Académique Documents

Professionnel Documents

Culture Documents

Horizons September 2014

Transféré par

Nikolas VaporisCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Horizons September 2014

Transféré par

Nikolas VaporisDroits d'auteur :

Formats disponibles

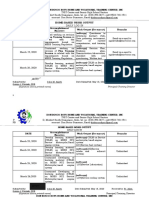

September 2014 Issue 41

LNG-fuelled future

A review of Lloyd's Register's gas

projects including some notable

ferries around the globe

Germany delivers

Meet Lloyd's Register's new team in

their grand Hamburg HQ and read

about some exciting LR projects

Boxing clever

New generations of safe, secure

and effcient large container ships

The Greek

Shipping Miracle

The story of George

M. Foustanos

Loch Seaforth

A hybrid German

project for a Scottish

owner

26

Port state

control

LR tops the Paris

MoU ratings

8

News

Stories about LR and

our activities round

the world

Type approval

LR streamlines a

major service for

clients

LNG-fuelled

shipping

Going global with

Lloyds Register

Container ships

New generations

Gateway to

Germany

Meet the

Hamburg team

Oldendorff

Carriers

The rise and rise of

a leading dry bulk

carrier

TSC

German trio launch

ship management

company

Yachts

Sector thrives as

demand rises

3

9

22

16

32

34 30

18

10

Contents

Horizons is the journal for Lloyds Register

Marine clients and employees, delivering

news and analysis on our global activities.

The Horizons teamare:

Editor: Christopher Browne

E chris.browne@lr.org

T (0)2380 249604

Marine Communications Manager:

Nick Brown

Design & production:

Clever Clogs Creative

Horizons is produced by Marine

Communications. Care is taken to ensure the

information it contains is accurate and up to

date. However Lloyds Register accepts no

responsibility for inaccuracies in, or changes

to, such information.

Lloyds Register is a trading name of Lloyds

Register Group Limited and its subsidiaries

and affliates. For further details please see

www.lr.org/entities

Lloyds Register 2014

September 2014 Issue 41

Lloyds Register EMEA

T +44 (0)20 7709 9166

F +44 (0)20 7488 4796

E emea@lr.org

71 Fenchurch Street, London

EC3M4BS, UK

Lloyds Register Asia

T +852 2287 9333

F +852 2845 2616

E asia@lr.org

22nd Floor, Dah Sing Financial Centre,

108 Gloucester Road, Wanchai,

Hong Kong, SAR of PRC

Lloyds Register Americas, Inc

T +1 (1)281 675 3100

F +1 (1)281 675 3139

E americas@lr.org

1330 Enclave Parkway, Suite 200,

Houston, Texas 77077, USA

Cover image shows the LR-classed MSC London (left) shortly before she was delivered

at STX Offshore & Shipbuilding, South Korea, in July. Owned by Zodiac Maritime, the

Panama-fagged vessel is the largest container ship in the MSC feet.

The Lloyd's Register Global Technology

Centre in Southampton. The new home

for LR's global Marine business, from the

autumn of 2014, will help drive innovation

and commercial and environmental

performance in shipping underpinned by

LR's commitment to safety

Sharper focus

Nick Brown is a 19-year LR veteran. He began

his career as a graduate engineer before

starting work as a feld surveyor. Since leaving

the feld he has held increasingly important

business development and operational roles

in London and Asia. Before returning to the

Marine headquarters in Southampton to take

up his most recent role as Director, Business

Development & Innovation, he was in charge of

LRs Greater China activities and operations.

Nick retains leadership of the Business

Development & Innovation team, including Luis

Benito (Marketing), Hector Sewell (Sales) and

Gwynne Lewis (Consulting), who will be joined

by LRs other Nick Brown, the Global Marine

Communications Manager.

Nick Brown, COO, said: We move into our

new Marine headquarters at the LR Global

Technology Centre in Southampton as the

commercial pressures and technical challenges

continue to mount in our industry. I will be

focused on connecting current and future client

needs with service innovation and operational

excellence to provide the support that our

clients and stakeholders need. Class continues

to evolve and we are working hard to provide

the right combination of expertise in safety,

environmental and effciency performance of

both assets and operations.

Nick Brown, previously Director Business

Development & Innovation, has been

appointed Marine Chief Operating Offcer

(COO). The change refects the growth in

Lloyds Registers Marine business, both in scale

and breadth of services.

Reporting to Marine Director Tom Boardley,

Nick is responsible for LRs four global

operating regions Asia, the Americas,

Northern Europe and Southern Europe.

Tom Boardley commented: Nicks key leadership

appointment will enable us to provide continued,

and ever-improving, delivery of our technical and

operational excellence. His appointment is driven

by growth in Lloyds Registers Marine activities and

Nick is well placed to co-ordinate global operations

to ensure successful delivery of the large orderbook

of ships being built to LR class. Nicks leadership will

also ensure that LR has the best understanding of

the technical and commercial challenges facing the

marine industry and continues to innovate services to

support our clients in meeting ever increasing safety,

environmental and effciency ambitions.

Nick Brown, Lloyds Registers Marine COO

Nick Brown

appointed Lloyds Registers

Marine Chief Operating Offcer

MHI-built Sayaendo LNG carrier launched this month

The frst of two Lloyds Register classed

155,000m LNG carriers constructed at the

Nagasaki Shipyard and Machinery Works of

Mitsubishi Heavy Industries (MHI) is due to be

delivered this month (September), with the

second expected in December.

The MHI-owned ships which are named Sayaendo

meaning peas in a pod in Japanese are ftted with

continuous tank covers instead of the semi-spherical

Moss tanks usually associated with LNG carriers of this

type. The vessels will be among the frst LNG carriers

to be ftted with a reheat steam turbine propulsion

plant, giving them increased overall energy effciency.

They will play a vital role in Japans energy supply

security in the aftermath of the 2011 Tohoku

earthquake. Since then, LNG has made up most of the

shortfall previously flled by nuclear energy.

While these ships are compatible with most export and

import terminals, the size, capacity and arrangement

are also specifcally designed for transiting the

widened Panama Canal, scheduled to re-open in 2015,

allowing LNG exports from the US Gulf and east coasts

to reach Japan via the Pacifc Ocean.

In between the delivery of the two Sayaendos MHI

will deliver an LR-classed 145,000m conventional

Moss LNG carrier, also ftted with a reheat steam

turbine. Since the 1980s, LR has classed 20 LNG

carriers ftted with Moss spherical tanks.

Our association with shipbuilding in Japan can be

traced to the survey of the frst ocean-going ships

constructed in Nagasaki in the 1890s. Today, LR

remains committed to serving Japanese industry

and clients with our expanded portfolio of services

delivered via our main offces in Yokohama, Nagasaki

and Kobe.

An LR-classed Sayaendo LNG carrier shortly before delivery

To fnd out more about the MHI Sayaendos

and other LNG carrier projects, gas as a

marine fuel and gas technology in general

read LRs March 2014 Gas Technology Report

www.lr.org/horizons www.lr.org/horizons

Horizons September 2014

2 3

News

LR has signed a memorandum of

understanding (MoU) with GE Marine, a

leading global manufacturer of marine

propulsion systems, products and services,

to identify potential gas turbine-powered

commercial ship projects.

Through the MoU we will identify target segments

and commercial customers for our highly-effcient

marine has turbine systems, said Brien Bolsinger,

VP Marine Operations, of GE Marine, based in

Evendale, Ohio. GE already has an established base

of 90 marine gas turbines operating on 17 cruise

ships, fve high-speed yachts and 19 fast ferries.

GEs gas turbine systems are unique in their

ability to offer power density (i.e. high power in a

lightweight, small footprint unit), fuel fexibility,

and optional, highly reliable Dry Low NOx Emissions

(DLE) combustion system technology. GEs DL

combustion system can meet Tier III IMO/Tier IV US

Environmental Protection Agency requirements

needing no exhaust treatment when operating on

natural gas or on liquid fuels in combined cycle.

Nick Brown, LRs Marine COO, said:This MoU

will allow us to work with some of the leading

shipyards to approve in principle GE gas turbine-

powered commercial vessels for global customers.

GE Marine and LR sign gas turbine power agreement

We can assist shipping industry stakeholders with

understanding how the technical performance

of these gas turbines can help meet commercial

requirements. We always welcome shipowners and

operators who would like to participate in joint

development projects involving new applications.

In December last year, it was announced that GE

Marine, Dalian Shipbuilding Industry Company

(DSIC) and LR have jointly developed a design for

a gas turbine-powered LNG carrier. The carrier

will provide low-lifecycle-cost, high environmental

performance and fexible design.

Signing ceremony: LRs Marine Director Tom Boardley (l)

with Brien Bolsinger, VP Marine Operations, GE Marine

Our business decisions need to become more

resilient to these changes in global trends. We

need to transform the way we work, thinking more

long term rather than adopting the swapability

approach, said Palmer. LRs expertise is helping

to create this change and supporting our clients to

make sure they make the right sustainable business

decisions.

Our evolving approach also refects the Sustainable

Shipping Initiative launched three years ago by

shipping leaders from around the world, with LR

as one of the founder members. This ambitious

coalition is taking practical steps to change some

of the maritime sectors greatest challenges and

opportunities.

We have seen a discernible shift in the shipping

industry as it moves from operating within

compliance to a far deeper understanding of

the social value of shipping and how embedding

sustainability as part of business-making decisions

creates opportunities, said Palmer.

At LR we recognise the need for transformation

and, through collaboration and innovation, with

the move to the GTC, it seems timely that this

should occur now, she added.

To refect the greater emphasis on a

sustainable maritime transportation system,

Lloyds Register has changed the focus of its

Marine Environment team to Environment and

Sustainability.

The reason for the shift is to refect the need for

a more sustainable outlook in the shipping supply

chain. The maritime industry needs to ensure it

remains a sustainable mode of transportation and

the role it plays in the global supply chain is vital to

sustainable development, said Katharine Palmer,

Manager of the Environment and Sustainability team.

The impact of sustainable development was the

theme of the 2013 Maritime Day when, in his

address, IMO Secretary General Koji Sekimizu

said: Maritime transport is central to sustainable

development and the maritime transportation

system itself must, therefore, ensure that its

development is also sustainable.

Sustainable development is development

that meets the needs of the present without

compromising the ability of future generations

to meet their own needs this defnition was

issued as long ago as 1987 but were still trying to

understand what this means. The concept can be

interpreted in many different ways but at its core

is the balance and often competing needs of the

environmental, social and economic limitations

society faces. All too often, our business decisions

are driven by one particular need.

In our recent Global Marine Trends 2030 study

we forecast the major changes likely to occur

before 2030 such as the growth of world trade, a

rising global population and an increase in living

standards a changing agenda with sustainability

at its core.

Setting the agenda with sustainability

Katharine Palmer,

LRs Environment and

Sustainability Manager

Lloyds Register has been shortlisted for the

prestigious Lloyds List Global Awards. The EU

LYNCEUS project, of which LR is one of several

industry partners, has been shortlisted for the

Innovation Award. LRs Ship Emergency Response

Service (SERS) has been shortlisted for the

Environment Award, which honours those that

have done the most to reduce the pollution of our

oceans through ship design or environmental policy.

The Innovation Award recognises new ideas,

ship designs, equipment and services that offer

distinct business improvements. The award is given

to the technology solution the judges believe

demonstrates the innovation needed to move

shipping forward.

LYNCEUS has been nominated for the technology

it is developing to revolutionise ship emergency

management and evacuation. The system at the

centre of the project uses a combination of ultra-

low power wireless body-area-network technology

and lifejacket-mounted refectors tracked by an

Unmanned Aerial Vehicle (UAV). This technology

enables the swift location and rescue of people in

danger, either on board or in the sea.

LR nominated for Lloyds List awards

SERS has been recognised for its commitment to

effectively responding to ship emergencies and

reducing risks to the environment, passengers, crew

and cargo. With experience of more than 250 live

incidents and over 1,400 emergency exercises, SERS

has earned a worldwide reputation as the leading

provider of emergency response damage calculation

and support services.

The winners of the Lloyds List Global awards will

be announced at a special ceremony at Londons

Lancaster Hotel on 30 September this year.

The Lloyds List Global Awards recognise

the industrys successes, set a benchmark for

excellence and reward innovative ideas that

have pushed the boundaries of what is possible.

The awards have earned a reputation for being

diffcult to win and are seen as a signifcant

achievement by the industry.

DFDS, northern Europes largest integrated shipping

and logistics company, is transferring eight ships into

Lloyds Register class to help further support DFDS

Seaways operational activities.

DFDS Seaways operates a network of 30 routes

with 50 freight and passenger ships, while DFDS

Logistics provides freight and logistics services in

Europe with trailers, containers and rail.

Lloyds Registers Ship Emergency Response

Programme (SERS) has also been contracted feetwide

to provide damage stability and crisis support to DFDS,

further extending the safety and operational services

available to DFDS.

Kasper Moos, Vice President of DFDS, said: We have

decided to transfer a number of our ships to LR in

order to reduce the number of partners and achieve

a leaner process in our daily work with the class. LR

has already proven that they have the size and the

services we need for fully covering our needs for a

safe and effcient operation of our ships.

Lloyds Registers Kim Wiese, Marine Business

Development Manager for Denmark, said: Our

relationship has been strengthened through the

agreement to transfer a number of vessels to LR

Class. Furthermore, enrolling their feet into our SERS

programme shows DFDSs commitment to safety of

life at sea and their care for the environment.

Lloyds Register signs ToC contract with DFDS

www.lr.org/horizons www.lr.org/horizons

Horizons September 2014

4 5

News

LR is working with Portsmouth International Port to

identify technical specifcations and develop operating

procedures for safe bunkering at the port. The project

will enable the port to further its ambitions to become

the UKs frst LNG bunkering facility and hub.

Leonidas Karistios, LRs Global Gas Technology

Manager, said: Obviously with growing demand

for LNG, ports are looking to ensure that they have

the right, safe, approach to support operational

and commercial ambitions. With a city adjacent

to the port, signifcant ferry traffc and a large

naval presence, there are substantial and varied

stakeholder aspects to be addressed.

Brittany Ferries latest newbuild, which is gas-fuelled and

scheduled for delivery in 2016 (see LRs Gas Technology

Report, March 2014, at www.lr.org/gas), will call at

Portsmouth, where LNG bunkering will take place.

LRs Global Special Projects Manager, Thanos

Koliopulos, said: We can use experience gained

in projects like Singapore Port and Viking Grace to

apply real project experience to deliver advice for

the planning and execution of LNG bunkering to

both the port and its bunkering service providers.

Particular attention is given to the effective

planning and execution of the ports main clients

compatibility of operations and all technical aspects

for bunker tanker and receiving ships facilities.

We can help Portsmouth get ready for real LNG

bunkering operations, not only for ferry and shortsea

shipping, but our global expertise and perspective

can also help them to prepare for supporting LNG-

fuelled deepsea shipping requirements.

LR project supports safe bunkering in Portsmouth

Portsmouth International Port

Computer-generated image of Brittany Ferries LNG-fuelled ferry

The Lloyds Register Foundation has linked

with The Welding Institute (TWI) to provide

15 million research funding for the UKs frst

National Structural Integrity Research Centre

(NSIRC) now nearing completion in Cambridge.

The collaboration between the LR Foundation and

TWI over the next 10 years is aimed at inspiring and

engaging the next generation of marine and energy

engineers at the NSIRC, providing fundamental

science and industry-driven research opportunities

aligned with a postgraduate education programme.

As a founder sponsor of the NSIRC initiative,

the LR Foundations funding will create up to

83 PhD and EngD studentships. The research

will help to support the Foundations charitable

aims by focusing on improving the safety of

the critical infrastructure that todays society

relies on, particularly in the energy, marine and

transportation sectors.

LR Foundation and Welding Institute in research link-up

By conducting research

into different areas of

structural integrity and

new areas of technology,

Foundation students

will be able to gain

recognised postgraduate degree qualifcations

through NSIRCs established relationships with

leading universities in the UK and overseas.

Professor Richard Clegg, Managing Director of the

LR Foundation, said:Our vision is to be known

worldwide as a leading supporter of engineering-

related research, training and education. This

funding agreement is a signifcant step in the

delivery of our new funding strategy and provides

a model for future investments. We want to focus

on long-term grants with targeted institutions that

deliver both impact and excellence.

A Lloyds Register report looks at the commercial landscape, regulatory

issues and technical realities of a new trade in ethane emerging as a

result of increased US gas production and the technology required

for large ethane carriers

Seaborne ethane and demand for a new

ship type very large ethane carriers (VLECs)

US ethane production capability, as a by-product of

total increased US gas production, is under-utilised.

The potential exists for annual exports of 1 million

tonnes of ethane to provide employment for 0.18

million m of shipping capacity if shipped to North

Europe, a further 0.32 million m if shipped to

South Asia and a similar amount to China through

the Panama Canal. Projects are now underway to

produce and move this ethane.

Seaborne ethane: a report into the commercial

need and technical requirements for very large

ethane carriers released by LR looks at the risks and

challenges in developing a safe and effcient trade

in ethane using larger ships and requiring ethane-

specifc technical solutions.

The window of opportunity to tie up ethane

exports and secure tonnage to serve this trade is

now open to feed potential markets in Europe and

Asia, says Tim Protheroe, President, Lloyds Register

North America Inc. Lloyds Register has identifed

the technical risks and best technical pathways

to help ensure that near-term demand for large

VLECs can be met by shipyards and gas containment

system suppliers.

Our job is to help anyone looking at trading

ethane to make the best commercial decisions

based on the best technical insight as well as

working with regulatory bodies such as the US

Coast Guard and fag administrations to ensure that

the risks are understood.

One of the critical factors to be addressed is the

containment technology used in very large ethane

carriers (VLECs) as traders look for the most effcient

shipping options.

Leonidas Karistios, LRs Global Gas Technology

Manager, says: We have been studying the

potential for ethane for over a year and we asked

the question, What would a safe and effcient

80,000 m ethane carrier look like?. The answer

is that to transport larger quantities in a single

hull will almost certainly require the adoption of

alternatives to Type C gas containment systems.

Historically ethane has been transported in small

liquefed ethane/ethylene carriers (LECs) designed

and constructed to carry ethylene (boiling point

104C) as well as ethane and other normal LPG

cargoes. All these vessels have Type C containment

systems and it is estimated that the maximum

feasible size of a ships with Type C cargo tanks is

around 40,000 m. Its not impossible that Type

C tanks could work, and it is important to keep

reviewing the technology being developed, says

Karistios.

The study evaluates all tank technology options and

identifes that, for ethane carriers of 80,000 m and

over, the adoption of either prismatic Type B tanks

or membrane systems would provide the likely best

technical design pathways based on a ship with

three to four tanks.

Cover of Lloyd's Register's report into seaborne ethane

and very large ethane carriers (VLECs) You can obtain a

copy of the report on www.lr.org/ethane

www.lr.org/horizons www.lr.org/horizons

Horizons September 2014

6 7

News

A major recruitment drive was recently

launched by Lloyds Register to further

expand our role as a leading Type Approval

(TA) specialist for materials, component

and equipment manufacturers in the global

marine, shipping and engineering industries.

Over the past year, 12 new roles have been created

in Shanghai and Hamburg and a further 18 jobs are

set to be flled over the next few months. LR is also

streamlining the TA service. Clients can now obtain

and renew certifcates and access LRs existing

database on the LR website at http://www.lr.org/

en/marine/compliance/type-approval/ which will

include a new client database early in 2015.

Bob Smart, LRs Global Marine Technical Services

Manager, said: Our objective with the recruitment

drive and all the improvements we are making is

to offer our TA clients an even better and more

hands-on service than we have done before.

Upgrading our databases and associated systems

will make it easier to issue certifcates and make

them available for clients online. It will also

automate some of our processes, fagging up

renewals and making it possible to offer our

clients a more proactive service.

LR issues Type Approval certifcates on behalf of

Flag states, MED certifcates, EU MR certifcates and

LR Type Approval certifcates. It covers a wide range

of products including Works Approvals, Approval of

Welding Consumables, Type Approval of Electrical

and Machinery Equipment and Components, Fire

Safety products and Life Saving Appliances among

others. Interestingly, there are estimated to be

another 12,000 products that could qualify for the

TA service.

Apart from the teams in Hamburg and Shanghai, a

team of nine specialists in Lloyds Registers Marine

Technical and Engineering Services department in

Southampton have been assigned to handle TA

work and applications.

Flans Kemp, who was until recently a Lead Specialist

in LR Shanghai, was appointed Type Approval

Business Development Manager in July this year. His

responsibilities will be to co-ordinate the TA teams

and to drive its market growth.

LR raises the profle

of Type Approval

A focus on improved service, online certifcation and more people

leads to new look TA

He told Horizons: Its not just our technical support

offces and business development teams that need

to support the growth of Type Approval. Our target

clients are not the usual owners and builders of

ships, but the manufacturers of the equipment and

components themselves. And it is our surveyors who

daily work with these companies that need to feel

confdent in recommending LR Type Approval as

a worthwhile investment.

A two-page factsheet on LRs TA capabilities is

being distributed at SMM in Hamburg.

Flans Kemp profle

Flans Kemp, LRs new Type Approval Business

Development Manager, will be responsible

for the global performance of our TA services.

Flans was born and raised in the Netherlands

and studied Mechanical Engineering in

Rotterdam.

He joined Lloyds Register in Rotterdam

in 1996 as a plan approval surveyor for

machinery. During this period he developed

an in-depth knowledge of machinery piping

systems, equipment and components, pressure

equipment and machinery dynamics.

From 2008 to 2011, he led LRs machinery

team in Rotterdam before moving to Shanghai

where he led the machinery, electrical and Type

Approval teams.

Lloyds Register was the top-performing

recognised organisation (RO) at the Paris

Memorandum of Understanding (MoU) for the

three years from 2011 to 2013, fgures from the

leading port state control organisation reveal.

This means inspections carried out by LR on classed

ships in that period were better than any other RO

in the European and North Atlantic region covered

by the Paris MoU, which is one of nine international

organisations that supervise the inspection of

foreign vessels at port state control.

During this period, 11,405 inspections were carried

out on LR-classed ships, but only 10 ships were

detained for what are known as class-related factors.

Tom Boardley, LRs Marine Director, commented:

"This is a signifcant achievement, as the ranking

system is encouraging all ROs to continuously

improve their performance. In 2009, LR was

in eighth position and we realised this was

unsatisfactory, not just for our own reputation but

particularly for our clients who had put their faith

in our ability to keep their vessels trading without

the disruption of detentions. We set out to improve

our position with the initial aim of attaining a top

three position and then remaining there.

"We began a concentrated effort to improve feet

quality and help owners, managers and ships

crews to avoid detentions. This activity aligns with

our mission to promote safety and to improve the

operational performance of the feets we serve."

Lloyds Register tops European

port state control rankings

Port state control

Richard Schiferli, General Secretary of the Paris MoU

Port state control is important

Port state control is the term for inspection

regimes set up at the national level and organised

in regional areas - such as the Paris MoU - to

help ensure all ships are in compliance with

the requirements of international regulations

and that the ships are manned and operated in

compliance with these rules.

There are nine regional PSC organisations and

nine agreements on PSC, known as memoranda

of understanding (MoUs) , have been signed

covering all of the worlds oceans. They are:

Europe and the north Atlantic (Paris MoU); Asia

and the Pacifc (Tokyo MoU) ); Latin America

(Acuerdo de Via del Mar); Caribbean (Caribbean

MoU); West and Central Africa (Abuja MoU);

the Black Sea region (Black Sea MoU); the

Mediterranean (Mediterranean MoU); the Indian

Ocean (Indian Ocean MoU); and the Riyadh MoU.

A ship visiting a port in one country will normally

go to other countries in the same region before

starting its return voyage and it is to everybody's

advantage if inspections can be closely co-

ordinated. This ensures that as many ships as

possible are inspected and also prevents ships

being delayed by unnecessary inspections.

The main responsibility for a ships standards lies

with its fag state, but PSC provides a safety net

to catch substandard ships.

Tom Boardley, Lloyds Registers Marine Director

www.lr.org/horizons www.lr.org/horizons

Horizons September 2014

8 9

Type approval

LNG-fuelled shipping

going global with

Lloyds Register

Lloyds Register is now working on a wide and growing variety of LNG

projects worldwide supporting the expansion of LNG-fuelled shipping.

The broad spectrum of ship types and spread across the world

underlines LRs capabilities as the leading, independent classifcation

society involved in the development of LNG as a marine fuel

Lloyds Register classed newbuilding projects

won in 2014 include a large ferry in the

Netherlands, a bulk carrier project for Swedish

principals Thun; a car carrier project for

Norwegian operators and an ice breaker for the

Finnish Government.

In June, during Posidonia, Lloyds Register

announced a joint development project (JDP) for an

18,000 teu LNG-fuelled container ship design with

Piraeus, Greece based Capital Shipmanagement and

Koreas Daewoo Shipbuilding (DSME).

Then in July there was a series of announcements

involving LR and the LNG-fuelled future. LR is

supporting Portsmouth as the UK port prepares

to receive Brittany Ferries new large LNG-fuelled

ferries. While the frst of Quebec ferry operator

STQs new gas fuelled ferries, the 130-metre-long

F.-A.-Gauthier was launched at Fincantieris yard at

Castellamare di Stabia near Naples.

BC Ferries was pleased to welcome LR as the

classifcation society for its order of three new-

breed ferries. And GE Marine and Lloyds Register

signed a memorandum of understanding (MoU)

to collaborate on applying gas turbines to power

commercial ships (see News story, page 5).

Luis Benito, LRs Global Marine Marketing Manager,

is closely involved with developing LNG as fuel

opportunities working closely with Leonidas

Karistios, LRs Global Gas Technology Manager.

Says Benito: I think were seeing the evolution of

LNG-fuelled shipping in line with our analysis of the

markets, ship types and geographies that would go

for gas. You cant predict exactly who will choose

LNG or when some of these projects have been

in development for a long time. But the emphasis

on ferry trades and short sea trades within ECAs is

very much a refection of the progression we can

expect for gas-fuelled shipping. Some of these ships

are of course deep sea ready and capable but the

economics of decisions made so far has been all

about ECA operations.

Karistios explains that although LNG-fuelled

shipping has yet to be adopted by large deep sea

operators there are no technical or technology

impediments. However an area where the industry

needs to maintain high standards is in ensuring that

the risks of bunkering are managed effectively. If

serious incidents involving LNG bunkering occur

it could set back the potential for the continued

expansion of gas fuelled shipping, he says.

Luis Benito, LRs Global Marine Marketing Manager Leonidas Karistios, LRs Global Gas Technology Manager

F.- A.-Gauthier, STQs LNG-fuelled ferry

www.lr.org/horizons www.lr.org/horizons

Horizons September 2014

10 11

LNG-fuelled shipping

Computer-generated image of Texelstroom

A series of revolutionary LNG and dual-fuelled

ferries have been approved and classed by Lloyds

Register in 2014, demonstrating our unique

expertise and specialist knowledge in the cruise

ship and ferry technology sector. As LNG-fuelled

shipping goes global into major economies, LR is

supporting the projects that are taking the ferry

trades into a new and cleaner era.

In the ferry sector gas is particularly suitable

for short-range, ECA operations to fxed points

enabling investment in LNG refuelling capability

and regular access to bunkering opportunities.

LR recently signed a contract to class Texelstroom, a

large double-ended ferry able to carry up to 1,750

people and 350 vehicles between the island of Texel

and Dan Helder, the northernmost province of the

Netherlands. Texelstroom will be a multi-fuelled

ship with an advanced energy management system.

Predominantly dual-fuel LNG with diesel, the ship

will be supported by electric batteries and 700m of

solar panels.

The 135-metre-long, 16,400 gt vessel, which is owned

by Royal N.V. Texels Eigen Stoomboot Onderneming

(TESO), is being built at Spains La Naval Shipyard for

delivery by the end of 2015. Its revolutionary design

was supported by the European Unions iTransfer

programme which aims to make ferry transport more

freely accessible and sustainable and to encourage

more people to travel by water.

LNG focus strong on ferries

Texelstroom will have two independent engine

rooms. One engine room will be ftted with two

ABC diesel engines (2 x 2000 kW), and the other

with two ABC dual-fuel engines (also 2 x 2000 kW).

Two Rolls-Royce azimuth propellers will be installed

on each ship end, to achieve a speed of 10 knots

(economic) and 15 knots (maximum).

When it needs to switch to alternative power, it

is planned that the ferry will operate mainly on

natural gas stored in two batteries of compressed

natural gas (CNG) bottles installed on the top deck.

As well as a unique powering capability, the design

has several other features that are signifcant

for ferries operating in the north European

region. The vessel is Ice Class, which means it will

have a strengthened hull to safely navigate icy

waters. It also has LRs PCAC (Passenger and Crew

Accommodation Comfort) notation, ensuring a safe

and comfortable journey for passengers and crew.

John Hicks, LRs VP for Global Passenger Ships and

American Business Development, said: Winning

this groundbreaking contract is yet another

example of how LR is moving towards its aspiration

to be a marine advisor and innovator.

There was a huge effort put in by teams in both

Spain and the Netherlands who really demonstrated

Marines customer-centric values to understand the

clients challenges and win this exciting contract.

LNG-powered icebreaker built by Finlands Arctech Helsinki Shipyard.

Photo credit: Liikennevirasto/Flickr under Creative Commons Licence http://bit.ly/1cfOzXY;

Signing of ULCS agreement at Posidonia: (l-r) Apostolos

Poulovassilis, Regional Marine Manager EMEA, Lloyds

Register, Richard Sadler, CEO, Lloyds Register, J.H. Ko,

President and CEO, DSME, Evangelos Marinakis, Chairman

of the Board of Capital Product Partners LP, Y.Y. Koh, Senior

Executive Vice President, DSME, and Jerry Ventouris, Chief

Commercial Offcer, Capital Maritime & Trading Corp

Pictures show: (left) Computer-generated image (CGI) of an LNG-fuelled dry bulk carrier designed by Swedens Eric Thun

and classed by Lloyds Register; (right) CGI of dual fuel car carrier project for Norways UECC

Lloyds Registers gas expertise

stems from decades of LNG carrier

classifcation leadership and

understanding the ship-to-ship (STS)

transfer of LNG. STS has been a principal

area of development for large-scale

transfer of gas and is an important

experience. Risk leadership undertaken

for bunkering operations at the Port of

Stockholm to support the high-volume

bunkering required for the Viking Grace

passenger ship project, now successfully

in operation, carrying 2,800 passengers

between Stockholm and Turku, has

helped set the template for LRs

involvement in projects for ports like

Singapore and Portsmouth.

www.lr.org/horizons www.lr.org/horizons

Horizons September 2014

12 13

LNG-fuelled shipping

LNG bunkering frst for UK

LR achieved a notable frst recently when a

project to identify the technical specifcations

and operating procedures needed to make

Portsmouth International Port the UKs frst LNG

bunkering port began this summer (see News,

page 6).

Brittany Ferries latest newbuild ferry, which

is gas fuelled and ftted with GTT membrane

technology and scheduled for delivery in 2016

(see LRs March 2014 Gas Technology Report

at www.lr.org/gas), will call at Portsmouth

where LNG bunkering will take place. Brittany is

converting three existing ships to LNG power too.

Kalvin Baugh, Portsmouths Deputy Ferry Port

Manager, said: With changes in the regulations

governing emissions, it is clear that in the future

more shipping will be fuelled by LNG. To help

safeguard the port and meet the needs of our

customers, Portsmouth International Port needs

to be able to offer this facility. Safety is of course

the main priority, and we are delighted that

Lloyds Register has agreed to help us identify the

technical specifcations and operating procedures

that will help to deliver this.

Computer-generated image of Brittany Ferries LNG-powered ferry which will be bunkering at Portsmouth International Port

BC Ferries orders a gas-fuelled trio

Another Canadian operator, BC Ferries, is building

three dual-fuelled passenger Intermediate Class

ferries to be classed by LR. The vessels will be built

at Remontowa Shipbuilding S.A. in Gdansk, Poland.

Bud Streeter, President of LR Canada, said: This

project is the culmination of a great deal of hard

work. The outlook is good for LNG in Canada

there is availability of Canadian gas at highly

competitive prices, so commercially this is looking

like a smart decision for BC Ferries. Our job was,

and will be, to help ensure safety and reliability in

the design, build and the bunkering and operation

of these ships.

Passengers are the most valuable cargo so we

will endeavour to contribute to the safe operation

of these ships. LNG can provide signifcant

environmental benefts and, as BC Ferries is well

aware, safety comes frst. We are pleased to provide

BC Ferries with our assistance and expertise.

Mark Wilson, BC Ferries Vice President of

Engineering, said: BC Ferries is very pleased to have

LR as the classifcation society on these new

Intermediate Class ferries. LR has had a strong

relationship with BC Ferries over the years and has

the necessary experience and presence in Canada as

we make this important transition to LNG-fuelled

ferries.

The vessels will be the frst dual fuel capable ferries

using Liquefed Natural Gas (LNG) or diesel fuel

for propulsion and power in the BC feet. This is

an exciting initiative for BC Ferries that can reduce

upward pressure on fares due to lower fuel costs

for LNG, and reduce the environmental emissions

substantially as LNG is a cleaner and greener fuel

compared to current alternatives, added Wilson.

The ferries will be built to LR Rules, with LRs

surveyors surveying the ship during construction

to check for compliance and, once the ferries have

met LR class requirements and placed in service, LR

will survey them at regular intervals through their

operational lives. In addition, BC Ferries has drawn

on LRs LNG fuel expertise to support overall risk

management of the project and so help ensure the

safety of bunkering and all LNG operations.

A 133-metre-long LNG-fuelled and LNG-classed ferry

was launched at Fincantieris Castellamare di Stabia

shipyard near Naples in July. The vessel represents

the latest generation of ferry that Fincantieri is

building for Socit des traversiers du Qubec (STQ),

a Qubec government corporation that operates in

maritime passenger transport.

The ship, F.-A.-Gauthier, is named after Flix-Adrien

Gauthier, mayor of the Canadian town of Matane

from 1960 to 1963 and founder of the Matane

Godbout ferry route.

F.-A.-Gauthier is scheduled for delivery in late 2014

in Canada and represents a genuine technological

revolution.

It will be the frst ever gas-powered ferry built in

Italy and the frst such vessel to operate in North

America. The vessel adopts the most advanced

solutions in terms of energy saving and low

environmental impact, enabling a major reduction

in emissions of CO

2

(carbon dioxide), NO

x

(nitrogen

oxides) and SO

x

(sulphur oxides, which will actually

be reduced to zero).

First LNG-powered ferry for North America

In fact, this ship is equipped with a unique

integrated diesel electric propulsion system similar

to modern cruise ships, but the four diesel power

generators are dual fuel running on either gas

(liquid natural gas LNG) or marine diesel oil.

Gianpaolo Dalla Vedova, Lloyds Registers Marine

Operations Manager for Italy and South East

Europe, commented: The ferrys propulsion system

is equipped with counter-rotating propellers and

transverse propellers which make it exceptionally

manoeuvrable. Together with a complex and

extensive system of ramps and doors at both bow

and stern, the vessel can be loaded and unloaded

very quickly.

F.-A.-Gauthier will have a service speed of 20 knots

and will be able to carry more than 800 passengers.

The ferry will be used in the Province of Qubec,

transporting more than 205,000 passengers and

over 118,000 vehicles a year.

Gianpaolo continued: F.-A.-Gauthier will also be

able to operate in the Gulf of St. Lawrence, known

for its adverse weather conditions. This is thanks to

its innovative bow and stern, designed by Fincantieri,

and its Ice Class Notation which mean the vessel will

be very capable of breaking through ice.

STQs LNG-fuelled ferry

www.lr.org/horizons www.lr.org/horizons

Horizons September 2014

14 15

LNG-fuelled shipping

The evolving demands of global shipping

World trade is now totally reliant on safe, secure

and effcient container shipping. Without it,

the connected global economy simply could

not function. It is a constantly evolving feld.

The emphasis of ship designers and operators

in recent years has been on reducing shippings

environmental impact. This is certainly vital in

both ecological and economic terms, but must

not overshadow the similarly essential challenge:

ship performance and effciency are founded on

assurance of the hulls structural integrity.

Why does structural integrity continue to

be such a concern?

One might assume that most structural issues had

been solved years ago. The problem persists because

of changes of scale: the rules for small container

ships cannot be increased linearly to larger ones.

Big ships are different and present new challenges.

An extraordinary rate of increase

Even when the large container ships of the early

1990s broke through the 4,000 teu barrier, no one

could have predicted the degree to which sizes

would further increase or the speed with which it

would happen. Today we are looking at designs for

20,000 teu ships a fve-fold increase in little more

than 20 years.

Is the end in sight?

22,000 teu might currently seem to be about the

limit. Increased beams and higher stack heights

would require signifcant changes in port capability

(gantry outreach, for example) and container

strength. Nevertheless, the trend is towards

continued growth. 24,000 teu and beyond? Such a

revolutionary shift should surprise nobody.

The challenges are already urgent

The sea can be a hazardous place for ships of any

size, with increased dimensions bringing their own

structural risks. Furthermore, as sizes increase, so do

the potential losses involved in a single hull. Recent

large container ship losses due to structural failures

have highlighted the issue. MSC Napoli and, most

recently and signifcantly, MOL Comfort, provide

prominent examples. Just one such loss erodes

savings in capital, effciency and environmental

protection across hundreds of ships, and insurers

New generations of safe, secure

and effcient large container ships

Lloyds Register is helping develop new generations of safe, secure

and effcient large container ships

Getting ship structures right

and fulflling our mission to

beneft shipping and society

Lloyds Registers Structural Analysis &

Hydrodynamics Team, part of Marine

Technology & Engineering Services based

at LRs Global Technology Centre (GTC) in

Southampton, is the team researching the

challenges of container ship structures. The

team is part of the wider group, based in

Southampton but working with design support

colleagues worldwide, who are giving meaning

to Technology through pure research, leading

to the technical understanding that leads to the

effective classifcation rules that the shipping

industry demands.

Our new Marine Technology Report 01: What is the

future of shipping? reviews what is required to build

a new generation of safe, large container ships

become concerned about the concentration of risk

in one hull. With further increases in ship scale on

the horizon, understanding the forces at play is

more critical than ever.

Our mission is to beneft shipping and society

Over the years Lloyds Register has relentlessly

kept pace with the changes, continually investing

in research and development to measure and

understand the forces involved. Quite simply, as

ships get bigger, we enable ship designers, builders

and operators to make the best possible commercial

decisions based on the best possible technical

insight.

Understanding the risks

Modern container ships have very large deck

openings, long, fne hull forms, a large bow fare

(the projection of the forward deck outwards

above the waterline) and operate at fairly high

operational speeds (roughly 18 knots or over). They

must, of course, meet the structural strength and

fatigue requirements imposed by all sea conditions.

While the basic rules that underpin container ship

structural strength are well established, as ship sizes

increase, new challenges emerge making continued

research into the implications essential. To some

extent, the scales now possible mean we may be

moving beyond the gradual evolution of ship rules

to a revolution in rule development.

Our understanding of container ship

structures addresses the critical challenges

and identifes the ships at risk

Lloyds Registers research on large container

ships has been ongoing over the past decade and

includes a full-scale measurement programme

conducted over fve years on a large container ship.

This research has helped to identify the challenges

faced by builders and operators of such ships

and ensure that the ships structures are properly

designed and remain within acceptable limits

throughout their operational lives. More generally,

Lloyd Registers research and operational experience

has provided the tools to properly and effectively

assess the forces involved in large container ship

operation and thereby provide the appropriate

rules and guidance.

New container ship rules based on extensive

research and operational experience

Lloyds Registers 2014 container ship rules have

had major revisions, which explicitly address the

principal design challenges mentioned above.

Effective Rules, supported by a new

Procedure for ships at risk

Lloyds Registers updated Container ship Rules

came into effect in July 2014. These are supported

by the development of new Lloyds Register

ShipRight Procedures covering whipping and

springing for ships at risk.

This means that when ships are built to Lloyd

Registers Rules there is a mandate to follow the

ShipRight Procedure.

For the bigger picture on the risks and solutions

involved in building large container ships, ask

Lloyds Register for a meeting.

Guidance notes on the

assessment of global

design loads of large

container ships and

other ships prone to

whipping and springing

www.lr.org/horizons www.lr.org/horizons

Horizons September 2014

16 17

Container ship technology

Lloyds Registers growth in Germany has very

much mirrored the success of the German

economy. A period of continued expansion has

meant we needed to fnd larger premises to

house our growing team at our Hamburg head

offce. The result is a grand suite of offces in

the 23-storey HTC (Hanseatic Trade Centre)

tower overlooking the port of Hamburg.

In this special SMM issue, we introduce the key

members of our Hamburg management team and

interview two specialists in their twenties and what

they have to say about shipping both present

and future. So sit back and enjoy this German

supplement and the cross-section of stories we have

produced for you about German companies making

a difference in their respective sectors.

The Hamburg team is headed by Jrgen Gerdes,

Marine Business Development Manager for the

Central and East European Area (CEA), with Thomas

Aschert, Marine Operations Manager (CEA), and

Robert Sluijter, Area General Manager and Area

Financial Controller (CEA).

Jrgen is responsible for Consultancy, Marketing

and PR as well as New Construction, Fleet Services

and Marine Business Development. He moved to

Moin Moin Hamburg

LR in May after more than 20 years with Wartsla,

latterly as a Strategic Account Manager responsible

for VIP clients and energy effciency challenges

in shipping. He also created the idea of selective

turbocharger cut-off for main propulsion engines.

Thomas is in charge of the Marine Operational

Field and Technical Support Staff at the Hamburg

Technical Support Offce (TSO), Marine Management

Systems and the Marine Operational Support Offce

in CEA; while Robert has overall responsibility for

Finance and Shared Services in CEA.

The other key members of the team are: Steffen

Gau, New Construction Business Development

Manager; Jrg Hnig, In-Service Fleet Manager;

Uwe Bollwinkel, Yachts & Naval Segment Manager;

Denis Bauer, Area Financial Planning & Analysis

Manager (Marine); Will Andreas-Dagobert,

Communications and Marketing Manager; Claudia

Ohlendorf, Contract Manager for the Business

Development Department; Jrgen Rischmann,

Deputy for Marine Field Operations; Michael Pohl,

Senior Surveyor in Charge; Brit Ewerlin, Head of

Marine Operational Support Offce; Manuel Ortuno,

Technical Support Offce Manager.

Jrgen Gerdes (centre)

Marine Business

Development Manager

(CEA)

Thomas Aschert (left)

Marine Operations Manager

(CEA)

Robert Sluijter (right)

Area General Manager and

Area Financial Controller

(CEA)

Meet the team

We profle the LR team in Germany and success stories in German

shipping from innovations in the dry bulk sector to German

shipbuilding and design and new methods of ship management plus

some exciting developments in the yachting industry

Steffen Gau, New

Construction Business

Development Manager

Jrg Hnig, In-Service

Fleet Manager

Uwe Bollwinkel, Yachts

& Naval Segment

Manager

Denis Bauer, Area

Financial Planning &

Analysis Manager (Marine)

Will Andreas-Dagobert,

Communications and

Marketing Manager

Claudia Ohlendorf,

Contract Manager for the

Business Development

Department

Jrgen Rischmann,

Deputy for Marine Field

Operations

Michael Pohl, Senior

Surveyor in Charge

Brit Ewerlin, Head of

Marine Operational

Support Offce

Manuel Ortuno,

Technical Support Offce

Manager

www.lr.org/horizons www.lr.org/horizons

Horizons September 2014

18 19

The German team

Three qualities stand out above all others in the

six years Dietmar Bondzio has spent at Lloyds

Register. They are, he says, The variety of work,

the opportunity to see different parts of the marine

industry and working with a lot of enthusiastic and

spirited people.

Dietmar joined LR Hamburg in 2008 after

gaining a degree in electronic engineering from

Hamburg University of Applied Sciences and

the Nordakademie Elmshorn and working with

electrical power distribution and navigation/

communication systems in the marine industry.

As a Senior Specialist for New Construction,

Dietmar is responsible for plan approval, type

approval and occasionally onboard surveys of

newbuilds. In 2011, Dietmar was relocated to

Shanghai where he worked on a variety of ship

types bulk carriers, container ships, MPVs, VLCCs,

chemical tankers, LNG carriers and naval ships

built in local Chinese shipyards.

After a spell back in Germany, Dietmar was

transferred to the Toronto offce to train newly

employed LR surveyors on the techniques and

application of electro-technical systems. Just

as I have developed my career at LR, I get great

satisfaction from helping other surveyors evolve their

careers and improve their decision-making ability and

judgement based on sound technical knowledge.

I get great satisfaction from

helping other surveyors

evolve their careers.

Dietmar Bondzio

Senior Specialist for

New Construction

Dietmar moved back to Shanghai for a second

spell working in the technical support offce in the

summer. The LR staff in China work extremely hard

and effciently and its a pleasure for me to work

with this team again.

Working at LR has given me the scope and

freedom to develop different interests and to move

into new felds of engineering plus of course the

technical know-how gained from working with

German manufacturers, adds Dietmar.

Sara Baftechi has worked as a Technical Support

Offce Specialist at Lloyds Registers Hamburg offce

for the past fve years. She is mainly involved in the

appraisal of offshore cranes and lifting appliances

which I fnd very challenging, particularly with the

emphasis on safety in the offshore sector, she says.

Although the equipment we inspect has already

been appraised by a team of engineers, we are like

a second pair of eyes to make sure everything is in

its place and to check for areas of improvement.

Some appliances are straightforward, some are not

and each project has its own challenges, Sara says.

Sara originally joined the Hamburg offce on

a three-month contract. I really liked the

atmosphere of the city and the general German

working environment. Also my Lloyds Register

colleagues were very supportive and I found the

work very rewarding, so when a job offer came up

in Hamburg I decided to take it, says Sara who

originally joined Martec in Canada in 2008 as a

trainee shortly before it was bought by LR.

Since I have been in Hamburg I have watched the

offce grow from fve employees to 11 or 12 and the

work continues to get busier and busier, she says.

I fnd that working in a mainly mans world, is

a question of confdence and acceptance and

defnitely not competence! Thankfully more and

more women are entering this feld and in the

Hamburg offce over the past fve years the number

of women in the technical sector has almost tripled

which is a big step forward.

The number of women

in the Technical Support

Offce has almost tripled

in the past fve years.

Sara Baftechi

Specialist at Hamburg

Technical Support Offce

While engineering and the marine business

have traditionally been more of a mans domain,

this tradition is now changing towards a more

homogenous working environment which everyone

will beneft from.

Adds Sara: Working here gives me a real chance to

explore other felds that LR is involved in for the

past 12 months many of my colleagues have been

doing appraisal work on pipe-laying vessels and

seabed installations and I am really keen to develop

my project management skills as well as carrying out

business assurance and consulting work.

Two young LR Hamburg specialists discuss their careers and aspirations with Horizons

Horizons September 2014

20 21

www.lr.org/horizons www.lr.org/horizons

The German team

Jan Scharffetter, Oldendorff Carriers Fleet Manager

Oldendorff Carriers Jan Scharffetter has risen through the ranks

to a senior position with the bulk carrier. Ask him a question about

anything from Capesizes to hopper selfunloaders and hell invariably

know the answer. He shared some of this knowledge with Horizons.

When Fleet Manager Jan Scharffetter joined

Oldendorff Carriers as chief mate on one of

its bulk carriers in 1996 it was a respected

shipping company with an operating outft

based in the north German port city of Lbeck.

However in a very short 18 years Scharffetter has

seen the company grow into one of the worlds

leading dry bulk operators with a feet of 450 to

500 chartered and owned vessels, 18 global offces

and a staff of 2,100. Founded by Egon Oldendorff

in Hamburg in 1921, the company was operating

13 steamships trading in dry bulk by the 1940s and,

after earning a growing reputation as a carrier of

Baltic bulk and forest products, became Germanys

largest bulk shipowner in the 1980s.

Company philosophy

In 1984 Egons son Henning became Oldendorffs

majority shareholder. Five years later he opened a

second offce in Asia and in 1995 started Concept

Carriers, a separate cargo and parcel operation,

merging both companies into Oldendorff Carriers

in 2001. Interestingly, Henning Oldendorff

introduced a philosophy of what he calls bottom-

up management, delegating much of the decision-

making to the employees who work closest to the

companys clients and suppliers and thus creating a

powerful young team.

We continue to use the bottom-up approach so

that everyones views are considered which enables

us to reach decisions very quickly. We also have

open-plan offces to promote the concept of team-

working. We are a very client-oriented company. We

often need to fnd logistical solutions for companies

in transhipment and combine these with our core

business of ocean-freight-carrying, says Scharffetter.

Fleet Manager Scharffetter s career has been as

rapid as Oldendorffs, rising from chief mate to

master and then moving ashore as a superintendent

before being appointed feet manager in 2003. I

have seen many changes since then. We have grown

quickly and been through various fnancial and

organisational exercises till we arrived where we

are today, he tells Horizons.

In 2003 we owned 88 of the ships we controlled,

however between 2006 and 2008 when prices rose

to extraordinarily high levels we took advantage

of the market and sold a lot of them until our feet

of Oldendorff-owned vessels dwindled to about

20 ships. When prices returned to normal levels in

2012 we were willing to invest in ships again. It

was a double-whammy, as both the time was right

and the ships were low-consuming eco-types, says

Scharffetter.

Now Oldendorff has 64 newbuild vessels on order

for delivery between now and 2017 including 24

Newcastlemaxes, 17 ultramaxes, 12 handysize, six

kamsarmax and two transloader vessels. The ships,

some of which are being classed and approved by

Lloyds Register, are being constructed in yards in

China, Korea and Japan. The deliveries will be

evenly spread until 2017 although the peak of the

orders will be delivered in 2015, he says.

The markets have been

very volatile even

though the dry bulk sector

has not been hit as hard as

the containers sector.

Jan Scharffetter

www.lr.org/horizons www.lr.org/horizons

Horizons September 2014

22 23

Oldendorff Carriers

Newbuild orders

Historians will probably trace the frst phase of the

companys recent growth back to 2002, the year

before Scharffetter took over as manager of its

feet. Oldendorff designed and built a foating coal

transhipment terminal in the Gulf of iskenderun in

Turkey aided by two hopper selfunloading units and

two pusher tugs. Around three million tonnes of coal

are discharged annually, mainly from Capesize vessels

from Colombia and South Africa, at the isken terminal

before being shipped to a nearby power station.

Since the isken project, the company has started

transhipment terminals in Guyana, the Arabian Gulf

and Trinidad and operates seven selfunloading bulk

carriers. Oldendorff has its own dedicated team that

oversees the delivery of the correct equipment for

its transhipment clients. Most of these projects are

highly technical as they need specialist technology

and need to respond to a clients varying demands.

If a client needs a special type of transloader the

project department liaises with the newbuildings

section and makes sure it is built and delivered,

says Scharffetter.

Bisect the globe

Just as Oldendorffs transhipment projects are set up

in response to client demand, the bulk carriers offces

which bisect the globe from Singapore to Melbourne

and Vancouver to Cape Town are opened close to

its specialist clients too. We arrange our offces like

satellites so as to be close to our clients and their

specialist needs and interests, says Scharffetter.

With its expansion into new global markets,

Oldendorff recognised the need to forecast

trends and anticipate an often changeable global

economy. So, four years ago the company opened

a specialist unit in Singapore where a team of

14 employees study such felds as global mining

activities, changing weather and sea states,

infrastructure, the global economy and the latest

commodity and dry bulk activities.

What has also been especially important with the

enormous number of rules and regulations that

have been introduced in the shipping industry in

the past few years and the amount of paperwork

we have to deal with on a daily basis is to work very

closely with the main classifcation societies like

Lloyds Register with whom we have a very strong

relationship to make sure we stay on course with

our various activities.

The markets have been very volatile even though

the dry bulk sector has not been hit as hard as the

containers sector. Because of this we have purposely

not burdened ourselves with a lot of expensive ships,

although we have made sure we have our company-

owned feet of vessels as a hedge against market

forces and changes, as well as responding to the needs

of our clients, adds Oldendorffs Fleet Manager.

Sherry Li, LRs Lead Client Relationship Manager,

Hamburg, says: As the dedicated point of contact

for Oldendorff Carriers, LR Germany has been

working together with LR China in providing design

selection, yard selection and design optimisation

support to their special needs for various bulk

carrier newbuilding projects. Currently there

are twelve 64K ultramaxes at CSC Qingshan, six

Kamsarmaxes at Jingling, two 94K transloaders at

Yangzijiang and two 97K eco post-Panamaxes at

JEHI on the orderbook to LR class.

Major surveys

Jrg Hnig, LRs Hamburg-based In-Service

Fleet Manager, says: We have worked with

Oldendorff Carriers for many years and we have

a good relationship with Jan Scharffetter and his

superintendents. We have supported them in the

preparation of major surveys such as class renewal

surveys and also by giving advice in respect of

the implementation of new rule and convention

requirements. Oldendorff Carriers is highly

specialised in the dry bulk business and operation

of bulk carriers so that we too beneft from their

knowledge and experience.

Oldendorff Carriers

ultra-modern HQ in Lbeck

The hybrid selfunloader Alice Oldendorff

discharging at Brooklyn Navy Yard, New York, USA

Lloyds Register has a thriving number of orders for

bulk carriers from German owners. Of a 100-strong

orderbook between July 2012 and June 2014, 73

vessels were bulk carriers or almost three-quarters

of the orders were for German owners to be built

at Chinese, Korean and Japansese shipyards.

Jrg Hnig, LRs In-Service Fleet Manager, Hamburg,

said: We are trying to assist our bulk carrier owners

to cope with the diffcult trading conditions. One

issue is the fexibility of the vessels to carry a wide

range of different cargoes.

We are currently working with one of our clients

on a project to allow their bulk carriers to carry

cargo on deck for which the vessels were not

designed at the new construction stage. Another

project has meanwhile been completed where the

vessels were investigated for sailing on a deeper

draught which ultimately led to an increase in the

vessels deadweight. Both solutions help the owners

make their vessels commercially more attractive and

fexible.

Jan Scharffetter profle

Birthplace: Born in Lbeck in 1963

1996: Joined Oldendorff as chief mate and later master on Panamax

and Handysize vessels

1997: Promoted to superintendent

2003: Appointed to his current position as Fleet Manager

2007: Became a board member of Oldendorff Carriers

Germanys Oldendorff Carriers is one of the

worlds largest dry bulk operators. It controls

a feet of 450-500 chartered and owned ships

ranging from Capesize to Handysize vessels,

reloaders and unloaders. Every year it transports

around 300 million tonnes of raw materials and

semi-fnished products to global ports. Founded

in 1921, it is privately owned by the family

holding company, Egon Oldendorff, and has a

network of 18 offces at key ports and trading

cities throughout the world.

Oldendorffs interests are many and diverse. It is a

leading carrier of steel cargoes and steel products

from aluminium as bars, to industrial metals

and construction materials to windmill towers

and blades. It also carries an extensive range of

drybulk commodities including coal, petcoke and

other minerals, grains and agriproducts, cements,

forest products, scrap, concentrates and fertilisers.

The company specialises in fnding logistical

bulk-carrying solutions for its clients. Since 2002,

it has run transhipment operations in Turkey,

Guyana, Trinidad and the Arabian Gulf, enabling

its clients to use larger ships in shallow waters.

As its website www.oldendorff.com explains:

High ocean transportation costs and increasing

throughput requirements combined with factors

like

draft limited ports, lack of port loading or

unloading facilities and local environmental

restrictions are driving shippers and receivers to

think in terms of tailor-made logistical solutions.

A growing percentage of the Lbeck-

headquartered companys feet is run on index-

based foating charter or bareboat charter

instead of pool employment. Vessels of all sizes

are chartered with the daily rate determined

by the average time charter routes of the

corresponding Baltic indices. Floating charters

offer continuous employment and owners are

able to immediately beneft from market upturns.

Lloyds Register and the German bulk carrier market

Oldendorff Carriers: a company portrait

www.lr.org/horizons www.lr.org/horizons

Horizons September 2014

24 25

Oldendorff Carriers

After many years as a builder of

ro-ro vessels, one of Germanys

main shipyards is moving into a

new sector specialist vessels

starting with a dual-power ferry

for a Scottish owner

FSG delivers hybrid

fuel-saving ferry

Computer-generated image of Loch Seaforth

A new ferry that is faster, 30% more fuel-effcient

and has more environmental features than

its predecessors has been built by Germanys

Flensburger Schiffbau-Gesellschaft (FSG) shipyard

in Flensburg.

The 118-metre-long passenger and vehicle ferry,

Loch Seaforth, which is due to be delivered

this month (September), is another complex

newbuild vessel for the shipyard which after

many years of building ro-ro cargo ships is

focusing on specialist vessels for a growing

international network of owners and operators.

A distinctive aspect of this particular newbuild,

developed jointly between the vessels prospective

owner, Scotland-based Caledonian Maritime Assets

(CMAL), and the shipyard, is its propulsion and

power generation concept.

The ferry is propelled by MAN Diesel & Turbo

controllable-pitch Kappel propellers. As part of the

vessels concept, she can switch to onboard auxiliary

propulsion when at berth or else manoeuvring in

port. The ferry is then powered by a direct diesel-

mechanical drive routed through a shaft generator.

Loch Seaforth, which will carry up to 700 passengers

and 143 cars and 20 commercial vehicles on a 24-

hour axis, can travel at speeds of up to 19.2 knots

almost two knots faster than the two ferries the

new vessel is replacing on the route it will serve

between Stornaway, on the Hebridean Isle of Lewis,

and Ullapool, on the north-west coast of Scotland.

Lloyds Registers Hamburg and Kiel offces have

been involved with the newbuild ferry project from

the outset when the vessel was originally specifed

and planned by CMAL, the Glasgow-based operator,

CalMac Ferries and FSG. Raimon Strunck, FSGs Vice

President (Sales), told Horizons: We approached

Lloyds Register right from the start, in the spring of

2012, parallel to the tendering process and before

the contracts were signed.

www.lr.org/horizons www.lr.org/horizons

Horizons September 2014

26 27

Loch Seaforth

LR helped to supervise the planning of the vessel

and approved the design after we undertook

model testing in Hamburg. The various teams

then studied the sea state of the route the ferry

would be taking between the Isle of Lewis and

the Scottish mainland. We then assessed the

hydrodynamic features the vessel would need

to cope with the wind, waves and swell that it

would face, so as to give it maximum seakeeping

performance on the route.

We also studied the routes changing weather

conditions using our own inhouse simulation tools

and the weather and wave data from the vessels

operator CalMac Ferries. One feature, which is

peculiar to the area that we needed to deal with

at the design stage, was the slamming impact of

the waves as they grow in size off the coast of

Stornoway on the Isle of Lewis. So we devised some

special technology that enables the vessel to pierce

the waves with the aid of fn stabilisers to give

maximum comfort to the onboard passengers at the

same time.

Added Strunck: The ferrys hybrid concept saves

the owner and operator around 30% of their fuel.

One of the many merits of auxiliary power is that

it enables the vessel to provide electricity and air

conditioning in the public areas when passengers

are embarking or disembarking while the vessel is

in port. It also provides onboard power for the crew

and shipyard teams when the vessel is undergoing

maintenance work.

FSGs Vice President (Sales) Raimon Strunck LR Engine Surveyor Michael Naujocks

in the engine room of Loch Seaforth

Specialised vessels

Engine Surveyor Michael Naujoks from Lloyds

Registers Kiel offce said: This has been a very

challenging project especially as the shipyard

is now expanding into specialised vessels and

moving away from their ro-ro cargo ships. The

newbuilding has also been assigned to help update