Académique Documents

Professionnel Documents

Culture Documents

DEWRANCE Tyco Welded in Seat

Transféré par

jones0055Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DEWRANCE Tyco Welded in Seat

Transféré par

jones0055Droits d'auteur :

Formats disponibles

High Performance

Line Valves

Dewrance manufactures a wide range of

valves for applications within the power

generation industry. Established in 1844 by

John Dewrance the company has been

involved in steam and power generation from

its conception.

John Dewrance was the chief engineer on

the Rocket, the Worlds first commercial steam

locomotive, and from this experience he

founded his own company based on innovation

and design.

The company has kept pace with an ever

changing industry and the products that have

been developed give the optimum performance

for the applicaton through superior design,

manufacture and quality. Dewrance specialise in

products that have a tight shut off, low pressure

drop and long service.

Customer Service

Dewrance is a truly Global

company that supplies the majority

of power generation contractors

and end users throughout the

World. Quality through design

matched with competitive prices,

has made Dewrance one of the

leading suppliers for steam

generation applications over the

past 160 years. With our customer

focused approach we believe

Dewrance will continue to be a

main supplier for power generation

valves well into the future.

Dewrance is now part of the Tyco

Engineered Products Group, that

can also offer a complete package

of valves utilising other Tyco

company products to suit

individual customers needs.

Market experience

Dewrance is best known for and enjoys a

World wide reputation for its range of Parallel

Slide Valves. In addition to this the company

offers an unrivalled range of other high

performance valves for power generation and

associated industries.

Through innovation, Dewrance has a

product line specifically designed to meet both

system and customer requirements, these

include main steam isolation, turbine

protection, feedheater bypass, and reheater

isolation valves.

Dewrance follows all new developments in

power generation design and technology, and

is at the forefront in meeting customer needs,

such as modified 9% Cr Material for high

temperature and supercritical applications.

Quality Philosophy

Quality through proven design and

manufacturing techniques are paramount to the

success of Dewrance. The companies range of

ANSI/ASME products are versatile enough to

meet individual customer specifications and

requirements. Dewrance is fully accredited to

ISO9001 and see a total quality product as the

key to its continued success.

An unrivalled range of high peformance Line Valves

for power generation applications

High Pressure

Cast Steel

Parallel Slide

Valves

High Pressure

Forged Steel

Parallel Slide

Valves

Low Pressure

Cast Steel

Parallel Slide

Valves

High Pressure

Cast Steel

Tilting Disc

Check Valves

Low Pressure

Cast Steel

Swing Check

Valves

Bled Steam

Check Valves

Main Steam Isolation

Boiler Feed Pump Isolation

HP Feed Heater

Isolation/Bypass

Main Applications Size and materials Features

Sizes

3

/4 - 4 (20 - 100mm)

Pressure Class 1690 - 4500

Materials Carbon/Alloy Steel

A105, F11, F22, F91

Standards ASME B16.34.1996

(Addendum ASME B16.34a.1998)

ASME B16.10.1992

Eyelet follower providing a smooth flow

path & maximum performance

Welded in seats hard faced with Stellite

Expanded graphite pressure seal

& gland packing

Lower pressure drop characteristics than

than wedge gate valve

Welded in seats hard faced with Stellite

or equivalent

Expanded graphite pressure seal/gasket

& gland packing

Lower pressure drop characteristics than

than wedge gate valve

Improved sealing assisted by line pressure

Welded in seats hard faced with Stellite

or equivalent

Robust fixing of disc prevents possibility

of failure (no fixing nut)

No external bearings and seals

Main Steam Drain

Main Steam Vents

Main Steam Isolation

Gland Steam Drains

Sizes 2

1

/2 - 24 (65 - 600mm)

Pressure Class 1000 - 2850

Materials Carbon/Alloy Steel

WCB, WC6, WC9, C12A

Standards ASME B16.34.1996

(Addendum ASME B16.34a.1998)

ASME B16.10.1992

Sizes 6 - 40 (150 - 1000mm)

Pressure Class 150 - 1200

Materials Carbon/Alloy Steel

WCB, WC6, WC9, C12A

Standards ASME B16.34.1996

(Addendum ASME B16.34a.1998)

Sizes 16 - 36 (400 - 900mm)

Pressure Class 500 - 900

Materials Carbon/Alloy Steel

WCB, WC6

Standards ASME B16.34.1996

(Addendum ASME B16.34a.1998)

ASME B16.10.1992

Direct Deposited seats hard faced

with Stellite

or equivalent

Tilting Disc Design balanced for quick

opening and immediate closing on

flow reversal

Lightweight disc with minimum travel

Optimum performance under all flow

conditions

Main Steam Non Return

Boiler Feed Pump Non Return

Enocomiser Recirculation

Spray Water Non Return

Main Steam Service Non Return

Boiler Feed Pump Non Return

Enocomiser Recirculation

Spray Water Non Return

Feed Water

Bypass Valves

Reheater Isolation

Device

Sizes 5 - 24 (125 - 600mm)

Pressure Class 1000 - 2850

Materials Carbon/Alloy Steel

WCB, WC6, WCB C12A

Standards ASME B16.34.1996

(Addendum ASME B16.34a.1998)

ASME B16.10.1992

Low Pressure Steam Isolation

Low Pressure Feed Heater

Isolation

Low Pressure Spray Water

Isolation

Low Pressure Boiler Feed

Pump Isolation

Four Pillar on 300 & 600 Class for rigidity

and accessibility

Hard faced Stellite

or equivalent discs

and seats

Modular body design accomodates a wide

range of flanged and weld connections

Internal Counterweight to balance

disc under low load conditions

Tilting Disc design for quick closing

due to lower centre of gravity

Lightweight Disc with minimum travel,

for quick closing in less than 1 second

Optimum performance under all flow conditions

Pneumatic Power Assistance acts directly onto

disc, without linkages to inhibit operation

Extraction Steam Non Return

Bled Steam Non Return

Turbine Protection

Dewrance Patented profiled steam and port

arrangement to damp movement and prevent

disc slamming onto seat when closing

Upper valve seat*, hard faced with Stellite

or equivalent

Valve Disc self aligning, double seated and

hard faced with Stellite

or equivalent

Lower valve seat hard faced with Stellite

or equivalent

Controlled speed of operation between

3-20 seconds

Feedwater Heater Isolation

and Bypass

Pressure seal bonnet design gives maximum

reliability with minimum maintenance

Low cost isolating device

Low pressure drop. Once the isolator body is

installed, it literally becomes part of the piping

system. The straight in-line design allows a

smooth, in-line flow with unobstructed

passage. Pressure drop is therfore held to an

absolute minimum.

Isolation of Boiler Reheat Tubes

for hydro testing

Extensive product line-up

Sizes 2 - 24 (50 - 600mm)

Pressure Class 150 - 600

Materials Carbon/Alloy Steel

WCB, WC6

Standards ASME B16.34.1996

(Addendum ASME B16.34a.1998)

ASME B16.10.1992

Sizes 2 - 20 (50 - 500mm)

Pressure Class 150 - 600

Materials Carbon/Alloy Steel

WCB, WC6

Standards ASME B16.34.1996

(Addendum ASME B16.34a.1998)

ASME B16.10.1992

Sizes 6 - 20 (150 - 500mm)

Pressure Class 1690 - 2500

Materials Carbon Steel

A105, WCB

Standards ASME B16.34.1996

(Addendum ASME B16.34a.1998)

White Moss Business Park

Moss Lane View, Skelmersdale

Lancashire, WN8 9TN

Tel: +44 (0)1695 554800

Fax: +44 (0)1695 554835

E-Mail: dewrance@tyco-valves.com

Dewrance

tep/DEW 01/12-99

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- ISO 8501 Photo ReferDocument5 pagesISO 8501 Photo Referapi-386436191% (11)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- APCO Air Valve 613Document4 pagesAPCO Air Valve 613jones0055Pas encore d'évaluation

- Pub002 003 00 - 1011Document88 pagesPub002 003 00 - 1011jones0055Pas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- แบบมาตรฐานสถานีสุบน้ำแบบโรงสูบDocument15 pagesแบบมาตรฐานสถานีสุบน้ำแบบโรงสูบjones0055Pas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- How To Control SurgeDocument22 pagesHow To Control SurgeGlishna Peushan WidanapathiranaPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Numerical Methods For Modeling Transient Flow: in Distribution SystemsDocument0 pageNumerical Methods For Modeling Transient Flow: in Distribution Systemsjones0055Pas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Transient Article On Energy Savings With Air ValvesDocument2 pagesTransient Article On Energy Savings With Air Valvesjones0055Pas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- NT3BB-4PWN Quick Installation GuideDocument14 pagesNT3BB-4PWN Quick Installation Guidejones0055Pas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Pressure Surges and Air Valve Specification PDFDocument22 pagesPressure Surges and Air Valve Specification PDFTONPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Characteristic Curve PDFDocument1 pageCharacteristic Curve PDFjones0055Pas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- An Introduction To Total Productive Maintenance (TPM) - VenkateshDocument22 pagesAn Introduction To Total Productive Maintenance (TPM) - Venkateshtehky63Pas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- A4 Water Treatment ProcessDocument22 pagesA4 Water Treatment Processjones0055Pas encore d'évaluation

- Waterman Telescoping ValvesDocument4 pagesWaterman Telescoping Valvesjones0055Pas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- PerarEC-EB 0 PDFDocument21 pagesPerarEC-EB 0 PDFadrianioantomaPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Operation Book PDFDocument118 pagesOperation Book PDFArvind Shukla100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Steam Turbine: Working Principle, Types, CompoundingDocument31 pagesSteam Turbine: Working Principle, Types, Compoundingkarthikeyan murugesanPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Lab Guide - Pelton TurbineDocument22 pagesLab Guide - Pelton TurbineBonifacioPas encore d'évaluation

- Experiment 4 OrificeDocument17 pagesExperiment 4 OrificeAnis Nurfarahanim Abdul HalimPas encore d'évaluation

- WL Turbocharger EN WEBDocument3 pagesWL Turbocharger EN WEBDandy MartinPas encore d'évaluation

- Hydraulic Power Supply System MNT Manual (Curso)Document28 pagesHydraulic Power Supply System MNT Manual (Curso)William Jaldin CorralesPas encore d'évaluation

- FORT VALE SuperMaxiReliefValve PDFDocument70 pagesFORT VALE SuperMaxiReliefValve PDFlorenzoPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Facts at Your Fingertips-200410-Fluid MechanicsDocument1 pageFacts at Your Fingertips-200410-Fluid Mechanicsonizuka-t2263Pas encore d'évaluation

- Gas TurbineDocument16 pagesGas TurbinehusnainyasirPas encore d'évaluation

- Hydraulic BenchDocument18 pagesHydraulic Benchchesca marasigan100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Power Shift Pressure - Check 374Document4 pagesPower Shift Pressure - Check 374Guido Asqui FloresPas encore d'évaluation

- TA-Modulator NPT ANSI US LowDocument16 pagesTA-Modulator NPT ANSI US LowPablo CastroPas encore d'évaluation

- 1450RPM PDFDocument111 pages1450RPM PDFFulton Xavier ZambranoPas encore d'évaluation

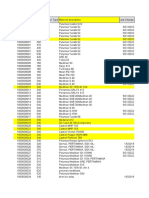

- EXPORT MM60 Material List - 22092022Document1 920 pagesEXPORT MM60 Material List - 22092022robbi wahyudiPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Cepex Electric Butterfly Valve ExtremeDocument2 pagesCepex Electric Butterfly Valve ExtremegastonPas encore d'évaluation

- Question PaperDocument3 pagesQuestion PaperParanthaman RamanPas encore d'évaluation

- Flow of Fluids: Answers SheetDocument2 pagesFlow of Fluids: Answers SheetJohn P. BandoquilloPas encore d'évaluation

- Hytrol Valve: ModelDocument4 pagesHytrol Valve: ModeljajakaPas encore d'évaluation

- Physics ProjectDocument23 pagesPhysics Projecttanish jainPas encore d'évaluation

- 3AS 38320 App. Water Steam Diagram SFBW2728226SATFGDocument1 page3AS 38320 App. Water Steam Diagram SFBW2728226SATFGRabindranath Hendy TagorePas encore d'évaluation

- N° Codice / Code Descrizione Description Q.tà: VERSION 07/2012 From Serial 476Document3 pagesN° Codice / Code Descrizione Description Q.tà: VERSION 07/2012 From Serial 476Ahmad ShaheenPas encore d'évaluation

- Drag Coefficient ReportDocument13 pagesDrag Coefficient ReportMuhamad Aiman0% (1)

- Asl Ga18 37vsd+Document48 pagesAsl Ga18 37vsd+Hitesh sharmaPas encore d'évaluation

- Turbofan Engine Database As A Preliminary Design ToolDocument15 pagesTurbofan Engine Database As A Preliminary Design Toolcramerps2084Pas encore d'évaluation

- A Report On Design and Fabrication of Portable TMT Bending MachineDocument33 pagesA Report On Design and Fabrication of Portable TMT Bending MachineSriram MuruganPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Piping Design: Two Weeks Job Oriented Certificate Course OnDocument8 pagesPiping Design: Two Weeks Job Oriented Certificate Course OncontgautamPas encore d'évaluation

- Coiled Tubing Skid-Mount UnitDocument5 pagesCoiled Tubing Skid-Mount Unitnoel chris Jindjou100% (1)

- Window Air Conditioners Technical Specification and Scope of WorkDocument4 pagesWindow Air Conditioners Technical Specification and Scope of WorkRajivPas encore d'évaluation