynamics are used to model each of the

system's components. Fuel cell work transfer can be described by the following relation.

W f = nH20 (T 1 SH20e - hH20e) - nH2 (T 1 sH2i - hH2i) - n02 (T 1 s02i - h02i) - TIS gf (1)

Figure 2 shows a schematic of the fuel cell system and its flow streams. The work is in the form

of electrical current flow. The fuel cell is assumed to operate at the temperature of its surrounding

environment. Property values for the incoming hydrogen and oxygen streams are assumed to be at

the fuel cell operating temperature, T 1, the heat exchanger's performance limit.

A similar relation can be written for the electrochemical cell's work.

We = -nH20 (T2 SH20i -hH20i) + nH2 (T2 SH2e -hH2e) + n02 (T2 s02e - h02e) -T2 Sge (2)

Figure 3 shows a schematic of the electrochemical cell system. The cell work input is in the form

of electrical current flow. The electrochemical cell is assumed to operate at the temperature of its

surrounding environment, T2. Water flowing into the electrochemical cell enters at a temperature

somewhat elevated above the cell temperature due to thermodynamic limitations in the heat

exchanger located between the two cells.

Heat transfer for the fuel cell and the electrochemical cell are found from a 1 st Law energy

balance. These relations are shown in equations 3 and 4, respectively.

Qf = nH20 hH20e - nH2 hH2i - n02 h02i + Wf

(3)

(4)

A heat exchanger is used in order to exchange energy between the low temperature gas

streams and the higher temperature water stream. As will be shown later, because water's heat

capacity is greater than that of the combined oxygen and hydrogen streams, the gas streams can

exit at the water's inlet temperature in the limiting case. Water exiting from the exchanger cannot

reach the gas streams' entering temperature. Figure 4 is a schematic of the heat exchanger system.

A 1st Law analysis for the heat exchanger is:

(5)

This set of relations is sufficient for finding the cycle efficiency when given system operating

temperatures and pressures for the fuel cell and electrochemical cell. A simplified set of relations

can be developed that takes advantage of the gas stream components' ideal gas nature and the water

stream's liquid characteristics. Utilizing these characteristics allows the system's operating

3

temperatures and pressures to be used directly in the governing equations. The work relations for

the fuel cell and the electrochemical cell can be rewritten as:

Wf = [Tl (SH20

0

+ CH20 In(Tl/29SK - (hH200 + cH20 (T1-29SK] (6)

- [Tl (SH2

0

+ CH2In(Tl/29SK) - R In(Pl/latm - CH2 (T1-29SK)]

- O.5[TI (802

0

+ c02In(Tl/29SK) - R In(Pl/latm - C02 (Tl-29SK)]

We = - [T2 (SH20

0

+ CH20 In(T2*/29SK - (hH20

0

+ CH20 (T2*-29SK] (7)

+ [T2 (SH2

0

+ CH2In(Tzl29SK) - R In(Pzllatm - CH2 (T2-29SK)]

+ O.5[T2 (S02

0

+ C02In(Tzl29SK) - R In(Pzllatm - C02 (T2-29SK)]

Reversibility has been assumed in equations 6 and 7 because the operational limits of the cycle are

to be analyzed. Standard state enthalpies for oxygen and hydrogen are zero. Water's standard

state enthalpy is assumed to be in the liquid state for the temperatures and pressures considered for

system operation. Note that the gas pressures are total pressures because the gas streams enter and

exit the fuel cell and electrochemical cell separated at the component operating pressures.

Equations 3 and 4 using ideal gas and liquid water characteristics are:

qr = hH20

0

+ CH20 (Tl-29SK) - CH2 (Tl-29SK) - 0.5 CO2 (Tl-29SK) + Wf (S)

qe = - hH20

0

- CH20 (T2*-29SK) + CH2 (T2-29SK) + 0.5 C02 (T2-29SK) +We (9)

When specific heat relations are substituted into equation (5) for the heat exchanger, an expression

is obtained for water's exiting temperature. This expression is based on observing that both

hydrogen and oxygen specific heats are less than that of liquid water, indicating that water must

exit at some temperature higher than the inlet gas temperature.

T2* = Tl -(CH2 + 0.5 C02 )(Tl - T2 )!cH20

(10)

Water's elevated temperature at the heat exchanger is a source of irreversibility.

Equations 6 through 10 can be solved for the work and heat transfers, and for the water exit

temperature from the exchanger for a given set of operating temperatures and pressures.

4

H2

02

In In

,

1

Water

Out

- Tl, P 1

\

,

Heat and

Work OUT

Figure 2 Schematic of the fuel cell system analyzed. The fuel cell is assumed to operate at the

temperature of its ambient surrounds. Inlet and outlet flows are at the same temperature

as the cell operating temperature.

Wat

In

at T

er

2*

H2 02

Out Out

..

T2, P2

,

Heat and

Work 0 UT

Figure 3 Schematic of the electrochemical cell system analyzed. The cell is assumed to operate at

the temperature of its ambient surrounds. Outlet flows are at the same temperature as

the cell operating temperature. The inlet water flow, due to thermodynamic limitations

in the heat exchanger, enters at temperature T 2*.

H2 (T2)

(T2*)

02 (T2)

..

...

(Tl)

H20 (Tl)

(Tl )

Figure 4 Schematic of the heat exchanger system between hydrogen, oxygen, and water flows.

The exchanger is assumed to operate at its thermodynamic limit allowing the oxygen

and hydrogen to exit at the water stream's inlet temperature.

5

RESULTS

Conditions have been assumed for operating the cycle for air conditioning. A range of cold

side temperatures from 273K to 318K have been used with the warm side of the cycle at 323K and

333K. Entropy generation in the fuel cell and electrochemical cell have been assumed to be zero in

order to observe operational performance limits. All cycle components are assumed to operate at

atmospheric pressure. Standard state property values and specific heat values have been taken

from a standard thermodynamics textbook (Moran and Shapiro (1995. Variation of the cycle's

refrigeration coefficient of performance, heat transfer, work, and voltage levels have been

determined.

Figure 5 shows the variation of the cycle's coefficient of performance (COP) for two different

fuel cell operational temperatures. The low temperature conditions of the electrochemical cell have

been varied from 273K to 318K. The COPs are within one percent of the COP of a fully

reversible cycle, indicating that the irreversibility from the heat exchanger is not significant.

a.. 30

o

o

r::::

o

-

as

...

II

C)

;:

-

II

a:

20

10

T1 (fuel cell) = 323K

T1 (fuel cell) = 333K

~ ~ ~ ~ ~ ~

270 280 290 300 310 320

T2 (electrochemical cell) K

Figure 5 Refrigeration COP for the electrochemical system over a range of low temperatures

(electrochemical cell temperatures) and two high temperatures (fuel cell temperatures).

Figure 6 shows the fuel cell and electrochemical cell heat transfers over a range of cold-side

temperatures. The fuel cell's heat transfer per mass of water increases with increasing operational

temperature. The electrochemical cell's heat transfer is relatively unaffected by the fuel cell's

operational temperature. The opposite is also true. That is, the electrochemical cell's operational

condition is relatively unaffected by the fuel cell's temperature. The primary factor that links the

performance of the two cells is the heat exchanger. Because the heat capacities between the water

6

and gas streams are not perfectly matched, variation of the fuel cell and electrochemical cell

operational temperatures affects the water temperature that enters the electrochemical cell. The

mismatch, however, results in a small irreversibility to the overall system. Figure 7 shows the

variation of the water outlet temperature from the heat exchanger relative to the operational

temperatures of the fuel cell and electrochemical cell.

3000

..

"

-

"

c

!,::"

t-"

..

.. II

II

2500

" .

::I:

m

~

- ,,-'

.. ~

::s-

323K ::::::

electrochemical cell

'0 T1

=

"

fuel cell

.a

333K ::::::

electrochemical cell

c(

T1

=

fuel cell

2000

270 280 290 300 310 320

T2 (electrochemical cell) K

Figure 6 Electrochemical cell and fuel cell absolute heat transfer per water mass for two fuel cell

temperatures over a range of electrochemical cell temperatures.

400

--a-- fuel cell = 323K

--r- heat exchanger water outlet

--0- fuel cell = 333K

......

~

350

---+-- heat exchanger water outlet

.....

"

0 0 0 0 0 0 0 0 0 0

..

::s

..

II

..

"

a.

E 300

"

t-

--+- electrochemical cell temperature

2 5 0 ~ ~ ~ ~ ~

270 280 290 300 310 320

T2 (electrochemical cell) K

Figure 7 Plot of the water outlet temperature from the heat exchanger relative to the fuel cell and

electrochemical cell temperatures.

7

Figure 8 shows the work required by the electrochemical cell and the work produced by the

fuel cell. The fuel cell's work output is reduced as its temperature is increased. The work

produced by the fuel cell is lower than the work required by the electrochemical cell. As the

electrochemical cell's temperature approaches the fuel cell's temperature, the work difference is

reduced to zero.

1 4 0 0 0 ~ ~ ~ . ~ ~ ~ ~ ~

13500

, -

~

......

o CD

=:;

CD i:

13000

- I

:J CJ)

- ,

0 __

CII..,

323K --Is;-

electrochemical cell J:I,

T1

c( __

=

12500

--.....- fuel cell

T1 333K=:=

electrochemical cell

=

fuel cell

12000

270 280 290 300 310 320

T2(electrochemical cell) K

Figure 8 Electrochemical cell and fuel cell work per water mass for two fuel cell temperatures

over a range of electrochemical cell temperatures.

Figure 9 shows the voltages across the fuel cell and the electrochemical cell for the assumed

range of conditions. Voltages are determined by calculating the current flow per mole of water.

The current, relative to the work per mole in the fuel cell and electrochemical cell, determines the

voltage across each cell.

Irreversibilities in the fuel cell and electrochemical cell affect the system operation in different

manners. Irreversibilities, in general, lower the cycle's performance. In the fuel cell, a lower

voltage output occurs, thus requiring a larger voltage boost for driving the electrochemical cell.

Irreversibilities in the electrochemical cell affect the cycle in two ways. First, the voltage required

to operate the cell increases. The second, and more significant effect, is internal heat generation

that limits the amount of heat transferred into the electrochemical cell from its surroundings. When

the level of irreversibility increases sufficiently, a "neutral" voltage level is reached. This is the

limit where no external heat transfer occurs. Above the neutral voltage limit, the electrochemical

cell exhausts thermal energy to its surroundings. Ohta (1978) describes the types of

irreversibilities within hydrogen/oxygen electrolysis systems.

8

1.28

T1 323K=:=

fuel cell

=

electrochemical cell

1.26

T1 333K:::=

fuel cell

= electrochemical cell

1.24

C)

II

= 0

1.22

>

c c c c c c c c

1.20

0 0 0 0 0 0 0 0 0 0

1.18

270 280 290 300 310 320

T2 (electrochemical cell) K

Figure 9 Electrochemical cell and fuel cell voltages for two fuel cell temperatures over a range of

electrochemical cell temperatures.

The operational limit of the cycle, when ireversibilities in the electrochemical cell reach the

neutral voltage level, can be determined by setting the electrochemical cell's heat transfer to zero.

The entropy generation term is included in the electrochemical cell's work relation, or alternatively,

the cell's reversible work can be divided by an efficiency parameter. Figure 10 shows the

electrochemical cell efficiency when irreversibilities cause the cell to operate at the neutral voltage

level. When cell efficiencies are below those shown in Figure 10, the system can no longer operate

in the refrigeration mode. The actual neutral voltage level is insensitive to the operational

conditions shown in Figure 10. The neutral voltage varies between 1.476 and 1.478 volts for the

conditions plotted. Brown, et.al. (1980) describe electrode surfaces with low overvoltage

characterisitics. Current densities less than 10 milliamps per square centimeter may be operated

with overvoltages that are 0.01 volts above the reversible limit.

The mass flow rate for achieving a desired level of refrigeration is shown in Figure 11.

Water flow rates for one "ton" (12,000 Btu/hr = 12,600 kJ/hr) of refrigeration is plotted over a

range of cell temperatures with reversible cell operation assumed. One ton of refrigeration is

typical of room air conditioners (window units). Mass flows are sensitive to the electrochemical

cell's temperature, however, the fuel cell's temperature is not as significant.

All results presented have assumed that the system operates uniformly at atmospheric

pressure. Variation of the system's pressure does not significantly affect the performance values

shown in the previous figures as long as a uniform pressure is assumed throughout the system. A

9

configuration which relies on surface tension or gravitational bases for moving fluids between

system components has been assumed. Unrestrained pressure drops between the components will

lead to irreversibilities that adversely affect system performance.

0.90

..

.!!

--6-

T1 =323K

E>o

~ T1 =333K

u

z: c

u

0-

.. u

... -

u=

0.85

.!!W

w=

EO

:::s

E

c

2

0.80

270 280 290 300 310 320

T2 (electrochemical cell) K

Figure 10 Minimum electrochemical cell efficiency over a range of operating conditions.

5.4

C

T1 = 323K

5.2

0

T1 = 333K

0

u::-

5.0 c

" 0 ~

II ..

::E:!!:

Q

4.8

.. ~

.-

...

II

==

4.6

4.4

270 280 290 300 310 320

T2 (electrochemical cell) K

Figure 11 Water flow per "ton" of refrigeration capacity over a range of operational conditions.

10

CONCLUSIONS

A method for operating a refrigeration cycle has been described. Practical development of the

system depends on several factors. High quality electrode surfaces must be used in order to keep

voltage drops and reaction resistances to a minimum. Electrolytes for the fuel cell and

electrochemical cell must be chosen. The costs associated with these components is another factor

affecting the economic feasibility of the proposed system.

A beneficial aspect of the proposed system is that it may be coupled to a variety of low

voltage, direct current electrical energy generators. Photovoltaic solar cells would be one example

of an energy source that may be directly compatible with the "current pumping" required by this

system. Cell modules would need to be "stacked" in a series configuration in order to have the

overall voltage differential match the voltage level available for driving the system. Stacking cell

modules is also desirable in order to keep current flow, and therefore electric circuit resistive losses

small.

Environmentally, the system is free of refrigerant compounds with ozone depletion and global

warming concerns. Safety issues regarding the movement of oxygen and hydrogen must be

address, however, the mass flow rates are quite small per ton of refrigeration effect and reasonable

designs should be able to minimize the actual system mass and volume in hydrogen and oxygen.

11

NOMENCLATURE

Co2 molar constant pressure specific heat of oxygen

CH2 molar constant pressure specific heat of hydrogen

CH20 molar constant pressure specific heat of water

h02 molar enthalpy of oxygen

hH2 molar enthalpy of hydrogen

hH20 molar enthalpy of water

n02 moles of oxygen transported

nH2 moles of hydrogen transported

nH20 moles of water transported

Oc electrochemical cell heat transfer

Qr fuel cell heat transfer

qc electrochemical cell heat transfer per mole of water

qr fuel cell heat transfer per mole of water

R universal gas constant

S02 molar entropy of oxygen

SH2 molar entropy of hydrogen

SH20 molar entropy of water

S gc entropy generation in the fuel cell

S gf entropy generation in the fuel cell

T 1 fuel cell operating temperature

T 2 electrochemical cell operating temperature

T2* water outlet temperature from the heat exchanger

We electrochemical cell work

W f fuel cell work

We electrochemical cell work per mole of water

Wf fuel cell work per mole of water

superscript

o indicates property (enthalpy or entropy) at standard state value (1 atmosphere and 298K)

subscripts

i indicates inlet stream to the system of interest

e indicates an exit stream from the component of interest

12

REFERENCES

Appleby, A.I. and Foulkes, F.R., 1989, Fuel Cell Handbook, Van Nostrand Reinhold.

Brown, D.E., Mahmoud, M.N., Turner, A.K., Hall, S.M., Fogarty, P.O., 1980, Low

overvoltage electrocatalysts for hydrogen evolving electrodes, Hydrogen Energy Progress,

3rd World Energy Conf., Tokyo, pp.151-164.

Casper, M.S., 1978, Hydrogen Manufacture by Electrolysis, Thermal Decomposition and

Unusual Techniques, Noyes Data Corp.

Howell, I.R. and Buckius, R.O., 1992, Fundamental of Engineering Thermodynamics, 2nd Ed.,

McGraw-Hill, Inc., Ch. 11.

Moran, M.l and Shapiro, H.N., 1995, Fundamentals of Engineering Thermodynamics, 3rd Ed.,

Wiley, Ch.13.

Ohta, T., 1979, Solar-Hydrogen Energy Systems, Pergamon Press.

Soo, S.L., 1968, Direct Energy Conversion, Prentice-Hall, Chapter 3.

13

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Corruption and The Bureaucratic Elite in Pakistan: The 1960s and 1970s RevisitedDocument17 pagesCorruption and The Bureaucratic Elite in Pakistan: The 1960s and 1970s RevisitedMawaz Khan MirzaPas encore d'évaluation

- Privatisation and Reform Programme of Public Sector Enterprises in Pakistan 1960-2004Document10 pagesPrivatisation and Reform Programme of Public Sector Enterprises in Pakistan 1960-2004Mawaz Khan MirzaPas encore d'évaluation

- The Financial and Economic Crisis of 2008-2009 and Developing CountriesDocument340 pagesThe Financial and Economic Crisis of 2008-2009 and Developing CountriesROWLAND PASARIBU100% (2)

- Economic History of PakistanDocument8 pagesEconomic History of PakistanFarrukh SairPas encore d'évaluation

- Infrastructure Redux Crisis, Progress in Industrial Pakistan Beyond by Nausheen AnwarDocument267 pagesInfrastructure Redux Crisis, Progress in Industrial Pakistan Beyond by Nausheen AnwarMawaz Khan MirzaPas encore d'évaluation

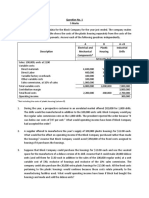

- Question No. 1 5 Marks: Not Including The Costs of Plastic Housing (Column B)Document13 pagesQuestion No. 1 5 Marks: Not Including The Costs of Plastic Housing (Column B)Mawaz Khan MirzaPas encore d'évaluation

- The Impact of The 2008 Financial Crisis On Innovation 10.1016@j.jbusres.2020.01.048Document10 pagesThe Impact of The 2008 Financial Crisis On Innovation 10.1016@j.jbusres.2020.01.048Mawaz Khan MirzaPas encore d'évaluation

- The 2008 Financial Crisis Changes in Social Capital 10.1016socscimed.2016.02.008Document10 pagesThe 2008 Financial Crisis Changes in Social Capital 10.1016socscimed.2016.02.008Mawaz Khan MirzaPas encore d'évaluation

- The Role of Derivatives in The Global Financial Crisis of 2008Document15 pagesThe Role of Derivatives in The Global Financial Crisis of 2008Mawaz Khan MirzaPas encore d'évaluation

- The Financial and Economic Crisis of 2008-2009 and Developing CountriesDocument340 pagesThe Financial and Economic Crisis of 2008-2009 and Developing CountriesROWLAND PASARIBU100% (2)

- Financial Institutions and Markets 2007-2008 - The Year of Crisis by Robert R. Bliss and George G. Kaufman (Editors)Document226 pagesFinancial Institutions and Markets 2007-2008 - The Year of Crisis by Robert R. Bliss and George G. Kaufman (Editors)Mawaz Khan MirzaPas encore d'évaluation

- The Impact of The 2008 Financial Crisis On Innovation 10.1016@j.jbusres.2020.01.048Document10 pagesThe Impact of The 2008 Financial Crisis On Innovation 10.1016@j.jbusres.2020.01.048Mawaz Khan MirzaPas encore d'évaluation

- Journal of Asian Economics: Stijn Claessens, M. Ayhan KoseDocument3 pagesJournal of Asian Economics: Stijn Claessens, M. Ayhan KoseMawaz Khan MirzaPas encore d'évaluation

- System Dynamics Modeling and SimulationDocument287 pagesSystem Dynamics Modeling and Simulationswjaffry86% (7)

- How To Write An Excellent EssayDocument7 pagesHow To Write An Excellent EssayMawaz Khan MirzaPas encore d'évaluation

- The 2008 Financial Crisis Changes in Social Capital 10.1016socscimed.2016.02.008Document10 pagesThe 2008 Financial Crisis Changes in Social Capital 10.1016socscimed.2016.02.008Mawaz Khan MirzaPas encore d'évaluation

- Difference in Difference PDFDocument16 pagesDifference in Difference PDFMawaz Khan MirzaPas encore d'évaluation

- Python Matplotlib Cheat SheetDocument1 pagePython Matplotlib Cheat SheetsreedharPas encore d'évaluation

- Doth RakiDocument19 pagesDoth RakiMawaz Khan MirzaPas encore d'évaluation

- Difference in Difference PDFDocument16 pagesDifference in Difference PDFMawaz Khan MirzaPas encore d'évaluation

- Engaging Consumers Through Word of Mouth Marketing: Red Bull Wings Team Red Bull Cliff DivingDocument4 pagesEngaging Consumers Through Word of Mouth Marketing: Red Bull Wings Team Red Bull Cliff DivingMawaz Khan MirzaPas encore d'évaluation

- Hyundai Contactors HiMCDocument12 pagesHyundai Contactors HiMCMawaz Khan MirzaPas encore d'évaluation

- Engaging Consumers Through Word of Mouth Marketing: Red Bull Wings Team Red Bull Cliff DivingDocument4 pagesEngaging Consumers Through Word of Mouth Marketing: Red Bull Wings Team Red Bull Cliff DivingMawaz Khan MirzaPas encore d'évaluation

- Engineering Letter: SystemcalculationDocument4 pagesEngineering Letter: SystemcalculationjmartinezmoyPas encore d'évaluation

- A Brief Study of The Effects of Turbofan-Engine Bypass Ratio On Short and Long Haul Cruise AircraftDocument46 pagesA Brief Study of The Effects of Turbofan-Engine Bypass Ratio On Short and Long Haul Cruise AircraftMawaz Khan MirzaPas encore d'évaluation

- Elementos Finitos FEM - Finite Element Procedures - K.-J. Bathe - 1996Document1 052 pagesElementos Finitos FEM - Finite Element Procedures - K.-J. Bathe - 1996Eugenio Ferreras100% (1)

- UnderStanding Centrifugal FansDocument3 pagesUnderStanding Centrifugal FanssantanuantaraPas encore d'évaluation

- Chapter 6 - Referenced StandardsDocument4 pagesChapter 6 - Referenced StandardsMawaz Khan MirzaPas encore d'évaluation

- FEM Lecture NotesDocument188 pagesFEM Lecture NotesHenry Martinez CarmonaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- EST QB - StudentsDocument8 pagesEST QB - Students114-Lobhan PatilPas encore d'évaluation

- GpcalcsDocument7 pagesGpcalcsesakkiraj1590Pas encore d'évaluation

- Lecture 6Document1 pageLecture 6Mark AmgadPas encore d'évaluation

- Gas Enginee Vs Gas TurbineDocument13 pagesGas Enginee Vs Gas TurbineTrung Quan VoPas encore d'évaluation

- Hydroelectric Power PlantDocument7 pagesHydroelectric Power PlantKristine Ann ReclosadoPas encore d'évaluation

- Sustainable BiofuelsDocument2 pagesSustainable BiofuelsEdzwan RedzaPas encore d'évaluation

- FINAL SYNOPSIS On It ParkDocument11 pagesFINAL SYNOPSIS On It ParkAr Sonali Hadke0% (2)

- Performance of TurbineDocument31 pagesPerformance of TurbineJomariBobadillaPas encore d'évaluation

- Design Construction EjectorDocument136 pagesDesign Construction Ejectorssmith2007100% (1)

- GE Smart Grid OverviewDocument457 pagesGE Smart Grid OverviewFirman Sasongko67% (3)

- AesvDocument32 pagesAesvKhusnulPas encore d'évaluation

- AHU Supply Front PackageDocument10 pagesAHU Supply Front PackagejnmanivannanPas encore d'évaluation

- Green BuildingDocument6 pagesGreen BuildingAbood Buriahi100% (1)

- Calculate Size of Inverter & Battery Bank: Electrical Notes & ArticlesDocument7 pagesCalculate Size of Inverter & Battery Bank: Electrical Notes & ArticlesRitesh SharmaPas encore d'évaluation

- HevDocument14 pagesHevjungdjudfPas encore d'évaluation

- GRI 302 - Energy 2016Document18 pagesGRI 302 - Energy 2016Shalini DevarajPas encore d'évaluation

- BD CAL FPSO (HULL) 014 002+M40218 014 002JS 轮机主要设备计算书Document17 pagesBD CAL FPSO (HULL) 014 002+M40218 014 002JS 轮机主要设备计算书Ben Wong100% (1)

- Mining 03 00001 v2Document25 pagesMining 03 00001 v2Majid KhodsianiPas encore d'évaluation

- Demo Weld Cost Calc XLDocument9 pagesDemo Weld Cost Calc XLharry_1981Pas encore d'évaluation

- Construction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDocument23 pagesConstruction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDevendra SharmaPas encore d'évaluation

- 415 V System Stage-1Document18 pages415 V System Stage-1raghavendran raghuPas encore d'évaluation

- Combined Cycle Power Plant PDFDocument10 pagesCombined Cycle Power Plant PDFputriPas encore d'évaluation

- Hubbell Model GXDocument6 pagesHubbell Model GXast654Pas encore d'évaluation

- Heat Exchanger Technology Review From PEI MagazineDocument4 pagesHeat Exchanger Technology Review From PEI MagazineStephen ChuaPas encore d'évaluation

- Loadshedding Research - Final ReportDocument21 pagesLoadshedding Research - Final Reportacidreign100% (2)

- VCB SpecificationsDocument17 pagesVCB SpecificationsHarsh GuptaPas encore d'évaluation

- Dom QB Fina 1-5Document11 pagesDom QB Fina 1-5manipacetPas encore d'évaluation

- Exposure RateDocument20 pagesExposure RatephanthanhhungPas encore d'évaluation

- Green SeminarDocument24 pagesGreen SeminarDebraajBaglungPas encore d'évaluation

- Soal Try Out MGMP SMA 5Document11 pagesSoal Try Out MGMP SMA 5Syafaruddin MarpaungPas encore d'évaluation