Académique Documents

Professionnel Documents

Culture Documents

Tick Ener

Transféré par

EDUARDO0 évaluation0% ont trouvé ce document utile (0 vote)

45 vues4 pagesCopyright

© © All Rights Reserved

Formats disponibles

XLS, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme XLS, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

45 vues4 pagesTick Ener

Transféré par

EDUARDODroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme XLS, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

Rev: 0

1 Rev DESIGN DATA

2 MATERIAL

3 Description: Physical Characteristics:

4 Specific Gravity of Feed: Solid Liquid Slurry pH of Feed

5 Material Temp ( F ) Normal Maximum Minimum Settling Rate (tons/hr)

6 Solids in Overflow (By Wt.): (ppm) Normal Maximum Method of Determination of Settling

7 Viscosity (cP) : Feed Overflow Underflow Solids in Underflow (%)

8 Sieve Size Profile ( % Cumulative Retained )

9 Mesh Size

10 %

11 LOCATION, SITE AND OPERATING CONDITIONS

12 Ambient temperature Min Max (F)

13 Electrical class.: CL Gr Div Relative humidity Min Max

14 Wind Pressure (psia) Elevation (ft)

15 Environment: Operation: Accessibility

16 Operating schedule: ( hr/day ) Days/Year No. Starts per Hour No. Starts per Day

17 CAPACITY AND POWER REQUIREMENTS

18 Solids Feed Rate (tons/hr) Normal Design Liquid Feed Rate (tons/hr)

19 Overflow Rate (tons/hr) Underflow Rate (tons/hr) Floc/Conc.of Floc (oz/USgal)

20 THICKENER PROFILE

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43 DIMENSIONS

44 A B D H h R Z

45

46

47

48

DATE BY CHK'D APP'D

Plant/Area: Equip. No:

ADL Doc. No: ENG-DAT-000105

WO #: Equip. Name:

Client:

DATA SHEET

Project: THICKENER

SKETCH IS AN EXAMPLE - ALTERNATE SKETCHES MAY BE SELECTED

OR MODIFIED FROM ATTACHED PAGES

REVISION LOG

REV: DESCRIPTION

Launder

Feed Well

Discharge Nozzle (Typ)

Overflow

Slope (Z)

Drain

A

R R

D

h

H

B

Indoor Outdoor Heated Unheated

Winterization Required Tropicalization Required

Toxic Corrosive Flammable Continuous Intermittent

Source Doc: DS.131.0041US.CAL.R00 Page 1 of 4

Rev: 0

Plant/Area: Equip. No:

ADL Doc. No: ENG-DAT-000105

WO #: Equip. Name:

Client:

DATA SHEET

Project: THICKENER

1 Rev CONSTRUCTION

2 TANK

3 Inside Diameter (ft) Inside Wall Height (ft) Manufacturer

4 Inside Center Depth (excl. disch. cone) (ft) Type Size

5 Slope on Bottom () Rating: Mech. / Thermal (hp) /

6 RAKE ASSEMBLY RPM (Input / Output) /

7 Manufacturer Service Factor Overload Torque (lb-ft)

8 No. of Arms Slope of Arms ( ) Worm wheel Pitch Dia (in)

9 RPM of Arms Vertical Adjustment Worm wheel Face Width (in)

10 Method of Attachment to Center Shaft No. of Teeth on Worm wheel

11 Removable Reduction Ratio

12 No. of Blades No. of Cone Scrapers

13 Slope of Scrapers () Material Thickness Weight

14 Operating Torque (lb-ft) Overload Torque (lb-ft) (in) (lb)

15 Automatic Lift Torque (lb-ft) Tank

16 Clearance bet'n Blade and Bottom Rake Arms

17 Vertical Stub Shaft Diameter (in) Scraper Blades

18 FEED WELL Feed Well

19 Type Discharge Cone

20 Diameter (in) Depth (in) Worm wheel

21 Trash Screen Included Feed Well Liner

22 DISCHARGE CONE Disch. Cone Liner

23 Diameter at Top (in) Height (in) Drive Housing

24 Outlet Diameter (in) No. of Outlets Vertical Stub Shaft

25 Slope ()

26 RAKE ASSEMBLY

27 MOTOR DRIVE

28 Manufacturer Manufacturer

29 Type Size ( hp ) RPM Type Size ( hp ) RPM

30 Frame Enclosure S.F. / P.F. / Frame Enclosure S.F. / P.F. /

31 Insul Class Starter Type Insul Class Starter Type

32 Rating Excitation Voltage Rating Excitation Voltage

33 Torque Indicator Overload Alarm

34 COUPLING COUPLING

35

36 Manufacturer / / Manufacturer / /

37 Type / Size / / Type / Size / /

38 Basic Rating / S.F. / / Basic Rating / S.F. / /

39 Max / Min Bore Dia(in) / / Max / Min Bore Dia(in) / /

40 V-BELT DRIVE

41 Manufacturer Manufacturer

42 Belt Section Type Belt Rating (hp/Belt) Belt Section Type Belt Rating (hp/Belt)

43 S.F. No. Belts Req'd S.F. No. Belts Req'd

44 Centre Distance (in) Belt Length (in) Centre Distance (in) Belt Length (in)

45 Belt Speed (ft/s) V-Belt Guard Belt Speed (ft/s) V-Belt Guard

46 SHEAVES SHEAVES

47 Manufacturer Manufacturer

48 Speed Ratio No. of Grooves Speed Ratio No. of Grooves

49 Outside Dia. Driver / Driven (in) / Outside Dia. Driver / Driven (in) /

50 Bore Dia. Driver / Driven (in) / Bore Dia. Driver / Driven (in) /

51 Hub Type: Driver / Driven / Hub Type: Driver / Driven /

52

53

Low Speed High Speed

DRIVE HEAD ASSEMBLY

MATERIALS

LIFTING DEVICE

MOTOR DRIVE

V-BELT DRIVE

Low Speed High Speed

Yes No

Yes No

Source Doc: DS.131.0041US.CAL.R00 Page 2 of 4

Rev: 0

Plant/Area: Equip. No:

ADL Doc. No: ENG-DAT-000105

WO #: Equip. Name:

Client:

DATA SHEET

Project: THICKENER

1 Rev RAKE ASSEMBLY (cont)

2 CHAIN DRIVE CHAIN DRIVE

3 Manufacturer Manufacturer

4 Chain Type / ANSI No.: / Chain Type / ANSI No.: /

5 Ultimate Strength ( lb ) No. of Strands Ultimate Strength ( lb ) No. of Strands

6 Pitch (in) Pitch (in)

7 SPROCKETS SPROCKETS

8 Manufacturer Manufacturer

9 Outside Dia. Driver / Driven (in) / Outside Dia. Driver / Driven (in) /

10 Bore Dia. Driver / Driven (in) / Bore Dia. Driver / Driven (in) /

11 Hub Type: Driver / Driven / Hub Type: Driver / Driven /

12 No. of Teeth: Driver / Driven / No. of Teeth: Driver / Driven /

13 Speed Ratio Speed Ratio

14 SPEED REDUCER

15 Manufacturer Manufacturer

16 Type Size Efficiency Type Size Efficiency

17 Rating: Mech. / Thermal (hp) / Rating: Mech. / Thermal (hp) /

18 S.F. RPM: Input / Output / S.F. RPM: Input / Output /

19

20 UTILITIES

21 Water Quantity ( Usgal/min ) Pressure (psig)

22 Water Quality Electric (kW)

23 Plant Air Quantity ( ft3 /h) Pressure (psig)

24 Instrument Air ( ft3 /h) Pressure (psig)

25 Steam Quantity ( ft3 /h) Pressure (psig)

26 Other

27 NOTES

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

SPEED REDUCER

LIFTING DEVICE (cont)

Source Doc: DS.131.0041US.CAL.R00 Page 3 of 4

Launder

Feed Well

Drain

Discharge Nozzle (Typ)

Overflow

Slope (Z)

A

R R

D

h

H

B

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Differentiation Questions and AnswerDocument10 pagesDifferentiation Questions and AnswerNazurah Kamaruzzaman KamariPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Reciprocating CompressorDocument6 pagesReciprocating CompressorEDUARDOPas encore d'évaluation

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document12 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDOPas encore d'évaluation

- Steam BoilerDocument10 pagesSteam BoilerEDUARDOPas encore d'évaluation

- Spectral FFT Max Ms PDocument17 pagesSpectral FFT Max Ms Phockey66patPas encore d'évaluation

- Screw ConveyorDocument5 pagesScrew ConveyorEDUARDO100% (3)

- 830 CB 120 M07 - Rev0Document1 page830 CB 120 M07 - Rev0EDUARDOPas encore d'évaluation

- 2 0 Tdi SSPDocument90 pages2 0 Tdi SSPmicol53100% (1)

- Durban Classic Cover + Caposide in One Side (Shougang Project)Document4 pagesDurban Classic Cover + Caposide in One Side (Shougang Project)EDUARDOPas encore d'évaluation

- 5720 D E DWG 0201 - RevADocument4 pages5720 D E DWG 0201 - RevAEDUARDOPas encore d'évaluation

- Chapter7 DigitalData 2Document217 pagesChapter7 DigitalData 2orizaPas encore d'évaluation

- 10th Class-Maths Text Book-NewDocument400 pages10th Class-Maths Text Book-NewVishnu Muddasani100% (1)

- 5 - WQU - 622 CTSP - M5 - CompiledContentDocument34 pages5 - WQU - 622 CTSP - M5 - CompiledContentJoe NgPas encore d'évaluation

- Mechanical Data Sheet Pressure Vessel: GeneralDocument2 pagesMechanical Data Sheet Pressure Vessel: GeneralEDUARDOPas encore d'évaluation

- Data Sheet: Description Unit Design DataDocument1 pageData Sheet: Description Unit Design DataEDUARDOPas encore d'évaluation

- Data Sheet: Description and Site ConditionsDocument2 pagesData Sheet: Description and Site ConditionsEDUARDOPas encore d'évaluation

- Data Sheet: DescriptionDocument6 pagesData Sheet: DescriptionEDUARDOPas encore d'évaluation

- 820 CB 120G WM25 - Rev0Document1 page820 CB 120G WM25 - Rev0EDUARDOPas encore d'évaluation

- Plate ExchangerDocument2 pagesPlate ExchangerEDUARDOPas encore d'évaluation

- 820 CB 120G WM26 - Rev0Document1 page820 CB 120G WM26 - Rev0EDUARDOPas encore d'évaluation

- Rotary Compressor API 619Document26 pagesRotary Compressor API 619EDUARDO25% (4)

- Dry CobbingDocument1 pageDry CobbingEDUARDOPas encore d'évaluation

- Mine Operation Expansion Project and Benefit PlantDocument10 pagesMine Operation Expansion Project and Benefit PlantEDUARDOPas encore d'évaluation

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDOPas encore d'évaluation

- Mine Operation Expansion Project and Benefit PlantDocument10 pagesMine Operation Expansion Project and Benefit PlantEDUARDOPas encore d'évaluation

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.09.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.09.2014EDUARDOPas encore d'évaluation

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDOPas encore d'évaluation

- Schedule Levels - Major Projects: Core Scheduling Papers: #6Document5 pagesSchedule Levels - Major Projects: Core Scheduling Papers: #6EDUARDOPas encore d'évaluation

- 5921 D E DWG 0205 - RevADocument6 pages5921 D E DWG 0205 - RevAEDUARDOPas encore d'évaluation

- Sewagw Treatment FilterDocument1 pageSewagw Treatment FilterEDUARDOPas encore d'évaluation

- MixerDocument2 pagesMixerEDUARDOPas encore d'évaluation

- Datasheet ECM 5158 Interface 4pgv1 A80401 PressDocument4 pagesDatasheet ECM 5158 Interface 4pgv1 A80401 Presslgreilly4Pas encore d'évaluation

- ACT Geometry - PolygonsDocument8 pagesACT Geometry - PolygonsaftabPas encore d'évaluation

- Cytomat Software InformationDocument34 pagesCytomat Software InformationCarlosReisPas encore d'évaluation

- CELLSDocument21 pagesCELLSPhia LhiceraPas encore d'évaluation

- Noise in Fiber Optic Communication LinksDocument14 pagesNoise in Fiber Optic Communication Linksian.maximillianPas encore d'évaluation

- A Presentation OF Vocational Training On Combined Cycle Power PlantDocument20 pagesA Presentation OF Vocational Training On Combined Cycle Power PlantramezhosnyPas encore d'évaluation

- Ap Computer Science A Course OverviewDocument2 pagesAp Computer Science A Course Overviewbaojia chenPas encore d'évaluation

- AnswerDocument51 pagesAnswersamPas encore d'évaluation

- Metoda Securiti Pada DNP3 ProtokolDocument16 pagesMetoda Securiti Pada DNP3 ProtokolDeny AriefPas encore d'évaluation

- Chapter 3Document21 pagesChapter 3aloneirPas encore d'évaluation

- Huaweigpon PDFDocument1 pageHuaweigpon PDFRobPas encore d'évaluation

- Data StructuresDocument2 pagesData StructuresRavi PalPas encore d'évaluation

- User AgentDocument2 pagesUser AgenthuongPas encore d'évaluation

- Flatpack2 IntegratedDocument2 pagesFlatpack2 IntegratedNeil BailliePas encore d'évaluation

- Supertester 680 RDocument39 pagesSupertester 680 Rdomingos.sanchezPas encore d'évaluation

- A Lightweight Secure Data Sharing SchemeDocument7 pagesA Lightweight Secure Data Sharing SchemeGopi KrishnaPas encore d'évaluation

- Dosing Technology: eco-CONTROL EC200-KDocument2 pagesDosing Technology: eco-CONTROL EC200-KMario Vargas VegaPas encore d'évaluation

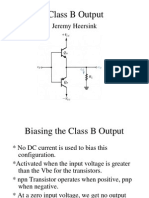

- Class B Output: Jeremy HeersinkDocument10 pagesClass B Output: Jeremy Heersinkdummy1957jPas encore d'évaluation

- Experiment 6Document11 pagesExperiment 6CarlosLorenzoSaninPas encore d'évaluation

- 03 - Random Effect ModelDocument10 pages03 - Random Effect ModelAdji Pelangi SaputriPas encore d'évaluation

- BBBBBDocument11 pagesBBBBBAlfredo ErguetaPas encore d'évaluation

- Mobile Communications: Chapter 4: Wireless Telecommunication SystemsDocument108 pagesMobile Communications: Chapter 4: Wireless Telecommunication Systemsradislamy-1Pas encore d'évaluation

- Sr. Grand Test Key and HintsDocument7 pagesSr. Grand Test Key and HintsM JEEVARATHNAM NAIDUPas encore d'évaluation