Académique Documents

Professionnel Documents

Culture Documents

Ags0700m en

Transféré par

adityaprazttTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ags0700m en

Transféré par

adityaprazttDroits d'auteur :

Formats disponibles

DIESEL GENERATOR SET

665/730 kVA

Type

AGS0700M

T

e

c

h

n

i

c

a

l

D

a

t

a

S

h

e

e

t

Diesel Generator Set

Type AGS0700M

665/730 kVA

Engine Data

Crankcase made of gray cast iron; dropforged crankshaft and connecting

rod shanks

Four valve cylinderheads

Rigid construction - low-vibration engine

High efciency - low fuel consumption

Vibration damper

Common Rail- fuel injection system; electronically controlled injection

Hand primer for rst ll and ventilation (low- pressure system)

Forced feed lubrication and piston cooling

Lube oil pump with safety valve

Lube oil lter

Closed crankcase ventilation

Controlling and monitoring - integrated electronic system for engine

management and monitoring ADEC + Smart Connect.

Genset Rating

Prime Power (PRP)

Limited Time Power (LTP)

2

Power Factor (cos phi)

Nominal Voltage

Nominal Current

Frequency

Speed

Load Acceptance

665 kVA / 532 kWe

730 kVA

0.8 pf

400 V / 230 V

961 A

50 Hz

1 500 min

-1

approx. 70 %

Noise Emission (Sound Proof)

4

Sound pressure L

PA

@ 7 m approx. 72 dB(A)

Dimensions and Weights

Length

Width

Height

Weight (approx.)

Open Set / Sound Proof

3 668 mm 5 182 mm

1 315 mm 1 810 mm

2 239 mm 2 830 mm

4 500 kg 6 800 kg

192 g/kWh

197 g/kWh

206 g/kWh

223 g/kWh

208 g/kWh

205 g/kWh

211 g/kWh

227 g/kWh

Fuel Consumption and Fuel Tank Capacity

3

Fuel Consumption at 100 % Load

(Fuel consumption 75 % Load

optimised) 50 % Load

25 % Load

Fuel Consumption at 100 % Load

(Exhaust emission 75 % Load

optimised) 50 % Load

25 % Load

Capacity of base frame fuel tank

(Open Set)

Capacity of base frame fuel tank

(Sound Proof Genset)

132.4 l/h

101.9 l/h

71.1 l/h

38.5 l/h

143.5 l/h

106.1 l/h

72.8 l/h

39.1 l/h

345 l

1250 l

Manufacturer

Type

Gross Output (PRP/LTP)

Speed

No. of cylinders / Conguration

Bore / Stroke

Displacement per cylinder / total

Compression ratio

Weight

Injection system

Standard of cooling system

Flywheel housing

Flywheel connection

No. of turbocharges

Govenor type

Average piston speed

Brake mean effective pressure

Electric starter

MTU

12V 1600

576 kW / 634 kW

1 500 min

-1

12 / V

122 mm / 150 mm

1.75 l / 21.00 l

17.5 : 1

approx. 1 950 kg

Common Rail-fuel

injection system

water

SAE 1

DISC 14

2

electronic

7.5 m/s

21.96 bar

24 V

Exhaust Emission (TA Luft 2000)

5

Nitrogen oxide (No

x

) in mg/m

3

Carbon monoxide (CO) in mg/m

3

Dust (C) in mg/m

3

allowed values / MTU values

4 000 < 1 500

650 < 300

130 < 50

104 dB(A)

109 dB(A)

109 dB(A)

Noise Emission (Open Set)

4

Surface noise @ 1 m

Undamped exhaust noise @ 1 m

- Fuel consumption optimised

- Exhaust emission optimised

Fuel delivery

Max. fuel inlet temperature

Fuel pressure at fuel inlet connection max.

Fuel pressure at fuel inlet connection min.

Recommended inside diameter for fuel

pipes with a length of max.10 m

Max. suction height

Max. height difference between tank and

fuel pump

Fuel System

5.7 l/min

70 C

0.5 bar

-0.5 bar

ow DN 15 (18 mm)

return DN 12 (15 mm)

1.3 m

3.0 m

Heat Rejection

Optimised for:

Heat rejection to coolant

Heat rejection to charge air cooler

Engine radiation and convection

Heat rejection of alternator

Fuel cons. / Exhaust emis.

236 kW 250 kW

104 kW 121 kW

25 kW 24 kW

32 kW 32 kW

Exhaust System

Exhaust gas ow

- Fuel consumption optimised

- Exhaust emission optimised

Exhaust gas temp. after turbocharger

- Fuel consumption optimised

- Exhaust emission optimised

Exhaust back pressure max.

7 560 m

3

/h

6 120 m

3

/h

483 C

470 C

85 mbar

Lubrication System

Oil capacity (sump) min. / max.

Lube oil consumption (in % of fuel cons.)

Oil pressure min. / max.

Oil pressure (Shutdown)

- Fuel consumption optimised

- Exhaust emission optimised

Oil temperature min. / max.

56 l / 64 l

0.5

4.0 bar / 5.0 bar

2.4 bar

2.4 bar

87 C / 101 C

Combustion Air

Combustion air volume

- Fuel consumption optimised

- Exhaust emission optimised

Max. air intake restriction

Air cleaner type

2 880 m

3

/h

2 268 m

3

/h

50 mbar

dry, replaceable element

with safety cartridge

Alternator Data

Manufacturer

Type

Output (PRP)

Voltage control

Short circuit capability

AC wavefactor total harmonic distorsion

No. of poles

Radio interference

Efciency at

100 % Load

75 % Load

50 % Load

25 % Load

Mechanical protection (IP class)

Insulation class

Cooling air volume

Moment of inertia

Weight

Aggretech

ACG0700-4-400

700 kVA

electronic, self- regulating,

+/- 1%

3 x Nominal current

< 2 %

4

EN 55011 Class B, Group 1

cos phi 0.8 / 1.0

0.947 / 0.961

0.946 / -

0.938 / -

0.901 / -

IP 23

H

4 134 m

3

/h

6.663 kgm

2

approx. 1 600 kg

2/3 pitch winding

With damper cage, suitable for parallel working

Brushless, self-exciting synchronous alternator

Cooling System

Voltage of water jacket heater

Output of water jacket heater

Preheating temperature min. / max.

Max. ambient temperature

Antifreezing compound for radiator to

Fan power

Cooling air ow

Max. air pressure loss

Dimensions of cooling system approx.

Max. coolant temperature (at engine outlet

in front of cooling equipment)

Max. coolant temp. after engine (Alarm)

Max. coolant temp. after engine (Stop)

Coolant ow rate

Coolant pump inlet pressure min. / max.

230 V

3 kW

32 C / 70 C

40 C

6

-25 C

18 kW

40 320 m

3

/h

approx. 2 mbar

B 1 315 x H 1 383 mm

95 C

105 C

105 C

26 m

3

/h

1.4 bar / 3.5 bar

Legend:

1

PRP (Prime Power) is the variable load with an average load factor < 75%. 10% overload

capabilty for governing purposes for 1 hour in every 12 hours.

PRP according to ISO 8528. 10% overload capability according to ISO 3046, AS 2789;

DIN 6271 and BS 5514.

2

LTP (Limited Time Power) is limited to 300 hours annual usage with an average load factor

< 75%. No overload is permitted on Limited Time Power. LTP according to ISO 8528.

3

Fuel consumption according to MTU datasheet.

4

At 75% load, according to EU guideline 2000/14/EG

5

Exhaust emission optimised type meets German TA-Luft 2000, fuel consumption optimised

type meets TA-Luft 4000. Exhaust emission optimised type is optionally available. Exhaust

emission limits are based on German TA-Luft guideline (Edition 1986): the stated MTU values

are sample values of MTU load tests (at ISO standard conditions and 100 % load)

6

Cooling equipment for higher ambient temperatures is optionally available.

Quality Standards:

VDE 0530, DIN 6280, ISO 8528, IEC 34, BS 4999, BS 5000, BS 5514

Performance gures according to ISO standard ambient conditions as follows:

ambient temperature 25 C, 100 m above sea level, rel. humidity 30 %;

We reserve the right to change specications without notice.

Your authorised dealer Drawings are not true to scale.

Weights refer to the dry weights and represent a set with standard features. Accesso-

ries and loose parts are not accounted. Drawings are for illustrative purposes only and

might include special accessories.

We reserve the right to change specications without notice.

A 3 / AGS0700M 27/06/2011 E

AGGRETECH AG

Division Generator Sets

Rotthofer Str. 8, 94099 Ruhstorf

Germany

Phone +49 (0) 8531 9782-0

Fax +49 (0) 8531 9782-1510

gensets@aggretech.de

www.aggretech.de

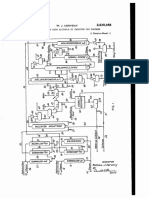

Diesel Generator Set

Type AGS0700M

665/730 kVA

5182

1

2

0

1780

2

8

3

0

2

6

2

5

3668

2

2

3

9

3

3

5

5

0

0

1

2

0

1315

1215

1152

1

3

8

3

6

1

9

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- YamYFM80Moto4Man IndexedDocument179 pagesYamYFM80Moto4Man IndexedaschubartPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Chevron Static ElectrictyDocument42 pagesChevron Static ElectrictyASHUTOSH100% (1)

- Catalogo de Peças H40-H70FT - Sub Serie L177Document970 pagesCatalogo de Peças H40-H70FT - Sub Serie L177Suziane Sousa Victor80% (5)

- Rockwell Automation - Basics of Circuit BreakersDocument102 pagesRockwell Automation - Basics of Circuit Breakersrobertspiteri100% (1)

- ShovelDocument17 pagesShovelAr Dheeraj MauryaPas encore d'évaluation

- EB8870Document2 pagesEB8870Miguel RojasPas encore d'évaluation

- GST Fire Alarm System-CatalogDocument72 pagesGST Fire Alarm System-Catalogadityapraztt75% (4)

- Typical Wear Mechanism 2 Stroke Exhaust ValvesDocument5 pagesTypical Wear Mechanism 2 Stroke Exhaust ValvesdragoscodPas encore d'évaluation

- C1100 D5 - Spec Sheet (2013) PDFDocument4 pagesC1100 D5 - Spec Sheet (2013) PDFMauroPas encore d'évaluation

- Emcp4.1 PanelDocument2 pagesEmcp4.1 Paneladityapraztt0% (1)

- Land Rover Ilustrated Parts Catalogue 101fcDocument399 pagesLand Rover Ilustrated Parts Catalogue 101fcDavid SeddonPas encore d'évaluation

- Flaring and Venting PhilosophyDocument10 pagesFlaring and Venting PhilosophyRexx Mexx100% (1)

- Autogreider Hidromek HMK MG 330Document2 pagesAutogreider Hidromek HMK MG 330dicon100% (1)

- TGT-P-H01-RP-0002 Rev.0 PDFDocument41 pagesTGT-P-H01-RP-0002 Rev.0 PDFThái Xuân QuangPas encore d'évaluation

- Catalogo Brazos de Cargue OPWDocument40 pagesCatalogo Brazos de Cargue OPWCARLITOS 25Pas encore d'évaluation

- Imsyak Mataram 2020Document2 pagesImsyak Mataram 2020adityaprazttPas encore d'évaluation

- VMD420 Series: Digital Voltage, Frequency, Asymmetry, and Phase Loss Relay For Three-Phase AC SystemsDocument6 pagesVMD420 Series: Digital Voltage, Frequency, Asymmetry, and Phase Loss Relay For Three-Phase AC SystemsadityaprazttPas encore d'évaluation

- 6 Solar LED LampDocument4 pages6 Solar LED LampadityaprazttPas encore d'évaluation

- En Generator Testing Programs FlyerDocument2 pagesEn Generator Testing Programs FlyeradityaprazttPas encore d'évaluation

- Baker d12rDocument110 pagesBaker d12rPlaneamiento MecanicoPas encore d'évaluation

- 1 WarrantyDocument1 page1 WarrantyadityaprazttPas encore d'évaluation

- 6 Solar LED LampDocument4 pages6 Solar LED LampadityaprazttPas encore d'évaluation

- 1 Solar Energi SystemDocument4 pages1 Solar Energi SystemadityaprazttPas encore d'évaluation

- 3 Solar Charge ControllerDocument4 pages3 Solar Charge ControlleradityaprazttPas encore d'évaluation

- 1 Solar Energi SystemDocument4 pages1 Solar Energi SystemadityaprazttPas encore d'évaluation

- 5 Solar Charge Battery: Maintenance-Free Rechargeable Sealed Lead-Acid BatteryDocument1 page5 Solar Charge Battery: Maintenance-Free Rechargeable Sealed Lead-Acid BatteryadityaprazttPas encore d'évaluation

- 2 Solar PanelDocument4 pages2 Solar PaneladityaprazttPas encore d'évaluation

- 4 InverterDocument4 pages4 InverteradityaprazttPas encore d'évaluation

- ANSI Codes PDFDocument3 pagesANSI Codes PDFelectrical_1012000100% (2)

- Instruction Cadweld Grounding ConnectionsDocument2 pagesInstruction Cadweld Grounding ConnectionsadityaprazttPas encore d'évaluation

- ANSI Codes PDFDocument3 pagesANSI Codes PDFelectrical_1012000100% (2)

- 16 CH SNVR Datasheet PDFDocument2 pages16 CH SNVR Datasheet PDFadityaprazttPas encore d'évaluation

- ANSI Codes PDFDocument3 pagesANSI Codes PDFelectrical_1012000100% (2)

- ANSI Codes PDFDocument3 pagesANSI Codes PDFelectrical_1012000100% (2)

- Datasheet B7210 PDFDocument2 pagesDatasheet B7210 PDFadityaprazttPas encore d'évaluation

- Alstom T155Document2 pagesAlstom T155adityaprazttPas encore d'évaluation

- 16 CH SNVR Datasheet PDFDocument2 pages16 CH SNVR Datasheet PDFadityaprazttPas encore d'évaluation

- SD01G05B03 01eDocument2 pagesSD01G05B03 01eadityaprazttPas encore d'évaluation

- Ansi - Neta AtsDocument7 pagesAnsi - Neta AtsJavier AyalaPas encore d'évaluation

- Datasheet B7210 PDFDocument2 pagesDatasheet B7210 PDFadityaprazttPas encore d'évaluation

- E T ReactorsDocument16 pagesE T ReactorsFleancuCatalinPas encore d'évaluation

- Schlumberger WELL ActivitiesDocument17 pagesSchlumberger WELL ActivitiesEduardo Paulini VillanuevaPas encore d'évaluation

- CN4123 AY17-18-FinalDocument10 pagesCN4123 AY17-18-FinalTan Song KaiPas encore d'évaluation

- 919 Test Bench Price List FullDocument3 pages919 Test Bench Price List FullMynor Witt100% (1)

- SSP 020 Common - RailDocument30 pagesSSP 020 Common - Railvenkateshyadav2116Pas encore d'évaluation

- Introduction To N.G Sheet 1Document2 pagesIntroduction To N.G Sheet 1Eng Said ElsayedPas encore d'évaluation

- CTN0036 Multi Throttle Tuning MethodDocument4 pagesCTN0036 Multi Throttle Tuning MethodRajibPas encore d'évaluation

- Range Rover Maunual ElectricsDocument146 pagesRange Rover Maunual ElectricsLouise RogersPas encore d'évaluation

- 625HD DG Set - 625HD KOEL GensetDocument3 pages625HD DG Set - 625HD KOEL GensetMothilalPas encore d'évaluation

- DFGHFHDocument16 pagesDFGHFHvansifiedPas encore d'évaluation

- Engine Complete 2Document43 pagesEngine Complete 2Garcia CruzPas encore d'évaluation

- Thermalysis-Converting Waste Plastic To DieselDocument8 pagesThermalysis-Converting Waste Plastic To DieselRavi KumarPas encore d'évaluation

- Commodityfocus WorldcoalDocument17 pagesCommodityfocus WorldcoalJohn Davis100% (1)

- Heavy Duty, Radially Split, Two-Stage Pumps: API 610 / ISO 13709Document10 pagesHeavy Duty, Radially Split, Two-Stage Pumps: API 610 / ISO 13709bandmmillwardPas encore d'évaluation

- Oxygen Sensor Certification ManualDocument20 pagesOxygen Sensor Certification ManualSR BangashPas encore d'évaluation

- LP Gas Detector KP-35D: FeaturesDocument3 pagesLP Gas Detector KP-35D: FeaturesdonghoangsonPas encore d'évaluation

- 2010 CC 3.6 Engine Schematic R36Document19 pages2010 CC 3.6 Engine Schematic R36Dungani AllanPas encore d'évaluation

- Ss S Ss S William J. Cerveny: 57.7/osyp/22 SN GDocument11 pagesSs S Ss S William J. Cerveny: 57.7/osyp/22 SN GAndrea' MezaPas encore d'évaluation