Académique Documents

Professionnel Documents

Culture Documents

Machinery Operating Manual Transfer

Transféré par

Emin AlimCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Machinery Operating Manual Transfer

Transféré par

Emin AlimDroits d'auteur :

Formats disponibles

LNGC GRACE ACACIA

Machinery Operating Manual

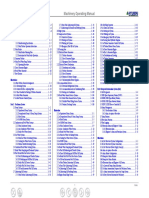

1 Index

Symbols and Colour Scheme ............................................................................. 2

Electrical Symbol List ........................................................................................ 3

Abbreviation ....................................................................................................... 4

Part 1 : Engineering Data for Main Equipment

1.1 Main Turbine..................................................................................... 1 - 1

1.1.1 Manufacturing Specification................................................... 1 - 5

1.1.2 Main Turbine Operation Instructions...................................... 1 - 7

1.2 Main Boilers.................................................................................... 1 - 10

1.2.1 Main Boilers Planning Data.................................................. 1 - 10

1.2.2 Instructions for Main Boiler Operation................................. 1 - 13

1.3 Generator Turbine ........................................................................... 1 - 19

1.4 Main Feed Water Pump Turbine ..................................................... 1 - 25

1.4.1 Operating Procedure ............................................................. 1 - 26

1.5 Diesel Generator Engine ................................................................. 1 - 27

1.6 Fresh Water Generator .................................................................... 1 - 30

1.7 Bow Thruster................................................................................... 1 - 32

Illustrations

1.1a Main Turbine General Arrangement................................................ 1 - 4

1.3.1a Governing System .................................................................... 1 - 20

1.3.1b Control Oil Press. Adjusting Valve ........................................... 1 - 22

1.3.1c Time Schedule for Starting of Turbine Generator .................... 1 - 23

1.6.1a Fresh Water Generator................................................................ 1 - 29

1.7.1a Bow Thruster Control System.................................................... 1 - 31

Part 2 : Machinery System

2.1 Steam Systems ................................................................................ 2 - 2

2.1.1 Superheated Steam System................................................... 2 - 2

2.1.2 Desuperheated Steam & Steam Dump Systems ................... 2 - 4

2.1.3 Bleed System........................................................................ 2 - 6

2.1.4 0.6MPa Steam System.......................................................... 2 - 8

2.2 Condensate and Feed Water Systems ............................................ 2 - 10

2.2.1 Main Condensate System.................................................... 2 - 10

2.2.2 Aux.Condensate Water System.......................................... 2 - 14

2.2.3 Boiler Feed Water System.................................................. 2 - 18

2.3 Sea Water Systems........................................................................ 2 - 22

2.3.1 Main Sea Water Circulating Systems ................................. 2 - 22

2.3.2 Cooling Sea Water Service System.................................... 2 - 26

2.3.3 Marine Growth Preventing System..................................... 2 - 28

2.4 Centralised Fresh Water Cooling System...................................... 2 - 30

2.5 Boiler Water Sampling and Treatment Systems ............................ 2 - 32

2.6 Fuel Oil and Fuel Gas Service Systems ........................................ 2 - 36

2.6.1 Fuel Oil Bunkering and Transfer Systems.......................... 2 - 36

2.6.2 DO Purifying and G/E Fuel Oil System ............................. 2 - 40

2.6.3 Boiler Fuel Oil Service Systems ......................................... 2 - 42

2.6.4 Boiler Fuel Gas Service System......................................... 2 - 46

2.6.5 IGG and Incinerator Fuel Oil System................................. 2 - 48

2.7 Lubricating Oil Systems................................................................ 2 - 50

2.7.1 Main Turbine Lubricating Oil System................................ 2 - 50

2.7.2 Stern Tube Lubricating Oil System..................................... 2 - 54

2.7.3 Lubricating Oil Transfer and Purifying System.................. 2 - 56

2.8 Bilge System ................................................................................. 2 - 60

2.9 Compressed Air Systems............................................................... 2 - 64

2.9.1 Control Air Systems............................................................ 2 - 64

2.9.2 Starting Air Systems ........................................................... 2 - 66

2.9.3 Working Air Systems.......................................................... 2 - 68

2.9.4 Emergency Shut Off Air System......................................... 2 - 70

2.10 Steering Gear............................................................................... 2 - 72

2.11 Electrical Power Generators ........................................................ 2 - 74

2.11.1 Turbine Generator............................................................. 2 - 74

2.11.2 Diesel Generator Engine ................................................... 2 - 78

2.11.3 Emergency Diesel Generator ............................................ 2 - 82

2.12 Electrical Power Distribution ...................................................... 2 - 84

2.12.1 Distribution and Loading .................................................. 2 - 84

2.12.2 Turbine Generators ........................................................... 2 - 87

2.12.3 Diesel Generator ............................................................... 2 - 88

2.12.4 Batteries & Battery Charger.............................................. 2 - 90

2.12.5 Un-Interruptible Power Supplies....................................... 2 - 91

2.13 Accommodation Services ............................................................ 2 - 94

2.13.1 Provision Refrigeration System........................................ 2 - 94

2.13.2 Accommodation and Air Conditioning Plant.................... 2 - 98

2.13.3 Package Air Conditioner................................................. 2 - 102

2.14 Fresh Water General Service Systems ....................................... 2 - 104

2.14.1 Fresh Water General Service System.............................. 2 - 104

2.14.2 Distilled Water Filling Service System........................... 2 - 104

2.14.3 Sanitary Discharge System............................................. 2 - 106

Illustration

2.1.1a Superheated Steam System......................................................... 2 - 1

2.1.2a Desuperheated Steam & Steam Dump System........................... 2 - 3

2.1.3a Bleed System.............................................................................. 2 - 5

2.1.4a 0.6MPa Steam System................................................................ 2 - 7

2.2.1a Main Condensate System........................................................... 2 - 9

2.2.2a Aux. Condensate Water System................................................ 2 - 13

2.2.3a Boiler Feed Water System........................................................ 2 - 17

2.3.1a Main Sea Water Circulating System......................................... 2 - 21

2.3.2a Cooling Sea Water Service System.......................................... 2 - 25

2.3.3a MGPS System .......................................................................... 2 - 27

2.4a Centralised Fresh Water System.................................................. 2 - 29

2.5a Boiler Water Sampling and Treatment System ........................... 2 - 31

2.6.1a Fuel Oil Bunkering and Transfer System................................. 2 - 35

2.6.2a Diesel Oil Purifying and G/E Fuel Oil System......................... 2 - 39

2.6.3a Boiler Fuel Oil & Fuel Gas Service System............................. 2 - 41

2.6.5a IGG and Incinerator Fuel Oil System....................................... 2 - 47

2.7.1a Main Turbine Lubrication Oil System...................................... 2 - 49

2.7.2a Stern Tube Lubricating Oil System.......................................... 2 - 53

2.7.3a Lubricating Oil Transfer System.............................................. 2 - 55

2.7.3b Lubricating Oil Purifying System............................................. 2 - 57

2.8a Engine Room Bilge System......................................................... 2 - 59

2.8b Oily Bilge Separator ....................................................................2 - 61

2.9.1a Control Air System...................................................................2 - 63

2.9.2a Starting Air System...................................................................2 - 65

2.9.3a Working Air System.................................................................2 - 67

2.9.4a Emergency Shut-Off Air System..............................................2 - 69

2.10a Steering Gear Hydraulic Diagram..............................................2 - 71

2.11.1a Turbine Generators Control Oil System..................................2 - 73

2.11.1b Turbine Exhaust Steam System ..............................................2 - 75

2.11.2a Diesel Generator Engine .........................................................2 - 77

2.11.3a Emcy Generator Engine.........................................................2 - 81

2.12.1a Distribution and Loading........................................................2 - 83

2.12.2a Turbine Generators .................................................................2 - 87

2.12.3a Diesel Generator .....................................................................2 - 88

2.12.4a Battery Charger Alarm Display Monitor ................................2 - 89

2.13.1a Provision Refrigeration System..............................................2 - 93

2.13.2a Aux. Air Conditioning Plant ...................................................2 - 97

2.13.2b Main Air Conditioning Plant ..................................................2 - 99

2.13.3a Package Air Conditioner .......................................................2 - 101

2.14.1a Fresh Water General Service System....................................2 - 103

2.14.3a Sanitary Discharge System...................................................2 - 105

Part 3 Integrated Automation System (IAS)

3.1 IAS for general.................................................................................. 3 - 4

3.2 DEO Open Supervisory Station (DOSS)......................................... 3 - 4

3.3 DOHS (DEO Open History Station) ................................................. 3 - 8

3.4 DOGS (DEO Open Gateway Station) ............................................... 3 - 8

3.5 DOPC (DEO Process Controller ) .............................................. 3 - 8

3.6 Alarm Management........................................................................... 3 - 9

3.6.1 Classification of Alarm .......................................................... 3 - 9

3.6.2 Alarm Acceptance Procedure ................................................. 3 - 9

3.7 Alarm Printout................................................................................. 3 - 10

3.8 Fast Alarm Function........................................................................ 3 - 10

3.9 Data Logging................................................................................... 3 - 10

3.10 Extension Alarm and Engineers Alarm........................................ 3 - 11

3.10.1 Extension Alarm................................................................. 3 - 12

3.10.2 Engineers Alarm and Patrolman System........................... 3 - 15

Illustration

3.1.1a IAS Overview (System Configuration) ........................................ 3 - 1

3.1.1b IAS Overview (System Connection)............................................ 3 - 2

3.1.1c IAS Overview (Power Supply Concept) ...................................... 3 - 3

3.6a Alarm Acceptance Procedure .......................................................... 3 - 9

3.7a Alarm Printer Configuration.......................................................... 3 - 10

3.7b Example of Alarm Printout ........................................................... 3 - 10

3.8a Example of Alarm Printout............................................................ 3 - 10

3.10a Extension Alarm and Engineer Call System................................ 3 - 11

3.10.1a Layout of Group Alarm Indication........................................... 3 - 12

3.10.1b Alarm Annunciation Sequence for Machinery System............. 3 - 13

3.10.1c Alarm Annunciation Sequence for Cargo System.................... 3 - 14

3.10.1d Duty Selector Indication for Machinery................................... 3 - 14

LNGC GRACE ACACIA

Machinery Operating Manual

2 Index

3.10.1e Duty Selector Indication for Cargo .................................. 3 - 14

Part 4 : Main Boiler Control System

4.1 Main Boiler Control System............................................................. 4 - 1

4.2 Burner Management System............................................................. 4 - 3

4.3 Automatic Combustion Control ........................................................ 4 - 5

4.4 BMS and ACC Logic Diagram......................................................... 4 - 7

4.4.1 Burner Management System Logic Diagram.......................... 4 - 7

4.4.2 Automatic Boiler Control System Diagram.......................... 4 - 23

Part 5 : Main Turbine Remote Control System

5.1 Main Turbine Remote Control Specification ....................................5 - 2

5.2 Control Function ...............................................................................5 - 4

5.3 Transfter of Control Location ..........................................................5 - 4

5.4 Telegraph...........................................................................................5 - 8

5.5 Function and Interlock ......................................................................5 - 9

5.5.1 Program Control .........................................................................5 - 9

5.5.2 Auto Slow Down and Preventing Alarm.....................................5 - 9

5.5.3 Auto Spinning...........................................................................5 - 10

Illustration

5.1a System Block Diagram....................................................................5 - 1

5.2a Main Turbine Remote Contorl Diagram..........................................5 - 3

5.4a Telegraph System Block Diagram...................................................5 - 7

5.5.3a Auto Spinning ...........................................................................5 - 10

Part 6 : Description of Critical Operation

6.1 Flooding in the Engine Room........................................................... 6 - 1

6.2 Main Boiler Emergency Operation ................................................... 6 - 2

6.2.1 One-Boiler Operation ............................................................. 6 - 2

6.2.2 Operation of Stand by FDF..................................................... 6 - 4

6.2.3 Emergency Operationl ............................................................ 6 - 6

6.3 H.P. and L.P. Turbine Solo Running Operation................................. 6 - 8

6.4 Restore Engine Room Plant from Dead Ship Condition................... 6 - 9

Illustrations

6.1a Floodable time, control position and method for valve operation... 6 - 1

6.2.2a 6.2.2a Operation of Stand by FDF .............................................. 6 - 3

6.2.3a Boiler Emergency Operation Panel .............................................. 6 - 5

6.3a H.P. and L.P. Turbine Solo Running Operation............................... 6 - 7

Part 7 : Steam Plant Heat Balance System

7.1 100% MCR FO Burning Condition................................................. 7 - 1

7.2 100% MCR DUAL Burning Condition........................................... 7 - 2

7.3 100% MCR BOIL OFF GAS Burning Condition ........................... 7 - 3

7.4 90% MCR FO Burning Condition (Guarantee Condition).............. 7 - 4

7.5 90% MCR FO Burning Condition .................................................. 7 - 5

7.6 90% MCR DUAL Burning Condition............................................. 7 - 6

7.7 90% MCR BOIL OFF GAS Burning Condition ............................. 7 - 7

7.8 50% MCR FO Burning Condition .................................................. 7 - 8

7.9 30% MCR FO Burning Condition................................................... 7 - 9

7.10 Cargo Unloading Condition (FO)................................................ 7 - 10

7.11 Cargo Loading Condition (FO) ................................................... 7 - 11

7.12 Hotel Load Condition (FO) ......................................................... 7 - 12

Part 8 : General Information

8.1 Maker List .........................................................................................8 - 1

8.2 Tank Capacity Plan and List ..............................................................8 - 5

8.3 Lubrication Oil Chart ........................................................................8 - 7

LNGC GRACE ACACIA

Machinery Operating Manual

3 Symbols and Colour Scheme

Symbols and Colour Scheme

Description Symbol Description Symbol Description Symbol Description Symbol

Sliding Type Expansion Joint

Crossing Pipe, Not Connected

Crossing Pipe, Connected

Sleeve Type Expansion Joint

Expansion Bend

Bellows type Expansion Joint

Blank Flange

Spectacle Flange

Orifice

Center Flange

Reducer

Spool Piece

Globe Angle

Flexible Hose

Angle Valve

Three Way Valve

Y-type Strainer

Steam Trap

Three Way Cock

Ball Valve

Solenoid Valve

Lift Check Valve (Globe)

Lift Check Valve (Angle)

Swing Check Valve

Flap Check Valve

Relief Valve (Globe)

Screw Down Non-return Valve (Globe)

Screw Down Non-return Valve (Angle)

Relief Valve (Angle)

Self Closing Valve (Globe)

Hose Globe Valve

Hose Angle Valve

Pressure Reducing Valve

Self Closing Valve (Angle)

Gate Valve (Sluice)

S

Air Motor Operated Valve

A

Electric Motor Operated Valve

Pressure Control Valve

Manual Operated Butterfly Valve

Hydraulic Remote Operated Butterfly Valve

Hydraulic Cylinder Type Actuator

M

Pneumatic Cylinder Type Actuator

Intermediate Position Control Valve Actuator

Auto Control Valve Actuator

Surface Valve

Vapour Control Valve

Hand Operated

Deck Stand

Goose Neck Air Vent Pipe

Filling Cap

Rose Box

Pneumatic Remote Operated Butterfly Valve

A A

Box Type Strainer

Cast Steel or Duct Cast Iron

Mud Box

Manual Hydraulic Operated Deck Stand

Float Type Air Vent Head Without Fire Screen

Float Type Air Vent Head With Fire Screen

Sounding Head With Cap (Deck Stand Type)

Sounding Head with Self Closing Valve

Steam Trap With Strainer

Hand Pump

Ejector, Eductor

Drain Hold With Plug

Oil Coaming

Suction Bellmouth

Open Scupper

Scupper for Indoor Part

Electric Motor Driven Pump

Pressure Gauge

Compound Gauge

Flow Meter

Sight Glass

Three Way Control Valve

Colour

LNG Liquid

Description

LNG Spray

LNG Vapour

Superheated Steam

Inert Gas

Compressed Air

Nitrogen

Lubricating Oil

Heavy Fuel Oil

Glycol Water

Sea Water

Fresh Water

Hydraulic Oil

Diesel Oil

Condensate/Distilled Water

Sludge & Waste Oil

Bilge

Fire Sea Water

De-superheated Steam

LNGC GRACE ACACIA

Machinery Operating Manual

4 Electric symbol List

Electrical Symbol List

GSP

C

P

LD

L

LD

DG

EG

M

GM

PD

LD

I

P

P

I

RPM

IS

ZBK

LM

VR

J

J J

HS

WT

AMS

I

O

SIG

R B

GJB/XX

10A

RL

D-D

BZ

BL

Trip

STARTER (DIRECT ON LINE)

M

LOCAL GROUP

STARTER PANEL

CONTROL PANEL

440V DIST. BOARD

220V POWER DIST. BOARD

LIGHTING DIST. BOARD

AIR CIRCUIT BREAKER

MCCB 1 PHASE

MCCB 3 PHASE

BATTERY CHARGER

BATTERY

SPACE HEATER

(ELEMENT TYPE)

DIESEL GENERATOR

EMERGENCY GENERATOR

AC INDUCTION MOTOR

GOVERNOR MOTOR

EARTH

SHIELD WIRE

TRANSFORMER

LIQUID SENSOR

CURRENT TO PRESS

CONVERTER

PRESS TO CURRENT

CONVERTER

RPM PICK-UP

GAUGE

INTRINSICALLY SAFE

CIRCUIT

POWER SUPPLY UNIT

ZENER BARRIER BOX

LIMIT SWITCH

SOLENOID VALVE

VOLTAGE REFERENCE

SELECTOR

RECEPTACLE

NWT JOINT BOX

WT JOINT BOX

2 GLANDS (4 GLANDS)

HUMIDISTAT

WATER TRANSDUCER

ALARM MONITORING

SYSTEM

OVERCURRENT RELAY

I/O CABINET (ALARM

MONITORING SYSTEM)

WHISTLE RELAY BOX

RESISTOR

GROUP JUNCTION BOX XX

(XX=LOCATION)

VARIABLE RESISTOR

DIMMER

DIODE

CAPACITOR

FUSE

FUSE

DISCONNECTION SWITCH

SNAP SWITCH

CHANGEOVER SWITCH

(CAM SWITCH)

INDICATOR LAMP

WITH TRANSFORMER

INDICATOR LAMP

RELAY COIL

BUZZER

BELL

RECTIFIER EQUIPMENT

MAKING CONTACT

BREAKING

MAKING CONTACT

BREAKING

MAKING CONTACT

BREAKING

MAKING CONTACT

BREAKING

AUXILIARY

RELAY

CONTRACT

WITH TIME

LIMIT IN

CLOSING

WITH TIME

LIMIT IN

OPENING

FLICKER

RELAY

PUSHBUTTON SWITCH

(ALTERNATIVE)

PUSHBUTTON SWITCH

(ALTERNATIVE)

PUSHBUTTON (START/STOP)

PUSHBUTTON

(START/STOP/RUNNING)

EMERGENCY STOP

PUSHBUTTON BOX

CP COMPOUND GAUGE

DPI DIFFERENTIAL PRESSURE INDICATOR

DPS DIFFERENTIAL PRESSURE SWITCH

DPT DIFFERENTIAL PRESSURE TRANSMITTER

FD FLOW DETECTOR

FS FLOW SWITCH

FT FLOW TRANSMITTER

IL INDICATION LAMP

LAH LEVEL ALARM HIGH

LAL LEVEL ALARM LOW

LI LEVEL INDICATOR

LIC LEVEL INDICATING CONTROLLER

LS LEVEL SWITCH

LT LEVEL TRANSMITTER

PAH PRESSURE ALARM HIGH

PAL PRESSURE ALARM LOW

PI PRESSURE INDICATOR

PIC PRESSURE INDICATING CONTROLLER

PIAH PRESSURE INDICATOR ALARM HIGH

PIAL PRESSURE INDICATOR ALARM LOW

PIAHL PRESSURE INDICATOR ALARM HIGH LOW

PS PRESSURE SWITCH

PT PRESSURE TRANSMITTER

SAH SALINITY ALARM HIGH

SD SALINITY DETECTOR

SI SALINITY INDICATOR

SV SOLENOID VALVE

TAH TEMPERATURE ALARM HIGH

TAL TEMPERATURE ALARM LOW

TI TEMPERATURE INDICATOR

TIC TEMPERATURE INDICATING CONTROLLER

TIAH TEMPERATURE INDICATOR ALARM HIGH

TIAL TEMPERATURE INDICATOR ALARM LOW

TIAHL TEMPERATURE INDICATOR ALARM HIGH LOW

TS TEMPERATURE SWITCH

TT TEMPERATURE TRANSMITTER

VAH VISCOSITY ALARM HIGH

VAL VISCOSITY ALARM LOW

VCA VACUUM ALARM

VCI VACUUM INDICATOR

VCT VACUUM TRANSMITTER

XS AUXILIARY UNSPECIFIED SWITCH

ZI POSITION INDICATOR

ZS LIMIT SWITCH

XXX

XXX

XXXX

LOCALLY MOUNTED

INSTRUMENT

REMOTELY MOUNTED

INSTRUMENT

AUTOMATIC TRIP

LNGC GRACE ACACIA

Machinery Operating Manual

5 Abbreviation

Abbreviation

A AIR

ABNOR ABNORMAL

ABP AFTER BOTTOM PORT

ABS ABSOLUTE

ABS AFTER BOTTOM STBD

AC ALTERNATING CURRENT

A/C AIR CONDITIONER

ACB AIR CIRCUIT BREAKER

ACC AUTOMATIC COMBUSTION CONTROL

ACCOM ACCOMMODATION

ACCU ACCUMULATOR

ACK ACKNOWLEDGE

ACM AFTER CENTRAL MIDDLE

ACT ACTIVATE

ADJ ADJUSTING

ADV ADVANCE

AE AUXILIARY ENGINE

AFT AFT

AHD AHEAD

AHU AIR HANDLING UNIT

AIM ADVANCED INTEGRATED MULTIFUNCION

SYSTEM

ALM ALARM

ALS AFTER LOWER STBD

AMP AMPERE

APT AFT PEAK TANK

AST ASTERN

ATOM ATOMIZING

AUS AFTER UPPER STBD

AUTO AUTOMATIC

AUX AUXILIARY

AVAIL AVAILABLE

B BASE

B/ATOM BURNER ATOMIZING

B/L BALLAST / LADEN

B/THR BOW THRUSTER

BALL BALLAST

BATT BATTERY

BC BOTTOM CENTRAL

BGB BOILER GAUGE BOARD

BH TK BILGE HOLDING TANK

BHD BULKHEAD

BLK BLOCK

BLR BOILER

BLWR BLOWER

BMS BURNER MANAGEMENT SYSTEM

BNR BURNER

BO BOIL-OFF

BO/WU BOIL-OFF / WARM-UP

BOG BOIL OFF GAS

BOSUN ST BOSUN STORE

BRG BEARING

BW BILGE WELL

BWC BRIDGE WING CONSOLE

BZ BUZZER

C CARGO

CAB CABINET

CAN CONTROLLER AREA NETWORK

CCC CARGO CONTROL ROOM CONSOLE

CCR CARGO CONTROL ROOM

CCW COUNTER-CLOCK WISE

CENT CENTRAL / CENTRIFUGAL

CER CARGO EQUIPMENT ROOM

CFW COOLING FRESH WATER

CIRC CIRCULATING

CL CLOSE

CLK CLOCK

CLR COOLER

CMR CARGO MOTOR ROOM

CN COMMUNICATION NETWORK

CNR CORNER

C-O CHANGE-OVER

CO2 CARBON DIOXIDE

COFF COFFERDAM

COMP COMPRESSOR

COMP RM CARGO COMPRESSOR ROOM

COND CONDENSATE / CONDENSER

CONDUCT CONDUCTIVITY

CONT CONTROL

COOL COOL, COOLING

COUNT COUNT, COUNTER

CPP CONTROLLABLE PITCH PROPELLER

CSBD CARGO SWITCHBOARD

CSL CONSOLE

CSW COOLING SEA WATER

CTS CUSTODY TRANSFER SYSTEM

CUR CURRENT

CW COOLING WATER

CW CLOCK WISE

CYL CYLINDER

D DUMP

DAMP DAMPER

DB DOUBLE BOTTOM

D/B DISTRIBUTION BOARD

DEARTR DEAERATOR

DEL DELIVERY

DET DETECTOR / DETECTION

DG DIESEL GENERATOR

DIFF DIFFERENTIAL

DIS DISCHARGE

DISCON DISCONNECT

DK DECK

DO DIESEL OIL

DP DIFFERENTIAL PRESS

DRK W DRINKING WATER

DRN DRAIN

DRV DRIVE, DRIVING

DRY DRYER

DSHTR DESUPERHEATED STEAM HEATER

DW DISTILLED WATER

EBU EMULSION BREAKING UNIT

ECC ENGINE CONTROL ROOM CONSOLE

ECONM EXHAUST GAS ECONOMIZER

ECR ENGINE CONTROL ROOM

EDR ELECTRIC DISTRIBUTING PANEL ROOM

EDSHTR EXTERNAL DESUPERHEATED STEAM

. HEATER

EDUCT EDUCTOR

EER ELECTRIC EQUIPMENT ROOM

EHQ EMERGENCY HEADQUARTER

ELEC ELECTRIC

ELEV ELEVATOR

EMCY EMERGENCY

EMR ELECTRIC MOTOR ROOM

ENG ENGINE

EQP EQUIPMENT

ER ENGINE ROOM

ESBD EMERGENCY SWITCHBOARD

ESD EMERGENCY SHUT DOWN

ESDS EMERGENCY SHUT DOWN SYSTEM

EXH EXHAUST

EXP EXPANSION

EXT EXTENSION

EXTR EXTRACTOR

F FRESH

F/VPR FORCING VAPORIZER

FCL FWD CENTRAL LOWER

FOSCLE FORECASTLE

FCU FWD CENTRAL UPPER

FCV FLOW CONTROL VALVE

FDB FORWARD DEEP BALLAST

FDF FORCED DRAFT FAN

FDWC FEED WATER CONTROL

FE FLAME EYE

FG FUEL GAS

FLP FWD LOWER PORT

FM FROM

FO FUEL OIL

FORC FORCING

FPT FORWARD PEAK TANK

FREQ FREQUENCY

F-ST FOLLOW AUTO START

FUNC FUNCTION

FUP FWD UPPER PORT

FW FRESH WATER

FWC FRESH WATER CONTROL

FWD FORWARD

FWE FINISHED WITH ENGINE

GACP GENERATOR AUTO CONTROL PANEL

GEN GENERATOR

GMS GAS MANAGEMENT SYSTEM

GMS GRAPHIC MODELLING SYSTEM

GRAV GRAVITY

GRP GROUP

GS GENERAL SERVICE

GUI GRAPHICAL USER INTERFACE

GVNOR GOVERNOR

GW GLYCOL WATER

H HIGH

HAND HANDLE/HANDLING

HD HIGH DUTY

HDR HEADER

HFO HEAVY FUEL OIL

HH HIGH-HIGH

HP HIGH PRESSURE

HPT HIGH PRESSURE TURBINE

HS HISTORY STATION

HSC HIGH SEA CHEST

HTML HYPER TEXT MARKUP LANGUAGE

HTR HEATER

HYD HYDRAULIC

IAS INTEGRATED AUTOMATION SYSTEM

IG INERT GAS

IGG INERT GAS GENERATOR

IGV INLET GUIDE VANE

IN INLET

INCIN INCINERATOR

INCOM INCOMING

IND INDICATION

INH INHIBIT

INJECT INJECTION

INSPT INSPECTION

INSUL INSULATION

INTERM INTERMEDIATE

INTLK INTERLOCK

IR INFRA-RED

ISO ISOLATING

L LOW

LAN LOCAL AREA NETWORK

LNGC GRACE ACACIA

Machinery Operating Manual

6 Abbreviation

L/VPR LNG VAPORIZER

LCD LIQUID CRYSTAL DISPLAY

LCV LEVEL CONTROL VALVE

LD LOW DUTY

LDO LIGHT DIESEL OIL

LED LIGHT EMITTING DIODE

LIQ LIQUID

LL LOW-LOW

LNG LIQUEFIED NATURAL GAS

LO LUBRICATION OIL

LP LOW PRESSURE

LPT LOW PRESS TURBINE

LSC LOW SEA CHEST

LTG LIGHTING

LVL LEVEL

LWR LOWER

M MACHINERY

M/COND MAIN CONDENSER

M/LOADER MANUAL LOADER

M/WHEEL MAIN WHEEL

MAN MANUAL

MANI MANIFOLD

MANO MANOEUVRING

MB MAIN BOILER

MD MAIN DIESEL GENERATOR

MDO MARINE DIESEL OIL

MFWPT MAIN FEED WATER PUMP TURBINE

MG MASTER GAS

MGPS MARINE GROWTH PREVENTING SYSTEM

MID MIDDLE

MSBD MAIN SWITCHBOARD

MSBR MAIN SWITCHBOARD ROOM

MT MAIN TURBINE

MTR MOTOR

NDU NETWORK DISTRIBUTION NETWORK UNIT

MV MANOEUVRED VALUE

N2 NITROGEN

NAV NAVIGATION

NOR NORMAL

NZL NOZZLE

O/C OPEN/CLOSE

O2 OXYGEN

OMD OIL MIST DETECTOR

OP OPEN

OS OPERATOR STATION

OUT OUTLET

OVBD OVERBOARD

OVFL OVERFLOW

OVLD OVERLOAD

OVRD OVERRIDE

OW SEP OILY WATER SEPARATOR

PORT PORT

P/WAY PASSAGE WAY

PB PUSH BUTTON

PC PERSONAL COMPUTER

PCU PROCESS CONTROL UNIT

PCV PRESSURE CONTROL VALVE

PD PIPE DUCT

PDU POWER DISTRIBUTION UNIT

PID PROPORTIONAL INTEGRAL DERIVATIVE

PIST PISTON

PKG PACKAGE

PLU PROCESS MAP LOGICAL UNIT

PMS POWER MANAGEMENT SYSTEM

PNEUM PNEUMATIC

PNL PANEL

POS POSITION

PP PUMP

PPTW PUMP TOWER

PRES PRESSURE

PRI PRIMARY/PRIMING

PROCESS PROCESS

PROTECT PROTECT

PROV PROVISION

PRP PROVISION REFRIGERATION PLANT

PS PROCESS STATION

PSU POWER SUPPLY UNIT

PU PROCESS UNIT (RCA SYSTEM)

PURGE PURGE

PURIF PURIFIER

PWR POWER

RCA REDUNDANCY AND CRITICALITY

ASSESSMENT

RECIRC RECIRCULATING

REDUC REDUCTION

REF REFRIGERATION TYPE

REG REGENERATION TYPE

REGUL REGULATOR

RESV RESERVOIR

REV REVERSE

RIO REMOTE IO

RM ROOM

RPB REMOTE PUSH BUTTON

RPM REVOLUTIONS PER MINUTE

RTN RETURN

RVI ROTOR VIBRATION INDICATION

S STARBOARD

S/D SCHEMATIC DIAGRAM

S/S SHIP SIDE

S/T STERN TUBE

SAH STEAM AIR HEATER

SAL SALINITY

SB SOOT BLOWER

SBC SINGLE BOARD COMPUTER

SC SEA CHEST

SCRUB SCRUBBER

SDC STEAM DUMP CONTROL

SEC SECONDARY

SEL SELECT

SEP SEPARATOR

SEQ SEQUENCE

SERV SERVICE

SETTL SETTLING

SG STEERING GEAR

SHTR SUPERHEATED STEAM HEATER

SIN PH SINGLE PHASE

SOL SOLENOID

SP SPACE

SPM SIMRAD POSITION MOORING

SPR SPRAY

SPV SINGLE POINT VIEW

SS SUB-SYSTEM (RCA SYSTEM)

SSS SIMRAD SAFETY SYSTEM

ST START

STT STERN TUBE

STBY STAND BY

STC STEAM TEMPERATURE CONTROL

STM STEAM

STOR STORAGE

STR STARTER

STRIP STRIPPING

SUC SUCTION

SUPP SUPPLY

SV SOLENOID VALVE

SVC SIMRAD VESSEL CONTROL

SVB SOLENOID VALVE BOX

SW SEA WATER

SWBD SWITCHBOARD

SYNC SYNCHRONIZE

SYS SYSTEM

TC TURBOCHARGER, THERMOCOUPLE

TCV TEMPERATURE CONTROL VALVE

TEMP TEMPERATURE

TG TURBO GENERATOR

THR THRUSTER

TK TANK

TOPP UP TOPPING UP

TRIP TRIP

TPS TANK PROTECTION SYSTEM

TRANS TRANSMITTER/TRANSFER

TRBL TROUBLE

TURN GEAR TURNING GEAR

UMS UNMANNED MACHINERY SPACE

UPP UPPER

UPS UNINTERRUPTED POWER SUPPLY

URL UNIFORM RESOURCE LOCATOR

UTC UNIVERSAL TIME CODRDINATE

V VOLTAGE

V/F VOLTAGE/FREQUENCY

VAC VACUUM

VAP VAPOUR

VIB VIBRATION

VISC VISCOSITY

VL VERY LOW

VPR VAPORIZER

VRC VALVE REMOTE CONTROL

VV VALVE

WBU WATCH BRIDGE UNIT (Bridge Watch Call panel)

WCU WATCH CABIN UNIT (Cabin Watch Call panel)

WTR WATER

WH WHEELHOUSE

WHC WHEELHOUSE CONSOLE

WIND WINDING

WO WASTE OIL

WS WORKSHOP

WU WARM UP

X CROSS

LNGC GRACE ACACIA Machinery Operating Manual

Part 1 Engineering Data for Main Equipment

Part 1 : Engineering Data for Main Equipment

1.1 Main Turbine..................................................................................... 1 - 1

1.1.1 Manufacturing Specification................................................... 1 - 5

1.1.2 Main Turbine Operation Instructions...................................... 1 - 7

1.2 Main Boilers.................................................................................... 1 - 10

1.2.1 Main Boilers Planning Data.................................................. 1 - 10

1.2.2 Instructions for Main Boiler Operation................................. 1 - 13

1.3 Generator Turbine ........................................................................... 1 - 19

1.4 Main Feed Water Pump Turbine...................................................... 1 - 25

1.4.1 Operating Procedure ............................................................. 1 - 26

1.5 Diesel Generator Engine ................................................................. 1 - 27

1.6 Fresh Water Generator..................................................................... 1 - 30

1.7 Bow Thruster................................................................................... 1 - 32

Illustrations

1.1a Main Turbine General Arrangement................................................ 1 - 4

1.3.1a Governing System .................................................................... 1 - 20

1.3.1b Control Oil Press. Adjusting Valve ........................................... 1 - 22

1.3.1c Time Schedule for Starting of Turbine Generator ..................... 1 - 23

1.6.1a Fresh Water Generator................................................................ 1 - 29

1.7.1a Bow Thruster Control System.................................................... 1 - 31

Part 1

Engineering Data for Main Equipment

LNGC GRACE ACACIA Machinery Operating Manual

1- 1 Part 1 Engineering Data for Main Equipment

Part 1 : Engineering Data for Main Equipment

1.1 Main Turbine

1. Main Particulars :

Type : Mitsubishi cross-compound, impulse, double reduction geared marine turbine

Item NCR MCR

Output kW Abt. 26,478 Abt. 29,420

HP Turbine rpm Abt. 5,651 Abt. 5,854

LP Turbine rpm Abt. 3,298 Abt. 3,416

Revolution

Propeller rpm Abt. 85.0 Abt. 88.0

Steam Pressure

at manoeuvring. valve inlet

5.88 MpaG

Steam Temperature

at manoeuvring valve inlet

510C

Exhaust vacuum at the condenser top (when sea

water temperature is 27)

722 mmHg

Limited S.H.P in emergency operation

(HP turbine only)

abt. 10,091kW X 61.6rpm

Limited S.H.P in emergency operation

(LP turbine only)

abt. 10,091kW X 61.6rpm

Ahead rotating direction Clockwise looking from aft

Critical speed due to shaft torsional vibration 1

st

abt. 29.2 rpm 2

nd

abt. 46.9 rpm 3

rd

abt. 212.3 rpm

HP Turbine abt. 4,320 rpm abt. 48.4 rpm (at propeller)

Natural frequency of turbine rotor

LP Turbine abt. 2,280 rpm abt. 40.5 rpm (at propeller)

2. Reduction Gear : One (1) Unit

Type : Tandem articulated, double reduction, double helical type

Item P.C.D. mm No. of Teeth

HP 258.3 45

1st red. pinion

LP 385.1 67

HP 1,698.7 296

1st red. wheel

LP 1,701.3 296

HP 489.5 53

2nd red. pinion

LP 563.4 61

2nd red. wheel HP & LP

4,950.8 536

1st red 260 x 2 + 70 (gap)

Tooth width

2nd red 520 x 2 + 80 (gap)

3. Main Condenser : One (1) Unit

Type Radial flow surface type with dump steam chamber

Vacuum (at cond. Top) mmHgV 722

Cooling surface m

2

3,490

Quantity of cooling water m

3

/h 18,605

Number of cooling tubes pieces 10,631

Distance between tube sheets mm 5,500

Cooling tubes Dia. / Thickness mm 19.0 / 0.7

Protection system Sacrifice Anode (Soft iron)

LNGC GRACE ACACIA Machinery Operating Manual

1- 2 Part 1 Engineering Data for Main Equipment

4. Vacuum Pump : Two (2) Unit

Type NASH AT-1006

Number of sets set 2

Capacity (dry air removal) SCFM 7.5

Motor output kW 55

Electric source AC 440V x 3 x 60Hz

Pump speed rpm 880

5. Gland Steam Condenser : One (1) Unit

Type Horizontal Surface cooled type

Number of flows 2

Cooling surface m

2

25

Distance between tube sheets mm 1,896

Size of cooling tube Dia. / Thickness mm 19 / 1.2

Number of cooling tubes pieces 224

6. Gland Exhaust Fan : Two (2) Unit

Type Horizontal Centrifugal Type

Number of sets set 2

Capacity (at delivery) m

3

/min. / mmAg 7 / 300

Fan Speed rpm 3,500

Motor output kW 1.5

Electric source AC 440V x 3 x 60Hz

7. Main Lub. Oil Pump (Main Turbine Driven) : One (1) Unit

Type Horizontal gear type driven by second gear

Number of sets set 1

Capacity m

3

/h 170

Discharge pressure MPaG 0.294

8. Control Oil Pump : Two (2) Unit

Type Motor driven, horizontal vane type

Number of sets set 2

Capacity m

3

/h 2.4

Discharge pressure MPag 1.5

Pump speed rpm 1,800

Motor output kW 2.2

Electric source AC 440V x 3 x 60Hz

9. Control Oil Filter : One (1) Unit

Type Duplex notch wire type

Number of sets set 1

Mesh mesh 200

10. Control Device

Item Set of controller

LO temperature controller Temperature about 44

Gland seal steam receiver pressure Pressure 0.5 ~ 25kPaG

LNGC GRACE ACACIA Machinery Operating Manual

1- 3 Part 1 Engineering Data for Main Equipment

11. Alarm Device

Item Detector Set

L.O .low pressure Pressure transmitter and alarm setter (PI-308) Abt. 0.07MPaG

Control oil strainer outlet low press. Pressure transmitter and alarm setter (PI-312) Abt. 1.0MPaG

Main condenser low vacuum Pressure transmitter and alarm setter (PI-341) Abt. - 0.08MPaG

low 0.0MPaG

Gland packing steam

high

Pressure transmitter and alarm setter (PI-347)

35kPaG

Control oil strainer differential high

press

Differential pressure transmitter and alarm setter

(DPI-313)

Abt. 0.3MPaG

H.P. turbine thrust bearing excess

axial displacement

H.P. turbine rotor position indication monitor (AX-521)

Fore & aft side

0.5mm (*1)

L.P. turbine thrust bearing excess

axial displacement

H.P. turbine rotor position indication monitor (AX-521)

Fore & aft side

0.5mm (*1)

Turbines vibration

(H.P. & L.P. turbine both)

Vibration monitor (VI-522) 75 microns (*1)

Reduction inclination (HP & LP 1

st

Pinion both)

Inclination monitor (IM-524)

* According to

estimated strsss

level

Main L.O. inlet high & low temp. Thermo-resistance bulb (TI-130)

High: 54C

Low: 34C

Low

Abt. 250mm above

N.W. level with 10

sec. Timer Main condenser level high /

low alarm

High

Level transmitter (LT-515)

Abt. 300mm above

N.W. level with 10

sec. Timer

Main steam inlet low temp. Thermo resistance bulb (TI-141) Abt. 490

Astern steam leak Thermal switch (TI-148)

350 with 2 hour

timer after ahead

operation

H.P. & L.P. turbine journal and thrust

bearings

Thermo-resistance bulb and alarm setter

(HP turbine thrust bearing TI-101)

(HP turbine fore bearing TI-102)

(HP turbine aft bearing TI-103)

(HP turbine thrust bearing TI-104)

(HP turbine fore bearing TI-105)

(HP turbine aft bearing TI-106)

80C

H.P. 1

st

pinion bearings

(HP 1

st

pinion fore bearing TI-107)

(HP 1

st

pinion aft bearing TI-108)

80C

H.P. 1

st

wheel upper & aft bearings

(HP 1

st

wheel upper fore bearing TI-109)

(HP 1

st

wheel upper aft bearing TI-110)

(HP 1

st

wheel lower fore bearing TI-111)

(HP 1

st

wheel lower aft bearing TI-112)

70C

H.P. 2

nd

pinion upper & aft bearings

(HP 2

nd

pinion upper fore bearing TI-113)

(HP 2

nd

pinion upper aft bearing TI-114)

(HP 2

nd

pinion lower for bearing TI-115)

(HP 2

nd

pinion lower aft bearing TI-116)

80C

L.P. 1

st

pinion bearings

(LP 1

st

pinion fore bearing TI-117)

(LP 1

st

pinion aft bearing TI-118)

80C

L.P. 1

st

wheel upper & aft bearings

(LP 1

st

wheel upper fore bearing TI-119)

(LP 1

st

wheel upper aft bearing TI-120)

(LP 1

st

wheel lower fore bearing TI-121)

(LP 1

st

wheel lower aft bearing TI-122)

70C

L.P. 2

nd

pinion upper & aft bearings

(LP 2

nd

pinion upper fore bearing TI-123)

(LP 2

nd

pinion upper aft bearing TI-124)

(LP 2

nd

pinion lower for bearing TI-125)

(LP 2

nd

pinion lower aft bearing TI-126)

80C

2

nd

wheel bearings

(2

nd

wheel fore bearing TI-127)

(2

nd

wheel aft bearing TI-128)

60C

(Main thrust bearing TI-129) 60C

Main thrust bearing

(Main thrust bearing pad TI-131) 80C

Inlet steam temperature high Thermal-switch (TI-141) Abt. 518C

Inlet steam pressure low alarm Pressure transmitter and alarm setter (PI-321)

Abt. 5.2 0.1

MPaG

LP turbine exhaust chamber high

pressure

Sentinel valve (Non contact alarm) 0.03MPaG

*1) Common use to trip function

LNGC GRACE ACACIA Machinery Operating Manual

1- 4 Part 1 Engineering Data for Main Equipment

Illustration 1.1a Main Turbine General Arrangement

Plan View

Looking From Forward

Looking From Starboard

Ahead Stop

Valve

Ahead Emergency

Operation

Generator Turbine

Exhaust Inlet

Astern Maneuvering

Valve

Astern Emergency

Operation Ahead Stop Valve

Main Thrust

Bearing

Astern Guard

Valve

L

.

P

T

u

r

b

i

n

e

(

E

x

h

a

u

s

t

)

2

n

d

R

e

d

u

c

t

i

o

n

L

.

P

T

u

r

b

i

n

e

(

E

x

h

a

u

s

t

)

2nd

Reduction

Dump Steam

Inlet

Main Condenser

Turning Gear

H.P Turbine

Ahead Emergency

Operation

Main Thrust

Bearing

Reduction Gear

Astern Guard Valve

Main Condenser

Astern Maneuvering

Valve

Gland Condenser

Control Pump Unit

Ahead Stop Valve

Main LO Pump

Gland Condenser

Astern Emergency

Operation

LNGC GRACE ACACIA Machinery Operating Manual

1- 5 Part 1 Engineering Data for Main Equipment

1.1.1 Manufacturing Specification

1. General

The turbine is the cross-compound, impulse-reaction type, consisting of the

high and the low pressure turbines and is designed to assure a high efficiency

and reliability. The high pressure is of the impulse single-flow type is which

steam enters the turbine through the ahead stop valve connected to H.P.

turbine directly, five ahead nozzle valves, five groups of the first stage

nozzles, and transfers its energy to the rotating element, i.e. two-rows Curtis

stage and seven Rateau stages, and flows to the exhaust chamber in the aft

side of the H.P. turbine. It is lead from the exhaust chamber to the low

pressure turbine through the cross-under pipe.

The low pressure turbine is of the impulse reaction single-flow type in which

steam flows toward the forward side, through the steam chest, transfers its

energy to four Rateau stages and four stages, and exhausts, into the

condenser.

The astern turbine is of the impulse type, arranged at the forward end of the

low pressure turbine, and steam enters through the astern manoeuvring valve,

astern guard valve, and transfers its energy to two-row two Curtis stages,

toward the aft side, and exhausts into the condenser. Both the high pressure

turbine and the low pressure turbine rotors are connected to the first pinions

of the reduction gear by each flexible coupling.

1) Main Turbine

(1) Casing

The high pressure turbine casing consists of the Cr-Mo steel-casted

high pressure section and the steel-casted low pressure section.

Each section has the upper and lower casings that are bolted

together through the horizontal flange. The steam chest of the

nozzle box type is welded to the forward side of the upper casing

to reduce the thermal stress.

The panting plate is provided in the lower casing so that the turbine

casing can expand freely in the forward direction from the aft end

fixed. The fixed aft end of the turbine casing is supported in such a

manner as to freely expand radically without becoming decentered.

The bearing pedestals are fixed to the lower casing at the forward

and aft ends of the turbine. Under no circumstance is the rotor and

casing decentered.

(2) Nozzle

The unit type welded nozzle are arranged for the first stage of the

high pressure turbine and the astern turbine, while the shrouded

type welded nozzles are used for other stages. The throat and the

outlet portion of the nozzle are carefully finished and the cross-

section of it is determined from the results of various kinds of

hydrodynamic tests so as to get the optimum steam flow.

While the nozzle on the H.P. turbine first stage are divided into five

groups, the steam supply to these nozzle groups is controlled by

the nozzle valve so that a most economical performance may be

obtained over an extensive operating range according to the turbine

load.

(3) Blade

The blades are milled out of the forged, rolled or the die-forged

material and their surfaces are finished with the puffed polish.

The profile of the blade is made so as to ensure high durability and

performance having done regards to the results of various kinds of

hydrodynamic tests and to the vibrational stress in the blades, etc.

The shroud bands are fitted by calking to the blade tips for guiding

the steam flow and preventing the blade vibration.

The curtis stage moving blades in the 1

st

stage of high pressure

turbine and astern turbine are provided on the infinite cascade

principle, with all the blades connected continuously by means of

shrouds, on the basis of two neighboring blades with one shroud,

360

0

in the circumferential direction. The blades in the reaction

stages of low pressure turbine (5

th

~ 8

th

stages) are provided on the

semi-infinite cascade principle with friction damper.

The blade fastenings are of X mas-tree, side-entry type in all stages

of both H.P. and L.P. turbines.

As the steam wetness at the last stage of the low pressure turbine is

high, the leading edge of the blade is stellitecoated for preventing

damage from drain.

(4) Rotor

The high pressure turbine rotor is made of the Ni-Cr-Mo-V steel

forging and the low pressure turbine rotor of the Cr-Mo steel

forging. Wheel discs are machined integral with the shaft.

(5) Diaphragm & Internal Packing

The diaphragms of the high and the low pressure turbines are

divided into the upper and lower halves at the horizontal flanges.

They are supported respectively from the upper and lower casings

thereby allowing a free expansion of the diaphragm. Furthermore,

the diaphragm is so constructed as not to cause any decentering

from such a free thermal expansion. The contact surfaces of the

upper and lower halves of the diaphragm are keyed to reduce the

steam leakage.

The part of the diaphragm where the rotor extends through is

provided with the metallic labyrinth packing to minimize the steam

leakage from stage to stage along the shaft.

The diaphragm packing for both the high and the low pressure

turbines, with the nickel-brass fin fitted and calked to the inside of

the forged steel packing rings equally divided into some sections

are fitted into the packing groove on the diaphragm and are

supported by the coil springs.

Drain catchers are provided on the low pressure stages where the

steam wetness increases, it is sp designed that only drain may be

separated and discharged out of the steam passage taking

advantage of the centrifugal force of the drain itself in the steam

flow.

(6) Gland Packing

The part of the casing where the rotor extends through is provided

with the metallic labyrinth packing to minimize the steam leakage

from the casing and the air leakage into the casing.

The packing sleeve is of forged steel or cast steel and is separated

at the horizontal plane: the packing ring with the nickel-brass fin is

fitted into the packing sleeve groove and is supported by the coil

spring or spring steel in a concentric alignment with the rotor so as

not to receive an impulse from the rotor. The rotor is provided with

the multi-row steps corresponding to the fin lengths.

Since the packing is supported by the spring, if any contact

between the rotor and the fin is occurred, it is allowed that the

packing is push away by the spring, thereby it can be escaped

outward to prevent an excessive friction and heating.

(7) Bearing

Both the high and the low pressure turbines are provided with two

journal bearings for each being lubricated by the forced lubrication

system. The bearing metal with the cast-in white metal is vertically

split at the horizontal plane.

The bearing metal is provided with the stopper screw to prevent

the bearing from rotating together with the rotation of the turbine

rotor and also with the dowel pins for setting the positions of the

upper and lower bearing metals longitudinally and athwart.

LNGC GRACE ACACIA Machinery Operating Manual

1- 6 Part 1 Engineering Data for Main Equipment

(8) Thrust Bearing

The thrust bearing is of Mitchell type, and that for the high

pressure turbine is arranged on the forward side while that for the

low pressure turbine is provided on the aft side whereby keeping

the axial clearance between the rotor and the casing constant.

With both of the high and the low pressure turbines, the thrust

bearings are vertically halved at the horizontal coupling plane for

the facility of assembly and overhaul; the turbine thrust is

transmitted to each bronze pad with the cast-in white metal and

supported through the pivot & pad stopper.

As the pivot position is dislocated a little in the rotating direction

from the centerline of each pad, a wedge oil film is easily formed

on the sliding surface during the rotation.

Between the turbine rotor and socket ring, oil seal rings are

furnished to restrict the oil leakage. Upper and lower socket rings

are fixed by the pad stopper and furnish the hasp for preventing

from rotating with rotor.

The adjusting liner is provided for adjustments of the clearances

between the thrust collar and the pads and of the axial position of

the turbine rotor.

(9) Flexible Coupling

While both the high and low pressure turbines, the fine teeth type

flexible couplings are furnished between the each turbine rotor

and the reduction gear first pinion.

Each flexible coupling sleeve is fitted to the turbine rotor flange

and to the first pinion flange by the reamer bolts and these two

sleeves are connected to each other by the claw.

The engaging parts of the sleeve teeth and of the claw teeth are

lubricated by the spray nozzle, and the oil receiver is provided on

each sleeve to get the teeth surface sufficiently oil-soaked during

the operation.

The central parts of top surface of the claw teeth are finished to a

spherical surface such as allowing a sound operation even with a

certain amount of ill alignment of the turbine rotor with the first

pinion.

2) Main Reduction Gear

The speed reducing unit between the turbine and the propeller is a

double reduction, dual tandem articulated type of reduction gear.

The reducing gear consist of two first pinions, four first gear wheels,

four second pinions and one second gear wheel.

(1) Reduction gear casing

Reduction gear casing is welded steel plate, which is split into the

upper and the lower casing at the horizontal plane including the

central axis of the second wheel. The lower casing is of double

wall construction of steel plate box type having a sufficient

rigidity.

The gas escape is furnished at the top of the main wheel cover to

exhaust oil vapour and moisture that would otherwise accumulate

in the casing whereby preventing the deterioration of lubricating

oil.

The peephole with covers core provided in adequate positions on

the casing for the inspection of the casing inside including the

gear teeth and the gear mesh lubrication.

(2) First reduction gears

The first pinion are connected through flexible coupling to the

high and the low pressure turbine shafts respectively. The first

gear wheels are of welded construction, consisting of a rim, spoke,

and shaft, connected to the second pinion through the quill shaft

and gear coupling.

(3) Second reduction gear

The second wheels are of welded construction, consisting of a rim,

spoke, and shaft and the aft-end of the shaft is connected to the

main thrust shaft.

(4) Main reduction gear flexible coupling.

The first gear wheel is connected to the second pinion through the

fine teeth type gear flexible coupling. Of each quill shaft extends

through the hollow first gear wheel and second pinion, the

forward end is connected by the key to the engaging coupling

claw and the aft end is done through the flange coupling to the

second pinion. Therefore, the turbine revolutions are transmitted

to the first gear wheels, and to the quill shaft through the coupling

claw and the sleeve, then to the aft-end of the second pinions.

The lubricating oil is supplied to the engaging coupling by the

exclusive L.O. spray nozzles.

(5) Journal bearing

Each gear is supported by two journal bearings. Each bearing, of

steel shell made through centrifugal casting of white metal, is split

at the surface place of horizontal flanges. The lubricating oil to

the journal bearings is supplied through the oil passages provided

on the upper and the lower bearing metals.

(6) Main thrust bearing

The main thrust bearing of Mitchell type, installed in a separate

casing located at the aft end of the reduction gear, transmits the

net propeller thrusts to the hull.

The Thrust pads have such a sufficient area as to fully stand the

propeller thrust, and the lubricating oil thereto is supplied through

the branch line from the oil line for main reduction gear.

(7) Turning gear

The turning gear consists of the electric motor, planetary gear and

the bevel gear, and serves to do uniform warming up and cooling

down of the turbine rotor respectively at turbine warm-up and

after turbine stop through the rotations of the turbine rotor,

besides it is also used at the inspection of the tooth surfaces of the

reduction gear.

LNGC GRACE ACACIA Machinery Operating Manual

1- 7 Part 1 Engineering Data for Main Equipment

1.1.2 Main Turbine Operation Instructions

1.1.2.1 Preparation for Start-up

1. Starting the condensing system

1) Open the sea water inlet and the outlet valve of the main condenser.

2) Start main circulating pump.

3) Ensure that the condensate level in the condenser is higher than

normal. If the level is lower, make-up distilled water is to be supplied.

4) Ensure that the suction valves for two condensate pumps are open.

These valves are to be usually kept open except when repairing the

pump. When the running pump stops, the other pump will start

automatically.

5) Start the main condensate pump with the delivery valve closed, after

the pump is started, open the delivery valve gradually.

CAUTION

After starting the condensate pump, confirm that the level control for

main condenser being in good condition.

6) Open the gland leak-off valve between the main turbine and the gland

condenser.

2. Starting the Lub. Oil system

1) Check the oil level in the oil tank by means of the oil level indicator

and the float gauge.

2) Open the delivery valves of the motor-driven auxiliary lube. oil pumps.

(The pumps can be changed over automatically)

3) Open the air valve and close the drain valve of the strainers on the

delivery side.

4) Ensure that the inlet and outlet valves of the lube. oil line for lube. oil

cooler are open.

5) Close the drain valves and open the air valves of the lube. oil coolers.

6) Set the lube. oil temperature controller to about 44C.

7) Start the motor-driven auxiliary lube. oil pump.

8) Open the sea water inlet valve and the outlet valve of the lube. oil

cooler.

9) Ensure that oil tank oil level and the overflow of the control oil tank

are normal.

10) Start the control oil pump.

11) Ensure of the overflow of the control oil tank again.

CAUTION

Check the oil pressure in normal. Normal pressure are

0.1 ~ 0.15MPa For Lubricating Oil

1.4 ~ 1.5MPa For Control Oil.

3. Warming up the Turbine

After the condensate system and the lub. oil system are started and in normal

condition, the turbines can be started.

CAUTION

Ensure that the main stop valve, ahead nozzle valves, astern

manoeuvring valve, and astern guard valve are closed.

1) Before the turning gear is engaged, the emergency device should be

checked.

2) Keep the intermediate stop valve and ahead stop valve between the

boiler and the turbine to be closed. Open up the drain valves for the

main steam strainer, high pressure steam chest, and turbine casing.

These valves are automatically kept open while in manoeuvring mode

for removal of water drain.

Then, Open up the by-pass valve gradually for the intermediate stop

valve so that the pressure in the main steam line can be kept at about

1.0MPaG in pressure and about 320 in temperature as a warming up

steam near the turbine.

CAUTION

Ensure that there is no leak from any point of piping.

3) The turning gear is to be engaged (The red lamp lights showing

engaged). Start the turning gear and confirm the turbine rotor rotated.

4) Steam is to be supplied to the turbine gland packings and the gland

exhaust fan is to be started.

Ensure that the packing steam pressure is in normal pressure about

0.01~0.02MPaG

CAUTION

While the gland packing steam is supplied, the turbine rotor should

be turned continuously.

5) Start vacuum pump after confirming the water level of separate tank

and water flow of seal water cooler, condenser vacuum is to be raised

to the rated level.

6) After the engagement of the turning gear, open the warming up steam

valve and the turbine is to be kept running for more than 60 minutes.

(This operating time depends on the turbine casing temperature ).

While the turning is going on, the main steam pipe is to be warmed up.

NOTE

The tentatively aimed condition for turbine warming up before

starting the turbine shall be as follows.

HP turbine casing in/out : abt. 200~250.

CAUTION

Ensure that turbine rotors are not rotated and cooled down from the

present when using the warming up steam for turbine warming

up.

CAUTION

After starting the turbine gear, pay attention to lubricating system,

steam system and drain lines.

7) Upon completed the turning process to warm up the turbine in

accordance with its casing temperature, the warming up system is to

be finished and close the by -pass valves associated with the

intermediate stop valves and open the stop valves gradually to the full.

CAUTION

When the ship is moved by means of a tugboat, the turning gear is

to be disengaged. If not, the turning gear will be turned and

damaged due to the idling of the propeller. During the period, lube.

oil should always be supplied.

1.1.2.2 Start-up

1. Try Engine

After the Vacuum in the condenser has reached a required level (approx. 722

mmHg) and the turbine has been turned for more than 60 minutes, the try

engine will be carried out in the following manner.

1) When all the preparations for the try engine have been made in the

engine room, a message will be sent by telephone to the bridge to that

effect.

2) Upon receipt of the message from the engine room, the bridge should

check the surroundings of vessel for safety and a go-ahead message

should be send to the engine room from the bridge.

3) After receipt of the message from the bridge room,, stop the turning

motor and disengage the turning gear (a green lamp lights upon the

control console signifying the disengaged).

LNGC GRACE ACACIA Machinery Operating Manual

1- 8 Part 1 Engineering Data for Main Equipment

4) Upon confirming that the ahead nozzle valves and astern manoeuvring

valve are completely closed, the ahead stop valves will be opened

slightly to warm up the entire ahead nozzle box including the valves.

5) Control lever on the control console will be turned to the ahead

position until the main shaft rotate.

CAUTION

Pay attention to the tachometer and ahead nozzle valves and

manoeuvring valve position indicator.

6) When the tachometer gives the sign of turbine rotation, the control

lever will be turned back to the stop position.

7) The control lever will then be turned to the astern position in the

similar manner as ahead.

8) The ahead and astern processes will be repeated several times (to

promote the warming-up of engine as well as to check for any disorder

in the engine room) pay attention to the for friction, etc., between the

stationary and the rotating parts by listening for any abnormal noise.

9) Termination of the try engine will be reported to the bridge and the

ahead stop valve will be fully opened.

NOTE

The warming up condition for the main steam piping & turbines can

be carried out and finished completely during the time schedule

control operation until MCR load, using much amount of steam flow.

10) While awaiting an order for sailing, check each equipment again for

example. Check easy equipment, such as lubricating system, cooling

water system, and other auxiliary machinery be in order or not.

11) If time is abundant before sailing and there is need for preventing

thermal deflection of turbine rotor, the auto-spinning switch on the

control console will be turned on for automatic repetition of the

ahead and astern spinning. Start of the rotor revolution can be

recognized by watching the tachometer.

CAUTION

AUTO SPINNING often have an influence of cooling down in main

turbine according to the warming-up condition at turbine.

CAUTION

Do not allow the rotors to remain stationary for longer than three

minutes after seal steam has been admitted to the gland packing.

2. Manoeuvring

1) After warming up and trying the engine several times, the speed is to

be increased gradually (Within the manoeuvring range, the number of

revolutions is automatically adjusted).

2) The speed is to be increased keeping watch over the shaft revolution

and the steam pressure.

3) Pay attention to the gland packing steam pressure when the revolution

is being changed, though the pressure is to be controlled automatically

by gland packing steam controller

3. Open-Sea Operation

1) The normal indicating lamp on the control console lights up after

the control lever and ahead nozzle valve lift is beyond predetermined

position. The drain valves around the turbine and the astern guard

valve are to be closed.

2) Turn the time schedule switch to ON.

3) Turn the control lever to the required position. The ahead nozzle

valves open automatically little by little according to the time schedule,

and the propeller revolution will reach the ordered speed.

4) Pay attention to the turbine vibration while the speed is on the increase.

Once there occurs vibration, the turbine revolution is to be reduced

slightly to find out the cause for the vibration. If it is judged that the

vibration is caused by the rotor deflection, after conticuous running for

a short period of time, the speed is to be increased gradually.

5) Ensure by the meters on the supervisory panel that the turbine is

running in rated conditions.

6) Pay attention to the lube. oil pressure and the beating temperature at

every moment.

7) Check the oil supply for the bearings by observing the each sight flow.

CAUTION

In case of emergency, the time schedule may be by-passed and the

turbine speed will be increased by operating the control lever

gradually.

4. Auto-Spinning and increasing of turbine speed

The auto-spinning is not intended for warming the turbine but for preventing

the turbine rotor from bending during a prolonged engine shut-down.

However, although the auto-spinning is carried out with a little amount of

steam, it can have the same effect as cooling the turbines of heated up. So

pay attention to turbine condition before using auto-spinning device.

The turbines must be started very carefully as the condition they were started

from cold state.

Accordingly, the turbine speed should be increased after spinning the

turbines by manual control at 10 ~ 20 rpm several times. Also, the speed

should be increased not at once but by stages as far as practicable, watching

carefully for abnormal vibration on the vibration monitor.

5. Astern Operation

Since a fewer number of stages are used in the astern turbine, the exhaust

steam temperature of the turbine is higher than ahead operation. Because of

the differences in material thickness and composition between the rotor and

casing, the exhaust casing temperature will be lower than the rotor

temperature, the rotor and stationary parts will expand differently.

Because of this differential expansion, some precautions are required when

operating astern.

Full power astern operation

1) The engine must not be operated full astern for longer than 120

minutes.

2) After prolonged full power astern running, a rapid increase in ahead

load should be avoided. The speed should be increased gradually by

using the normal time schedule (approx. 80 minutes) in the remote

control program. In no case, except in an extreme emergency, full

power ahead should be restored in less than 30 minutes, after full

power astern operation.

Following chart indicates recommended time schedule for manually

increasing speed to full ahead in 30 minutes should this be essential.

Time (minutes)

(RPM)

30 15

AST

MCR

MCR

FULL

6

Time schedule for manually increasing speed to full ahead

(crash stop and full ahead operation)

Remark : 45 rpm or more, it is recommended to use time

schedule for increasing speed.

LNGC GRACE ACACIA Machinery Operating Manual

1- 9 Part 1 Engineering Data for Main Equipment

6. Securing

1) When finished with the engine, the intermediate stop valve and the

ahead stop valve are to be closed, and make sure that ahead nozzle

valves, the astern maneuvring and the astern guard valves are tightly

closed.

2) Open all drain valves associated with the turbine. (While in

maneuvring mode, the drain valves are automatically kept open).

3) engage the turning gear and start the turning.

4) Switchover will be made from the main generator to the auxiliary

generator.

5) Stop the vacuum pump and confirm the vacuum being down in the

main condenser.

6) When the condenser vacuum drops to less than 50mmHgV, close the

gland seal steam supply valve.

CAUTION

If the gland seal is stopped while the vacuum level is not low

enough, cold air may leak into the turbine through the gland and

cause the rotor deflection.

7) Stop the condensate pump.

8) Even after the gland steam is shut off, the main circulating pump is to

be kept running until the temperature of the LP turbine exhaust being

dropped enough.

9) The turbine is to be kept turning long enough. It should be kept turning

for six hours or more. Cooling the turbine is very important for

preventing the rotor deflection. Turing is to be continued until the

turbine is cooled properly.

10) As soon as the turning is stopped, the turning gear is to be disengaged,

and then the lube oil pump is to be stopped.

11) When the ship is at anchor for a long period, the condensate in the

condenser is to be removed through the discharge valve to prevent

rusting. And to prevent the steam from leaking into the interior of the

turbine, the main steam strainer drain valve before the ahead nozzle

control valve is to be kept open and the other drain valves is to be kept

closed manually with a handle.

12) when the turbine is stopped for a short period of time, continue the

turning until the next departure with operating the lube oil pump and

maintaining the condenser vacuum at least approximately 700mmHgV.

In this case, the turbine may be started immediately for departure

according to the turbine casing temperature.

13) When the condensate pump stops, close the valve for condensate

recirculating system of the main condenser.

LNGC GRACE ACACIA Machinery Operating Manual

1- 10 Part 1 Engineering Data for Main Equipment

1.2 Main Boilers

1.2.1 Main Boilers Planning Data

1. Performance Data

Boiler Type MB-4E-KS

Oil Firing

LOAD B.MAX 100%NOR 75% NOR 50% NOR 25% NOR

Total kg/h 70,000 53,000 40,000 27,000 14,000

SH Steam kg/h 68,000 52,000 39,000 26,000 13,000 Evaporation

DSH Steam kg/h 2,000 1,000 1,000 1,000 1,000

Drum MPa 6.8 6.47 6.28 6.14 6.06

Steam

Press

SH Oulet MPa 6.03 6.03 6.03 6.03 6.03

Eco. Inlet C 145.0 145.0 145.0 145.0 145.0

SH Inlet C 285 282 280 278 277

SH Outlet C 515 515 507 482 442

Water &

Steam

Temperature

DSH Oulet C 293 288 288 288 288

FDF Oulet C 38 38 38 38 38

Air Temp

SAH Oulet C 120 120 120 120 120

Efficiency (HHV Base) % 88.5 88.5 88.3 87.7 85.7

HHV MJ/kg 43.04 43.04 43.04 43.04 43.04

Calorific

Value

LHV MJ/kg 40.68 40.68 40.68 40.68 40.68

Fuel Oil Consumption kg/h 5,021 3,808 2,856 1,894 961

Excess Air Rate % 10.0 10.0 12.5 19.2 36.0

O2 Rate % 1.9 1.9 2.3 3.4 5.6

Combustion Air Flow kg/h 76,905 58,324 44,735 31,434 18,201

Flue Gas Flow kg/h 81,926 62,132 47,591 33,328 19,162

Eco Outlet Gas Temp C 174 169 165 161 157

Total Draft Loss kPa 4.93 2.83 1.66 0.82 0.27

Gas Firing

LOAD B.MAX 100% NOR 75% NOR 50% NOR 25% NOR

Total kg/h 70,000 53,000 40,000 27,000 14,000

SH Steam kg/h 68,000 52,000 39,000 26,000 13,000 Evaporation

DSH Steam kg/h 2,000 1,000 1,000 1,000 1,000

Drum MPa 6.8 6.47 6.28 6.14 6.06

Steam Press

SH Outlet MPa 6.03 6.03 6.03 6.03 6.03

Eco. Inlet C 145.0 145.0 145.0 145.0 145.0

SH Inlet C 285 282 280 278 277

SH Outlet C 515.0 515.0 515.0 515.0 479

Water & Steam

Temperature

DSH Outlet C 293 288 288 288 288

FDF Outlet C 38 38 38 38 38

Air Temp

SAH Outlet C 120 120 120 120 120

Efficiency (HHV Base) % 83.9 84.0 83.9 83.3 81.5

HHV MJ/kg 55.56 55.56 55.56 55.56 55.56

Calorific Value

LHV MJ/kg 50.09 50.09 50.09 50.09 50.59

Fuel Gas Consumption kg/h 4,123 3,125 2,358 1,595 812

Excess Air Rate % 10.0 10.0 12.5 19.2 36.0

O2 Rate % 1.9 1.9 2.3 3.4 5.6

Combustion Air Flow kg/h 79,062 59,916 46,234 33,133 19,253

Flue Gas Flow kg/h 83,185 63,041 48,591 34,727 20,065

Eco Outlet Gas Temp C 178 171 166 161 156

Total Draft Loss kPa 5.08 2.92 1.73 0.88 0.3

LNGC GRACE ACACIA Machinery Operating Manual

1- 11 Part 1 Engineering Data for Main Equipment

2. Steam, Air & Electric Consumption

Air Consumption (per one boiler)

Equipment Name Supply Air Consumption Operating Condition

A.C.C. (Actuator) 0.9MPa 120 Nl/min Continuous

F.W.R. (Actuator) 0.9MPa 50 Nl/min Continuous

Boiler Flame Eye Sealing 7.4kPa 150 x 6 = 900 Nl/min Continuous

Soot Blower Scavenging 5.5kPa 78 x 10 = 780 Nl/min Continuous

Soot Blower Sealing 5.5kPa 220 x 10 = 2,200 Nl/min Continuous

Steam Consumption (per one boiler)

Equipment Name Supply Steam Consumption Operating Condition

Soot Blower 6.03MPa 110 kg/min/set

Soot Blower Operation

(Operate Time : 15 min)

Burner 0.8MPa 180 kg/h Max. Consumption

Steam Air Heater 0.59MPa 2,992 kg/h Boiler Maximum

F.O. Heater 1.9MPa 908 kg/H Boiler Maximum

Electric Consumption (per one ship)

Equipment Name Supply Power Consumption Operating Condition

Boiler Control Panel 220V 30 A Continuous

Forced Draft Fan 440V 300 A Continuous

Fuel Oil Service Pump 440V 36 A Continuous

LNGC GRACE ACACIA Machinery Operating Manual

1- 12 Part 1 Engineering Data for Main Equipment

3. Alarm & Trip List

Set Point

No. Description

Alarm Trip Nor

Timer

186B Drum Level Ex High +240 mm -

185B Drum Level Very High F.W. Motor Valve Close +220 mm 10 sec