Académique Documents

Professionnel Documents

Culture Documents

Lecture 5 X 6

Transféré par

Sushil Kumar0 évaluation0% ont trouvé ce document utile (0 vote)

25 vues6 pagesok

Titre original

Lecture5x6

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentok

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

25 vues6 pagesLecture 5 X 6

Transféré par

Sushil Kumarok

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 6

1

Alloy steels and Cast iron

MECH2300 - Structures and Materials

Materials Lecture 5

Dr Rowan Truss

Division of Materials

School of Engineering

Alloy steels

Many steels contain other elements other

than Fe and C

non-carbon elements < 5% - low alloy

steels

non carbon elements > 5% - high alloy

steels

Why add alloying elements?

form solid solution with iron

solid solution strengthening

e.g. C, Cr, Mn, Ni, Mo, Si, Co

form carbides (other than Fe

3

C)

hardness and high Temp. strength

e.g. Ti, W, V

Why add alloying elements? (cont.)

combine with oxygen in liquid steel

improved properties

e.g. Al, Si, Cu, Mn

remain undissolved as separate phase

improved machinability, damping

e.g. Pb, S, P

control the phases present

control hardenability (discussed next week)

Controlling phases present

alloying elements affect stability of different

phases

extends regions of Fe/C equilibrium phase diagram

where one phase or another is stable

some elements form intermetallics - i.e. new phase

a) austenite stabilizers

eg. Mn, Ni, Cu

2

b) ferrite stabilizers

eg. Si, Cr, W, Mo, V, P, Ti, Al

Stainless Steels

Steel to which a minimum 10.5% Cr added

(usually more added)

Cr gives corrosion resistance (discussed in

later lectures)

Ferritic, austenitic, martensitic (discussed

next week), duplex structures depending on

alloy composition

Alloy additions to Stainless Steel

Carbon

Usually kept low ~ 0.05% - avoid chromium

carbide formation

Higher C (0.15% - 1.2%) heat treatable to

give martensite

Chromium

Corrosion protection (minimum 10.5% -26%)

Molybdenum

Improves resistance to pitting corrosion

(316 grade 2% Mo)

Alloy additions to Stainless Steel

(Cont.)

Nickel

Promotes austenitic structure (304 grade

18%Cr,8%Ni fully austenitic)

Lower Ni - duplex structure (ferritic/austenitic)

Manganese/Nitrogen

Promotes Austenite structure

Used with or to partially replace Ni

Alloy additions to Stainless Steel

(Cont.)

Titanium

Strong carbide former, forms carbides rather

than chromium carbides

Niobium & tantalum

Similar effect to Ti (Ti usually preferred)

Silicon

Improves casting

Improves scaling resistance for austenitic steels

steel designation systems

a system of numbers (and symbols)

designates alloying type and carbon

content

3

AISI system

first two numbers - alloy type

e.g 10XX - plain carbon steel

23XX - Nickel steel (3.5)

43XX - Ni-Cr-Mo, etc

last two or three numbers - carbon content

(hundredths of wt %)

eg. 1030 plain with 0.3 wt% C

4340- Ni Cr Mo steel with 0.4wt% C

Designation system:

stainless steel

AISI three digit

Eg 304, 316

Extra letters to differentiate new alloys ie.

304L, 316N

UNS number

Letter + 5 digits

S-wrought, J cast, N nickel based

DIN, proprietary designations

Steel processing

Steel cast into ingots

Hot rolled into billets, slabs, blooms

Hot or cold rolled into final products

Hot rolling

Plastically deforming steel above recrystallisation

temperature

Grain structure is continually undergoing recrystallisation

Little strengthening or work hardening so large changes

in shape possible

Cold rolling

Deformation below

recrystallisation

temperature

Changes grain structure

into elongated /

deformed grains

increases strength but

introduces anisotropic

properties

CAST IRON

Fe/C alloys with

2 % < C < 4.5%

- CAST IRONS

related to eutectic at

4.2 % C and 1153 C

Note: eutectics give lower

melting point

ie material is easier to cast

4

Note: phase diagram is

slightly different to Fe/

Fe

3

C

Fe

3

C - metastable

true equilibrium phase

- Graphite (C)

Fe/graphite phase diagram

T

e

(graphite) = 1153 C

T

e

(Fe

3

C) = 1148 C

eutectic reaction involving carbide

L + Fe

3

C

favoured by: rapid cooling

presence of Cr

true equilibrium eutectic reaction (graphite)

L + graphite

favoured by: slow cooling

presence of Si, P, high C

cast iron microstructures

white cast iron - contains Fe

3

C

(use Fe/Fe

3

C diagram)

grey cast iron - forms graphite

(use Fe/graphite diagram)

white cast irons (typically 3% C)

microstructure development

1300 C - 1148 C

primary dendrites form

at 1148 C

L (2.0% C) + Fe

3

C(6.7% C)

between 1148 C and 727 C

solubility of C in decreases from 2.0%

to 0.8% C

more carbides ppt on eutectic carbide, or

on interface between primary and

eutectic

at 727 C

pearlite { (0.025%C) + Fe

3

C}

final

microstructure

dendrites transformed to

pearlite

carbide around pearlite

eutectic

Properties of white cast iron

lots of Fe

3

C in microstructure

little ductility in white cast iron

very hard and brittle

good wear resistance

5

malleable cast iron

to improve ductility of white iron -

reheat at 940C for 3 - 20 hrs

clusters of graphite in iron

cooled slowly, + more graphite

cooled quickly, pearlite

White iron Malleable iron

Yield stress

MPa

strain at

break %

White cast iron 275 very low

maleable

pearlite matrix

310 6-8%

maleable

ferrite matrix

225 10%

Microstructure of

Grey Cast Iron

at eutectic

L + graphite

at eutectoid

+ graphite

carbon forms graphite

rosettes in a matrix of low

carbon ferrite

properties

graphite forms long flakes

easy path for cracks to propagate

act as stress concentrators

grey cast iron - brittle, low toughness

graphite - high damping (machine bases)

provides lubrication

on sliding surfaces

Grey cast iron

steel

Nodular Cast Irons (Ductile Iron)

to improve ductility and toughness

add Mg, Ce just before casting

nucleates graphite during solidification

graphite now in nodular form

6

Grey cast iron Ductile iron

flake graphite nodular graphite

Vous aimerez peut-être aussi

- Applied Welding Engineering: Processes, Codes, and StandardsD'EverandApplied Welding Engineering: Processes, Codes, and StandardsPas encore d'évaluation

- RA - Angle GrinderDocument4 pagesRA - Angle GrinderMurugan RajaPas encore d'évaluation

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelD'EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelÉvaluation : 5 sur 5 étoiles5/5 (4)

- Callister 8th Edition - Chapter 11 - Applications and Processing of Metal AlloysDocument35 pagesCallister 8th Edition - Chapter 11 - Applications and Processing of Metal AlloysRini ArtikaPas encore d'évaluation

- Welding MetallurgyDocument37 pagesWelding Metallurgyhemant1886100% (4)

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonD'EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonPas encore d'évaluation

- Ferrous Material Structure and Binary Alloy SystemDocument68 pagesFerrous Material Structure and Binary Alloy SystemUsman FarooqPas encore d'évaluation

- Cast IronDocument43 pagesCast IronThulasi Ram100% (1)

- Confirmation - Your Booking Confirmation and Reference - FlydubaiDocument2 pagesConfirmation - Your Booking Confirmation and Reference - FlydubaiMurugan Raja67% (9)

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39D'EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Évaluation : 5 sur 5 étoiles5/5 (1)

- Metallurgy - Chapter (5) - Steels and Cast IronsDocument79 pagesMetallurgy - Chapter (5) - Steels and Cast IronsKarim Mamdouh100% (1)

- Heat TreatmentDocument56 pagesHeat TreatmentAakarsh RastogiPas encore d'évaluation

- The Essentials of Material Science and Technology for EngineersD'EverandThe Essentials of Material Science and Technology for EngineersÉvaluation : 5 sur 5 étoiles5/5 (1)

- Iron and Steel Production-Class LetureDocument30 pagesIron and Steel Production-Class LetureAustin Okoth Omondi100% (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonD'EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonPas encore d'évaluation

- Basic MetallurgyDocument55 pagesBasic MetallurgyTina Miller100% (2)

- Ferrous Alloys - Group 05Document36 pagesFerrous Alloys - Group 05Nipun HarshaPas encore d'évaluation

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelD'EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelPas encore d'évaluation

- Stainless SteelDocument34 pagesStainless SteelMohammed HilalPas encore d'évaluation

- Cast IronDocument27 pagesCast IronSanthoshsharma Devaraju100% (1)

- Iron (Fe) - Cementite (Fe C) Phase Diagram: Asst. Prof. Sandeep Parida Dept. of Mechanical Engineering CUTM, ParlakhemundiDocument41 pagesIron (Fe) - Cementite (Fe C) Phase Diagram: Asst. Prof. Sandeep Parida Dept. of Mechanical Engineering CUTM, ParlakhemundiAmrit MallickPas encore d'évaluation

- Cathodic Protection: The BasicsDocument8 pagesCathodic Protection: The BasicsbookbumPas encore d'évaluation

- Cathodic Protection: The BasicsDocument8 pagesCathodic Protection: The BasicsbookbumPas encore d'évaluation

- Cast IronDocument34 pagesCast IronMKPashaPasha100% (1)

- Classification of Steels-1Document85 pagesClassification of Steels-1Saptarshi SenguptaPas encore d'évaluation

- Lecture 10 (x6) PDFDocument6 pagesLecture 10 (x6) PDFOzanPas encore d'évaluation

- MT 305 Heat Treatment: TemperingDocument13 pagesMT 305 Heat Treatment: TemperingaarvPas encore d'évaluation

- Lecture n.9 Cast IronDocument25 pagesLecture n.9 Cast IronMOHAMMAD JAWAD QASIMPas encore d'évaluation

- Classification of Materials NotesDocument9 pagesClassification of Materials NotesJohn K KikwaiPas encore d'évaluation

- Melting PracticeDocument12 pagesMelting PracticeJaya Ram MPas encore d'évaluation

- Heat Treatment of SteelsDocument41 pagesHeat Treatment of Steelsyaswanth1992Pas encore d'évaluation

- Lecture 9 - Plain Carbon Steels - 2013Document45 pagesLecture 9 - Plain Carbon Steels - 2013ArunPas encore d'évaluation

- IE 337 W10 Lecture 3 Alloys&Heat - TreatDocument62 pagesIE 337 W10 Lecture 3 Alloys&Heat - Treatdm1680Pas encore d'évaluation

- Heat Treatment of SteelDocument51 pagesHeat Treatment of SteelRAMA BAGAS ADITYA TM 2DPas encore d'évaluation

- Materials Science MetalsDocument35 pagesMaterials Science MetalsPelajar IndonesiaPas encore d'évaluation

- Unit III - Heat TreatmentDocument62 pagesUnit III - Heat TreatmentHarsha MallaPas encore d'évaluation

- Iron Carbon Diagram (ChE Handbook)Document21 pagesIron Carbon Diagram (ChE Handbook)Mohamed Ismail100% (1)

- Metallurgy of Grey Cast IronDocument15 pagesMetallurgy of Grey Cast IronAmit PathakPas encore d'évaluation

- 4 Ferrous MetalsDocument36 pages4 Ferrous MetalsAnusha NoorPas encore d'évaluation

- 7 - Carbon Steel & Heat TreatmentDocument32 pages7 - Carbon Steel & Heat TreatmentAbdelrahmanPas encore d'évaluation

- Assignment 3 PMTDocument2 pagesAssignment 3 PMTDewi Lestari Natalia MarpaungPas encore d'évaluation

- Heat TreatmentDocument179 pagesHeat TreatmentDebye101100% (1)

- Chapter 13 - Heat Treatment of SteelsDocument60 pagesChapter 13 - Heat Treatment of Steelsahmedmagdi2009100% (1)

- 1Document72 pages1aarvPas encore d'évaluation

- Fe CdiagramDocument36 pagesFe CdiagramGeorge SingerPas encore d'évaluation

- Cast IronsDocument34 pagesCast IronsAbdallah MansourPas encore d'évaluation

- Presentation14 ALLOY STEELDocument41 pagesPresentation14 ALLOY STEELMahadi HasanPas encore d'évaluation

- HEAT Presentation Slides, CEP-03Document14 pagesHEAT Presentation Slides, CEP-03jawad arifPas encore d'évaluation

- Lecture 9 - Ferrous AlloysDocument31 pagesLecture 9 - Ferrous Alloysmahmoud foudaPas encore d'évaluation

- CH 04-06 - Metals & AlloysDocument25 pagesCH 04-06 - Metals & AlloysBelgium WafflesPas encore d'évaluation

- Classification of SteelDocument39 pagesClassification of SteelSudarshan GPas encore d'évaluation

- Unit 5: Alloy Steels and Cast IronsDocument61 pagesUnit 5: Alloy Steels and Cast IronsAaditya NaikPas encore d'évaluation

- Steel and Cast IronDocument20 pagesSteel and Cast IronAek JayPas encore d'évaluation

- Steel: CE 2330 Jul - Nov 2017 IIT TirupatiDocument32 pagesSteel: CE 2330 Jul - Nov 2017 IIT TirupatiUmar AlamPas encore d'évaluation

- Maraging Steel: 1. Introduction and General CharacteristicsDocument12 pagesMaraging Steel: 1. Introduction and General CharacteristicsMubash Abd100% (1)

- 5 Applications and Processing of Metal AlloysDocument31 pages5 Applications and Processing of Metal AlloysJeffersonTalanPas encore d'évaluation

- Properties and Applications of MaterialsDocument65 pagesProperties and Applications of MaterialsSeashell BernzPas encore d'évaluation

- Heat Treating BasicsDocument36 pagesHeat Treating BasicsSuphi YükselPas encore d'évaluation

- Review 4Document17 pagesReview 4EDENPas encore d'évaluation

- Aeronautical Alloys Part IiDocument6 pagesAeronautical Alloys Part IimaximinogarciaalejandraPas encore d'évaluation

- Cast Iron: Alloys of Iron and Carbon With More Than 2.11% Carbon Are Called Cast IronsDocument24 pagesCast Iron: Alloys of Iron and Carbon With More Than 2.11% Carbon Are Called Cast IronsArun Bongale100% (1)

- High Temperature Corrosion: Fundamentals and EngineeringD'EverandHigh Temperature Corrosion: Fundamentals and EngineeringPas encore d'évaluation

- Eticket RMTN6JA54Z362Document1 pageEticket RMTN6JA54Z362Murugan RajaPas encore d'évaluation

- Details of UKAS Recalibration Due of Mechanical Test EquipmentsDocument1 pageDetails of UKAS Recalibration Due of Mechanical Test EquipmentsMurugan RajaPas encore d'évaluation

- Eticket RMTN6JA54Z362Document1 pageEticket RMTN6JA54Z362Murugan RajaPas encore d'évaluation

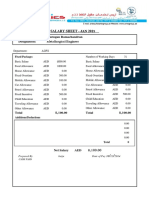

- Salary Sheet - Jan 201: Employee Name: Murugan Ramachandran Designation: Metallurgical EngineerDocument1 pageSalary Sheet - Jan 201: Employee Name: Murugan Ramachandran Designation: Metallurgical EngineerMurugan RajaPas encore d'évaluation

- New English Book PDFDocument239 pagesNew English Book PDFMurugan Raja0% (1)

- Surface AreaDocument5 pagesSurface AreaMurugan RajaPas encore d'évaluation

- Ticket From HWH To DhanbadDocument3 pagesTicket From HWH To Dhanbadpradeep kumarPas encore d'évaluation

- Jobs AppliedDocument5 pagesJobs AppliedMurugan RajaPas encore d'évaluation

- Failure Investigation TemplateDocument11 pagesFailure Investigation TemplateMurugan Raja100% (1)

- E1351 - 01Document6 pagesE1351 - 01Murugan RajaPas encore d'évaluation

- Information To Be Gathered From ClientDocument1 pageInformation To Be Gathered From ClientMurugan Raja0% (1)

- Surface AreaDocument5 pagesSurface AreaMurugan RajaPas encore d'évaluation

- By Laws - 26 Février 2013Document17 pagesBy Laws - 26 Février 2013Murugan RajaPas encore d'évaluation

- IMSP NO.28-Chemical Handling Control ProcecdureDocument6 pagesIMSP NO.28-Chemical Handling Control ProcecdureMurugan RajaPas encore d'évaluation

- Sgs Ogc RDK Brochure A4 Web LRDocument4 pagesSgs Ogc RDK Brochure A4 Web LRMurugan RajaPas encore d'évaluation

- Waslab PrintDocument1 pageWaslab PrintMurugan RajaPas encore d'évaluation

- wp136 enDocument26 pageswp136 enMurugan RajaPas encore d'évaluation

- Subject: Requisition of Advance For Home ConstructionDocument1 pageSubject: Requisition of Advance For Home ConstructionMurugan RajaPas encore d'évaluation

- Ref No. Project No: Revision No. 0 Date: 04.06.13: Risk AssessmentDocument2 pagesRef No. Project No: Revision No. 0 Date: 04.06.13: Risk AssessmentMurugan RajaPas encore d'évaluation

- ARIES Marine Sample Testing of Different QualitiesDocument1 pageARIES Marine Sample Testing of Different QualitiesMurugan RajaPas encore d'évaluation

- ARIES Marine Sample Testing of Different QualitiesDocument1 pageARIES Marine Sample Testing of Different QualitiesMurugan RajaPas encore d'évaluation

- Jebel Ali Client ListDocument5 pagesJebel Ali Client ListMurugan RajaPas encore d'évaluation

- Lathe Work InstructionsDocument3 pagesLathe Work InstructionsMurugan RajaPas encore d'évaluation

- Ref No. Project No: Revision No. 0 Date: 04.06.13: Risk AssessmentDocument2 pagesRef No. Project No: Revision No. 0 Date: 04.06.13: Risk AssessmentMurugan RajaPas encore d'évaluation

- JafzaDocument6 pagesJafzaMurugan RajaPas encore d'évaluation

- UAE Power Plant ListDocument2 pagesUAE Power Plant ListMurugan Raja0% (1)