Académique Documents

Professionnel Documents

Culture Documents

PWM Off-Line Switching Regulator Ics: Str-A6000H Series

Transféré par

Anonymous Lfgk6vygDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PWM Off-Line Switching Regulator Ics: Str-A6000H Series

Transféré par

Anonymous Lfgk6vygDroits d'auteur :

Formats disponibles

SANKEN ELECTRIC CO., LTD.

http://www.sanken-ele.co.jp/en/

Description

The STR-A6059H, STR-A6061H, STR-A6062H, and

STR-A6069H are power ICs for switching power supplies,

incorporating a power MOSFET and a current mode PWM

controller IC in one package.

To achieve low power consumption, these products include

a startup circuit and a standby function in the controller. The

switching modes are automatically changed according to load

conditions: in normal operation, PWM mode, and in light load

conditions, burst mode. The rich set of protection features

helps to realize low component counts, and high performance-

to-cost power supply.

Features and Benefits

Current mode PWM control

Brown-In and Brown-Out function: auto-restart, prevents

excess input current and heat rise at low input voltage

Auto Standby function: improves efficiency by Burst

mode operation in light load

Normal load operation: PWM mode

Light load operation: Burst mode

No load power consumption < 25 mW

Operating frequency, f

OSC(AVG)

(typ) = 100 kHz

Random Switching function: reduces EMI noise, and

simplifies EMI filters

Slope Compensation function: avoids subharmonic

oscillation

Leading Edge Blanking function

PWM Off-Line Switching Regulator ICs

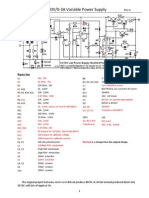

Typical Application Circuit

Not to scale

Continued on the next page

STR-A6000H Series

STR-A6000H-DS January 8, 2013

Applications:

Switching power supplies for electronic devices such as:

Battery charger

Standby power supply

Small switch-mode power supply (SMPS)

Auxiliary power supply for controller

Package: DIP8

VAC

C1

C5 R1

D1

BR1

R2

C2

T1

D

P

PC1

C3

R

OCP C9

CRD clamp snubber

C4

CCR

Dumper snubber

1 2 3 4

D/ST D/ST

BR

NC

S/OCP FB/OLP GND

VCC

8 7 5

STR-A6000

U1

D2

C10

RC

R

B

R

A

D51

C51

R51

R52

U51

R54

R56

C52

S

PC1

R53

R55

L51

C53

VOUT

GND

2

SANKEN ELECTRIC CO., LTD.

STR-A6000H-DS

PWM Off-Line Switching Regulator ICs

STR-A6000H

Series

January 8, 2013

Selection Guide

Part Number

Power MOSFET Output Power*, P

OUT

(W)

V

DSS

(min)

(V)

R

DS(ON)

(max)

()

Open Frame Adaptor

230 VAC

85 to

265 VAC

230 VAC

85 to

265 VAC

STR-A6059H 650 6 30 19 17 11

STR-A6069H 700 6 30 19 17 11

STR-A6061H 700 3.95 35 24 21 15

STR-A6062H 700 2.8 38 26 23 18

*The listed output power is based on the thermal ratings, and the peak output power can be 120% to 140% of the value stated

here. At low output voltage and short duty cycle, the output power may be less than the value stated here.

Features and Benefits (continued)

The polarity value for current specifies a sink as "+," and a source as , referencing the IC.

Absolute Maximum Ratings Unless otherwise specified, T

A

= 25C

Characteristic Symbol Notes Pins Rating Unit

Drain Peak Current

1

I

DPEAK

STR-A6059H

STR-A6069H

Single pulse 8 1

1.8 A

STR-A6061H 2.5 A

STR-A6062H 3.0 A

Avalanche Energy

2

E

AS

STR-A6059H

STR-A6069H

Single pulse, V

DD

= 99 V,

L = 20 mH, I

LPEAK

= 1.8 A

8 1

24 mJ

STR-A6061H

Single pulse, V

DD

= 99 V,

L = 20 mH, I

LPEAK

= 2 A

46 mJ

STR-A6062H

Single pulse, V

DD

= 99 V,

L = 20 mH, I

LPEAK

= 2.2 A

56 mJ

S/OCP Pin Voltage V

OCP

1 3 2 to 6 V

Control Part Input Voltage V

CC

5 3 32 V

FB/OLP Pin Voltage V

FB

4 3 0.3 to 14 V

FB/OLP Pin Sink Current I

FB

4 3 1.0 mA

BR Pin Voltage V

BR

2 3 0.3 to 7 V

BR Pin Sink Current I

BR

2 3 1.0 mA

Power Dissipation of MOSFET

3

P

D1

Mounted on 15 mm 15 mm printed circuit board 8 1 1.35 W

Power Dissipation of Control Part P

D2

5 3 1.2 W

Operating Ambient Temperature

4

T

OP

20 to 125 C

Storage Temperature T

stg

40 to 125 C

Channel Temperature T

ch

150 C

1

Refer to MOSFET Safe Operating Area Curve.

2

Refer to MOSFET Avalanche Energy Derating Coefficient Curve.

3

Refer to MOSFET Temperature versus Power Dissipation Curve.

4

The recommended internal frame temperature, T

F

, is 115C (max).

Audible Noise Suppression function during Standby mode

Protection features

Overcurrent protection (OCP): pulse-by-pulse,

with input compensation function

Overvoltage protection (OVP): latched shutdown

Overload protection (OLP): auto-restart, with timer

Thermal shutdown protection (TSD): latched shutdown

3

SANKEN ELECTRIC CO., LTD.

STR-A6000H-DS

PWM Off-Line Switching Regulator ICs

STR-A6000H

Series

January 8, 2013

Electrical Characteristics of Control Part Unless otherwise specified, T

A

= 25C, V

CC

= 18 V

Characteristic Symbol Test Conditions Pins Min. Typ. Max. Unit

Operation Start Voltage V

CC(ON)

5 3 13.8 15.3 16.8 V

Operation Stop Voltage

1

V

CC(OFF)

5 3 7.3 8.1 8.9 V

Circuit Current in Operation I

CC(ON)

V

CC

= 12 V 5 3 2.5 mA

Minimum Start Voltage V

ST(ON)

5 3 38 V

Startup Current I

STARTUP

V

CC

= 13.5 V 5 3 3.7 2.5 1.5 mA

Startup Current Threshold Biasing Voltage

1

V

CC(BIAS)

I

CC

= 100 A 5 3 8.5 9.5 10.5 V

Average Operation Frequency f

OSC(AVG)

8 3 90 100 110 kHz

Frequency Modulation Deviation f 8 3 8 kHz

Maximum Duty Cycle D

MAX

8 3 77 83 89 %

Minimum On-Time t

ON(MIN)

470 ns

Leading Edge Blanking Time t

BW

280 ns

OCP Compensation Coefficient DPC 33 mV/s

OCP Compensation Duty Cycle Limit D

DPC

36 %

OCP Threshold Voltage at Zero Duty Cycle V

OCP(L)

1 3 0.70 0.78 0.86 V

OCP Threshold Voltage at 36% Duty Cycle V

OCP(H)

V

CC

= 32 V 1 3 0.81 0.9 0.99 V

Maximum Feedback Current I

FB(MAX)

V

CC

= 12 V 4 3 340 230 150 A

Minimum Feedback Current I

FB(MIN)

4 3 30 15 7 A

FB/OLP Pin Oscillation Stop Threshold

Voltage

V

FB(STB)

4 3 0.85 0.95 1.05 V

OLP Threshold Voltage V

FB(OLP)

4 3 7.3 8.1 8.9 V

OLP Delay Time t

OLP

4 3 54 68 82 ms

OLP Operation Current I

CC(OLP)

V

CC

= 12 V 5 3 300 600 A

FB/OLP Pin Clamp Voltage V

FB(CLAMP)

4 3 11 12.8 14 V

Brown-In Threshold Voltage V

BR(IN)

V

CC

= 32 V 2 3 5.2 5.6 6 V

Brown-Out Threshold Voltage V

BR(OUT)

V

CC

= 32 V 2 3 4.45 4.8 5.15 V

BR Pin Clamp Voltage V

BR(CLAMP)

V

CC

= 32 V 2 3 6 6.4 7 V

BR Function Disabling Threshold Voltage V

BR(DIS)

V

CC

= 32 V 2 3 0.3 0.48 0.7 V

VCC Pin OVP Threshold Voltage V

CC(OVP)

5 3 26 29 32 V

Latch Circuits Holding Current

2

I

CC(LATCH)

V

CC

= 9.5 V 5 3 700 A

Thermal Shutdown Temperature T

j(TSD)

135 C

1

V

CC(BIAS)

> V

CC(OFF)

always.

2

A latch circuit is a circuit operated with Overvoltage Protection (OVP) and/or Thermal Shutdown Protection (TSD) in operation.

4

SANKEN ELECTRIC CO., LTD.

STR-A6000H-DS

PWM Off-Line Switching Regulator ICs

STR-A6000H

Series

January 8, 2013

Electrical Characteristics of MOSFET Unless otherwise specified, T

A

is 25C

Characteristic Symbol Test Conditions Pins Min. Typ. Max. Unit

Drain-to-Source Breakdown Voltage V

DSS

STR-A6059H

8 1

650 V

STR-A6061H

STR-A6062H

STR-A6069H

700 V

Drain Leakage Current I

DSS

8 1 300 A

On-Resistance R

DS(ON)

STR-A6059H

STR-A6069H

8 1

6

STR-A6061H 3.95

STR-A6062H 2.8

Switching Time t

f

8 1 250 ns

Thermal Resistance R

ch-C

The thermal resistance between

the channels of the MOSFET and

the case. Case temperature, T

C

, is

measured at the center of the case

top surface.

22 C/W

5

SANKEN ELECTRIC CO., LTD.

STR-A6000H-DS

PWM Off-Line Switching Regulator ICs

STR-A6000H

Series

January 8, 2013

Time (s)

10

1

0.1

0.01

10

-6

10

-5

10

-4

10

-3

10

-2

10

-1

T

r

a

n

s

i

e

n

t

T

h

e

r

m

a

l

R

e

s

i

s

t

a

n

c

e

,

R

c

h

-

c

(

C

/

W

)

Transient Thermal Resistance Curve

Ambient Temperature, T

A

(C)

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

0 20 40 60 80 120 100 160 140

A

l

l

o

w

a

b

l

e

P

o

w

e

r

D

i

s

s

i

p

a

t

i

o

n

,

P

D

1

(

W

)

MOSFET Temperature versus Power Dissipation Curve

P

D1

= 1.35 W

Channel Temperature, T

ch

(C)

100

80

60

40

20

0

25 50 75 125 100 150

E

A

S

T

e

m

p

e

r

a

t

u

r

e

D

e

r

a

t

i

n

g

C

o

e

f

f

i

c

i

e

n

t

(

%

)

MOSFET Avalanche Energy Derating Coefficient Curve

Drain-to-Source Voltage, V

DS

(V)

10

1

0.1

0.01

1 10 100 1000

D

r

a

i

n

C

u

r

r

e

n

t

,

I

D

(

A

)

MOSFET Safe Operating Area Curve

Drain current limited

by on-resistance

T

A

= 25C

Single Pulse

To use this graph, apply the S.O.A

temperature derating coefficient

taken from the graph at the left

1 ms

0.1 ms

Channel Temperature, T

ch

(C)

100

80

60

40

20

0

0 25 50 75 100 125 150

S

a

f

e

O

p

e

r

a

t

i

n

g

A

r

e

a

T

e

m

p

e

r

a

t

u

r

e

D

e

r

a

t

i

n

g

C

o

e

f

f

i

c

i

e

n

t

(

%

)

S. O. A. Temperature Derating Coefficient Curve

Characteristic Performance

STR-A6059H

6

SANKEN ELECTRIC CO., LTD.

STR-A6000H-DS

PWM Off-Line Switching Regulator ICs

STR-A6000H

Series

January 8, 2013

Time (s)

10

1

0.1

0.01

10

-6

10

-5

10

-4

10

-3

10

-2

10

-1

T

r

a

n

s

i

e

n

t

T

h

e

r

m

a

l

R

e

s

i

s

t

a

n

c

e

,

R

c

h

-

c

(

C

/

W

)

Transient Thermal Resistance Curve

Ambient Temperature, T

A

(C)

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

0 20 40 60 80 120 100 160 140

A

l

l

o

w

a

b

l

e

P

o

w

e

r

D

i

s

s

i

p

a

t

i

o

n

,

P

D

1

(

W

)

MOSFET Temperature versus Power Dissipation Curve

P

D1

= 1.35 W

Channel Temperature, T

ch

(C)

100

80

60

40

20

0

25 50 75 125 100 150

E

A

S

T

e

m

p

e

r

a

t

u

r

e

D

e

r

a

t

i

n

g

C

o

e

f

f

i

c

i

e

n

t

(

%

)

MOSFET Avalanche Energy Derating Coefficient Curve

Drain-to-Source Voltage, V

DS

(V)

10

1

0.1

0.01

1 10 100 1000

D

r

a

i

n

C

u

r

r

e

n

t

,

I

D

(

A

)

MOSFET Safe Operating Area Curve

Drain current limited

by on-resistance

T

A

= 25C

Single Pulse

To use this graph, apply the S.O.A

temperature derating coefficient

taken from the graph at the left

1 ms

0.1 ms

Channel Temperature, T

ch

(C)

100

80

60

40

20

0

0 25 50 75 100 125 150

S

a

f

e

O

p

e

r

a

t

i

n

g

A

r

e

a

T

e

m

p

e

r

a

t

u

r

e

D

e

r

a

t

i

n

g

C

o

e

f

f

i

c

i

e

n

t

(

%

)

S. O. A. Temperature Derating Coefficient Curve

Characteristic Performance

STR-A6061H

7

SANKEN ELECTRIC CO., LTD.

STR-A6000H-DS

PWM Off-Line Switching Regulator ICs

STR-A6000H

Series

January 8, 2013

Time (s)

10

1

0.1

0.01

10

-6

10

-5

10

-4

10

-3

10

-2

10

-1

T

r

a

n

s

i

e

n

t

T

h

e

r

m

a

l

R

e

s

i

s

t

a

n

c

e

,

R

c

h

-

c

(

C

/

W

)

Transient Thermal Resistance Curve

Ambient Temperature, T

A

(C)

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

0 20 40 60 80 120 100 160 140

A

l

l

o

w

a

b

l

e

P

o

w

e

r

D

i

s

s

i

p

a

t

i

o

n

,

P

D

1

(

W

)

MOSFET Temperature versus Power Dissipation Curve

P

D1

= 1.35 W

Channel Temperature, T

ch

(C)

100

80

60

40

20

0

25 50 75 125 100 150

E

A

S

T

e

m

p

e

r

a

t

u

r

e

D

e

r

a

t

i

n

g

C

o

e

f

f

i

c

i

e

n

t

(

%

)

MOSFET Avalanche Energy Derating Coefficient Curve

Drain-to-Source Voltage, V

DS

(V)

10

1

0.1

0.01

1 10 100 1000

D

r

a

i

n

C

u

r

r

e

n

t

,

I

D

(

A

)

MOSFET Safe Operating Area Curve

Drain current limited

by on-resistance

T

A

= 25C

Single Pulse

To use this graph, apply the S.O.A

temperature derating coefficient

taken from the graph at the left

1 ms

0.1 ms

Channel Temperature, T

ch

(C)

100

80

60

40

20

0

0 25 50 75 100 125 150

S

a

f

e

O

p

e

r

a

t

i

n

g

A

r

e

a

T

e

m

p

e

r

a

t

u

r

e

D

e

r

a

t

i

n

g

C

o

e

f

f

i

c

i

e

n

t

(

%

)

S. O. A. Temperature Derating Coefficient Curve

Characteristic Performance

STR-A6062H

8

SANKEN ELECTRIC CO., LTD.

STR-A6000H-DS

PWM Off-Line Switching Regulator ICs

STR-A6000H

Series

January 8, 2013

Time (s)

10

1

0.1

0.01

10

-6

10

-5

10

-4

10

-3

10

-2

10

-1

T

r

a

n

s

i

e

n

t

T

h

e

r

m

a

l

R

e

s

i

s

t

a

n

c

e

,

R

c

h

-

c

(

C

/

W

)

Transient Thermal Resistance Curve

Ambient Temperature, T

A

(C)

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

0 20 40 60 80 120 100 160 140

A

l

l

o

w

a

b

l

e

P

o

w

e

r

D

i

s

s

i

p

a

t

i

o

n

,

P

D

1

(

W

)

MOSFET Temperature versus Power Dissipation Curve

P

D1

= 1.35 W

Channel Temperature, T

ch

(C)

100

80

60

40

20

0

25 50 75 125 100 150

E

A

S

T

e

m

p

e

r

a

t

u

r

e

D

e

r

a

t

i

n

g

C

o

e

f

f

i

c

i

e

n

t

(

%

)

MOSFET Avalanche Energy Derating Coefficient Curve

Drain-to-Source Voltage, V

DS

(V)

10

1

0.1

0.01

1 10 100 1000

D

r

a

i

n

C

u

r

r

e

n

t

,

I

D

(

A

)

MOSFET Safe Operating Area Curve

Drain current limited

by on-resistance

T

A

= 25C

Single Pulse

To use this graph, apply the S.O.A

temperature derating coefficient

taken from the graph at the left

1 ms

0.1 ms

Channel Temperature, T

ch

(C)

100

80

60

40

20

0

0 25 50 75 100 125 150

S

a

f

e

O

p

e

r

a

t

i

n

g

A

r

e

a

T

e

m

p

e

r

a

t

u

r

e

D

e

r

a

t

i

n

g

C

o

e

f

f

i

c

i

e

n

t

(

%

)

S. O. A. Temperature Derating Coefficient Curve

Characteristic Performance

STR-A6069H

9

SANKEN ELECTRIC CO., LTD.

STR-A6000H-DS

PWM Off-Line Switching Regulator ICs

STR-A6000H

Series

January 8, 2013

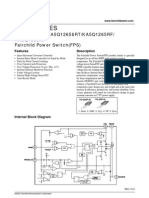

D/ST VCC

5

2

4

S/OCP

FB/OLP

GND

BR

DRV

PWM OSC

REG

SQ

R

Slope

Compensation

6.4 V

V

REG

Feedback

Control

OCP

Drain Peak Current

Compensation

7 V

12.8 V

V

CC

LEB

OLP

OVP TSD

Startup

UVLO

Brown-In/

Brown-Out

7,8

1

3

Functional Block Diagram

1

2

3

4

8

7

5

D/ST

D/ST

VCC

S/OCP

BR

GND

FB/OLP

Pin-out Diagram

Pin List Table

Number Name Function

1 S/OCP MOSFET source, and input for Overcurrent Protection (OCP) signal

2 BR Input for Brown-In and Brown-Out detection voltage

3 GND Ground

4 FB/OLP

Feedback signal input for constant voltage control signal, and input of Overload

Protection (OLP) signal

5 VCC

Power supply voltage input for Control Part and input of Overvoltage Protection

(OVP) signal

6 (Pin removed)

7, 8 D/ST MOSFET drain, and input of the startup current

10

SANKEN ELECTRIC CO., LTD.

STR-A6000H-DS

PWM Off-Line Switching Regulator ICs

STR-A6000H

Series

January 8, 2013

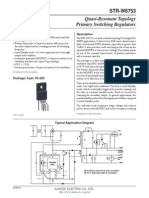

VAC

C1

C5 R1

D1

BR1

R2

C2

T1

D

P

PC1

C3

ROCP C9

CRD clamp snubber

C4

CCR

Dumper snubber

1 2 3 4

D/ST D/ST

BR

NC

S/OCP FB/OLP GND

VCC

8 7 5

STR-A6000

U1

D2

C10

RC

RB

RA

D51

C51

R51

R52

U51

R54

R56

C52

S

PC1

R53

R55

L51

C53

VOUT

GND

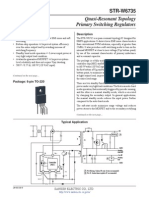

VAC

C1

C5 R1

D1

BR1

R2

C2

T1

D

P

PC1

C3

ROCP

C9

CRD clamp snubber

C4

CCR

Dumper snubber

1 2 3 4

D/ST D/ST

BR

NC

S/OCP FB/OLP GND

VCC

8 7 5

STR-A6000

U1

D2

D51

C51

R51

R52

U51

R54

R56

C52

S

PC1

R53

R55

L51

C53

VOUT

GND

Typical Application Circuits

Typical application circuit example, enabled Brown-In/Brown-Out function (DC line detection)

Typical application circuit example, disabled Brown-In/Brown-Out function

11

SANKEN ELECTRIC CO., LTD.

STR-A6000H-DS

PWM Off-Line Switching Regulator ICs

STR-A6000H

Series

January 8, 2013

0.2

5

+

0.1

-

0

.0

5

6

.

5

1 4

5 8

9.4 0.3

0.5 0.1 0.89 TYP

4

.

2

0

.

3

3

.

3

3

.

4

0

.

1

0

.

2

(7.6 TYP)

2.54 TYP

-0.05 -0.05

0

.

2

0

.

5

7

.

5

+0.3 +0.3

1.0

1.52

Unitmm

Part Number

Lot Number

Sanken Control Number

A60xxH

SK YMD

Y is the last digit of the year (0 to 9)

M is the month (1 to 9, O, N, or D)

D is a period of days (1 to 3):

1 1

st

to 10

th

2 11

th

to 20

th

3 21

st

to 31

st

8

1

Package Diagram

Device composition compliant with the RoHS directive.

DIP8 package

The following show a representative type of DIP8.

The pin 6 is removed to provide greater creepage and clearance isolation between the high

voltage pins (pins 7 and 8: D/ST) and the low voltage pin (pin 5: VCC).

12

SANKEN ELECTRIC CO., LTD.

STR-A6000H-DS

PWM Off-Line Switching Regulator ICs

STR-A6000H

Series

January 8, 2013

Operating Precautions

In the case that you use Sanken products or design your prod-

ucts by using Sanken products, the reliability largely depends

on the degree of derating to be made to the rated values. Derat-

ing may be interpreted as a case that an operation range is set

by derating the load from each rated value or surge voltage or

noise is considered for derating in order to assure or improve

the reliability. In general, derating factors include electric

stresses such as electric voltage, electric current, electric power

etc., environmental stresses such as ambient temperature,

humidity etc. and thermal stress caused due to self-heating of

semiconductor products. For these stresses, instantaneous val-

ues, maximum values and minimum values must be taken into

consideration. In addition, it should be noted that since power

devices or ICs including power devices have large self-heating

value, the degree of derating of junction temperature affects the

reliability significantly.

Because reliability can be affected adversely by improper stor-

age environments and handling methods, please observe the

following cautions.

Cautions for Storage

Ensure that storage conditions comply with the standard tem-

perature (5 to 35C) and the standard relative humidity (around

40 to 75%); avoid storage locations that experience extreme

changes in temperature or humidity.

Avoid locations where dust or harmful gases are present and

avoid direct sunlight.

Reinspect for rust on leads and solderability of the products

that have been stored for a long time.

Cautions for Testing and Handling

When tests are carried out during inspection testing and other

standard test periods, protect the products from power surges

from the testing device, shorts between the product pins, and

wrong connections. Ensure all test parameters are within the

ratings specified by Sanken for the products.

Remarks About Using Silicone Grease with a Heatsink

When silicone grease is used in mounting the products on a

heatsink, it shall be applied evenly and thinly. If more silicone

grease than required is applied, it may produce excess stress.

Volatile-type silicone greases may crack after long periods of

time, resulting in reduced heat radiation effect. Silicone greases

with low consistency (hard grease) may cause cracks in the

mold resin when screwing the products to a heatsink.

Our recommended silicone greases for heat radiation purposes,

which will not cause any adverse effect on the product life, are

indicated below:

Type Suppliers

G746 Shin-Etsu Chemical Co., Ltd.

YG6260 Momentive Performance Materials Inc.

SC102 Dow Corning Toray Co., Ltd.

Soldering

When soldering the products, please be sure to minimize the

working time, within the following limits:

260 5 C 10 1 s (Flow, 2 times)

380 10 C 3.5 0.5 s (Soldering iron, 1 time)

Soldering should be at a distance of at least 1.5 mm from the

body of the products.

Electrostatic Discharge

When handling the products, the operator must be grounded.

Grounded wrist straps worn should have at least 1M of resis-

tance from the operator to ground to prevent shock hazard, and

it should be placed near the operator.

Workbenches where the products are handled should be

grounded and be provided with conductive table and floor mats.

When using measuring equipment such as a curve tracer, the

equipment should be grounded.

When soldering the products, the head of soldering irons or

the solder bath must be grounded in order to prevent leak volt-

ages generated by them from being applied to the products.

The products should always be stored and transported in

Sanken shipping containers or conductive containers, or be

wrapped in aluminum foil.

13

SANKEN ELECTRIC CO., LTD.

STR-A6000H-DS

PWM Off-Line Switching Regulator ICs

STR-A6000H

Series

January 8, 2013

The contents in this document are subject to changes, for improvement and other purposes, without notice. Make sure that this is the

latest revision of the document before use.

Application and operation examples described in this document are quoted for the sole purpose of reference for the use of the prod-

ucts herein and Sanken can assume no responsibility for any infringement of industrial property rights, intellectual property rights or

any other rights of Sanken or any third party which may result from its use. Unless otherwise agreed in writing by Sanken, Sanken

makes no warranties of any kind, whether express or implied, as to the products, including product merchantability, and fitness for a

particular purpose and special environment, and the information, including its accuracy, usefulness, and reliability, included in this

document.

Although Sanken undertakes to enhance the quality and reliability of its products, the occurrence of failure and defect of semicon-

ductor products at a certain rate is inevitable. Users of Sanken products are requested to take, at their own risk, preventative measures

including safety design of the equipment or systems against any possible injury, death, fires or damages to the society due to device

failure or malfunction.

Sanken products listed in this document are designed and intended for the use as components in general purpose electronic equip-

ment or apparatus (home appliances, office equipment, telecommunication equipment, measuring equipment, etc.).

When considering the use of Sanken products in the applications where higher reliability is required (transportation equipment and

its control systems, traffic signal control systems or equipment, fire/crime alarm systems, various safety devices, etc.), and whenever

long life expectancy is required even in general purpose electronic equipment or apparatus, please contact your nearest Sanken sales

representative to discuss, prior to the use of the products herein.

The use of Sanken products without the written consent of Sanken in the applications where extremely high reliability is required

(aerospace equipment, nuclear power control systems, life support systems, etc.) is strictly prohibited.

When using the products specified herein by either (i) combining other products or materials therewith or (ii) physically, chemically

or otherwise processing or treating the products, please duly consider all possible risks that may result from all such uses in advance

and proceed therewith at your own responsibility.

Anti radioactive ray design is not considered for the products listed herein.

Sanken assumes no responsibility for any troubles, such as dropping products caused during transportation out of Sankens distribu-

tion network.

The contents in this document must not be transcribed or copied without Sankens written consent.

IMPORTANT NOTES

Vous aimerez peut-être aussi

- Switch Mode Power Supply (SMPS) Topologies (Part II)Document108 pagesSwitch Mode Power Supply (SMPS) Topologies (Part II)Willie WalkerPas encore d'évaluation

- 7cw SMD Mmbt2222a - NXPDocument8 pages7cw SMD Mmbt2222a - NXPnikkoninPas encore d'évaluation

- Transformerless Power SupplyDocument3 pagesTransformerless Power SupplyRafael Vazquez VillamarPas encore d'évaluation

- UOC III 21 G-III Chassis Service ManualDocument33 pagesUOC III 21 G-III Chassis Service ManualAlexandra BarzaianuPas encore d'évaluation

- Ac Voltage Controller Using Thyristor Project Report by SandeepDocument29 pagesAc Voltage Controller Using Thyristor Project Report by SandeepSANDEEP DHANDA100% (1)

- การติดตั้งแผงโซล่าเซลล์ในบ้านรุปแบบวิธีการและเอกสารDocument39 pagesการติดตั้งแผงโซล่าเซลล์ในบ้านรุปแบบวิธีการและเอกสารChanade WichasilpPas encore d'évaluation

- How An Smps Works: Rectifier StageDocument7 pagesHow An Smps Works: Rectifier StageImran AshrafPas encore d'évaluation

- Review of a simple adjustable power supply using linear and switching componentsDocument4 pagesReview of a simple adjustable power supply using linear and switching componentsramesh ranjitPas encore d'évaluation

- Report On Power SupplyDocument16 pagesReport On Power SupplyKshitij GuptaPas encore d'évaluation

- LM2480NADocument5 pagesLM2480NAFranklin JimenezPas encore d'évaluation

- IR2110 Squarewave Inverter Using 555 TimerDocument37 pagesIR2110 Squarewave Inverter Using 555 TimerКети ТаневскаPas encore d'évaluation

- Service Manual - LG Monitor - 500E-G - Chassis CA-133Document32 pagesService Manual - LG Monitor - 500E-G - Chassis CA-133Juan Carlos Sanchez Flores100% (1)

- Control IC For Single-Ended and Push-Pull Switched-Mode Power Supplies (SMPS) TDA 4718 ADocument17 pagesControl IC For Single-Ended and Push-Pull Switched-Mode Power Supplies (SMPS) TDA 4718 ASledge HammerPas encore d'évaluation

- 02A Lesson Proper For Week 7Document9 pages02A Lesson Proper For Week 7Maxela CastroPas encore d'évaluation

- Datasheet DMO565RDocument21 pagesDatasheet DMO565RSteve Bravo83% (6)

- Regulated Power Supply1Document4 pagesRegulated Power Supply1hamed razaPas encore d'évaluation

- Sanyo Avm2751s Service ManualDocument26 pagesSanyo Avm2751s Service ManualKastaliaPas encore d'évaluation

- Chapter 8. Switched-Inductor Supplies With Design Insight and Intuition (Power IC Design)Document29 pagesChapter 8. Switched-Inductor Supplies With Design Insight and Intuition (Power IC Design)Minh Hai RungPas encore d'évaluation

- Tcon V320Document32 pagesTcon V320CARLOS EDUARDO BASTIDAS BERRIOSPas encore d'évaluation

- Schematic Diagram of MC-418 TV ReceiverDocument1 pageSchematic Diagram of MC-418 TV ReceiverEduard Dorneanu100% (1)

- Switch Mode Power Supply Topologies Compared - Wurth Electronics MidcomDocument4 pagesSwitch Mode Power Supply Topologies Compared - Wurth Electronics Midcommayank shuklaPas encore d'évaluation

- Max 17126Document34 pagesMax 17126918329078250% (2)

- BN44-00554B PD32GV0Document3 pagesBN44-00554B PD32GV0Devorador De PecadosPas encore d'évaluation

- LG Eay62609701 Pspi-L103aDocument23 pagesLG Eay62609701 Pspi-L103aIvanilto Martins da Cruz100% (1)

- Modified 0-30V - 0-3A Variable Power Supply - Rev.2Document2 pagesModified 0-30V - 0-3A Variable Power Supply - Rev.2Manuel Cereijo NeiraPas encore d'évaluation

- Nikkai 800W Inverter Repair ReportDocument4 pagesNikkai 800W Inverter Repair ReportRichard SmithPas encore d'évaluation

- Power SupplyDocument9 pagesPower SupplyMuhammed HuzaifaPas encore d'évaluation

- Design: IdeasDocument6 pagesDesign: IdeasSamantha EwingPas encore d'évaluation

- Pure Sine Invereter InfoDocument107 pagesPure Sine Invereter Infoolawale gbadeboPas encore d'évaluation

- TV Sanyo Cm29af8x (La76818)Document34 pagesTV Sanyo Cm29af8x (La76818)deimos1Pas encore d'évaluation

- Service Manual: Multi Channel Av ReceiverDocument78 pagesService Manual: Multi Channel Av Receivermarcelo vintagePas encore d'évaluation

- 5Q1265RFDocument16 pages5Q1265RFAron Indra Lezcano GalvezPas encore d'évaluation

- Articolo SWR EngDocument4 pagesArticolo SWR EngLuis Enrique Castillejo GonzalesPas encore d'évaluation

- Digital Modified Sine Wave Inverter CircuitDocument6 pagesDigital Modified Sine Wave Inverter CircuitMaster RajaPas encore d'évaluation

- DC BRUSHLESS DRIVER BLDC-5015A manualDocument5 pagesDC BRUSHLESS DRIVER BLDC-5015A manualroozbehxoxPas encore d'évaluation

- SMD Resistor Code Calculator: How To Calculate The Value of An SMD ResistorDocument6 pagesSMD Resistor Code Calculator: How To Calculate The Value of An SMD ResistorBeskaria SmbPas encore d'évaluation

- Microcontroller Based Solar Charge Controller ProjectDocument5 pagesMicrocontroller Based Solar Charge Controller ProjectAbir AhmedPas encore d'évaluation

- 1 SamsungDocument106 pages1 SamsungBeni GiurgiuPas encore d'évaluation

- SCR 1 70 Amperes DatasheetDocument12 pagesSCR 1 70 Amperes DatasheetJose Antonio Guadiana SánchezPas encore d'évaluation

- Digital Phase Selector: A Mini-Project Report Submitted in Partial Fulfillment Requirements For The Award ofDocument53 pagesDigital Phase Selector: A Mini-Project Report Submitted in Partial Fulfillment Requirements For The Award ofdondbPas encore d'évaluation

- Sony KDL-60W610B - RB2G 9-888-602-01 PDFDocument27 pagesSony KDL-60W610B - RB2G 9-888-602-01 PDFIDGG2011Pas encore d'évaluation

- Vestel 17mb62-1 SCHDocument9 pagesVestel 17mb62-1 SCHb.nedelkov100% (2)

- LCD Display Troubleshooting ManualDocument54 pagesLCD Display Troubleshooting Manualjl1225Pas encore d'évaluation

- DatasheetDocument12 pagesDatasheetDjalma MoreiraPas encore d'évaluation

- Quasi-Resonant Topology Primary Switching Regulators: STR-W6756Document8 pagesQuasi-Resonant Topology Primary Switching Regulators: STR-W6756perro sPas encore d'évaluation

- Off-Line Quasi-Resonant Switching Regulators: STR-X6729Document9 pagesOff-Line Quasi-Resonant Switching Regulators: STR-X6729perro sPas encore d'évaluation

- STR W6753 DatasheetDocument8 pagesSTR W6753 DatasheetjgerabmPas encore d'évaluation

- Quasi-Resonant Topology Primary Switching Regulators: STR-W6735Document13 pagesQuasi-Resonant Topology Primary Switching Regulators: STR-W6735perro sPas encore d'évaluation

- Switching IC for compact power supply STR-A6252Document9 pagesSwitching IC for compact power supply STR-A6252Fernando ChingaPas encore d'évaluation

- Dse STR A6000mDocument13 pagesDse STR A6000mAlanPas encore d'évaluation

- STR W6053SDocument14 pagesSTR W6053SMarcos Rangel100% (1)

- Ane Str3a100Document17 pagesAne Str3a100vietanh_askPas encore d'évaluation

- Off-Line Quasi-Resonant Switching Regulators Features and Benefits (39Document9 pagesOff-Line Quasi-Resonant Switching Regulators Features and Benefits (39ch3o10836266Pas encore d'évaluation

- Off-Line Quasi-Resonant Switching Regulators: STR-X6769Document9 pagesOff-Line Quasi-Resonant Switching Regulators: STR-X6769Alfredo Valencia RodriguezPas encore d'évaluation

- Datasheet STR 6757Document11 pagesDatasheet STR 6757Walter CarreroPas encore d'évaluation

- STR W6735 DatasheetDocument13 pagesSTR W6735 DatasheetloagerPas encore d'évaluation

- UC2842B/3B/4B/5B UC3842B/3B/4B/5B: High Performance Current Mode PWM ControllerDocument15 pagesUC2842B/3B/4B/5B UC3842B/3B/4B/5B: High Performance Current Mode PWM ControllertoajuicePas encore d'évaluation

- MVC-CD500 L3 C1Document2 pagesMVC-CD500 L3 C1Anonymous Lfgk6vygPas encore d'évaluation

- MVC Cd500 AdjDocument45 pagesMVC Cd500 AdjAnonymous Lfgk6vygPas encore d'évaluation

- Mvc-cd500 Adj c1Document2 pagesMvc-cd500 Adj c1Anonymous Lfgk6vygPas encore d'évaluation

- DSC-V1 L1,2 e 3Document98 pagesDSC-V1 L1,2 e 3Anonymous Lfgk6vygPas encore d'évaluation

- KX TC1400Document48 pagesKX TC1400Anonymous Lfgk6vygPas encore d'évaluation

- KX Tga272lxsDocument74 pagesKX Tga272lxsAnonymous Lfgk6vygPas encore d'évaluation

- KX TCM418Document86 pagesKX TCM418Anonymous Lfgk6vygPas encore d'évaluation

- Mvc-cd500 Adj c2Document1 pageMvc-cd500 Adj c2Anonymous Lfgk6vygPas encore d'évaluation

- MDR If230Document8 pagesMDR If230Anonymous Lfgk6vygPas encore d'évaluation

- DSC-V1 AdjDocument40 pagesDSC-V1 AdjAnonymous Lfgk6vygPas encore d'évaluation

- KX TC1468LBBDocument64 pagesKX TC1468LBBapi-3702225Pas encore d'évaluation

- Service Manual: Personal Audio SystemDocument46 pagesService Manual: Personal Audio SystemAnonymous Lfgk6vygPas encore d'évaluation

- Telefone PanassonicDocument20 pagesTelefone PanassonicasccorreaPas encore d'évaluation

- KX TC1709LBBDocument75 pagesKX TC1709LBBapi-3702225100% (1)

- KX TG2559LBSDocument90 pagesKX TG2559LBSAnonymous Lfgk6vygPas encore d'évaluation

- Service Manual: SRF-M55Document12 pagesService Manual: SRF-M55Anonymous Lfgk6vygPas encore d'évaluation

- Sony MZ-R70 Service ManualDocument51 pagesSony MZ-R70 Service ManualEhud TamirPas encore d'évaluation

- Sony XM-222 STEREO POWER AMPLIFIER Service ManualDocument10 pagesSony XM-222 STEREO POWER AMPLIFIER Service Manualtm5u2rPas encore d'évaluation

- Amplificador Da SonyDocument9 pagesAmplificador Da SonydanielcastrosPas encore d'évaluation

- Service Manual: MVC-FD95Document150 pagesService Manual: MVC-FD95Anonymous Lfgk6vygPas encore d'évaluation

- Service Manual: Portable Minidisc PlayerDocument26 pagesService Manual: Portable Minidisc PlayerAnonymous Lfgk6vygPas encore d'évaluation

- Service Manual: Portable Minidisc RecorderDocument48 pagesService Manual: Portable Minidisc RecorderAnonymous Lfgk6vygPas encore d'évaluation

- Service Manual: MVC-FD85/FD90Document112 pagesService Manual: MVC-FD85/FD90Anonymous Lfgk6vygPas encore d'évaluation

- Service Manual: MZ-E44/E45Document25 pagesService Manual: MZ-E44/E45Anonymous Lfgk6vygPas encore d'évaluation

- Service Manual: Minidisc ChangerDocument38 pagesService Manual: Minidisc ChangerAnonymous Lfgk6vygPas encore d'évaluation

- Service Manual: MDX-C6500XDocument12 pagesService Manual: MDX-C6500XAnonymous Lfgk6vygPas encore d'évaluation

- Service Manual: Fm/Am Minidisc PlayerDocument58 pagesService Manual: Fm/Am Minidisc PlayerAnonymous Lfgk6vygPas encore d'évaluation

- Manual de ServiçoDocument3 pagesManual de ServiçoAnonymous Lfgk6vygPas encore d'évaluation

- Service Manual: M-530V/535V/630V/635VKDocument26 pagesService Manual: M-530V/535V/630V/635VKAnonymous Lfgk6vygPas encore d'évaluation

- KV 25FV12BDocument34 pagesKV 25FV12BZamalo Franko100% (1)

- 4.3 Inch LCD MULTI-FUNCTIONAL GENERATORS GENSET CONTROLLER DC72DDocument5 pages4.3 Inch LCD MULTI-FUNCTIONAL GENERATORS GENSET CONTROLLER DC72DJuan José Tovar PérezPas encore d'évaluation

- Comsats University Islamabad Applied Physics Lab FinalDocument42 pagesComsats University Islamabad Applied Physics Lab FinalmalkPas encore d'évaluation

- GTG 1383om Piel Sul 48mchpDocument18 pagesGTG 1383om Piel Sul 48mchpjohn smithyPas encore d'évaluation

- Samsung S20 G780F Service ManualDocument111 pagesSamsung S20 G780F Service ManualEdson Ferreira Santos JuniorPas encore d'évaluation

- Designing battery management systems for portable devicesDocument5 pagesDesigning battery management systems for portable devicesAnonymous ZRyj23t36b100% (2)

- InteliDrive IPU DatasheetDocument4 pagesInteliDrive IPU DatasheetMuhammad Shoaib HussainPas encore d'évaluation

- Artemis MK V PDFDocument2 pagesArtemis MK V PDFdeepsea74Pas encore d'évaluation

- BVP621 Led1008cw 960W 220-240V NB GM PDFDocument3 pagesBVP621 Led1008cw 960W 220-240V NB GM PDFLauw Tjun NjiPas encore d'évaluation

- Cl21a551mlmxzx CL21B501HLMXZP Cs21a530fj Cs21b501hu KSCB (N)Document22 pagesCl21a551mlmxzx CL21B501HLMXZP Cs21a530fj Cs21b501hu KSCB (N)Javier RodriguezPas encore d'évaluation

- SureWave Touchless Switch - Options and Applications PDFDocument18 pagesSureWave Touchless Switch - Options and Applications PDFDavidGracePas encore d'évaluation

- 7 Sets PhysicsDocument26 pages7 Sets PhysicsManish GuptaPas encore d'évaluation

- Cooling of TransformersDocument15 pagesCooling of TransformersJatin YadavPas encore d'évaluation

- Schematic Diagram of Unit Auxiliary Transfer SchemeDocument8 pagesSchematic Diagram of Unit Auxiliary Transfer Schemerashm006ranjanPas encore d'évaluation

- RTD Questions and AnswersDocument19 pagesRTD Questions and AnswersJêmš NavikPas encore d'évaluation

- Electrical Machines: by Dr. Krishna Roy Dr. Krishna Roy Assistant Professor Electrical Engineering Department NitrDocument214 pagesElectrical Machines: by Dr. Krishna Roy Dr. Krishna Roy Assistant Professor Electrical Engineering Department NitrManjitPas encore d'évaluation

- ST12 Encoder DecoderDocument6 pagesST12 Encoder Decodersloke123Pas encore d'évaluation

- 09 12 MG33MF02Document209 pages09 12 MG33MF02Aleksandar StankovićPas encore d'évaluation

- Gcm02 MT Ing r6bDocument57 pagesGcm02 MT Ing r6bKaiser Iqbal100% (1)

- (Railway) Signaling System - Catalog - EN - 202106Document98 pages(Railway) Signaling System - Catalog - EN - 202106sylver_manPas encore d'évaluation

- Isscc 2019 / Session 18 / Analog Techniques / 18.7: 18.7 A 0.7V, 2.35% 3 σ-Accuracy Bandgap Reference in 12nm CmosDocument3 pagesIsscc 2019 / Session 18 / Analog Techniques / 18.7: 18.7 A 0.7V, 2.35% 3 σ-Accuracy Bandgap Reference in 12nm CmosLuis CasmaPas encore d'évaluation

- Reactive Power Compensation in The Four Load Quadrants: 7.1.1 Technical ConsiderationDocument3 pagesReactive Power Compensation in The Four Load Quadrants: 7.1.1 Technical ConsiderationNM GroupPas encore d'évaluation

- Battery Technology: Lithium Flow BatteriesDocument14 pagesBattery Technology: Lithium Flow BatteriesdepakPas encore d'évaluation

- Hs35a 2011Document11 pagesHs35a 2011Ross Mathew0% (1)

- DXX-1710-2690 EasyRET 4-Port Antenna with Integrated RCUsDocument2 pagesDXX-1710-2690 EasyRET 4-Port Antenna with Integrated RCUsРоманКочнев93% (15)

- Ricoh FW780 Service ManualDocument481 pagesRicoh FW780 Service ManualDocuSystems100% (1)

- Cold Test Report 3Document1 pageCold Test Report 3Venkitesh PG100% (1)

- Harness Catc15 24Document5 pagesHarness Catc15 24Manuel MoralesPas encore d'évaluation

- RISHABH INSTRUMENTS P11 POWER TRANSDUCER MANUALDocument4 pagesRISHABH INSTRUMENTS P11 POWER TRANSDUCER MANUALjigyeshPas encore d'évaluation

- AU6860B Datasheet v01Document14 pagesAU6860B Datasheet v01david29xPas encore d'évaluation

- Product Data: DescriptionDocument2 pagesProduct Data: DescriptionChris AntoniouPas encore d'évaluation