Académique Documents

Professionnel Documents

Culture Documents

Circuit Breakers

Transféré par

Jitendra KumarDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Circuit Breakers

Transféré par

Jitendra KumarDroits d'auteur :

Formats disponibles

Circuit breakers

When selecting a circuit breaker for a particular application the principal factors to consider are; system

voltage, rated load current, and fault level at the point of installation

Voltage rating

At medium voltages the phase to neutral voltage may be 250v but the potential difference between two

phases with the neutral insulated would be 440v At these voltages no difficulties should arise in selecting

the circuit breaker e!uipment "owever, on a ##k$ insulated neutral system the phase to neutral voltage

is ##k$%& # ' ()k$ *f an earth fault develops on one phase the potential of the other two phases to

earth is ##k$ +o ensure the insulation is not sub,ect to e-cessive stress a circuit breaker designed for a

normal system voltage of ..k$ may be fitted Also on insulated neutral systems high over voltages may

be caused by arcing faults /edium voltage systems switch gear insulation should be able to withstand

such voltages, but ##k$ and above, the margin of safety is reduced When a high voltage system is

installed both the voltage rating of the circuit breaker and the method of earthing must be considered

Current rating

Consider three factors;

a. Maximum permissible temperature of circuit breaker copperwork and contacts

b. temperature due to LOAD CURR!"

c. Ambient temperature

*n industrial use the ambient temperature considered is usually #5

o

0 *f uses in a marine

environment temperature of 40

o

0 12estricted areas3 and 45

o

0 1unrestricted areas3 are used, therefore the

circuit breaker rating may be 4free air4 value and this does not consider the degree of ventillation, the

number and position of the circuit breakers or the layout of the bus bars +he final switchboard

arrangement could be only 50 to )06 of the free air rating

Fault rating

7reakers should be rated to accept a breaking current of about (0 times the full load current +he breaker

should also be able to make against a fault condition where the making current may be 25 times the full

load current when the contact first make 0ircuit breakers must remain closed for a short time when a

fault occurs in order to allow other devices which are nearer to the fault to trip first +he breaker should

be capable of carrying its breaking current for a specified time of usually about one second

Arc suppression

7low force at right angles to arc and field

+he blow out coils, which are connected in series with the circuit breaker contacts, form an electro8

magnetic field which reacts with the arc to give a deflecting force which tends to bloe the arc outwards

+he increase in effective length of the arc causes it to e-tinguish more !uickly +he blow out coils are

protected form the arc by arc resistant material which may be in the form of an air shute

"ot ionised gases around the arc and contacts are displaced by cold air forming eddy current

air flow +his helps to increase resistance between contacts

Contacts

Attention should be paid to all contacts likely to deteriorate due to wear, burning, inade!uate pressure,

the formation of a high resistance film or becoming welded together 9aulty contacts are often indicated by

overheating when loaded :ifferent contact materials may need different treatment

0opper is widely used but is liable to develop a high resistance film, and copper contacts may

become welded together if the contact pressure is low and the contents have to carry a high current

0opper is commonly used for contacts which have a wiping action when closing and opening, this action

removing the film 0opper contacts are used on knife switches, laminated 1brush3 contacts of regulators

and other controllers, drum contacts, etc

0arbon and metalli;ed carbon contacts are unsuitable for carrying high currents for long

periods but, as they do not weld together, they are used for arcing contacts on some control gear <ure

silver and silver ally contacts tends to blacken in service but the o-ide film has a low resistance 0opper8

tungsten 1sintered compound3, grey * colour, is used in contact facing +his material has a high surface

resistance which resists heavy arcing and does not weld =ilver tungsten 1sintered3 has similar properties

to copper tungsten but has a lower contact resistance and is less liable to overheat on continuous load

Servicing contacts

0opper contacts should be filed up if necessary to restore the profile re!uired to ensure correct wiping

action 0opper contacts which have become burnt or pitted or otherwise damaged, may be carefully

dressed with a file >mery cloth should not be used =ome contacts are provided with pressure

ad,ustment, so if the contact pressure is reduced by dressing it should be read,usted ?sing a spring

balance pulled in a direction normal to the contact surface a reading should be taken when a piece of

paper placed between the contacts is released *nade!uate spring pressure may also be due to the

pressure springs becoming weak due to fatigue or overheating

0arbon contacts should receive the same attention as copper contacts e-cept that they should

not need lubrication =ilver, =ilver alloy and copper tungsten contacts do not re!uire cleaning As there is

no need to remove surface film from pure silver contacts they may be used for light butt contacts

Where some contacts have the appearance of pitting on both faces this is sometimes referred

to as being 4burnt in4 =ome manufacturers recommend that the contacts, unless there is loss of material,

are not dressed as this may destroy the contact area

Vous aimerez peut-être aussi

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaD'EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaPas encore d'évaluation

- Circuit BreakersDocument4 pagesCircuit BreakersMeghali BorlePas encore d'évaluation

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesD'EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesPas encore d'évaluation

- Circuit Breakers FactorsDocument6 pagesCircuit Breakers FactorsBhalchandra MurariPas encore d'évaluation

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsD'EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsÉvaluation : 3 sur 5 étoiles3/5 (2)

- Health, Safety and Accident PreventionDocument5 pagesHealth, Safety and Accident Preventionsn200709Pas encore d'évaluation

- Introduction to Power System ProtectionD'EverandIntroduction to Power System ProtectionPas encore d'évaluation

- Welding-ARC WELDINGDocument6 pagesWelding-ARC WELDINGraghbirPas encore d'évaluation

- Summary Ac Contactor Failure Cause and EffectDocument9 pagesSummary Ac Contactor Failure Cause and EffectVinci Valcu ParnePas encore d'évaluation

- Quasar Electronics Kit No. 1065 Inverter 12 VDC To 220 Vac: General DescriptionDocument6 pagesQuasar Electronics Kit No. 1065 Inverter 12 VDC To 220 Vac: General Descriptionapi-3864578Pas encore d'évaluation

- Long Answer Questions: X y Z X y ZDocument5 pagesLong Answer Questions: X y Z X y ZJulie OsbornePas encore d'évaluation

- EWISDocument170 pagesEWISHollins starsPas encore d'évaluation

- De Leon, Jennica L. DMET 2-2 - SMAW 2Document5 pagesDe Leon, Jennica L. DMET 2-2 - SMAW 2Mark Jaynard SerranoPas encore d'évaluation

- Conductor Dimensioning For HV Surge ArrestersDocument3 pagesConductor Dimensioning For HV Surge ArrestersmartinpellsPas encore d'évaluation

- CKT BreakerDocument48 pagesCKT BreakerSharmishtha KulkarniPas encore d'évaluation

- Operation Manual Final PDFDocument35 pagesOperation Manual Final PDFAbraham FebruanoPas encore d'évaluation

- Cautions For Using Aluminum Electrolytic CapacitorsDocument4 pagesCautions For Using Aluminum Electrolytic CapacitorsFrank GonzalezPas encore d'évaluation

- Trade Theory 2 Electronics MechanicDocument439 pagesTrade Theory 2 Electronics MechanicChittaranjan SethiPas encore d'évaluation

- Ews Ex100Document37 pagesEws Ex100Lars HagbergPas encore d'évaluation

- Zenith 32-37-42lc2da Chassis La63e SMDocument113 pagesZenith 32-37-42lc2da Chassis La63e SMraver1213Pas encore d'évaluation

- Panasonic Tc-p55vt50 Chassis Gpf15duDocument108 pagesPanasonic Tc-p55vt50 Chassis Gpf15duOK100% (1)

- Fuses: CAMTECH/2000/S/FUSEDocument11 pagesFuses: CAMTECH/2000/S/FUSEPankaj PalawatPas encore d'évaluation

- Experiment No-6 SGPDocument21 pagesExperiment No-6 SGPSaroj kumar BiswasPas encore d'évaluation

- Electrical Equipment: Circuit BreakerDocument43 pagesElectrical Equipment: Circuit BreakerKenneth LewisPas encore d'évaluation

- Initiation: Components Used in Electric BlastingDocument18 pagesInitiation: Components Used in Electric BlastingariellopezPas encore d'évaluation

- Cable SelectionDocument8 pagesCable SelectionaramirezbenitesPas encore d'évaluation

- Sr80 Manual - PSLDocument8 pagesSr80 Manual - PSLChitranjan AgrawalPas encore d'évaluation

- Circuit BreakerDocument21 pagesCircuit BreakerDahir kheyrePas encore d'évaluation

- BTC30 40insDocument4 pagesBTC30 40inspatgarettPas encore d'évaluation

- Circuit BreakerDocument10 pagesCircuit BreakerGadam Siva Charan DasPas encore d'évaluation

- LG 32lv2500-zg 32lv250a-N-U-Zg 32lv2540-zl Chassis ld01mDocument41 pagesLG 32lv2500-zg 32lv250a-N-U-Zg 32lv2540-zl Chassis ld01mSilvina CappelloPas encore d'évaluation

- Circuit BreakerDocument12 pagesCircuit BreakerJintoKJames100% (1)

- SGP Assignment Kaustubh Urade Types of Circuit Breakers 2017bel018Document7 pagesSGP Assignment Kaustubh Urade Types of Circuit Breakers 2017bel018Kaustubh UradePas encore d'évaluation

- Module - 5: Circuits BreakersDocument25 pagesModule - 5: Circuits BreakersGyanaranjan pandaPas encore d'évaluation

- Air Circuit Breaker Types of ACBsDocument7 pagesAir Circuit Breaker Types of ACBsNeeraj RahiPas encore d'évaluation

- Dakshin Haryana Bijli: Technical Specification FORDocument29 pagesDakshin Haryana Bijli: Technical Specification FORDipen SoniPas encore d'évaluation

- Philippine Electronics Code - Volume 1 - IdentificationDocument4 pagesPhilippine Electronics Code - Volume 1 - IdentificationDonovan Paul Uy DoroinPas encore d'évaluation

- Spot Welder PlansDocument4 pagesSpot Welder Planscesargramcko100% (2)

- Finder CatalogueDocument18 pagesFinder CatalogueGeorge GeorgePas encore d'évaluation

- Switchgear Lab ManualDocument40 pagesSwitchgear Lab ManualZeeshan Ahmed100% (2)

- Electrical InstallationDocument41 pagesElectrical InstallationMalshi EkanayakaPas encore d'évaluation

- Chapter No. 05 Distribution EquipmentDocument59 pagesChapter No. 05 Distribution EquipmentNoman KhalidPas encore d'évaluation

- Circuit Breaker TypesDocument39 pagesCircuit Breaker TypesKenneth Lewis100% (1)

- Circuit Breaker - WikipediaDocument9 pagesCircuit Breaker - WikipediaManigandan212Pas encore d'évaluation

- Circuit Breakers Operating Principles of Circuit BreakersDocument16 pagesCircuit Breakers Operating Principles of Circuit BreakersmutuaPas encore d'évaluation

- Circuit Breaker - Wikipedia, The Free EncyclopediaDocument12 pagesCircuit Breaker - Wikipedia, The Free EncyclopediaMuhammad NabilPas encore d'évaluation

- TC-L32E6H: 32 Inch Class 1080p LCD HDTVDocument30 pagesTC-L32E6H: 32 Inch Class 1080p LCD HDTVJosé Ivan Bonillas GranadosPas encore d'évaluation

- An Overview of Cathodic Protection Potential MeasurementDocument7 pagesAn Overview of Cathodic Protection Potential MeasurementKhanh DTPas encore d'évaluation

- TC-L32B6H ManualDocument27 pagesTC-L32B6H ManualmemepiPas encore d'évaluation

- Industrial Training: AcknowledgementDocument21 pagesIndustrial Training: AcknowledgementBharat Bhushan TiwariPas encore d'évaluation

- Circuit BreakerDocument5 pagesCircuit BreakerPankil ShridharPas encore d'évaluation

- Rme Reviewer Chapter 1Document4 pagesRme Reviewer Chapter 1Edward Roy “Ying” AyingPas encore d'évaluation

- Switches &MODsDocument14 pagesSwitches &MODsZack GroothousePas encore d'évaluation

- 11KV - 415V Overhead Line Specification (REC) - Electrical Notes & ArticlesDocument64 pages11KV - 415V Overhead Line Specification (REC) - Electrical Notes & ArticlesPradeepKrYadavPas encore d'évaluation

- CT Internal StructureDocument3 pagesCT Internal StructureSudhakar KethireddyPas encore d'évaluation

- Wea High Voltage Circuit Breaker PresentDocument53 pagesWea High Voltage Circuit Breaker PresentМарат ХакимьяновPas encore d'évaluation

- ElectricalDocument7 pagesElectricalUFC Fight ClubPas encore d'évaluation

- AnswersDocument11 pagesAnswersAlok SinghPas encore d'évaluation

- 07a. 07. EwisDocument109 pages07a. 07. EwisAhsan Gani100% (1)

- Electrode Maintenance For Resistance Spot WeldingDocument3 pagesElectrode Maintenance For Resistance Spot Weldingottou812Pas encore d'évaluation

- Brochure o Pumps Deepwell Gas CarriersDocument4 pagesBrochure o Pumps Deepwell Gas CarriersJohn MarxisPas encore d'évaluation

- Overall Arrangement: Description of The Salient PartsDocument6 pagesOverall Arrangement: Description of The Salient PartsJitendra KumarPas encore d'évaluation

- Oxygen AnalysersDocument2 pagesOxygen AnalysersJitendra KumarPas encore d'évaluation

- Overview of Microbiological AttackDocument10 pagesOverview of Microbiological AttackJitendra KumarPas encore d'évaluation

- Parallel Operation of GeneratorsDocument5 pagesParallel Operation of GeneratorsJitendra KumarPas encore d'évaluation

- Oil WhirlDocument2 pagesOil WhirlJitendra KumarPas encore d'évaluation

- Pilgrim NutDocument2 pagesPilgrim NutJitendra KumarPas encore d'évaluation

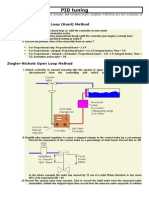

- PID TuningDocument4 pagesPID TuningJitendra Kumar100% (1)

- Oil Distribution Within A Journal BearingDocument2 pagesOil Distribution Within A Journal BearingAnkit DedhiyaPas encore d'évaluation

- Microbes of Microbiological Attac1Document3 pagesMicrobes of Microbiological Attac1Jitendra KumarPas encore d'évaluation

- Operation of A Centrifugal Oil PurifersDocument3 pagesOperation of A Centrifugal Oil PurifersJitendra KumarPas encore d'évaluation

- Oily Water SeperatorsDocument2 pagesOily Water SeperatorsJitendra KumarPas encore d'évaluation

- Increasing Propulsive EfficiencyDocument6 pagesIncreasing Propulsive EfficiencyJitendra KumarPas encore d'évaluation

- Motor Ship Steam Plan1Document3 pagesMotor Ship Steam Plan1Jitendra KumarPas encore d'évaluation

- Tooth Design: Forces Acting On Spur GearsDocument77 pagesTooth Design: Forces Acting On Spur GearsJitendra KumarPas encore d'évaluation

- Metallurgical TestingDocument1 pageMetallurgical TestingJitendra KumarPas encore d'évaluation

- Motor Ship Steam Plant ControlDocument1 pageMotor Ship Steam Plant ControlJitendra KumarPas encore d'évaluation

- Molybdenum DiSulphideDocument1 pageMolybdenum DiSulphideJitendra KumarPas encore d'évaluation

- Navigation LightingDocument1 pageNavigation LightingJitendra KumarPas encore d'évaluation

- Marpol 73Document12 pagesMarpol 73Jitendra KumarPas encore d'évaluation

- LNG Reliquifactio1Document1 pageLNG Reliquifactio1Jitendra KumarPas encore d'évaluation

- Materials Used in Ships Sea Water SystemsDocument1 pageMaterials Used in Ships Sea Water SystemsAnkit DedhiyaPas encore d'évaluation

- Microbes of Microbiological Attac1Document3 pagesMicrobes of Microbiological Attac1Jitendra KumarPas encore d'évaluation

- LNG Containment DesignsDocument3 pagesLNG Containment DesignsJitendra KumarPas encore d'évaluation

- Lifting Using Accessories: Calculation of LoadDocument2 pagesLifting Using Accessories: Calculation of LoadJitendra KumarPas encore d'évaluation

- Mechanical GovernorsDocument1 pageMechanical GovernorsJitendra KumarPas encore d'évaluation

- Low Sulphur FuelsDocument1 pageLow Sulphur FuelsJitendra KumarPas encore d'évaluation

- Lube Oil Requirements For Diesel EnginesDocument3 pagesLube Oil Requirements For Diesel EnginesJitendra KumarPas encore d'évaluation

- Liquified Gas CargoesDocument2 pagesLiquified Gas CargoesJitendra KumarPas encore d'évaluation

- Jacket Water SystemDocument2 pagesJacket Water SystemJitendra KumarPas encore d'évaluation

- Brushless Excitation SystemDocument27 pagesBrushless Excitation SystemSam100% (2)

- HPS2D Operation ManualDocument33 pagesHPS2D Operation Manualsanjeewa12Pas encore d'évaluation

- ABB REF542plus Manuale ENGDocument32 pagesABB REF542plus Manuale ENGAbrakain69Pas encore d'évaluation

- InterPSS Editor User Guide - English - EditionDocument104 pagesInterPSS Editor User Guide - English - EditionscutparisPas encore d'évaluation

- Ji32Iweqhjhjhjjop, E9Uweeiowuweuhjqwhjwqhhwqjdhjwjk Xjasljxlassja Short-Circuit Design Forces in Power Lines and SubstationsDocument14 pagesJi32Iweqhjhjhjjop, E9Uweeiowuweuhjqwhjwqhhwqjdhjwjk Xjasljxlassja Short-Circuit Design Forces in Power Lines and Substationsamit77999Pas encore d'évaluation

- Theory LecturesDocument522 pagesTheory LecturesboopelectraPas encore d'évaluation

- Codigos de ZF TransmisionDocument9 pagesCodigos de ZF TransmisionAlex BravoPas encore d'évaluation

- Air Blast Circuit BreakerDocument25 pagesAir Blast Circuit BreakerBhavya ChauhanPas encore d'évaluation

- Siprotec 7ut61Document360 pagesSiprotec 7ut61coleiro100% (1)

- High Voltage Busbar ProtectionDocument45 pagesHigh Voltage Busbar ProtectionabhinavksauravPas encore d'évaluation

- SP 1107 Electrical Protection Systems PDFDocument119 pagesSP 1107 Electrical Protection Systems PDFabdou100% (3)

- Soft StartsDocument48 pagesSoft Startsdejanoski_aPas encore d'évaluation

- NGR Sizing Calculation-MURALIDocument16 pagesNGR Sizing Calculation-MURALIsureshn82960633% (3)

- Generator GroundingDocument3 pagesGenerator GroundingNoneya BidnessPas encore d'évaluation

- 50BFDocument8 pages50BFSven del PinoPas encore d'évaluation

- C1358Document6 pagesC1358Lucas CamposPas encore d'évaluation

- 3 Schneider P546 kb4Document190 pages3 Schneider P546 kb4comportPas encore d'évaluation

- Is 14494 1998Document37 pagesIs 14494 1998Anand Agrawal100% (1)

- Manual Aid 2Document136 pagesManual Aid 2Luis Chinchilla CruzPas encore d'évaluation

- AUX Air Conditioner 410a Series DC Service Manual PDFDocument50 pagesAUX Air Conditioner 410a Series DC Service Manual PDFdimasPas encore d'évaluation

- Testing of Electrical EquipmentsDocument23 pagesTesting of Electrical EquipmentsPrashanth Reddy Gouni100% (5)

- Surge Arresters Ohio BrassDocument48 pagesSurge Arresters Ohio BrassalpcruzPas encore d'évaluation

- HAL ReportDocument48 pagesHAL ReportGaurav ChaturvediPas encore d'évaluation

- 20210E00Document32 pages20210E00brome2014Pas encore d'évaluation

- Instruction Manual Directional Overcurrent Protection Relay Grd140 - XXXDDocument438 pagesInstruction Manual Directional Overcurrent Protection Relay Grd140 - XXXDEpsp MedPas encore d'évaluation

- Easypact MVS: CatalogueDocument96 pagesEasypact MVS: Catalogueanant7388Pas encore d'évaluation

- Rxocf I2A 57 RX Path Imbalance: Moty Fault Class Fault Code DescriptionDocument42 pagesRxocf I2A 57 RX Path Imbalance: Moty Fault Class Fault Code DescriptionAli MohadesPas encore d'évaluation

- Selection of Main & Branch CB As Per NEC-210 (1.1.17)Document7 pagesSelection of Main & Branch CB As Per NEC-210 (1.1.17)kisan singhPas encore d'évaluation

- Generator ProtectionDocument41 pagesGenerator Protectionwaseem100% (1)

- C-H MP3000 Instructions PDFDocument103 pagesC-H MP3000 Instructions PDFJulio Perez Rodriguez100% (1)

- Well Integrity for Workovers and RecompletionsD'EverandWell Integrity for Workovers and RecompletionsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Flow Analysis for Hydrocarbon Pipeline EngineeringD'EverandFlow Analysis for Hydrocarbon Pipeline EngineeringPas encore d'évaluation

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Practical Reservoir Engineering and CharacterizationD'EverandPractical Reservoir Engineering and CharacterizationÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Abrasive Water Jet Perforation and Multi-Stage FracturingD'EverandAbrasive Water Jet Perforation and Multi-Stage FracturingPas encore d'évaluation

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsD'EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsÉvaluation : 4 sur 5 étoiles4/5 (4)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesD'EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesÉvaluation : 4 sur 5 étoiles4/5 (2)

- Casing and Liners for Drilling and Completion: Design and ApplicationD'EverandCasing and Liners for Drilling and Completion: Design and ApplicationÉvaluation : 5 sur 5 étoiles5/5 (3)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesD'EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesPas encore d'évaluation

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityD'EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityÉvaluation : 3 sur 5 étoiles3/5 (2)

- Well Testing Project Management: Onshore and Offshore OperationsD'EverandWell Testing Project Management: Onshore and Offshore OperationsPas encore d'évaluation

- Fundamentals and Applications of Bionic Drilling FluidsD'EverandFundamentals and Applications of Bionic Drilling FluidsPas encore d'évaluation

- Guide to the Practical Use of Chemicals in Refineries and PipelinesD'EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsD'EverandThe Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsÉvaluation : 3.5 sur 5 étoiles3.5/5 (5)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsD'EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsÉvaluation : 4 sur 5 étoiles4/5 (6)

- Advanced Production Decline Analysis and ApplicationD'EverandAdvanced Production Decline Analysis and ApplicationÉvaluation : 3.5 sur 5 étoiles3.5/5 (4)

- Heavy and Extra-heavy Oil Upgrading TechnologiesD'EverandHeavy and Extra-heavy Oil Upgrading TechnologiesÉvaluation : 4 sur 5 étoiles4/5 (2)

- Gas-Liquid And Liquid-Liquid SeparatorsD'EverandGas-Liquid And Liquid-Liquid SeparatorsÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)