Académique Documents

Professionnel Documents

Culture Documents

Manufacture of Oxygen by Linde Frankl's Process

Transféré par

Ahmed AliCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Manufacture of Oxygen by Linde Frankl's Process

Transféré par

Ahmed AliDroits d'auteur :

Formats disponibles

1

Abstract

Liquefaction of air and subsequent rectification of the liquid air is the basis of the Linde-

frankls processon which this project is based . Prof.Linde is credited today with the first man

producing liquid oxygen on a commercial scale. This thesis report is a design of an oxygen

plant of capacity 205 tonnes /day, along with oxygen this plant also produces nitrogen of very

high purity . In it a complete design of a distiallation column and a 1-2 shell and tube condenser

has been done.

The Linde Frankls process is the most important process for the commercial production of

oxygen in this process in which the air stream is divided in two , one is cooled by J-T effect and

the other by incoming pure nitrogen which is the most striking thing about this process and

which makes it more economical .

Results have been obtained with mechanical calculation and then verified by chemical

enggineering software chemsep ,kamlex and chem office. Fianlly a safety and preventions have

been delat with along with breif overview of plant layout and locations of the plant.

2

Contents

Chapter page no.

1.Introduction 1

2. Selection of process 8

3.Mass & Energy balance 19

4. Equipment Design 30

5. Conclusion and discussion 51

3

List of Tables

Table page no.

1. Analysis of air 20

2. Conditions and enthalpy of streams 24

3. Enthalpy chart 27

4. The equilibrium data for lower column 28

5. Excell sheet 37

4

List of figures

Fig. Page no.

1. T-S diagram for cla 10

2. Flowsheet of the linde frankls process 12

3. T-S for linde frankls process 13

4. Typical distillation column 31

5. Condenser flow pattern 43

6. LMTD calculation 44

7. Designed condenser 49

8. Schematic diagram 50

5

List of graphs

Graph page no.

1. Equilibrium data 34

2. McCabe Thiele rough 35

3. McCabe Thiele by chemsep 38

4. Relative volatility vs stage 39

5. Entropy Vs stage 41

6

Chapter 1.

Introduction

7

INTRODUCTION, PROPERTIES AND USES

Oxygen has been known to the scientists from as early as the 3

rd

and 4

th

centuries. The Chinese

were the first to detect its presence as an essential element in the atmosphere without which life

and combustion is not possible.

In 1770, Henry Cavendish, Joseph priestly and Karl withelm Scheele investigated the properties

of oxygen. Later on priestly carried out some experiments and produced it in small quantities.

It combines with hydrogen forming water covering around 70% of earth crust combine with

various metals and nonmetals to be present in around 99% of rocks. Overall oxygen constitutes

49.2%of the mass of the earth and 23.2%of the atmosphere is oxygen.

Oxygen can be produced in the laboratory by heating oxides, peroxides, permanganates and

bicarbonates in the presence of sulphuric acid.

One of the first industrial manufactures of oxygen was Brin process which was based on the

property possessed by the monoxide of barium of absorbing oxygen readily from the air at a

temperature of about 54

0

C forming dioxide, this dioxide at 870

0

C gives up the oxygen absorbed,

barium being restored to monoxide.

Another process is the electrolysis of water using caustic soda solution in distilled water as

electrolyte.

Now coming to the modern process, which is the liquefaction of air and subsequent rectification

of the liquid air. Which will be the main concern in this report; few pioneers who were

responsible in the gradual development are Noothmore, who was the first to produce chlorine in

its liquid form in 1806,

8

Faraday who succeeded in liquefying many gases by the application of pressure. But still gases

such as H

2

, O2, and N2

for many years resisted all attempts to liquefy them and were therefore

called permanent gases.

Investigations in 1863by Andrew revealed that gases could not be liquefied however great the

pressure applied, until the temperature of the gas is below a certain limit, this temperature is

called critical temperature. Further in this field two French scientists Pictat and Caillete in 1877

actually succeeded in liquefying first oxygen and then many other gases.

Pictat merely elaborated the Faraday tube experiment using high pressure and low temp gas

already liquefied as the refrigerant, while Caillete on the other hand obtained this refrigerating

effect by suddenly expanding a gas under high pressure

Rest was for Deval, Linde and Hampson in 1844 to adopt Cailletets method to a practical

continuous process and prof.Linde is credited today with the first man producing liquid oxygen

on a commercial scale.

9

PROPERTIES AND USES

OXYGEN IN SOLID STATE: It is a hard, pale blue, doubly refracting crystalline solid.

Melting point: -218.81

0

C

Density at -252.5

0

C: 1.4256 gm/cc

Specific heat at -256

0

C: 0.078 cal

Heat of fusion at -219

0

C : 313 cal/gm

OXYGEN IN LIQUID STATE : It is a pale steel blue, transparent and very mobile liquid

Boiling point : -182.02

0

C

Density at boiling point: 1.14gm/cc

Surface tension at B.P. : 13074 dynes/cm

It is a non conductor of electricity and strongly magnetic when compared to iron.

OXYGEN IN GASEOUS STATE: It is a colorless, odorless, tasteless, diatomic gas, a volume of

it slightly heavier than equal volume of air. One Litre of oxygen under standard condition weighs

1.42901gm and the corresponding weight of air is 1.2929gm. The oxygen is only slightly soluble

in water at ordinary temperature and pressures

The value of Ostwald coefficient=conc. in liquid phase/conc. in gas phase

=0.308 at 25

0

C and 1atm.

Physiochemical properties:

Atomic mass: 15.9994

10

Atomic number: 8

Isotopes: O

16

99.759%

O

17

0.037%

O

18

0.204%

Thermo physical properties:

Gas at 1 atm:

Density (0): 1.42908gm/lit

Density (21.11): 1.327gm/lit

Density at B.P: 4.467gm/lit

Density at triple point: 0.0108

Viscosity, at 25

0

: 206.39 mili poise

CHEMICAL PROPERTIES:

Action of oxygen with hydrogen: oxygen and hydrogen at an ambient temperature when

activated by a catalyst such as platinum metal, forms water.

2H

2

+O

2

= 2H

2

O

Action of oxygen on metals: all metals react with oxygen, although not with same rate or the

same energy.

Action of metals on non metals: oxygen reacts directly with all the non metals although direct

action often is not the most effective way of producing oxide. Even fluorine forms a compound

with oxygen, OF

2

11

USES

Iron and steel applications:

Around 98%pure oxygen is needed in steel industry for blast furnace to enrich the air from

21%normal oxygen to 26%.

It is required for cutting and welding and for scarfing billets, for this purpose oxygen should be

99.5% pure

Application in chemical industry:

In chemical industry, oxygen is used in the manufacturing of synthetic materials such as

acetylene, ethyline oxide, methanol, acrolein, hydrogen peroxide, titaniumdioxide etc.

Also find its wide application in waste water treatment.

Oxygen for cutting purposes:

oxygen cutting of ferrous metals into shapes for fabrication is practiced on a large scale, in this

technique the metal is heated first by means of a fuel oxygen torch to the point of combustion

&then a narrow, high velocity(1500ft/sec or more)stream of oxygen is introduced through the

center of the flame. It is used that oxygen should be of high purity of 99.55 or better.

Aerospace uses:

Aerospace activities have placed an expanding demand on oxygen production. Oxygen continues

to be the preferred oxidant for large scale& first stage firing because it is readily prepared at

nominal cost and unlike fluorine or the oxides of nitrogen, use does not make an area

uninhabitable or require extensive decontamination.

\

12

Oxygen in life support systems:

The development of high fly commercial aircraft, recent projects to explore both inner and outer

space require oxygen in the life support systems.

Moreover under the sea as well as well above the sea level in the mountains oxygen cylinders are

needed. In the medical applications, oxygen cylinders are employed almost routinely for patients

suffering respiratory function &represent the most frequent contact of the patient with medical

oxygen.

Use of oxygen in pediatrics incubator has been an important factor in increasing the survival rate

of premature infants.

Modern anesthesia routinely uses oxygen as a component of the gaseous mixture, herby

overcoming the diluting effects of gaseous mixture, herby overcoming the diluting effects of

gaseous anesthetics & ensuring an adequate supply for life support.

13

Chapter 2

Selection of

process

14

DIFFERENT PROCESSES AND SELECTION OF PROCESS

DIFFERENT MANUFACTURING PROCESS:

There are four different processes for the manufacture of oxygen from air,they are:

1. Low temp. rectification of liquid air

2. Electrolysis of water.

3. Cyclic chemical absorption& desorption from air by barium oxide at elevated temp. This

is called Brin process.

4. A process similar to Brin process but using cobalt compounds.

Out of these only low temp. Rectification process was found to be the most economical &

feasible.

This process mainly comprises of two steps. One is the liquefaction & then the separation of

liquid air into oxygen & nitrogen. Since the process mainly requires low temp., refrigeration is

necessary. Different cycles are in use to have required refrigerating effect.

For the separation also different types of columns are in use like simple, compund & double.

Taking into consideration the two stages various combinations were proposed.

1. Heylandt liquid oxygen process

2.Le rought process

3. Kellog low pressure process

4. Claude process

5. Linde frankl process

Out of the above processes the Claude process and lindey frankl process are really important

processes for the manufacture of oxygen.

Briefly giving an overview of these two processes.

15

CLAUDE PROCESS:

This process is characterized by the double expansion engine. After passing through the

preliminary heat exchanger, at 60 atm pressure, part of the air traverses the liquefier from top to

bottom & is admitted to the base of the dephlagmetar after expanded to 4 atm.The reset is

expanded like wise to 4 atm,in the first stage of the expansion engine, after which it is again

separated into two portions. One is added to the partially liquid air behind the valve, the other is

warmed by passing up the upper part of the liquefier,& is then expanded to 1 atm.

In the second stage of the engine, the expanded air there upon mixes with the cold nitrogen vapor

emerging from the top of the column & returns through the lower part of the liquefier & through

the preliminary heat exchanger. The oxygen in this air is wasted. The refrigerant between the

tubes of the dephlagmator is liquid oxygen from the column, part of which is withdrawn through

tube.

fig 1 t-s diagram for claud process.

16

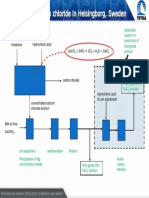

LINDE-FRANKL PROCESS:

This is the most important process for the commercial production of oxygen in this process at

first air is filtered & compressed to 6.8 atm in turbo compressor. During the compression cooling

is done to maintain the temp to 35 -40

0

C.

After compression the air is divided into two streams. One is 65% stream & the other is 35%,

now the larger stream is then passed through after cooler and heat exchanger where it is cooled

to -150

0

C to -170

0

C by the incoming pure nitrogen & waste nitrogen streams produced from

rectification columns. The smaller stream is passed through reciprocating compressor to increase

the pressure to about 200atm.Here the air temp is maintained at 4-8

0

C by intermediate cooling

between stages using cold water obtained by ammonia refrigeration. Then the air goes through

high pressure heat exchanger where the temp of air is brought down to about-120 -140

0

C. Now

the air undergoes expansion to about 6.5 atm in the expansion engine .The temperature of air is

brought down to -170 to-174

0

Cby joule Thompson effect. Now the air will be in liquid state

&mixes with the larger stream & changes the whole air stream into saturated liquid state.

This saturation liquid is fed to Linde rectification column. This column may be single, double or

compound depending on requirement. the liquid product coming out will have a purity of about

99.4 -99.99%.This liquid is partially vaporized in condenser, to liquefy the nitrogen vapor &the

rest may be taken as liquid product or it may be obtained in gaseous state if it is used for cooling

of incoming air, the other products that obtained are pure nitrogen of purity above 98% & waste

nitrogen product of purity of about 92-96%.These cold streams are utilized for cooling air, this

process is most economical for tonnage oxygen plants &most widely used in the world.

17

Fig 2. Flow sheet of linde frankl process

18

Fig 3.T-S diagram for the process

19

PROCESS VARIABLES:

1. Initial temperature: The initial or the entrance temp for air is an independent variable.

Although it varies from 10 to 50

0

C depending on the weather conditions and the type of after

cooler, for most cases, it is assumed as 27-30

0

C.

2. Initial pressure: This is an important variable; it is independent in the case of liquid oxygen

process. The lowest allowable value of pressure is controlled by the saturation temp. Of air

or nitrogen, this must be higher than the boiling point of oxygen at column pressure. In a

double column, the air pressure must be such that the nitrogen will condense at the temp of

boiling point of oxygen in order to produce reflux. This will be in the 4-6.5atm range,

depending on the pressure in the lower pressure column, and on the necessary temperature

difference in the condenser boiler.

3. Temperature approaches: An analysis of the process shows that it is necessary to establish

the minimum temp approaches for heat exchangers. For the exchange of sensible heat, the

minimum approach has to be 3-5

0

C

4. Temperature level of refrigerants: vapor liquid refrigerants may be used at almost any

temp level down to liquid air temperature provided the right material is chosen. The

following is a list of common refrigerants with the temp to which they can cool air.

Refrigerant temperature (

0

K)

Sulphur dioxide 263

Methyl chloride 249

F_12 244

Ammonia 240

Propane 231

Ethane 184

Ethylene 169

20

Methane 111

Nitrogen 77

5. Intake temperature to expander: this variable has the flexibility of being at almost any

value between the room temp and one close to that of air liquefaction, without appreciable

effect on the efficiency of expander. It is so chosen that the exhaust is saturated vapor.

6. Purity of product gases: this is fixed at some value less than 100%,with due regard to

certain limitation that may set a definite upper limit with a single column, the product

nitrogen purity cannot exceed 93%.in case of producing liquid oxygen, the available

refrigeration may set a still lower limit.

7. Heat leak: this is one of the most difficult variables to be selected since it depends on

factors which cannot readily be evaluated in advance. For e.g. the size of the plant is of at

most importance. Although the leak on an hourly basis increases when expressed the basis

increases as plant size increases when expressed the basis of a unit of air treated or oxygen

produced, it decreases and in large plants, is almost negligible.

8. Energy requirement: once the various quantities, temp, pressure are established the work

done by the compressors and expanders, and hence the energy requirements can be easily

calculated.

9. Sizes of equipment units: The thermodynamic analysis plays an important role in this

variable, since it deals with the driving forces in the heat exchangers and in distillation

columns.

The type of column chosen also plays a big role in the operation of the unit. There are

3 types of columns that can be used for rectification namely simple, double and compound.

21

Simple consists of only an exhausting column and liquid feed to it consists only the reflux. It

has an adv of simplicity and economy of distribution and construction, but the disadvantage

is that it suits only moderate yield of oxygen since nitrogen leaving the column can never be

enriched beyond 93%.

The compound column has both exhausting and enriching sections, but it must be provided

with a source of refrigeration at a very low temp, ie below the B.P.of nitrogen at the

operating pressure of the column.

The double column has two rectification columns operated at two different pressures, so

chosen that the nitrogen at high pressure column condenses at a temperature above the

boiling point of oxygen of low pressure column. Usually the pressure in the high pressure

column is 6-7 atm and in the other is 1.5-2 atm. This has the adv of high yield without

auxiliary refrigeration, but it is expensive and complicated to manufacture. But on the

tonnage scale, double column is preferred of high yield and high purity.

22

THEORETICAL MINIMUM ENERGY REQUIREMENT

The computation of absolute minimum work required for air separation and oxygen

liquefaction with the case is possible. It known that this work is given as:

W=H-T

0

.S

In air separation is zero if one neglects the enthalpy of mixing. The valve of S may be shown

that the enthalpy change accompanying the mixing of pure oxygen and pure nitrogen to yield

one mole of a mixture of x mole fraction of O

2

is

S = RX lnX+R(1-X)ln(1-X)

A similar expr may be written for a mix of mole fraction Y

So the entropy of M1 moles of air relative to pure O

2

andN

2

is

0.21Rln0.21+0.79ln0.79

Accordingly if M1 moles of air to be separated into M2 moles of O

2

rich gas of composition

X

2

mole fraction O

2

and M3 moles of oxygen lean gas of X

3

mole fraction of O

2

,the overall

entropy change will be,

S = R [ M2 { (2X

2

lnX

2

)+(1-X

2

)ln(1-X

2

) } + M3{ (X

3

lnX

3

)+(1- X

3

)ln(1-X

3

) }]

-RM1 {0.21ln0.21+0.79ln0.79}

This expr when multiplied by ambient temp., usually taken as 303K yields the theoretical

minimum energy requirement.

Now the material balance equations are:

M1=M2+M3

0.21M1=X

3

M3+X

3

M3

Defining M2 and M3 for chosen values of M1,X

2

and X

2

.

23

SELECTION OF THE PROCESS

Prior to the selection of the process it should be emphasized that there are so many adjustable

variables involved, it is very difficult to put all on a comparable basis. Usually on the smallest

scale, the most important economic factors are capital and labor charges. Thermodynamic

efficiency and hence power charges for compression are of less consequence.

Charges for material such as compressor oil, chemicals for air purification are small in relation

to the other costs. The labor charges also decreases when the scale increases and in this cases the

capital costs and power costs dominate. When the plant produce a liquid product, as in this case

the power requirement to provide necessary refrigeration is considerably increased and

thermodynamic efficiency is of much importance.

The essential requirement on a general scale is a cheap and simple plant, easy to operate for

which a thermodynamic efficiency is not needed. But if the liquid is produced on a large scale,

the thermodynamic efficiency becomes important.

As the purpose of this project is to design large scale oxygen product plant the only process that

seems economical is the LINDE FRANKL PROCESS.

As the most important adv here is the high purity of oxygen (99.5) %, although the work of

liquefaction of air is about 3.5kwh/gallon which is relatively higher than other process. Also the

outgoing streams from the rectification column are used effectively in supplying the required

refrigeration for cooling the incoming air.

In view of all the above cited advantages the process For this project is linde-frankl.

24

Chapter 3

Mass & Energy

balance

25

MASS AND ENERGY BALANCE

CAPACITY of the unit is, 205 T/day of gaseous oxygen of 99.95 purity.

And 10 t/day of liquid oxygen of 99.97% purity.

So total oxygen production = 215 T/day

= (215*1000)/(24*32)

= 281.25 kg moles/hr

At standard temperature and pressure,

1kg.mole occupies 22.4m

3

Oxygen produced in volumetric units =281.25*22.4

=6300Nm

3

/hr

Standard analysis of air:

Component volume%

Nitrogen 78.03

Oxygen 20.99

Argon 0.94

Hydrogen 0.01

Helium 0.0003

Krypton 0.00011

Xenon 0.00009

Carbon dioxide 0.03-0.06

Moisture 0.02-0.05

Table 1.

26

Quantity of intake air:

Capacity of the unit = 6300m

3

/hr of oxygen

Volume % of oxygen in the air =21%

Quantity of air needed =6300/0.21

=30000m

3

/hr

Assuming about 15% less of air due to removal of moisture,CO

2

and from possible leaks.

The quantity needed = 30000+30000 *.15

=34500m

3

/hr

Atmospheric conditions :

Temperature =30

0

C,relative humidity =60%

Now the air passes through elements of the system

Enthalpy of air at 1 atm and 30

0

C=kcal/kgmol.

Enthalpy of air at 6.8 atm and38

0

C=3766.23 kcal/kgmol

Moles of air entering compressor=34500Nm

3

=1540.18 kgmol/hr

Enthalpy of air entering compressor=1540.1883701kcal/hr=5701515.3kcal/hr

Enthalpy of air leaving the compressor=1540.18*3766.23=5800672.1kcal/hr.

So change in enthalpy of air = 5800672.1-5701515.3

99156.8kcal/hr

Now the air is split into two streams one is 65% and the other is 35%. Larger stream passes

through refrigeration cycle and the smaller stream passes through compression cycle and then

expanded in expansion engine.

27

Mass & energy balance for the refrigeration cycle

65% stream

Amount of air passing = 1540.18*0.65 = 1001.117 kg moles /hr

First air passes through water cooler

Water cooler

Inlet 6.8 atm and 38

0

C

Outlet 6.5 atm and 8

0

C

Relative humidity = 60%

So partial pressure of water at 38

0

C=.6*49.692=29.82cm of Hg

Total pressure is 760*6.8 = 5168 mmHg

Now

P = (H

1

*P

t

)/(Mw/Ma+H

1

) from Perrys handbook eq 15.6

Where

P = partial pressure in mm Hg

P

t

= total pressure in mm Hg

Mw = molecular weight of water = 18

Ma = molecular weight of air =29

H

1

= molal absolute humidity in kg moles of water vapor / kg moles of dry air

Substituting the values in the formula,

We get H

1

= 3.6*10

-3

Let us assume air coming out from the cooler is saturated

28

So final humidity = 100%

Vapor pressure of water at 80

0

C =8.045 mm Hg.

Final partial pressure of water = 8.045 mm of Hg

Total pressure = 6.5 *760 =4940 mm of Hg

Using the same eq

We get H

2

= 9.68*10

-4

kg moles of water vapor /kg moles of dry air

Let the amount of dry air be M kg moles

Now M +.0036M=1001.117

So M=997.52

So amount of water contained =997.52(.0036-.000968)

=2.625kg moles /hr

Moles of air coming out of cooler

1001.117 - 2.625 =998.492 kg moles/hr

Coming to energy balance, from enthalpy chart of air

Enthalpy of entering air = 3766.23 kcal/kgmol

Enthalpy of outgoing air = 3573.09 kcal/kgmole

Enthalpy of entering air =1001.117*3766.23 = 37770436.8 kcal/hr

Enthalpy of leaving air = 998.492*3573.09=3567701.7 kcal/hr

Change in enthalpy of air = 202735.1 kcal/hr

29

Heat exchanger

Air entering = 99.2492 kg moles /hr

Volume % of CO

2

in air = 0.045%

Moles of CO2 present in air entering

= 998.492*0.045/100= 0.4493 kg moles/hr

Amount of dry air leaving heat exchanger = 997.52-0.4493 = 997.07kg moles /hr

This is cooled to -168

0

C by circulating pure nitrogen and waste nitrogen streams coming from

distillation column. Total

Amount of pure nitrogen is 361.61 kg moles /hr

It splits into 2 streams one passes through this heat exchanger and other through high pressure

heat exchanger in the compression cycle

Let the amount of pure nitrogen stream passing this exchanger is M kg.

Amount of waste nitrogen 892.69 kg moles /hr

Conditions and enthalpy of streams: from enthalpy chart.

Stream Flow rate

Kg moles/hr

temp

0

C Pressure (atm) Enthalpy(kcal/kg)

Dry air In-997.07 8 6.5 3573.09

30

Out -997.07 -168 6.5 2092.35

Pure N

2

In- M

Out M

-178

4

1.5

1.5

1500

2750

Waste N

2

In 892.69

Out 892.69

-172

6

1.5

1.5

1510

2800

CO

2

In- 0.4493

Out- nil

8

solidifies at -

56.6

Calculated below

Moisture In-.972

Out-nil

8

Solidifies at - 4

Calculated below.

table 2

Heat given up by dry air = 997.07(3573.09-2092.35)=1476401.4 kcal/hr

Heat given up by CO

2

:

CO

2

at first cools from 8 to -56.6

0

C and then solidifies

Specific heat Cp is 10.34 +0.0027T-195500/T in kcal/kg mol

k

T is absolute temp in k

Heat lost by CO

2

on cooling to -56.6

=

T2

M CpdT

T1

= 411.95 kcal/hr

31

Heat of sublimation of CO

2

= 1993.83 kcal/kg mole

Heat lost by CO

2

on freezing

=

0.4498*1993.83 kcal/hr = 896.83 kcal/hr

Total heat lost by CO

2

411.95 +896.83 = 1308.78 kcal/hr

Heat lost by water molecule by cooling to -4= .972 *18(8-(-4))= 209.952 kcal /hr

Heat lost by water molecule on freezing 0.972 *80*18 = 1399.6 kcal/hr

Latent heat of condensation = 80 kcal/hr

So total heat lost by water = 209.52+1399.6=1609.632 kcal /hr

Heat joined by water nitrogen stream 892.67 (2800-1500) = 1160497 kcal /hr

Heat gained by pure nitrogen = M(2750-1510) = 1240M

11160497+1240M = 1476401.4+1308.78+1609.632

Or 1204M=318822.81

M = 257.115 kg moles/hr

The amount of waste nitrogen passing through heat exchanger = 257 kg moles /hr

Amount of air passing

= 34500*.35=12075

1207/22.4=539.063 kg moles/hr

This air passes through compressor

Compressor

Before compression, air is at 6.5 atm and 38 0C

And after it is at 800 atm & 6 0C

Enthalpy of inlet air = 3766.23 kcal/kgmol

Enthalpy of outlet air = 3251.119 kcal/kgmol

So net enthalpy of entrance = 3766.23*539.063 kcal/hr = 2030235.2 kcal/hr

32

And for exit air 539.063*3251.119 kcal/hr

Assuming no condensation of water vapor

The net change in enthalpy of air =

27677.3 kcal/hr

CO

2

absorber: volume % ofCO

2

in air =.045$%

Moles of V present = .045*539.063/100=.2426 kg moles/hr

From the earlier calculations, molar humidity of air + 3.6*10

-3

If G is the amount of dry air in kg mole/hr then G+.0036G=539.063

So G=538.478 kg moles/hr

Moisture present 539.063-538.478 = 0.535kgmoles/hr

In the adsorber most of the moisture and CO

2

is removed

High pressure heat exchanger

No change in mass. Now heat balance, from enthalpy chart in Perrys handbook

Stream Flow rate

Kg

moles/hr

Temp.

0

C

Pressure

atm

Enthalpy

Kcal/kg

Pure

nitrogen

In- 104.495

Out-

104.495

-178

4

1.5

1.5

1500

2750

Oxygen In -267.86 -178.2

2

30

30

2161.6

3328.64

Air In

538.478

Out-

538.478

6

?

200

200

3251.119

?

Table 3.

33

Heat taken by pure nitrogen stream= 104.495(2750-1500)= 130618.75 kcal/hr

Heat taken up by oxygen = 267.86 (3328.64-2161.6) = 312603.33 kcal/hr

Heat lost by air = 538.478(3251.119-H)

Now H=2428.91 kcal/kg mol

Now the corresponding temp of air is -150

0

C

So the air entering the expansion engine is at 200 atm and -150

0

C

Here air is expanded to 6.5 atm the temp. Of air after compression is -174

0

C(liquid state)

Now both the air streams are mixed. And finally the temp. Is at -172

0

C and will be in

saturated liquid state and fed to lower distillation column.

The set up of oxygen plant consists of two linde column:

Upper column (1.5 atm)

Lower column (6.5atm)

The equilibrium data is as follows For lower column.

Temp.

0

C Liquid composition

X%

Vapor composition

Y%

-160.9 0 0

-163 2.5 6.5

-165 17 32.5

-167 27 48.5

-168 32.5 50

-170 45 68

34

-172 60 79.5

-174 79 90

-175 89 95

-176 100 100

Table 4.

35

Chapter 4

Equipment

design

36

Equipment design

Distillation column

Fig.4.

Typical distillation column with reflux and reboiler

For mass balance, total air entering the column=

997.07+538.478=1535.55 kg moles/hr

From an overall balance of linde column kg moles of oxygen coming out = 6300/22.4

37

=281.25kgmoles/hr

So amount of waste nitrogen issuing out = 1535.55-(361.61+281.25)

=892.69 kg moles/hr

Let the liquid to vapor ratio at the top of both columns to be .58

So L1/V1=L2/V2=.58

Suffix 1 for upper column

Now V2=361.61

L2=.58*361.61=209.734 kg moles /hr

This L2 comes out of condenser in vapor state and fed at the top of upper column as

liquid after passing through expansion valve

.58V1+209.734=V1

.42V1=209.734 so V1=499.366 kg moles/hr

The amount L1 refluxed to the lower column after condensation occurs in the condenser

=.58*499.366

= 289.632 kg moles/hrLet F=amount of feed =1535.55kgmoles/hr

W=bottom product from lower which is refluxed back to the top column ( rich liq)

S=side stream from lower column, which is refluxed back to top column (impure liquid)

Xf=mole fraction of N

2

in feed = .79

Xw=mole fraction of N

2

in rich liquid =.65

Xs= mole fraction of N

2

in IPL=.96

X1= mole fraction of N

2

in top product = .9999

Now, from overall& component balance

F=W+S+L2 (1)

38

FX

F

=WX

w

+SXs + X1L2 (2)

From (1) 1535.55 = W + S +209.734

W +S = 1325.816

From (2) (1535.55 *.079) = (W*.65)+(S*.96)+(209.734*0.9999) (4)

1003.3714 = .65W + .96S

Multiplying (3) by .65

0.65W +0.65S = 0.65 * 1325.816 (5) subtracting 5 from 4

141.591= s (0.96-0.65)

S=456.746 kg moles /hr

From 3

W = 1325.816-456.746 = 869.07 kg moles/hr

Also L1/V1 = .58

L1/V1 = (456.746-289.633)/499.366

= .335

The stream S is taken out as liquid

V1 = V1=V1

L!/V1 = (1535.55+167.112)/499.366=3.4

Using the equilibrium composition data at 6.5 atm, the curve is drawn from XL1=.9999

the operating line is drawn with L1/V1=0.58

The side stream being taken out is impure liquid of 96% of N

2

For this point from which the operating line of slope L1/V1 = 0.335 is drawn will be

Xs1 = [(456.746*.96) + (209.734*0.9999)]/456.746+209.734

= 0.978

These 2 operating lines are seen to be intersecting at X =0.96

39

Now the operating line for exhausting section is drawn from Xw =0.65 with slope

L1/V1 =3.4

Hence from the graph no. of theoretical plates = 17.3

Graph 1.

0

10

20

30

40

50

60

70

80

90

100

0 20 40 60 80 100

equilibrium data

40

Graph 2.

Plate efficiency

Where is the average molal viscosity of the feed in cp

41

Of liquid O

2

= 0.19 Cp

Of liquid N

2

=0.24 Cp

Avg molal of feed = .79*.24 +.21*.19

= .2295 Cp

= .6127

So actual no. of plates = 17.3/.6127= 27.249 =28

So no. of plates =28

From graph, feed enters the 15

th

plate.

Actual plate at which feed enters = 15/.6127 = 23.952 = 24

Feed enter 24

th

plate

From graph, side stream is taken out from 5

th

plate

Actual plate from which side stream is taken out is 5/0.6127=8.16 = 9

th

plate

Height of column :

No. of plates =28

Plate spacing = 12

Spacing at top & bottom = 12each

Spacing for feed = 12

Total height =( 28+2)*12 =360 = 9.146

42

Computer aided design of column

The software CHEMSEP from chem. Office was used, data were fed and the following excel

sheet obtained.

Stream Feed1 Top Bottom

Stage 14 1 28

Pressure (N/m2) 650000 200000 650000

Vapour fraction (-) 1 1 0

Temperature (K) 105 83.686 104.821

Enthalpy (J/kmol) 5624000 6248000 11000000

Entropy (J/kmol/K) 41261.1 42611.3 92166.4

Mole flows (kmol/s)

Oxygen 120 0.390691 119.609

Nitrogen 379 300.729 78.2712

Total molar flow 499 301.12 197.88

Mole fractions (-)

Oxygen 0.240481 0.001297 0.604452

Nitrogen 0.759519 0.998703 0.395548

Mass flows (kg/s)

Oxygen 3839.88 12.5017 3827.38

Nitrogen 10617.3 8424.62 2192.69

Total mass flow 14457.2 8437.13 6020.06

Mass fractions (-)

Oxygen 0.265604 0.001482 0.63577

Nitrogen 0.734396 0.998518 0.36423

Vapour:

Mole weight (kg/kmol) 28.9723 28.0192

Density (kg/m3) 21.5723 8.0542

Viscosity (N/m2.s) 7.7E-06 5.67E-06

Heat capacity (J/kmol/K) 29204.5 29254.8

Thermal cond. (J/s/m/K) 0.010864 0.008368

43

Liquid:

Mole weight (kg/kmol) 30.4227

Density (kg/m3) 889.88

Viscosity (N/m2.s) 0.0001

Heat capacity (J/kmol/K) 60360.7

Thermal cond. (J/s/m/K) 0.112383

Table 6.

With the help of software the mcabe thiele diagram was obtained .

Graph 3. With chem. sep

44

Chem. Sep data sheet

45

Graph 4. The above graph gives the variation of relative volatility with stage no.

Following the similar pattern design of upper column can be done in the same fashion.

46

Graph 5.This is entropy vs stage graph.as obtained by the chemsep,from chemoffice

47

CONDENSER DESI GN

Basic Theory

The fundamental equations for heat transfer across a surface are given by:

Where w is tube side flow and W is shell side flow and CPt is specific heat fr tube side and CPs

is for shell side

In design, a correction factor is applied to the LMTD to allow for the departure from true

countercurrent flow

to determine the true temperature difference.

Tm = Ft Tm

The correction factor is a function of the fluid temperatures and the number of tube and shell

passes and is correlated as a function of two dimensionless temperature ratios

The overall heat transfer coefficient U is the sum of several individual resistances as follows

48

Continuing with our problem .Nitrogen vapors enter counter currently through the tubes of the

condenser, where it meets the liquid oxygen coming out on the bottom product of the top

column. for this purpose, a 1-2 shell and tube condenser is chosen. It is a vertical type condenser.

fig 5.diagram indicating the flow pattern

Enthalpy of N

2

vapor at 96.5K is 238.35 J/gm=1595.16 cal/kgmol

=1595.16 Kcal/kgmol.

Enthalpy of N

2

vapor at 94.8 K is1592.05 cal/kgmol

Enthalpy of N

2

liquid at 94.8K is 443.52 cal/kg mol

So total enthalpy change of stream= (499.367*1595.16) (209.734*1592.02+289.633*443.52)

= 1399009.42KJ/hr

49

LMTD calculations:

fig.6

Tha is inlet temp of nitrogen vapor = -176.5

0

C

Thb is outlet temp of nitrogen = -178.2

0

C

Tca is inlet oxygen liquid =-179.5

0

C

Tcb is outlet oxygen =-178.2

0

C

T

l

= 1.491

Taking overall heat transfer coefficient as 100 Btu/hrft

2

F

0

567W/m

2

0

C

now Q = UAT

l

From this A comes around 460 m

2

Let N is the no. of tubes so total heat transfer area =N*DL

Where D is tube OD

And L is the length

50

We are choosing 1 inch OD. and 14 BWG cu tubes of 8 inch length and calculating the no. of

tubes obtained is 2360

Also taking a triangular pitch of 1.25 inch that ,nearest no of tubes found from TEMA

regulations is 2362 and shell dia as 1.67 meters

Now the corrected area becomes 460.5m

2

So using this value of heat transfer area the U becomes 560.6W/m

2

0

C

Inside and outside coefficient calculations:

a. Nitrogen in tube side

Flow area for the given tube is 3.52cm

2

Gas mass velocity = 499.367*28/(3.52*2362/10000*2)=33634.52kg/m

2

hr

Density of nitrogen =802.6kg/m3

So velocity = .01155 m/sec

So Nre = 822

Condensate loading per linear foot is G = W/DN = 88.955 kg /m hr

From graph in kern we get the value of hi = 240 btu/hr ft

2

0

F

Also ho = hi*id/od= 22.16 btu/hr ft

2 0

F

Oxygen on shell side

Density = 1140 kg/m3

Thermal conductivity =k= 0.07 btu/ft.hr.

0

F

Here flow area = As = ID*C*B/144pt

C is clearance taken as 0.25 inch B = baffle spacing = 1 inch i.d. =66 inch Pt =1.25 inch so

As = 1.1 ft

2

=11.84m

2

51

Gas mass velocity Gs = W/As = 1535.55*32/11.84=4150.135kg/m

2

hr

From this NRE can be calculated by DeGs/

We get it as 72824

Now from the graph of jH Vs Nre

jH =175

now ho = jHk/De*(c/k)^-1/3

solving ho= 223.61 btu/hr ft

2

F

=1267.8w/m

2 0

C

Clean overall coefficient

Uc=hio*ho/(hio+ho)=598.865 w/m

2 0

C

Dirt factor :

Rd = Uc-Ud/(Uc*Ud)= 0.0000952m

2 0

C/w

Pressure drop:

Shell side

No. of crosses = N+1 =8 so no. of baffles =8-1 = 7

For Nre 72824

Friction factor =0001.4 (graph)

Sp gravity of oxygen = .00624

Ds= inside diameter in ft and n is the no. of tube passes

52

So Ps=fGs

2

Ds(N+1)/(5.22*10^10De*S)

So Ps =1.522psi

For tube side:

Pt= fGt

2

Ln/(5.22*10^10*DS) ,psi

= 0.155*10^-3 psi

Return losses: Pr = 4nV

2

/2Sg = 2.2 *10 ^-4 psi

So PT = Pt+Pr = 3.75*10 ^-4

Design summary: no. of tubes =2362

Shell ID = 66 inch

Clean overall H.T.C. = Uc =598.865 w/m

2 0

C

Design overall = 560.6W/m

2

0

C

Dirt factor Rd=) 0.0000952m

2 0

C/w

Pressure drop for tube side = 0.000375 psi

Pressure drop for shell side = 1.522 psi

53

Computer aided design of condenser Used KAMLEX heat

exchanger software to design and test my results obtained from my design

54

Results and diagram.

Fig 7.Condenser with geometry

55

Schematic diagram

Fig 8.

Results from kamlex.:

No of tubes = 2362

Overall heat transfer coefficient:

Heat exchanged = 563.2 W/m

2

0

C

Heat exchanged =1406504.1KJ/hr

Pressure drop for shell side: 11574.35 P

Pressure drop for tube side: 30.2Pascal

56

Chapter 5

Conclusion

and discussion

57

CONCLUSION AND DISCUSSION

On the basis of above calculations, I propose an oxygen plant with a capacity of 205 T/day with

the above design specifications. This plant can be actually called as an oxygen cum nitrogen

plant as it is producing pure nitrogen along side the oxygen.

Apart from equipment design there are certain other factors which have to kept in mind before

designing and finally establishing a plant., like location analysis and a plant layout .

Plant lay out and location

But before making such a choice, he has to go through the detailed locational analysis

considering various factors, which influence his decision. It is a long-term strategic decision,

which cannot be changed once taken. An optimum location can reduce the cost of production and

distribution to a great extent. Thus great care and appropriate planning is required to select the

most appropriate location.

The efficiency of production depends on how well the various machines;

production facilities and amenities are located in a plant. An ideal plant layout

should provide the optimum relationship among the output, floor area and

manufacturing process. An efficient plant layout is one that aims at achieving various objectives

like efficient utilization of available floor space, minimizes cost, allows flexibility of operation,

provides for employees convenience, improves productivity etc. The entrepreneurs must possess

the expertise to lay down a proper layout for new or

existing plants. It differs from one plant to another. But basic principles to be followed are more

or less same.

Plant layout is applicable to all types of industries or plants. At the end, the layout

should be conducive to health and safety of employees. It should ensure free and

efficient flow of men and materials. Future expansion and diversification may

also be considered while planning factory layout

Safety precaution

All personnel being employed for work in connection with oxygen/rich air should be cautioned

concerning the hazards involved and precautions to be observed. Oil grease or similar substances

58

must not be allowed to come into contact with compressed oxygen or liquid oxygen. Contact of

this substance with oxygen may result in an explosion. Personnel working in an area of possible

oxygen concentration, such as near an oxygen vent or a liquid oxygen spillage, or in a trench

where oxygen seepage and concentration might occur, must ensure that their clothing is free

from contaminations of oxygen before lighting a cigarette or approaching a naked flames. It is

essential that the clothes be dries for at least 15 minutes before approaching a flame after any

such contamination.

The following precautions must be strictly observed at all times:

1. Thoroughly wash all oxygen fittings, valves and parts with clean Tricolor Ethylene / carbon

tetra chloride (CTC) before installation. Never use petrol, kerosene or other hydrocarbon

solvents for this purpose. All tubing, lines valves etc. to be used in oxygen service, must be of an

approved type and must be thoroughly degreased and blown out with clean oil-free compressed

air or Nitrogen before being placed in service.

2. Do not permit the release of Acetylene or other flammable gases in the vicinity of the plant air

intake. A concentration of Acetylene exceeding 5 parts per million in liquid oxygen may explode

with extreme violence. Strict supervision is essential to minimize the possibility of

contamination.

3. The plant and the plant vicinity must be kept clean and free from abstractions at all times. Any

oil leak within the plant surrounding must be rectified without delay. Oil spillage must be

cleaned up immediately using rag and carbon Tetra Chloride.

4. Do not lubricate oxygen valves, regulators, gauges or fitting with oil or any other substance.

5. Ensure that insulation removed from the Air Separator jacket is not contaminated with oil or

other inflammable materials. Personnel carrying out maintenance on the Air Separation Plant

equipment must wear clean overalls and their hands and tools must be free of oil. This ensures

that the insulation and equipment within the jacket is not contaminated with oil. Should

59

contamination take place the affected materials must be discarded and replaced by clean new

material?

6. Do not fasten electric conduits to the plant or its pipelines.

7. Do not use oxygen as a substitute for compressed air, spark present in an atmosphere of

oxygen will immediately burst into flame.

8. Do not fill any container or pipe line with oxygen unless it has been thoroughly degreased

with clean CTC or TCE.

9. When discharging liquid oxygen or rich liquid from drains, valves or pipe lines, open valves

slowly to avoid the possibility of being splashed. In particular ensure that liquid does not run into

shoes or gloves. Contact with liquid oxygen rich liquid will cause frostbite evidenced by

whiteness and numbness of the skin. The affected parts must be batched at once in cold (not box)

water and seek medical attention immediately.

10. Do not breathe cold oxygen vapor. The temperature of the vapor rising from liquid oxygen is

approximately - 181 Deg C. A deep breath of vapor at this temperature can result in frost-bitten

lungs with resultant serious illness and permanent disability or death.

60

References

Basic Theoretical Physics ,Springer new York ,part 4 ,pages 313-325

Cryogenic Engineering, Springer new York ,part 1,pages 3-27 and 146-160

US Patent 4072023 - Air-rectification process and apparatus

Chemical and Petroleum Engineering journal, Air separation in plants with an external

source of refrigeration ,,volume 4 ,pages 825-829

American Chemical society journal , some aspects of gas separation at low temperatures

by W. H. Granville

air liquefaction: distillation

encyclopedia of separation science, 2007, pages 1895-1910,science direct

R. agrawal, D.M. herron

Cryogenic Process Engineering

Encyclopedia of Physical Science and Technology, 2004, Pages 13-36

Klaus D. Timmerhaus

Vous aimerez peut-être aussi

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4D'EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Évaluation : 5 sur 5 étoiles5/5 (1)

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsD'EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsPas encore d'évaluation

- Material and Energy BalanceDocument28 pagesMaterial and Energy Balancemuhammad arslan100% (1)

- Lecture Notes 3Document70 pagesLecture Notes 3joshuaPas encore d'évaluation

- Distillation Column Reboiler DesignDocument13 pagesDistillation Column Reboiler DesignLouie GresulaPas encore d'évaluation

- Design of packed absorber column for multi-component gas scrubbingDocument104 pagesDesign of packed absorber column for multi-component gas scrubbingNana kwadwoPas encore d'évaluation

- MATERIAL BALANCE TITLEDocument46 pagesMATERIAL BALANCE TITLEG Vamsee KrishnaPas encore d'évaluation

- 2 - Heat of Solution and Mixing PDFDocument33 pages2 - Heat of Solution and Mixing PDFshifa veronicaPas encore d'évaluation

- Final ProjectDocument73 pagesFinal ProjectKedar Yadav100% (2)

- Ammonium 2520sulphate Material 2520balance.Document9 pagesAmmonium 2520sulphate Material 2520balance.AgadmatorPas encore d'évaluation

- Overall Flowsheet Simulation Benzene Cyclohexane TW6Document7 pagesOverall Flowsheet Simulation Benzene Cyclohexane TW6Mitesh ParmarPas encore d'évaluation

- Ammonia MEB Final PDFDocument30 pagesAmmonia MEB Final PDFMANU BTech MCA Third YearPas encore d'évaluation

- Allyl Chloride Production A Case Study in Debottlenecking Retrofitting and DesignDocument7 pagesAllyl Chloride Production A Case Study in Debottlenecking Retrofitting and DesignPaola PorrasPas encore d'évaluation

- Perry's Heat of CombustionDocument4 pagesPerry's Heat of CombustionAayush GoyalPas encore d'évaluation

- KAFCO: Bangladesh's Leading Fertilizer ProducerDocument40 pagesKAFCO: Bangladesh's Leading Fertilizer ProducerpktruthPas encore d'évaluation

- Production of Power From HeatDocument3 pagesProduction of Power From Heathameed1966Pas encore d'évaluation

- Cre Una PDFDocument164 pagesCre Una PDFChetana PatilPas encore d'évaluation

- AcetoneDocument14 pagesAcetoneAddison JuttiePas encore d'évaluation

- Ammonium Sulfate Manufacturing MethodsDocument7 pagesAmmonium Sulfate Manufacturing MethodsVishal Thakare100% (1)

- Monoethanolamine Design 2520of 2520equipmentsDocument54 pagesMonoethanolamine Design 2520of 2520equipmentsbhaskar5377Pas encore d'évaluation

- HCl Gas Absorption ProcessDocument2 pagesHCl Gas Absorption Processsundhar100% (2)

- CHAPTER 4 Energy BalanceDocument35 pagesCHAPTER 4 Energy BalanceZafirahAhmadFauziPas encore d'évaluation

- 04combustion TechnologyDocument70 pages04combustion TechnologySheensky V. SalasaPas encore d'évaluation

- Achieveing Zero Liquid Discharge Through Mechanical Vapour Recompression-2015Document25 pagesAchieveing Zero Liquid Discharge Through Mechanical Vapour Recompression-2015ansarPas encore d'évaluation

- Design of CondenserDocument2 pagesDesign of CondenserEngr Renato Arriola0% (1)

- Fuel Ethanol Distillation - Fundamentals - KatzenDocument18 pagesFuel Ethanol Distillation - Fundamentals - Katzenaseptman1Pas encore d'évaluation

- Basic Heat Exchanger DesignDocument10 pagesBasic Heat Exchanger DesignKvspavan KumarPas encore d'évaluation

- Che 2Document25 pagesChe 2Jaynie Lee VillaranPas encore d'évaluation

- Switch CondenserDocument14 pagesSwitch CondenserKader GüngörPas encore d'évaluation

- Ammonia Synthesis ReactorsDocument4 pagesAmmonia Synthesis ReactorsShivangi PancholiPas encore d'évaluation

- Class Example Pump Sizing-Module 5 - Sep28Document6 pagesClass Example Pump Sizing-Module 5 - Sep28Stefan De BeerPas encore d'évaluation

- Types of condensers and design calculationsDocument17 pagesTypes of condensers and design calculationsfarhaPas encore d'évaluation

- Melt CrystallizationDocument10 pagesMelt Crystallizationarsh19706636Pas encore d'évaluation

- Convection Heat Transfer Types Laminar Flow Boiling CondensationDocument22 pagesConvection Heat Transfer Types Laminar Flow Boiling CondensationKelmy Thomas MariaPas encore d'évaluation

- Material and Balance For Sohio Process That Produce AcrytonitrileDocument2 pagesMaterial and Balance For Sohio Process That Produce Acrytonitrileafnan_lion940% (1)

- Psych Ro MetricDocument11 pagesPsych Ro MetricLucia Kara Chance100% (1)

- A01 031Document17 pagesA01 031jaimePas encore d'évaluation

- Complete PFDDocument5 pagesComplete PFDAriff FikriPas encore d'évaluation

- Allyl BDocument9 pagesAllyl BDemet AcargilPas encore d'évaluation

- How Acetylene is Produced from Calcium Carbide and Natural GasDocument3 pagesHow Acetylene is Produced from Calcium Carbide and Natural GasJoy MukherjePas encore d'évaluation

- Material and energy balance for methanol productionDocument14 pagesMaterial and energy balance for methanol productionShah Ali NaqviPas encore d'évaluation

- Ammonia ReactorDocument11 pagesAmmonia ReactorRh GladysPas encore d'évaluation

- Simulation of Ammonia Production From Synthesis GaDocument12 pagesSimulation of Ammonia Production From Synthesis Gasagar dasguptaPas encore d'évaluation

- Design of a Vacuum Distillation ColumnDocument20 pagesDesign of a Vacuum Distillation Columndefred100% (1)

- Fischer Tropsch - Process 2Document14 pagesFischer Tropsch - Process 2bryan lillibridgePas encore d'évaluation

- Hydro CarbonDocument6 pagesHydro CarbonAlpesh PatelPas encore d'évaluation

- Calculation of Bubble and Dew PointDocument9 pagesCalculation of Bubble and Dew Pointrgopinath5Pas encore d'évaluation

- CEB 2063 Evaporation Process Design and AnalysisDocument28 pagesCEB 2063 Evaporation Process Design and AnalysisScorpion RoyalPas encore d'évaluation

- Natural Gas Purification (Water Absorption Only)Document18 pagesNatural Gas Purification (Water Absorption Only)austingoewertPas encore d'évaluation

- PM3125 Lectures 13to15 EvaporationDocument46 pagesPM3125 Lectures 13to15 EvaporationMukesh Tiwari0% (1)

- Experiment 4a – Pressure Drop in Packed ColumnsDocument21 pagesExperiment 4a – Pressure Drop in Packed ColumnsMohamad Samer KansouPas encore d'évaluation

- LECTURE - 4: ChloromethaneDocument4 pagesLECTURE - 4: Chloromethaneمحمود محمدPas encore d'évaluation

- Extraction of MetalDocument17 pagesExtraction of MetalSyahmi RodziPas encore d'évaluation

- Benitez Cap9Document44 pagesBenitez Cap9Srinivasa Rao VenkumahanthiPas encore d'évaluation

- Highly selective MEG process via ethylene carbonateDocument5 pagesHighly selective MEG process via ethylene carbonateirfanPas encore d'évaluation

- Slides of Prilling TowerDocument12 pagesSlides of Prilling TowerCHUCHUPas encore d'évaluation

- Production of Aniline by Hydrogenation of NitrobenzeneDocument4 pagesProduction of Aniline by Hydrogenation of Nitrobenzenezainab zebPas encore d'évaluation

- Chlorine: International Thermodynamic Tables of the Fluid StateD'EverandChlorine: International Thermodynamic Tables of the Fluid StatePas encore d'évaluation

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationD'EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationPas encore d'évaluation

- Evaluation of Dissolved Air Flotation Unit For OilDocument8 pagesEvaluation of Dissolved Air Flotation Unit For OilAhmed AliPas encore d'évaluation

- Water Treatment Processes and Chemical CalculationsDocument6 pagesWater Treatment Processes and Chemical CalculationsAhmed AliPas encore d'évaluation

- Ijrerd A085 PDFDocument4 pagesIjrerd A085 PDFAhmed AliPas encore d'évaluation

- 04-Control of Volatile Organic Compounds (VOCs)Document187 pages04-Control of Volatile Organic Compounds (VOCs)Ahmed AliPas encore d'évaluation

- Project 33Document8 pagesProject 33Ahmed AliPas encore d'évaluation

- Ms-09-Development of A Paper Recycling ProcessDocument7 pagesMs-09-Development of A Paper Recycling ProcesshidaiPas encore d'évaluation

- Airlift Bioreactors and Mechanically Stirred Tanks Are Widely Used in BioprocessingDocument2 pagesAirlift Bioreactors and Mechanically Stirred Tanks Are Widely Used in BioprocessingAhmed AliPas encore d'évaluation

- Applications of Egg Shell and Egg Shell Membrane As AdsorbentsDocument13 pagesApplications of Egg Shell and Egg Shell Membrane As AdsorbentsAhmed AliPas encore d'évaluation

- Problems: CHEM1020Document45 pagesProblems: CHEM1020Ahmed AliPas encore d'évaluation

- URUAE Full Proceeding Sept (1) - 12-14-110-114 PDFDocument5 pagesURUAE Full Proceeding Sept (1) - 12-14-110-114 PDFAhmed AliPas encore d'évaluation

- Investigation of Surfactant Effect On The Operational Characteristics PDFDocument11 pagesInvestigation of Surfactant Effect On The Operational Characteristics PDFAhmed AliPas encore d'évaluation

- Study On The Hydrodynamics of Stirred Vessels PDFDocument6 pagesStudy On The Hydrodynamics of Stirred Vessels PDFAhmed AliPas encore d'évaluation

- J. Basic. Appl. Sci. Res., 1 (11) 2314-2318, 2011Document5 pagesJ. Basic. Appl. Sci. Res., 1 (11) 2314-2318, 2011Ahmed AliPas encore d'évaluation

- Thermochemistry Problems CalculatorDocument17 pagesThermochemistry Problems CalculatorAhmed AliPas encore d'évaluation

- DF Manual of PulverizerDocument3 pagesDF Manual of PulverizerAhmed AliPas encore d'évaluation

- Cool Lab ManualDocument12 pagesCool Lab Manualgiri_shwetaPas encore d'évaluation

- Produce Food Grade Calcium Chloride from Limestone Using HClDocument1 pageProduce Food Grade Calcium Chloride from Limestone Using HClAhmed AliPas encore d'évaluation

- Design and Construction of Waste Paper' Recycling PlantDocument12 pagesDesign and Construction of Waste Paper' Recycling PlantAhmed Ali100% (1)

- Evap DesignDocument16 pagesEvap DesignAhmed Ali100% (3)

- An Example of Sizing of A Heat Exchanger in Which A Stream Undergoes Both A Phase Change and Temperature Change in The Vapor And/or LiquidDocument4 pagesAn Example of Sizing of A Heat Exchanger in Which A Stream Undergoes Both A Phase Change and Temperature Change in The Vapor And/or LiquidJoshua JohnsonPas encore d'évaluation

- CH CW AmmoniaandureaDocument12 pagesCH CW AmmoniaandureaAhmed AliPas encore d'évaluation

- Progress of Styrene ProductionDocument2 pagesProgress of Styrene ProductionAhmed AliPas encore d'évaluation

- Xylenes Material 2520balanceDocument8 pagesXylenes Material 2520balanceAhmed AliPas encore d'évaluation

- 19890204Document11 pages19890204Ahmed AliPas encore d'évaluation

- Hariom ReportDocument60 pagesHariom Reportहरिओम हरी100% (2)

- Benzene Toluene EquilibriumDocument2 pagesBenzene Toluene EquilibriumAhmed AliPas encore d'évaluation

- Optimize The ProductionDocument103 pagesOptimize The Productionferik2Pas encore d'évaluation

- Urea Synthesis ProcessDocument5 pagesUrea Synthesis ProcessrajmaneamitPas encore d'évaluation

- Al Zoubi2015Document9 pagesAl Zoubi2015Ahmed AliPas encore d'évaluation

- 1992 Lazaridis Daf Metal IonsDocument16 pages1992 Lazaridis Daf Metal IonsAhmed AliPas encore d'évaluation