Académique Documents

Professionnel Documents

Culture Documents

CV Air Valve Catalog

Transféré par

arvint_1999Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CV Air Valve Catalog

Transféré par

arvint_1999Droits d'auteur :

Formats disponibles

Water Wastewater

Air Valves Check Valves

For Water and Wastewater Applications

Water

Air Valves

Air Release

Air and Vacuum

Combination

Vacuum Breaker

Check Valves

Silent Check

Swing Check

Two-Door Check

Foot Valve

Flex Check

Wastewater &

Sewage

Air Valves

Air Release

Air and Vacuum

Combination

Vacuum Breaker

Check Valves

Flex Check

2

Series

580

Series

501A

WH E R E T O F I N D I T . . .

Air Release Valves Air and Vacuum Valves Combination Air Valves

High Performance

Combination Air Valves

Well Service Air Valves Vacuum Breaker Valves Foot Valves

Note Engineers....Cla-Val Air Valve are Manufactured to Meet ANSI-AWWA C512-04 Standards.

Page 3 Page 16 Page 22 Page 42

Page 36

Page 44 Page 87

W a s t e w a t e r A i r V a l v e s

Air Release Air and Vacuum

Page 55 Page 58 Page 63

Combination

Check

Valves

Page 71 Page 73

Page 83

Page 75

Priming Air Release Valve

Pump Protector

Series

582

Wastewater Valve Backwash Kit Specifications - Pg 70

Check Valve Feature & Pressure/Temp Ratings - Pg 86

Air/Check & Pinch Valve Mfgr. Mod. No. Comparisons - Pg 92

Page 13

Series

581

Page 90

Flex-Check Valve

3

The float shall be of all stainless steel construction and guar-

anteed to withstand the designed system surge pressure with-

out failure. The body and the cover shall be cast iron and valve

internal parts shall be stainless steel and the Viton

TM

Buna-N

for

water tight shut-off. All T316 Stainless Steel shall be Austenitic.

The air release valve shall be manufactured per

ANSI/AWWA C512-04 Series 34 from

Cla-Val in Newport Beach, CA, U.S.A.

Stainless Steel T316 Trim Standard

Stainless Steel Floats Guaranteed

Easily Serviced Without Removal From Pipeline

Working Pressures to 800 PSI

Engineered For Drip Tight Seal At Low Pressures

Cla-Val Series 34 Air Release Valves are designed to vent entrained

air that collects at high points in a pipeline. This valve continuously

eliminates air from a system by releasing small quantities of air before

large air pockets can occur. In many installations, continuing accumu-

lations of air in the pipeline (lacking air release valves); cause flow

capacity to slowly decrease; power consumption slowly increases; un-

noticeable at first, until flow drops dramatically, even stopping due to

air blocks in the piping. Another problem resulting from excessive air

accumulation is un-explained pipeline rupture. These ruptures are

passed off as the result of ground settling or defective pipe, Where as

in reality its large air pockets that greatly increase pressure surges

(normally occurring) when flow stops and starts causing the rupture.

During normal pipeline operation, air accumulation at the high point will

displace the liquid within the air valve and lower the water level in rela-

tion to the float. As level of the liquid lowers, where the float is no longer

buoyant, the float drops and opens the valve orifice seat and permitting

accumulated air to be exhausted to atmosphere. After air is released,

the liquid level in the air valve rises and closes the valve orifice seat.

This cycle automatically repeats as air accumulates inside the air

release valve, thereby preventing the formation of air pockets

Series 34

Air Release Valves

Installation

Series 34 Air Release Valves are typically installed at high-

points in pipelines and at regular intervals, of approximate

1/2 mile, along uniform grade line pipe.

Mount the unit in the vertical position on top of the pipeline

with an isolation valve installed below each valve in the

event servicing is required. A vault with adequate air venting

and drainage is recommended.

Note:

Vacuum check valves can be supplied on the discharge of

all size air release valves to prevent air re-entering the system;

during negative pressure conditions

Purchase Specifications

The air release valve shall be of the float operated, simple

lever or compound lever design, and capable of

automatically releasing accumulated air from a fluid system

while the system is pressurized and operating.

An adjustable designed orifice button shall be used to seal

the valve discharge port with drip-tight shut-off. The orifice

diameter must be sized for use within a given operating

pressure range to insure maximum air venting capacity.

Specifications

Sizes

1/2", 3/4", 1", 2", 3" NPT

Pressure Ratings

(see note)

150 psi

300 psi

800 psi

Temperature Range

Water to 180F

Note: Specify when operating

pressure below 10 PSI

Materials

Body and Cover:

Cast Iron ASTM-

A-126, Class B

Float:

Stainless Steel T316

Internal Parts:

Stainless Steel T316

Seal:

Viton

TM

, Buna-N

Sample Pipeline Profile

For Selection and Placement of Air Valves

Long Horizontal Runs

All Peaks

Increase in

Slope

Datum Line

COMBINATION

AIR & VACUUM

AIR RELEASE

DRAIN VALVE

FLOW

X

X X

X

X

X

4

Air Release Valve Sizing for Water and Wastewater Pipelines

1. Air release valve sizing requires determining the volume of air that must be released from pipeline high points during normal operation and the

diameter of the pipeline. Series 34 Air Release Valves are primarily used to continuously release pockets of air (as they develop) from high points.

Hence it is not critical to determine exact volume of air to be released.

2. If the volume of air to be released has been determined, then use the venting capacity chart on page 5 to assist in sizing the air release

valve. Use maximum pipeline operating pressure (in psi) and flow (in SCFM) to determine orifice size. Select the largest inlet size for each

valve to insure adequate venting capacity.

FOR WATER AND

INSTALLATION TIPS

1. The effectiveness of Series 34 Air Release Valve is dependent upon it being located at appropriate high points in a pipeline and

at uniform intervals of approximately 2500 feet on horizontal pipelines.

2. There are four variables that can cause an air pocket to form slightly downstream of the true high point in a piping system:

1. Severity of the slope adjacent to the high point or change of gradient

2. Velocity of the liquid

3. Texture of the inside surface of the pipe being used

4. Viscosity of the fluid

It is recommended where an air pocket can form slightly downstream of the high point, to install additional Series 34 Air Release

Valve at this point.

3. Cla-Val has available, upon request, a Slide Rule Air Valve Calculator. It will greatly reduce the amount of time to size

valves for pipeline service.

AIR RELEASE VALVE DATA

When Ordering,

Please Specify:

1. Model Number

2. Inlet Size (NPT)

3. Inlet Pressure Rating

4. Orifice Size

Pipeline

Diameter

(Inches)

Pumping

Capacity

(gpm)

PIPELINE OPERATING PRESSURE

1 to 175 psi 1 to 300 psi

Model No. Inlet Size Orifice Size Model No. Inlet Size Orifice Size

2" - 3" - 4"

Diameter

200/800

gpm

34AR-116

34AR-116

34AR-116

1/2"

3/4"

1"

1/16" N/A

6" - 8" - 10"

Diameter

800/2,200

gpm

34AR-332

34AR-332

34AR-332

1/2"

3/4"

1"

3/32"

34AR-116.3

34AR-116.3

34AR-116.3

1/2"

3/4"

1"

1/16"

12" - 14"- 16"

Diameter

2,000/5,000

gpm

34AR-018

34AR-018

3/4"

1"

1/8"

34AR-116.3

34AR-116.3

3/4"

1"

5/64"

18" - 20"

Diameter

5,000/15,000

gpm

34AR-316C

34AR-316C

1"

2"

3/16"

34AR-332.3C

34AR-332.3C

1"

2"

3/32"

24" & Larger

Diameter

15,000/50,000

gpm

34AR-38C

34AR-38C

2"

3"

3/8"

3/8"

34AR-732.3C

34AR-732.3C

2"

3"

7/32"

7/32"

AIR RELEASE VALVE SIZING CHART FOR WATER PIPELINES

Pipeline

Diameter

(Inches)

Pumping

Capacity

(gpm)

PIPELINE OPERATING PRESSURE

1 to 175 psi 1 to 300 psi

Model No. Inlet Size Orifice Size Model No. Inlet Size Orifice Size

4" - 12"

0 - 4,000

gpm

34WW25-316

34WW35-316

34WW45-316

2"

3"

4"

3/16"

34WW25-332

34WW35-332

34WW45-332

2"

3"

4"

3/16"

14" & Larger

4,100 & Up

gpm

34WW21-716

34WW31-716

34WW41-716

2"

3"

4"

7/16"

34WW21-732

34WW31-732

34WW41-732

2"

3"

4"

7/32"

Note: Use large as possible inlet size to allow best wastewater exchange to lesson clogged inlets.

Optional: Back Wash Kit recommended for maintenance.

AIR RELEASE VALVE SIZING GUIDE FOR WASTEWATER PIPELINES

5

E-34 (R-3/2011)

WASTEWATER

AND SIZING GUIDE

Simple Lever Type

(For Water)

For service up

to 300 psi

Optional: Vacuum Check

Valve prevents air

re-entering system.

1/2 Model 50 VC

1 Model 1 VC

For service up

to 800 psi

Compound Lever Type

(For Water)

For Wastewater

6" Air Release Valve

Series 34

Series 34-WW

N

o

A

i

r

i

n

A

i

r

O

u

t

Model No. Orifice Size Inlet Size NPT Outlet Size NPT Max/ W.P.

34AR-116 1/16" 1/2" - 3/4" -1" 3/8" 175 psi

34AR-332 3/32" 1/2" - 3/4" -1" 1/2" 175 psi

34AR-018 1/8" 3/4" -1" 1/2" 175 psi

34AR-316C 3/16" 1" 1/2" 175 psi

34AR-332.3C 3/32" 1" 1/2" 300 psi

34AR-316C 3/16" 2" 1/2" 175 psi

34AR-332.3C 3/32" 2" 1/2" 300 psi

34AR-038C 3/8" 2" 1" 175 psi

34AR-732.3C 7/32" 2" 1" 300 psi

34AR-038C 3/8" 2" 1" 175 psi

34AR-732.3C 7/32" 2" 1" 300 psi

34AR-732.2C 7/32" 2" 1" 500 psi

34AR-018C 1/8" 2" 1" 800 psi

34AR-1.6C 1" 6" Flanged 1" 150 psi

Air Release Valve for Wastewater

34WW25-316 3/16" 2" - 3" -4" 1/2" 175 psi

34WW25-332 3/32" 2" - 3" -4" 1/2" 300 psi

34WW21-716 7/16" 2" - 3" -4" 1" 175 psi

34WW21-732 7/32" 2" - 3" -4" 1" 300 psi

Air Release Valve for Water

ORIFICE SIZES WITH VENTING CAPACIT

FOR CLA-VAL AIR RELEASE VALVES

300

275

250

225

200

175

150

125

100

75

50

25

0

1 10 100 1000

1/16

5/64

3/32

5/32

1/8

3/16

1/4

5/16

3/8

7/16

1/2

AIR FLOW RATE (SCFM)

P

R

E

S

S

U

R

E

D

R

O

P

A

C

R

O

S

S

O

R

I

F

I

C

E

(

P

S

I

D

)

Air Release Valve

(Pump Protector)

Note: Manufactured to meet ANSI/AWWA C512-04

Air Release Valve Simple Lever Type

OUTLET

17

34

PIPE PLUG

OPTIONAL

4 3/4"

INLET

5 1/4"

21

4

2

6

3

13

12

10

11

7

5

1

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

Valve 175 psi 175 psi Inlet Outlet Wt.

Size Max. W.P. Orifice Size Size Lbs.

1/2" 3450AR-116 1/16" 1/2" 1/2" NPT 6

3/4" 3475AR-116 1/16" 3/4" 1/2" NPT 6

1" 3410AR-116 1/16" 1" 1/2" NPT 6

Model No.

Series 34

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

PL-34AR116 (1/2 - 1) (R-3/2011)

PARTS LIST

Detail No.

1

2

3

4

5

6

7

Part Name

Body

Cover

Lever Frame

Seat

Float

Gasket

Cover Bolt

Material

Cast Iron ASTM A126, Class B

Cast Iron ASTM A126, Class B

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Garlock #3000 (Non-Asbestos)

Alloy Steel SAE Grade 5

Detail No.

10

11

12

13

17

21

34

Part Name

Float Arm

Orifice Button

Pivot Pin

Pin Retainer

Float Retainer

Locator

Lock Washer

Material

Stainless Steel T316, ASTM A276

Viton

TM

Stainless Steel T316, ASTM A276

Stainless Steel PH 15-7 Mo

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

6

Note: Manufactured to meet ANSI/AWWA C512-04

Air Release Valve Simple Lever Type

OUTLET

INLET

21

4

2

6

3

13

12

10

11

17

5

7

34

1

5

1

8

"

6"

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

Valve 175 psi 175 psi 300 psi 300 psi Inlet Outlet Wt.

Size Max. W.P. Orifice Max. W.P. Orifice Size Size Lbs

1/2" 3450AR-332 3/32" 3450AR-116.3 1/16" 1/2" 1/2" NPT 8

3/4" 3475AR-332 3/32" 3475AR-116.3 1/16" 3/4" 1/2" NPT 8

1" 3410AR-332 3/32" 3410AR-116.3 1/16" 1" 1/2" NPT 8

Model No. Model No.

Series 34

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

PL-34AR (332/116) (R-3/2011)

PARTS LIST

Detail No.

1

2

3

4

5

6

7

Part Name

Body

Cover

Lever Frame

Seat

Float

Gasket

Cover Bolt

Material

Cast Iron ASTM A126, Class B

Cast Iron ASTM A126, Class B

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Garlock #3000 (Non-Asbestos)

Alloy Steel SAE Grade 5

Detail No.

10

11

12

13

17

21

34

Part Name

Float Arm

Orifice Button

Pivot Pin

Pin Retainer

Float Retainer

Locator

Lock Washer

Material

Stainless Steel T316, ASTM A276

Viton

TM

Stainless Steel T316, ASTM A276

Stainless Steel PH 15-7 Mo

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

7

Note: Manufactured to meet ANSI/AWWA C512-04

Wt.

Lbs.

12

12

8

34

6

1/8"

OUTLET

INLET

21

4

2

6

3

13

12

10

11

17

5

1

7

7"

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

Air Release Valve Simple Lever Type

Valve 175 psi 175 psi 300 psi 300 psi Inlet Outlet

Size Max. W.P. Orifice Max. W.P. Orifice Size Size

3/4" 3475AR-018 1/8" 3475-AR564.3 5/64" 3/4" 1/2" N.P.T.

1" 3410AR-018 1/8" 3410-AR564.3 5/64" 1" 1/2" N.P.T.

Model No. Model No.

Series 34

PL-34AR (018/564) (R-3/2011)

PARTS LIST

Detail No.

1

2

3

4

5

6

7

Part Name

Body

Cover

Lever Frame

Seat

Float

Gasket

Cover Bolt

Material

Cast Iron ASTM A126, Class B

Cast Iron ASTM A126, Class B

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Garlock #3000 (Non-Asbestos)

Alloy Steel SAE A449 Grade 5

Detail No.

10

11

12

13

17

21

34

Part Name

Float Arm

Orifice Button

Pivot Pin

Pin Retainer

Float Retainer

Locator

Lock Washer

Material

Stainless Steel T316, ASTM A276

Viton

TM

- 70 Duro

Stainless Steel T316, ASTM A276

Stainless Steel PH 15-7 Mo

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

Note: Manufactured to meet ANSI/AWWA C512-04

Valve 175 psi 175 psi 300 psi 300 psi Inlet Outlet

Size Max. W.P. Orifice Max. W.P. Orifice Size Size

1" 3410-AR316C 3/16" 3410-AR332.3C 3/32" 1" 1/2" N.P.T.

2" 3420-AR316C 3/16" 3420-AR332.3C 3/32" 2" 1/2" N.P.T.

Model No. Model No.

9

INLET

OUTLET

4

7

2

6

11

22

34

18

3

33

1

5

14

30

8

12

13

19

10

17

14

21

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

7"

10"

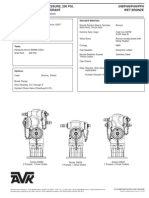

Air Release Valve Compound Lever Type

Series 34

PL-34AR (516/316/332) (R-3/2011)

PARTS LIST

Detail No.

1

2

3

4

5

6

7

8

10

11

12

Part Name

Body

Cover

Lever Frame

Seat

Float

Gasket

Cover Bolt

Retaining Screw

Float Arm

Orifice Button

Pivot Pin

Material

Cast Iron ASTM A126, Class B

Cast Iron ASTM A126, Class B

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Lexide NK-511 (Non-Asbestos)

Alloy Steel ASTM A449 Grade 5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel & Buna-N

Stainless Steel T316, ASTM A276

Detail No.

13

14

17

18

19

21

22

30

33

34

Part Name

Retaining Ring

Pipe Plug

Float Retainer

Lock Nut

Link

Locating Pin

Orifice Button Arm

Washer

Clevis

Lock Washer

Material

Stainless Steel PH 15-7 Mo

Malleable Iron

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T420

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Wt.

Lbs.

24

24

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

Note: Manufactured to meet ANSI/AWWA C512-04

10

Air Release Valve Compound Lever Type

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

3

12

13

19

30

12 1/4"

8

21 28

4

7

2

6

11

22

34

18

17

10

1

5

14

91/2"

OUTLET

INLET

Valve 150 psi 150 psi 300 psi 300 psi Inlet Outlet

Size Max. W.P. Orifice Max. W.P. Orifice Size Size

2" 3420AR-038C 3/8" 3420AR-732.3C 7/32" 2" 1" N.P.T.

3" 3430AR-038C 3/8" 3430AR-732.3C 7/32" 3" 1" N.P.T.

Model No. Model No.

Series 34

PL-34AR (038C-732C) (R-3/2011)

PARTS LIST

Detail No.

1

2

3

4

5

6

7

8

10

11

12

Part Name

Body

Cover

Lever Frame

Seat

Float

Gasket

Cover Bolt

Retaining Screw

Float Arm

Orifice Button

Pivot Pin

Material

Cast Iron ASTM A126, Class B

Cast Iron ASTM A126, Class B

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Lexide NK-511 (Non-Asbestos)

Alloy Steel ASTM A449 Grade 5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316 & Buna-N

Stainless Steel T316, ASTM A276

Detail No.

13

14

17

18

19

21

22

28

30

34

Part Name

Retaining Ring

Pipe Plug

Float Retainer

Lock Nut

Link

Locating Pin

Orifice Button Arm

Pipe Plug

Washer

Lock Washer

Material

Stainless Steel PH 15-7 Mo

Malleable Iron

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Malleable Iron

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Wt.

Lbs.

24

24

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

Note: Manufactured to meet ANSI/AWWA C512-04

11

(High Pressure) Air Release Valve Compound Lever Type

13"

10 7/8"

4

7

2

6

11

22

34

18

17

10

1

5

14

28

8

21

3

12

13

19

30

INLET

OUTLET

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

Valve 500 psi 500 psi 800 psi 800 psi Inlet Outlet

Size Max. W.P. Orifice Max. W.P. Orifice Size Size

2" 3420AR-732.5C 7/32" 3420AR-018.8C 1/8" 2" 1" N.P.T.

Model No. Model No.

Series 34

PL-34AR (732.5C-018.8C) (R-3/2011)

PARTS LIST

Detail No.

1

1

2

2

3

4

5

6

7

8

10

11

Part Name

Body (500 psi)

Body (800 psi)

Cover (500 psi)

Cover (800 psi)

Lever Frame

Seat

Float

Gasket

Cover Bolt

Retaining Screw

Float Arm

Orifice Button

Material

Cast Iron ASTM A126, Class B

Ductile Iron ASTM A536

Cast Iron ASTM A126, Class B

Ductile Iron ASTM A536

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Lexide NK-511 (Non-Asbestos)

Alloy Steel ASTM A449 Grade 5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316 & Buna-N

Detail No.

12

13

14

17

18

19

21

22

28

30

34

Part Name

Pivot Pin

Retaining Ring

Pipe Plug

Float Retainer

Lock Nut

Link

Locating Pin

Orifice Button Arm

Pipe Plug

Washer

Lock Washer

Material

Stainless Steel T316, ASTM A276

Stainless Steel PH 15-7 Mo

Malleable Iron

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Malleable Iron

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Wt.

Lbs.

72

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

Note: Manufactured to meet ANSI/AWWA C512-04

12

(Large Orifice) Air Release Valve Compound Lever Type

ORIFICE

6" DIA. INLET

1" N.P.T.

OUTLET

6" 125 LB. Flange or

250 LB Flange

7

2

3

8

13 12

19

22

11

34

30

18

1

15

14

6

21

4

17

10

5

22"

18 3/4"

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

Valve 150 psi 150 psi 300 psi 300 psi Inlet Outlet

Size Max. W.P. Orifice Max. W.P. Orifice Size Size

6" 3460AR-1.C 1" 3460AR-750.3C 3/4" 6" 1" N.P.T.

Model No. Model No.

Series 34

PL-34AR (750.6C-1.6C) (R-3/2011)

PARTS LIST

Detail No.

1

2

3

4

5

6

7

8

10

11

12

Part Name

Body

Cover

Lever Frame

Seat

Float

Gasket

Cover Bolt

Retaining Screw

Float Arm

Orifice Button

Pivot Pin

Material

Cast Iron ASTM A126, Class B

Cast Iron ASTM A126, Class B

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Lexide NK-511 (Non-Asbestos)

Alloy Steel ASTM A449 Grade 5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316 & Buna-N

Stainless Steel T316, ASTM A276

Detail No.

13

14

15

17

18

19

21

22

28

30

34

Part Name

Retaining Ring

Pipe Plug

Cushion

Float Retainer

Lock Nut

Link

Locating Pin

Orifice Button Arm

Pipe Plug

Washer

Lock Washer

Material

Stainless Steel PH 15-7 Mo

Malleable Iron

Buna-N

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Malleable Iron

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Wt.

Lbs.

200

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

Note: Manufactured to meet ANSI/AWWA C512-04

PL-34P-WLCS (R-9-2011)

13

Priming Air Release Valve - Pump Protector

Series 34P-WLCS

2 NPT

Inlet

Pump On

Pump Off

Install on

Pump Volute

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

PARTS LIST

Height Width Depth

25 23 7

Wt.

Lbs.

105

Valve

Inlet

Size

2

OUTLET MODEL NUMBER FOR

STANDARD 150WP

WITH OPTIONAL SWITCH

3420P-WLCS

Air

Release

1/2 NPT

SMALL ORIFICE

DIAMETER

150WP INCHES

3/16

Item No.

1

2

3

4

5

6

7

8

10

11

12

Part Name

Body

Cover

Lever Frame

Seat

Float

Gasket

Cover Bolt

Retaining Screw

Float Arm

Orifice Button

Pivot Pin

Material

Cast Iron ASTM A126, Class B

Cast Iron ASTM A126, Class B

Stainless Steel T316 ASTM A276

Stainless Steel T316 ASTM A276

Stainless Steel T316 ASTM A276

Lexide NK-511 (Non-Asbestos)

Alloy Steel ASTM A449 Grade 5

Stainless Steel T316 ASTM A276

Stainless Steel T316 ASTM A276

Stainless Steel T316 & Buna-N

Stainless Steel T316 ASTM A276

Item No.

13

14

17

18

19

20

21

22

30

33

34

35

Part Name

Retaining Ring

Pipe Plug

Float Retainer

Lock Nut

Link

Extension Shaft

Locating Pin

Orifice Button Arm

Washer

Clevis

Lock Washer

Retaining Screw

Material

Stainless Steel PH 15-7 Mo

Malleable Iron

Stainless Steel T316 ASTM A276

Stainless Steel T316 ASTM A276

Stainless Steel T316 ASTM A276

Stainless Steel T316 ASTM A276

Stainless Steel T420

Stainless Steel T316 ASTM A276

Stainless Steel T316 ASTM A276

Stainless Steel T316 ASTM A276

Stainless Steel T316 ASTM A276

Stainless Steel T316 ASTM A276

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

Note: Manufactured to meet ANSI/AWWA C512-04

14

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

Air and Vacuum Valve Sizing - Combination Air Vacuum Valves - Vacuum Breaker Valves

1. Series 35 Air and Vacuum Valves should be sized to handle the maximum amount of air to be exhausted or admitted into the

pipeline and not exceed an acceptable pressure differential across the valve.

2. Each high point or change in grade must be examined independently when determining valve size. Use the steepest slope

for calculations.

3. Use the flow capacity charts (A) and (B) on page 15 to assist sizing Air and Vacuum Valves.

4. Determine the smallest valve size capable of exhausting air equal to the filling rate of the pipeline in CFS while

not exceeding a pressure differential of 2 psi across the valve orifice. (Based on pump capacity).

The following formula is recommended to calculate the rate of flow in CFS for filling the pipeline:

Where: CFS = Cubic feet per second

GPM= Gallons per minute

5. Determine the smallest valve size capable of admitting air equal to the potential flow in CFS while not exceeding a pressure

differential of 5 psi across the valve orifice. (Based on gravity flow).

The following formula should be used to calculate the rate of flow in CFS that can occur within the pipeline under gravity flow

conditions. (During Initial Filling During Intentional Draining During A Pipeline Rupture)

Where: Q = Flow of water in cubic feet per second

C = Coefficient in Chezys formula = 110

S = Slope in feet per foot of length

D = Inside pipe diameter in inches

6. If thin wall pipe is being used, the risk of pipeline collapse due to the formation of vacuum must be considered. The following formula

may be used to calculate the collapsing pressure of thin walled cylindrical steel pipe using a safety factor of four:

Where: P = Collapsing pressure in psi

T = Thickness of pipe in inches

D = Diameter of pipe in inches

7. For other pipe materials or thickness consult pipe manufacturer for pipe collapsing pressure.

8. Determine the smallest valve size capable of admitting the required air in CFS (as found in step 5) without exceeding the

collapsing pressure (as found in step 6) or 5 psi, whichever is less. Do not exceed a pressure differential greater than 5 psi.

9. Finally compare the valve size determined in step 4 with the valve size determined in steps 5 or 6. If they differ, always

select the larger valve size.

Note: Cla-Val has available upon request, a Slide Rule Air Vacuum Valve Calculator that greatly reduces the amount of time

necessary to size valves for pipeline service. Includes-GPM, MGD, CFS, Liter/Sec. & Pipeline Velocity Conversions.

P = 16,250,000

D

3

T

Q = .0007872 C S D

5

CFS =

GPM

448.83

Sizing Guide for - Air and Vacuum

Air Valves and Vacuum

Wastewater

Sample Pipeline Profile

For Selection and Placement of Air Valves

Long Horizontal Runs

All Peaks

Increase in

Slope

Datum Line

COMBINATION

AIR & VACUUM

AIR RELEASE

DRAIN VALVE

FLOW

X

X X

X

X

X

E-35 Sizing Guide (R-3/2011)

10

12

14

16

20

5 10 20 30 40 50 75 100 125 150 200 250 300 400

1/2

1

2

3

4

6

8

500 750 1000 1

V

A

C

U

U

M

D

I

F

F

E

R

E

N

T

I

A

L

A

C

R

O

S

S

O

R

I

F

I

C

E

1

2

3

4

5

0

Series 35

Series 36

Series 38

15

E-35 (R-3/2011)

1/2"Through 3" Sizes

See Page 17 for Details

1"Through 4" Sizes

See Page 23 for Details

3"Through 16" Sizes

See Page 46 for Details

2"Through 8" Sizes

See Page 59 for Details

Valves - Combination

Breaker Valves for Water and

Service

A

I

R

I

N

A

I

I

N

R

4"Through 24" Sizes

See Page 18 for Details

6"Through 8" Sizes

See Page 24 for Details

4"Through 24" Sizes

See Page 26 for Details

2"Through 4" Sizes

See Page 64 for Details

Seat

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

.

I

.

S

.

P

E

C

I

F

I

R

O

S

S

O

R

C

A

L

A

I

T

N

E

R

E

F

F

I

D

E

R

U

S

S

E

R

P

10

12

14

16

20

5

4

3

2

1

0

5 10 20 30 40 50 75 100 125 150 200 250 300 400

1/

2

1

2

3

4

6

8

500 750 1000 1

Air Outflow/Inflow Capacities

in cubic feet of Free

Air Per Second, (SCFS)

for above Air Valves

Note: Curves are approximate flow

capacities at 14.7 psi atmospheric

pressure and ambient

temperature

Air Inflow

Air Outflow

Valves

Sizes

Valves

Sizes

Note: Manufactured to meet

ANSI/AWWA C512-04

16

Provides High Capacity Air Venting and Air Intake

Stainless Steel T316 Trim Standard

Stainless Steel Floats Guaranteed

Fully Ported Valves - No Restrictions

Designed For Drip Tight Seal At Low Pressures

The Cla-Val Series 35 Air and Vacuum Valve is designed to perform

two separate functions. First, it will allow large quantities of air to be

exhausted from the pipeline as it is being filled with water. When

this air has been vented completely, water will enter the valve

causing the float to seal tightly against the seat to prevent water

flow. Secondly, if the line is being drained, either intentionally or as

a result of pipeline breakage, the valve responds to the loss in

pressure and opens. This allows air to re-enter the pipeline and

prevents potentially damaging vacuum from developing.

Note: The Series 35 does not open under pressure to exhaust

small quantities of air which may collect at high points during

system normal operation. Series 34 Air Release Valve is required

for this function.

Note: See Sizing Guide Pages 14 & 15

Design Specifications

Sizes

1/2", 1", 2", 3" NPT

4" through 16"

125 lb. flanged ANSI Rated

250 lb. flanged ANSI Rated

Pressure Ratings

175 psi

300 psi

Temperature Range

Water to 180F

Note: Specify when operating

pressure below 10 PSI

Materials

Body and Cover:

Cast Iron ASTM

126, Class B

Float:

Stainless Steel T316

Internal Parts:

Stainless Steel T316

Seal:

Buna-N

Rubber

Installation

Series 35 Air and Vacuum Valves should be installed at high

points or at grade changes within the pipeline. Mount the unit

in the vertical on top of the pipeline with isolation valve below

each valve in the event servicing is required. A vault with

adequate venting and drainage should also be provided.

Purchase Specifications

The air and vacuum valve shall be able to automatically

exhaust large quantities of air during filling of a pipeline and

allows air to re-enter pipeline during the draining or when a

negative pressure occurs.

The inlet and outlet of the air and vacuum valve shall have the

same cross-section area as the pipe size. The float shall be

guided by a stainless steel bottom guide shaft. The 4" and

larger valve floats shall have top and bottom guide shafts of

hexagonal cross section and have a protective steel discharge

hood.

The float shall be of all stainless steel construction guaranteed

to withstanding the design system surge pressure without failure.

The body and cover shall be concentrically located and of cast

iron and the valve internal parts shall be of stainless steel

T316 with Buna-N

rubber seat. All T316 Stainless Steel shall

be Austenitic.

The Air and Vacuum Valve shall be manufactured per

ANSI/AWWA C512-04Series 35 from Cla-Val., Newport

Beach, CA U.S.A

When Ordering, Please Specify:

1. Model Number

2. Inlet Size - NPT or Flanged

3. Inlet Pressure Rating

Optional:

For anti-shock air valve shut-off order

with arrestor check device (suffix AC).

See data sheet pages 34 & 35.

Series 35

Air and Vacuum Valves

17

Air and Vacuum Valve

INLET

14

A

B

2

8

4

7

6

3

5

20

9

1

14

14

A

B

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

OPTIONAL FLANGE

125 OR 250 CLASS

INLET

Series 35

PL-35AV(1/2"- 3") (R-3/2011)

PARTS LIST

Detail No.

1

2

3

4

5

6

Part Name

Body

Cover

Baffle

Seat

Float

Gasket

Material

Cast Iron ASTM A126, Class B

Cast Iron ASTM A126, Class B

Ductile Iron ASTM A536-51T

Buna-N

Stainless Steel T316, ASTM A276

Garlock #3000 (Non-Asbestos)

Detail No.

7

8

9

14

20

Part Name

Cover Bolt

Retaining Screw

Guide Bushing

Pipe Plug

Guide Shaft

Material

Stainless Steel ASTM A449 Grade5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Malleable Iron

Stainless Steel T316, ASTM A276

Valve Size Model No

A B

Inlet Size Outlet Size

1/2"

1"

2"

3"

350-AV.3

351-AV.3

352-AV.3

353-AV.3

6 1/8"

7"

9 1/2"

9 1/2"

7"

9 1/2"

12"

12"

1/2" N.P.T.

1" N.P.T.

2" N.P.T.

3" N.P.T.

1/2" N.P.T.

1" N.P.T.

2" N.P.T.

3" N.P.T.

Wt. Lbs.

15

26

48

50

Note: Manufactured to meet ANSI/AWWA C512-04

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

Note: Manufactured to meet ANSI/AWWA C512-04

Air and Vacuum Valve with Threaded Outlet

18

CLA-VAL Copyright Cla-Val 2013 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

26

2

6

7

8

4

5

15

9

1

125 LB. FLG.

or

250 LB. FLG.

INLET

9

28

28

B

A

OUTLET

Y

Series 35

PL-35AVT (6"-16") (R-7/2013)

PARTS LIST

Detail No.

1

2

4

5

6

7

8

9

Part Name

Body

Cover

Seat

Float

Gasket

Cover Bolt

Retaining Screw

Guide Bushing

Material

Cast Iron ASTM A126, Class B

Cast Iron ASTM A126, Class B

Buna-N

Stainless Steel T316, ASTM A276

Lexide NK-511 (Non-Asbestos)

Alloy Steel ASTM A449, Grade 5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Detail No.

15

26

27

28

Part Name

Cushion

Seat Retaining Sleeve

Washer-Internal

Pipe Plug

Material

Buna-N

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Malleable Iron

Note: Manufactured to meet ANSI/AWWA C512-04

Model No.

125 Lb.

(175 MWP)

Model No.

250 Lb.

(300 MWP)

Valve

Size

A B

Butterfly Valve

*Y

Disc Clearance

Inlet

Size

Outlet

Size

Wt. Lbs.

125 Lb. 250 Lb.

354-AVF 354-AVT.3 4" 12" 17" 1 3/8" 4" FLG. 4" NPT 105 120

356-AVF 356-AVT.3 6" 14" 20" 2 1/2" 6" FLG. 6" NPT 160 275

358-AVF 358-AVT.3 8" 18" 22 3/4" 7/8" 8" FLG. 8" 208 220

3510-AVF 3510-AVT.3 10" 20" 24 1/2" 1" 10" FLG. 10" 370 390

3512-AVF 3512-AVT.3 12" 24" 30" 2 3/4" 12" FLG. 12" 590 620

3514-AVF 3514-AVT.3 14" 27" 30" 1 1/2" 14" FLG. 14" 680 710

3516-AVF 3516-AVT.3 16" 30 1/2" 32 1/2" 1 5/8" 16" FLG. 16" 900 920

19

Model No.

125 Lb.

Model No.

250 Lb.

Valve

Size

A B

Butterfly Valve

*Y

Disc Clearance

Inlet

Size

Outlet

Size

Wt. Lbs.

175 MWP 300 MWP 125 Lb. 250 Lb.

354-AV 354-AV.3 4" 12" 17" 1 3/8" 4" FLG. 4" 105 120

356-AV 356-AV.3 6" 14" 20" 2 1/2" 6" FLG. 6" 160 275

358-AV 358-AV.3 8" 18" 23" 7/8" 8" FLG. 8" 208 220

3510-AV 3510-AV.3 10" 20" 26" 1" 10" FLG. 10" 370 390

3512-AV 3512-AV.3 12" 24" 31" 2 3/4" 12" FLG. 12" 590 620

3514-AV 3514-AV.3 14" 27" 34" 1 1/2" 14" FLG. 14" 681 710

3516-AV 3516-AV.3 16" 30 1/2" 34" 1 5/8" 16" FLG. 16" 879 910

Air and Vacuum Valve

Y

23

24

25

26

2

6

7

8

4

5

15

1

9

28

9

28

B

27

A

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

Optional Hood

Series 35

PL-35AV(4"-16") (R-3/2011)

PARTS LIST

Detail No.

1

2

4

5

6

7

8

9

Part Name

Body

Cover

Seat

Float

Gasket

Cover Bolt

Retaining Screw

Guide Bushings

Material

Cast Iron ASTM A126, Class B

Cast Iron ASTM A126, Class B

Buna-N

Stainless Steel T316, ASTM A276

lexide NK-511 (non-Asbestos)

Alloy Steel ASTM A449, Grade 5

Stainless Steel T316 ASTM A276

Stainless Steel T316, ASTM A276

Detail No.

15

23

24

25

26

27

28

Part Name

Cushion

Hood (Optional Hood)

Hood Retaining Screw

Washer - External

Seat Retaining Sleeve

Washer - Internal

Pipe Plug

Material

Buna-N

Steel - #1020 (Optional Hood)

Steel (Cadmium Plated)

Steel (Cadmium Plated)

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Malleable Iron

Note: Manufactured to meet ANSI/AWWA C512-04

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

20

Air & Vacuum Valve with Arrestor Check

Air and

Vacuum

Valve

A

B

Arrestor

Check

23

24

25

26

2

6

7

8

4

5

15

1

9

28

27

2

4

3

1

7

5

125 Lb. Flg.

or

250 Lb. Flg.

OUTLET

INLET

E

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

Optional Hood

(For Slow Closing Action)

Series 35AV-AC

PARTS LIST

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

PL-35AV-AC (4"-16") (R-3/2011)

Detail No.

1

2

4

5

6

7

8

9

15

23

24

25

26

27

28

Part Name

Body

Cover

Seat

Float

Gasket

Cover Bolt

Retaining Screw

Guide Bushing

Cushion

Hood (Optional)

Hood Retaining

Screw

Washer - External

Seat Retaining

Sleeve

Washer - Internal

Pipe Plug

Material

Cast Iron ASTM A126 Class B

Cast Iron ASTM A126 Class B

Buna -N

Stainless Steel T316 ASTM A276

Lexide Nk-511 (Non-Asbestos)

Alloy Steel ASTM A449, Grade 5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Buna-N

Steel - #1020 (Optional Hood)

Steel (Cadmium Plated)

Steel (Cadmium Plated)

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Malleable Iron

Air & Vacuum Valve

Detail No.

1

2

3

4

5

7

Part Name

Body

Seat

Plug

Spring

Bushing

Retainer

Arrestor Check

Material

Cast Iron ASTM A126B

Bronze ASTM B584

Bronze ASTM B584

Stainless Steel T302

Bronze ASTM B584

Stainless Steel T316

Valve Model No. Large Dimensions Wt. Lbs.

Size 125 LB. (175 MWP) 250 LB. (175 MWP) Orifice A B E 125 250

4" 354-AV-AC 354-AV-AC.3 4" 11" 25" 1 3/4 175 192

6" 356-AV-AC 356-AV-AC.3 6" 14" 33" 1 1/2 260 280

8" 358-AV-AC 358-AV-AC.3 8" 18" 38" 3 1/4 365 390

10" 3510-AV-AC 3510-AV-AC.3 10" 21" 43" 4 1/4 600 680

12" 3512-AV-AC 3512-AV-AC.3 12" 24" 45" 5/8 900 1026

14" 3514-AV-AC 3514-AV-AC.3 14" 27" 46" 15/16 1165 1230

16" 3516-AV-AC 3516-AV-AC.3 16" 31" 51" 2 1/8 1376 1685

Note: Manufactured to meet ANSI/AWWA C512-04

21

PARTS LIST

Air Vacuum Valve with Wafer Butterfly Isolation Valve

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

Series 35AV-BFV

125 Lb Class 4" Thru 12"

SPACER RING

D

B

WAFER BUTTERFLY

VALVE (LUG STYLE WITH

MANUAL HAND LEVER

OPERATOR

125 LB CLASS (175 MWP)

A

23

24

25

26

2

6

7

8

4

5

15

1

9

28

28

27

Major

Width

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

Optional Hood

PL-35AV-BFV (R-3/2011)

Note: The Spacer is required to allow full open clearance between the butterfly valve disc and the air valve float guide.

Detail No.

1

2

4

5

6

7

8

9

Part Name

Body

Cover

Seat

Float

Gasket

Cover Bolt

Retaining Screw

Guide Bushing

Material

Cast Iron ASTM A126 Class B

Cast Iron ASTM A126 Class B

Buna -N

Stainless Steel T316, ASTM A276

Lexide Nk-511 (Non-Asbestos)

Alloy Steel ASTM A449, Grade 5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Detail No.

15

23

24

25

26

27

28

Part Name

Cushion

Hood (Optional Hood)

Hood Retaining Screw

Washer - External

Seat Retaining Sleeve

Washer - Internal

Pipe Plug

Material

Buna-N

Steel - #1020

Steel (Cadmium Plated)

Steel (Cadmium Plated)

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Malleable Iron

Large Orifice Air & Vacuum Valve

Size Model A B

Spacer

Ring

D

Major

Width

Wt.

4" 354AV-BFV 19 3/8" 9 1/8" 1/2" 1 7/8" 16" 170

6" 356AV-BFV 22 5/8" 10 1/8" 1/2" 2 1/16" 20" 260

8" 358AV-BFV 30 3/4" 12" 2 3/8" 2 3/8" 22" 325

10" 3510AV-BFV 31 5/8" 13 1/4" 3 1/8" 2 1/2" 24" 555

12" 3512AV-BFV 36 3/8" 15 1/16" 3 /3/8 3" 28" 800

Note: Manufactured to meet ANSI/AWWA C512-04

22

Design / Purchase Specifications

The combination air valve shall combine the operating

features of both an air and vacuum valve and an air

release valve in one housing. The air and vacuum valve

portion shall automatically exhaust large quantities of air

during the filling of the pipeline and automatically allow air

to reenter the pipeline when the internal pressure of the

pipeline approaches a negative value due to column sepa-

ration, draining of the pipeline, or other emergency. The air

release valve portion shall automatically release small

amounts of air from the pipeline while it is under pressure.

The inlet and outlet of the valve shall have the same cross-

section area. The float shall be guided by a stainless steel

guide shaft and seat drip tight against a synthetic rubber

seal. 4" and larger valves shall have dual guided shafts of

hexagonal cross section and a protective discharge hood.

The float shall be of all stainless steel construction and capable

of withstanding maximum system surge pressure without

failure. The body and cover shall be concentrically located

and of cast iron and the valve internal parts shall be of T316

stainless steel or Buna-N

rubber.

The Combination Air Release and Vacuum Valve shall be

manufactured per ANSI/AWWA C512-04 Series 36 from Cla-

Val., Newport Beach, CA, U.S.A.

Combination Air Release and

Vacuum Valve

Stainless Steel T316 Standard

Stainless Steel T316 Floats Guaranteed

Fully Ported Valves - No Restrictions

Easily Serviced Without Removal From Pipeline

Engineered For Drip Tight Seal At Low Pressures

The Cla-Val Series 36 Air and Vacuum Valve is a multipurpose

valve that combines the operation of both the Model 34 Air

Release Valve and Model 35 Air and Vacuum Valve. It functions

to exhaust large quantities of air in the pipeline during the filling

cycle and to admit air, as necessary, to prevent potentially

dangerous vacuum from forming when being emptied either

intentionally or as a result of pipeline breakage.

Installation

The Series 36 Combination Air Valve should be installed at

high points at grade changes within the pipeline.

Mount the unit in the vertical position on top of the pipeline

with an isolation valve installed below each valve in the

event servicing is required. A vault with adequate venting

and drainage should also be provided.

Design Specifications

Size Inlet/Outlet

1", 2", 3", 4" NPT or Flanged

3" through 8"

125 lb. flange & ANSI

300 lb. flange & ANSI

Pressure Ratings

(see note)

150 psi

300 psi

Temperature Range

Water to 180F

Note: Specify when operating

pressure is below 10 PSI

Materials

Body and Cover:

Cast Iron ASTM

A 126, Class B

Float:

Stainless Steel T316

Plug:

Stainless Steel T316

Internal Parts:

Stainless Steel T316

Seal: Buna-N

Rubber

When Ordering, Please Specify

1. Model Number

2. Inlet/Outlet Size

3. Inlet Pressure Rating

4. Orifice Size

Optional:

For Anti-Shock Air Valve shut-off, order with

arrestor check device (suffix AC).

See Data Sheet Page 34 & 35

Series 36

Note: Manufactured to meet ANSI/AWWA C512-04

Note: See Sizing Guide Pages 14 & 15

FOR ILLUSTRATION ONLY

SPOKE SHOWN 90

FROM ACTUAL ANGLE

OPTIONAL FLANGE

125 or 250 CLASS INLET

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

34

9

7

2

6

4

16

3

9

12

13

10

18

5

15

1

A

C

B

14

8

11

17

29

30

34

18

14

23

VIEW A-A

E

F

(HEX.)

Optional

Hood

OUTLET

INLET

VIEW A-A

E

F

(HEX.)

D

23

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

PL-36-CAV (1"-4") (R-3/2011)

PARTS LIST

Combination Air Valve Single Body Style

Series 36

Detail No.

1

2

3

4

5

6

7

8

9

10

Detail No.

11

12

13

14

15

16

17

18

23

29

30

34

Part Name

Orifice Button

Pivot Pin

Retaining Ring

Pipe Plug

Cushion

Plug

Float Retainer

Lock Nut

Screened Hood

Cushion Retainer

Washer (internal)

Washer (external)

Material

Stainless Steel T316 & Buna-N

Stainless Steel T316, ASTM A276

Stainless Steel PH 15-7 MO

Malleable Iron

Buna-N

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Optional-Screened Outlet Hood

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Part Name

Body

Cover

Baffle

Seat

Float

Gasket

Cover Bolt

Retaining Screw

Guide Bushing

Float Arm

Material

Cast Iron ASTM A126, Class B

Cast Iron ASTM A126, Class B

Cast Iron ASTM A126, Class B

Buna-N

Stainless Steel T316, ASTM A276

Lexide NK - 511 ( Non-Asbestos)

Alloy Steel ASTM A449, Grade 5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Note 1: All Stainless Steel Parts Austenitic

Note 2: Manufactured to meet ANSI/AWWA C512-04

Valve

Size

Model No. A B C

D

Approx.

E F

Inlet

Size

Outlet

Size

Orifice

Size

CWP

PSI

Wt.

Lbs.

1" 361-CAV564.3 11 3/8" 10 1/2" 12" 2" 7" 2" 1" N.P.T 1" N.P.T 5/64" 300 40

2" 362-CAV332.3 14" 13" 15" 3" 8" 3" 2" N.P.T 2" N.P.T 3/32" 300 71

3" 363-CAV332.3 16" 15" 17" 4" 9 5/8" 4 3/8" 3" N.P.T. 3" N.P.T 3/32" 300 112

4" 364-CAV332.3 18 1/2 17" 19" 5" 11" 5 3/8" 4" N.P.T 4" N.P.T 3/32" 300 170

24

PL-36-CAV (6"-8") (R-3/2011)

Combination Air Valves Single Body Style

23

24

25

9

4

26

2

6

8

5

1

15

28

9

19 21

30 8A

4A

28

11

7

12

22

34

18

3

13

17

10

5A

B

A

INLET

OUTLET

Air Vacuum

Outlet

Air Release

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

Optional Hood

D C

VIEW A-A

Series 36

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

PARTS LIST

Detail No.

1

2

3

4

4a

5

5a

6

7

8

8a

9

10

11

Detail No.

12

13

15

17

18

19

21

22

23

24

25

26

28

30

34

Part Name

Body

Cover

Leverage Frame

Seat

Seat

Float

Float

Gasket

Cover Bolt

Retaining Screw

Retaining Screw

Guide Bushing

Float Arm

Orifice Button

Part Name

Pivot Pin

Retaining Ring

Cushion

Float Retainer

Lock Nut

Link

Locating Pin

Orifice Button Arm

Hood (Optional Hood)

Hood Retaining Screw

Washer - External

Seat Retaining Sleeve

Pipe Plug

Washer

Lock Washer

Material

Cast Iron ASTM A126 Class B

Cast Iron ASTM A126 Class B

Stainless Steel ASTM A240

Buna -N

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Lexide NK - 511 (Non - Asbestos)

Alloy Steel ASTM A449, Grade 5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316 & Buna -N

Material

Stainless Steel T316, ASTM A276

Stainless Steel - PH 15-7

Buna-N

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Steel - #1020

Steel (Cadmium Plated)

Steel (Cadmium Plated)

Stainless Steel T316, ASTM A276

Malleable

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Note: Manufactured to meet ANSI/AWWA C512-04

Valve

Size

Model No.

175 psi

Max. W.P.

175 psi

Orifice

Model No.

300 psi

Max. W.P.

300 psi

Orifice

A B C D Y

Inlet

Size

Air/Vac

Outlet

Air

Release

Outlet

Wt.

Lbs.

6" 366-CAV038 3/8" 366-CAV732.3 7/32" 21" 20 1/4" 14" 10 7/8" 2 3/8" 6" 6" Hood 3/32" 225

8" 368-CAV038 3/8" 366-CAV732.3 7/32" 25" 23 1/2" 17" 11" 7/8" 8" 8" Hood 3/32" 330

25

Detail No.

1

2

3

4

5

6

7

10

11

12

13

17

21

34

Part Name

Body

Cover

Lever Frame

Seat

Float

Gasket

Cover Bolt

Float Arm

Orifice Button

Pivot Pin

Pin Retainer

Float Retainer

Locator

Lock Washer

Material

Cast Iron ASTM A126 Class B

Cast Iron ASTM A126 Class B

Stainless Steel T316, ASTM A276

Stainless Steel T316 ASTM A276

Stainless Steel T316, ASTM A276

Garlock #3000 (Non-Asbestos)

Alloy Steel SAE Grade 5

Stainless Steel T316, ASTM A276

Viton

TM

Stainless Steel T316 ASTM A276

Stainless Steel PH 15-7 Mo

Stainless Steel T316 ASTM A276

Stainless Steel T316, ASTM A2766

Stainless Steel T316, ASTM A276

Series 34 Air Release Valve

Combination Air Valves Dual Body Style

Series MTP36

B

INLET

OUTLET

2

8

4

7

6

3

5

20

9

1

14

A

OUTLET

21

4

2

6

3

13

12

10

11

7

5

1

17

34

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

PL-MTP36 Series (1"-3") (R-3/2011)

PARTS LIST

Detail No.

1

2

3

4

5

6

7

8

9

14

20

Part Name

Body

Cover

Baffle

Seat

Float

Gasket

Cover Bolt

Retaining

Screw

Guide

Bushing

Pipe Plug

Guide Shaft

Material

Cast Iron ASTM A126 Class B

Cast Iron ASTM A126 Class B

Ductile Iron ASTM A536-51T

Buna -N

Stainless Steel T316, ASTM A276

Garlock #3000 (Non-Asbestos)

Stainless Steel ASTM A449 Grade5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Malleable

Stainless Steel T316, ASTM A276

Series 35 Air Vacuum Valve

Note: Manufactured to meet ANSI/AWWA C512-04

Model No.

Large Orifice

Inlet/Outlet

Inches

Small

Orifice

Inches

Weight

Lbs.

150 PSI 300 PSI Height Width

MTP361-CAV116 MTP361-CAV116.3 1 x 1 1/16" 16" 8" 35

MTP362-CAV116 MTP362-CAV116.3 2 x 2 1/16" 18" 10 1/2" 55

MTP363-CAV116 MTP363-CAV116.3 3 x 3 1/16" 18" 10 1/2" 58

26

PL-MTP36-CAV (4"-16") (R-2/2012)

CLA-VAL Copyright Cla-Val 2012 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

Combination Air Valves Dual Body Style

Series MTP36

PARTS LIST

Detail No.

1

2

4

5

6

7

8

9

Part Name

Body

Cover

Seat

Float

Gasket

Cover Bolt

Retaining Screw

Guide Bushing

Material

Cast Iron ASTM A126 Class B

Cast Iron ASTM A126 Class B

Buna -N

Stainless Steel T316, ASTM A276

Lexide Nk-511 (Non-Asbestos)

Alloy Steel ASTM A449, Grade 5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Detail No.

1

2

3

4

5

6

7

Part Name

Body

Cover

Lever Frame

Seat

Float

Gasket

Cover Bolt

Material

Cast Iron ASTM A126 Class B

Cast Iron ASTM A126 Class B

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Garlock #3000 (Non-Asbestos)

Alloy Steel SAE Grade 5

Detail No.

15

23

24

25

26

27

28

Part Name

Cushion

Hood (Optional Hood)

Hood Retaining Screw

Washer - External

Seat Retaining Sleeve

Washer - Internal

Pipe Plug

Material

Buna-N

Steel - #1020

Steel (Cadmium Plated)

Steel (Cadmium Plated)

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Malleable Iron

Detail No.

10

11

12

13

17

21

34

Part Name

Float Arm

Orifice Button

Pivot Pin

Pin Retainer

Float Retainer

Locator

Lock Washer

Material

Stainless Steel T316, ASTM A276

Viton

TM

Stainless Steel T316, ASTM A276

Stainless Steel PH 15-7 Mo

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A210

Air & Vacuum Valve (Large Orifice)

Air Release Valve (Small Orifice)

23

24

25

26

2

6

7

8

4

5

15

1

9

28

27

A

OUTLET

21

4

2

6

3

13

12

10

11

7

5

1

17

34

B

Air Vacuum

Valve

Air Release

Valve

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

Optional Hood

Note: Manufactured to meet ANSI/AWWA C512-04

Model No. Large Orifice

Inlet/Outlet

Small Orifice

Inches

Inches

Weight Lbs.

125 Lb. 250 Lb. A B

175 MWP 300 MWP Inches 125 Lbs. 250 Lbs. Width Height 125 Lbs. 250 Lbs.

MTP364-CAV116 MTP364-CAV116.3 4x4 3/32 1/16 21 22 125 132

MTP366-CAV116 MTP366-CAV116.3 6x6 3/32 1/16 24 23 175 195

MTP368-CAV116 MTP368-CAV116.3 8x8 3/32 1/16 27 26 226 255

MTP3610-CAV116 MTP3610-CAV116.3 10x10 3/32 1/16 30 28 385 425

MTP3612-CAV116 MTP3612-CAV116.3 12x12 3/32 1/16 33 32 580 625

MTP3614-CAV116 MTP3614-CAV116.3 14x14 3/32 1/16 36 34 685 750

MTP3616-CAV116 MTP3616-CAV116.3 16x16 3/32 1/16 39 34 875 985

27

PL-MTP36CAV-BFV (R-/2012)

CLA-VAL Copyright Cla-Val 2012 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

PARTS LIST

Combination Air Valve with Wafer Butterfly Isolation Valve

Series MTP36-CAV-BFV

4" Thru 12"

Air Release

Valve

SPACER RING

D

C

WAFER BUTTERFLY

VALVE-LUG STYLE WITH

MANUAL HAND LEVER

OPERATOR

125 LB CLASS

B

23

24

25

26

2

6

7

8

4

5

15

1

9

28

27 Air

Vacuum

Valve

OUTLET

21

4

2

6

3

13

12

10

7

5

1

17

34

11

A

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

Optional Hood

Note: The Spacer is required to allow full open clearance between the butterfly valve disc and the air valve float guide.

Detail No.

1

2

4

5

6

7

8

9

Part Name

Body

Cover

Seat

Float

Gasket

Cover Bolt

Retaining Screw

Guide Bushing

Material

Cast Iron ASTM A126 Class B

Cast Iron ASTM A126 Class B

Buna -N

Stainless Steel T316, ASTM A276

Lexide Nk-511 (Non-Asbestos)

Alloy Steel ASTM A449, Grade 5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Detail No.

1

2

3

4

5

6

7

Part Name

Body

Cover

Lever Frame

Seat

Float

Gasket

Cover Bolt

Material

Cast Iron ASTM A126 Class B

Cast Iron ASTM A126 Class B

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Garlock #3000 (Non-Asbestos)

Alloy Steel SAE Grade 5

Detail No.

15

23

24

25

26

27

28

Part Name

Cushion

Hood (Optional Hood)

Hood Retaining Screw

Washer - External

Seat Retaining Sleeve

Washer - Internal

Pipe Plug

Material

Buna-N

Steel - #1020

Steel (Cadmium Plated)

Steel (Cadmium Plated)

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Malleable Iron

Detail No.

10

11

12

13

17

21

34

Part Name

Float Arm

Orifice Button

Pivot Pin

Pin Retainer

Float Retainer

Locator

Lock Washer

Material

Stainless Steel T316, ASTM A276

Viton

TM

Stainless Steel T316, ASTM A276

Stainless Steel PH 15-7 Mo

Stainless Steel T316, ASTM A276

Stainless Steel T18-8 ASTM A276

Stainless Steel T316, ASTM A210

Large Orifice Air & Vacuum Valve

Small Orifice Air Release Valve

Size

Model

175 MWP

A

Width

B

Height

C

Spacer

Ring

D Wt.

4" MTP364CAV-116BFV 21" 24 5/8" 9 1/8" 1/2" 2 1/8" 185

6" MTP366CAV-116BFV 22" 25 3/4" 10 1/4" 1/2" 2 1/4" 275

8" MTP368CAV-116BFV 27" 30 7/8" 12" 2 3/8" 2 1/2" 340

10" MTP3610CAV-116BFV 29" 33 7/8" 13 1/4" 3 1/8" 2 3/4" 570

12" MTP3612CAV-116BFV 33" 38 1/2" 15" 3 3/8 3 1/8" 815

Note:

Manufactured to meet

ANSI/AWWA C512-04

28

Combination Air Valve with Flanged Butterfly Valve

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

PL-MTP36-CAV-FBV (4 & 16)

PARTS LIST

Series MTP36-CAV-FBV

125 Lb and 250 Lb Class 4" & 16"

Detail No.

1

2

3

4

5

6

7

10

11

12

13

17

21

34

Part Name

Body

Cover

Lever Frame

Seat

Float

Gasket

Cover Bolt

Float Arm

Orifice Button

Pivot Pin

Pin Retainer

Float Retainer

Locator

Lock Washer

Material

Cast Iron ASTM A126 Class B

Cast Iron ASTM A126 Class B

Stainless Steel T316 ASTM A276

Stainless Steel T316 ASTM A276

Stainless Steel T316 ASTM A276

Garlock #3000 (Non-Asbestos)

Alloy Steel SAE Grade 5

Stainless Steel T316 ASTM A276

Viton

TM

Stainless Steel T316 ASTM A276

Stainless Steel PH 15-7 Mo

Stainless Steel T316 ASTM A276

Stainless Steel T316 ASTM A276

Stainless Steel T316 ASTM A276

Small Orifice Air Release Valve

Detail No.

1

2

4

5

6

7

8

9

15

23

24

25

26

27

28

Part Name

Body

Cover

Seat

Float

Gasket

Cover Bolt

Retaining Screw

Guide Bushing

Cushion

Hood (Optional)

Hood Retaining

Screw

Washer - External

Seat Retaining

Sleeve

Washer - Internal

Pipe Plug

Material

Cast Iron ASTM A126 Class B

Cast Iron ASTM A126 Class B

Buna -N

Stainless Steel T316 ASTM A276

Lexide Nk-511 (Non-Asbestos)

Alloy Steel ASTM A449, Grade 5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Buna-N

Steel - #1020

Steel (Cadmium Plated)

Steel (Cadmium Plated)

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Malleable Iron

Large Orifice Air & Vacuum Valve Air and

Vacuum

Valve

B

23

24

25

26

2

6

7

8

4

5

15

1

9

28

27

1" Piping &

Shut-off Valve

(Shipped Separate)

Air Release

Valve

OUTLET

21

4

2

6

3

13

12

10

11

7

5

1

17

34

A

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

Optional Hood

125 Lb. Class

(150CWP)

250 Lb. Class

(250 CWP)

AWWA Butterfly Valve

C

J

D

T

K

INLET

O

P

E

N

C

L

O

S

E

D

L

(Dia.)

Spacer

Valve

Size

Model No

A B

C D J

K L

T Spacer Wt.

125 Lb / 175 MWP 250 Lb. / 300 MWP 125 250 125 250 125 250 125 250 Lbs.

4 MTP364CAV116-FBV MTP364CAV116-FBV.3 21 22 27 27

5

8 5 5 5/8 1 1/8 1 9 3/8 8 N/R N/R 222

6 MTP366CAV116-FBV MTP366CAV116-FBV.3 22

1

2 23 28 28

7

8 5 5 7/8 1 1/8 11/16 9 3/8 8 N/R N/R 335

8 MTP368CAV116-FBV MTP368CAV116-FBV.3 27 26 32 33 6 7 5/8 1 1/8 9 3/8 8 N/R N/R 435

10 MTP3610CAV116-FBV MTP3610CAV116-FBV.3 29 28 36 37

3

8 8 9 3/8 1/4 0 10 3/8 12 N/R N/R 687

12 MTP3612CAV116-FBV MTP3612CAV116-FBV.3 33 32 40 41

1

2 8 9 1/2 1/4 0 10 3/8 12 N/R N/R 961

14 MTP3614CAV116-FBV MTP3614CAV116-FBV.3 35

1

2 34 44 44

1

2 8 9 1/2 3 1/8 2 3/8 15 1/16 20 2 3/4 1 1188

16 MTP3616CAV116-FBV MTP3616CAV116-FBV.3 44

3

4 34 44

3

4 45

3

8 8 9 5/8 3 1/8 2 3/8 15 1/16 20 4 3/8 2 1550

Note: Manufactured to meet ANSI/AWWA C512-04

29

Combination Air Valve with Arrestor Check

14

OUTLET

2

8

4

7

6

3

5

20

9

1

14

1" Piping &

Shut-off Valve

A

B

5

1" or 2" INLET

Air Vacuum

Valve

Arrestor Check

OUTLET

21

4

2

6

3

13

12

10

11

7

5

1

17

34

Air Release

Valve

2

3

4

TEST PRESSURE

1.5 TIMES

WORKING PRESSURE

CLA-VAL Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

PL-MTP36-CAV-AC (1-2in) (R-3/2011)

PARTS LIST

Series MTP36-CAV-AC

Detail No.

1

2

3

4

5

6

Part Name

Body

Cover

Baffle

Seat

Float

Gasket

Material

Cast Iron ASTM A126, Class B

Cast Iron ASTM A126, Class B

Ductile Iron ASTM A536-51T

Buna-N

Stainless Steel T316, ASTM A276

Garlock #3000 (Non-Asbestos)

Detail No.

7

8

9

14

20

Part Name

Cover Bolt

Retaining Screw

Guide Bushing

Pipe Plug

Guide Shaft

Material

Stainless Steel ASTM A449 Grade5

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Malleable Iron

Stainless Steel T316, ASTM A276

Detail No.

1

2

3

4

5

6

7

Part Name

Body

Cover

Lever Frame

Seat

Float

Gasket

Cover Bolt

Material

Cast Iron ASTM A126, Class B

Cast Iron ASTM A126, Class B

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Garlock #3000 (Non-Asbestos)

Alloy Steel SAE Grade 5

Detail No.

10

11

12

13

17

21

34

Part Name

Float Arm

Orifice Button

Pivot Pin

Pin Retainer

Float Retainer

Locator

Lock Washer

Material

Stainless Steel T316, ASTM A276

Viton

TM

Stainless Steel T316, ASTM A276

Stainless Steel PH 15-7 Mo

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Stainless Steel T316, ASTM A276

Air Vacuum Valve

Detail No.

1

2

3

4

5

Part Name

Body

Seat

Disc

Stem

Seat Screw

Arrestor Check

Air Release Valve

1" and 2"

Material

Bronze ASTM B584

Teflon

Stainless Steel T302

Stainless Steel T302

Stainless Steel T302

Note:

Manufactured to meet

ANSI/AWWA C512-04

Model

Sizes A B Depth Wt.

300 MWP

MTP361CAV/ACAR116 1" 14 1/2 16 1/2 7" 40

MTP362CAV/ACAR116 2" 16 1/2 22 1/4 9 1/2" 70

30

PL-MTP363CAV/ACAR116 (R-3/2011)

Combination Air Valve with Arrestor Check

2

4

3

1

7

5

14

2

8

4

7

6

3

5

20

9

1

14

1" Piping &

Shut-off Valve

A

B

Air Vacuum

Valve

125 or

250 LB

Class

TEST PRESSURE

1.5 TIMES