Académique Documents

Professionnel Documents

Culture Documents

Astm Bolts&Nuts

Transféré par

hasan_676489616Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Astm Bolts&Nuts

Transféré par

hasan_676489616Droits d'auteur :

Formats disponibles

High Temperature High Tension Alloy Bolt Material Chemical & Mechanical

Requirements

ASTM A193 B7 (Cr- Mo AISI 4140,4142,4145 )

This material is considered as the most suitable for bolts to be used at temperature below 450 .

C, with a minimum effect on its structural strength during application at a high temperature.

The material has the following chemical properties and physical Characteristics.

C Mn P S Si Cr Mo

0.37-0.49 0.65-1.10 0.035 Max 0.04 Max 0.15-0.35 0.75-1.20 0.15-0.25

Dia

Minimum

Tempering

Temperature

( F )

Tensile

Strength

min, ksi

( MPa)

Yield

Strength.

min,

0.2% offset,

Ksi

( MPa)

Elongation

in

4D

min %

Reduction of

Area

min %

Hardness

max

21/2" and

under

1,100

(593 C )

125(860) 105(720) 16 50

321HB

or 35 HRc

over 21/2" to

4"

1,100

(593 C )

115(795) 95(655) 16 50

302HB

or 35 HRc

over 4" to

7"

1,100

(593 C )

100(690) 75(515) 18 50

277HB

or 29 HRc

ASTM A1193 B7M (Cr- Mo AISI 4140,4142,4145 )

C Mn P S Si Cr Mo

0.37-0.49 0.65-1.10 0.035 Max 0.04 Max 0.15-0.35 0.75-1.20 0.15-0.25

Dia

Minimum

Tempering

Temperature

F (C)

Tensile

Strength

min, ksi

MPa

Yield

Strength.

min,

0.2% offset,

Ksi

Elongation

in

2"

min %

Reduction of

Area

min %

Hardness

max

21/2" and

under

1150

(620 C )

100(690) 80(550) 18 50

235HB,

99HRB

ASTM A193 B16 (Cr- Mo -V )

This material is considered as the most suitable for bolts to be used at temperature below 450 .

C,even at a high temperature range, the material has superior physical characterestics

compared to ASTM A193 B7 previously mentioned.

The chemical properties and physical characteristics are as follows

C Mn P S Si Cr Mo Al V

0.36-0.47 0.45-0.70

0.035

Max

0.04 Max 0.15-0.35 0.80-1.15

0.50-

0.65

0.015Max

0.25-

0.35

Dia

Minimum

Temperature

F (C)

Tensile

Strength

min, ksi

( MPa)

Yield

Strength.

min,

0.2%

offset,

Ksi

( MPa)

Elongation

in

4D

min %

Reduction

of

Area

min %

Hardness

max

21/2" and 1200(650) 125(860) 105(725) 18 50 321HB

under or 35 HRC

over

21/2" to 4"

1200(650) 110(760) 95(655) 17 45

302HB

or 33 HRC

over 4" to

7"

1200(650 ) 100(690) 85(586) 16 45

227HB

or 29 HRC

ASTM A193 B5 (5% Cr AISI 501)

C Mn P S Si Cr Mo

0.10 max 1.00 max 0.040 max 0.030 Max 1.0 Max 4.00 - 6.00 0.40 -0.65

Dia

Minimum

Tempering

Temperature

F (C)

Tensile

Strength

min, ksi

(MPa)

Yield

Strength.

min,

0.2% offset,

Ksi

(MPa)

Elongation

in

2"

min %

Reduction of

Area

min %

Hardness

max

up to 4" incl 1.100 (593 ) 100(690) 80(550) 16 50 -

ASTM A193 B8 (AISI 304) B8A Chemical Requirements

C Mn P S Si Cr Ni

0.08 Max 2.00 Max 0.045 Max 0.030 Max 1.00 Max

18.00 -

20.00

8.00 -10.50

ASTM A193 B8C (AISI 347) B8CA

C Mn P S Si Cr Ni

Columbium

+

Tantalum

0.08 Max 2.00 Max 0.045 Max 0.030 Max 1.00 Max

17.00 -

19.00

9.00 -

13.00

10 x

Carbon

content,

min

ASTM A193 B8N (AISI 304N) B8NA

C Mn P S Si Cr Ni Nitrogen

0.08 Max 2.00 Max 0.045 Max 0.030 Max 1.00 Max

18.00 -

20.00

8.00 -

10.50

0.10 -

0.16

ASTM A193 B8MN (AISI 316N) B8MNA

C Mn P S Si Cr Ni Mo Nitrogen

0.08 Max 2.00 Max

0.045

Max

0.030

Max

1.00 Max

16.00 -

18.00

10.00 -

14.00

2.00 -

3.00

0.10 -

0.16

ASTM A193 B8P (AISI 305) B8PA

C Mn P S Si Cr Ni

0.08 Max 2.00 Max 0.045 Max 0.030 Max 1.00 Max

17.00 -

19.00

10.50 -13.00

ASTM A193 B8T (AISI 321) B8TA

C Mn P S Si Cr Ni Titanium

0.08 Max 2.00 Max 0.045 Max 0.030 Max 1.00 Max

17.00 -

19.00

9.00 -

12.00

5 x

Carbon

content,

min

ASTM A193 B8R B8RA

C Mn P S Si Cr Ni Mo Nitrogen

Columbium

+ Tanalum

V

0.06

Max

4.00 -

6.00

0.040

Max

0.030

Max

1.00

Max

20.50 -

23.50

11.50 -

13.50

1.50 -

3.00

0.20 -

0.40

0.10 - 0.30

0.10

-

0.30

ASTM A193 B8S B8SA

C Mn P S Si Cr Ni Nitrogen

0.10 Max

7.00 -

9.00

0.040 Max 0.030 Max

3.50 -

4.50

16.00 -

18.00

8.00 -

9.00

0.08 -

0.18

ASTM A193 B8LN, B8LNA

C Mn P S Si Cr Ni Mo Nitrogen

0.030

Max

2.00

0.045

Max

0.030

Max

1.00

18.00 -

20.00

8.00 -

10.50

-

0.10 -

0.16

B8MLN, B8MLNA

C Mn P S Si Cr Ni Mo Nitrogen

0.030

Max

2.00

0.045

Max

0.030

Max

1.00

16.00 -

18.00

10.00 -

14.00

2.00 -

3.00

0.10 -

0.16

CLASS I: B8, B8C, B8M, B8P, B8T, B8LN, B8MLN Mechanical Requirements

Dia

Heat

Treatement

Tensile

Strength

min, ksi

(MPa)

Yield

Strength.

min,

0.2% offset,

Ksi

(MPa)

Elongation

in

2"

min %

Reduction

of

Area

min %

Hardness

max

All

diameters

Carbide

Solution

Treated

75(515) 30(205) 30 50

223 HB or

96HRB

(3/4" in &

smaller,

241HB or 100

HRB)

CLASS IA: B8A, B8CA, B8MA, B8PA, B8TA, B8LNA, B8MLNA, B8NA, B8MN4

Dia

Heat

Treatement

Tensile

Strength

min, ksi

(MPa)

Yield

Strength.

min,

0.2% offset,

Ksi

(MPa)

Elongation

in

2"

min %

Reduction

of

Area

min %

Hardness

max

All

diameters

Carbide

Solution

Treated in the

finished

conditions

75(515) 30(205) 30 50

192 HB

or 90HRB

CLASS IB: B8N, B8MN

Dia

Heat

Treatement

Tensile

Strength

min, ksi

(MPa)

Yield

Strength.

min,

0.2% offset,

Ksi

(MPa)

Elongation

in

2"

min %

Reduction

of

Area

min %

Hardness

max

All

diameters

Carbide

Solution

Treated

80(550) 35(240) 30 40

223 HB or

96HRB

(3/4" in &

smaller,

241HB or 100

HRB)

CLASS IC: B8R

Dia

Heat

Treatement

Tensile

Strength

min, ksi

(MPa)

Yield

Strength.

min,

0.2% offset,

Ksi

(MPa)

Elongation

in

2"

min %

Reduction

of

Area

min %

Hardness

max

All

diameters

Carbide

Solution

Treated

100(690) 55(380) 35 55

271 HB

or 28 HRC

CLASS IC: B8RA

Dia

Heat

Treatement

Tensile

Strength

min, ksi

(MPa)

Yield

Strength.

min,

0.2% offset,

Ksi

(MPa)

Elongation

in

2"

min %

Reduction

of

Area

min %

Hardness

max

All

diameters

Carbide

Solution

Treated in the

finished

100(690) 55(380) 35 55

271 HB

or 28 HRC

condition

CLASS IC: B8S

Dia

Heat

Treatement

Tensile

Strength

min, ksi

(MPa)

Yield

Strength.

min,

0.2% offset,

Ksi

(MPa)

Elongation

in

2"

min %

Reduction

of

Area

min %

Hardness

max

All

diameters

Carbide

Solution

Treated

95(655) 50(345) 35 55

271 HB

or 28 HRC

CLASS IC: B8SA

Dia

Heat

Treatement

Tensile

Strength

min, ksi

(MPa)

Yield

Strength.

min,

0.2% offset,

Ksi

(MPa)

Elongation

in

2"

min %

Reduction

of

Area

min %

Hardness

max

All

diameters

Carbide

Solution

Treated in the

finished

condition

95(655) 50(345) 35 55

271 HB

or 28 HRC

CLASS 2: B8, B8C, B8P, B8T, B8N

Dia

Heat

Treatement

Tensile

Strength

min, ksi

(MPa)

Yield

Strength.

min,

0.2% offset,

Ksi

(MPa)

Elongation

in

2"

min %

Reduction

of

Area

min %

Hardness

max

3/4" &

under

Carbide

Solution

Treated and

strain

Hardened

125(860) 100(690) 12 35

321 HB

or 35 HRC

over 3/4" &

1" incl

115(795) 80(550) 15 35

over 1" &

11/4" incl

105(725) 65(450) 20 35

11/4" to 11/2"

incl

100(690) 50(345) 28 45

CLASS 2: B8MN / B8M

Dia

Heat

Treatement

Tensile

Strength

min, ksi

(MPa)

Yield

Strength.

min,

0.2% offset,

Ksi

(MPa)

Elongation

in

2"

min %

Reduction

of

Area

min %

Hardness

max

3/4" &

under

Carbide

Solution

Treated and

strain

Hardened

110(760) 95(655) 15 45

321 HB

or 35 HRC

over 3/4" &

1" incl

100(690) 80(550) 20 45

over 1" &

11/4" incl

95(655) 65(450) 25 45

11/4" to 11/2"

incl

95(655) 75(515) 25 40

CLASS 2B: B8M2

Dia

Heat

Treatement

Tensile

Strength

min, ksi

(MPa)

Yield

Strength.

min,

0.2% offset,

Ksi

(MPa)

Elongation

in

2"

min %

Reduction

of

Area

min %

Hardnessmax

2" & under

Carbide

Solution

Treated and

strain

Hardened

95(655) 75(515) 25 40

321 HB

or 35 HRC

over 2" &

21/2" incl

90(620) 65(450) 30 40

over 21/2" to

3" incl

80(550) 55(380) 30 40

Low-Temperature Alloy Steel Bolt Material Chemical & Mechanical Requirements

ASTM A320-L7 (Cr- Mo AISI 4140,4142,4145 )

This material is considered as the most suitable for bolts to be used at temperature 0-(-)100

C,

The chemical properties and physical characteristics are as follows:

C Mn P S Si Cr Mo

Impact Energy

Absorption

Requirements

0.38-

0.48

0.75-

1.00

0.035

Max

0.04 Max 0.15-0.35 0.80-1.10

0.15-

0.25

Minimum

Impact

Value

Minimum

Impact

Value

Dia

Tensile

Strength

min, ksi

(MPa)

Yield

Strength.

min,

0.2%

offset,

Ksi

(MPa)

Elongation

in

2"

min %

Reduction

of

Area

min %

Hardness

max

Required for

Average of

Each set of

three

specimens

ft lbf [J]

Permitted

for

Specimen

only of a

set

ft lbf [J

21/2"

and

under

125

( 860 )

105

( 725 )

16 50

277-

321HB

for

reference

20[27] 15[20]

ASTM A 320 L7M

Dia. Heat Tensile Yield Elongation Reduction of Hardness

Treatment Strength

min, ksi

(MPa)

Strength.

min,

0.2% offset,

Ksi

(MPa)

in

2"

min %

Area

min %

max

21/2" and

under

Quenched

and

tempered at

1,150 F

(620 C)

min

100(690) 80(550) 18 50

235HB

or 99HRB

ASTM A320 B8 (18Cr-8Ni AISI 304)

This material is considered as the most suitable for bolts and nuts to be used at temperatures (-

)100-(-)200 C The chemical properties are as follows:

C Mn P S Si Cr Ni

0.08 Max 2.00 Max

0.045

Max

0.030

Max

1.00 Max

18.00-

20.00

8.00-10.50

ASTM A320 B8M

C Mn P S Si Cr Ni Mo

0.08 Max 2.00 Max

0.045

Max

0.030

Max

1.00 Max

16.00-

18.00

10.00-

14.00

2.00-3.00

ASTM A320 B8C

C Mn P S Si Cr Ni

Columbium

+ Tantulum

0.08 Max 2.00 Max

0.045

Max

0.030

Max

1.00 Max

17.00-

19.00

9.00-13.00

10 *

Carbon

content,

min

ASTM A320 B8T

C Mn P S Si Cr Ni Titanium

0.08 Max 2.00 Max

0.045

Max

0.030

Max

1.00 Max

17.00-

19.00

9.00-12.00

5 * Carbon

content,

min

Super High Temperature Resistant Bolt Material Chemical & Mechanical

Requirements

This material is considered as suitable for bolts to be used as temperature below 1,200 F (650

C) and the material has superior resistence to oxidation and shrinkage to those high

temperature resistant bolt material mentioned so far. The chemical properties and physical

characteristics are as follows:

ASTM A453 Gr. 660

C Mn P S Si Cr

0.08 Max 2.00 Max 0.040 Max 0.030 Max 1.00 Max 24.00-27.00

Cr Mo Ti Al V Boron

13.50-16.00 1.00-1.50 1.90-2.35 0.35 Max 0.10-0.50 0.0010 - 0.010

CLASS

Tensile

Strength

min, ks

(MPa)

Yield

Strength. min,

0.2% offset,

Ksi

(MPa)

Elongation in

4x Dia.

min,%

Reduction of

Area

min, %

Brinell

Hardness

Number

A,B and C 130(895) 85(585) 15 18

248-341 (min

99HRB, max

37HRC)

ASTM A453 Gr. 651

C Mn P S Si Cr

0.28 - 0.35 0.75 -1.50 max 0.040 max 0.030 0.30 - 0.80 8.00-11.00

Cr Mo Ti W Cb Cu

18.00-21.00 1.00-1.75 0.10 - 0.35 1.00 - 1.75 025 - 0.60 max 0.50

CLASS

Tensile

Strength

min, ks

(MPa)

Yield

Strength. min,

0.2% offset,

Ksi

(MPa)

Elongation in

4x Dia

min, %

Reduction of

Area

min, %

Brinell

Hardness

Number

A ( 3" and

under)

100(690) 70(485) 18 35

217-277 (min

95HRB, max

28HRC)

A (over 3") 60(415)

B ( 3" and

under)

95(655) 60(415) 18 35

217-277 (min

95HRB, max

28HRC)

B (over 3") 50(345)

ASTM B408 (800,800H)

Ni Cr Fe Mu C Cu Si S Al Ti

30.0 -

35.0

19.0 -

23.0

*39.5

min

1.5 Max

0.10

Max

0.75

Max

1.0 Max

0.015

Max

0.15 -

0.60

0.15 -

0.60

* = Iron shall be determined arithmetically by differenece

CLASS CONDITION

Tensile

Strength

min, ksi

(MPa)

Yield

Strength.

min, Ksi

(MPa)

Elongation in

%

min

800

(all sizes) Hot finished rods and

bars

80(550) 35(240) 25

(all sizes) Cold drawn and

(annealed) Hot finished rods and

bars

75(520) 30(205) 30

800H

(all sizes) Cold drawn and

(annealed) Hot finished rods and

bars

65(450) 25(170) 30

HASTALLOY C/ASME SB336,UNS N10002

Class Ni Co Cr Mo W Fe Si Mn C

C Balance < 2.5 16 16 4 5 < 1.00 < 1.00 < 0.08

Monel K-500

Ni C Mn Fe S Si Cu Al Ti

63 - 70 0.25 Max 1.50 Max 2.00 Max 0.01 Max 0.5 Max balance

2.3 -

3.15

0.35 -

0.85

Monel 400

Ni C Mn Fe S Si Cu

63 - 70 0.30 Max 2.0 Max 2.5 Max 0.024 Max 0.050 Max balance

Nut Material Chemical & Mechanical Requirements

ASTM A194 Gr.2H

This is the material for bolts made from ASTM A-193 B7, considered to be used with suitable

heat treatment. The chemical properties and physical characteristics are as follows :

C Mn P S Si

Brinell

Hardness

Rockwell

Hardness

0.40 Min 1.00 Max 0.040 Max 0.050 Max 0.40 Max

To 11/2" incl

248 to 352

24 to 38

HRC

Over

11/2",212 to

352

38 HRC Max

ASTM A194 Gr.2HM

C Mn P S Si

Brinell

Hardness

Rockwell

Hardness

0.40 Min 1.00 Max 0.040 Max 0.050 Max 0.40 Max 159 to 237 22 HRC Max

ASTM A194 Gr.4

This material is considered as the most suitable for nuts,when they are used with bolts made

from ASTM A-193 B16 and A-320 L7. Even at high temperature range. then material has superior

physical characteristics to those ASTMA A-194 2H previously mentioned. The chemical

properties and physical characteristics are as follows :

C Mn P S Si Mo

Brinell

Hardness

Rockwell

Hardness

0.40 -

0.50

0.70 -

0.90

0.035

Max

0.04 Max 0.15 - 0.35 0.20 - 0.30 248 to 352

24 to 38

HRC

ASTM A194 Gr. 8 (AISI 304)

This is nut material for bolts made from ASTM A-193 B8, considered to be used with suitable

heat treatment. The chemical properties and physical characteristics are as follows :

C Mn P S Si Cr Ni

Brinell

Hardness

Rockwell

Hardness

0.08 Max 2.00 Max

0.045

Max

0.030

Max

1.00 Max

18.00 -

20.00

8.00 -

10.50

126 to

300

60 to

105 HRB

ASTM A194 Gr. 8M (AISI 316)

This is nut material for bolts made from ASTM A-193 B8M and A-320 B8M, considered to be

used with suitable heat treatment. The chemical properties and physical characteristics are as

follows :

C Mn P S Si Cr Ni Mo

Brinell

Hardness

Rockwell

Hardness

0.08

Max

2.00

Max

0.045

Max

0.030

Max

1.00

Max

16.00 -

18.00

10.00 -

14.00

2.00 -

3.00

126 to

300

60 to

105 HRB

ASTM A194 Gr. 8C (AISI 347)

This is nut material for bolts made from ASTM A-193 B8C, A-320 B8Cand A-320 B8T,

considered to be used with suitable heat treatment. The chemical properties and physical

characteristics are as follows :

C Mn P S Si Cr Ni

Cb +

Ta

Brinell

Hardness

Rockwell

Hardness

0.08

Max

2.00

Max

0.045

Max

0.030 Max

1.00

Max

17.00

-

19.00

9.00 -

13.00

10 *

C%

min

126 to

300

60 to

105 HRB

ASTM A194 Gr. 8T (AISI 321)

This is nut material for bolts made from ASTM A-193 B8Tand A-320 B8T, considered to be used

with suitable heat treatment. The chemical properties and physical characteristics are as follows :

C Mn P S Si Cr Ni Ti

Brinell

Hardness

Rockwell

Hardness

0.08

Max

2.00

Max

0.045

Max

0.030

Max

1.00

Max

17.00 -

19.00

9.00 -

12.00

5 C%

min

126 to

300

60 to

105 HRB

ASTM A307

This material is suitable in structural application where nominal strength alongwith weldability is

required.

Grade P S

Tensile

Strength

min, ksi

(MPa)

Yield

Strength.

min,

0.2% offset,

Ksi

(MPa)

Elongation

in

2"

min %

Hardness

max

A 0.06 Max 0.15 Max 60 (415) - 18 121 - 241 BHN

B 0.04 Max 0.05 Max

60 - 100

(415 - 690)

- 18 121 - 212 BHN

C - -

58 - 80

(400 - 550)

36(50) 23 Not Required

ASTM A563

This specification of material is used for manufactoring nuts for balts/styds made from ASTM

A307

Grade C Mn (Max) P (Max) S (Max)

O,A,B,C 0.58 Max - 0.13 -

D 0.58 Max 0.27 0.048 0.058

DH 0.18-0.58 0.57 0.048 0.058

Grade Hardness Required

O 103 to 302 BHN

A 116 to 302 BHN

B 90 to 121 BHN

C 143 to 352 BHN

D 159 to 352 BHN

DH 248 to 352 BHN

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Acid PipingDocument1 pageAcid Pipinghasan_676489616Pas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Method of Statement Piping Fab. ErectionDocument22 pagesMethod of Statement Piping Fab. Erectionhasan_676489616Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Delayed PWHTDocument4 pagesDelayed PWHThasan_676489616Pas encore d'évaluation

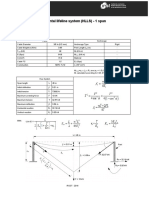

- Horizontal Life Line CalculationDocument1 pageHorizontal Life Line Calculationhasan_676489616100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- ITP For Piping WorksDocument91 pagesITP For Piping Workshasan_676489616100% (1)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Cross Cut TestDocument1 pageCross Cut Testhasan_676489616Pas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- LNG Tank Dismantling MS RevCDocument14 pagesLNG Tank Dismantling MS RevChasan_676489616100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- E SN883Document2 pagesE SN883hasan_676489616100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- ITP For Piping WorksDocument91 pagesITP For Piping Workshasan_676489616100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- E SN834Document3 pagesE SN834hasan_676489616Pas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Din 2614Document11 pagesDin 2614hasan_676489616Pas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- OSHA - 29CFR - Construction StandardsDocument22 pagesOSHA - 29CFR - Construction Standardshasan_676489616100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Steel Grades ComparisonDocument14 pagesSteel Grades Comparisonhasan_676489616Pas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- ASME B16.47 Series B FlangeDocument4 pagesASME B16.47 Series B Flange41h189Pas encore d'évaluation

- Din 17240Document24 pagesDin 17240hasan_676489616100% (1)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Din 30678Document6 pagesDin 30678hasan_676489616Pas encore d'évaluation

- Din 17221Document9 pagesDin 17221hasan_676489616100% (1)

- Din 55928Document16 pagesDin 55928hasan_676489616Pas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- E SN759Document2 pagesE SN759hasan_676489616Pas encore d'évaluation

- Din en Iso 4014Document16 pagesDin en Iso 4014hasan_676489616100% (7)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Din 17155Document16 pagesDin 17155hasan_676489616Pas encore d'évaluation

- Weld-On Pipe Coupling SN 789: Type ASDocument1 pageWeld-On Pipe Coupling SN 789: Type AShasan_676489616Pas encore d'évaluation

- DIN2391 1EN10305 1 - 2003 02 - eDocument27 pagesDIN2391 1EN10305 1 - 2003 02 - ehasan_676489616Pas encore d'évaluation

- E SN753Document2 pagesE SN753hasan_676489616Pas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- E SN752Document3 pagesE SN752hasan_676489616Pas encore d'évaluation

- b53 3271 Emboutillage para Argentina y BrasilDocument9 pagesb53 3271 Emboutillage para Argentina y BrasilGT-LUCAS BARCIPas encore d'évaluation

- BCS-CRM No. 179/2: High-Tensile Brass (Cast)Document2 pagesBCS-CRM No. 179/2: High-Tensile Brass (Cast)Ishmael WoolooPas encore d'évaluation

- Biological WastwaterDocument486 pagesBiological WastwaterLeanne MartinPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Lab Manual FSI 12803 Exp 3 7.11.2022Document4 pagesLab Manual FSI 12803 Exp 3 7.11.2022alyea atiraPas encore d'évaluation

- 1.8 Revision Guide Thermodynamics AqaDocument8 pages1.8 Revision Guide Thermodynamics AqaRabia RafiquePas encore d'évaluation

- CBSE Sample Papers Class 10 Science SA 2 Solved 2 PDFDocument15 pagesCBSE Sample Papers Class 10 Science SA 2 Solved 2 PDFDeep AdhiaPas encore d'évaluation

- Chemistry Question Bank RKLDocument31 pagesChemistry Question Bank RKLSahil GuptaPas encore d'évaluation

- Astm A 572 A 572m 15pdfDocument4 pagesAstm A 572 A 572m 15pdfKartik DoblekarPas encore d'évaluation

- Microstructure Evolution of HP40-Nb Alloys During Aging UnderDocument9 pagesMicrostructure Evolution of HP40-Nb Alloys During Aging UnderOmarPas encore d'évaluation

- Curriculum Map in Science 7 First QuarterDocument2 pagesCurriculum Map in Science 7 First QuarterSaber johndroPas encore d'évaluation

- c68700 Aluminum BrassDocument1 pagec68700 Aluminum Brassm_f_deathPas encore d'évaluation

- Acid and Base CalculationsDocument9 pagesAcid and Base CalculationsDaniel McDermott0% (1)

- Compatibilidade de Mangueiras ApacheDocument41 pagesCompatibilidade de Mangueiras ApacheDiego S. FreitasPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- E-Cld-3108 - Astm C-1602Document5 pagesE-Cld-3108 - Astm C-1602Andre FarfanPas encore d'évaluation

- B2.1 B2.1M 2021 Web - PVDocument14 pagesB2.1 B2.1M 2021 Web - PVIsabel BurnettePas encore d'évaluation

- Operational Pollution of ShippingDocument24 pagesOperational Pollution of ShippingKamal RahimPas encore d'évaluation

- Safety and Basic Laboratory Techniques (SIC1011) Inorganic ChemistryDocument9 pagesSafety and Basic Laboratory Techniques (SIC1011) Inorganic ChemistryU2103536 STUDENTPas encore d'évaluation

- PM Is 3589Document8 pagesPM Is 3589Pavul RajPas encore d'évaluation

- Clasificator Medicamente 30.11.2016Document1 038 pagesClasificator Medicamente 30.11.2016Cătălina GîlcaPas encore d'évaluation

- Periodic Table of Elements - Sorted by 1st Ionization Potential (EV) (EnvironmentalChemistryDocument2 pagesPeriodic Table of Elements - Sorted by 1st Ionization Potential (EV) (EnvironmentalChemistryTrushar ParmarPas encore d'évaluation

- Amicon Ultra 4 ML GuideDocument12 pagesAmicon Ultra 4 ML Guidemohit16ukPas encore d'évaluation

- 13 General EquilibriumDocument11 pages13 General Equilibriumapi-234034801Pas encore d'évaluation

- Laboratory Manual (Inorganic and Organic Chem)Document89 pagesLaboratory Manual (Inorganic and Organic Chem)renPas encore d'évaluation

- 9.1.1 Introduction To Oxidation and ReductionDocument24 pages9.1.1 Introduction To Oxidation and ReductionPatrick AbidraPas encore d'évaluation

- ISO 8217 2010 Fuel Standard For Marine Distillate FuelsDocument2 pagesISO 8217 2010 Fuel Standard For Marine Distillate FuelstamailhamPas encore d'évaluation

- GLXXMobilgrease XHP 220 SeriesDocument3 pagesGLXXMobilgrease XHP 220 SeriesJavier Cayampi PomallihuaPas encore d'évaluation

- CaseinDocument11 pagesCaseinsudhuPas encore d'évaluation

- 5070 s17 QP 41Document12 pages5070 s17 QP 41Waleed Bin AhmadPas encore d'évaluation

- Rubber Industries (Handouts)Document18 pagesRubber Industries (Handouts)daabgchi100% (1)

- Acid Base Part II Test 1516 (Corrected)Document7 pagesAcid Base Part II Test 1516 (Corrected)etiosamiPas encore d'évaluation