Académique Documents

Professionnel Documents

Culture Documents

Ladle Car Design

Transféré par

Mrinal ChakrabortyDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ladle Car Design

Transféré par

Mrinal ChakrabortyDroits d'auteur :

Formats disponibles

World Journal of Science and Technology 2012, 2(4):20-23

ISSN: 2231 2587

Available Online: www.worldjournalofscience.com

Proceedings of " A National Conference on Advances in Mechanical Engineering (NCAME-2012)

Held at R.C.Patel Institute of Technology, Shirpur, Dist. Dhule,Maharastra,India.

April 21, 2012

Design of tilting ladle transfer car for steel Industries

Prajakta Bawiskar1, Sachin Kamble1 and Kiran Bhole1

1Datta

Meghe College of Engineering, Airoli, Navi Mumbai, India

Abstract- This paper gives idea about designing of tilting ladle transfer car for steel Industries. Tilting Ladle transfer cars are

used to carry hot metal ladle from the HMDS section (Hot metal dispensing section) to the convertor section. The ladle

carrying the hot metal consists of impurities in the form of slag which is precipitated over the hot metal. This precipitated slag

is removed in tilting operation by slag raking machine. After titling operation the transfer car carries the material to the

convertor section. The paper includes designing of structural and hydraulic circuit for carrying and tilting ladle of ladle transfer

car. The design process involves hand calculation and the prepared design is then presented in the 3D drawings using

modeling software.

Keywords: Tilting ladle, Transfer car, Design steps

INTRODUCTION

Tilting Ladle transfer cars are used to carry hot metal ladles

from the HMDS Plant to the convertor section. The molten metal

consists of slag and impurities which affect the purity of the final

metal. The titling operation of the tilting car is used to tilt the ladle

carrying the hot metal and the slag raking machine removes the slag

from the tilted ladle. This innovative system is used to carry the hot

metal as well as remove the slag over the molten metal.

of tilting ladle transfer car.The operation of the car is in a hot region .

The ladle carrying the molten metal consists of liquid metal which is

at 1350 C. The ladle carrying the liquid metal is lined by a refractory

which protects the ladle metal contact with the molten metal. The

ladle is provided with a trunion on the either side by which the ladle

can be lifted or kept on the car by a lifting tackle . The lifting tackle is

engaged in the main hook of the main hoist of the crane . The crane

required for handling this huge capacity ladle is a four girder 350 T

EOT crane.The ladle is provided with a lip section which has a spout

with lip at 12 degrees. This spout is required for the generation of

smooth pouring of the liquid metal during the pouring in

convertor.Ladle car is to be designed using the safety parameters

and most of the operations are automatic or should have a remote

control to avoid the human intervention in the working of car.

TECHNICAL AND FUNCTIONAL DESCRIPTION

The tilting car is to be designed for the following technical

specifications. Weight of the molten metal with the ladle and

refractory lining to be carried: 280 Tonnes

Fig1. Proposed tilting ladle car

The figure. 1 shows the pictorial sketch of the proposed idea

*Corresponding Author

Srihari Prasad A

Department of Mechanical Engineering, K.L.University, Vaddeswaram, Guntur,

A.P., 522502., India

Email: srihari.anne@gmail.com

Speed of the car : 0 to 30 m/ min

Tilting angle of the ladle : 0 to 40

Tilting Speed : Three minutes for 40 tilting (forward movement )

Rail for the movement of the car : CR120

Rail Span : 3800 mm

Tilting initiation : By joystick

Distance of the remote control operation : 300 mm

Design standard : IS 807 for structural design.

With these inputs the task is to design a tilting car

The transfer car shall be self-propelled type and shall have

two (2) individual wheel drives The power shall be transmitted from a

squirrel cage motor through a flexible coupling to gear unit. The gear

unit shall be coupled to the driven track wheel and connected with

car frame by a torque arm or should be bolted to the frame. The two

World Journal of Science and Technology 2012, 2(4):20-23

electric motors shall be provided with brakes and shall be easily

detachable from gearbox during maintenance. The hot metal ladle

should be placed by EOT crane whose hook will be given by the

customer. After placement of the ladle the crane hooks should be

released easily without any interference with car frame. There should

be sufficient maintenance. Suitable refractory lining provision to be

made on the platform and sides to prevent damage due to accidental

spillage of metal at pouring and HMD station. The tilting of the ladle

shall be done with the hydraulic system. The hydraulic power pack

shall be operated from locally and from control room. The tilting

cylinders shall be operated with the help of joysticks. The tilting

cylinders mounting arrangement shall be strong enough to handle

the 280 ton ladle. Enough protection for cylinders to be provided and

cylinder seals to withstand the temperature

surrounding the heat

zone. Hydraulic hoses should withstand the temperature in case any

spillage of hot metal around the car. The ladle tilting should operate

between Zero (ladle vertical) to 40 deg only. Two proximity/limit

switches have to be used to sense two positions of ladle. One

proximity switch senses ladle fully tilted position at 40 deg. while the

other senses ladle in vertical position. Suitable provisions to be

made to mount safety switches. When Car is travelling on rail, i.e.

the tilting cylinder should not operate even if joystick operation is

done. Once hydraulic power pack is

started , car should not travel

even if supply to gear motor is given. Hydraulic Cylinder operated by

joystick. Joystick operation energies solenoid of direction control

valve causing cylinder to move. Once ladle has reached 40 deg.

tilted position, proximity switch activates. This signal is used to cut off

solenoid of direction control valve from joystick. Similarly when ladle

has returned back from tilted position, 0 deg. proximity switch at 0

deg. position activates. This signal is also used to cut off joystick

from solenoid of direction control valve. This will not allow

operation of Hydraulic cylinder even if joystick is operated for return

motion of cylinder The protection/heat shields shall be provided for

the car drive units, hydraulic system and cables to prevent damage

due to leakage/spillage of metal from sides of the ladles at pouring

station and slag raking machines. Rest technical specification

and dimensions as per the attached reference tilting transfer car and

hot metal ladle drawings. General Arrangement drawing shall be

submitted for approval with showing the ladle over car, hook

clearance, protection heat shield, drive, hydraulic power pack,

cylinders, make of components, technical specification, etc.,.

21

800 mm.

RPM of wheel = Speed/(3.14*d) =30000/(3.14*807)= 11.83 m/m

Considering the rpm of the wheel we select the drive elements

Gear box and the motor

Motor used in steel plants is a three phase supply. The motor to be

used is a six pole.

Speed of the motor = (120 * f)/P

= 120*50/ 6

= 1000 rpm

Hence the rated rpm = 960 rpm .

Gear box ratio = 960/11.83 = 81.12(82)

Motor KW rating

Power at the wheel

P= 2*pi*N*T/(60*1000)

P =2*3.14*11.83*T/(60*1000)

Torque on the wheel = 170000*(Wheel dia /2) =170000*(403.5)=

68595000kg-mm =685950000N-mm

P =2*3.14*11.83*685950000/60*1000=849.347

For 150% over load = 849.347*1.5=1274.1 KW

Gear box ration =80

Motor KW required = 16 KW

Considering the intermittent loading and the impact factor the motor

KW is 30KW

STRUCTURAL ELEMENT DESIGN.

As the ladle is hot when it carries the hot metal the material

used in the transfer car should be also able to with stand the heat

dissipated without any distortion.

Hence the material which is selected for Construction in IS 2002

which is a material having a very less thermal coefficient of

expansion.

DRIVE ELEMENT DESIGN.

Design of the wheels of the tilting transfer Car.

Speed of the Car 30 m/ min =30000mm/min

Load on the tilting car : 280T (carrying wt)+ 60T self weight= 340 T

Deciding the no of wheels

As the surface of the rail is wavy or has troughs and crests the

design of wheel is to be done by considering pin joints. Hence the

number of wheel for pin joint will be two at every location.

Hence the no. Of wheel = 8 nos.

Load on each wheel = 42.5 Tonnes

Speed = (pi)*d*n=3.14*d*n

As the load is 42.5 tonnes and as per crane design standard and

considering CR120 Rail

Diameter= 1.5 W/ a = (1.5*42500/90)= 708 .33mm.

Considering a further factor of safety the standard wheel selected is

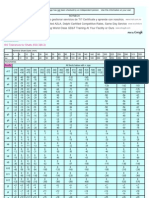

Fig 2.Transfer car in about to tilt position

The loading pattern is considered by taking the beam as a

simply supported beam .

The highest loading will be as shown in Fig.2 The ladle rests

at three points on the tilting frame surface .

Srihari Prasad A et al.,

22

Fig 4. Box Design

Hence each surface has been considerd with a load of 108 Tonnes.

Reaction at the point A + Reaction at the point E =50+108+5= 163T

In a simply supported beam the moments at the supported point are

zero.

MA= -108*500-50*649-5*250+1450RE

RE=61 T

RA=101T

Max bending moment = 108* 500= 54000000 kg-mm

Section modulus is now to be worked out.

The section modulus of the above box section considered

=17326950 mm3

Hence the stresses will be = 54000000/17326950 =3.11 kg/mm2

HYDRAULIC SYSTEM DESIGN

The hydraulic system will be designed as shown in the

Fig. 8. CG design during tilting ,The CG were calculated in each

stage of tilting as in fig. 7. CAD software of Autocad is used. Now the

design will be optimized using the solidworks The design of trolley in

Solid works is as shown in Fig.6

Fig 3. Transfer car in Tilt position.

The section to withstand the heavy bending moment will be a

box which would be developed by using plates and welded

connections.

Fig 5. Section Modulus Of Box.

Fig 7. CG calculation at different angle

. Fig 8. Hydraulic system Design

World Journal of Science and Technology 2012, 2(4):20-23

There are two cylinders which do the tilting operation .These

cylinders work on hydraulic pressure . The following are the

engineering considerations in the design of this cylinders.

Load on the cylinders 320 tonnes

Operating pressure considered is 120 bar

Pressure =Force /Area

Area of cylinder = 320/120

As there are two cylinders

Area= 320*1000/(120*0.01*2)=133333mm2

Diameter of the cylinder = 210 mm

During design we will take higher bore on availability.

Hence the bore diameter is taken as 280 mm

The hydraulic power pack has the following features

Hydraulic oil : VG 68

No of cylinders 2

The tilting operation valve : proportional valve PVG32( directional as

wellas a proportional control valve)

Flow of the pump 63 litre sper minute .

Forward speed = 485 mm/s

Rod end diameter 140 mm .

23

CONCLUSION

The design of the structures their optimisation is done using

hand calculations and Finite element analysis by using softwares like

Solidworks.The drive calculations are done by using the drive

standards and are effective for the VVVF drive also. The hydraulic

design is done using the Rexroth and Sauer danfoss instruction

codes. This is the basis of implementation in steel plant design.

REFERENCES

[1]. Solidworks User manual guide :Dassault Systems

[2]. Hydraulics Design Manual : Gl Rexroth

[3]. Structural design: IS 807

[4]. Transfer Planning of Molten Metals in Steel Works by

Decentralized Agent Junji KIKUCHI , Masami KONISHI and

Jun IMAI.

[5]. Tilt Testing Of two Heavy Vehicles and related performance

issue. By Dr Hans Prem ,Director and Senior Consultant.

[6]. E.J. Reilly and A.C. Nelson.1920.Metal transfer car

PatentAug 3.

Vous aimerez peut-être aussi

- Stacker ReclaimerDocument4 pagesStacker ReclaimerVinoth Ravi100% (1)

- Elecon KCN Gear BoxDocument43 pagesElecon KCN Gear BoxGourav Choudhuri100% (12)

- Specifications For Design of Hot Metal Ladles AISE Standard No PDFDocument17 pagesSpecifications For Design of Hot Metal Ladles AISE Standard No PDFBuda PestePas encore d'évaluation

- Grey Iron Castings Specification: Indian StandardDocument12 pagesGrey Iron Castings Specification: Indian StandardS Karthi100% (3)

- En9 070M55Document1 pageEn9 070M55Tridib DeyPas encore d'évaluation

- Westermann Tables NewDocument157 pagesWestermann Tables NewArul Gnana John100% (2)

- Is 2708 - Manganize Steel CastingDocument6 pagesIs 2708 - Manganize Steel CastingJanak MistryPas encore d'évaluation

- Steel-Smith PDF CatalogueDocument93 pagesSteel-Smith PDF CatalogueneetadaeroPas encore d'évaluation

- Usha Company Profile Product & CatloguesDocument29 pagesUsha Company Profile Product & Catloguesvipul bhatt100% (1)

- SKF Spherical Roller Bearing ClearanceDocument2 pagesSKF Spherical Roller Bearing ClearanceKumaran GopalPas encore d'évaluation

- Catalog Gear CouplingsDocument2 pagesCatalog Gear CouplingsDev Misra0% (1)

- Elecon EON Series GearboxDocument70 pagesElecon EON Series GearboxSumit Chugh0% (1)

- L&T O&M ManualDocument156 pagesL&T O&M Manualranajoy71971Pas encore d'évaluation

- Gear Coupling 2014Document4 pagesGear Coupling 2014Dado Maja ArseninPas encore d'évaluation

- Elecon Gear Box CatalogueDocument15 pagesElecon Gear Box CatalogueKARTHIGEYAN.R79% (14)

- Rotomotive Motor ManualDocument19 pagesRotomotive Motor ManualMiki SinghPas encore d'évaluation

- Conveyor Pulley DesignDocument2 pagesConveyor Pulley DesignZoebair100% (1)

- W3-311E Bar and Wire Rod Mills PDFDocument32 pagesW3-311E Bar and Wire Rod Mills PDFMohammed IrfanPas encore d'évaluation

- Centrifugally Cast Inserted Grinding Rollers SpecificationDocument6 pagesCentrifugally Cast Inserted Grinding Rollers Specificationsiva100% (1)

- Example 1 For Gearbox SelectionDocument11 pagesExample 1 For Gearbox SelectionNakkolop100% (1)

- Proven Tech + Low Cost + Great ServiceDocument20 pagesProven Tech + Low Cost + Great ServicePintu SarkarPas encore d'évaluation

- Elecon Gear Box O&M ManualDocument38 pagesElecon Gear Box O&M ManualSrinivasa Rao PallelaPas encore d'évaluation

- Load Calculation - Bar Mill - 20 02 2020Document15 pagesLoad Calculation - Bar Mill - 20 02 2020DARA SINGH100% (1)

- Technical Specification For Rollling Mill-20200922Document15 pagesTechnical Specification For Rollling Mill-20200922Nilton Bruno Salazar MartinezPas encore d'évaluation

- DIN 17100 STEELS GUIDEDocument7 pagesDIN 17100 STEELS GUIDEsardhan.rajender84Pas encore d'évaluation

- Belt Pulley Is.3142.1993 PDFDocument14 pagesBelt Pulley Is.3142.1993 PDFchidambaram kasiPas encore d'évaluation

- Motor Calculation of CraneDocument6 pagesMotor Calculation of Craneliftline engineersPas encore d'évaluation

- Essential guide to EOT crane mechanicsDocument3 pagesEssential guide to EOT crane mechanicspjustino19700% (1)

- Screw Conveyors PDFDocument121 pagesScrew Conveyors PDFzackii90Pas encore d'évaluation

- Mill Liner Bolt Torque SpecificationsDocument1 pageMill Liner Bolt Torque SpecificationsAugusto TorresPas encore d'évaluation

- TS of Travelling TripperDocument10 pagesTS of Travelling TripperShashank HegdePas encore d'évaluation

- Mumbai University Lecture Notes Mechanical Systems DesignDocument15 pagesMumbai University Lecture Notes Mechanical Systems DesignPrajwal NaikPas encore d'évaluation

- Abb Crane Duty Motor CatalogDocument10 pagesAbb Crane Duty Motor Catalogyaduvanshi1Pas encore d'évaluation

- TCDPDocument88 pagesTCDPPrakash KumarPas encore d'évaluation

- ISO 286-2 Shaft Limits TolerancesDocument2 pagesISO 286-2 Shaft Limits TolerancesMixtli Garcia100% (1)

- Rotary Kiln Drive With Planetary Gear UnitDocument37 pagesRotary Kiln Drive With Planetary Gear UnitRahmat HidayatPas encore d'évaluation

- High Pressure Vessel Thickness CalculationsDocument11 pagesHigh Pressure Vessel Thickness CalculationsShriyash DeshpandePas encore d'évaluation

- Rack and Pinion Drive Unite1009Document34 pagesRack and Pinion Drive Unite1009Tiago HorstmannPas encore d'évaluation

- Crane Design Basics Webpage Provides IntroductionDocument13 pagesCrane Design Basics Webpage Provides IntroductionAnandh PsPas encore d'évaluation

- CM-3.01INP0316 - SERIES M GEARED MOTORS AND REDUCERS GUIDEDocument121 pagesCM-3.01INP0316 - SERIES M GEARED MOTORS AND REDUCERS GUIDEshivanandr2481100% (6)

- Product Leaflet - Portable CNC Cutting MachineDocument2 pagesProduct Leaflet - Portable CNC Cutting Machineabhics67Pas encore d'évaluation

- Mot Spur GearDocument8 pagesMot Spur GearRavi MirzaPas encore d'évaluation

- Sprocket DesignDocument4 pagesSprocket DesignchethanPas encore d'évaluation

- Dri InternshipDocument38 pagesDri InternshipGuruprasad Sanga100% (3)

- Is 3177 Eot CraneDocument62 pagesIs 3177 Eot CraneDnyanesh Bhalerao75% (4)

- Rotating TrolleyDocument12 pagesRotating TrolleyInderdeep TatlaPas encore d'évaluation

- Operation Manual For San 1400 TPP HDR IV CC BG 135TDocument155 pagesOperation Manual For San 1400 TPP HDR IV CC BG 135TCat Tom90% (10)

- 002005ea 2Document34 pages002005ea 2AliArababadiPas encore d'évaluation

- Details About Motorized Screw JackDocument24 pagesDetails About Motorized Screw JackSyko GamingPas encore d'évaluation

- Specification of GHR 1520 - 3BDDocument3 pagesSpecification of GHR 1520 - 3BDDoãn VănPas encore d'évaluation

- Ladle TurretDocument27 pagesLadle Turretsati55009100% (6)

- 5-50t Electric Hook Overhead CraneDocument28 pages5-50t Electric Hook Overhead Cranemohamed100% (1)

- Technical Analysis of BakerDocument27 pagesTechnical Analysis of BakerManu KhodPas encore d'évaluation

- Drive Technology: Rope Winches and GearboxesDocument20 pagesDrive Technology: Rope Winches and GearboxesAnonymous ODKk6IgUJNPas encore d'évaluation

- Industrial Diesel Hydraulic Crane: TIL LimitedDocument4 pagesIndustrial Diesel Hydraulic Crane: TIL LimitedNageswara Reddy GajjalaPas encore d'évaluation

- EOT CRANE - Rev 2Document6 pagesEOT CRANE - Rev 2Koushik BhaumikPas encore d'évaluation

- Ball Transfer Units GuideDocument20 pagesBall Transfer Units GuideconradoralPas encore d'évaluation

- Machine Design Answer KeyDocument16 pagesMachine Design Answer KeyK.KESAVARAJ HICET STAFF MCTSPas encore d'évaluation

- Design of Multi-Axis Welding Positioner WithDocument7 pagesDesign of Multi-Axis Welding Positioner Withsuraj dhulannavarPas encore d'évaluation

- Spiral Pipe Mill Project ReportDocument24 pagesSpiral Pipe Mill Project ReportVikalp Shri Bachchan50% (2)

- Sample Resume Mechanical Designer MidlevelDocument2 pagesSample Resume Mechanical Designer MidlevelMrinal ChakrabortyPas encore d'évaluation

- Kolkata Medical Facilities ListDocument10 pagesKolkata Medical Facilities ListMrinal ChakrabortyPas encore d'évaluation

- Kolkata GDocument4 pagesKolkata Ghirak12Pas encore d'évaluation

- Subject - Re: How To Give Password To A Folder?????Document2 pagesSubject - Re: How To Give Password To A Folder?????Mrinal ChakrabortyPas encore d'évaluation

- Metric fits and tolerances chartDocument1 pageMetric fits and tolerances chartChin Yuan GohPas encore d'évaluation

- Is 808-1989 Steel TableDocument24 pagesIs 808-1989 Steel TableAtul Kumar Engineer86% (28)

- 00 - User Manual - Netsure 702IC4 - For ODUDocument53 pages00 - User Manual - Netsure 702IC4 - For ODUSameera MilindaPas encore d'évaluation

- Summary Sheets Complete Version F2013Document58 pagesSummary Sheets Complete Version F2013Minjae LeePas encore d'évaluation

- Portable welding load banks for testing AC/DC welding powerDocument2 pagesPortable welding load banks for testing AC/DC welding powerlauguicoPas encore d'évaluation

- Ae3491e7 Yearly Review of National Affairs 2018 PDFDocument280 pagesAe3491e7 Yearly Review of National Affairs 2018 PDFManjunath MallannavarPas encore d'évaluation

- Centrifugal Compressor Settle Out Conditions TutorialDocument5 pagesCentrifugal Compressor Settle Out Conditions TutorialJHOEARGPas encore d'évaluation

- Acid Gas Cleaning Demo: Working InstructionsDocument13 pagesAcid Gas Cleaning Demo: Working Instructionsreclatis14Pas encore d'évaluation

- Concept of Net Zero Energy Buildings (NZEB) - A Literature ReviewDocument16 pagesConcept of Net Zero Energy Buildings (NZEB) - A Literature ReviewJaime PazPas encore d'évaluation

- Application of Evaporation in Pharmacy 1Document9 pagesApplication of Evaporation in Pharmacy 1Parthiba GhoshPas encore d'évaluation

- Tesla meter,Gauss meter、Magnetic flux densimeter、Introduction Handy typeDocument2 pagesTesla meter,Gauss meter、Magnetic flux densimeter、Introduction Handy typesomkiat kongprasiatPas encore d'évaluation

- Whirlpool Europe Service Manual for GSI 6587 IN DishwasherDocument17 pagesWhirlpool Europe Service Manual for GSI 6587 IN DishwasherDEKOEBERPas encore d'évaluation

- At Range / Gamme At: Weatherproof Multi-Turn Actuators Servomoteurs Multi-Tours EtanchesDocument57 pagesAt Range / Gamme At: Weatherproof Multi-Turn Actuators Servomoteurs Multi-Tours EtancheszaidPas encore d'évaluation

- General Purpose US FusesDocument69 pagesGeneral Purpose US FusesEliasPas encore d'évaluation

- Bs 8010-25-1989 Pipelines On Land Glass Reinforced Thermosetting PlasticsDocument30 pagesBs 8010-25-1989 Pipelines On Land Glass Reinforced Thermosetting PlasticsFatty-bom-bomPas encore d'évaluation

- Lecol Catalogue.dDocument20 pagesLecol Catalogue.dmuzeiaPas encore d'évaluation

- Low Voltage Capacitors For Improved Power Quality: Produc T BrochureDocument20 pagesLow Voltage Capacitors For Improved Power Quality: Produc T BrochureJuan Alberto Cayetano GomezPas encore d'évaluation

- 4 - Kama - Kde 6500 TWDocument2 pages4 - Kama - Kde 6500 TWJavadPas encore d'évaluation

- Guidelines: Commercial Office SpacesDocument14 pagesGuidelines: Commercial Office SpacesapoyoPas encore d'évaluation

- D-155 D-179 D-206 D-239 D-246 D-268 D-310 D-358 DT-239 DT-358 DT-402 Electrical EquipmentDocument52 pagesD-155 D-179 D-206 D-239 D-246 D-268 D-310 D-358 DT-239 DT-358 DT-402 Electrical EquipmentTanase MariusPas encore d'évaluation

- Effects On The Human Body: Extremely Low Frequency RFDocument1 pageEffects On The Human Body: Extremely Low Frequency RFGokul KrishPas encore d'évaluation

- NS1 Work Plan Procedure For Erection of Circulating Water Pump Rev.0 - Part 1 of 3Document53 pagesNS1 Work Plan Procedure For Erection of Circulating Water Pump Rev.0 - Part 1 of 3namdq-1Pas encore d'évaluation

- Faculty of Engineering Technology Department of Civil Engineering TechnologyDocument3 pagesFaculty of Engineering Technology Department of Civil Engineering TechnologyNrlFlztiPas encore d'évaluation

- OSE5312 Slides Class ZZ - Summary For Final - 2upDocument40 pagesOSE5312 Slides Class ZZ - Summary For Final - 2upDiana PhiriPas encore d'évaluation

- Perkins Systems Operation Testing and Adjusting 1106d Industrial EngineDocument8 pagesPerkins Systems Operation Testing and Adjusting 1106d Industrial Enginecarolyn100% (43)

- Light Energy Lesson Plan: Students Will Students Will Describe HowDocument3 pagesLight Energy Lesson Plan: Students Will Students Will Describe HowolamhenPas encore d'évaluation

- 3 Term Worksheet (2018 - 19) : Subject - Science Class - V Name: Sec.Document10 pages3 Term Worksheet (2018 - 19) : Subject - Science Class - V Name: Sec.Paulo C. CruzPas encore d'évaluation

- Richard Nakka's Experimental Rocketry SiteDocument8 pagesRichard Nakka's Experimental Rocketry Siteazrim02Pas encore d'évaluation

- BT-3 200 PDFDocument3 pagesBT-3 200 PDFaqil khanPas encore d'évaluation

- Introduction To Current Electricity and A.C Theory FinalDocument76 pagesIntroduction To Current Electricity and A.C Theory FinaldeoPas encore d'évaluation

- Tutorial 19 - Thermal Stress - SwitchDocument11 pagesTutorial 19 - Thermal Stress - SwitchKelvin HewPas encore d'évaluation

- SCBA CertDocument2 pagesSCBA CertSup ChomPas encore d'évaluation