Académique Documents

Professionnel Documents

Culture Documents

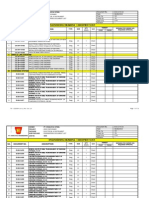

EE 01728 1 - 44 R006 Device Summary of STG

Transféré par

Vinoth KumarTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

EE 01728 1 - 44 R006 Device Summary of STG

Transféré par

Vinoth KumarDroits d'auteur :

Formats disponibles

Project Title

Client

Consultant

Contractor

G.B.BANG S.H.YOON 006 06.08.11

Wang,

Zhongshun

Issue for Information T.W.KIM

S.H.YOON

004 17.09.10

Wang,

Zhongshun

Issue for Information T.W.KIM G.B.BANG S.H.YOON

005 16.11.10

Wang,

Zhongshun

Issue for Information T.W.KIM G.B.BANG

S.H.YOON

002 30.06.10

Wang,

Zhongshun

Issue for Information T.W.KIM G.B.BANG S.H.YOON

003 18.08.10

Wang,

Zhongshun

Issue for Information T.W.KIM G.B.BANG

S.H.YOON

000 19.02.10

Wang,

Zhongshun

Issue for Information T.W.KIM G.B.BANG S.H.YOON

001 08.04.10

Wang,

Zhongshun

Issue for Information T.W.KIM G.B.BANG

REV DATE BY: DESCRIPTION CHKD. CERT. APPD.

CONVERSION OF QURAYYAH OPEN CYCLE POWER

PLANT TO COMBINED CYCLE POWER PLANT

PROJECT C

Document Title

CREATED BY: CHECKED BY:

DATE STARTED: DATE COMPLETED:

OPR'G. DEPT.: ENG. DEPT.:

DOC. NO. REV. NO.

QURAYYAH SAUDI ARABIA

DEVICE SUMMARY OF STG

Wang, Zhongshun T.W.KIM

THIS DOCUMENT IS NOT TO BE USED FOR

CONSTRUCTION OR FOR ORDERING

MATERIAL UNTIL CERTIFIED AND DATED

APPROVAL/CERTIFICATION INFORMATION

J OB ORDER NO.

30621127 000 3PS EE-01728 006

J OB NO. PROJ ECT SUBDIVISION DOCUMENT TYPE CODE DOCUMENT NUMBER REV. NO.

1-0923053.01

SIZE DWG NO SH REV

A

THIRD ANGLE PROJECTION

REVISIONS

REV DESCRIPTION

SHT/

ZONE

APPROVED

DATE

(YYYY-MM-DD)

THIS DOCUMENT SHALL BE

REVISED IN ITS ENTIRETY.

ALL SHEETS OF THIS

DOCUMENT ARE THE SAME

REVISION LEVEL AS

INDICATED

REVISION DESCRIPTION IS

FULLY STATED ON FIRST

SHEET OF DOCUMENT.

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ON

2 PL DECIMALS +-

3 PL DECIMALS +-

ANGELS +-

FRACTIONS +-

SIGNATURES

DATE

(YYYY-MM-DD)

DRAWN

CHECKED

ENGRG

ISSUED

GENERAL ELECTRIC COMPANY

GE Energy

APPLIED PRACTICES

SIM TO:

SIZE CAGE CODE DWG NO

A

SCALE SHEET

397A3135

397A3135

NONE NONE

1 F

DM:270T811 CC:VE14

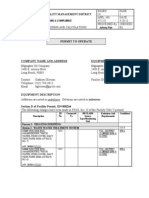

Device Summary

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved.

The information contained herein is GE Energy STEAM Proprietary Technical Information that

belongs to the General Electric Company, GE Energy (USA), LLC and/or their affiliates, which

has been provided solely for the express reason of restricted private use. All persons, firms,

or corporations who receive such information shall be deemed by the act of their receiving the

same to have agreed to make no duplication, or other disclosure, or use whatsoever for any, or

all such information except as expressly authorized in writing by the General Electric Company,

GE Energy (USA), LLC and/or its affiliates.

GE CLASS II (INTERNAL NON-CRITICAL)

g

2010-02-17 NESHEWAIT, ADI

NESHEWAIT, ADI

NESHEWAUIT, ADI

BENES, LINDA

C UPDATED SYSTEM 6.5A PER DCI

10008335 - UPDATED DEVICE

MOV-VBV-1 SYSTEM 5.0A PER

DCI 10012309 - ADDED GXM-

1, GXM-2, PS-212C, SP-GXM-

1,SP-GXM-2, PS-213 AND PS-

214. DCI 10014837 - UPDATED

SYSTEM 4.0 ADDED PDS-221

MS# CE37383 AN# 10012736

2010-07-27 DRAWN

LB

D MODIFIED DEVICES INFO PER

DCI 10016613 TO ADD VOLTAGE

FREQ AND PHASE . MS# CE37901

2010-08-26 DRAWN

LB

E CHANGED VOLTAGE RATINGS OF

MOV-VBV PER DCI 10024804.

MSAN CE38430.

2010-12-16 DRAWN

LB

F SYSTEM 3.5 UPDATED PER

DCI11009288 , SYSTEM 3.1

UPDATED PER DCI11006301

AN#11017536 MS#CE39774

2011-07-13 DRAWN

BENES

LINDA

ENGINEER

EDARA SIRE

1 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

2 F

System Title

1.1 STEAM/METAL THERMOCOUPLES

1.2 AXIAL POSITION

1.3 SHELL/ROTOR EXPANSION

1.4 ECCENTRICITY

1.5 BEARING VIBRATION

1.5B STC VIBRATION MONITORS

1.6A BEARING AND DRAIN THERMOCOUPLES

1.7 EXHAUST INSTRUMENTATION

2.0 TURNING GEAR

2.1 TURNING GEAR PANEL

3.1 OIL LUBE TANK

3.4 SEAL OIL

3.5 LUBE & HYDRAULIC SKID ENCLOSURE & VENTILATION DEVICES

4.0 HYDRAULIC POWER UNIT

5.0A GLAND CONDENSERS

5.0B STEAM SEAL SYSTEM

5.0C EXHAUST HOOD SPRAY SYSTEM

6.1 SPEED/LOAD

6.2 STEAM LINE PRESSURE TRANSMITTERS

6.3 EXTRACTION/ADMISSION

6.4C COMBINED STOP AND CONTROL VALVES

6.4D COMBINED REHEAT VALVES

6.4L ADMISSION CONTROL VALVES

6.4M ADMISSION STOP VALVES

6.4R EQUALIZING VALVES

6.4S REVERSE FLOW VALVES

6.4U REVERSE FLOW DISCHARGE VALVE

6.5 MOTOR OPERATED VALVES

6.5B AIR OPERATED VALVES

6.7B TRIP PUSHBUTTONS

7.0 GENERATOR

7.5 HYDROGEN GAS SYSTEM

7.5A G70 STEAM TURBINE ENCLOSURE & SKIRT LAGGING

2 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

3 F

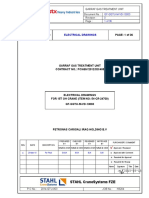

NOTES

Rev A - DCI 10004482 - Changed UNITS to BARS.

Added the following devices per revised instrumentation list

REDP-1A

REDX-1A

REDP-1B

REDX-1B

DEDX-1 (DEDP-1 is already on the Instrumentation List and VE14, but the prox was omitted)

DEDP-2

DEDX-2

EP-2

EX-2

EP-3

EX-3

Note: VE14 to be revised to change tag names for the existing eccentricity probe and prox from EP to EP-1 and EX to EX-1.

Rev B Updated system 7.5 devices to identify devices that will wired to TCP VIA MODBUS PROTOCOL

Rev C . Updated system 6.5A per DCI 10008335 - Updated Device MOV-VBV-1

System 5.0A per DCI 10012309 - Added GXM-1, GXM-2, PS-212C, SP-GXM-1,SP-GXM-2, PS-213 and PS-214. DCI

10014837 - Updated System 4.0 added PDS-221

Rev D - Modified devices info per DCI 10016613 to add missing Voltage Freq and Phase

3 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

4 F

SWITCH SETTINGS

Contact Condition Additional Contacts

NO- Normally open CEC

-

Additional contact:

Normally closed

Electrically common

NC- Normally closed CES

-

Additional contact:

Normally closed

Electrically separate

()- Parenthesis indicates sets of

contacts

OEC

-

Additional contact:

Normally open

Electrically common

OES

-

Additional contact:

Normally open

Electrically separate

Example: NORM=(2) NO-CEC

4 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

5 F

Device System Settings

23HG-1 7.0 SPACE HEATER-GENERATOR

2.250 KW; 480 VAC; 3 PH; 60 HZ;

23HG-2 7.0 SPACE HEATER-GENERATOR

2.250 KW; 480 VAC; 3 PH; 60 HZ;

23KE-1 7.0 HEATER-GENERATOR COLLECTOR ENCLOSURE

472.0 W; 120 VAC; 1 PH; 50/60 HZ;

23QB-1 3.1 SPACE HEATER-LIFT OIL PUMP MOTOR

200.0 W; 120 VAC; 1 PH; 60 HZ;

200W IS MAXIMUM, ACTUAL RATING MAY BE LESS.

23QB-2 3.1 SPACE HEATER-LIFT OIL PUMP MOTOR

200.0 W; 120 VAC; 1 PH; 60 HZ;

200W IS MAXIMUM, ACTUAL RATING MAY BE LESS.

39VS-101 7.0 VIBRATION SENSOR (NON-CONT) GEN COLLECTOR END

BENTLEY NEVADA, 3300 SERIES

PROXIMITY PROBE FOR GENERATOR SHAFT

RANGE:200 MV PER MILLIINCH

39VS-102 7.0 VIBRATION SENSOR (NON-CONT) GEN COLLECTOR END

BENTLEY NEVADA, 3300 SERIES

PROXIMITY PROBE FOR GENERATOR SHAFT

RANGE:200 MV PER MILLIINCH

39VS-91 7.0 VIBRATION SENSOR (NON-CONT) GEN COUPLING END

BENTLEY NEVADA, 3300 SERIES

PROXIMITY PROBE FOR GENERATOR SHAFT

RANGE:200 MV PER MILLIINCH

39VS-92 7.0 VIBRATION SENSOR (NON-CONT) GEN COUPLING END

BENTLEY NEVADA, 3300 SERIES

PROXIMITY PROBE FOR GENERATOR SHAFT

RANGE:200 MV PER MILLIINCH

45FG-40A 7.0 FIRE DETECTOR-GENERATOR COMPARTMENT

125VDC

45FG-40B 7.0 FIRE DETECTOR-GENERATOR COMPARTMENT

125VDC

63QB-2 3.1 BEARING LIFT OIL SUPPLY PRESSURE

DECREASING: 2740+-40.00 PSIG OR 189.0+-2.759 BARG

(INCREASING: 2900+-40.00 PSIG OR 200.0+-2.759 BARG)

NORM=(2) NO-CEC;

TO TURNING GEAR MCC

63QB-3 3.1 BEARING LIFT OIL SUPPLY PRESSURE

DECREASING: 2740+-40.00 PSIG OR 189.0+-2.759 BARG

(INCREASING: 2900+-40.00 PSIG OR 200.0+-2.759 BARG)

NORM=(2) NO-CEC;

TO TURNING GEAR MCC

63QBF-1 3.1 LIFT OIL FILTER DIFFERENTIAL PRESSURE

INCREASING: 100.0+-5.000 PSIG OR 6.897+-0.3449 BARG

(DECREASING: 46.00+-5.000 PSIG OR 3.173+-0.3449 BARG)

74 2.1 RELAY

NORM=NC;

74-1 2.1 DC TRIPPING BLOWN FUSE MONITOR RELAY

NORM=NC;

FUNCTION: PROVIDE THE CONTACT FOR K-PBM

5 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

6 F

Device System Settings

88QB-1 3.1 BEARING LIFT OIL PUMP MOTOR

75.00 HP; 55.93 KW; 1800 RPM; 460 VAC; 3 PH; 60 HZ;

IEC 60034 & IEC 60072

88QB-2 3.1 BEARING LIFT OIL PUMP MOTOR

75.00 HP; 55.93 KW; 1800 RPM; 460 VAC; 3 PH; 60 HZ;

IEC 60034 & IEC 60072

95FP-1 7.0 GENERATOR AIR GAP FLUX PROBE

96VS-1 7.0 SHAFT VOLTAGE TRANSDUCER

AIT3350 7.5 GENERATOR CONDITION TRANSMITTER

4.000 MA=0.0 INH2O OR 0.0 MBAR

20.00 MA=100.0 INH2O OR 249.2 MBAR

UNITS ARE IN %.

HAZARDOUS ZONE 2

PROTECTION METHOD: ``D`` - EXPLOSION PROOF.

SIGNAL TO TCP VIA MODBUS PROTOCOL

AL-201 7.5A AC LIGHT - HPIP ENCLOSURE

120 VAC

60HZ, 1 PHASE

AL-202 7.5A AC LIGHT - HPIP ENCLOSURE

120 VAC

60HZ, 1 PHASE

AL-203 7.5A AC LIGHT - HPIP ENCLOSURE

120 VAC

60HZ, 1 PHASE

AL-204 7.5A AC LIGHT - HPIP ENCLOSURE

120 VAC

60HZ, 1 PHASE

AL-301 3.5 AC LIGHT - LUBE AND HYDRAULIC ENCLOSURE

AL-302 3.5 AC LIGHT - LUBE AND HYDRAULIC ENCLOSURE

AL-303 3.5 AC LIGHT - LUBE AND HYDRAULIC ENCLOSURE

AL-304 3.5 AC LIGHT - LUBE AND HYDRAULIC ENCLOSURE

AL-305 3.5 AC LIGHT - LUBE AND HYDRAULIC ENCLOSURE

AL-306 3.5 AC LIGHT - LUBE AND HYDRAULIC ENCLOSURE

AL-501 7.5A AC LIGHT - COUPLING COMPARTMENT

120 VAC

60HZ, 1 PHASE

AL-502 7.5A AC LIGHT-COUPLING COMPARTMENT

120 VAC

60HZ, 1 PHASE

AOV-SSDV 6.5B STEAM SEAL DUMP VALVE

MKVI CONTROLLED VALVE 4-20 MA POSITIONER

4 MA =VALVE CLOSE

20 MA =VALVE OPEN

HAZARDOUS ZONE: NON RATED

AOV-SSFV 6.5B STEAM SEAL FEED VALVE

MKVI CONTROLLED VALVE 4-20 MA POSITIONER

4 MA =VALVE OPEN

20 MA =VALVE CLOSE

HAZARDOUS ZONE: NON RATED

6 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

7 F

Device System Settings

AOV-WSV 6.5B EXHAUST HOOD WATER SPRAY VALVE

MKVI CONTROLLED VALVE 4-20 MA POSITIONER

4 MA =VALVE CLOSE

20 MA =VALVE OPEN

HAZARDOUS ZONE: NON RATED

AR-301 3.5 AC RECEPTACLE - LUBE AND HYDRAULIC ENCLOSURE

AR-302 3.5 AC RECEPTACLE - LUBE AND HYDRAULIC ENCLOSURE

ASW-201 7.5A AC 3 WAY SWITCH - HPIP ENCLOSURE

120 VAC THREE WAY LIGHT SWITCH

60HZ, 1 PHASE

ASW-202 7.5A AC 3 WAY SWITCH - HPIP ENCLOSURE

120 VAC THREE WAY LIGHT SWITCH

60HZ, 1 PHASE

ASW-211 7.5A AC 4 WAY SWITCH - HPIP ENCLOSURE

120 VAC

FOUR WAY LIGHT SWITCH

60HZ, 1 PHASE

ASW-212 7.5A AC 4 WAY SWITCH - HPIP ENCLOSURE

120 VAC

FOUR WAY LIGHT SWITCH

60HZ, 1 PHASE

ASW-301 3.5 AC 3-WAY LIGHT SWITCH - LUBE AND HYDRAULIC ENCLOSURE

ASW-302 3.5 AC 3-WAY LIGHT SWITCH - LUBE AND HYDRAULIC ENCLOSURE

ASW-501 7.5A AC 3 WAY LIGHT SWITCH - COUPLING COMPARTMENT

120 VAC THREE WAY LIGHT SWITCH

60HZ, 1 PHASE

ASW-502 7.5A AC 3 WAY LIGHT SWITCH - COUPLING COMPARTMENT

120 VAC THREE WAY LIGHT SWITCH

60HZ, 1 PHASE

BPM-1 3.1 LUBE OIL PUMP MOTOR NO.1

125.0 HP; 3600 RPM; 460 VAC; 3 PH; 60 HZ;

FUNCTION: DRIVE LUBE OIL PUMP NO. 1

IEC 60034 & IEC 60072

BPM-2 3.1 LUBE OIL PUMP MOTOR NO.2

125.0 HP; 3600 RPM; 460 VAC; 3 PH; 60 HZ;

FUNCTION: DRIVE LUBE OIL PUMP NO. 2

IEC 60034 & IEC 60072

BT-GJ 1-1A 7.0 BEARING METAL TEMP-GENERATOR BEARING #1

TYPE K THERMOCOUPLE

1 ELEMENT;

ONE HALF OF DUAL ELEMENT DEVICE - BT-GJ 1-1

BT-GJ 1-1B 7.0 BEARING METAL TEMP-GENERATOR BEARING #1

TYPE K THERMOCOUPLE

1 ELEMENT;

ONE HALF OF DUAL ELEMENT DEVICE - BT-GJ 1-1

BT-GJ 1-2A 7.0 BEARING METAL TEMP-GENERATOR BEARING #1

TYPE K THERMOCOUPLE

1 ELEMENT;

ONE HALF OF DUAL ELEMENT DEVICE - BT-GJ 1-2

7 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

8 F

Device System Settings

BT-GJ 1-2B 7.0 BEARING METAL TEMP-GENERATOR BEARING #1

TYPE K THERMOCOUPLE

1 ELEMENT;

ONE HALF OF DUAL ELEMENT DEVICE - BT-GJ 1-2

BT-GJ 2-1A 7.0 BEARING METAL TEMP-GENERATOR BEARING #2

TYPE K THERMOCOUPLE

1 ELEMENT;

ONE HALF OF DUAL ELEMENT DEVICE - BT-GJ 2-1

BT-GJ 2-1B 7.0 BEARING METAL TEMP-GENERATOR BEARING #2

TYPE K THERMOCOUPLE

1 ELEMENT;

ONE HALF OF DUAL ELEMENT DEVICE - BT-GJ 2-1

BT-GJ 2-2A 7.0 BEARING METAL TEMP-GENERATOR BEARING #2

TYPE K THERMOCOUPLE

1 ELEMENT;

ONE HALF OF DUAL ELEMENT DEVICE - BT-GJ 2-2

BT-GJ 2-2B 7.0 BEARING METAL TEMP-GENERATOR BEARING #2

TYPE K THERMOCOUPLE

1 ELEMENT;

ONE HALF OF DUAL ELEMENT DEVICE - BT-GJ 2-2

CAFM-1 3.5 COOLING AIR FAN MOTOR #1

6.169 HP; 4.600 KW; 1166 RPM; 460 VAC; 3 PH; 60 HZ;

CAFM-2 3.5 COOLING AIR FAN MOTOR #2

6.169 HP; 4.600 KW; 1166 RPM; 460 VAC; 3 PH; 60 HZ;

CB-1 2.1 CIRCUIT BREAKER FOR TURNING GEAR CONTROL POWER

FUNCTION: CIRCUIT PROTECTION FOR TURNING GEAR CONTROL CIRCUIT

CFM-1 7.5A COOLING AIR FAN #1 - HP/IP ENCLOSURE

3.000 HP; 1180 RPM; 460 VAC; 3 PH; 60 HZ;

CFM-2 7.5A COOLING AIR FAN #2 HP/IP ENCLOSURE

3.000 HP; 1180 RPM; 460 VAC; 3 PH; 60 HZ;

CFM-3 7.5A COOLING AIR FAN #1 COUPLING COMPARTMENT

1.000 HP; 1180 RPM; 460 VAC; 3 PH; 60 HZ;

CFM-4 7.5A COOLING AIR FAN #2 COUPLING COMPARTMENT

1.000 HP; 1180 RPM; 460 VAC; 3 PH; 60 HZ;

CONT 3.1 IMMERSION HEATER CONTACTOR

FUNCTION: CONTROLS POWER TO HTR-1/2/3.

CT-1 2.1 CURRENT TRANSFORMER

FUNCTION: MEASURE TURNING GEAR MOTOR CURRENT FOR DISPLAY ON

LOCAL AMP METER

DEDP-1 1.3 DIFF EXPANSION DETECTOR PROBE

50MM PROBE

FUNCTION: MONITOR, DISPLAY, ALARM, TRIP

DEDP-2 1.3 DIFF EXPANSION DETECTOR PROBE

50MM PROBE

FUNCTION: MONITOR, DISPLAY, ALARM, TRIP

DEDX-1 1.3 PROXIMITOR-DIFF EXPANSION STC MONITOR

RANGE: 100 - 1100 MILS

FUNCTION: PROVIDES HIGH FREQUENCY EXCITATION TO PROBE NO.1

DEDX-2 1.3 PROXIMITOR-DIFF EXPANSION STC MONITOR

RANGE: 100 - 1100 MILS

FUNCTION: PROVIDES HIGH FREQUENCY EXCITATION TO PROBE NO.2

8 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

9 F

Device System Settings

DHCP 7.5 HYDROGEN CONTROL PANEL POWER SUPPLY

HYDROGEN CONTROL PANEL SUPPLY POWER 120 VAC 60 HZ AND 600 WATTS.

EQUIPMENT POWERED BY UPS. REFER TO ML-G2B0 FOR ADDITIONAL

ELECTRICAL CONNECTION INFORMATION.

DL-301 3.5 EMERGENCY DC LIGHT - LUBE AND HYDRAULIC ENCLOSURE

DL-302 3.5 EMERGENCY DC LIGHT - LUBE AND HYDRAULIC ENCLOSURE

DT-GAC-23 7.0 GENERATOR COLLECTOR-COLD AIR

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GAH-17 7.0 GENERATOR COLLECTOR-HOT AIR

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GGC-10 7.0 GENERATOR TEMP-COLD GAS COUPLING END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GGC-11 7.0 GENERATOR TEMP-COLD GAS COLLECTOR END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GGC-12 7.0 GENERATOR TEMP-COLD GAS COLLECTOR END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GGC-13 7.0 GENERATOR TEMP-COLD GAS COUPLING END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GGH-15 7.0 GENERATOR TEMP-HOT GAS COLLECTOR END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GGH-16 7.0 GENERATOR TEMP-HOT GAS COUPLING END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GGH-18 7.0 GENERATOR TEMP-HOT GAS COUPLING END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GGH-19 7.0 GENERATOR TEMP-HOT GAS COLLECTOR END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GGK-24 7.0 GENERATOR FRAME-COMMON COLD GAS

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

ALSO IDENTIFIED AS GTG-2

DT-GSA-34 7.0 GENERATOR TEMP-STATOR COLLECTOR END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GSA-35 7.0 GENERATOR TEMP-STATOR COLLECTOR END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GSA-36 7.0 GENERATOR TEMP-STATOR COLLECTOR END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GSA-4 7.0 GENERATOR TEMP-STATOR COLLECTOR END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

9 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

10 F

Device System Settings

DT-GSA-5 7.0 GENERATOR TEMP-STATOR COLLECTOR END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GSA-6 7.0 GENERATOR TEMP-STATOR COLLECTOR END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GSC-20 7.0 GENERATOR TEMP-STATOR CENTER

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS; GROUNDED;

DT-GSC-21 7.0 GENERATOR TEMP-STATOR CENTER

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS; GROUNDED;

DT-GSC-22 7.0 GENERATOR TEMP-STATOR CENTER

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS; GROUNDED;

DT-GSF-1 7.0 GENERATOR TEMP-STATOR COUPLING END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GSF-2 7.0 GENERATOR TEMP-STATOR COUPLING END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GSF-3 7.0 GENERATOR TEMP-STATOR COUPLING END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GSF-31 7.0 GENERATOR TEMP-STATOR COUPLING END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GSF-32 7.0 GENERATOR TEMP-STATOR COUPLING END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

DT-GSF-33 7.0 GENERATOR TEMP-STATOR COUPLING END

100 OHM PLATINUM (DIN 43760) RTD

2 ELEMENTS;

EBPM 3.1 DC EMERGENCY BRG OIL PUMP MOTOR

40.00 HP; 2500 RPM; 120 VDC;

FUNCTION: DRIVE EMERGENCY LUBE OIL PUMP

IEC 60034 & IEC 60072

EP-1 1.4 ECCENTRICITY PROBE

8 MM PROBE

FUNCTION: MONITOR AND ALARM

HAZARDOUS ZONE: 2

PROTECTION METHOD: `N` NON-SPARKING

EP-2 1.4 ECCENTRICITY PROBE

8 MM PROBE

FUNCTION: MONITOR AND ALARM

HAZARDOUS ZONE: 2

PROTECTION METHOD: `N` NON-SPARKING

EP-3 1.4 ECCENTRICITY PROBE

8 MM PROBE

FUNCTION: MONITOR AND ALARM

HAZARDOUS ZONE: 2

PROTECTION METHOD: `N` NON-SPARKING

10 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

11 F

Device System Settings

ESL-301 3.5 ENCLOSURE SELF CLN FILTER HOUSE UNDERVOLTAGE ALARM

FUNCTION: ALARM ON LOW VOLTAGE SUPPLY TO SELF CLEANING FILTER

HOUSE

ESPM 3.1 EMERGENCY SEAL OIL PUMP MOTOR

30.00 HP; 2500 RPM; 120 VDC;

FUNCTION: DRIVE EMERGENCY LUBE OIL PUMP

IEC 60034 & IEC 60072

EX-1 1.4 PROXIMITOR-ECCENTRICITY PROBE FOR STC MONITOR

RANGE: 10-90 MILS

FUNCTION: PROVIDES HIGH FREQUENCY EXCITATION TO PROBE

HAZARDOUS ZONE: NON-RATED

EX-2 1.4 PROXIMITOR-ECCENTRICITY PROBE FOR STC MONITOR

RANGE: 10-90 MILS

FUNCTION: PROVIDES HIGH FREQUENCY EXCITATION TO PROBE

HAZARDOUS ZONE: NON-RATED

EX-3 1.4 PROXIMITOR-ECCENTRICITY PROBE FOR STC MONITOR

RANGE: 10-90 MILS

FUNCTION: PROVIDES HIGH FREQUENCY EXCITATION TO PROBE

HAZARDOUS ZONE: NON-RATED

FHPS 3.5 ENCLOSURE SELF CLEANING FILTER HOUSE POWER SUPPLY

120 VAC; 1 PH; 60 HZ; 240W

FM-2996A 7.5 GAS DRYER BLOWER MOTOR.

0.5000 HP; 1800 RPM; 480 VAC; 3 PH; 60 HZ;

DUAL TOWER GAS DRYER BLOWER MOTOR.

0.5 HP =0.37 KW

FM-2996B 7.5 GAS DRYER BLOWER MOTOR.

0.5000 HP; 1800 RPM; 480 VAC; 3 PH; 60 HZ;

DUAL TOWER GAS DRYER BLOWER MOTOR.

0.5 HP =0.37 KW

FQIC-2950 7.5 HYDROGEN GAS FLOW TOTALIZER

4.00 MA =65.00 OR .00

20.00 MA =3000 OR 3000

FUNCTION: MONITOR HYDROGEN MAKE-UP GAS CONSUMPTION.

4 MA =65 SCFD (1.84 SCMD)

20 MA =3000 SCFD (85 SCMF)

FE-2950 IS THE FLOW ELEMENT

POWER REQUIREMENTS 1PH, 16W, 120VAC

SIGNAL TO TCP VIA MODBUS PROTOCOL

FY-1203 6.4D RIGHT INTERCEPT VALVE SOLENOID

110 VAC; 60 HZ;

FUNCTION: ACTIVATE DUMP VALVE ON IV TRIGGER AND ON TEST WHEN

ENERGIZED

ACTIVATE FOR AIR BLEED

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

PHASE:SINGLE

11 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

12 F

Device System Settings

FY-1204 6.4D LEFT INTERCEPT VALVE SOLENOID

110 VAC; 60 HZ;

FUNCTION: ACTIVATE DUMP VALVE ON IV TRIGGER AND ON TEST WHEN

ENERGIZED

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

PHASE:SINGLE

FY-1212A 6.4D RIGHT REHEAT STOP VALVE TEST SOLENOID VALVE

110 VAC; 60 HZ;

FUNCTION: MOVE VALVE TO TEST POSITION ON ENERGIZE

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

PHASE:SINGLE

FY-1212B 6.4D RIGHT REHEAT STOP VALVE FAST CLOSING SOLENOID VALVE

110 VAC; 60 HZ;

FUNCTION: FAST CLOSE VALVE ON ENERGIZE

ACTIVATE FOR AIR BLEED

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

PHASE:SINGLE

FY-1213A 6.4D LEFT REHEAT STOP VALVE TEST SOLENOID VALVE

110 VAC; 60 HZ;

FUNCTION: MOVE VALVE TO TEST POSITION ON ENERGIZE

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

PHASE:SINGLE

FY-1213B 6.4D LEFT REHEAT STOP VALVE FAST CLOSING SOLENOID VALVE

110 VAC; 60 HZ;

FUNCTION: FAST CLOSE VALVE ON ENERGIZE

ACTIVATE FOR AIR BLEED

PHASE:SINGLE

FY-1214 6.4R EQUALIZER VALVE SOLENOID

120 VAC; 60 HZ;

FUNCTION: OPEN EV#2 ON ENERGIZE VIA AIR ACTUATOR

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

FY-1215 6.4R SOLENOID VALVE-LH EQUALIZER VLV AIR ACTUATOR

120 VAC; 60 HZ;

FUNCTION: OPEN EV#1 ON ENERGIZE

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

FY-200 6.4C STOP VALVE TEST SOLENOID VALVE

110 VAC; 60 HZ;

FUNCTION: MOVE SV #1 TO TEST POS ON ENERGIZE

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

PHASE: SINGLE

12 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

13 F

Device System Settings

FY-200B 6.4C STOP VLV #1 FAST CLOSING SOL. VLV.

110 VAC; 60 HZ;

FUNCTION : ACTIVATE DUMP VALVE (SV#1) FOR VALVE CLOSURE AND ON

TEST WHEN ENERGIZED

ACTIVATE FOR AIR BLEED

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

PHASE:SINGLE

FY-201 6.4C STOP VALVE NO.2 TEST SOLENOID VALVE

110 VAC; 60 HZ;

FUNCTION: MOVE SV #2 TO TEST POS ON ENERGIZE

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

PHASE:SINGLE

FY-201B 6.4C STOP VLV. NO. 2 FAST CLOSING SOL. VLV.

110 VAC; 60 HZ;

FUNCTION : ACTIVATE DUMP VALVE (SV#2) FOR VALVE CLOSURE AND ON

TEST WHEN ENERGIZED

ACTIVATE FOR AIR BLEED

PHASE:SINGLE

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

FY-203 6.4M LP ADM STOP VALVE TEST SOLENOID VALVE

120 VAC; 60 HZ; 7.700 W;

FUNCTION: MOVE STOP VALVE TO TEST POSITION

HAZARDOUS ZONE: NON RATED

FY-211A 6.4C CONTROL VALVE FASV LEFT OR UPPER

110 VAC; 60 HZ;

FUNCTION: ACTIVATE DUMP VALVE (CV#1) ON CV TRIGGER

ACTIVATE FOR AIR BLEED

HAZARDOUS ZONE: NON-RATED

PHASE:SINGLE

PROTECTION METHOD: SIMPLE

FY-211B 6.4C CONTROL VALVE FASV RIGHT OR LOWER

110 VAC; 60 HZ;

FUNCTION: ACTIVATE DUMP VALVE (CV#2) ON CV TRIGGER

ACTIVATE FOR AIR BLEED

HAZARDOUS ZONE: NON-RATED

PHASE:SINGLE

PROTECTION METHOD: SIMPLE

FY-220 6.4S REVERSE FLOW VALVE SOLENOID

120 VAC; 60 HZ;

ENERGIZE TO OPEN

HAZARDOUS ZONE: NON RATED

FY-2445 6.4U REVERSE FLOW DISCHARGE VALVE SOLENOID VALVE

120 VAC; 60 HZ;

FUNCTION: OPEN RFDV ON ENERGIZE

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

13 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

14 F

Device System Settings

FY-265 3.1 BRG & SEAL OIL PUMP NO.1 & NO.2 TEST SOLENOID VALVE

120 VAC; 60 HZ; 42.00 W;

FUNCTION: DROPS PRESSURE TO START STANDBY OIL PUMP

FY-266 3.1 EMERGENCY BRG & SEAL OIL PUMP TEST SOLENOID VALVE

120 VAC; 60 HZ; 42.00 W;

FUNCTION: DROPS PRESSURE TO START STANDBY OIL PUMP

FY-281 4.0 HYD FLUID PUMP TEST SOLENOID VALVE

120 VAC; 60 HZ;

30 W

FUNCTION: REMOTE OR LOCAL TEST OF PUMP START CIRCUITS

HAZARDOUS AREA : NON-RATED

FY-288A 2.0 TURNING GEAR ENGAGING SOLENOID VALVE A (AIR)

120 VAC; 50/60 HZ; 6.100 W;

CONTROLS PROVIDED STEP DOWN TRANSFORMER PROVIDES 120V, AC,

50/60HZ REGARDLESS OF CUSTOMER SUPPLIED VOLTAGE.

FUNCTION: CAUSES ENGAGEMENT OF TURNING GEAR

FY-288B 2.0 TURNING GEAR ENGAGING SOLENOID VALVE B (AIR)

120 VAC; 50/60 HZ; 6.100 W;

CONTROLS PROVIDED STEP DOWN TRANSFORMER PROVIDES 120V, AC,

50/60HZ REGARDLESS OF CUSTOMER SUPPLIED VOLTAGE.

FUNCTION: CAUSES ENGAGEMENT OF TURNING GEAR

FY-2955A 7.5 CORE MONITOR SOLENOID

120 VAC; 60 HZ; 1 PHASE

THIS SOLENOID IS POWERED BY THE GCM-X.

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `M` - ENCAPSULATION

FY-2955B 7.5 PYROLYSATE COLLECTOR SOLENOID

120 VAC; 60 HZ; 1 PHASE

THIS SOLENOID IS POWERED BY THE GCM-X.

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `M` - ENCAPSULATION

FY-2971 7.5 TURBINE END SCAVENGING SOLENOID

1 PHASE

120 VAC; 60 HZ;

THIS SOLENOID IS POWERED BY THE H2 PANEL UPS.

SIGNAL 20SCAV1 ENERGIZES SOLENOID VALVE FY-2971 ON THE H2 CTRL

PANEL TO INCREASE SCAVENGING OF TE AT LOW PURITY

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `M` - ENCAPSULATION

SIGNAL TO TCP VIA MODBUS

FY-2972 7.5 COLLECTOR END GAS SOLENOID

1 PHASE

120 VAC; 60 HZ;

THIS SOLENOID IS POWERED BY THE H2 PANEL UPS.

SIGNAL 20CASE1 ENERGIZES SOLENOID VALVE FY-2972 ON THE H2 CTRL

PANEL TO DIRECT GEN CASING GAS TO ANALYZER 1 (QT-290A) HAZARDOUS

ZONE: ZONE 2

PROTECTION METHOD: `M` - ENCAPSULATION

SIGNAL TO TCP VIA MODBUS

14 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

15 F

Device System Settings

FY-2973 7.5 COLLECTOR END SCAVENGING SOLENOID

1 PHASE

120 VAC; 60 HZ;

THIS SOLENOID IS POWERED BY THE H2 PANEL UPS.

SIGNAL 20SCAV2 ENERGIZES SOLENOID VALVE FY-2973 ON THE H2 CTRL

PANEL TO INCREASE SCAVENGING OF CE AT LOW PURITY;HAZARDOUS ZONE:

ZONE 2

PROTECTION METHOD: `M` - ENCAPSULATION

SIGNAL TO TCP VIA MODBUS PROT

FY-2974 7.5 COLLECTOR END GAS SOLENOID.

1 PHASE

120 VAC; 60 HZ;

THIS SOLENOID IS POWERED BY THE H2 PANEL UPS.

SIGNAL 20CASE2 ENERGIZES SOLENOID VALVE FY-2974 ON THE H2 CTRL

PANEL TO DIRECT GEN CASING GAS TO ANALYZER 2 (QT-290B);HAZARDOUS

ZONE: ZONE 2

PROTECTION METHOD: `M` - ENCAPSULATION

SIGNAL TO TCP VIA MODBUS

FY-2981 7.5 CASE, PURGE, CALIBRATION SOLENOID.

1 PHASE

120 VAC; 60 HZ;

DE-ENERGIZED STATE ALLOWS FLOW FROM GEN CASE TO FY-2972 AND FY-

2974. REFER TO SYSTEM P&ID. THIS SOLENOID IS POWERED BY THE H2 PANEL

UPS.

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `M` - ENCAPSULATION

SIGNAL TO TCP VIA MODBUS PROTOCOL

FY-2996A 7.5 DUAL GAS DRYER TOWER 1 SOLENOID

1 PHASE

120 VAC; 60 HZ;

POWERED BY THE GAS DRYER AND CONTROLLED THE GAS DRYER`S PLC. NO

MARK VI INTERFACE.

FY-2996B 7.5 DUAL GAS DRYER TOWER 2 SOLENOID

1 PHASE

120 VAC; 60 HZ;

POWERED BY THE GAS DRYER AND CONTROLLED THE GAS DRYER`S PLC. NO

MARK VI INTERFACE.

FY-CSBV 6.5B COOLING STEAM BLOCKING VALVE SOLENOID

DE-ENERGIZED: 3 TO 1 OPEN; 2 PLUGGED

ENERGIZED: 1 TO 2 OPEN; 3 PLUGGED

120 VAC; 60 HZ; 2.800 W;

ENERGIZE TO CLOSE AOV-CSBV

HAZARDOUS ZONE: NON RATED

FY-LRSV 6.5B LEAKOFF RE-ENTRY STOP VALVE SOLENOID

DE-ENERGIZED: 3 TO 1 OPEN; 2 PLUGGED

ENERGIZED: 1 TO 2 OPEN; 3 PLUGGED

120 VAC; 60 HZ; 2.800 W;

ENERGIZE TO CLOSE AOV-LRSV

HAZARDOUS ZONE: NON RATED

FY2253 6.5B 1ST STAGE REHEAT COOLING VALVE SOLENOID

120 VAC; 60 HZ; 2.800 W;

ENERGIZE TO OPEN

HAZARDOUS ZONE: NON RATED

15 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

16 F

Device System Settings

FY5000 4.0 ELECTRICAL TRIP SOLENOID FOR ETD-1

550 OHM COIL.

30 W

125 VDC;

FUNCTION: IF DE-ENERGIZED DROPS HYD HEADER PRESS TO STOP VLV

HAZARDOUS AREA : NON-RATED

FY5002 4.0 ELECTRICAL TRIP SOLENOID FOR ETD-2

550 OHM COIL.

30 W

125 VDC;

FUNCTION: IF DE-ENERGIZED DROPS HYD HEADER PRESS TO STOP VLV

HAZARDOUS AREA : NON-RATED

FY5004 4.0 ELECTRICAL TRIP SOLENOID FOR ETD-3

550 OHM COIL.

30 W

125 VDC;

FUNCTION: IF DE-ENERGIZED DROPS HYD HEADER PRESS TO STOP VLV

HAZARDOUS AREA : NON-RATED

GASDRYER 7.5 GAS DRYER POWER SUPPLY

THE GAS DRYER REQUIRES 480 VAC 3 PHASE 60 HZ POWER WITH A 2500

WATT LOAD. PLEASE REFER TO MLI-G2B0 FOR ADDITIONAL ELECTRICAL

CONNECTION INFORMATION.

GCMX 7.5 CORE MONITOR WITH PYROLYSATE COLLECTOR

THE CORE MONITOR/PYROLYSATE COLLECTOR REQUIRES A 120 VAC 60 HZ

POWER SUPPLY AND THE POWER DRAW IS 500 WATTS. PLEASE REFER TO ML-

G2B0 FOR ADDITIONAL ELECTRICAL CONNECTION INFORMATION.

GXM-1 5.0A GLAND EXHAUSTER BLOWER MOTOR NO.1

20.11 HP; 3540 RPM; 460 VAC; 3 PH; 60 HZ;

FUNCTION: EXHAUSTS STEAM/AIR FROM CONDENSER/SPRAY CHAMBER

HAZARDOUS ZONE: NON RATED

GXM-2 5.0A GLAND EXHAUSTER BLOWER MOTOR NO.2

20.11 HP; 3540 RPM; 460 VAC; 3 PH; 60 HZ;

FUNCTION: EXHAUSTS STEAM/AIR FROM CONDENSER/SPRAY CHAMBER

HAZARDOUS ZONE: NON RATED

HCCM 4.0 HEATING / COOLING CIRCULATION PUMP MOTOR

5.000 HP; 3600 RPM; 460 VAC; 3 PH; 60 HZ;

IEC 60034 & IEC 60072

FUNCTION: DRIVES FLUID HEATING/COOLING PUMP TO MAINTAIN HYDRAULIC

FLUID TEMPERATURE

HAZARDOUS AREA : NON-RATED

HFPM-A 4.0 HYDRAULIC FLUID PUMP MOTOR A.

25.00 HP; 1800 RPM; 460 VAC; 3 PH; 60 HZ;

IEC 60034 & IEC 60072

FUNCTION: DRIVES FLUID PUMP NO. 1

HAZARDOUS AREA : NON-RATED

HFPM-B 4.0 HYDRAULIC FLUID PUMP MOTOR B.

25.00 HP; 1800 RPM; 460 VAC; 3 PH; 60 HZ;

IEC 60034 & IEC 60072

FUNCTION: DRIVES FLUID PUMP NO. 2

HAZARDOUS AREA : NON-RATED

HS-288 2.1 MANUAL TURNING GEAR RUN SWITCH

FUNCTION: LOCAL CONTROL SWITCH TO START AND J OG TURNING GEAR

16 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

17 F

Device System Settings

HTR-1 3.1 OIL TANK HEATER 1

10.00 KW; 460 VAC; 3 PH; 60 HZ;

FUNCTION: KEEP RESERVIOR TEMP FROM FALLING BELOW MINIMUM

REQUIRED.

HTR-2 3.1 OIL TANK HEATER 2

10.00 KW; 460 VAC; 3 PH; 60 HZ;

FUNCTION: KEEP RESERVIOR TEMP FROM FALLING BELOW MINIMUM

REQUIRED.

HTR-3 3.1 OIL TANK HEATER 3

10.00 KW; 460 VAC; 3 PH; 60 HZ;

FUNCTION: KEEP RESERVIOR TEMP FROM FALLING BELOW MINIMUM

REQUIRED.

K-288 2.1 STOP VALVE CLOSED MULTIPLYING SIGNAL RELAY

FUNCTION: PERMIT TURNING GEAR START, ENGAGE, AND OIL

K-289 2.1 MANUAL TURNING GEAR RUN SWITCH LOCKOUT CONTACT

FUNCTION: ALARM IF TURNING GEAR NOT IN STANDBY

K-290 2.1 J OG MODE INDICATION ALARM

FUNCTION: ALARM IF TURNING GEAR IN J OG

K-PBM 2.1 CONTACTOR MULTIPLIER FOR PBM MOTOR STARTER SIGNAL

FUNCTION: CONTROLS STARTING CONTACTOR FOR PIGGY BACK MOTOR

K-TGM 2.1 CONTACT MULTIPLIER FOR TGM MOTOR STARTER SIGNAL

FUNCTION: CONTROLS STARTING CONTACTOR FOR TURNING GEAR MOTOR

L-288 2.1 TURNING GEAR MOTOR NOT RUNNING INDICATOR LIGHT

120 VAC

FUNCTION: LOCAL INDICATION

L-289 2.1 TURNING GEAR RUNNING INDICATOR LIGHT

120 VAC

FUNCTION: LOCAL INDICATION

L-290 2.1 TURNING GEAR DISENGAGED INDICATOR LIGHT

120 VAC

FUNCTION: LOCAL INDICATION

L-291 2.1 TURNING GEAR ENGAGED INDICATOR LIGHT

120 VAC

FUNCTION: LOCAL INDICATION

L-292 2.1 TURNING GEAR REMOTE J OG ENABLED LIGHT

120 VAC

FUNCTION: LOCAL INDICATION (ON PANEL)

L-ZSP 2.1 SAFE ENGAGE SPEED INDICATOR LIGHT

120 VAC

FUNCTION: LOCAL INDICATION

LS-232 5.0A GLAND EXHAUSTER CONDENSER CONDENSATE LEVEL HIGH

SETTING: 3 INCHES (76.2 MM) ABOVE NORMAL OPERATING LEVEL

FUNCTION: MONITOR AND ALARM

HAZARDOUS ZONE: NON RATED

KKS DESIGNATION: MAW70 CL301

LS-260 3.1 LUBE OIL LEVEL IMMERSION HEATER PERMISSIVE SWITCH

DECREASING: 8.0+-0.5 INCHES (203.2 MM) BELOW OPERATING OIL LEVEL

INCREASING: 7.0+-0.5 INCHES (177.8 MM) BELOW NORMAL

FUNCTION: PREVENTS HEATER OPERATION WHEN OIL LEVEL IS LOW

17 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

18 F

Device System Settings

LSH-2990 7.5 LIQUID LEVEL DETECTOR HIGH LEVEL SWITCH

NORM=(4) NO-CEC;

DPDT SWITCH.

FUNCTION: ALARM WHEN FLUID ENTERS THE LIQUID LEVEL DETECTOR

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `D` - EXPLOSION PROOF

SIGNAL TO TCP VIA MODBUS PROTOCOL

LSH-3401 7.5 SEAL OIL DRAIN HIGH LEVEL SWITCH

NORM=(4) NO-CEC;

DPDT SWITCH.

FUNCTION: ALARM WHEN FLUID ENTERS THE LIQUID LEVEL DETECTOR

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `D` - EXPLOSION PROOF

SIGNAL TO TCP VIA MODBUS PROTOCOL

LSHH-2990 7.5 LIQUID LEVEL DETECTOR HIGH HIGH LEVEL SWITCH

NORM=(4) NO-CEC;

DPDT SWITCH.

FUNCTION: ALARM WHEN FLUID ENTERS THE LIQUID LEVEL DETECTOR

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `D` - EXPLOSION PROOF

SIGNAL TO TCP VIA MODBUS PROTOCOL

LT-260 3.1 LUBE OIL TANK LEVEL

4-20MA FOR 0-100% OF MEASURED LEVEL

HIGH LEVEL ALARM: 13.37 MA

NORMAL LEVEL: 12.00 MA

LOW LEVEL ALARM: 10.80 MA

LOW LOW LEVEL ALARM: 8.80 MA

BASED ON A 45`` PROBE LENGTH

LT-280 4.0 HYDRAULIC FLUID RESERVOIR LEVEL TRANSMITTER

4.000 MA=0.0 OR 0.0

20.00 MA=100.0 OR 100.0

HIGH LEVEL ALARM: 13.37 MA

NORMAL LEVEL: 12.00 MA

LOW LEVEL ALARM: 10.80 MA

LOW LOW LEVEL ALARM: 8.80 MA

BASED ON A 45`` PROBE LENGTH

HAZARDOUS AREA : NON-RATED

LT-G1D-1A 7.0 LUBE SYSTEM TEMP-GENERATOR #1 BEARING DRAIN

TYPE K THERMOCOUPLE

1 ELEMENT; GROUNDED;

ONE HALF OF DUAL ELEMENT DEVICE - LT-G1D-1

LT-G1D-1B 7.0 LUBE SYSTEM TEMP-GENERATOR #1 BEARING DRAIN

TYPE K THERMOCOUPLE

1 ELEMENT; GROUNDED;

ONE HALF OF DUAL ELEMENT DEVICE - LT-G1D-1

LT-G2D-1A 7.0 LUBE SYSTEM TEMP-GENERATOR #2 BEARING DRAIN

TYPE K THERMOCOUPLE

1 ELEMENT; GROUNDED;

ONE HALF OF DUAL ELEMENT DEVICE - LT-G2D-1

18 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

19 F

Device System Settings

LT-G2D-1B 7.0 LUBE SYSTEM TEMP-GENERATOR #2 BEARING DRAIN

TYPE K THERMOCOUPLE

1 ELEMENT; GROUNDED;

ONE HALF OF DUAL ELEMENT DEVICE - LT-G2D-1

ME-2996 7.5 GAS DRYER INLET HYGROMETER PROBE

4.000 MA=60.00 F OR 15.56 C

20.00 MA=-60.00 F OR -51.11 C

FUNCTION: PROBE FOR MEASURING INLET GAS DEW POINT ONLY. ALARM

CONTACTS ARE LOCATED ON DEVICE MIC-2996

MIC-2951 7.5 DEW POINT SENSOR PROCESSOR

4.0MA =-148 F OR -100C

20.0MA =68.0 F OR 20.000 C

HIGH ALARM 32 F INC., HIGH-HIGH ALARM AT 68 F INC.

SIGNAL TO TCP VIA MODBUS PROTOCOL

MIC-2996 7.5 GAS DRYER DEW POINT SENSOR

NORM=(2) NC; CONTACT OPENS AT SET POINT;

HIGH DEW POINT ALARM, SIGNAL NAME =30DRYMH, SET AT +20 F

INCREASING.

DEW POINT SENSOR FAULT, SIGNAL NAME =30DRYFAULT

CONTACT OPENS OPEN ON GAS DRYER COMMON TROUBLE

MOV-B 6.5 STEAM SEAL DUMP BYPASS VALVE

460 VAC; 3 PH; 60 HZ

0.16 HP

0.8 FULL CURRENT AMPS

2.1 LOCKED ROTOR AMPS

FUNCTION: STEAM SEAL SYSTEM

HAZARDOUS ZONE: NON RATED

MOV-S1 6.5 STEAM SEAL FEED VALVE BLOCK

460 VAC; 3 PH; 60 HZ

0.16 HP

0.8 FULL CURRENT AMPS

2.1 LOCKED ROTOR AMPS

FUNCTION: FUNCTION: USED TO ISOLATE STEAM SEAL SYSTEM FROM MAIN

STEAM

HAZARDOUS ZONE: NON RATED

MOV-S2 6.5 STEAM SEAL FEED SUPPLEMENTARY VALVE

460 VAC; 3 PH; 60 HZ

0.16 HP

0.8 FULL CURRENT AMPS

2.1 LOCKED ROTOR AMPS

FUNCTION: FUNCTION: AID SSFV IN MAINTAINING STEAM SEAL PRESSURE

HAZARDOUS ZONE: NON RATED

MOV-SAD-1 6.5 DRAIN VALVE-ADM CONTROL VALVE BEFORE SEAT

460 VAC; 3 PH; 60 HZ; 1700 RPM

0.16 HP

0.8 FULL CURRENT AMPS

2.1 LOCKED ROTOR AMPS

FUNCTION: CONDENSATE DRAIN

HAZARDOUS ZONE: NON RATED

19 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

20 F

Device System Settings

MOV-SAD-2 6.5 DRAIN VALVE-ADM CONTROL VALVE AFTER SEAT

460 VAC; 3 PH; 60 HZ; 1700 RPM

0.16 HP

0.8 FULL CURRENT AMPS

2.1 LOCKED ROTOR AMPS

FUNCTION: CONDENSATE DRAIN

HAZARDOUS ZONE: NON RATED

MOV-SPD 6.5 DRAIN VALVE STEAM PACKING RE-ENTRY

460 VAC; 3 PH; 60 HZ; 1700 RPM

0.16 HP

0.8 FULL CURRENT AMPS

2.1 LOCKED ROTOR AMPS

FUNCTION: CONDENSATE DRAIN

HAZARDOUS ZONE: NON RATED

MOV-SPDV-1 6.5 DRAIN VALVE MAIN STEAM LINE #1 LOW POINT

460 VAC; 3 PH; 60 HZ; 1700 RPM

0.37 HP

1.5 FULL CURRENT AMPS

5.6 LOCKED ROTOR AMPS

FUNCTION: CONDENSATE DRAIN

MOV-SSV-1A 6.5 DRAIN VALVE MAIN STOP VALVE A BEFORE SEAT

460 VAC; 3 PH; 60 HZ; 1700 RPM

0.37 HP

1.5 FULL CURRENT AMPS

5.6 LOCKED ROTOR AMPS

FUNCTION: CONDENSATE DRAIN

HAZARDOUS ZONE: NON RATED

MOV-SSV-1B 6.5 DRAIN VALVE MAIN STOP VALVE B BEFORE SEAT

460 VAC; 3 PH; 60 HZ;1700 RPM

0.37 HP

1.5 FULL CURRENT AMPS

5.6 LOCKED ROTOR AMPS

FUNCTION: CONDENSATE DRAIN

HAZARDOUS ZONE: NON RATED

MOV-SSV-4A 6.5 DRAIN VALVE REHEAT STOP VALVE A AFTER SEAT

460 VAC; 3 PH; 60 HZ; 1700 RPM

0.16 HP

0.8 FULL CURRENT AMPS

2.1 LOCKED ROTOR AMPS

FUNCTION: CONDENSATE DRAIN

HAZARDOUS ZONE: NON RATED

MOV-SSV-4B 6.5 DRAIN VALVE REHEAT STOP VALVE B AFTER SEAT

460 VAC; 3 PH; 60 HZ; 1700 RPM

0.16 HP

0.8 FULL CURRENT AMPS

2.1 LOCKED ROTOR AMPS

FUNCTION: CONDENSATE DRAIN

HAZARDOUS ZONE: NON RATED

20 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

21 F

Device System Settings

MOV-VBV-1 6.5 VACUUM BREAKER VALVE

460 VAC, 3 PH, 60 HZ

0.16 HP

0.5 FULL CURRENT AMPS

9.0 LOCKED ROTOR AMPS

FUNCTION: OPEN VLV TO BREAK CONDENSER VACUUM

HAZARDOUS ZONE: NON RATED

OCM 3.1 OIL CONDITIONER PUMP MOTOR

5.000 HP; 460 VAC; 3 PH; 60 HZ;

FUNCTION: DRIVE LUBE OIL CONDITIONER PUMP

IEC 60034 & IEC 60072

PB-283A 6.7B CUSTOMER MOUNTED EMERGENCY TRIP PUSHBUTTON

ON TURBINE DECK

PB-283T 6.7B EMERGENCY TRIP PUSHBUTTON AT FRONT STANDARD

FUNCTION: ALARM AND ELECTRICAL TRIP

PB-284A 6.7B EMERGENCY TRIP PUSHBUTTON AT STC/BU PANEL

FUNCTION: CAUSES TRIP THROUGH TRIP BUS

PB-285A 6.7B CUSTOMER TRIP BUTTON AT 2ND OIM LOCATION

FUNCTION: CAUSES TRIP THROUGH TRIP BUS

PB-286A 6.7B EMERGENCY TRIP PUSHBUTTON AT 2ND OIM LOCATION

FUNCTION: CAUSES TRIP THROUGH TRIP BUS

PB-289 2.1 LOCAL TURNING GEAR J OG PUSH BUTTON

FUNCTION: PUSH TO J OG TURNING GEAR (WHEN PERMISSIVES SATISFIED)

PBM 2.0 TURNING GEAR MOTOR/PIGGY BACK MOTOR

1.000 HP; 600 RPM; 460 VAC; 3 PH; 60 HZ;

F.L.C. =3.9 AMP; L.R.C =10.2 AMP

FUCTION: TURN SHAFT/PRE-ENGAGEMENT OF TGM

PDS-221 4.0 PARTICULATE FILTER HIGH DIFF. PRESSURE

INCREASING: 70.00+-5.000 PSIG OR 4.828+-0.3449 BARG

HAZARDOUS AREA : NON-RATED

PDS-222 4.0 POLISHING FILTER HIGH DIFF PRESSURE

INCREASING: 70.00+-5.000 PSIG OR 4.828+-0.3449 BARG

HAZARDOUS AREA : NON-RATED

PDS-223 4.0 HEAT & COOLING PARTICULATE FILTER HIGH DIFF PRESSURE

INCREASING: 70.00+-5.000 PSIG OR 4.828+-0.3449 BARG

HAZARDOUS AREA : NON-RATED

PDS-287A 4.0 DUPLEX FILTER HIGH DIFF PRESSURE NO.1

INCREASING: 100.0+-5.000 PSID OR 6.897+-0.3449 BARD

NORM=(2) NO-OEC;

FUNCTION: PROVIDES ALARM IF FILTER REQUIRES REPLACEMENT

HAZARDOUS AREA : NON-RATED

PDS-287B 4.0 DUPLEX FILTER HIGH DIFF PRESSURE NO.2

INCREASING: 100.0+-5.000 PSIG OR 6.897+-0.3449 BARG

NORM=(2) NO-OEC;

FUNCTION: PROVIDES ALARM IF FILTER REQUIRES REPLACEMENT

HAZARDOUS AREA : NON-RATED

21 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

22 F

Device System Settings

PDSL-3402 3.4 SEAL OIL DIFFERENTIAL PRESSURE LOW SWITCH

DECREASING: 4.500 PSID OR 0.3104 BARD

NORM=(2) NC-CEC;

FUNCTION: ALARM

NOTE: SWITCH MUST BE COMPENSATED IN THE FIELD SINCE THE HGF AND

HSF-2 SENSING LINES ARE AT DIFFERENT ELEVATIONS.

DEAD BAND =.35 PSID

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `D` - FLAME PROOF

PDSL-3406 3.4 SEAL OIL DIFF PRESSURE LOW-LOW, START DC PUMP

DECREASING: 3.500 PSID OR 0.2414 BARD

FUNCTION: START DC PUMP

NOTE: SWITCH MUST BE COMPENSATED IN THE FIELD SINCE THE HGF & HSF-2

SENSING LINES ARE AT DIFFERENT ELEVATIONS.

DEAD BAND =0.35 PSID

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `D` - FLAME PROOF

PDT-216 6.3 LP ADMISSION STRAINER DIFFERENTIAL PRESSURE

4.0 MA =0.0 PSID

20.0 MA =100.0 PSID

PDT-251 5.0B STEAM SEAL DUMP VALVE DIFFERENTIAL PRESSURE TRANSMITTER

4.000 MA=0.0 PSID OR 0.0 BARD

20.00 MA=20.00 PSID OR 1.379 BARD

MONITOR STEAM SEAL CONDITIONS

HAZARDOUS ZONE: NON RATED

PDT-292 7.5 GENERATOR ROTOR FAN PRESSURE DIFFERENTIAL

4.000 MA=0.0 INH2O OR 0.0 MBAR

20.00 MA=30.00 INH2O OR 74.75 MBAR

FUNCTION: ALARM AT 12 IN H2O (304.8 MM H2O)

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `D` - FLAME PROOF

SIGNAL TO TCP VIA MODBUS PROTOCOL

PDT-2955 7.5 CORE MONITOR FLOW TRANSMITTER

4.0 MA =0.0 INH20 OR 0.000 MBAR

20.0 MA =3.0 INH20 OR 7.4752 MBAR

LOW FLOW LIMIT=1.1 INH20 (27.9 MMH2O), HIGH FLOW LIMIT=1.9 INH20 (48.3

MMH2O)

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `D` - FLAME PROOF

SIGNAL TO TCP VIA MODBUS PROTOCOL

PDT-303 3.5 ENCLOSURE SELF CLN FILTER HOUSE DIFF PRESSURE

4.000 MA=0.0 INH2O OR 0.0 MBAR

20.00 MA=4.000 INH2O OR 9.967 MBAR

FUNCTION: MONITOR AIR FILTER DP, ALARM ON 2.1 IN H2O

PDT-3402 3.4 SEAL OIL DIFFERENTIAL PRESSURE, SEAL OIL VS GAS PRESSURE

4.000 MA=0.0 PSID OR 0.0 BARD

20.00 MA=15.00 PSID OR 1.035 BARD

FUNCTION: FOR MONITORING DP THRU TURBINE CONTROLLER, DP SET TO 5.5

PSID (37.92 KPAD)

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `D` - FLAME PROOF

22 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

23 F

Device System Settings

PS-212C 5.0A GLAND SEAL EXHAUSTER BLOWER MOTOR RUNNING

DECREASING: 5.000 INH2O OR 12.46 MBAR

NORM=(2) NC-CES;

FUNCTION: ALARM NOT RUNNING

HAZARDOUS ZONE: NON RATED

PS-213 5.0A GSC EXHAUSTER AMBIENT AIR BLEED FILTER HIGH DIFF PRES

DECREASING: 13.60 INH2O OR 33.89 MBAR

NORM=(2) NC-CES;

FUNCTION: MONITOR AND ALARM

HAZARDOUS ZONE: NON RATED

PS-214 5.0A GSC EXHAUSTER AMBIENT AIR BLEED FILTER HIGH DIFF PRES

DECREASING: 13.60 INH2O OR 33.89 MBAR

NORM=(2) NC-CES;

FUNCTION: MONITOR AND ALARM

HAZARDOUS ZONE: NON RATED

PS-263 3.1 EMERGENCY SEAL OIL PUMP RUNNING SWITCH

INCREASING: 40.00+-2.000 PSIG OR 2.759+-0.1379 BARG

(DECREASING: 35.00+-2.000 PSIG OR 2.414+-0.1379 BARG)

NORM=(2) NO-CES;

FUNCTION: SENSES EMERGENCY DC PUMP OUTPUT PRESSURE

PS-265A 3.1 LUBE OIL PUMP NO 1. AND NO 2. START

DECREASING: 111.0+-4.000 PSIG OR 7.656+-0.2759 BARG

(INCREASING: 123.0+-4.500 PSIG OR 8.483+-0.3104 BARG)

NORM=(2) NC-CEC;

PS-266A 3.1 FUNCTION: STARTS EBOP AND ESOP

DECREASING: 95.00+-4.000 PSIG OR 6.552+-0.2759 BARG

(INCREASING: 107.0+-4.500 PSIG OR 7.380+-0.3104 BARG)

NORM=(2) NC-CEC;

FUNCTION: STARTS EMERGENCY DC LUBE OIL PUMP

PS-267A 3.1 LUBE OIL PUMP NO.1 RUNNING PRESSURE SWITCH

INCREASING: 40.00+-2.000 PSIG OR 2.759+-0.1379 BARG

(DECREASING: 35.00+-2.000 PSIG OR 2.414+-0.1379 BARG)

NORM=(2) NO-CES;

FUNCTION: SENSES PUMP NO.1 OUTPUT PRESSURE

PS-267B 3.1 LUBE OIL PUMP NO.2 RUNNING PRESSURE SWITCH

INCREASING: 40.00+-2.000 PSIG OR 2.759+-0.1379 BARG

(DECREASING: 35.00+-2.000 PSIG OR 2.414+-0.1379 BARG)

NORM=(2) NO-CES;

FUNCTION: SENSES PUMP NO.2 OUTPUT PRESSURE

PS-268 3.1 EMERGENCY LUBE OIL PUMP RUNNING PRESSURE SWITCH

INCREASING: 40.00+-2.000 PSIG OR 2.759+-0.1379 BARG

(DECREASING: 35.00+-2.000 PSIG OR 2.414+-0.1379 BARG)

NORM=(2) NO-CES;

FUNCTION: SENSES EMERGENCY DC PUMP OUTPUT PRESSURE

PS-270A 3.1 LUBE OIL LOW PRESSURE ALARM SWITCH

DECREASING: 10.00+-1.000 PSIG OR 0.6897+-0.0690 BARG

(INCREASING: 12.00+-1.000 PSIG OR 0.8276+-0.0690 BARG)

NORM=(2) NC-CES;

FUNCTION: ALARM LOW LUBE OIL PRESSURE

(10PSIG BASED ON TURBINE CENTERLINE PRESSURE, SKID MANUFACTURER

SHOULD PRE-SET SWITCH TO 25PSIG)

23 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

24 F

Device System Settings

PS-270B 3.1 LOW LUBE OIL HEADER PRESSURE TRIP & ALARM

DECREASING: 6.000+-1.000 PSIG OR 0.4138+-0.0690 BARG

(INCREASING: 8.000+-1.000 PSIG OR 0.5518+-0.0690 BARG)

NORM=(2) NC-CES;

FUNCTION: TRIPS TRUB ON LOW LUBE OIL PRESSURE AND ALARMS

(6PSIG BASED ON TURBINE CENTERLINE PRESSURE, SKID MANUFACTURER

SHOULD PRE-SET SWITCH TO 21PSIG)

PS-270C 3.1 LOW LUBE OIL HEADER PRESSURE TRIP & ALARM

DECREASING: 6.000+-1.000 PSIG OR 0.4138+-0.0690 BARG

(INCREASING: 8.000+-1.000 PSIG OR 0.5518+-0.0690 BARG)

NORM=(2) NC-CES;

FUNCTION: TRIPS TURB AND ALARMS ON LOW LUBE OIL PRESSURE

(6PSIG BASED ON TURBINE CENTERLINE PRESSURE, SKID MANUFACTURER

SHOULD PRE-SET SWITCH TO 21PSIG)

PS-270D 3.1 LOW LUBE OIL HEADER PRESSURE TRIP & ALARM

DECREASING: 6.000+-1.000 PSIG OR 0.4138+-0.0690 BARG

(INCREASING: 8.000+-1.000 PSIG OR 0.5518+-0.0690 BARG)

NORM=(2) NC-CES;

FUNCTION: TRIPS TURB AND ALARMS ON LOW LUBE OIL PRESSURE

(6PSIG BASED ON TURBINE CENTERLINE PRESSURE, SKID MANUFACTURER

SHOULD PRE-SET SWITCH TO 21PSIG)

PS-270E 3.1 LIFT OIL PRESSURE PERMISSIVE

INCREASING: 6.000+-1.000 PSIG OR 0.4138+-0.0690 BARG

(DECREASING: 8.000+-1.000 PSIG OR 0.5518+-0.0690 BARG)

NORM=(2) NC-CES;

FUNCTION: PRESSURE PERMISSIVE FOR LIFT OIL PUMP

(6PSIG BASED ON TURBINE CENTERLINE PRESSURE, SKID MANUFACTURER

SHOULD PRE-SET SWITCH TO 21PSIG)

PS-271A 3.1 LUBE OIL FILTER HIGH DIFF PRESSURE ALARM

INCREASING: 15.00+-0.3000 PSID OR 1.035+-0.0207 BARD

(DECREASING: 11.00+-3.000 PSID OR 0.7587+-0.2069 BARD)

NORM=(1) NO-CEC;

FUNCTION: PROVIDES ALARM IF FILTER REQUIRES REPLACEMENT

PS-271B 3.1 LUBE OIL FILTER HIGH DIFF PRESSURE ALARM

INCREASING: 15.00+-0.3000 PSID OR 1.035+-0.0207 BARD

(DECREASING: 11.00+-0.3000 PSID OR 0.7587+-0.0207 BARD)

NORM=(1) NO-CEC;

FUNCTION: PROVIDES ALARM IF FILTER REQUIRES REPLACEMENT

PS-271G 3.1 LUBE OIL TANK LOW VACUUM SWITCH

DECREASING: 4.000+-0.1000 INH2O OR 9.967+-0.2492 MBAR

(INCREASING: 3.600+-0.1000 INH2O OR 8.970+-0.2492 MBAR)

NORM=(1) NO-CEC;

PS-273A 3.1 DIRTY ELEMENTS ALARMS

INCREASING: 25.00+-2.000 PSID OR 1.724+-0.1379 BARD

FUNCTION: SIGNALS NEED FOR FILTER CHANGE ACTIVATES WHEN DIFF.

PRESS. ACROSS ELEMENTS REACHES SETPOINT

PS-280A 4.0 HYD FLUID PUMP A DISCHARGE PRESSURE

INCREASING: 2300 PSIG OR 158.6 BARG

(DECREASING: 2200 PSIG OR 151.7 BARG)

NORM=(2) NO-OES;

FUNCTION: SENSES HYD PUMP A OUTPUT PRESSURE

HAZARDOUS AREA : NON-RATED

24 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

25 F

Device System Settings

PS-280B 4.0 HYD FLUID PUMP B DISCHARGE PRESSURE

INCREASING: 2300 PSIG OR 158.6 BARG

(DECREASING: 2200 PSIG OR 151.7 BARG)

NORM=(2) NO-OES;

FUNCTION: SENSES HYD PUMP B OUTPUT PRESSURE

HAZARDOUS AREA : NON-RATED

PS-281A 4.0 LOW HYD FLUID PRESSURE ALARM

DECREASING: 1950 PSIG OR 134.5 BARG

(INCREASING: 2150 PSIG OR 148.3 BARG)

NORM=(2) NC-CES;

FUNCTION: ALARM ON LOW HYD PRESSURE

HAZARDOUS AREA : NON-RATED

PS-281B 4.0 HYD FLUID PRESSURE LOW PUMP A START

DECREASING: 1950 PSIG OR 134.5 BARG

(INCREASING: 2150 PSIG OR 148.3 BARG)

NORM=(2) NC-CES;

FUNCTION: STARTS STANDBY PUMP ON LOW HYD PRESSURE.

HAZARDOUS AREA : NON-RATED

PS-281C 4.0 HYD FLUID PRESSURE LOW PUMP B START

DECREASING: 1950 PSIG OR 134.5 BARG

(INCREASING: 2150 PSIG OR 148.3 BARG)

NORM=(2) NC-CES;

FUNCTION: STARTS STANDBY PUMP ON LOW HYD PRESSURE.

HAZARDOUS AREA : NON-RATED

PS-281D 4.0 LOW HYD PRESSURE TRIP & ALARM

DECREASING: 1650 PSIG OR 113.8 BARG

(INCREASING: 2150 PSIG OR 148.3 BARG)

NORM=(2) NC-CES;

FUNCTION: TRIPS TURB ON LOW HYD PRESSURE

HAZARDOUS AREA : NON-RATED

PS-281E 4.0 LOW HYD PRESSURE TRIP & ALARM

DECREASING: 1650 PSIG OR 113.8 BARG

(INCREASING: 2150 PSIG OR 148.3 BARG)

NORM=(2) NC-CES;

FUNCTION: TRIPS TURB AND ALARMS ON LOW HYD PRESSURE

HAZARDOUS AREA : NON-RATED

PS-281F 4.0 LOW HYD PRESSURE TRIP & ALARM

DECREASING: 1650 PSIG OR 113.8 BARG

(INCREASING: 2150 PSIG OR 148.3 BARG)

NORM=(2) NC-CES;

FUNCTION: TRIPS TURB AND ALARMS ON LOW HYD PRESSURE

HAZARDOUS AREA : NON-RATED

PS-282 4.0 EMERGENCY TRIP HEADER TRIPPED

DECREASING: 200.0 PSIG OR 13.79 BARG

(INCREASING: 300.0 PSIG OR 20.69 BARG)

NORM=(2) NC-CES;

FUNCTION: SENSES LOW PRESSURE IN HYD LINE TO STOP VLV

HAZARDOUS AREA : NON-RATED

PS-301 3.5 ENCLOSURE SELF CLN FILTER HOUSE LOW PRESSURE ALARM

DECREASING: 60.00 PSIG OR 4.138 BARG

NORM=NO;

FUNCTION: ALARM ON LOW COMPRESSED AIR SUPPLY TO SELF CLEANING

FILTER HOUSE

25 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

26 F

Device System Settings

PS-302A 3.5 COOLING AIR FAN #1 RUNNING PRESSURE SWITCH

INCREASING: 0.4000 INH2O OR 0.9967 MBAR

NORM=NO-CEC;

PS-302B 3.5 COOLING AIR FAN #2 RUNNING PRESSURE SWITCH

INCREASING: 0.4000 INH2O OR 0.9967 MBAR

NORM=NO-CEC;

PS-303 3.5 LUBE AND HYDRAULIC ENCLOSURE LOW PRESSURE ALARM

DECREASING: 0.2000 INH2O OR 0.4983 MBAR

NORM=NC-CEC;

PS-3404 3.4 SEAL OIL INLET PRESS LOW, START DC PUMP

DECREASING: 96.00 PSIG OR 6.621 BARG

FUNCTION: START DC PUMP

DEAD BAND =0.1 TO 2.5 PSIG (5.86 TO 19.99 KPAG)

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `D` - FLAME PROOF

PSL-2930 7.5 H2 SUPPLY PRESSURE LOW

DECREASING: 110.0 PSIG OR 7.587 BARG

(INCREASING: 125.0 PSIG OR 8.621 BARG)

NORM=NO;

H2 SUPPLY PRESSURE LOW ALARM.

DEAD BAND =0.2 TO 1 PSIG (0.0141 TO 0.070 KG/CM2G)

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `D` - FLAME PROOF

SIGNAL TO TCP VIA MODBUS PROTOCOL

PSL-2950 7.5 GENERATOR GAS PRESSURE LOW

DECREASING: 58.00+-0.6000 PSIG OR 4.000+-0.0414 BARG

GENERATOR CASING GAS PRESSURE LOW ALARM.

DEAD BAND =0.2 TO 0.6 PSIG (0.0141 TO 0.0422 KG/CM2G)

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `D` - FLAME PROOF

SIGNAL TO TCP VIA MODBUS PROTOCOL

PT-071-1 6.2 1ST STAGE SHELL PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=2500 PSIG OR 172.4 BARG

FUNCTION: MONITOR, THRUST PROTECTION

PT-071-2 6.2 1ST STAGE SHELL PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=2500 PSIG OR 172.4 BARG

FUNCTION: MONITOR,THRUST PROTECTION

PT-071-3 6.2 1ST STAGE SHELL PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=2500 PSIG OR 172.4 BARG

FUNCTION: MONITOR, THRUST PROTECTION

PT-203-1 6.2 INLET STEAM PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=2500 PSIG OR 172.4 BARG

FUNCTION: INLET STEAM PRESSURE SIGNAL FOR CONTROL AND LIMITING

PT-203-2 6.2 INLET STEAM PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=2500 PSIG OR 172.4 BARG

FUNCTION: INLET STEAM PRESSURE SIGNAL FOR CONTROL AND LIMITING

26 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

27 F

Device System Settings

PT-203-3 6.2 INLET STEAM PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=2500 PSIG OR 172.4 BARG

FUNCTION: INLET STEAM PRESSURE SIGNAL FOR CONTROL AND LIMITING

PT-206-1 6.2 HOT REHEAT PRESSURE

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=1000 PSIG OR 68.97 BARG

FUNCTION: PRESSURE SIGNAL FOR IV CONTROL

PT-206-2 6.2 HOT REHEAT PRESSURE

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=1000 PSIG OR 68.97 BARG

FUNCTION: PRESSURE SIGNAL FOR IV CONTROL

PT-206-3 6.2 HOT REHEAT PRESSURE

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=1000 PSIG OR 68.97 BARG

FUNCTION: PRESSURE SIGNAL FOR IV CONTROL

PT-210A 1.7 EXHAUST VACUUM TRANSMITTER NO.1

4.000 MA=0.0 INHG OR 0.0 BAR

20.00 MA=30.00 INHG OR 1.003 BAR

FUNCTION: MONITOR, ALARM AND TRIP ON LOW EXHAUST VACUUM

PT-210B 1.7 EXHAUST VACUUM TRANSMITTER NO.2

4.000 MA=0.0 INHG OR 0.0 BAR

20.00 MA=30.00 INHG OR 1.003 BAR

FUNCTION: MONITOR, ALARM AND TRIP ON LOW EXHAUST VACUUM

PT-210C 1.7 EXHAUST VACUUM TRANSMITTER NO.3

4.000 MA=0.0 INHG OR 0.0 BAR

20.00 MA=30.00 INHG OR 1.003 BAR

FUNCTION: MONITOR, ALARM AND TRIP ON LOW EXHAUST VACUUM

PT-210E 5.0C EXHAUST HOOD WATER SPRAY SUPPLY AVAILABLE

4.000 MA=0.0 PSIA OR 0.0 BARA

20.00 MA=100.0 PSIA OR 6.897 BARA

HAZARDOUS ZONE: NON RATED

PT-211-1 6.2 COLD REHEAT PRESSURE (HP TURB EXHAUST) #1

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=1000 PSIG OR 68.97 BARG

FUNCTION: PRESSURE SIGNAL FOR IV CONTROL

PT-211-2 6.2 COLD REHEAT PRESSURE (HP TURB EXHAUST) #2

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=1000 PSIG OR 68.97 BARG

FUNCTION: PRESSURE SIGNAL FOR IV CONTROL

PT-212 5.0B STEAM SEAL MANIFOLD PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=125.0 PSIG OR 8.621 BARG

FUNCTION: PRESSURE SIGNAL FOR SSFV/SSDV CONTROL

HAZARDOUS ZONE: NON RATED

PT-213A 1.7 LP INLET PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=200.0 PSIG OR 13.79 BARG

PT-213B 1.7 LP INLET PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=200.0 PSIG OR 13.79 BARG

PT-213C 1.7 LP INLET PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=200.0 PSIG OR 13.79 BARG

27 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

28 F

Device System Settings

PT-218-1 6.3 LP ADM PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=200.0 PSIG OR 13.79 BARG

FUNCTION: LP ADM PRESSURE CONTROL

PT-218-2 6.3 LP ADM PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=200.0 PSIG OR 13.79 BARG

FUNCTION: LP ADM PRESSURE CONTROL

PT-218-3 6.3 LP ADM PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=200.0 PSIG OR 13.79 BARG

FUNCTION: LP ADM PRESSURE CONTROL

PT-225-1 6.2 CROSSOVER STEAM PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=200.0 PSIG OR 13.79 BARG

FUNCTION: MONITOR CROSSOVER STEAM PRESSURE

PT-232 5.0A PACKING GLAND EXHAUST PRESSURE TRANSMITTER

4.000 MA=0.0 INH2O OR 0.0 MBAR

20.00 MA=50.00 INH2O OR 124.6 MBAR

FUNCTION: MONITOR

HAZARDOUS ZONE: NON RATED

PT-245A 6.2 REHEAT BOWL PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=1000 PSIG OR 68.97 BARG

FUNCTION: MONITOR, THRUST PROTECTION

PT-245B 6.2 REHEAT BOWL PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=1000 PSIG OR 68.97 BARG

FUNCTION: MONITOR, THRUST PROTECTION

PT-245C 6.2 REHEAT BOWL PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=1000 PSIG OR 68.97 BARG

FUNCTION: MONITOR, THRUST PROTECTION

PT-250 5.0B AUX STEAM PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=500.0 PSIG OR 34.49 BARG

MAX EXPECTED STM SEAL SOURCE PRESSURE =290 PSIA (20.0 BARA)

HAZARDOUS ZONE: NON RATED

PT-252 6.2 RH COOLING STEAM LINE PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=1000 PSIG OR 68.97 BARG

FUNCTION: MONITOR

PT-270 3.1 BRG HEADER PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=90.00 PSIG OR 6.207 BARG

FUNCTION: MONITOR

PT-281 4.0 HYD FLUID PRESSURE TRANSMITTER

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=3000 PSIG OR 206.9 BARG

FUNCTION: MONITOR HYDRAULIC HEADER PRESSURE.

HAZARDOUS AREA : NON-RATED

28 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

29 F

Device System Settings

PT-2950 7.5 GENERATOR GAS PRESSURE

4.000 MA=0.0 PSIG OR 0.0 BARG

20.00 MA=100.0 PSIG OR 6.897 BARG

LOW PRESSURE ALARM AT 58 PSIG (4.08 KG/CM2G).

HIGH PRESSURE ALARM AT 64 PSIG (4.50 KG/CM2G).

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: `D` - FLAME PROOF

SIGNAL TO TCP VIA MODBUS PROTOCOL

QT-290A 7.5 CELL #1 TRANSMITTER SIGNAL

4.000 MA=70.00 OR 70.00

20.00 MA=100.0 OR 100.0

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: ``D`` AND ``IA``

SIGNAL TO TCP VIA MODBUS PROTOCOL

QT-290B 7.5 CELL #2 TRANSMITTER SIGNAL

4.000 MA=70.00 OR 70.00

20.00 MA=100.0 OR 100.0

HAZARDOUS ZONE: ZONE 2

PROTECTION METHOD: ``D`` AND ``IA``

SIGNAL TO TCP VIA MODBUS PROTOCOL

REDP-1A 1.3 ROTOR EXPANSION DETECTOR PROBE

50MM PROBE

FUNCTION: MONITOR, DISPLAY, ALARM, AND HP DIFF EXPANSION

CALCULATION

REDP-1B 1.3 ROTOR EXPANSION DETECTOR PROBE

50MM PROBE

FUNCTION: MONITOR, DISPLAY, ALARM, AND HP DIFF EXPANSION

CALCULATION

REDX-1A 1.3 PROXIMITOR-ROTOR EXPANSION

RANGE: 100 - 1100 MILS (2.54 - 27.9 MM)

FUNCTION: PROVIDES HIGH FREQUENCY EXCITATION TO PROBE NO. 1A

REDX-1B 1.3 PROXIMITOR-ROTOR EXPANSION

RANGE: 100 - 1100 MILS (2.54 - 27.9 MM)

FUNCTION: PROVIDE HIGH FREQUENCY EXCITATION TO PROBE NO. 1B

RP-1 1.5 REFERENCE PROBE

FUNCTION: PROVIDES ONCE PER REV SIGNAL

RX-1 1.5B PROXIMITOR-REFERENCE PROBE FOR VIB PHASE

FUNCTION: PROVIDE HIGH FREQUENCY EXCITATION FOR PROBE

S1 2.1 SHORTING TYPE SWITCH

FUNCTION: PROVIDE THE DIRECT CONTACT FOR TGM

SEDP-1 1.3 CASE EXPANSION DETECTOR TO STC MONITOR

RANGE: 0-2 INCHES

FUNCTION: MONITOR, DISPLAY, AND ALARM HIGH

SP-BPM-1 3.1 SPACE HEATER, LUBE OIL PUMP MOTOR #1

350.0 W; 120 VAC; 1 PH; 60 HZ;

IEC 60034 & IEC 60072

350W IS MAXIMUM, ACTUAL RATING MAY BE LESS.

SP-BPM-2 3.1 SPACE HEATER, LUBE OIL PUMP MOTOR #2

350.0 W; 120 VAC; 1 PH; 60 HZ;

IEC 60034 & IEC 60072

350W IS MAXIMUM, ACTUAL RATING MAY BE LESS.

29 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

30 F

Device System Settings

SP-CAFM-1 3.5 SPACE HEATER, COOLING AIR FAN MOTOR #1

60.00 W; 120 VAC; 1 PH; 60 HZ;

IEC MOTOR

SP-CAFM-2 3.5 SPACE HEATER, COOLING AIR FAN MOTOR #2

60.00 W; 120 VAC; 1 PH; 60 HZ;

IEC MOTOR

SP-CFM-1 7.5A SPACE HEATER FOR MOTOR CFM-1

120 VAC; 1 PH; 60 HZ;

SP-CFM-2 7.5A SPACE HEATER FOR MOTOR CFM-2

120 VAC; 1 PH; 60 HZ;

SP-CFM-3 7.5A SPACE HEATER FOR MOTOR CFM-3

120 VAC; 1 PH; 60 HZ;

SP-CFM-4 7.5A SPACE HEATER FOR MOTOR CFM-4

120 VAC; 1 PH; 60 HZ;

SP-EBPM 3.1 SPACE HEATER, EMRG. DC LUBE PUMP MOTOR

200.0 W; 120 VAC; 1 PH; 60 HZ;

IEC 60034 & IEC 60072

200W IS MAXIMUM, ACTUAL RATING MAY BE LESS.

SP-ESPM 3.1 SPACE HEATER, EMERG. DC SEAL PUMP MOTOR

200.0 W; 120 VAC; 1 PH; 60 HZ;

IEC 60034 & IEC 60072

200W IS MAXIMUM, ACTUAL RATING MAY BE LESS.

SP-GXM-1 5.0A SPACE HEATER, GLAND EXHAUSTER MOTOR #1

180.0 W; 120 VAC; 1 PH; 60 HZ;

HAZARDOUS ZONE: NON RATED

SP-GXM-2 5.0A SPACE HEATER, GLAND EXHAUSTER MOTOR #2

180.0 W; 120 VAC; 1 PH; 60 HZ;

HAZARDOUS ZONE: NON RATED

SP-HCCM 4.0 SPACE HEATER FOR HEATING & COOLING CIRC PUMP MOTOR.

200.0 W; 120 VAC; 1 PH; 60 HZ;

SPACE HEATER WATTAGE <=200 WATTS

HAZARDOUS AREA : NON-RATED

SP-HFPM-A 4.0 SPACE HEATER FOR HYD FLUID PUMP MOTOR A.

200.0 W; 120 VAC; 1 PH; 60 HZ;

SPACE HEATER RATING <=200 WATTS

HAZARDOUS AREA : NON-RATED

SP-HFPM-B 4.0 SPACE HEATER FOR HYD FLUID PUMP MOTOR B.

200.0 W; 120 VAC; 1 PH; 60 HZ;

SPACE HEATER RATING <=200 WATTS

HAZARDOUS AREA : NON-RATED

SP-OCM 3.1 SPACE HEATER, OIL CONDITIONER MOTOR

200.0 W; 120 VAC; 1 PH; 60 HZ;

IEC 60034 & IEC 60072

200W IS MAXIMUM, ACTUAL RATING MAY BE LESS.

SP-PBM 2.0 SPACE HEATER, PIGGY BACK MOTOR

65.00 W; 120 VAC; 1 PH; 60 HZ;

SP-TGM 2.0 SPACE HEATER, TURNING GEAR MOTOR

65.00 W; 120 VAC; 1 PH; 60 HZ;

30 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

31 F

Device System Settings

SP-VXM-1 3.1 SPACE HEATER, VAPOR EXTRACTOR #1

200.0 W; 120 VAC; 1 PH; 60 HZ;

IEC 60034 & IEC 60072

200W IS MAXIMUM, ACTUAL RATING MAY BE LESS.

SP-VXM-2 3.1 SPACE HEATER, VAPOR EXTRACTOR #2

200.0 W; 120 VAC; 1 PH; 60 HZ;

IEC 60034 & IEC 60072

200W IS MAXIMUM, ACTUAL RATING MAY BE LESS.

ST-201A 6.1 PRIMARY SPEED PROBE NO.1

FUNCTION: PROVIDES SPEED SIGNAL TO STC CABINET ELECTRONICS

ST-201B 6.1 PRIMARY SPEED PROBE NO.2

FUNCTION: PROVIDES SPEED SIGNAL TO STC CABINET ELECTRONICS

ST-201C 6.1 PRIMARY SPEED PROBE NO.3

FUNCTION: PROVIDES SPEED SIGNAL TO STC CABINET ELECTRONICS

ST-202A 6.1 EMERGENCY OVERSPEED PROBE NO.1

FUNCTION: PROVIDES OVERSPEED SIGNAL TO STC CABINET ELECTRONICS

ST-202B 6.1 EMERGENCY OVERSPEED PROBE NO.2

FUNCTION: PROVIDES OVERSPEED SIGNAL TO STC CABINET ELECTRONICS

ST-202C 6.1 EMERGENCY OVERSPEED PROBE NO.3

FUNCTION: PROVIDES OVERSPEED SIGNAL TO STC CABINET ELECTRONICS

SV-1203A 6.4D SERVO FOR RIGHT INTERCEPT VALVE POS CONTROL

RATED FLOW: 24.00 GPM AT 1000 PSID

4-WAY, 3-COIL (33 MA PER COIL)

FUNCTION: ACTUATOR FLOW CONTROL

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

SV-1204A 6.4D SERVO FOR LEFT INTERCEPT VALVE POS CONTROL

RATED FLOW: 24.00 GPM AT 1000 PSID

4-WAY, 3-COIL (33 MA PER COIL)

FUNCTION: ACTUATOR FLOW CONTROL

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

SV-211A 6.4C INLET CONTROL VALVE SERVO VALVE

RATED FLOW: 24.00 GPM AT 1000 PSID

4-WAY, 3-COIL, (33 MA PER COIL)

FUNCTON: CV #1 ACTUATOR FLOW CONTROL

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

SV-211B 6.4C INLET CONTROL VALVE SERVO VALVE

RATED FLOW: 24.00 GPM AT 1000 PSID

4-WAY, 3-COIL, (33 MA PER COIL)

FUNCTON: CV #2 ACTUATOR FLOW CONTROL

HAZARDOUS ZONE: NON-RATED

PROTECTION METHOD: SIMPLE

SV-216 6.4L LP ADM VALVE (OFF TURB) SERVO VALVE

RATED FLOW: 25.00 GPM AT 1000 PSID

(95 LPM @ 68.97 BARD)

FUNCTION: CONTROLS POS OF OFF TURB LP CONTROL VLV

HAZARDOUS ZONE: NON RATED

31 of 44

COPYRIGHT 2010-2011 GE ENERGY (USA), LLC AND/OR ITS AFFILIATES. All rights reserved. GE Energy STEAM Proprietary Technical Information

GE CLASS II (INTERNAL NON-CRITICAL)

SIZE DWG NO SH REV

A

GENERAL ELECTRIC COMPANY

SIZE CAGE CODE DWG NO

A

GE Energy

g

DRAWN

ISSUED SCALE SHEET

397A3135

397A3135

NESHEWAIT, ADI 2010-02-17

BENES, LINDA NONE

32 F

Device System Settings

T1 2.1 TRANSFORMER

FUNCTION: PROVIDE THE VOLTAGE FOR TURNING GEAR CIRCUIT

TAFM 4.0 TRANSFER & AUX FILTER UNIT MOTOR

0.5000 HP; 1800 RPM; 120 VAC; 1 PH; 60 HZ;

FUNCTION: POWERS PUMP ON HYD FLUID FILTERING SYSTEM

IEC 60034 7 IEC 60072

HAZARDOUS AREA : NON-RATED

TAFMS 4.0 TRANSFER & AUX FILTER PUMP MOTOR SWITCH

FUNCTION: CONTROLS PUMP ON HYD FLUID FILTERING SYSTEM

HAZARDOUS AREA : NON-RATED

TC-2996A 7.5 DESICCANT BED #1 TEMPERATURE SWITCH

INCREASING: 400.0 F OR 204.4 C

NORMAL READING =325 F +/- 25 F AT END OF HEATING CYCLE.

FUNCTION: HEATER PROTECTION

TC-2996B 7.5 DESICCANT BED #2 TEMPERATURE SWITCH

INCREASING: 400.0 F OR 204.4 C

NORMAL READING =325 F +/- 25 F AT END OF HEATING CYCLE.

FUNCTION: HEATER PROTECTION

TCV-260 6.5B VALVE POSITIONER

4 MA =OPEN

20 MA =CLOSED

FUNCTION: REGULATE COOLING WATER FLOW TO MAINTAIN CONSTANT LUBE

OIL TEMPERATURE

HAZARDOUS ZONE: NON RATED