Académique Documents

Professionnel Documents

Culture Documents

Ejemplo Cadena Fria Abbott

Transféré par

Mario Vazquez B0 évaluation0% ont trouvé ce document utile (0 vote)

34 vues17 pagesCold chain management for pharmaceutical products cGMP regulations enforce the compliance with strict temperature control along the process / distribution chain. Cold chain management is the process of ensuring that a process will meet pre-determined acceptance criteria.

Description originale:

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentCold chain management for pharmaceutical products cGMP regulations enforce the compliance with strict temperature control along the process / distribution chain. Cold chain management is the process of ensuring that a process will meet pre-determined acceptance criteria.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

34 vues17 pagesEjemplo Cadena Fria Abbott

Transféré par

Mario Vazquez BCold chain management for pharmaceutical products cGMP regulations enforce the compliance with strict temperature control along the process / distribution chain. Cold chain management is the process of ensuring that a process will meet pre-determined acceptance criteria.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 17

1

GMP aspects of cold chain management for

pharmaceutical products

Dr. Hans-Jrgen Krause, Pharmaceutical Development Parenteral Dosage Forms

Maha Noujeime, International Technical Service

Abbott GmbH & Co. KG, Ludwigshafen, Germany

Content

Introduction

Process flow analysis

Pratical approach to validation/qualification

-80C storage/ frozen shipment

2-8C shipment

Temperature excursion handling/data requirements

Training/documentation

Cold chain management for pharmaceutical products

2

Cold chain management for pharmaceutical products

Biotech products often require deep

frozen/refridgerated storage

Quality of pharmaceutical products is of primary

concern

Chemical and physico-chemical stability

depends on temperature

cGMP regulations enforce the compliance with

strict temperature control along the

process/distribution chain

Cold chain management for pharmaceutical products

cGMP regulations require

Complete tracking of temperature storage conditions

Validated storage areas

Qualified shipment

Documentation

Procedures to handle temperature excursions

3

Cold chain management for pharmaceutical products

Process Flow Diagram

1)

1) According to a draft medicinal cold chain guideline by PDA Cold chain working group, Nov. 03

Identify Product

Product stability profile

Transportation process flow consideration

Bulk & Intermediate Finished goods Analytical samples

Cold chain management for pharmaceutical products

Process Flow Diagram

1)

1) According to a draft medicinal cold chain guideline by PDA Cold chain working group, Nov. 03

Develop requirements documents

Component specification

Design testing

Develop OQ protocol Develop PQ protocol

OQ testing PQ testing

4

Cold chain management for pharmaceutical products

Process Flow Diagram

1)

1) According to a draft medicinal cold chain guideline by PDA Cold chain working group, Nov. 03

Implement the process

Distribution chain Develop training

training

Quality systems

Auditing distribution chain Regulatory perspective

Perform monitoring

Cold chain management for pharmaceutical products

Definition of validation

Validation is documented testing that consistently

produces a result meeting pre-determined specifications.

Definition of qualification

Qualification is documented testing that demonstrates

with a high degree of assurance that a specific process

will meet the pre-determined acceptance criteria.

5

Cold chain management for pharmaceutical products

Example of a cold chain

Drug substance manufacture East coast US

Shipment at 80C to drug product manufacturing site EU

Shipment of semi finished product at 2-8C

to distribution center in EU

Shipment of semi finished product to packaging site

in US at 2-8C

Distribution of final product to customer at 2-8C

Cold chain management for pharmaceutical products

Temperature tracking during processing

Each manufacturing step at RT is captured

Each manufacturing step has an acceptance limit

Sum of all manufacturing steps has to be within limit

Total processing time at RT is covered by analytical

stability data of the product

6

Cold chain management for pharmaceutical products

Qualification

1)

of storage equipment (eg freezer)

Calibration of sensors (pre/post validation)

Temperature distribution (empty/loaded)

Critical alarm functions tested

Predefined acceptance criteria

Written and preapproved protocols

1) Qualification: proving and documenting that equipment or ancillary systems are

properly installed, work correctly, and comply with specified requirements

Cold chain management for pharmaceutical products

Validation of a freezer

External sensors calibrated to +/- 2C

Data recording:

Every 5 min

Continously over 3 days

15 sensors distributed within (bottom/middle/top) freezer

Equilibration period 3 h

Acceptance criteria:

No single value +/- 20C of target

Mean of data per h: +/- 5C

Recalibration every year

Revalidation every 2 years

7

Cold chain management for pharmaceutical products

Shipment qualification 80C (endurotherm E90)

Cold chain management for pharmaceutical products

Shipment qualification 80C (endurotherm E90)

8

Cold chain management for pharmaceutical products

Shipment qualification endurotherm E 90

Thermal qualification

Product temperature NMT 25C for at least 66 h

Ambient temperature profile (+18C to +55 C)

2 x 2L of product

Approx. 32 lbs dry ice refrigerant

Transportation qualification

Free fall testing (ASTM D 5276)

Vibration test (ASTM D 999)

Random vibration test (ASTM D 4228)

9

Cold chain management for pharmaceutical products

Shipment qualification EF 6100

1)

Thermal qualification

Product temperature 0 - 10C for at least 72 h

2 temperature profiles (-15C to +18 C and 25C to 40C)

25600 units of product

Approx. 396 lbs refrigerant (48 oz ice brix, 5C and 20C)

1) manufactured by Tuscarora Thermosafe, formerly Insulated Shipping Container

10

EF-6100AB Packaging Diagram

Winter Profile

EF-6100AB Packaging Diagram

Winter Profile

11

EF-6100AB Packaging Diagram

Winter Profile

EF-6100AB Packaging Diagram

Winter Profile

12

EF-6100AB Packaging Diagram

Winter Profile

EF-6100AB Packaging Diagram

Winter Profile

13

EF-6100AB Packaging Diagram

Winter Profile

14

15

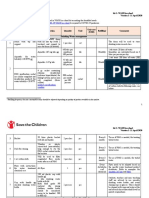

Cold chain management for pharmaceutical products

Example of a Temperature Excursion Study

1)

1) According to a draft medicinal cold chain guideline by PDA Cold chain working group, Nov. 03

1) 25C/60% RH for 2 days Freezer condition

-20 to 10C

1) -20C for 2 days

2) 40C/75% RH for 2 days

Refridgerated condition

2-8C

1) 20C for 2 days

2) 60C/75% RH for 2 days

Controlled room temperature

20-25C

Testing condition Storage condition

Cold chain management for pharmaceutical products

Example of a Thermal Cycling Study

1)

1) According to a draft medicinal cold chain guideline by PDA Cold chain working group, Nov. 03

-20C for 2 days followed by

5C for 2 days

Repeat for a total of 3 cycles

Freezer condition

-20 to 10C

-20C for 2 days followed by

25C/60% RH for 2 days

Repeat for a total of 3 cycles

Refridgerated condition

2-8C

20C for 2 days followed by

40C/75% RH for 2 days

Repeat for a total of 3 cycles

Controlled room temperature

20-25C

Testing condition Storage condition

16

Cold chain management for pharmaceutical products

Example for Temperature Excursion Handling of a

refrigerated product

1)

1) According to a draft medicinal cold chain guideline by PDA Cold chain working group, Nov. 03

Do not use > 40C

2 days 25 to 40C

6 days 8 to 25C

Until Expiry 2 to 8C

2 days -20C to 2C

Do not use <-20C

Time Temperature Range

Cold chain management for pharmaceutical products

Training/documentation

According to written SOPs

Training must be documented

Specific with regards to

Preconditioning of refrigerants to be used

Packaging instructions

Handling of thermologgers

Paper work (preshipment notification, contact persons, deviation

handling)

Temperature data for each shipment have to be evaluated

against defined criteria

17

Acknowledgement

Kevin ODonnell

Dr. M. Dickes

Joshua Froimson

ISC

End of Presentation

Vous aimerez peut-être aussi

- Articulo Cadena de FrioDocument5 pagesArticulo Cadena de FrioMario Vazquez BPas encore d'évaluation

- Guidance For Vaccine and Pharmaceutical Logistics and Distribution GloDocument36 pagesGuidance For Vaccine and Pharmaceutical Logistics and Distribution GloJimmy WangPas encore d'évaluation

- Nsai Determining Uncertainties MappingDocument4 pagesNsai Determining Uncertainties MappingMilagros BorhorquezPas encore d'évaluation

- IATA Certification CEIV WhitepaperDocument14 pagesIATA Certification CEIV WhitepaperMario Vazquez BPas encore d'évaluation

- Calificación Camaras de EstabilidadDocument4 pagesCalificación Camaras de EstabilidadMario Vazquez BPas encore d'évaluation

- Environmental Monitoring Risk Assessment PDFDocument26 pagesEnvironmental Monitoring Risk Assessment PDFEmte ZenPas encore d'évaluation

- Introduccion 3a Sanitary StandarsDocument58 pagesIntroduccion 3a Sanitary StandarsMario Vazquez BPas encore d'évaluation

- Green - Book - Chapter Cold Chain EnglandDocument20 pagesGreen - Book - Chapter Cold Chain EnglandMario Vazquez BPas encore d'évaluation

- Haccp Cold ChainDocument5 pagesHaccp Cold ChainMario Vazquez BPas encore d'évaluation

- Haccp Cold ChainDocument5 pagesHaccp Cold ChainMario Vazquez BPas encore d'évaluation

- Green - Book - Chapter Cold Chain EnglandDocument20 pagesGreen - Book - Chapter Cold Chain EnglandMario Vazquez BPas encore d'évaluation

- Guia SupacDocument44 pagesGuia SupacMario Vazquez BPas encore d'évaluation

- Qualification of Purified Water Systems PDFDocument12 pagesQualification of Purified Water Systems PDFMario Vazquez B100% (1)

- USP 1058 AIQ Risk Based Instrument Qualification GuidelinesDocument1 pageUSP 1058 AIQ Risk Based Instrument Qualification GuidelinesluroguitaPas encore d'évaluation

- Wh0 Trs 937 HvacDocument478 pagesWh0 Trs 937 HvacCristiano FrancaPas encore d'évaluation

- USP Guidances On Environmental Control Including Related USP FDA EMEA PDA Activities PDFDocument86 pagesUSP Guidances On Environmental Control Including Related USP FDA EMEA PDA Activities PDFMario Vazquez BPas encore d'évaluation

- Validation Aspects of Water Treatment SystemsDocument10 pagesValidation Aspects of Water Treatment SystemshumballerPas encore d'évaluation

- Monitoreo Ambiental HVAC y Aire Comprimido PDFDocument13 pagesMonitoreo Ambiental HVAC y Aire Comprimido PDFMario Vazquez BPas encore d'évaluation

- Pics Verificaci N de Instalaciones PDFDocument11 pagesPics Verificaci N de Instalaciones PDFMario Vazquez BPas encore d'évaluation

- 4.cleanroom Qualification (Mark)Document14 pages4.cleanroom Qualification (Mark)mci_rathodPas encore d'évaluation

- OIL-Xplus Filtros Aire ComprimidoDocument8 pagesOIL-Xplus Filtros Aire ComprimidoMario Vazquez BPas encore d'évaluation

- Asme BpeDocument41 pagesAsme BpeSiva Venkateswara Rao Bolla67% (3)

- Monitoreo Ambiental HVAC y Aire Comprimido PDFDocument13 pagesMonitoreo Ambiental HVAC y Aire Comprimido PDFMario Vazquez BPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Ewellery Ndustry: Presentation OnDocument26 pagesEwellery Ndustry: Presentation Onharishgnr0% (1)

- Software Hackathon Problem StatementsDocument2 pagesSoftware Hackathon Problem StatementsLinusNelson100% (2)

- Labor Law 1Document24 pagesLabor Law 1Naomi Cartagena100% (1)

- 3.1 Radiation in Class Exercises IIDocument2 pages3.1 Radiation in Class Exercises IIPabloPas encore d'évaluation

- Database Management System and SQL CommandsDocument3 pagesDatabase Management System and SQL Commandsdev guptaPas encore d'évaluation

- 1.functional Specification PTP With EDIDocument36 pages1.functional Specification PTP With EDIAnil Kumar100% (4)

- A Varactor Tuned Indoor Loop AntennaDocument12 pagesA Varactor Tuned Indoor Loop Antennabayman66Pas encore d'évaluation

- Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)Document28 pagesSelf-Instructional Manual (SIM) For Self-Directed Learning (SDL)Monique Dianne Dela VegaPas encore d'évaluation

- CC Anbcc FD 002 Enr0Document5 pagesCC Anbcc FD 002 Enr0ssierroPas encore d'évaluation

- Chapter03 - How To Retrieve Data From A Single TableDocument35 pagesChapter03 - How To Retrieve Data From A Single TableGML KillPas encore d'évaluation

- h6811 Datadomain DsDocument5 pagesh6811 Datadomain DsChristian EstebanPas encore d'évaluation

- Land Use Paln in La Trinidad BenguetDocument19 pagesLand Use Paln in La Trinidad BenguetErin FontanillaPas encore d'évaluation

- SDM Case AssignmentDocument15 pagesSDM Case Assignmentcharith sai t 122013601002Pas encore d'évaluation

- CENT - Company Presentation Q1 2020 PDFDocument22 pagesCENT - Company Presentation Q1 2020 PDFsabrina rahmawatiPas encore d'évaluation

- IBMC Competition Booklet 2013Document40 pagesIBMC Competition Booklet 2013Rollins Center at BYUPas encore d'évaluation

- Media SchedulingDocument4 pagesMedia SchedulingShreyansh PriyamPas encore d'évaluation

- Occupational Therapy in Mental HealthDocument16 pagesOccupational Therapy in Mental HealthjethasPas encore d'évaluation

- Moparm Action - December 2014 USADocument100 pagesMoparm Action - December 2014 USAenricoioPas encore d'évaluation

- 8524Document8 pages8524Ghulam MurtazaPas encore d'évaluation

- Relationship Between Principal Leadership Skills and Teachers' Organizational Citizenship BehaviourDocument16 pagesRelationship Between Principal Leadership Skills and Teachers' Organizational Citizenship BehaviourToe ToePas encore d'évaluation

- Standard Cost EstimatesDocument12 pagesStandard Cost EstimatesMasroon ẨśầŕPas encore d'évaluation

- Pharmaceutical Microbiology NewsletterDocument12 pagesPharmaceutical Microbiology NewsletterTim SandlePas encore d'évaluation

- Options Trading For Beginners Aug15 v1Document187 pagesOptions Trading For Beginners Aug15 v1Glo BerriPas encore d'évaluation

- R 18 Model B Installation of TC Auxiliary Lights and WingletsDocument29 pagesR 18 Model B Installation of TC Auxiliary Lights and WingletsAlejandro RodríguezPas encore d'évaluation

- Incoterms 2010 PresentationDocument47 pagesIncoterms 2010 PresentationBiswajit DuttaPas encore d'évaluation

- Karmex 80df Diuron MsdsDocument9 pagesKarmex 80df Diuron MsdsSouth Santee Aquaculture100% (1)

- Kit 2: Essential COVID-19 WASH in SchoolDocument8 pagesKit 2: Essential COVID-19 WASH in SchooltamanimoPas encore d'évaluation

- Computer System Sevicing NC Ii: SectorDocument44 pagesComputer System Sevicing NC Ii: SectorJess QuizzaganPas encore d'évaluation

- European Steel and Alloy Grades: 16Mncr5 (1.7131)Document3 pagesEuropean Steel and Alloy Grades: 16Mncr5 (1.7131)farshid KarpasandPas encore d'évaluation

- DPC SEMESTER X B Project ListDocument2 pagesDPC SEMESTER X B Project ListVaibhav SharmaPas encore d'évaluation