Académique Documents

Professionnel Documents

Culture Documents

Basic Data Viper40 15066 en

Transféré par

Armando RiveraTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Basic Data Viper40 15066 en

Transféré par

Armando RiveraDroits d'auteur :

Formats disponibles

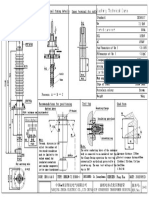

Basic data VIPER 40

3

Basic data VIPER 40

1 Overview

1

9

8

4

0

200 398

2

7

4

0

(

Y

=

1

9

0

0

)

Z

50

m

i

n

.

8

9

0

80 n x 240

5

0

40

M6 (4x)

7

0

195

730

15

85

40 220

5

0

235 740

M12

2

4

4

0

(

Y

=

1

6

0

0

)

2

1

4

0

(

Y

=

1

3

0

0

)

1

8

4

0

(

Y

=

1

0

0

0

)

151

Takeover head plug:

25 pole D-sub

Line connections 6 mm

Drilling template, 75 Nm C-compact axis-

M

a

s

c

h

i

n

e

n

m

i

t

t

e

b

e

i

A

b

l

a

g

e

B

e

d

i

e

n

g

e

g

e

n

s

e

i

t

e

u

n

d

B

a

u

-

f

o

r

m

S

t

a

n

d

a

r

d

Basic data VIPER 40

4 TVHB - EAT | Version G/14/500-1/436/6

Z

X

2

5

200

1

9

8

5

0

40

M6 (4x)

7

0

195

15

85

40 220

5

0

235 740

M12

730

474

50

m

i

n

.

9

4

5

80 n x 240

Y

1

9

2

0

(

Y

=

1

9

0

0

)

1

7

7

0

(

Y

=

1

6

0

0

)

1

6

2

0

(

Y

=

1

3

0

0

)

1

4

7

0

(

Y

=

1

0

0

0

)

75

Takeover head plug:

25 pole D-sub

Line connections 6 mm

Drilling template, 75 Nm C-compact axis-

M

a

s

c

h

i

n

e

n

m

i

t

t

e

b

e

i

A

b

l

a

g

e

B

e

d

i

e

n

g

e

g

e

n

s

e

i

t

e

u

n

d

B

a

u

-

f

o

r

m

S

t

a

n

d

a

r

d

Basic data VIPER 40

5

Standard cycle for dry cycle

Z-axis=2360mm, SPB=1100mm

X-Achse=700mm =>350mm bei Teileentnahme, 700mm bei Teileablage

Y-axis=1300mm =>1000mm for part take-off, 1300mm for part depositing

Technical data VIPER 40

(speed)

VIPER 40

(regular)

VIPER 40

(load)

Manipulable mass max. (at 6 bar) kg

20

1

/ 25

2

1. At the end of the C-75Nm axis (other permissible axis combinations +manipulable masses +torque characteris-

tics see data sheet for ABC axes and manipulable weight calculator)

2. End of Y axis =>without ABC axes

35

1

/ 40

2

50

1

/ 55

2

Repeatability mm 0,05 0,05 0,05

X-axis (Demolding stroke) mm 700/900/1200 700/900/1200 700/900/1200

X-Geschwindigkeit nominal m/s 2,5 2,5 2

Y-axis (single) mm 1000/1300/1600/1900 1000/1300/1600/1900 1000/1300/1600/1900

Y-axis (tandem) mm - 1000/1300/1600/1900 -

Y-Geschwindigkeit nominal m/s 4 3 2

Z-axis (cross transport) in 480mm steps mm 1880 - 8120 1880 - 8120 1880 - 8120

Z-Geschwindigkeit nominal m/s 3,5 3 2

C-axis (0-90) pneu. Nm 60, 75, 120, 150 60, 75, 120, 150 75, 120, 150

C-axis (0-180) servo Nm 45, 125 45, 125 125

B-axis (0-270) servo Nm 28, 110 28, 110 110

A-axis (0-270) servo Nm 28, 45 28, 45 45

Dry cycle time in standard cycle s 10 15 30

Luftverbrauch pro Vakuumkreis (ohne Vakuumpumpe) L/s

0,33

3

3. pro vacuum circuit with 100% actuation duration

0,33

3

0,33

3

Durchflussmenge Ventil pro Druckluftkreis L/s 3,33 3,33 3,33

max. rated power kW 4 4 4

nominal consumption kW 0,7 0,7 0,7

Z-axis

Y-axis

Prohibited area SP

X-axis

Part deposit

Take-off of parts

Basic data VIPER 40

6 TVHB - EAT | Version G/14/500-1/436/6

2 Standard equipment of regular basic device (R)

Mechanics:

Permanently lubricated shaft with helical gearing on the z-axis (lubrication sensor for 12

months of operations)

Shaft with helical gearing on the x-axis

V belt on y-axis

Low-noise energy chain in all axes

Torsion-stiff vertical stroke

3 freely positioning servoaxes incl. absolute position measuring system

Drive by means of highly dynamic, maintenance-free servomotors

Hardened, ground and low-maintenance precision guides

Structure above the fixed mold fixing platen

Part depositing at rear of machine (in case of depositing at front of machine, robot is

executed as mirror image)

Pneumatics:

Air maintenance unit with shut-off valve (SMC) and pressure switch

Central valve ramp (SMC) with 4 valve slots and 3 valves mounted on y-arm

1. Valve reserved for C axis!

2 reversible vacuum / compressed air circuits

For each vacuum circuit: 1 vacuum monitoring (analog; directly configurable on control

unit)

For each compressed air circuit: 2 final positions monitoring or 1 final positions monitor-

ing and 1 parts monitoring

Vacuum generation by Venturi nozzle (SMC)

Compressed air and vacuum elements connected via pneum. Quick couplings incl. non

return valve on y-arm (SMC)

Electric system:

Compact switch cabinet mounted on z-axis (max. 900mm continuously adjustable)

EtherCAT - extremely fast and widespread Ethernet-based bus system; high bandwidth;

hub and spoke and easily extensible wiring topology

decentralized I/O technology

distributed safety technology and serial wiring of safety functions (evaluation is local

and not at switch cabinet)

Electric plug for takeover head (standard 25-pole D-Sub)

Zero-potential contact conveyor-belt actuation

Electric system prepared for 1 access door and external EMERGENCY STOP

Pluggable limit switches for pneumatic rotary axes

Control system RC 200 A02 Integrated:

Complete integration in the CC-200 A02 control unit on the ENGEL injection molding

machine

Fully graphic control surface

15Portrait format color screen with touch screen operation (machine screen ()

Shared data storage of robot, injection molding machine and mold parameters on a

USB memory stick

Basic data VIPER 40

7

Program access control and access authorization using key cards or passwords,

depending on the series and type of the injection molding machine

Software

Fully graphic control surface with touch operation

Graphical sequence programming with uniform control surface for injection molding

machine, robot and peripheral equipment

Teach-In programming, also via the hand terminal HBG C35

Absolute position measuring system (no referencing required)

Library with program sequences proven in practice, changeable in the Teach mode

Sequence variants for part take-off

Depositing in one or more grids, shot grid, individual part grid, teach grid

Quality control part depositing, rejects depositing, sprue depositing, intermediate layer

depositing

Switch off axis in the Teach-In

Conveyor-belt control

Quickset function for the rapid takeover of the actual position into a sequence position

Quickpos function for the rapid approach of a set sequence position

Speed override via pushbuttons

Work area monitoring with 3D display

automatic dynamic optimization

Free designation of variables (positions, markers etc.)

Addition of the variables on existing screen pages

Simulation of the screen depositing in the screen editor

Control for coordinated axis movements

Robot test run without machine (dry cycle)

Position correction of injection molding machine

analog vacuum monitoring

Switch language, context sensitive help, units either ISO or Imperial

Manuals as online help on control unit, note function

Printout on local printer, network printer or in file

Machine hours counter and maintenance interval display

Parts data storage on internal or external compact flash card, USB memory stick, or a

network drive

Ethernet interface for network connection

USB interfaces for printer, external keyboard, etc.

Vibration control and automatic mass identification

MANUAL CONTROL DEVICE C35

Standard manual control device for integrated execution (drop safe up to 1.5m)

32 Keys and 8-line graphic display

Assignment in color of the functions

EMERGENCY STOP switch and consent key

Basic data VIPER 40

8 TVHB - EAT | Version G/14/500-1/436/6

3 Optional equipment

Mechanics:

Compact low profile (Y Tandem)

Drive speed (S) or load (L) instead of regular (R)

Extension of Z axis from 1880 (in steps of 480mm) to 8120mm

Extension of x-axis from 700 to 900 or 1200mm

Extension of y-axis (single or tandem) from 1000 to 1300, 1600, or 1900mm

C-axis, pneum., 0-90, 60 Nm or 150 Nm, or C compact 75 Nm

C-Servo, 0-180, 45 Nm or 125 Nm

B-Servo, +90/-180, 28 Nm or 110 Nm

A-Servo, -90/+180, 28 Nm or 45 Nm

Standard stand, beak-shaped stand (for layout without support) or custom stand

Standard support (I beam), frame support (L frame) or portal support (free standing)

Moving area safeguarding x and/or z-axis (safe for persons)

Part depositing at front of machine (robot mirrored), or long side of machine

STD end of arm tooling Grip Tools Type S or M and spring-borne sprue gripper L+M+S

High speed head changing system Grip Tools end of arm tooling manual type S or M

Sprue nippers pneumatic on the transverse girder

Automatic central lubrication (each axis can be configured and lubricated individually)

Wear and tear parts kit

GRIP-TOOLS BASIC kit S or M (modular system for end of arm toolings)

As conversion robot in peripheral unit area for complex automation applications

Pneumatics:

1. Valve ramp (SMC) for up to max. 12 valves mounted on y-arm

2. Valve ramp (SMC) for up to max. 12 valves (for total of 24 valves) mounted on XY-

node

max. 8 vacuum/compressed air circuits reversible

max. 16 vacuum/compressed air circuits reversible +vacuum circuits)

max. 23 compressed air circuits

max. 16 vacuum circuits with air blast

Vacuum pump instead of Venturi nozzle (without vacuum accumulator for max. 8 vac-

uum circuits; with vacuum accumulator for max. 16 vacuum circuits)

Pneumatic preparation for sprue cutter

Peripheral unit:

Safety gate to EN ISO 13857 and light beam guard cat. 4

Conveyor-belt FB100 or FB200

Basic data VIPER 40

9

Parts chute

Balance for the weight testing and protection of the quality data

Tray server, sliding table, vision systems, transfer conveyors, peripheral units in gen-

eral, etc.

Basic data VIPER 40

10 TVHB - EAT | Version G/14/500-1/436/6

Electric system:

Universal switch cabinet movable instead of compact cabinet

Necessary if:

the number of servoaxes is >6, or

the robot is executed as a dual tower, or

the robot is positioned over 2 injection molding machines, or

switch cabinet illumination is sold, or

the robot is deployed in a cleanroom, or

the option "Switch cabinet dust-free" is sold, or

an air conditioning unit was sold, or

an air/water heat exchanger is planned

Isolating transformer for custom voltages

Electric equipment for USA and Canada

Reversing operations for conveyor-belt

Actuation for third party conveyors

2. Conveyor-belt actuation

Interface peripheral unit standard type with 4 zero-potential, freely-programable signals,

"EMERGENCY STOP" and "Safety gate closed of 2-channel type

Interface peripheral unit custom type

Interface peripheral unit EtherCat IP20

Extension packages IP20 (4 digital inputs or 4 digital outputs)

Interface peripheral unit EtherCat IP67

Switch cabinet illumination (only for universal cabinet)

Switch cabinet dust-free via microfilter (only for universal cabinet)

Air conditioning unit for switch cabinet (only for universal cabinet)

Air/water heat exchanger (only for universal cabinet)

Warning signal light incl. audible warning (85dB) on Z-axis or free standing

Craneway safeguarding

Custom operation mode "Robot over 2 injection moulding machines

Start key input for stand-alone

Input and output module (12 digital inputs +4 digital outputs) on y-axis incl. 25-pin. D-

Sub

Output module (24 DO) on y-axis incl. 25-pin. D-Sub

Adapter from injection moulding machine Euromap 12 to robot Euromap 67

Electric system prepared for additional access doors and external EMERGENCY STOP

Safety package 1 for accessible safety guarding (without access permission)

Safety package 2 for accessible safety guarding (with access permission)

Safety package 3 for production with rear machine safety gate open

Clearing circuit for conveyor-belt

Control unit options:

Connection point for manual control device C35 safety gate instead of switch cabinet

Software update for injection moulding machines with CC200 control unit (in case of ret-

rofitting)

Park position

Moving-on reversible vertically-horizontally

Basic data VIPER 40

11

Control accessories:

Color graphics printer (USB connection), PC input keyboard external, Compact Flash

Card or USB Memory Stick, Keycards for access control, reader for Compact Flash

Cards with USB interface, Card Adapter for Compact Flash Cards (for HBG C100)

Mold crane safeguarding

Take-off stroke correction

Axis synchronization with ejector

Axis synchronization for one robot axis with machine opening movement

Softservo

Torque monitoring

Virtual machine - offline programming on the PC with equipment simulation

Screen text in additional languages

Sprue separation

Depositing and take-up of peripheral unit

Data set storage integrated

Alarm Messaging via E-Mail

Remote Control and Teleservice

RC200 Control unit stand-alone

powerful microprocessor control unit for stand-alone applications

Interface according to Euromap 67 / AN-146

Manual control unit (C100) with 8 touch-screen color display and foil keyboard

Program scope (software) integrated as per RC 200

Access privileges via passwords

USB port for printer, external keyboard, or data archiving

Vibration control and automatic mass identification

MANUAL CONTROL DEVICE C100

Manual control unit with 8 touch screen color display for stand-alone applications-

Optional control unit for integrated applications with RC200 control unit as manual con-

trol unit screen

Robot and machine operations supported as on machine screen

EMERGENCY STOP switch and consent key

Author: Stefan Thurnn (KBL-PST)

Version: 10/2010

Basic data VIPER 40

12 TVHB - EAT | Version G/14/500-1/436/6

Subject to change without notice!

Vous aimerez peut-être aussi

- FANUC RoboGuide HELP PDFDocument456 pagesFANUC RoboGuide HELP PDFprathipbemech94% (16)

- Robot VIPER-SODocument374 pagesRobot VIPER-SOArmando RiveraPas encore d'évaluation

- 4G15 EngineDocument32 pages4G15 EngineLee Johnston75% (12)

- Wittmann CNC 6 ManualDocument186 pagesWittmann CNC 6 ManualScott LoewePas encore d'évaluation

- Engel RobotsDocument18 pagesEngel RobotsAnonymous hxQ7PNOQPas encore d'évaluation

- ENGEL Flomo E-Flomo EN Short ROM PDFDocument11 pagesENGEL Flomo E-Flomo EN Short ROM PDFMarius Vaida100% (1)

- Creating Cycles Production SeproDocument9 pagesCreating Cycles Production SeproPasarica AlexandruPas encore d'évaluation

- User Guide : CC300 Operator PanelDocument49 pagesUser Guide : CC300 Operator PanelilijaPas encore d'évaluation

- ENGEL Victory 2018-08 enDocument17 pagesENGEL Victory 2018-08 enVenomous To IbizaPas encore d'évaluation

- 3200AMMe Part 2Document224 pages3200AMMe Part 2Tanja KesicPas encore d'évaluation

- Ls-1670-S-Technical Data English VersionDocument26 pagesLs-1670-S-Technical Data English VersionThuy CunPas encore d'évaluation

- All-Electric Small-Sized Injection Molding Machine: Sumitomo Global NetworkDocument8 pagesAll-Electric Small-Sized Injection Molding Machine: Sumitomo Global NetworkRusmana Syamil0% (1)

- Ipcas Usb-Floppy-Emulator-V2-And-Slimline-Manual - v1.4Document21 pagesIpcas Usb-Floppy-Emulator-V2-And-Slimline-Manual - v1.4Ramon PazPas encore d'évaluation

- Tcfen-154-001 CFD Startup PDFDocument88 pagesTcfen-154-001 CFD Startup PDFPhasin Chitutsaha100% (1)

- Errores EngelDocument1 pageErrores EngelTormexPas encore d'évaluation

- Treinamento STEC-360A (NC Program) E PDFDocument107 pagesTreinamento STEC-360A (NC Program) E PDFArmando Rivera100% (2)

- Link Budget 2GDocument22 pagesLink Budget 2Gmanu waliaPas encore d'évaluation

- Security Specialization Sample Exam - ENDocument8 pagesSecurity Specialization Sample Exam - ENbloodscreamPas encore d'évaluation

- MasterRC Pile Cap DesignDocument4 pagesMasterRC Pile Cap DesignAl-Ain HomesPas encore d'évaluation

- ENGEL Training: More Efficiency in Injection MouldingDocument11 pagesENGEL Training: More Efficiency in Injection MouldingradzPas encore d'évaluation

- Wittmann M7 ManualDocument107 pagesWittmann M7 ManualBobby SchmaltzPas encore d'évaluation

- Training enDocument11 pagesTraining enShanArisPas encore d'évaluation

- S900 II Configuration V21Document71 pagesS900 II Configuration V21Francisco Macias100% (1)

- Ehb CC100 CC200 en PDFDocument118 pagesEhb CC100 CC200 en PDF123456789_2014Pas encore d'évaluation

- ENGEL E-Training enDocument7 pagesENGEL E-Training enMSK1989Pas encore d'évaluation

- PROJ MCS Synchronous Servo Motors - v5-0 - ENDocument140 pagesPROJ MCS Synchronous Servo Motors - v5-0 - ENDave CárdenasPas encore d'évaluation

- Robot Manual R8.3Document307 pagesRobot Manual R8.3Alhernan HernandezPas encore d'évaluation

- Regloplas RT50 Controller Manual PDFDocument28 pagesRegloplas RT50 Controller Manual PDFalso strong and durablePas encore d'évaluation

- EN-G 11 401 1 11-2007-01-05 0926 Tdo1 PDFDocument246 pagesEN-G 11 401 1 11-2007-01-05 0926 Tdo1 PDFbuburuzazboaraPas encore d'évaluation

- NC 5 Prezentare EngDocument33 pagesNC 5 Prezentare EngSolomon Bogdan-DanielPas encore d'évaluation

- Fundamentals of Electric CircuitsDocument7 pagesFundamentals of Electric CircuitsHiếu DươngPas encore d'évaluation

- Johnson Outboard Power PacksDocument6 pagesJohnson Outboard Power PacksMarine Parts ChinaPas encore d'évaluation

- Cy 600 800gii PDFDocument92 pagesCy 600 800gii PDFArmando Rivera100% (1)

- Johnson Outboard Connecting Rods & BearingsDocument3 pagesJohnson Outboard Connecting Rods & BearingsMarine Parts ChinaPas encore d'évaluation

- eSW-1200 eSW-1200s: Mechanical Edition For RobotDocument44 pageseSW-1200 eSW-1200s: Mechanical Edition For Robothung nguyenPas encore d'évaluation

- CZ-1700 CZ-1700s: Mechanical Edition For UnloaderDocument69 pagesCZ-1700 CZ-1700s: Mechanical Edition For Unloaderhung nguyenPas encore d'évaluation

- Smart Power User Manual PDFDocument1 030 pagesSmart Power User Manual PDFAntonio Lucas100% (4)

- نافخهDocument136 pagesنافخهmohamedPas encore d'évaluation

- Control SystemsDocument76 pagesControl SystemsEd KlbPas encore d'évaluation

- Subaru Engines Ex13 Ex17 Ex21 Ex27 sp170 sp210 Ex21efi Service PDFDocument113 pagesSubaru Engines Ex13 Ex17 Ex21 Ex27 sp170 sp210 Ex21efi Service PDFCristiano FerreiraPas encore d'évaluation

- Epson SCARA Robot BrochureDocument16 pagesEpson SCARA Robot BrochureProduccion TAM100% (1)

- Design of Ultraprecision Machine Tools With Applications To Manufacture of Miniature and Micro Components PDFDocument14 pagesDesign of Ultraprecision Machine Tools With Applications To Manufacture of Miniature and Micro Components PDFAUSTIN DSOUZAPas encore d'évaluation

- IMM BR IR enDocument13 pagesIMM BR IR enwatnaPas encore d'évaluation

- Iq Weight Control en PDFDocument31 pagesIq Weight Control en PDFMarius VaidaPas encore d'évaluation

- Molded Parts DefectsDocument9 pagesMolded Parts DefectsPadmanava DasguptaPas encore d'évaluation

- Iqclampcontrol Info EN PDFDocument8 pagesIqclampcontrol Info EN PDFMarius VaidaPas encore d'évaluation

- Tool Based Micro MachiningDocument8 pagesTool Based Micro MachiningAnmol SatsangiPas encore d'évaluation

- Catalogo Inyectoras ENGELDocument15 pagesCatalogo Inyectoras ENGELMarcWorldPas encore d'évaluation

- HA-SERIES OPERATION MANUAL 02ver PDFDocument354 pagesHA-SERIES OPERATION MANUAL 02ver PDFsunhuynhPas encore d'évaluation

- AR4 Robot Manul V1.5 PDFDocument292 pagesAR4 Robot Manul V1.5 PDFEusebio RivasPas encore d'évaluation

- A02-Injection Machine Robot Control System Operation Manual V1.14Document133 pagesA02-Injection Machine Robot Control System Operation Manual V1.14jagoklurukPas encore d'évaluation

- Parts Manual: EX27 EngineDocument44 pagesParts Manual: EX27 EngineDiego Leandro Garcia HernandezPas encore d'évaluation

- Arburg370&420C PDFDocument8 pagesArburg370&420C PDFMatoa Papeda0% (1)

- TSTA User ManualDocument218 pagesTSTA User ManualHieu NguyenPas encore d'évaluation

- 5092@feedmax BS6@ENDocument40 pages5092@feedmax BS6@ENALFONSO TORRESPas encore d'évaluation

- Operation Manual KH-212Document63 pagesOperation Manual KH-212Jorge Centeno Ramos100% (2)

- Automated Machine ToolsDocument29 pagesAutomated Machine ToolsSyafawati OsmanPas encore d'évaluation

- Epson Rc700 Rc700a Controller Manual (r27)Document328 pagesEpson Rc700 Rc700a Controller Manual (r27)TuxtronPas encore d'évaluation

- Service Manual E-Series: Original Instructions (EN)Document122 pagesService Manual E-Series: Original Instructions (EN)Jojo LynxiPas encore d'évaluation

- t999 User ManualDocument84 pagest999 User ManualRery Dwi SPas encore d'évaluation

- ADTECH QS7 Servo Drive ManualDocument61 pagesADTECH QS7 Servo Drive ManualdangkhuyenmaiPas encore d'évaluation

- Ball Screw Selection ExerciseDocument7 pagesBall Screw Selection ExercisemaddyaugPas encore d'évaluation

- Smiflexi en PDFDocument44 pagesSmiflexi en PDFLacosteiq6 HhPas encore d'évaluation

- Vibratory FeederDocument4 pagesVibratory FeederSaran CoolPas encore d'évaluation

- Microsystem - Presentation - MICRO MOULDINGDocument70 pagesMicrosystem - Presentation - MICRO MOULDINGrameshPas encore d'évaluation

- Advanced Thermoforming: Methods, Machines and Materials, Applications and AutomationD'EverandAdvanced Thermoforming: Methods, Machines and Materials, Applications and AutomationÉvaluation : 5 sur 5 étoiles5/5 (1)

- Payload: 80 KG: DX100 Controller Powerful Performance in A Mid-Size RobotDocument2 pagesPayload: 80 KG: DX100 Controller Powerful Performance in A Mid-Size RobotRuben AlvaradoPas encore d'évaluation

- 502Document72 pages502Armando RiveraPas encore d'évaluation

- IRC 5 - Product Specification - 2019Document162 pagesIRC 5 - Product Specification - 2019Armando RiveraPas encore d'évaluation

- Manual M9510GDocument28 pagesManual M9510GArmando RiveraPas encore d'évaluation

- Relief ValveDocument16 pagesRelief ValveArmando RiveraPas encore d'évaluation

- Cy 600 800gii PDFDocument92 pagesCy 600 800gii PDFArmando Rivera100% (1)

- Air Conditioning (Manual Control) : Wiring DiagramDocument5 pagesAir Conditioning (Manual Control) : Wiring DiagramArmando RiveraPas encore d'évaluation

- 750-96 CB 50-100 HP PDFDocument146 pages750-96 CB 50-100 HP PDFFrancisco Uribe ParraPas encore d'évaluation

- FFFFFFF FFDDDFFDDDocument1 pageFFFFFFF FFDDDFFDDArmando RiveraPas encore d'évaluation

- 06-0922 H-J Install ManualDocument23 pages06-0922 H-J Install ManualArmando RiveraPas encore d'évaluation

- Conair Temperature Control ManualDocument27 pagesConair Temperature Control ManualArmando RiveraPas encore d'évaluation

- 750-96 CB 50-100 HP PDFDocument146 pages750-96 CB 50-100 HP PDFFrancisco Uribe ParraPas encore d'évaluation

- HX: Evaporative Emission (EVAP) Monitor and System: 2003 Pced Obdii SECTION 5: Pinpoint TestsDocument11 pagesHX: Evaporative Emission (EVAP) Monitor and System: 2003 Pced Obdii SECTION 5: Pinpoint TestsArmando RiveraPas encore d'évaluation

- Tarjeta EncoderDocument22 pagesTarjeta EncoderArmando RiveraPas encore d'évaluation

- General Tire Supply Chain ProcessDocument3 pagesGeneral Tire Supply Chain ProcessSyed Burhan AhmadPas encore d'évaluation

- Manual Hand Drill: Mini - Project - CADDocument34 pagesManual Hand Drill: Mini - Project - CADKengsuen KhooPas encore d'évaluation

- Data Sheet mbr320 PDFDocument2 pagesData Sheet mbr320 PDFthanggimme.phanPas encore d'évaluation

- Gilat Product Sheet SkyEdge II C Capricorn 4Document2 pagesGilat Product Sheet SkyEdge II C Capricorn 4gilbertixPas encore d'évaluation

- CRM in Russia and U.S. - Case Study From American Financial Service IndustryDocument40 pagesCRM in Russia and U.S. - Case Study From American Financial Service IndustryebabjiPas encore d'évaluation

- An Overview On Evolution of Mobile Wireless Communication Networks: 1G-6GDocument4 pagesAn Overview On Evolution of Mobile Wireless Communication Networks: 1G-6GAsmaa AbduPas encore d'évaluation

- PLC Based Elevator Control System-1Document26 pagesPLC Based Elevator Control System-1Belete GetachewPas encore d'évaluation

- The 8086 BookDocument619 pagesThe 8086 BookFathi ZnaidiaPas encore d'évaluation

- Manual MCD SIMIT Model For CylinderPositioning V1 0 0Document20 pagesManual MCD SIMIT Model For CylinderPositioning V1 0 0PiraiyonePas encore d'évaluation

- Peterbilt Conventional Trucks Operators Manual After 1 07 SupplementalDocument20 pagesPeterbilt Conventional Trucks Operators Manual After 1 07 Supplementalmichael100% (44)

- JBT Exp-310 Brochure 0313cDocument2 pagesJBT Exp-310 Brochure 0313cCiprian OprescuPas encore d'évaluation

- BR4144A.8 英 (conector)Document1 pageBR4144A.8 英 (conector)Victor GuzmanPas encore d'évaluation

- Predatory JournalsDocument9 pagesPredatory JournalsNabeel MuhammadPas encore d'évaluation

- 2021 Campus Selection Process & EligibilityDocument1 page2021 Campus Selection Process & EligibilityNishant KumarPas encore d'évaluation

- PeopleSoft WorkFlowDocument20 pagesPeopleSoft WorkFlowSurya Prakash ReddyPas encore d'évaluation

- 0in CDC UG PDFDocument479 pages0in CDC UG PDFRamakrishnaRao Soogoori0% (1)

- 2oz Copper PCB Thickness and Its Design GuidelinesDocument14 pages2oz Copper PCB Thickness and Its Design GuidelinesjackPas encore d'évaluation

- Grp03 Blinking MiniprojectDocument3 pagesGrp03 Blinking MiniprojectYasin OmaryPas encore d'évaluation

- Trade Agreements in Microsoft Dynamics AX 2012Document24 pagesTrade Agreements in Microsoft Dynamics AX 2012Muawad OrabiPas encore d'évaluation

- Protocol Padlet - Online Projects 2020Document2 pagesProtocol Padlet - Online Projects 2020api-284373535Pas encore d'évaluation

- Aircraft Electrical Systems-OVDocument38 pagesAircraft Electrical Systems-OVbhargav_eede100% (1)

- Isms ServicesDocument2 pagesIsms ServicesDoanh DoanhPas encore d'évaluation

- Guide: Overclocking FX-8350 To 4.8GHz On Crosshair V Formula-ZDocument7 pagesGuide: Overclocking FX-8350 To 4.8GHz On Crosshair V Formula-ZBobapatatasPas encore d'évaluation

- From Tricksguide - Com "How To Configure Ilo On Your HP Proliant"Document35 pagesFrom Tricksguide - Com "How To Configure Ilo On Your HP Proliant"flavianalthaPas encore d'évaluation

- PDG - 2017 Latest (New Dryer)Document4 pagesPDG - 2017 Latest (New Dryer)mohd fadhilPas encore d'évaluation