Académique Documents

Professionnel Documents

Culture Documents

Rammed Earth

Transféré par

majanikolic73Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Rammed Earth

Transféré par

majanikolic73Droits d'auteur :

Formats disponibles

Resurrection: Rammed Earth Construction

Michael Padavic

Professor Mark Mulligan

GSD 6204

Building Technology

January 11, 2002

Padavic 1

Construction materials are at a peculiar stage in history. Decades ago, traditional

building methods were dropped in favor of the economic, disregarding the embodied energy of

these newer materials. Technology and environmental awareness have advanced enough,

however, to allow purely economic building methods to be questioned. One of the most

interesting materials affected by this heightened awareness is rammed earth a process by

which a soil mixture is lifted into formwork and compacted to make a strong, monolithic wall

(figure 1).

Building with earth is well known to

be an ancient practice, occurring more

frequently once the human race began

evolving from a nomadic lifestyle to an

agricultural one. Thousands of years later,

technology is allowing the reexamination of

earth construction. Developments prove

that earth construction is still a viable economic and environmentally conscious technique.

Further, the subcategory of rammed earth construction is worthy of financial support and

advancement. To see this, first it is important to have a deeper look at the history of earth

construction. Then it is informative to see recent examples of building with rammed earth. Next,

it is necessary to have a detailed explanation of the rammed earth construction method, thus

outlining its benefits and weaknesses. Putting these all together, including innovations that target

weaknesses, it will be evident that rammed earth is a viable construction technique, safer for the

environment, yet comparable in price. Rammed earth is a logical building material that has a

common place in todays economy and environment.

There is a good amount of information known about the early building techniques of the

human race. The nomadic lifestyle of the hunter didnt allow for a fixed dwelling. However,

knowledge and development of agriculture rendered the need for permanent shelter. Globally, a

chronology is difficult to understand, because civilizations developed independently and at

different speeds. In all places, though, dependant upon locale was the use of wood, stone, or

Figure 1

Padavic 2

neither, but in all cases was the use of earth in the form of mud

1

. An early advancement was

brick building to solve the need for an effective, rapid technique. Adobe was used most often, but

soil blocks were developed where adobe wouldnt work

2

. In the arid Middle East, buildings of

brick with no internal structure at all were developed

3

. During the expansion of the western

United States, bricks and lumber would be provided locally, with settlers completing construction

in the local tradition or style. It is difficult to specifically date rammed earth in particular, but it is

known to have been in use on the east coast through mid-19

th

century. A treatise was published

in 1839 extolling the virtues of rammed earth construction. It is a viable medium in virtually any

climate

4

. A gradual decline of building with earth came with the advent of railroads providing

an abundance of materials that could emulate the styles of the east. The big change, however,

came when the switch was made to economical, modern materials after WWII.

5

Today, rammed earth is reasserting itself in a few ways. Two of these ways are

environmentally and pragmatically. Environmentally, the Autonomous Environmental Centre

(Ateic), designed by Pat Borer with David Lea in Wales, showcases a number of alternative

building materials and has raised some discussion in the U.K.

6

In addition to non-reinforced

rammed earth walls there is locally sourced timber, woodwool sheathing, and lime-crete as

opposed to cement due to its high production of

carbon dioxide

7

. Whereas the Ateic building

expresses the environmental nature, Rick Joys

architecture expresses its pragmatic desirability.

In 1998, Joy designed the 2800-square-foot

Palmer/Rose residence outside Tucson, Arizona

(figure 2). It could almost go unsaid how

beautifully the residence blends in with the

1

McHenry, Paul Graham. Adobe and Rammed Earth Buildings: Design and Construction. New York: John Wiley & Sons,

1984. Page 2.

2

McHenry, 4.

3

McHenry, 6.

4

McHenry, 7.

5

McHenry, 8.

6

Hannay, Patrick. Ground Force. RIBA Journal 107 (Nov 2000): 34-40. Page 34.

7

Hannay, 36.

Figure 2

Padavic 3

Sonoran and the Santa Catalina Mountains

(Figure 3). Described as a modernist who

designs with an elemental palette of light, space,

and soil, Joy uses rammed earth because of its

low level of skill involved. As his own contractor,

skilled labor can be concentrated on other parts

of the design, creating a greater contrast with

the shell.

8

The specific construction of rammed earth consists of lifts or layers of earth poured into

formwork at a depth of eight inches and then compacted to five inches.

9

This creates a striated

earthen wall like a geological cut through time

10

. Similar to concrete, it is stronger than other

forms of earth construction because it is compacted in place and contains no mortar joints

11

.

Rammed earth construction begins with site selection and the acquisition of very specific

materials: soil mix, water, and an optional stabilizer. Since topsoil is organic and biodegrades, a

mix of subsoil is used

12

. The approximate proportion of subsoil is thirty percent clay/silt to

seventy percent sand/gravel

13

. Water has a direct impact on the strength of finished walls, and

depending on the soil mix, is eight to sixteen percent of the mix

14

. An optional stabilizer may be

added four to twelve percent depending on conditions such as bonding strength of the clay,

seismic activity, desired construction process, or desired wall proportions

15

. Stabilizers include

cement, lime, or pozzolan added to the mix

16

. There are numerous field and laboratory tests to

be run at all stages of the material gathering process, each to determine the specific mix peculiar

to the site. These include density, compressive strength, bond strength, and erosion and wear

resistance tests

17

.

8

Giovanni, Joseph. Earthwork: The Palmer/Rose Residence, Tucson, Arizona. Architecture 87 (Dec 1998: 90-97.

Page 91.

9

Keable, Julian. Rammed Earth Structures: A Code of Practice. London: Intermediate Publications, LTD, 1996.

10

Giovanni, 91.

11

King, Bruce. Buildings of Earth and Straw. Sausalito, California: Ecological Design Press, 1996. Page 55.

12

King, 53.

13

Keable, 18.

14

Keable, 24.

15

King, 64.

16

Keable, 34.

17

King, 59.

Figure 3

Padavic 4

If a good sand/clay mix is not attainable at the site, the lacking part may be brought to the

site and blended in. A variety in particle size is necessary so that the soil bonds to itself and

other materials (such as a concrete foundation or slab). Particle sizes range from gravel (one

inch 3/16 inch) to sand (3/16 inch a few thousands of an inch) to fines (less that three

thousands of an inch). Fines are a combination of clay and silt, with concentration on clay levels

too little wont bond the soil while too much will cause excess water absorption and cracking.

18

The soil must be mixed, usually manually by shovel, to allow the variety of particles to be spread

throughout

19

. At this time, a stabilizer is blended if desired. Reasons for adding a stabilizer far

outweigh not, as it speeds the construction process, improves durability, allows thinner walls, and

requires less of a surface treatment. However, with a stabilizer, the process is a bit more

complicated and expensive

20

. Finally, water is added to the mix, sprinkled on as to not saturate

any part of the mix. If a stabilizer has been added (especially cement), lifting the wall must begin

immediately thereafter.

Formwork (figure 4) is similar to that

for concrete, and should be in place before

water is added to the soil mix. However,

different from concrete, the formwork cannot

have ties running through it. This is

because all areas of the form must be

accessible to tamping

21

. This fact also

renders the minimum thickness of a wall to

about sixteen to eighteen inches, so that a

laborer can move within the form. Typical

thickness for walls is sixteen, eighteen, and

twenty-four inches with a height to weight

18

King, 53.

19

Keable, 28.

20

Keable, 20.

21

Keable, 44.

Figure 4

Padavic 5

ratio of approximately ten

22

. Concentration for formwork is on strength and stiffness, lightness,

and ease of alignment. Possible materials include plywood, wood planks and framing, mild steel,

or a combination for a desired finished appearance. Like concrete, sheet materials give good off-

form finished surfaces. Dependant on the quality of soil and presence of stabilizer is the height of

the formwork. Unstabilized soil is concentrated horizontally, and alignment is from layer to layer

of wall. Stabilized soil is concentrated vertically, and alignment is between forms. Openings for

doors and windows within the wall are created with blockouts. Corners are made stronger if

created as one piece as opposed to solely having a joint between two walls

23

.

Once formwork for a wall section

is complete, the soil is mixed, blended

and hydrated. Soon after, as mentioned

before, earth is laid in and compacted (or

tamped see figure 5). Both manual

and pneumatic tampers can be used.

Care is taken so that larger stones are

moved away from the form. The edges

are rammed first, and then the center

until no further impressions result from

blows from the tamper

24

. After the wall

completely goes up and is cured (twenty-

eight to fifty-six day period) any fixtures

may be added

25

. The roof is tied into the wall, and window and doorframes are added. Fixings

are buried deep within the wall to retain structural integrity

26

. In addition, utilities and systems,

22

King, 64.

23

Keable, 42-44.

24

Keable, 52.

25

King, 57.

26

Keable, 92.

Figure 5

Padavic 6

determined before construction, may pass within the wall to a certain degree

27

. The final part of

the construction process is to apply a wall finish, if desired or required

28

.

Through the construction process, it is possible to outline the strengths and weaknesses

of rammed earth construction. It is environmentally conscious, especially since the main material

is abundant and usually taken from the site itself

29

. Also, although a poor insulator, rammed earth

has good thermal mass properties, storing heat from the sun and releasing it during the cooler

night

30

. Finally, its a low cost, rapid construction technique of high compressive strength (300-

900 psi) and desirable aesthetics

31

. On the other hand, the main known weakness includes its

low-tensile strength (susceptibility to seismic activity)

32

, while perceived weaknesses are its

absorption of and erosion by water

33

. Additionally, there is one standpoint that is generally

unclear about rammed earth construction. Some claim that it is possible to achieve with unskilled

labor. Yet, one would assume that it takes a high degree of skilled labor to construct. The

conclusion that can be made from the given information, listed here and in other readings, would

suggest that a contractor skilled in rammed earth would have to be available for acquisition of

materials, testing, and designing formwork. However, after that, the process of mixing, hydrating,

lifting, and tamping is possible by unskilled labor

34

.

Since earth construction had been seldom used in the past sixty years, expertise on the

matter had all but disappeared. However, continuous research and experimentation in recent

years has improved knowledge about rammed earth. With knowledge of concrete construction,

many of the tensile problems of rammed earth are solved in the same way. Seismic activity, or

any overbearing force, causes cracking within the wall that in turn reduces its overall strength.

Exact calculations are not yet known, but problem areas can be targeted. Steel rebar can be

placed into the form and bound to the earth during the ramming process. This can occur at

27

Keable, 102.

28

Keable, 94.

29

Keable, 2.

30

www.greenbuilder.com, section 8.1.

31

King, 63.

32

Keable, 106.

33

www.greenbuilder.com, section 5.4.

34

Keable, 2.

Padavic 7

corners and over wall openings to provide stability

and tensile strength

35

. Instead of rebar, lintels of

various materials or even arches can also be used

over openings

36

(figure 6). Much of the general

concern with rammed earth, though, is its

susceptibility to water. If the wall absorbs water,

the bonds between particles lessen and crushing

strength is reduced. Driving rain loosens smaller

particles, which create larger holes and cracks

within the wall. Water can be combated easily

though. Common design techniques, such as

deep over hangs (usually one-third the height of

the wall), can begin to protect the wall. The addition of a stabilizer will help with the water

absorption (another advantage to adding a stabilizer)

37

. But as far as water damage goes,

surface treatment can provide the best protection for a rammed earth wall. Breathable finishes

should be used to allow for water evaporation. Traditionally, stucco or plaster has been used and

then painted over. Also, a lime wash (whitewash), bitumen emulsion with paint, emulsion paint,

or oil-based paint can protect the surface. Still, with the desire to express the earthen quality of

rammed earth, polymer emulsion (PVA) has more recently been used to seal the wall and protect

it from wind and rain, left transparent for aesthetics

38

.

Rammed earth is a logical building material in its economy, environmental awareness,

and construction technique. It has been accepted as a safe construction material that has an

aesthetic advantage. Once accepted on a larger scale for more frequent use and is supported

financially, further experimentation may be done to further this building material, and allow the

resurrection of earth construction.

35

Keable, 106.

36

Keable, 86.

37

Keable, 76-78.

38

Keable, 94.

Figure 6

Padavic 8

Bibliography

1. Giovanni, Joseph. Earthwork: The Palmer/Rose House, Tucson, Arizona. Architecture 87

(Dec 1998): 90-97.

2. Hannay, Patrick. Ground Force. RIBA Journal 107 (Nov 2000): 34-40.

3. Keable, Julian. Rammed Earth Construction: A Code of Practice. London: Intermediate

Publications, LTD, 1996.

4. King, Bruce. Buildings of Earth and Straw. Sausalito, California: Ecological Design Press,

1996.

5. McHenry, Paul Graham. Adobe and Rammed Earth Buildings: Design and Construction. New

York: John Wiley & Sons, 1984.

6. www.greenbuilder.com

7. www.nahbrc.org

Illustration Sources

cover: Giovanni, 94.

figure 1: www.nahbrc.org

figure 2: Giovanni, 94.

figure 3: Giovanni, 94.

figure 4: King, 50.

figure 5: King, 56.

figure 6: King, 70.

Vous aimerez peut-être aussi

- Rammed Earth Sample Production: Context, Recommendations and ConsistencyDocument6 pagesRammed Earth Sample Production: Context, Recommendations and ConsistencyTamas VanyiPas encore d'évaluation

- Types of Earth ConstructionDocument2 pagesTypes of Earth Constructionsy100% (2)

- Compressed Earth Building BlocksDocument21 pagesCompressed Earth Building BlocksGinette CasillaPas encore d'évaluation

- Earth Brick Construction 2007Document8 pagesEarth Brick Construction 2007syPas encore d'évaluation

- 34.traditional Earth Construction and GlazingDocument9 pages34.traditional Earth Construction and GlazingmariyaPas encore d'évaluation

- Earthen Floors: A Modern Approach to an Ancient PracticeD'EverandEarthen Floors: A Modern Approach to an Ancient PracticeÉvaluation : 4 sur 5 étoiles4/5 (1)

- Building With Earth PDFDocument32 pagesBuilding With Earth PDFNarayana Donadio100% (2)

- Stabilized Earth FloorsDocument26 pagesStabilized Earth Floorsrevathi hariharan100% (1)

- Case Study Construction of Rammed Earth House PDFDocument12 pagesCase Study Construction of Rammed Earth House PDFoanadraghicescuPas encore d'évaluation

- Rammed Earth: - Laterite Soil - Cement Stabilized - Slip Form Moulds - Developed With Soil Block ColumnsDocument12 pagesRammed Earth: - Laterite Soil - Cement Stabilized - Slip Form Moulds - Developed With Soil Block ColumnsMohamedPas encore d'évaluation

- Adobe Horno: by Blake BuffordDocument3 pagesAdobe Horno: by Blake BuffordGuillermo BustosPas encore d'évaluation

- AcsaDocument7 pagesAcsaGabriel Moyer-PerezPas encore d'évaluation

- "Rammed Earth": By: Jay Mark C. Sabubu Bsce-5ADocument22 pages"Rammed Earth": By: Jay Mark C. Sabubu Bsce-5AJet Espejon Javier100% (1)

- Handbook LearnWithClay PART IDocument54 pagesHandbook LearnWithClay PART Ibabapostol100% (4)

- Earth For Homes 1955Document80 pagesEarth For Homes 1955est_nu100% (1)

- These Solar Backup Generators Deliver 4 Times More Power Than Other Models!Document35 pagesThese Solar Backup Generators Deliver 4 Times More Power Than Other Models!Athiyo MartinPas encore d'évaluation

- Rammed Earth BuildingDocument25 pagesRammed Earth BuildingR kar heinPas encore d'évaluation

- A Sustainability Approach To Standards For Rammed Earth Construction in BhutanDocument52 pagesA Sustainability Approach To Standards For Rammed Earth Construction in BhutanEngineers Without Borders UK100% (1)

- Earth Construction TechniquesDocument22 pagesEarth Construction TechniquesPraveen Sharma100% (1)

- EARTH ConstructionDocument9 pagesEARTH ConstructionSasidhar DamodaranPas encore d'évaluation

- Building With Rammed Earth PDFDocument28 pagesBuilding With Rammed Earth PDFSara Black100% (10)

- Rammedearth 180816064240 PDFDocument14 pagesRammedearth 180816064240 PDFKaran100% (3)

- High Quality Rammed Earth StructuresDocument9 pagesHigh Quality Rammed Earth Structuresalicekubrickk100% (1)

- Straw Bale ConstructionDocument23 pagesStraw Bale Constructionjoshjeth67% (3)

- Handbook For Building Homes of EarthDocument144 pagesHandbook For Building Homes of EarthSantosh Athani100% (5)

- Rammed EarthDocument116 pagesRammed EarthGuillermoValeroLozano100% (5)

- Construction Materials and Techniques in Persian ArchitectureDocument18 pagesConstruction Materials and Techniques in Persian ArchitecturesarosathishcPas encore d'évaluation

- Rice Straw Bale Construction in Modern ArchitectureDocument36 pagesRice Straw Bale Construction in Modern ArchitectureTmt TarekPas encore d'évaluation

- ASR - Adobe Construction (Turkey)Document12 pagesASR - Adobe Construction (Turkey)John Johnson100% (1)

- A Concise History of The Use of The Rammed Earth Building Technique Including Information On Methods of Preservation, Repair, and MaintenanceDocument203 pagesA Concise History of The Use of The Rammed Earth Building Technique Including Information On Methods of Preservation, Repair, and MaintenanceGretaRetana100% (1)

- Peace Corps Handbook For Building Earth HomesDocument112 pagesPeace Corps Handbook For Building Earth HomesimmortalskyPas encore d'évaluation

- Stabilization of SoilDocument35 pagesStabilization of SoilDaniel HackinmadePas encore d'évaluation

- 1922 - Building in Cob and Pisé de Terre. A Collection of Notes From Various Sources On The Construction of Earth WallsDocument51 pages1922 - Building in Cob and Pisé de Terre. A Collection of Notes From Various Sources On The Construction of Earth WallsParisTiembi100% (1)

- Building With Earth 1Document80 pagesBuilding With Earth 1Naava BasiaPas encore d'évaluation

- Rammed Earth Building ReviewDocument118 pagesRammed Earth Building ReviewPeter W Gossner100% (2)

- Earth Building (Not Mine) Knowledge Belongs To EveryoneDocument20 pagesEarth Building (Not Mine) Knowledge Belongs To Everyonemorfeas85Pas encore d'évaluation

- Presentation SuperadobeDocument31 pagesPresentation SuperadobeRamaswamy Koodalloor Parasuraman0% (1)

- Building Hygienic and Earthquake-Resistant Adobe Houses Using Geomesh ReinforcementDocument41 pagesBuilding Hygienic and Earthquake-Resistant Adobe Houses Using Geomesh Reinforcementgkut100% (2)

- Rammed Earth - Module3Document24 pagesRammed Earth - Module3Aditi Sharma100% (1)

- AdobeUSA09 PAPER SantosFilhoDocument6 pagesAdobeUSA09 PAPER SantosFilhopliniosantosfilhoPas encore d'évaluation

- DESN30152: Technology & Environment in Architecture Project One: Material/ System StudyDocument16 pagesDESN30152: Technology & Environment in Architecture Project One: Material/ System StudyBoguus BoguusPas encore d'évaluation

- The Rammed Earth HouseDocument26 pagesThe Rammed Earth HouseLorenzo Figueroa100% (1)

- Himani Goyal Second Year, B Roll No:17 Vastu Kala Academy of ArchitectureDocument27 pagesHimani Goyal Second Year, B Roll No:17 Vastu Kala Academy of Architecturelokranjan100% (2)

- Rammed Earth Construction Part 21210466806514Document17 pagesRammed Earth Construction Part 21210466806514Jorge Alonso100% (3)

- Essential Hempcrete Construction: The Complete Step-by-Step GuideD'EverandEssential Hempcrete Construction: The Complete Step-by-Step GuideÉvaluation : 5 sur 5 étoiles5/5 (3)

- Earth Berming and Air TunnelsDocument27 pagesEarth Berming and Air TunnelsAbishaTeslin100% (1)

- Compressed Earth Building BlocksDocument21 pagesCompressed Earth Building BlocksEfremWakjiraHode100% (2)

- Shot-Earth For Sustainable Constructions PDFDocument13 pagesShot-Earth For Sustainable Constructions PDFFarida Diab SarmoukPas encore d'évaluation

- Farmer's Bulletin 1500-Rammed Earth Walls For BuildingsDocument26 pagesFarmer's Bulletin 1500-Rammed Earth Walls For BuildingsAniruddha RoyPas encore d'évaluation

- Preciado 2020Document10 pagesPreciado 2020Danica Joy AlfarPas encore d'évaluation

- Gier, Estiven M. - Module 1Document7 pagesGier, Estiven M. - Module 1Estiven GierPas encore d'évaluation

- Earthbag Building in The Humid Tropics, 2nd Ed.Document30 pagesEarthbag Building in The Humid Tropics, 2nd Ed.Patti Stouter100% (4)

- Using Mud Bricks As A Temporary Solution For Gaza ReconstructionDocument5 pagesUsing Mud Bricks As A Temporary Solution For Gaza ReconstructionSerbah hocinePas encore d'évaluation

- Mud ARCHITECTUREDocument8 pagesMud ARCHITECTURErincyPas encore d'évaluation

- Soil Reinforcement 1Document24 pagesSoil Reinforcement 1Rajat Mangal50% (2)

- Chapter-1: Introduction Chapter-2: Literature Review Chapter-3: Materials Used and Methodology Chapter-4: Objectives of The Work and ExperimentalDocument21 pagesChapter-1: Introduction Chapter-2: Literature Review Chapter-3: Materials Used and Methodology Chapter-4: Objectives of The Work and ExperimentalKuldip SharmaPas encore d'évaluation

- 7220 24887 1 SMDocument8 pages7220 24887 1 SMGobi NavaPas encore d'évaluation

- CLay Based Composite With Natural Polymer and FibreDocument7 pagesCLay Based Composite With Natural Polymer and FibrejinshadPas encore d'évaluation

- Comparison of The Strength of Block Made From Cement and Lateritic SoilDocument10 pagesComparison of The Strength of Block Made From Cement and Lateritic SoilStephen Hardeykunle OladapoPas encore d'évaluation

- C2 MAJOR FINAL DOCmentDocument72 pagesC2 MAJOR FINAL DOCmentVamshi ChinthalaPas encore d'évaluation

- School Zone MUTCD 2000 PDFDocument32 pagesSchool Zone MUTCD 2000 PDFmajanikolic73Pas encore d'évaluation

- Estimating With Microsoft ExcelDocument9 pagesEstimating With Microsoft ExcelBert EngPas encore d'évaluation

- Prirucnik - Kontaktna Fasada Sa Kamenom Vunom PDFDocument70 pagesPrirucnik - Kontaktna Fasada Sa Kamenom Vunom PDFShkixPas encore d'évaluation

- SITE BOOK Quantity Take Off Details PDFDocument20 pagesSITE BOOK Quantity Take Off Details PDFmajanikolic73Pas encore d'évaluation

- Quantity Take OffDocument14 pagesQuantity Take OffChicosi34Pas encore d'évaluation

- School Zone MUTCD 2000 PDFDocument32 pagesSchool Zone MUTCD 2000 PDFmajanikolic73Pas encore d'évaluation

- Austrotherm EPS A100 - MehanikaDocument4 pagesAustrotherm EPS A100 - Mehanikamajanikolic73Pas encore d'évaluation

- Fundamentals of Concrete DesignDocument12 pagesFundamentals of Concrete Designmajanikolic73Pas encore d'évaluation

- 900 91 92 601 C 0808 Green Roof System Gutter 5 2 1 23172Document1 page900 91 92 601 C 0808 Green Roof System Gutter 5 2 1 23172experthvachomePas encore d'évaluation

- 1 s2.0 S1877705813012678 MainDocument11 pages1 s2.0 S1877705813012678 Mainmajanikolic73Pas encore d'évaluation

- Straube Moisture TestsDocument53 pagesStraube Moisture Testsmajanikolic73Pas encore d'évaluation

- Qualities, Use, and Examples of Sustainable Building MaterialsDocument44 pagesQualities, Use, and Examples of Sustainable Building MaterialsAnne CadizPas encore d'évaluation

- Rammed Earth Building ReviewDocument118 pagesRammed Earth Building ReviewPeter W Gossner100% (2)

- Rammed EarthDocument9 pagesRammed Earthmajanikolic73Pas encore d'évaluation

- Straube Moisture TestsDocument53 pagesStraube Moisture Testsmajanikolic73Pas encore d'évaluation

- Engineering Report of Light Clay SpecimensDocument5 pagesEngineering Report of Light Clay Specimensmajanikolic73Pas encore d'évaluation

- 1 s2.0 S1877705813012678 MainDocument11 pages1 s2.0 S1877705813012678 Mainmajanikolic73Pas encore d'évaluation

- Qualities, Use, and Examples of Sustainable Building MaterialsDocument44 pagesQualities, Use, and Examples of Sustainable Building MaterialsAnne CadizPas encore d'évaluation

- 1 s2.0 S1877705813012678 MainDocument11 pages1 s2.0 S1877705813012678 Mainmajanikolic73Pas encore d'évaluation

- Straube Moisture TestsDocument53 pagesStraube Moisture Testsmajanikolic73Pas encore d'évaluation

- Engineering Report of Light Clay SpecimensDocument5 pagesEngineering Report of Light Clay Specimensmajanikolic73Pas encore d'évaluation

- Rammed EarthDocument9 pagesRammed Earthmajanikolic73Pas encore d'évaluation

- RammedEarthForAColdClimate StuFixDocument18 pagesRammedEarthForAColdClimate StuFixmajanikolic73Pas encore d'évaluation

- Milftoon Naruto Cómic Porno Español: Investigar Este SitioDocument2 pagesMilftoon Naruto Cómic Porno Español: Investigar Este Sitioquickkismet830520% (5)

- Neighbor Grids and Compass MarksDocument8 pagesNeighbor Grids and Compass MarksNico InfantePas encore d'évaluation

- PDS 4588W enDocument2 pagesPDS 4588W enNassim Ben AbdeddayemPas encore d'évaluation

- Who Was Van Gogh (Art Ebook) PDFDocument218 pagesWho Was Van Gogh (Art Ebook) PDFMiguel OliveiraPas encore d'évaluation

- Character Sheet v6.44 (A4) PDFDocument6 pagesCharacter Sheet v6.44 (A4) PDFpipninjaPas encore d'évaluation

- BIWTA - Narayanganj - Estimates 2020.09.04Document1 056 pagesBIWTA - Narayanganj - Estimates 2020.09.04Anand PandeyPas encore d'évaluation

- 1st ChapterDocument7 pages1st ChapterkrithicuttiePas encore d'évaluation

- Sampleexam Adobe IndesignDocument4 pagesSampleexam Adobe IndesignMoisés VásquezPas encore d'évaluation

- The Power of Distraction-LathamDocument23 pagesThe Power of Distraction-LathamErez PeryPas encore d'évaluation

- Uk Aad Product Catalogue 2015 PDFDocument109 pagesUk Aad Product Catalogue 2015 PDFWOLFWBEARWPas encore d'évaluation

- Republic of The Philippines Department of Education Region Iv-A Calabarzon St. Ignatius Technical Institute of Business and ArtsDocument59 pagesRepublic of The Philippines Department of Education Region Iv-A Calabarzon St. Ignatius Technical Institute of Business and ArtsIgnatians Santa RosaPas encore d'évaluation

- BASF Luwax PoligenDocument6 pagesBASF Luwax PoligenShyam YadavPas encore d'évaluation

- Mari KugaDocument357 pagesMari KugaDavid Bara EganPas encore d'évaluation

- Drawing ProjectionsDocument43 pagesDrawing ProjectionsGangu Maheswar ReddyPas encore d'évaluation

- 35 - Emissivity Coefficients of Some Common MaterialsDocument8 pages35 - Emissivity Coefficients of Some Common MaterialsBrucearturoPas encore d'évaluation

- Le CorbuseirDocument0 pageLe CorbuseirJelena RisticPas encore d'évaluation

- Summative Exam in Fine ArtsDocument2 pagesSummative Exam in Fine ArtsChristine Allen AcuñaPas encore d'évaluation

- Latin PaleographyDocument78 pagesLatin PaleographyTiago Cândido100% (2)

- Oblivion Mod Maker Manual v1.4Document184 pagesOblivion Mod Maker Manual v1.4dumashekPas encore d'évaluation

- Zaftig Knitted Bra by Joan McGowan - MichaelDocument2 pagesZaftig Knitted Bra by Joan McGowan - MichaelspidersunshinePas encore d'évaluation

- Gray, 2001 ReviwDocument26 pagesGray, 2001 ReviwNery MartinezPas encore d'évaluation

- 017 An Artist's Color WheelDocument2 pages017 An Artist's Color Wheeljohn rockwellPas encore d'évaluation

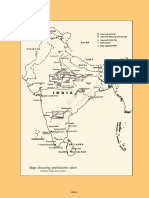

- Map Showing Prehistoric Sites: (Outline Map Not To Scale)Document9 pagesMap Showing Prehistoric Sites: (Outline Map Not To Scale)Tarang ChaudharyPas encore d'évaluation

- Contemporary ArtDocument4 pagesContemporary ArtSandra WendamPas encore d'évaluation

- Colour TheoryDocument12 pagesColour Theorytamil selviPas encore d'évaluation

- Kenny Dorham 30 CompositionsDocument49 pagesKenny Dorham 30 CompositionsRezahSampson97% (35)

- Arts K - 12Document1 pageArts K - 12Theresa Joy AlingasaPas encore d'évaluation

- Providing For Aesthetic Experience: Jason Holt Acadia UniversityDocument18 pagesProviding For Aesthetic Experience: Jason Holt Acadia UniversityKrns GrberPas encore d'évaluation

- DIY Cabin Building Plans PDFDocument6 pagesDIY Cabin Building Plans PDFRoberto Landa100% (5)