Académique Documents

Professionnel Documents

Culture Documents

TB019P Concrete Intersections - A Guide For Design and Construction

Transféré par

Gonzalo PradoDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TB019P Concrete Intersections - A Guide For Design and Construction

Transféré par

Gonzalo PradoDroits d'auteur :

Formats disponibles

Concrete Intersections

A Guide for Design and Construction

CONCRETE

PAVINGTechnology

Introduction

Traffic causes dam age to pavem ent of at-grade street

and road intersections perhaps m ore than any other

location. H eavy vehicle stopping and turning can

stress the pavem ent surface severely along the

approaches to an intersection. The pavem ent w ithin

the junction (physical area) of an intersection also m ay

receive nearly tw ice the traffic as the pavem ent on the

approaching roadw ays.

At busy intersections, the added load and stress from

heavy vehicles often cause asphalt pavem ents to

deteriorate prem aturely. Asphalt surfaces tend to rut

and shove under the strain of busses and trucks

stopping and turning. These deform ed surfaces

becom e a safety concern for drivers and a costly

m aintenance problem for the roadw ay agency.

C oncrete pavem ents better w ithstand the loading and

turning m ovem ents of heavy vehicles. As a result,

city, county and state roadw ay agencies have begun

rebuilding deteriorated asphalt intersections w ith con-

crete pavem ent. These agencies are extending road

and street system m aintenance funds by elim inating

the expense of intersections that require frequent

m aintenance.

At-grade intersections along business, industrial and

arterial corridor routes are som e of the busiest and

m ost vital pavem ents in an urban road netw ork.

C losing these roads and intersections for pavem ent

repair creates costly traffic delays and disruption to

local businesses. C oncrete pavem ents provide a long

service life for these m ajor corridors and intersections.

2

C oncrete pavem ents also offer other advantages for

intersections:

1. Low long-term m aintenance costs.

2. N o softening or deterioration caused by oil drippings.

3. G ood light reflectivity that enhances pedestrian and

vehicle safety at night and in inclem ent w eather.

4. A durable and skid resistant surface.

Successful construction of concrete intersections is

challenging, especially in urban areas, w here accom -

m odating traffic and adjacent business needs often

m ust supersede other engineering or construction

factors. H ow ever, m odern technology, including fast-

track construction, sim plifies these challenges.

Design Considerations

W hen building or rebuilding an intersection, the new

concrete pavem ent should cover at least the entire

functional area of the intersection. The functional area

includes the longitudinal lim its of any auxiliary lanes

(Figure 1).

(1,2)

N orm ally, the distress caused by heavy

vehicles braking and turning w ill occur w ithin an inter-

sections functional boundaries.

As a rule, it is im portant to evaluate the existing pave-

m ent condition before choosing lim its for the new

concrete pavem ent. O n busy routes, it m ay be desir-

able to extend the lim its for the new concrete pave-

m ent beyond the intersections functional boundaries.

Traffic congestion at a busy intersection m ay extend

the distance w here vehicles start and stop, w hich

m ay extend the length of distressed pavem ent. The

length that pavem ent distress extends beyond the

intersections functional boundaries w ill depend upon

the num ber, speed, and type of vehicles that use the

intersecting roadw ays. A sim ilar extension of dis-

tress is possible w here trucks cause dam age w hile

accelerating slow ly up a steep grade aw ay from an

intersection.

If significant changes to an intersection are required, it

is ideal to extend the new pavem ent to the bound-

aries of the intersections new functional area. Traffic

patterns change w ith m odifications to an intersec-

tions through-lanes, auxiliary lanes, and acceleration

and deceleration tapers. Therefore, the location

w here vehicles cause dam age also m ay change from

the location in the existing intersection configuration.

As a standard, som e agencies extend the new con-

crete pavem ent, from 30-60 m (100-200 ft) on each

leg of the intersection for all traffic lanes. O thers

extend the new pavem ent approaching the intersec-

tion farther than the new pavem ent leaving the inter-

section. In these cases, the concrete lanes

approaching the intersection m ay begin 60-120 m

(200-400 ft) from the intersections physical area, w hile

lanes leaving the intersection term inate about 15 m

(50 ft) beyond the physical area. For intersections

carrying m oderate traffic volum es and a low percent-

age of heavy vehicles, 15-30 m (50-100 ft) of new

pavem ent is usually sufficient to replace the distressed

pavem ent.

Concrete Slab Thickness

B ecause an intersections physical area carries traffic

from both roadw ays, the concrete slab thickness in

the physical area of the intersection m ay need to be

greater than the thickness on either approaching

roadw ay. The need for extra thickness w ill depend

upon the roadw ay or street classification and the aver-

age daily truck traffic (AD TT) that each route carries. Figure 1. Physical and functional areas of an intersection.

3

R eference 3 defines six roadw ay (street) classifica-

tions. These classifications depend upon traffic vol-

um e, vehicle type(s) and m axim um axle loading.

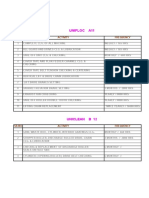

Table 1 describes these classifications.

D esigners should consider increasing the slab thick-

ness for at-grade intersections of industrial and arterial

roadw ays. The physical area w ill likely require 12-25 m m

(0.5-1.0 in.) of additional thickness (see Table 2 next

page).

W hen traffic w arrants extra concrete thickness in the

intersections physical area, it is generally easier to

change the thickness at a location before the radii for

the intersection. The slabs near the intersections radii

are built using fixed form s and separate hand-pours in

m ost cases. A transition length of about 1-2 m (3-6 ft)

for changing the thickness is usually adequate. The

decision on precisely w here to change thickness

should be left to the contractor. R equiring the transi-

tion to be at a specific location m ay com plicate con-

struction and conflict w ith other job site factors, such

as providing access to adjacent businesses.

At-grade intersections of light residential, residential,

collector, and business roadw ays should not require

any extra concrete thickness in the physical area. The

intersection thickness should be the sam e as the

thicker of the tw o approaching roadw ays.

J ointing

Joint design is arguably the m ost im portant design

aspect for concrete pavem ent intersections. At-grade

intersections often introduce jointing challenges that

do not exist along tangent sections of concrete road-

w ay- or street-pavem ents. H ow ever, these com plica-

tions can be overcom e by applying sim ple jointing

fundam entals.

Table 1. Street Classifications

(3)

.

Street Class Description Two-way Two-way Typical

Average Daily Average Daily Range of Slab

Traffic Truck Traffic Thickness

(ADT) (ADTT)

Light R esidential Short streets in subdivisions Less than 200 2-4 100-125 m m

and sim ilar residential areas -

often not through-streets. (4.0-5.0 in.)

R esidential Through-streets in subdivisions 200-1,000 10-50 125-175 m m

and sim ilar residential areas

that occasionally carry a heavy (5.0-7.0 in.)

vehicle (truck or bus).

C ollector Streets that collect traffic from 1,000-8,000 50-500 135-225 m m

several residential subdivisions,

and that m ay serve buses and (5.5-9.0 in.)

trucks.

B usiness Streets that provide access to 11,000-17,000 400-700 150-225 m m

shopping and urban central

business districts. (6.0-9.0 in.)

Industrial Streets that provide access to 2,000-4,000 300-800 175-260 m m

industrial areas or parks, and

typically carry heavier trucks (7.0-10.5 in.)

than the business class.

Arterial Streets that serve traffic from 4,000-15,000 300-600 150-225 m m

m ajor expressw ays and carry (m inor) (6.0-9.0 in.)

traffic through m etropolitan

areas. Truck and bus routes 4,000-30,000 700-1,500 175-275 m m

are prim arily on these roads. (m ajor) (7.0-11.0 in.)

4

Joints are necessary prim arily to control the location of

cracks that occur from natural actions on concrete

pavem ent. W hen designed correctly, joints accom m o-

date the expansion and contraction of concrete slabs

caused by tem perature fluctuations, and account for

stresses that develop from slab curling and w arping.

(6)

D uring construction, joints also divide the pavem ent

into suitable placem ent increm ents or elem ents for the

contractor. C ertain joints also accom m odate slab

m ovem ent against fixed structures.

For at-grade intersections, a designer should consider

three m ajor joint design elem ents: joint spacing, joint

type, and joint layout. Each factor can influence the

long-term perform ance of the pavem ent. In addition,

other factors to consider include: dow el bars for load

transfer, tiebars for tying lanes, and sealing joints*.

J oint Spacing For unreinforced concrete pave-

m ent, joint spacing or slab length depends upon slab

thickness, concrete aggregate, subbase, and cli-

m ate.

(6,7)

In m ost areas, the typical m axim um trans-

verse joint spacing for unreinforced (plain) pavem ent is

about 4.5 m (15 ft). Longitudinal joints on tw o-lane

and m ultilane street pavem ents are typically about

3.0-4.2 m (10-13 ft) apart, and serve the dual pur-

pose of crack control and lane delineation.

Equation 1 determ ines the m axim um allow able joint

spacing based on slab thickness and subbase type.

Slabs kept to dim ensions shorter than the equation

determ ines w ill have curling and w arping stresses w ith-

in safe lim its to ensure m inim al risk of random cracking:

M L = T x C S (Eq. 1)

w here:

M L = M axim um length betw een joints

(See N otes 1 and 2).

T = Slab thickness (Either m etric or English units).

C S = Support constant.

U se 24; for subgrades or granular subbases.

U se 21; for stabilized subbases, or existing

concrete or asphalt pavem ent (for conventional

overlays).

U se 12-15; for ultra-thin overlays of asphalt

(See N ote 3).

*If local experience indicates that it is necessary, joints should

be sealed to minimize infiltration of water and incompressible

particles. The effectiveness of joint sealing depends upon the

sealant type, installation technique, maintenance, concrete prop-

erties and joint configuration. For pavements with joints spaced

less than 4.5 m (15 ft), the impact of the sealant on pavement

performance is not as critical as it is for longer spacing. The

impact of joint sealing on pavement performance also may be

more noticeable in urban areas and Northern climates if pave-

ments carry heavy traffic and receive sand or salt applications

for snow and ice control. See Reference 8 for more details on

joint sealing techniques and materials.

Notes:

1. The spacing of transverse joints in plain (unreinforced)

concrete pavement should not exceed 6 m (20 ft) for slabs

less than 250 mm (10 in.) thick.

2. A general rule-of-thumb requires that the transverse joint

spacing should not exceed 150% of the longitudinal joint

spacing. This ratio is difficult to maintain within intersec-

tions due to islands, medians, auxiliary lanes and curved

areas, and can be disregarded in favor of common-sense

jointing patterns to accommodate these elements within

the intersection.

3. The spacing of transverse and longitudinal joints in ultra-

thin overlays range from 0.6 to 2.0 m (2 to 6 ft) depending

upon overlay thickness, support conditions, and lane width.

Intersecting Intersecting Physical Area Thickness*

Roadway 1 Roadway 2

Low AD TT (T1) Low AD TT (T2) T2

Low AD TT (T1) H igh AD TT (T3) T3

H igh AD TT (T3) H igh AD TT (T3) T3 + 25-50 m m **

Table 2. Slab thickness considerations for the physical area of at-grade intersections. Note that in this

table, thickness T3 is greater than T2, and T2 is greater than T1.

* Assumes thickness (T1, T2 or T3) for intersecting roadways based on anticipated traffic and

calculated in a rational design procedure such as that of AASHTO

(4)

or PCA

(3,5)

.

** The AASHTO thickness design procedure(4) shows that doubling the traffic loading requires about an

additional 25 mm (1 in.) of concrete pavement thickness. The PCA design procedure

(3,5)

shows that

an extra 12 mm (0.5 in.) of slab thickness is required when doubling traffic.

5

The clim ate and concrete aggregate com m on to som e

geographic regions m ay allow transverse joints to be fur-

ther apart, or require them to be closer together than

Equation 1 determ ines. For exam ple, concrete m ade

from granite and lim estone coarse aggregate is m uch

less sensitive to tem perature change than concrete

m ade from siliceous gravel, chert, or slag aggregate. A

less-tem perature-sensitive concrete does not expand or

contract m uch w ith tem perature change, w hich allow s a

longer spacing betw een pavem ent contraction joints

w ithout any greater chance of random cracking.

H ow ever, unless experience w ith local conditions and

concrete aggregates indicates otherw ise, use Equation 1

to determ ine the m axim um allow able transverse joint

spacing for unreinforced pavem ents.

A transverse joint spacing up to 9 m (30 ft) is allow able

for pavem ents reinforced w ith distributed steel reinforce-

m ent. The purpose of distributed steel is to hold to-

gether any interm ediate (m id-panel) cracks that w ill

develop in the long panels betw een transverse joints.**

D istributed steel neither adds to the load-carrying

capacity of the pavem ent nor com pensates for poor

subgrade conditions.

J oint Types There are three basic joint types for

concrete pavem ents: contraction, construction and iso-

lation. Specific design requirem ents for each type

depend upon orientation to the direction of the roadw ay

(transverse or longitudinal). M ost concrete intersections

w ill require each of the three joint types in both longitudi-

nal and transverse orientations. Figure 2 (page 6) pro-

vides cross-sections detailing each type.

Transverse J oints - Transverse contraction joints

run transverse to the pavem ent centerline and are

essential to control cracking from stresses caused by

shrinkage, therm al contraction, and m oisture or therm al

gradients. Typically these joints are at a right angle to

the pavem ent centerline and edges. H ow ever, som e

agencies skew transverse contraction joints to decrease

the dynam ic loading across the joints by elim inating the

sim ultaneous crossing of each w heel on a vehicles

axle.

(6,7)

R ight-angle transverse contraction joints are

preferable to skew ed joints for concrete intersections

because they do not create com plex jointing patterns

w ithin the intersections physical area. Skew ing joints is

not a substitute for the load transfer provided by dow els.

The need for dow els (sm ooth round bars) in transverse

contraction joints depends upon the roadw ay or street

classification. U ndow eled contraction joints (Type A-1,

Fig. 2) are usually sufficient for light residential, residen-

tial, or collector pavem ents. Industrial and arterial

streets that w ill carry heavy truck traffic for long periods

require dow eled contraction joints (Type A-2, Fig. 2).

(7)

D ow eled contraction joints are also necessary in pave-

m ents w ith distributed steel reinforcem ent, and should

be considered for slabs longer than 6 m (20 ft). Table 3

provides recom m ended dow el sizes.

Transverse construction joints (Type B -1, C -1, Fig. 2) are

necessary at the end of a paving segm ent, or at a place-

m ent interruption for a drivew ay or cross road. A dow -

eled butt joint (Type B -1) is preferable, and should be

used w henever the construction joint w ill correspond to

the location of a contraction joint or construction joint in

an adjacent lane. Som etim es it is not feasible to m atch

the location of a transverse joint in the adjacent lane,

w hich necessitates use of a tied construction joint (Type

C -1). The deform ed tiebars in a Type C -1 joint prevent

the joint from opening and causing sym pathy cracking in

adjacent lane(s).

** Pavements with distributed steel are often called jointed

reinforced concrete pavements (JRCP). In JRCP, the joint

spacing is purposely increased and reinforcing steel is used

to hold together intermediate cracks. If there is enough dis-

tributed steel within the pavement (0.10 to 0.25% per cross-

sectional area), the mid-panel cracks do not detract from the

pavements performance.

(9)

However, if there is not enough

steel, the steel can corrode or rupture and the cracks can

start to open and deteriorate.

Table 3. Dowel sizes for plain pavements and pavements

reinforced with distributed steel.

*Assumes thickness is based on anticipated traffic and is

calculated in a rational design procedure such as that of

AASHTO

(4)

or PCA

(3,5)

.

Slab Thickness Dowel Diameter Dowel Length

mm (in.) mm (in.) mm (in.)

Plain (unreinforced) Pavem ents*

<200 (<8) not necessary not necessary

200-249 (8-9.9) 32 (1.25) 450 (18)

250 (10) 38 (1.50) 450 (18)

D istributed Steel R einforced Pavem ents

150 (6) 20 (0.75) 360 (14)

165 (6.5) 22 (0.875) 360 (14)

180 (7) 25 (1.00) 400 (16)

190 (7.5) 28 (1.125) 400 (16)

200-249 (8-9.9) 32 (1.25) 450 (18)

250 (10) 38 (1.50) 450 (18)

6

Figure 2. Cross sections of different joint types.

7

Longitudinal J oints - Longitudinal contraction joints

(Type A-3, A-4, Fig. 2) also are necessary to control

cracking from stress caused by concrete volum e

changes and m oisture or therm al gradients through

the concrete. These joints run parallel to the pave-

m ent centerline and usually correspond to the edge of

a driving lane. O n tw o-lane and m ultilane pavem ents,

a spacing of 3.0 to 4.0 m (10 to 13 ft) serves the dual

purpose of crack control and lane delineation.

For unusual or special locations, such as ram ps and

turning areas betw een m edian islands, the m axim um

recom m ended slab w idth (distance betw een longitudi-

nal contraction joints) is 4.5 m (15 ft). H ow ever, this

m ay be excessive for thinner slabs, in w hich case

Equation 1 should be used to determ ine the m axi-

m um allow able longitudinal joint spacing.

The need to tie longitudinal contraction joints w ill

depend upon the degree of lateral restraint available

to prevent the joints from opening perm anently. M ost

longitudinal contraction joints on roadw ay tangent

sections contain #13M or #16M (N o. 4 or N o. 5)

deform ed reinforcing bars.

The deform ed bars are

usually about 600-750 m m (24-30 in.) long and are

spaced at 750-1000 m m (30-40 in.) intervals. W here

there are curbs on both sides of the pavem ent, it m ay

not be necessary to tie the joints unless local experi-

ence indicates otherw ise.

Longitudinal construction joints (Type B -2, C -2, Fig. 2)

join pavem ent lanes that are paved at different tim es.

C oncrete intersections require these joints because of

the num erous pours necessary to place pavem ent

around islands and m edians, and betw een the curves

connecting the tw o roadw ays.

The optional keyw ay for a tied longitudinal construc-

tion joint can be difficult to construct correctly in thin

pavem ents. Therefore, som e agencies avoid placing

keyw ays in slabs less than 250 m m (10 in.) thick.

(7)

Keyw ay shear failures can occur in thin slabs w hen

keyw ays are too large or too close to the slab sur-

face. Som e contractors report that half-round key-

w ays are easier to construct and less prone to prob-

lem s than trapezoidal keyw ays. W here a keyw ay is

deem ed necessary, the dim ensions indicated in Figure 3

w ill afford the optim um load-transfer perform ance.

Isolation J oints - Isolation joints (Type D , Fig. 2) are

essential at asym m etrical and T-intersections to isolate

the side road from the through street (Figure 4).

Isolation joints also are needed w here the pavem ent

abuts certain m anholes, drainage fixtures, sidew alks,

aprons, and structures. C ertain agencies and con-

tractors also prefer to use isolation joints at cross-

road intersections. W here used, the isolation joint w ill

For very wide roadways, there is a limit to width of pave-

ment that can be tied together without concern for cracking.

Current recommendations

(7)

limit the tied width of highway

pavement to about 14.5 m (48 ft) based on the subgrade drag

theory. However, there has been good field performance of

certain intersections with up to 21 m (70 ft) of tied pavement.

If local-experience records are not available for intersection

design, consider using an untied contraction joint (Type A-3)

or construction joint (Type C-2) near the centerline of roadway

sections that exceed 14.5 m (48 ft).

Figure 3. Keyway standard dimensions.

Figure 4. Asymmetrical and T-intersections that require

isolation joints.

8

allow independent m ovem ent of the pavem ent and

the structure, w ithout any connection that could

cause dam age. To be effective the preform ed com -

pressible filler should m eet the requirem ents of

ASTM

D 1751, D 1752, or D 994, and m ust cover

the entire depth of the concrete slab.

At asym m etrical or T-intersections, undow eled, thick-

ened-edge or sleeper-slab isolation joints (Type D -1 or

D -3, Fig. 2) are preferable to dow eled isolation joints,

because they each perm it independent lateral m ove-

m ent of the through-street concrete slabs. The

sleeper slab and thickened edge designs each pro-

vide im proved support to com pensate for the

absence of dow el bars. For a thickened edge joint,

the abutting edges of the concrete slabs should be 20%

thicker at the joint and taper back to the nom inal

thickness over about 1.5 m (5 ft).

At locations inaccessible to heavy vehicle loads, such

as those betw een a pavem ent and a structure, a

thickened-edge joint is not necessary. A butt joint

w ith a non-extruding, preform ed com pressible m aterial

is adequate.

For utility fixtures such as m anholes, catch basins and

drainage inlets, the need for isolation w ill depend

upon the casting design and potential for differential

m ovem ent. N on-telescoping m anholes w ith ribbed

cylinder w alls usually require a boxout w ith a perim e-

ter isolation joint to allow independent vertical and

horizontal slab m ovem ent. C om m on square boxouts

som etim es cause cracks to form at the boxouts cor-

ners. To avoid crack-inducing corners, consider using

rounded boxouts or placing fillets on the corners of

square boxouts. It is advantageous to place w elded-

w ire fabric or sm all-diam eter reinforcing bars in the

concrete pavem ent around any interior corners at

square boxouts to hold cracks tightly should they

develop. Figure 5 show s details for boxing out in-

pavem ent fixtures.

In som e circum stances, boxing out fixtures m ay be

undesirable. For instance, boxouts can im pede fast-

track construction because m ore tim e is needed to

place concrete around the casting after the pavem ent

gains strength. It is also very difficult to m aintain a

uniform joint pattern if there are too m any m anholes

random ly-positioned in an intersection. In these

cases it m ay be best to cast the fixtures into the con-

crete.

To isolate a fixture w ithout a boxout, som e contractors

and agencies w rap the casting w ith pliable expansion

joint filler or suitable bond breaker. If no differential

ASTM is now the official name of the organization originally

called the American Society for Testing and Materials.

Equivalent Canadian standards for all ASTM standards and

tests addressed in this publication are found on page 28.

Figure 5. Details for boxing out fixtures.

Notes: 1. Isolation joints should be at least 12 mm (1/2 in.) wide and filled with a compressible material.

2. Boxouts should be large enough to provide at least 0.3 m (1 ft) clearance between the fixture and the surrounding isolation joint.

9

m ovem ent is expected the m anhole can be cast

directly into the concrete. Telescoping m anhole fix-

tures have a tw o-piece casting, w hich allow s vertical

m ovem ent.

C oncrete pavem ent perform ance suffers if the pave-

m ent contains too m any transverse expansion (isola-

tion-type) joints. O utdated specifications som etim es

require expansion joints spaced uniform ly along tan-

gent sections. These joints create m aintenance prob-

lem s because nearby transverse contraction joints

open excessively as the expansion joint closes gradu-

ally over tim e. The open contraction joints then lose

load transfer, and develop distresses like faulting and

pum ping. Transverse expansion joints at regular inter-

vals m ay be needed w hen:

1. The pavem ent is divided into long panels [18 m (60 ft)

or m ore] w ithout contraction joints in-betw een.

2. The pavem ent is constructed w hile am bient tem -

peratures are below 4C (40F).

3. The contraction joints are allow ed to be infiltrated

by large incom pressible m aterials.

4. The pavem ent is constructed of m aterials that in

the past have show n high expansion characteristics.

In m ost situations, these criteria do not apply.

Therefore transverse expansion joints should not nor-

m ally be used.

J oint Layout A w ell-designed joint layout con-

tributes to good long-term perform ance of at-grade

intersections. A good jointing plan w ill ease construc-

tion by providing clear guidance to the contractor. It

is com m on practice for som e designers to leave inter-

section joint layout to the field engineer and contrac-

tor. These designers often justify this practice by cit-

ing the m any field adjustm ents that occur during con-

struction, w hich they contend negates the usefulness

of a jointing plan. H ow ever, it is not desirable to elim i-

nate the jointing plan entirely, except for very sim ple

intersections. A jointing plan and appropriate field

adjustm ents are both im portant for m ore com plex

intersections, because islands, m edians, and auxiliary

turning lanes com plicate joint layout and require som e

forethought before construction. A plan also enables

contractors to bid new projects m ore accurately.

D uring construction, it is likely that location changes

w ill be necessary for som e joints w ithin an intersec-

tion. The prim ary reason is to ensure that joints pass

through em bedded fixtures such as m anholes or

drainage inlets. It is com m on for the actual location

of m anholes or drainage inlets to vary from the loca-

tion show n on the plans. It w ill be necessary for the

construction crew to adjust the location of som e joints

during construction so that they coincide w ith the

actual location of a nearby m anhole or inlet. The

designer should consider placing a note on the plan

to give the field engineer and contractor the latitude to

m ake appropriate adjustm ents. R eference 10 pro-

vides a ten-step m ethod for laying out joints for con-

crete intersections.

Another im portant aspect of laying out intersection

joints is determ ining w here to use dow el bars or

tiebars near the intersections physical area. Figure 6

(page 10) show s exam ples of dow el and tiebar use in

intersections.

Phasing Construction

Phasing is alm ost alw ays a key elem ent of intersec-

tion construction plans. The need for a refined phas-

ing plan depends upon the need to m aintain traffic

flow through the intersection during construction.

There are four basic construction staging options:

com plete closure w ith detours, partial closure w ith

detours, com plete closure during tim e-w indow s, and

construction under traffic.

Intersections of rural or other low -traffic roadw ays do

not usually require the sam e level of consideration as

is necessary for intersections that carry high volum es

of traffic. C losing low -traffic intersections for the dura-

tion of construction is often the optim al solution and

should alw ays be considered. In som e cases, the

availability of convenient alternate routes (e.g., front-

age roads) m ay even perm it closing an intersection

that carries a high traffic volum e w ithout significant

concern for traffic flow or business disruption.

For the contractor, com plete closure is ideal.

C om plete closure elim inates com plex w ork-zone lane

configurations, w hich increases the safety of the con-

struction w ork zone. C om plete closure also allow s the

contractor to place m ore pavem ent in a continuous

operation, generally increasing pavem ent sm oothness,

im proving quality, and reducing construction tim e.

C om pletely closing an intersection for construction

requires developing a detour plan. C lear and under-

10

Figure 6. Use of dowel bars and tiebars in intersections

11

standable signing along the detour route w ill m ake the

detour m ore acceptable to m otorists. A sign indicat-

ing the date w hen the intersection w ill re-open also

can im prove public relations.

U nfortunately, closing intersections for the entire con-

struction period is often not viable along urban arterial

or corridor routes. For exam ple, the lack of traffic

over an extended period m ight cause businesses near

the closure to lose custom ers. In these circum -

stances one option is to lim it com plete intersection

closure to non-business hours. If it is feasible to

divert traffic around the intersection, even for a few

hours, the contractor can com plete critical construc-

tion phases quickly and expedite the entire project.

Som e agencies develop phasing plans that allow

com plete intersection closure during specific periods

(w indow s). U sually the w indow w ill begin at about 6

p.m . and last until about 6 a.m . the follow ing m orning.

The starting and ending tim e depends upon the local

rush-hour traffic pattern. W ithin the w indow the con-

tractor m ay close and occupy the entire intersection.

At the end of the w indow public traffic m ust be able

to use the intersection. In this m anner, the closure w ill

not hinder m orning, evening, or daytim e traffic flow .

U nder tim e-w indow phasing plans, contractors per-

form each sequential construction operation during

successive tim e-w indow s. For exam ple, if the project

includes rem oval of an existing pavem ent, the con-

tractor m ay place a tem porary pavem ent after rem ov-

ing the existing m aterial during one 12-hour w indow .

The tem porary pavem ent carries traffic until the con-

tractor rem oves it to pave the new concrete roadw ay

in a subsequent tim e w indow .

Another option to avoid closing an entire intersection

is to close one leg of the intersection at a tim e. This

is often feasible for intersections betw een residential

and collector streets. D etours along the closed resi-

dential street are usually short and not a burden to

local residents.

O n som e roadw ays, it m ay be unacceptable to close

the entire intersection at any tim e. M any agencies

have had good success replacing busy intersections

w ith concrete pavem ent w hile m aintaining norm al traf-

fic volum es. Figure 7 show s possible options for

phasing construction under traffic.

Figure 7. Possible options for phasing construction under traffic.

12

These options m ay reduce the num ber of available

through-lanes and m ay som ew hat lim it turning m ove-

m ents during construction. H ow ever, the degree of

these restrictions depends upon the num ber of lanes

on the approaching roadw ays. N one m ay be neces-

sary if the approaching roadw ays have at least three

through lanes in each direction. A detour for one leg

of the intersection or special alternating traffic signals

w ill be necessary if one or both of the approaching

streets has just one lane in each direction.

C onstruction under traffic can generally start on any

leg of an intersection. H ow ever, if an intersection

includes a m ajor road and a m inor cross road, the dri-

ving lanes of the m ajor roadw ay usually are built

before the cross road. C oncentrating on the m ajor

roadw ay pavem ent generally produces a sm oother-

riding intersection. After the m ajor roadw ay pavem ent

lanes are finished, other pavem ent areas are built

w ithout affecting the sm oothness through the inter-

section. This m ethod also is usually m ore productive

because the contractor can place m ore pavem ent in a

continuous operation w ithout gaps or changes in the

pavem ent w idth.

Quality Concrete Mixtures

A suitable concrete m ixture is necessary to ensure the

success of the construction phasing plan. W hether

the contractor or agency determ ines the concrete

m ixture proportions, the concrete m ust be capable of

m eeting strength requirem ents reliably w ithin any

specified tim e w indow s for construction, and m ust

have adequate long-term durability. The contractor

should have som e latitude to adjust the m ixture pro-

portions during construction if the m ixture does not

w ork properly for the required construction phasing

plan. B efore construction, contractors also m ay offer

valuable suggestions or value-engineering options to

expedite construction.

Strength C om pressive strength testing (ASTM C

39) is the m ost com m on and easiest w ay to evaluate

concrete strength. C oncrete w ith a 28-day com pres-

sive strength averaging 20-30 M Pa (3000-4000 psi) is

adequate for m ost intersections. D uring construction

the pavem ent m ay be opened to traffic at a strength

som ew hat less than the 28-day target value (see

page 22).

Som e highw ay agencies use flexural strength (ASTM

C 78) as the structural strength criterion to evaluate

load capacity. Flexural strength provides an assess-

m ent of the tensile strength at the bottom of the slab

w here w heel loads induce tensile stresses. H ow ever,

problem s casting and testing beam specim ens dis-

courage m any engineers and contractors from this

test m ethod.

Durability Strength is not a reliable m easure of

concretes durability. In frost-affected areas, a con-

crete pavem ent m ust be able to w ithstand m any

cycles of freezing and thaw ing and the effects of deic-

ing salts. This requires quality aggregate, a low

w ater-cem entitious m aterial ratio, an adequate

cem ent factor, and a sufficient quantity of entrained air

bubbles. The percentages of total air content neces-

sary for w eather-resistant concrete are show n in Table 4.

These recom m endations vary depending upon the

exposure condition of the concrete. Adequate curing

m easures also are necessary for developing durable

concrete pavem ent.

In addition to m aking the hardened concrete pave-

m ent w eather resistant, entrained air bubbles im prove

the concrete w hile it is still in a plastic state by:

1. R educing w ater required for satisfactory w orkability.

2. Preventing segregation.

3. R educing bleeding.

Table 4. Recommended* total air contents.

(11)

* Canadian standards differ, refer to CSA Standard A23.1.

** A tolerance of -1% to +2% is typical for paving concrete.

*** Severe exposure is an environment where concrete pavement is

exposed to wet freeze-thaw conditions or deicers. Moderate

exposure is an environment where concrete pavement is exposed

to freezing but will not be continually moist, exposed to water for

long periods before freezing, or in contact with deicers. Mild

exposure is an environment where concrete pavement is not

exposed to freezing conditions or deicers.

Nominal

Maximum Target** Percentage

Aggregate Air Content for Exposure

Size

mm (in.) Severe*** Moderate*** Mild***

50 (2) 5 4 2

37.5 (1-1/2) 5.5 4.5 2.5

25 (1) 6 4.5 3

19 (3/4) 6 5 3.5

12.5 (1/2) 7 5.5 4

9.5 (3/8) 7.5 6 4.5

13

B ecause of these beneficial and essential effects in both

plastic and hardened concrete, it is w ise to consider

using entrained air even in m ild exposure conditions.

The quantity of w ater in the m ixture also has a critical

influence on the durability and w eather resistance of

hardened concrete.

(11)

For a given quantity of cem en-

titious m aterials, a low er quantity of w ater w ill produce

a m ore durable m ixture in m ost cases. H ow ever, an

adequate quantity of w ater is necessary to produce a

w orkable concrete. Satisfactory pavem ent durability

is generally achieved w ith:

1. A w ater-cem entitious m aterial ratio not exceeding

0.53 w ith a m inim um cem entitious m aterial con-

tent of 310 kg/m

3

(520 lb/yd

3

) for m ild exposure

conditions.

2. A w ater-cem entitious m aterial ratio not exceeding

0.49 w ith a m inim um cem entitious m aterial con-

tent of 330 kg/m

3

(560 lb/yd

3

) for m oderate-to-

severe exposure conditions (frequent freezing and

thaw ing, and application of deicing agents).

C areful aggregate selection is im portant to avoid

future problem s w ith alkali aggregate reactions or D -

cracking. C oarse or fine aggregates that are suscep-

tible to alkali-silica or alkali-carbonate reactivity require

special m ixture proportions to produce durable con -

crete. M any agencies specify special m ixtures w hen

using locally available aggregates know n to have

reactivity potential. It is also possible to test a pro-

posed concrete m ixture to determ ine if there is reac-

tivity potential. For m ore inform ation refer to

R eferences 12 and 13.

Fast-track Concrete Mixtures Fast-track

concrete m ixtures develop strength rapidly and are

beneficial w hen early opening of the pavem ent is nec-

essary. For intersections, there are several practical

options available to produce concrete that gains

strength rapidly. The m ixture com ponents can be

selected or proportioned for rapid strength gain, and

the m ixture w ater can be heated so cem ent hydration

begins quickly.

Although proprietary cem ents are available, fast-track

m ixtures do not necessarily require these special

m aterials. R apid strength developm ent is possible by

using greater-than-norm al quantities of ordinary ASTM

C 150 Type I and Type II cem ents. H igh-early-

strength, ASTM C 150 Type III, cem ent is also com -

m only available. M ost aggregates and adm ixtures

available locally also can be used in fast-track m ix-

tures if com bined in the proper proportions.

(14,15)

Table 5 show s typical fast-track m ixture proportions.

The sooner the concrete tem perature rises, the faster

it w ill develop strength. O ne w ay to raise the tem per-

ature of plastic concrete is to heat the m ix w ater. This

m ay be practical for intersection projects that do not

require a large quantity of concrete.

Several factors influence the w ater tem perature need-

ed to produce a desirable m ixture tem perature at

placem ent. The critical factors are: am bient air tem -

perature, aggregate tem peratures, aggregate free-

m oisture content, and portland cem ent type. W hen

necessary, ready-m ix concrete producers heat w ater

to 60-66C (140-150F) to elevate m ixture tem pera-

ture sufficiently for cool-w eather construction. The

sam e practice w ill accelerate strength developm ent in

w arm er am bient tem peratures. H ow ever, to avoid a

flash set using this m ethod, com bine the hot w ater

and aggregates before adding the cem ent to the con-

crete m ixer.

(14)

Though hot w ater does facilitate early cem ent hydra-

tion, its benefits m ay be short-lived. Several hours of

heat containm ent w ith insulating blankets m ay be

necessary to achieve the desirable strength gain, par-

ticularly w hen cool w eather conditions prevail.

Table 5. Typical fast-track mix proportions.

(14)

Material Type Quantity

*

C em ent ASTM C 150 415-475 kg/m

3

Type I (700-800 lb/yd

3

)

ASTM C 150 415-475 kg/m

3

Type II (700-800 lb/yd

3

)

ASTM C 150 360-450 kg/m

3

Type III (600-750 lb/yd

3

)

Fly ash ASTM C 618 10-20% by w eight

of cem ent

W ater ASTM C 94 (See note below )

Air-entraining ASTM C 260 As necessary

adm ixture

Accelerating ASTM C 494 As necessary

Adm ixture

W ater-reducing ASTM C 494 As necessary

adm ixture

* Use quantity of water appropriate to produce sufficient workability

and maintain desired strength gain. Water-cementitious material

ratio should not exceed 0.37 - 0.43 under most circumstances.

14

Mixtures for Thin Overlays The concrete m ix-

ture for thin overlays is often selected based on

requirem ents for opening to traffic. A norm al thin-

overlay m ixture includes: cem ent, coarse and fine

aggregate, air-entraining agent, adm ixtures (w ater-

reducers or plasticizers), fibers (as specified), and a

low w ater-cem entitious m aterials ratio. C om pared to

aggregate used for thicker concrete pavem ents, the

top-size of coarse aggregate for ultra-thin w hitetop-

ping

(16)

is reduced appropriately for the thin pavem ent.

W hen fibers are used in an ultra-thin m ixture, the fiber

contents are usually in the range appropriate for the

specific fiber type, although on som e projects higher-

than-norm al dosages have been used.

Construction

Various m ethods and m achines are used to build con-

crete pavem ent intersections, including slipform and

fixed-form construction equipm ent. U nlike m ainline

roadw ay paving, intersection construction w ork usual-

ly necessitates som e use of fixed-form placem ent.

C ontractors m ay elect to use slipform equipm ent in

an intersection if the paving area is large enough to

w arrant its use, or if staging allow s the contractor to

build the driving lanes of the m ajor roadw ay through

the physical area of the intersection.

D espite the variety of possible equipm ent, the follow -

ing construction steps are typical for nearly all types of

concrete pavem ent.

1. R em oving or planing an existing pavem ent (w here

necessary).

2. Preparing the grade.

3. Setting form s (w here used).

4. Placing in-pavem ent objects (dow els, tiebars and

boxouts, w here used).

5. Placing and finishing the concrete.

6. Texturing the pavem ent surface.

7. C uring the concrete.

8. Jointing the pavem ent.

Removing or Planing Existing

Pavement

The first step in the com plete reconstruction of an

intersection is to rem ove the existing pavem ent. The

options for rem oving existing asphalt include: cold

m illing, scarifying, and excavating the m aterial w ith

equipm ent such as a front-end loader or bulldozer.

C old m illing offers productivity and suitable grade

control. C old m illing equipm ent uses carbide teeth

m ounted on a rotary drum . The teeth chip aw ay

existing asphalt as the drum rotates. The size of the

broken m aterial depends upon the tooth configura-

tion, drum rotation speed, forw ard m achine-speed,

and rem oval depth. Particle size also varies w ith the

tem perature, condition, and asphalt content of the old

hot-m ix asphalt. The ability to control particle size is

helpful w hen the asphalt m illings are reused on the

project for fill or subbase.

Attaining the desired rem oval depth m ay require sev-

eral m illing passes. C om m only available m achines

can rem ove 150 m m (6 in.) of asphalt m aterial in one

pass.

Scarifying or ripping is also com m on for rem oving thin

layers of existing asphalt. This m ethod uses m otor-

graders or bulldozers equipped w ith scarifying equip-

m ent. W hile scarifying is less expensive than cold

m illing, there is also less ability to control rem oval

depth or grade. N evertheless, scarifying equipm ent is

adequate w hen the rem oval goes below the depth of

all asphalt layers.

There also are three m ethods for rem oving existing

concrete or com posite pavem ents:

1. B reak the concrete into sm all fragm ents for

rem oval by backhoe and hand tools.

2. Lift the concrete out of place in large segm ents.

3. Scarify the concrete w ith large m illing m achines.

At urban intersections, the optim al m ethod depends

upon the size of the intersection, the allow able tim e

for rem oval, the land use in the surrounding area, and

concerns about noise and dust generation. The pres-

ence of sensitive utility pipes, conduits, or cables

beneath the pavem ent also m ay discourage use of

equipm ent that im parts im pact vibrations. In general,

the selection of the m ost productive rem oval m ethod

should be left to the contractor based on experience

and available equipm ent.

If an existing asphalt intersection w ill receive a con-

crete pavem ent overlay, rem oval of the existing

asphalt should stop short of the subbase or sub-

grade. B ecause cold m illing offers excellent grade

15

control, it is the best choice for rem oving controlled

layers of existing asphalt pavem ents. The rough sur-

face from m illing also provides an excellent bonding

surface for the overlay.

(16,17)

For ultra-thin w hitetop-

ping, an overlay less than 100 m m (4 in.) thick, cur-

rent recom m endations

(16)

suggest that at least 75 m m

(3 in.) of asphalt thickness rem ain after m illing to get

the benefits of com posite action.

Preparing the Grade

A reasonably uniform subgrade or subbase, w ith no

abrupt changes in support, is ideal for any concrete

pavem ent. Achieving this condition after pavem ent

rem oval operations w ill require som e effort even in the

relatively confined w ork area of an intersection. The

first step is to ensure that the subgrade soils are of

uniform m aterial and density.

C om pacting the subgrade surface adequately requires

a com pactor heavy enough to achieve 95 percent of

ASTM D 698 density. H ow ever, it m ay be difficult to

m aneuver large com pactors in a trench created by

rem oving an older pavem ent for an intersection. A

m ore effective strategy in a confined area m ay be to

apply m ore com paction effort using sm aller equip-

m ent.

The soil m oisture content should be reasonably uni-

form during com paction; excessively w et or dry spots

require correction to produce reasonable uniform ity.

For m ost soils, com paction should be done at m ois-

ture contents at or slightly above optim um .

Soft spots in the subgrade often becom e visible after

rem oving an old pavem ent. It is not acceptable to

m erely place a granular layer over these soft areas;

excavation is necessary to rem ove the suspect soils.

Ideally, the replacem ent soil should be of the sam e

type as in the surrounding subgrade to develop uni-

form support.

C ontractors m ust pay particular attention to sections

of the subgrade overlying any utility installations such

as sew ers, telephone and pow er conduits and w ater

lines. C areless com paction of fill m aterials in these

trenches often causes soft spots in the subgrade.

C ontrolled low -strength fill (flow able-fill) m aterials are

an econom ical alternative for these areas.

Flow able-fill m aterials do not need com paction and

flow easily to fill a trench. The m ixtures contain port-

land cem ent, sand, fly ash and w ater and typically

develop 28-day com pressive strengths of about 0.35-

0.70 M Pa (50-100 psi). Flow able-fill m aterials provide

enough strength to prevent settlem ent, but are easy

to rem ove using a bucket on a backhoe or front-end

loader if future excavation is necessary.

Subbase A subbase is a thin layer of granular

m aterial placed on top of the prepared subgrade.

Subbases provide uniform support to the pavem ent

and a stable platform for construction equipm ent.

Subbases also help prevent m ud-pum ping of fine-

grained subgrade soils at transverse pavem ent joints

in roads subject to a large volum e of unidirectional

truck traffic. Intersections at residential streets and

even som e streets that m ay carry heavier vehicles

usually do not require a subbase.

W here used, the granular subbase thickness generally

should not exceed 100 to 150 m m (4 to 6 in.). A

thicker subbase is not necessary or econom ical under

m ost conditions. G ood dense-graded, granular-sub -

base m aterials have a plasticity index of 6 or less, and

contain a m axim um of 15 percent fine particles that

pass the 75 (N o. 200) sieve. For stability, the sub-

base requires com paction to 100 percent of ASTM D

698 density.

Perm eable subbases w ith drainage system s are gen-

erally unnecessary for urban pavem ents, because in

m any cases, the presence of curbs and gutters w ith

Compacting subbase against existing curb and gutter after

removing existing pavement.

16

inlets to a m unicipal storm sew er system w ill ade-

quately rem ove surface w ater. Perm eable subbases

have becom e popular am ong state highw ay depart-

m ents for draining concrete highw ay pavem ents.

These subbases either m ay be untreated or stabilized

w ith portland cem ent or asphalt. To be effective, a

perm eable subbase requires a collector pipe and outlet

system to discharge w ater aw ay from the pavem ent.

Trimming The m ethod for trim m ing or shaping

the grade varies by project and m ay depend upon

intersection size. Typical specifications

(18)

require:

1. A subgrade surface that does not vary from the

design elevation by m ore than 12 m m (0.5 in.).

2. A granular subbase surface w ith deviations that

do not exceed 12 m m (0.5 in.), longitudinal or

transverse, by a 3 m (10 ft) straightedge.

O n large intersections, contractors m ay use autom atic

trim m ing equipm ent to shape the subbase or sub-

grade and deposit any excess m aterial outside the

paving area. For fixed-form paving, the autom atic

trim m ing m achine rides on the form s after they are

fastened into place. For slipform paving, the trim m ing

m achine references the stringline(s) for the slipform

paving m achine.

O n sm all projects and in confined w ork zones it m ay

not be practical to use autom atic trim m ing equipm ent,

and the contractor w ill probably trim the grade w ith a

m otor grader or sm all loader.

B ecause final trim m ing disturbs the subgrade or sub-

base surface slightly, additional com paction rolling is

usually necessary.

Placing Forms

Fixed-form paving is alm ost alw ays necessary for the

short paving segm ents, varying paving w idths, and

curved paving areas com m on to intersections.

Form placem ent at intersections does not vary m uch

from form placem ent along straight pavem ent sections.

Straight sections require standard 3 m (10 ft) steel form s

that fasten to the subgrade w ith three pins or stakes. A

stringline set to the top elevation of the pavem ent deter-

m ines the location and height for the form s. A stake

spacing for the stringline of about 7.5 m (25 ft) w ill pro-

duce good results for straight sections.

(19)

Each straight m etal form m ust be clean, and in

acceptable condition to produce a sm ooth pavem ent.

C ontractors should exam ine form s w ith a straightedge

or stringline before using the form s on a project.

Straight form sections that deviate by m ore than 3 m m

(0.125 in.) along the top, or 6 m m (0.25 in.) along the

inside edge should be replaced.

The quality of the support beneath the form depends

upon the trueness of the subgrade or subbase surface.

The base of the form should bear against the subbase

or subgrade surface com pletely and not lie on any

clum ps of dirt or large rocks. After setting the form s, the

form crew should visually check to ensure the form s are

aligned and fully supported, and also to be sure the form

ends are locked together securely. Adequately securing

form s also is crucial because the form s m ust support

equipm ent and rem ain in place until the concrete has

hardened. For ease of rem oval and cleaning, form s

require a thin application of oil before paving.

Standard 3 m (10 ft) straight form s are acceptable for

form ing com pound-radius curves and curve radii

exceeding 30 m (100 ft), but sm aller radii require

curved steel or flexible w ooden form s.

(19)

Short,

1.5-m (5-ft), straight form s also produce acceptable

results on curves less than 30 m (100 ft).

(20)

C urved sections require a tighter stringline staking

interval than straight sections. To ensure the form s

m eet the design location and surface elevation, a

stringline staking interval of 1.5 m (5 ft) is ideal for

curve radii less than 15 m (50 ft). Additional bracing

Forms should rest on a level surface, and should be fastened

securely and pinned in place.

17

is also som etim es necessary to secure form s around

sm aller curves; w here necessary a bracing interval of

0.6 m (2 ft) is usually sufficient.

Placing In-Pavement Objects

Ideally, in-pavem ent objects should be in position

before placing the concrete. This includes utility box-

outs, cast-in-place fixtures, traffic signal handholds,

dow el assem blies (baskets), tiebars, and w elded w ire

fabric. H ow ever, in som e cases it is necessary for the

contractor to use the prepared grade to haul concrete

to the paving equipm ent, requiring placem ent of fix-

tures as w ork progresses.

C ontraction-joint dow el assem blies should be fas-

tened to the subbase using steel staking pins for

granular m aterials or nailing clips for stabilized m ateri-

als. C are in positioning the baskets is necessary so

that the dow els align w ith the pavem ent centerline. A

perm anent m ark indicating the location of the dow el

baskets is necessary for reference w hen later saw ing

the contraction joints.

In som e cases for longitudinal joints, contractors elect

to place tiebars into position ahead of paving.

Straight deform ed bars on supporting chairs fasten to

the subbase or subgrade in a m anner sim ilar to dow el

baskets. In fixed-form construction, standard

deform ed tiebars or tw o-piece bars w ith a threaded

coupling m ay be inserted through holes in side form s

for longitudinal construction joints.

C ast-in-place utility fixtures and boxout form s that are

w ithin the paving area should be in position and

secured before paving. For either fixed-form or slip-

form paving, the boxouts top surface m ust be about

12 m m (0.5 in.) below the finished height of the slab.

This allow s a paver or screed to pass over the boxout

w ithout problem s, and eases surface shaping to pro-

vide proper drainage.

The tw o-piece casting of a telescoping m anhole has

several height positions. A position that places the

castings surface below the pavem ent surface also

allow s the paver or screed to pass. Just after the

paving equipm ent passes over the fixture, w orkers

m ust raise the casting into final position from a con-

struction bridge that spans the pavem ent.

Large-diam eter [up to 1270-m m (50-in)] coring equip-

m ent is another available option, w hich reduces con-

struction preparation tim e. The equipm ent can core

concrete around existing or planned m anholes and

elim inate the need to place utility boxouts before

paving.

In N orthern regions, consideration should be given to

leaving m anholes 6-12 m m (0.25-0.5 in.) below the

pavem ent elevation to ensure that snow plow s do not

catch on the m anhole lids.

Placing the Concrete

R egardless of placing equipm ent, the paving steadi-

ness im pacts the finished pavem ent sm oothness and

quality.

(19)

C onsistent delivery of concrete to an inter-

section project site is an im portant elem ent. D ense

urban areas require careful evaluation to predeterm ine

w hether traffic delays w ill ham per concrete delivery.

C onsideration of the concrete m ixture is also neces-

sary, w ith norm al-setting m ixtures allow ing longer trav-

el tim es than fast-track m ixtures.

G ood batch-to-batch consistency of the concrete

also im proves the quality of the finished pavem ent.

B atch-to batch consistency allow s the paving

m achine operator to m aintain the paver at a steady

forw ard speed, and produces uniform extrusion pres-

sure. B oth stationary (ready m ix) plants and on-site

batching and m ixing plants can produce concrete

w ith consistent properties.

B efore placing concrete, m oisten the subbase or sub-

grade surface. A dry surface m ay absorb w ater from Dowels, tiebars and utility fixtures in position for fixed-form paving.

18

the concrete and lead to unw anted shrinkage cracking

in the pavem ent. For larger paving areas, a w ater

truck is generally available for this purpose. R eady-m ix

trucks also have a tank that can supply the w ater nec-

essary to m oisten the subgrade in sm all paving areas.

W hen placing a concrete overlay on a m illed asphalt

surface, no m oistening is norm ally necessary. U ltra-

thin concrete overlays [overlays less than 100 m m

(4 in.)] w hich rely on bond to the asphalt, require a dry

surface. H ow ever, thick overlays, w hich do not rely

on bond, m ay require w hitew ashing to cool a dark

asphalt surface. The need for w hitew ash depends

upon the am bient and asphalt-surface tem perature.

M ore inform ation on w hitew ash is available in

R eference 17.

Fixed-Form There are a variety of fixed-form

paving m achines. The less com plex equipm ent such

as hand-operated and self-propelled vibratory

screeds, single-tube finishers and revolving triple

tubes are useful for alm ost all com plex paving

areas. The external (surface) vibration that this equip-

m ent produces is adequate to consolidate m ost pave-

m ent slabs. H ow ever, supplem entary internal vibra-

tion w ith hand-operated spud vibrators is usually nec-

essary for adequate consolidation of non-reinforced

concrete slabs thicker than 250 m m (10 in.). A com -

bination of internal- and surface-vibration is preferable

for reinforced slabs at any thickness.

(11)

B ecause sur-

face vibration of concrete is least effective near the

form s, it is beneficial to consolidate concrete along

the form s w ith a spud vibrator.

Larger, form -riding m achines can place and consoli-

date the concrete betw een form s in one pass. These

m achines either ride on the form s or pipes laid out-

side the form s. Since form -riding paving equipm ent

cannot produce acceptable results riding on w ooden

form s, m ost of the curved areas joining intersecting

pavem ents require use of hand-placem ent equipm ent,

such as vibratory or roller screeds.

Evenly depositing concrete onto the grade in front of

the fixed-form placem ent m achine eases paving.

Piling too m uch concrete in front of the m achine leads

to strikeoff difficulty. The concrete should not overly

exceed the height of the form s. H ow ever, piling too

little concrete in front of the m achine m ay produce

low spots in the pavem ent surface. Although it is

ideal to distribute the concrete evenly w ith the chute

from the ready m ix or other concrete hauling truck,

som e distribution of the concrete w ith hand tools is

usually necessary. Shovels are preferable to other

hand tools for this purpose, because they do not

cause concrete segregation.

W hen necessary, supplem ental vibration w ith hand-

held spud vibrators should precede the placem ent

screed. Standard practice for thicker slabs calls for

vertical plunges of the vibrator head. For thin slabs, it

is preferable to insert the vibrator head at an angle or

horizontally to keep it com pletely im m ersed in the

concrete. O perators should neither drag spud vibra-

tors through the concrete nor attem pt to m ove the

concrete laterally, as either w ill segregate the m ixture.

(A) Vibrating screed, (B) Roller screed, (C) Form-riding paver.

A

B

C

19

In general, proper consolidation of air-entrained con-

crete takes less tim e than non air-entrained concrete,

even w hen both m ixtures are prepared w ith the sam e

consistency (slum p). The vibration tim e necessary to

achieve adequate consolidation also depends upon

the size and type of vibrator. For m ost equipm ent,

leaving the vibrator head inserted for 5 to 15 seconds

is usually adequate.

(11,19)

Slipform U se of slipform paving equipm ent for

intersection reconstruction is probably the exception

rather than the rule. H ow ever, a contractor m ay elect

to use slipform equipm ent in an intersection if the

paving area is large enough to w arrant its use.

Paving the curb and gutter is another com m on use of

a slipform m achine for intersection construction.

There are m any sizes of slipform paving m achines,

w ith m any sm aller m odels available for urban paving.

Slipform paving m achines spread, consolidate,

screed, and float-finish the concrete in one pass w ith-

out the need for fixed side form s. G enerally, contrac-

tors preset stringlines to establish the line and grade

control for the paver.

Like fixed-form paving, depositing concrete in front of

the paver evenly w ill im prove the resulting pavem ent.

A slipform paver m ust further spread and consolidate

the concrete as it m oves forw ard, and cannot pro-

duce adequate results if it m ust push a large pile of

concrete. W hen operating properly, a w ell-consolidat-

ed and properly shaped slab em erges behind the slip-

form paver as it m oves steadily forw ard.

C ertain slipform paving equipm ent can pave curbs

and gutters, and easily pave around curves betw een

intersecting roadw ays. Som e slipform paving

m achines can place curbs integrally w ith the driving

lanes. In such cases, the contractor m ust attach a

curb m ule to the paver so that the curb section w ill

extrude out as the paver m oves forw ard. Integral

curbs elim inate a separate form ing or placing opera-

tion that is otherw ise necessary for m ost urban

roadw ays.

M ore detailed inform ation on properly setting up and

operating slipform equipm ent is available in

R eference 19.

Finishing the Surface

After the paving equipm ent passes, it m ay be neces-

sary to further finish the concrete surface to rem ove

sm all im perfections and sm ooth any bum ps. There

are a num ber of different autom atic and hand-operat-

ed finishing tools available for this purpose. In the

tight w ork zones typical of intersection construction,

m ost contractors w ill opt for hand finishing tools.

Finishing is necessary earlier w ith air-entrained con-

crete than non-air-entrained concrete because air-

entrained concrete develops m uch less bleed w ater.

It is custom ary to w ait until all bleed w ater leaves the

concrete slab surface before finishing non-air-

entrained concrete.

C hecking the surface behind the paving equipm ent

w ith a 3- to 4.8-m (10- to 16-ft) hand-operated

straightedge is a recom m ended procedure.

(19)

Successive straightedging should overlap by one-half

the length of the straightedge to ensure that the tool (A) Slipform curb and gutter. (B) Slipform pavement with integral curb.

A

B

20

rem oves high spots and fills low spots in the surface.

Experienced finishers can use the straightedge to

rem ove noticeable bum ps by em ploying a scraping

m otion. O therw ise, they use a long-handled float to

sm ooth bum ps and disturbed places in the surface.

Edging is necessary for any concrete placed against

fixed form s. The sm all edging-tool effectively

sm oothes the slab corner and separates the concrete

from the form . W ithout separation, the concrete m ay

adhere to the top of the form , and tear or spall upon

form rem oval.

Particular attention also m ay be necessary for finishing

around boxed-out fixtures and cast-in-place fixtures.

Ideally, the height adjustm ent and supplem ental vibra-

tion around the object are com plete before w orkers

need to finish the pavem ent surface. If properly posi-

tioned, the object should easily blend into the sur-

rounding pavem ent. Som e surface w arping m ay be

necessary if the object is too high or too low .

Smoothness Requirements Sm oothness or

rideability requirem ents can be applied to intersection

projects. H ow ever, less stringent requirem ents are

necessary than are norm ally required for high-speed

highw ays. W arping of slabs to m eet fixtures (m an-

holes, drainage inlets, etc.), existing curb and gutter

and cross- or side-road connections, m ake m eeting

highw ay-standard sm oothness requirem ents nearly

im possible in m any cases.

For C alifornia profilograph testing of intersection pro-

jects, the acceptable rideability index should be

relaxed, and certain areas should be excluded from

m easurem ent. Those areas at intersections w hich

should be excluded from testing include: acceleration

and deceleration tapers, auxiliary (right and left-turn)

lanes, sections less than 15 m (50 ft) and locations

that require surface w arping that m ake profile testing

irrelevant. For m ore inform ation see R eference 21.

For sm all projects, excluded areas, and odd-shaped

areas, surface testing w ith a 3-m (10-ft) straightedge

[3-5 m m (1/8 - 3/16 in.) allow able deviation] w ill pro-

duce acceptable sm oothness.

Texturing the Surface

The surface texture necessary for intersection pave-

m ents depends upon the speed lim it of the approach

roadw ays. For low -speed residential, m unicipal col-

lector or urban business streets, a burlap, turf-drag,

or coarse broom surface texture is usually sufficient to

provide the m icrotexture necessary for w et w eather

stopping.

(22)

H igh-speed [i.e., +80 km /h (+50 m ph)]

arterial roadw ays also require a good m acrotexture to

reduce the w ater film thickness enough to prevent

hydroplaning

.

The texture chosen for the intersection m ust be

applied after finishing and before curing the concrete.

Either m echanical or hand-operated equipm ent can

adequately apply the texture, how ever, confined inter-

section w ork zones m ay lim it the practical use of

m echanical equipm ent.

Curing the Concrete

C uring is the treatm ent or protection given concrete

during the hardening period. C uring m easures are

necessary to m aintain a satisfactory m oisture and

tem perature condition in the concrete, because inter-

nal tem perature and m oisture directly influence both

early and ultim ate concrete properties.

(11,14)

Proper

curing m easures prevent rapid w ater loss from the

m ixture and allow m ore thorough cem ent hydration.

Therefore to m axim ize concrete quality it is necessary

to apply curing m easures as early as possible after

placing concrete.

(11,14)

C uring is also critical to provid-

ing a durable pavem ent surface that w ill retain surface

texture.

A variety of curing m ethods and m aterials are avail-

able for concrete pavem ent, including: w ater spray or

fog, w et burlap sheets, plastic sheets, insulating blan-

kets, and liquid-m em brane-form ing com pounds.

For concrete pavement, macrotexture refers to texture

added to the surface of the slabs by mechanical means. All

state agency specifications require concrete pavement to

have a surface texture that aids stopping in wet weather. The

specific texture varies greatly among agencies, but the state-

specified texture is usually meant for high speed highways

and is commonly a transverse tine texture. One drawback to

certain transverse tine textures is that they produce high tire-

road noise levels. Fortunately noise generation is not sensi-

tive to the surface texture at low speeds, and tined, burlap-

drag, turf-drag and coarse broom textures produce similar

noise levels below 55 km/h (35 mph). Longitudinal tining also

provides a safe, quiet and durable texture. The current rec-

ommendation

(22)

for transverse tine dimensions to optimize

noise and skid resistance are as follows: tine depth: 3-6 mm

(1/8-1/4 in.); tine width: 3 mm (1/8 in.); tine spacing: 10-40

mm (1/2- 1-1/2 in.) random and variable with no more than

50% exceeding 25 mm (1 in.).

21

The application of a liquid-m em brane-form ing com -

pound to seal the concrete surface is the m ost com -

m on curing m ethod for concrete pavem ent. A liquid-

m em brane-form ing com pound that m eets ASTM C

309 m aterial requirem ents is adequate for m ost situa-

tions w hen applied at the follow ing rates:

1. 5.0 m

2

/L (200 ft

2

/gal) for norm al paving

applications.

2. 3.75 m

2

/L (150 ft

2

/gal) for fast-track concrete.

3. 2.5 m

2

/L (100 ft

2

/gal) for thin overlays.

W hite-pigm entation in the com pound is preferable to

a clear com pound so coverage is easily seen. The

pigm ent also reflects solar radiation that m ay other-

w ise heat the concrete surface excessively.

The first few hours after paving w hen the concrete

rem ains plastic are the m ost critical for good cur-

ing. As such, the contractor should apply a curing

com pound as soon as possible after the w ater sheen

has left the surface and texturing is com plete. A vari-

ety of spraying equipm ent is available, but on m ost

intersection projects sim ple hand sprayers are the

likely choice.

The initial application of curing com pound should coat

both the top and edges of slipform ed concrete. For

fixed-form paving, the curing com pound should initial-

ly coat the exposed concrete surface. If rem oving

form s early, a second coat should be applied to any

exposed vertical edges of the slab to provide a com -

plete seal.

Insulating blankets also are som etim es necessary for

curing fast-track concrete in intersection w ork. The

purpose of insulating fast-track concrete w ith blankets

is to aid early strength gain in cool w eather condi-

tions. The blankets reduce heat loss and lessen the

influence of both air tem perature and solar radiation

on the pavem ent tem perature. The blankets are not a

substitute for curing com pound, w hich is still needed

to contain m oisture for thorough hydration. Table 6

indicates w hen insulation is recom m ended for fast-

track concrete.

(14,15)

N orm al curing m easures w ithout insulation are

acceptable w here rapid strength gain is not required.

H ow ever, special precautions are necessary w hen the

intersection is being constructed either in very cold or

hot w eather. M ore inform ation on curing, including

w et curing, blanket insulation, and cold-w eather and

hot-w eather construction techniques, is available in

R eferences 11, 14 and 15.

Table 6. Recommended conditions requiring insulating blankets.

(14,15)

Minimum Air Temperature Opening Time, Hr

During Time Period 8 16 24 36 48

<10C (<50F) YES YES YES YES N O

10-18C (50-65F) YES YES YES N O N O

18-27C (65-80F) YES N O N O N O N O

>27C (>80F) N O N O N O N O N O

Curing blankets moved aside for sawing fast-track concrete.

22

J ointing the Pavement

At-grade concrete intersections usually require every

joint type. The design details and specific purpose

of each type are defined in Jointingon page 4.

Typical construction m ethods are described below .

Construction J oints At intersections, trans-

verse construction joints typically are built by hand

at predeterm ined locations. This requires a form

(header board) that can contain the concrete, and

secure dow els or tiebars positioned and aligned

properly. Vibration of concrete near the construc-

tion joint is im portant to ensure good encapsulation

of the steel bars. If the construction joint provides a

transition from concrete to asphalt pavem ent, spe-

cial transition form ing m ay be necessary (see page