Académique Documents

Professionnel Documents

Culture Documents

Project Work 1

Transféré par

Dilleswararao ChintalaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Project Work 1

Transféré par

Dilleswararao ChintalaDroits d'auteur :

Formats disponibles

ABSTRACT

As crude oil price reach a new high, the need for developing alternate fuels has become

acute. Alternate fuels should be economically attractive in order to compete with currently used

fossil fuels. In this work, biodiesel (ethyl ester) was prepared from waste cooking oil (WCO)

collected from restaurants. Ethyl alcohol with potassium hydroxide as a catalyst was used for the

transesterification process. The biodiesel was characterized by its physical and fuel properties

including density, viscosity, flash point according to ASTM standards. The viscosity of the

biodiesel ethyl ester was found to be 5.03 mm

2

/sec at 40

o

C. Production of biodiesel from waste

cooking oils for diesel substitute is particularly important because of the decreasing trend of

economical oil reserves, environmental problems caused due to fossil fuel use and the high price

of petroleum products in the international market.

The performance evaluation of a single cylinder four stroke VCR diesel engine has been

done when fuelled with different blends of diesel and biodiesel made of waste cooking oil. It was

found that brake thermal efficiency and SFC of engine slightly increases and with the increase in

percentage of biodiesel.

Exhaust gas analysis indicates that with the use of biodiesel, the percentage of CO and

CO

2

decreases and percentage of O

2

increases which is a good sign as far as ecological

conservation is concerned.

One can understand from this experiment that waste cooking oil, which is otherwise

wasted, is one of the most economical choices to produce biodiesel. Since one of the major

concerns on biodiesel production is the price of feedstock, utilization of waste cooking oil

significantly enhances the economic viability of biodiesel production.

INTRODUCTION

Increasing uncertainty about global energy production and supply, environmental

concerns due to the use of fossil fuels, and the high price of petroleum products are the major

reasons to search for alternatives to petrol / diesel. Scientists claimed that the global supply of oil

and natural gas from the conventional sources is unlikely to meet the growth in energy demand

over the next 25 years. In this perspective, considerable attention has been given towards the

production of biodiesel as a diesel substitute. Moreover, biodiesel fuel has become more

attractive because of its environmental benefits due to the fact that plants and vegetable oils and

animal fats are renewable biomass sources. Biodiesel represents a largely closed carbon dioxide

cycle (approximately 78%), as it is derived from renewable biomass sources. Compared to

petroleum diesel, biodiesel has lower emission of pollutants, it is biodegradable and enhances the

engine lubricity and contributes to sustainability Biodiesel has a higher cetane number than

diesel fuel, no aromatics, no sulfur, and contains 10 11% oxygen by weight. Use of neat

(unprocessed) vegetable oils in the compression ignition engines is reported to cause several

problems due to its high viscosity. Biodiesel which is accepted as an attractive alternative fuel,

is prepared by transesterification of vegetable oils and animal fats with an alcohol in presence of

a catalyst. However, the land use for production of edible oil for biodiesel feedstock competes

with the use of land for food production. Moreover, the price of edible plant and vegetable oils is

usually higher than petrol / diesel. The use of waste cooking oil as biodiesel feedstock reduces

the cost of biodiesel production since the feedstock costs constitutes approximately 70-95% of

the overall cost of biodiesel production. Hence, the use of waste cooking oils (WCO) and non-

edible oils should be given higher priority over the edible oils as biodiesel feedstock.

Huge quantities of waste cooking oils (WCO) and animal fats are available throughout

the world, both in the developed and developing countries. Management of such oils and fats

pose a significant challenge because of their disposal problems and possible contamination of the

water and land resources. Even though some of this waste cooking oil is used for soap

production, a major part of it is discharged into the environment. As large amounts of waste

cooking oils are illegally dumped into rivers and landfills, causing environmental pollution, the

use of waste cooking oil to produce biodiesel as petrol / diesel substitute offers significant

advantages because of the reduction in environmental pollution. Diesel fuel consumption

significantly contributes to the formation of greenhouse gases (GHG) and other global pollutant

emissions. Environmentalists pointed out that petroleum / diesel is also the major source for the

emission of NOx, SOx, CO, particulate matter and volatile organic compounds (VOCs).

Emission of such pollutants not only has negative impacts to the global environment but also

severe impacts in human health due to their persistence in the environment.

The global consumption of diesel fuel per year is approximately 934 million tons. If a 5%

mix in the total diesel consumption as a renewable portfolio standard (RPS) requirement, which

is, approximately 46.7 million tons per year, a substantial portion of this requirement can be

replaced by using biodiesel produced from waste cooking oil. The use of waste cooking oil as a

biodiesel source has a potential to reduce CO

2

, particulate matter and other greenhouse gases as

the carbon contained in biomass-derived fuel is largely biogenic and renewable.

Waste cooking oil, which is otherwise wasted, is one of the most economical choices to

produce biodiesel. Since one of the major concerns on biodiesel production is the price of

feedstock, utilization of waste cooking oil significantly enhances the economic viability of

biodiesel production. Production of biodiesel from waste cooking oils for diesel substitute is

particularly important because of the decreasing trend of economical extracted oil reserves and

the environmental problems caused due to the use of fossil fuel. Use of waste cooking oil helps

improve the biodiesel economics.

BIODIESEL PREPARATION

Basic Methods of Preparing Biodiesel: There are three basic methods of biodiesel (methyl ester)

production from oils and fats. They are:

Base catalyst transesterification of the oil with methanol.

Directed acid catalyzed esterification of the oil with methanol.

Conversion of the oil to fatty acids, and then to methyl esters with acid catalysis.

Production of biodiesel is usually done today using the base catalyzed reaction, as the base

catalyzed reaction is the most economic process. This process is the most economic, because the

process uses a low temperature and pressure, there is also a high conversion of 98% and there is

a direct conversion to biodiesel with no intermediate steps. The following steps are involved in

preparing the biodiesel from WCO.

A. Retrieving the WCO

WCO was collected from different hotels, restaurants, canteen and cafeterias. The sample was

allowed to settle for 2-3 days and filtration was done to separate unnecessary impurities and food

residues.

B. Pre-heating WCO

Before transesterification process, to ensure that the oil contained very little amount of water

droplets in it, the filtered WCO was subjected to pre-heating to 100

0

C for 15 minutes with

continuous stirring using magnetic stirrer. This helped in drying the oil.

C. Neutralization of free fatty acids

In the accumulated WCO, neutralization of free fatty acids (FFA) needs correct amount of

catalyst for avoidance of soap formation.

D. Alkali catalysed transesterification of WCO

The alkali catalyzed transesterification was performed due to presence of majority of free

fatty acids in WCO. For transesterification of WCO in laboratory, oil was heated in a flat bottom

conical flask upto 45

0

C. To ensure the prevention of methanol to reach its boiling point (57

0

C),

the optimum reaction temperature was set to be 45

0

C. Now, 1litre of filtered WCO is poured

into the reaction vessel and is stirred and simultaneously heated with the help of magnetic stirrer

apparatus.

Fig.1 Transesterification Reaction

The reaction products were poured into a separating funnel and kept for approx. 6 hours for

gravity separation of glycerol with WCO methyl esters. The glycerol forms a lower layer due to

higher density, which is separated out. This oil recovered from the separating funnel was again

subjected to same procedure with 80 ml of solution C to remove the traces of glycerol and

retrieve better quality of bio diesel from the WCO. This biodiesel is then blended with diesel and

various blends such as 5BD, 10BD, 15BD and 20BD are prepared for conducting CI engine

experiment for performance and emission characteristics. Proper characterization of biodiesel

blends and petroleum diesel is also done in laboratory as per ASTM norms. Specific gravity of

blends and kinematic viscosity is measured using Red Wood Viscometer.

First the methanol (MeOH) and the catalyst (sodium hydroxide) are mixed. After the

methanol and catalyst are mixed, they go into a reactor, where the WCO is added to the mix.

Used oil is first run through a filter to remove the fatty acids. This mixture is agitated

continuously for 1 to 4 hours and may also be heated. The fat or oil used is converted to esters

during this stage. Glycerin and methyl esters are the two major products created after the reaction

is complete and the excess methanol has been removed from the mixture. Gravity is used to

separate the two products, since they have different densities. Glycerin is the denser of the two

products. The glycerin is then drawn off the bottom of the tank and can be sold either as crude

glycerin which is useful in soap production or it can be used for making fertilizers.

Methyl Ester Biodiesel Ingredients:

For Methyl Ester Biodiesel

MeOH = 20 % of WCO

KOH = 3.5 g per litre of WCO

The catalyst is dissolved into the alcohol by vigorous stirring in a small reactor. The oil is

transferred into the biodiesel reactor and then the catalyst/alcohol mixture is pumped into the oil

and the final mixture is stirred vigorously for 2 hours. A successful reaction produces two liquid

phases: ester and crude glycerol. Crude glycerol, the heavier liquid will collect at the bottom

after several hours of settling. Phase separation can be observed within 10 minutes and can be

complete within 2 hours of settling. Complete settling can take as long as 20 hours.

HEAT ENGINE

Heat Engine is an engine which takes heat as input and releases work as output. Heat

engines can be classified as; external combustion type in which the working fluid is entirely

separated from the fuel- air mixture (ECE), and the internal - combustion (ICE) type, in which

the working fluid consists of the products of combustion of the fuel- air mixture itself.

Classification of heat engines is given in Fig.1.

Classification of Heat Engines

Fig.1 Heat Engine Classification

Advantages of I.C.E. over E.C.E

1. More mechanical simplicity and lower weight/power ratio.

2. They do not need auxiliary equipment, such as boiler & condenser.

3. They could be started and stopped in a short time.

4. Their thermal efficiency is higher than other heat engines.

5. Their initial cost is low.

These advantages make I.C.E. more suitable in the transport sector; motor cars, small ships,

submarines, and small aircrafts.

Types of Internal Combustion Engines

I.C.E. can be divided into several groups according different features as characteristics: operating

cycles, method of charging the cylinder, fuel used, general design (position and number of

cylinders, method of ignition, rotating speed, etc.), and method of cooling the engine.

Fuel Used

1. Liquid Fuels

a. Volatile liquid fuels: petrol, Alcohol, benzene. Fuel /Air mixture is usually ignited by a spark;

Spark ignition. b. Viscous liquid fuels: fuel oil, heavy and light diesel oil, gas-oil, bio-fuels.

Usually combustion of fuel takes place due to its contact with high temperature compressed air

(self-ignition); Compression ignition.

2. Gaseous fuels:

Liquid Petroleum Gas ( LPG ), Natural gas ( NG ), Town gas, Blast Furnace gas; ignition usually

by a spark.

3. Dual and Multi-Fuels:

Dual fuel engines are operated with two types of fuels, either separately or mixed together.

Multi-fuel engines could be operated by a mixture of more than two fuels, gaseous; such as:

Hydrogen, methane, L.P.G. etc., combined with one or more of liquid fuels, such as alcohol,

ethers, esters, gasoline, diesel etc.

Method of Charging the Engine

1. Naturally aspirated engine: Admission of charge at near atmospheric pressure.

2. Supercharged engine: Admission of charge at a pressure above atmospheric.

Number of Piston Stroke to Complete the Thermodynamic Cycle:

1. Four stroke engines: the cycle of operation is completed in four strokes of the piston or two

revolution of the crank shaft. Each stroke consists of 180 of crank shaft rotation. The series of

operations are shown in figure 2.

2. Two strokes engine: In two-stroke engine the cycle is completed in two strokes, i.e. one

revolution of the crank shaft. The difference between two-stroke and four-stroke engines is in the

method of filling the cylinder with the fresh charge and removing the products of combustion.

Cylinders Arrangement

1. In- line engines: all cylinders are arranged linearly.

2. "V" engines: cylinders are in two banks inclined at an angle to each other and with one crank-

shaft.

3. Opposed cylinder banks located in the same plane on opposite sides of the crank-shaft.

4. Opposed piston engine: when a single cylinder houses two pistons, each of which drives a

separate crank shaft.

5. Radial engine: the radial engine is an engine with more than two cylinders in each row equally

spaced around the crank shaft. Normally it is been used in air-crafts.

Fig. 2 Cylinder events of four- stroke cycle

1. Double- acting engine: the fuel burns on both sides of the piston.

2. Cylinders may be vertical or horizontal, vertical engines needs smaller area, when area is

available horizontal engines may be used, this would make all engine parts accessible and the

operation and maintenance are easier.

Use of the Engine

1. Marine engine: for propulsion of ships at sea.

2. Industrial engine: for power generation on land.

3. Automotive engine: for transport.

Method of Cooling the Engine

1. Water- cooled engines.

2. Air- cooled engines.

I.C.Engine Parts and Details

The main components of the reciprocating internal combustion engine are shown in Figure 3.

Engine parts are made of various materials and perform certain functions, some of which will be

explained: cylinder block (g) it is integral with crank case (m), both are made of cast iron. The

piston (e) reciprocates inside the cylinder, which include the combustion chamber.

The piston is connected to the connecting rod (h) by piston pin (f). This end of the connecting

rod is known as small end. The other end of the connecting rod called the big end is connected to

the crank arm by crank pin (l).

Camshaft (u) makes the cam (t) to rotate and move up and down the valve rod through the tappet

(r). Mainly each cylinder has two valves; one is admission or suction valve and the other is

exhaust valve.

The ignition system consists of a battery, an ignition coil, a distributor with cam and breaker

points, and spark plug for each cylinder. In diesel engines there is an injection system instead of

ignition system.

The piston is connected to the connecting rod (h) by piston pin (f). This end of the connecting

rod is known as small end. The other end of the connecting rod called the big end is connected to

the crank arm by crank pin (l).

Fig. 3 Components of the reciprocating internal combustion engine

The ignition system consists of a battery, an ignition coil, a distributor with cam and breaker

points, and spark plug for each cylinder. In diesel engines there is an injection system instead of

ignition system.

The piston is connected to the connecting rod (h) by piston pin (f). This end of the connecting

rod is known as small end. The other end of the connecting rod called the big end is connected to

the crank arm by crank pin (l).

Camshaft (u) makes the cam (t) to rotate and move up and down the valve rod through the tappet

(r). Mainly each cylinder has two valves; one is admission or suction valve and the other is

exhaust valve.

The ignition system consists of a battery, an ignition coil, a distributor with cam and breaker

points, and spark plug for each cylinder. In diesel engines there is an injection system instead of

ignition system.

Internal Combustion Engines Terminology

1. Cylinder bore (B): The nominal inner diameter of the working cylinder.

2. Piston area (A): the area of a circle diameter equal to the cylinder bore.

3. Top Dead Center (T.D.C.): the extreme position of the piston at the top of the

cylinder. In the case of the horizontal engines this is known as the outer dead center

(O.D.C.).

4. Bottom Dead Center (B.D.C.): the extreme position of the piston at the bottom of the cylinder.

In horizontal engine this is known as the Inner Dead Center (I.D.C.).

5. Stroke: the distance between TDC and BDC is called the stroke length and is equal to double

the crank radius (l).

6. Swept volume: the volume swept through by the piston in moving between TDC and is

denoted by V

s

,

2

S

V =

4

d l

Where d is the cylinder bore and l the stroke.

7. Clearance volume: the space above the piston head at the TDC, and is denoted by Vc:

8. Total Volume of the cylinder: V = V

c

+ V

s

Fig. 4 Engine Terminology

9. Compression ratio: It is the ratio of the total volume of the cylinder to the clearance volume,

and is denoted by (r

c

)

c

C

V

r =

V

S C

V

Diesel Engine

A diesel engine (also known as a compression-ignition engine) is an internal combustion

engine that uses the heat of compression to initiate ignition to burn the fuel that has been injected

into the combustion chamber. This is in contrast to spark ignition engines such as a petrol engine

(gasoline engine) or gas engine (using a gaseous fuel as opposed to gasoline), which uses a spark

plug to ignite an air-fuel mixture. Diesel engines are manufactured in two-stroke and four-stroke

versions.

The diesel engine has the highest thermal efficiency of any regular internal or external

combustion engine due to its very high compression ratio.

HISTORY

The engine was developed by German inventor Rudolf Diesel in 1893. Diesel Engines

originally used as a more efficient replacement for stationary steam engines. Since the 1910s

they have been used in submarines and ships. Use in locomotives, trucks, heavy equipment and

electric generating plants followed later. In the 1930s, they slowly began to be used in a few

automobiles. Since the 1970s, the use of diesel engines in larger on-road and off-road vehicles in

the world increased. As of 2012, about 75% of all new car sales in the world are diesel.

WORKING PRINCIPLE

The diesel internal combustion engine differs from the gasoline powered Otto cycle by

using highly compressed hot air to ignite the fuel rather than using a spark plug. In the true diesel

engine, only air is initially introduced into the combustion chamber. The air is then compressed

with a compression ratio typically between 15:1 and 22:1 resulting in 40-bar (4.0 MPa; 580 psi)

pressure compared to 8 to 14 bars (0.80 to 1.4 MPa) (about 200 psi) in the petrol engine.

Fig. 5 P-V Diagram for Ideal Diesel cycle

The diesel internal combustion engine differs from the gasoline powered Otto cycle by

using highly compressed hot air to ignite the fuel rather than using a spark plug. In the true diesel

engine, only air is initially introduced into the combustion chamber. The air is then compressed

with a compression ratio typically between 15:1 and 22:1 resulting in 40-bar (4.0 MPa; 580 psi)

pressure compared to 8 to 14 bars (0.80 to 1.4 MPa) (about 200 psi) in the petrol engine. This

high compression heats the air to 550 C (1,022 F). At about the top of the compression stroke,

fuel is injected directly into the compressed air in the combustion chamber. This may be into a

(typically toroidal) void in the top of the piston or a pre-chamber depending upon the design of

the engine. The fuel injector ensures that the fuel is broken down into small droplets, and that

the fuel is distributed evenly. The heat of the compressed air vaporizes fuel from the surface of

the droplets. The vapour is then ignited by the heat from the compressed air in the combustion

chamber, the droplets continue to vaporise from their surfaces and burn, getting smaller, until all

the fuel in the droplets has been burnt. The start of vaporisation causes a delay period during

ignition and the characteristic diesel knocking sound as the vapour reaches ignition temperature

and causes an abrupt increase in pressure above the piston. The rapid expansion of combustion

gases then drives the piston downward, supplying power to the crankshaft.

As well as the high level of compression allowing combustion to take place without a

separate ignition system, a high compression ratio greatly increases the engine's efficiency.

Increasing the compression ratio in a spark-ignition engine where fuel and air are mixed before

entry to the cylinder is limited by the need to prevent damaging pre-ignition. Since only air is

compressed in a diesel engine, and fuel is not introduced into the cylinder until shortly before top

dead centre (TDC), premature detonation is not an issue and compression ratios are much higher.

Diesel's original engine injected fuel with the assistance of compressed air, which

atomized the fuel and forced it into the engine through a nozzle (a similar principle to an aerosol

spray). The nozzle opening was closed by a pin valve lifted by the camshaft to initiate the fuel

injection before top dead centre (TDC). This is called an air-blast injection.

Driving the three stage compressor used some power but the efficiency and net power

output was more than any other combustion engine at that time. Diesel engines in service today

raise the fuel to extreme pressures by mechanical pumps and deliver it to the combustion

chamber by pressure-activated injectors without compressed air. With direct injected diesels,

injectors spray fuel through 4 to 12 small orifices in its nozzle. The early air injection diesels

always had a superior combustion without the sharp increase in pressure during combustion.

Research is now being performed and patents are being taken out to again use some form of air

injection to reduce the nitrogen oxides and pollution, reverting to Diesel's original

implementation with its superior combustion and possibly quieter operation. In all major aspects,

the modern diesel engine holds true to Rudolf Diesel's original design that of igniting fuel by

compression at an extremely high pressure within the cylinder.

A vital component of all diesel engines is a mechanical or electronic governor which

regulates the idling speed and maximum speed of the engine by controlling the rate of fuel

delivery. Unlike Otto-cycle engines, incoming air is not throttled and a diesel engine without a

governor cannot have a stable idling speed and can easily over speed, resulting in its destruction.

Mechanically governed fuel injection systems are driven by the engine's gear train. These

systems use a combination of springs and weights to control fuel delivery relative to both load

and speed. Modern electronically controlled diesel engines control fuel delivery by use of an

electronic control module (ECM) or electronic control unit (ECU). The ECM/ECU receives an

engine speed signal, as well as other operating parameters such as intake manifold pressure and

fuel temperature, from a sensor and controls the amount of fuel and start of injection timing

through actuators to maximise power and efficiency and minimise emissions. Controlling the

timing of the start of injection of fuel into the cylinder is a key to minimizing emissions, and

maximizing fuel economy (efficiency), of the engine. The timing is measured in degrees of crank

angle of the piston before top dead centre. For example, if the ECM/ECU initiates fuel injection

when the piston is 10 degrees before TDC, the start of injection, or timing, is said to be 10

BTDC. Optimal timing will depend on the engine design as well as its speed and load.

Advancing the start of injection (injecting before the piston reaches to its SOI-TDC) results in

higher in-cylinder pressure and temperature, and higher efficiency, but also results in elevated

engine noise and increased oxides of nitrogen (NO

x

) emissions due to higher combustion

temperatures. Delaying start of injection causes incomplete combustion, reduced fuel efficiency

and an increase in exhaust smoke, containing a considerable amount of particulate matter and

unburned hydrocarbons.

In diesel engines varying amounts of fuel, in the form of very fine droplets, are injected into

approximately the same amount of air, irrespective of the engines speed, to control the top

temperature and the torque. The AFR therefore varies (typically between 20 - 100:1), hence

Diesel engines are described as being QUALITY governed. Fuel burns (after a slight delay) on

injection. Compression ratios (r

c

, typically 18 - 22:1] are limited more by engine component

strength than thermodynamics. Diesel knock can also occur (initial rapid combustion). Fuel

ignitability is measured by 'CETANE' rating a temperature such that when liquid fuel is sprayed

into the combustion space in droplet form it self-ignites. This is why the compression ratios of

diesel engines are typically about twice those of petrol engines. The droplets move around in the

combustion space seeking oxygen and burning takes place on the droplet surface at a local AFR

of about 15 to 1. To promote finding oxygen turbulence is induced in the combustion space. In a

diesel engine only enough fuel is injected to produce the torque required at any given engine

speed. It is not possible to use the stoichiometric AFR because the fuel will never find enough

oxygen quickly enough - and unburned fuel in the form of black smoke (carbon particles) will be

emitted. At 300 RPM the time for combustion is about 8 milliseconds. In diesel engines varying

amounts of fuel, in the form of very fine droplets, are injected into approximately the same

amount of air, irrespective of the engines speed, to control the top temperature and the torque.

The AFR therefore varies (typically between 20 - 100:1), hence Diesel engines are described as

being QUALITY governed. Fuel burns (after a slight delay) on injection. Compression ratios (r

c

,

typically 18 - 22:1] are limited more by engine component strength than thermodynamics. Diesel

knock can also occur (initial rapid combustion). Fuel ignitability is measured by 'CETANE'

rating. Early diesel engines used constant pressure heat transfer rather than constant volume heat

transfer as in the Otto cycle. In practice this can be achieved by a relatively short air blast fuel

injection process. The ideal (or 'true') diesel cycle is shown in Fig.6 below in which the process

2-3 is constant pressure heat transfer to the cycle.

Fig. 6 P-V and T-S Diagrams for Ideal Diesel cycle

On the compression stroke 1-2, air is compressed adiabatically to a temperature such that

when liquid fuel is sprayed into the combustion space in droplet form it self-ignites. This is why

the compression ratios of diesel engines are typically about twice those of petrol engines. The

droplets move around in the combustion space seeking oxygen and burning takes place on the

droplet surface at a local AFR of about 15 to 1. Thermal efficiency of typical diesel engines is

Where r

c

= compression Ratio

= Cutoff Ratio

= Ratio of specific heats

This equation shows that thermal efficiency depends not only on r

c

but also on the cut-off ratio

and the working medium properties . As increase the work done per cycle increase but

th

decreases. When r

c

increase more than 22, the increase in

th

is small, on the other hand,

maximum pressure increases much and mass of the engine increases.

MAJOR ADVANTAGES

Diesel engines have several advantages over other internal combustion engines:

[1]. They burn less fuel than a petrol engine performing the same work, due to the engine's

higher temperature of combustion and greater expansion ratio. Gasoline engines are

typically 30% efficient while diesel engines can convert over 45% of the fuel energy into

mechanical energy.

[2]. They have no high voltage electrical ignition system, resulting in high reliability and easy

adaptation to damp environments. The absence of coils, spark plug wires, etc., also

eliminates a source of radio frequency emissions which can interfere with navigation and

communication equipment, which is especially important in marine and aircraft

applications.

[3]. The life of a diesel engine is generally about twice as long as that of a petrol engine due

to the increased strength of parts used. Diesel fuel has better lubrication properties than

petrol as well.

[4]. Diesel fuel is distilled directly from petroleum. Distillation yields some gasoline, but the

yield would be inadequate without catalytic reforming, which is a more costly process.

[5]. Diesel fuel is considered safer than petrol in many applications. Although diesel fuel will

burn in open air using a wick, it will not explode and does not release a large amount of

flammable vapor. The low vapor pressure of diesel is especially advantageous in marine

applications, where the accumulation of explosive fuel-air mixtures is a particular hazard.

For the same reason, diesel engines are immune to vapor lock.

[6]. For any given partial load the fuel efficiency (mass burned per energy produced) of a

diesel engine remains nearly constant, as opposed to petrol and turbine engines which use

proportionally more fuel with partial power outputs.

[7]. They generate less waste heat in cooling and exhaust.

[8]. Diesel engines can accept super- or turbo-charging pressure without any natural limit,

constrained only by the strength of engine components. This is unlike petrol engines,

which inevitably suffer detonation at higher pressure.

[9]. The carbon monoxide content of the exhaust is minimal; therefore diesel engines are used

in underground mines.

EXPERIMENTAL SET- UP

The setup consists of single cylinder, four stroke, Multi-fuel, research engine connected to eddy

current type dynamometer for loading. The operation mode of the engine can be changed from

diesel to Petrol or from Petrol to Diesel with some necessary changes. In both modes the

compression ratio can be varied without stopping the engine and without altering the combustion

chamber geometry by specially designed tilting cylinder block arrangement. The injection point

and spark point can be changed for research tests. Setup is provided with necessary instruments

for combustion pressure, Diesel line pressure and crank-angle measurements. These signals are

interfaced with computer for pressure crank-angle diagrams. Instruments are provided to

interface airflow, fuel flow, temperatures and load measurements. The set up has stand-alone

panel box consisting of air box, two fuel tanks for duel fuel test, manometer, fuel measuring unit,

transmitters for air and fuel flow measurements, process indicator and hardware interface.

Rotameters are provided for cooling water and calorimeter water flow measurement. A battery,

starter and battery charger is provided for engine electric start arrangement. The setup enables

study of VCR engine performance for brake power, indicated power, frictional power, BMEP,

IMEP, brake thermal efficiency, indicated thermal efficiency, Mechanical efficiency, volumetric

efficiency, specific fuel consumption, A/F ratio, heat balance and combustion analysis. Labview

based Engine Performance Analysis software package Enginesoft is provided for on line

performance evaluation. Diesel engine test rig used for investigations comprised of a single

cylinder, water cooled, constant speed, four stroke, variable compression ratio diesel engine

connected to an eddy current dynamometer for loading. The set up and its schematic (Fig. 7 and

Fig.8) includes necessary instruments for measuring temperatures at various points, load, speed

and fuel consumption. Rotameter was used for measuring cooling water and calorimeter water

flow. Thermocouples were used for measurement of temperature of exhaust gas, cooling water

and calorimeter inlet and outlet. These signals were sent to data acquisition system and to

computer for further processing. The specifications of engine and sensors used are given in Table

2. The engine was coupled with Indus five gas exhaust analyser which is used for measuring

exhaust gas emissions like CO, CO

2

and O

2

.

Fig.7 Test Setup

Fig.8 Schematic of Test Setup

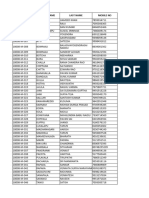

TABLE-2

EXPERIMENTAL PROCEDURE

Before starting the engine, the condition of the engine oil was checked and also the

availability of water was ensured.

Initially, engine was allowed to run with diesel fuel at no load till engine condition

stabilizes. The engine was then tested for different loads at compression ratio set by

manufacturer. For each load the engine was run for 4-5 minutes till engine parameters stabilizes.

At every load was repeated for three times and readings were averaged. Simultaneously the

values of CO

2

, CO and O

2

were recorded by using exhaust gas analyzer.

The engine then tested with blends of diesel and biodiesel (Easter of waste cooking oil) at

same setting to obtain base line data. The compression ratio at which the experiment was

conducted was 18. The performance of the engine at different loads was evaluated in terms of

brake power (BP), indicated power (IP), brake thermal efficiency (BTE), brake specific fuel

consumption (BSFC) and mechanical efficiency. CO

2

, CO and O

2

were recorded by using

exhaust gas analyzer while evaluating the performance of engine fuelled with different blends of

diesel and WCO by using exhaust gas analyzer.

RESULTS AND ANALYSIS

I. Performance Parameters:

(a) Brake Power: While comparing BP of engine with pure diesel, BP of engine when running

with various blends of biodiesel and diesel is slightly reduced (4.5 % only).

Table 3 BP of the engine at different loads

Load PD 5BD 10BD 15BD 20BD

0 0 0 0 0 0

1 0.305 0.286 0.285 0.286 0.285

3 0.888 0.854 0.847 0.852 0.852

6 1.756 1.694 1.688 1.688 1.688

9 2.61 2.53 2.5 2.525 2.523

Fig.9 BP at various loads

(b) Indicated Power: While comparing IP of engine with pure diesel, IP of engine when running

with various blends of biodiesel and diesel is increased by 23 %. This may be due to more

availability of oxygen in biodiesel which finally leads to increase in IP.

Table 4 IP of the engine at different loads

Load PD 5BD 10BD 15BD 20BD

0 0 0 0 0 0

1 1.05 1.48 1.555 1.516 1.475

3 1.638 2.05 2.117 2.082 2.042

6 2.506 2.89 2.958 2.918 2.878

9 3.36 3.72 3.77 3.755 3.713

0

1

2

3

0 5 10

B

P

(

k

W

)

Load (kg)

PD

5BD

10BD

15BD

20BD

Fig.10 IP at various loads

(c) Brake Thermal Efficiency: It increases with the increase in % of biodiesel by 8.8 %.

Table 5 BTE of the engine at different loads

Load PD 5BD 10BD 15BD 20BD

0 0 0 0 0 0

1 4.5 4.36 4.9 5.1 5.11

3 11.7 11 12.4 12.22 12.5

6 18.4 18.6 19.9 19.4 19.99

9 22.5 22.5 23.7 23.9 23.9

Fig.11 BTE at various loads

(d) Specific fuel consumption: It deceases with the increase in % biodiesel by 7 %.

0

1

2

3

4

0 5 10

I

P

(

k

W

)

Load (kg)

PD

5BD

10BD

15BD

20BD

0

5

10

15

20

25

30

0 5 10

B

T

E

(

%

)

Load (kg)

PD

5BD

10BD

15BD

20BD

Table 6 SFC of the engine at different loads

Load PD 5BD 10BD 15BD 20BD

1 1.869 1.964 1.75 1.687 1.691

3 0.729 0.781 0.691 0.701 0.688

6 0.465 0.462 0.432 0.443 0.432

9 0.38 0.381 0.362 0.359 0.359

Fig.12 SFC at various loads

(e) Mechanical Efficiency: It decreases by 21 % with the increase in % of biodiesel.

Table 7 Mechanical Efficiency of the engine at different loads

Load PD 5BD 10BD 15BD 20BD

1 28.99 18.91 18.3 18.84 19.32

3 54.22 41.46 40.01 40.93 41.71

6 70.07 58.47 57.05 57.84 58.64

9 77.67 67.74 66.31 67.24 67.94

Fig. 13 Mechanical Efficiency at different loads

0

0.5

1

1.5

2

2.5

0 5 10

S

F

C

(

k

g

/

k

W

-

H

)

Load (kg)

PD

5BD

10BD

15BD

20BD

0

20

40

60

80

100

0 5 10

M

e

c

h

.

E

f

f

i

c

i

e

n

c

y

(

%

)

Load (kg)

PD

5BD

10BD

15BD

20BD

II. Emission Parameters

(a). % of CO: It decreases with % increase in biodiesel by 27 %.

Table 8 % of CO at different loads

Load PD 5BD 10BD 15BD 20BD

0 0.167 0.149 0.14 0.119 0.113

1 0.128 0.118 0.094 0.095 0.099

3 0.095 0.085 0.061 0.073 0.07

6 0.084 0.072 0.052 0.07 0.058

9 0.071 0.067 0.068 0.066 0.054

Fig. 14 % of CO at different loads.

(b) % of CO

2

: It decreases with the % increase in biodiesel by 20 %.

Table 9 % of CO

2

at different loads

Load PD 5BD 10BD 15BD 20BD

0 2.98 2.53 2.32 2.25 2.25

1 3.53 3.14 2.93 2.76 2.25

3 3.95 3.82 3.62 3.36 3.2

6 4.99 4.87 4.64 4.77 4.62

9 6.8 6.15 6.06 6.05 5.78

Fig. 15 % of CO

2

at different loads.

0

0.05

0.1

0.15

0.2

0 5 10

C

O

(

%

)

Load (kg)

PD

5BD

10BD

15BD

20BD

0

2

4

6

8

0 5 10

C

O

2

(

%

)

Load (kg)

PD

5BD

10BD

15BD

20BD

(c) % of O

2

: It increases with the increase in % of biodiesel by 11%.

Table 10 % of O

2

at different loads

Load PD 5BD 10BD 15BD 20BD

0 16.77 17 17.32 17.4 17.52

1 16.02 16.16 16.5 16.77 17.32

3 14.46 15.13 15.4 15.55 15.76

6 12.71 13.53 14.05 14.52 14.88

9 10.38 11.19 11.8 12.12 12.25

Fig.16 % of O

2

at different loads

(d). % of NO

X

: It decreases with the increase in biodiesel by 5 %.

Table 11 % of NO

X

at different loads

Load PD 5BD 10BD 15BD 20BD

3 716 716 716 716 715

6 716 716 712 709 672

9 716 665 665 660 655

Fig. 17 % of NO

X

at different loads

0

5

10

15

20

0 5 10

O

2

(

%

)

Load (kg)

PD

5BD

10BD

15BD

20BD

640

660

680

700

720

740

0 2 4 6 8 10

%

o

f

N

O

X

Load (kg)

PD

5BD

10BD

15BD

20BD

CONCLUSIONS

It is concluded from this research work that, by using blends of biodiesel of WCO

1. The BP of engine reduces by 5 %.

2. The IP of engine increases by 23 %.

3. The Mechanical efficiency reduces by 21 %.

4. The brake thermal efficiency increases by 8.8 %.

5. The SFC decreases by 7 %.

7. The percentage of CO reduces by 27 %.

8. The percentage of CO

2

reduces by 20 %.

9. The percentage of O

2

increases by 11 %.

10. The percentage of NO

X

reduces by 5 %.

11. The performance evaluation indicates that use of biodiesel of WCO certainly is beneficial to

environment due to reduction in emissions of green house gasses.

12. The using of biodiesel of WCO certainly helps in reducing cost of imports of crude oil.

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- 3rd Year Cisco DataDocument4 pages3rd Year Cisco DataDilleswararao ChintalaPas encore d'évaluation

- 1st Years Cisco DataDocument4 pages1st Years Cisco DataDilleswararao ChintalaPas encore d'évaluation

- Encumbrance Form 97-109Document2 pagesEncumbrance Form 97-109Dilleswararao ChintalaPas encore d'évaluation

- Booklet - Polycet 22 31Document10 pagesBooklet - Polycet 22 31Dilleswararao ChintalaPas encore d'évaluation

- Lab FormatDocument33 pagesLab FormatDilleswararao ChintalaPas encore d'évaluation

- Auto CADDocument61 pagesAuto CADThiru MuruganPas encore d'évaluation

- M 403Document10 pagesM 403Dilleswararao ChintalaPas encore d'évaluation

- Original ResearchDocument9 pagesOriginal ResearchDilleswararao ChintalaPas encore d'évaluation

- 3 AnnDocument16 pages3 AnnDilleswararao ChintalaPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Tech GuidesDocument52 pagesTech GuidesAHMED MAHMOUD100% (1)

- 307Document140 pages307Mihail Barna100% (3)

- 2013 OutlanderDocument440 pages2013 OutlanderScenic777Pas encore d'évaluation

- 8860 ManualDocument100 pages8860 ManualAli Shafique0% (1)

- Trator Case 270 PDFDocument539 pagesTrator Case 270 PDFMarcio Soraia Zopi100% (1)

- مقترح الميزانية والاحتياجاتDocument16 pagesمقترح الميزانية والاحتياجاتMohamed SameerPas encore d'évaluation

- Workshop Manual, 9-16L Ind. (Group 30), EMS2Document208 pagesWorkshop Manual, 9-16L Ind. (Group 30), EMS2manuel93% (15)

- 17th Scheme 7th Sem PDFDocument12 pages17th Scheme 7th Sem PDFMadan V LPas encore d'évaluation

- Mazda5: Training ManualDocument140 pagesMazda5: Training ManualPablo De Miguel GonzálezPas encore d'évaluation

- Di9 074M 269 323Document2 pagesDi9 074M 269 323HASANPas encore d'évaluation

- NGV DG Flex BoschDocument16 pagesNGV DG Flex BoschThiago Hideki Yanai50% (2)

- Ford DEF Service InfoDocument17 pagesFord DEF Service InfoABBA PlantPas encore d'évaluation

- DTC P0418 Secondary Air Injection System Control "A" CircuitDocument7 pagesDTC P0418 Secondary Air Injection System Control "A" CircuitOrkhon GanchimegPas encore d'évaluation

- Alfa Laval Cat-Fine BookletDocument40 pagesAlfa Laval Cat-Fine BookleticeburnerPas encore d'évaluation

- TDI Injection and Glow Plug System 6-Cyl 3 0 LTR 4-Valve Common Rail Generation IIDocument87 pagesTDI Injection and Glow Plug System 6-Cyl 3 0 LTR 4-Valve Common Rail Generation IIergdegPas encore d'évaluation

- Renewable Energy: Murat Kadir YesilyurtDocument18 pagesRenewable Energy: Murat Kadir YesilyurtMUHAMMAD ABIEL PRADIPTAPas encore d'évaluation

- IMO MSC 1321 Prevention of Fire in ERDocument35 pagesIMO MSC 1321 Prevention of Fire in ERstefanPas encore d'évaluation

- Cat 330C Electric PlanDocument2 pagesCat 330C Electric PlanRajan Mullappilly67% (3)

- Engine Control Unit Modeling With Engine Feature C Code For HEV ApplicationsDocument12 pagesEngine Control Unit Modeling With Engine Feature C Code For HEV ApplicationsFahru ZainiPas encore d'évaluation

- Operating Experience and Teardown Analysis For Engines Operated On Biodiesel Blends (B20)Document12 pagesOperating Experience and Teardown Analysis For Engines Operated On Biodiesel Blends (B20)Singh KDPas encore d'évaluation

- Mitsubishi L200 Triton Parts CatalogDocument2 pagesMitsubishi L200 Triton Parts CatalogArnold Griffith100% (1)

- Saacke SKV Com MDocument12 pagesSaacke SKV Com MadnanfakharPas encore d'évaluation

- MoTeC Catalog 1.40Document77 pagesMoTeC Catalog 1.40Alberto RuizPas encore d'évaluation

- 6.0L Diagnostic Information: Scan ToolDocument8 pages6.0L Diagnostic Information: Scan Toolford62b100% (2)

- Milnor 30010 Cge ElectrónicaDocument47 pagesMilnor 30010 Cge ElectrónicaArturo De La Cruz GarciaPas encore d'évaluation

- wp6 (001 121) PDFDocument121 pageswp6 (001 121) PDFАлександр100% (2)

- 1221.2 1221.3 en Year 2009Document295 pages1221.2 1221.3 en Year 2009crismg1100% (1)

- 30 L Coffee Table Book DtsDocument70 pages30 L Coffee Table Book Dtscrisprusch1gmailcomPas encore d'évaluation

- Diesel Particle Filter Emergency RegenerationDocument4 pagesDiesel Particle Filter Emergency RegenerationBuga BuniciPas encore d'évaluation

- Improved Nozzles and Lines For New Scroll Fuel Systems (NSFS)Document11 pagesImproved Nozzles and Lines For New Scroll Fuel Systems (NSFS)betoven8437Pas encore d'évaluation