Académique Documents

Professionnel Documents

Culture Documents

Methodology

Transféré par

TeoHusmalaga0 évaluation0% ont trouvé ce document utile (0 vote)

46 vues5 pagesart

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentart

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

46 vues5 pagesMethodology

Transféré par

TeoHusmalagaart

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

METHODOLOGY

1.0 Mobilization / Demobilization

Mobilization and demobilization shall refer to the moving-in and moving out of equipment,

including the crew complement required to operate the equipment to be used in

undertaking the work under the contract. A unit of equipment under this section shall

mean one set of drilling rig complete with the attachment and accessories needed in the

work under this contract. The item of moving in moving out of equipment, to and from

jobsite, shall refer to the units of equipment required to complete the work within the

specified period as listed in the Contractors Proposal.

1.1 Preparatory Works

Preparatory work covers preparing for actual drilling works which include, but not limited

to:

a. Movement of personnel, supplies and incidentals to the jobsite.

b. Establishing campsite, access roads and other facilities and for any work and operation

which must be performed incident to the initiation of meaningful work at the jobsite.

1.2 Surface Geological Mapping

During the fieldworks, rock types shall be identified and boundaries delineated. Where

rocks are exposed and joints are presented, strikes and dips of faults, bedding, flow layers

and other discontinuities shall be measured and recorded. Likewise, solution channels, wet

areas and springs, slides and other significant geological features shall be mapped and

indicated on the geological map.

1.3 Drilling Exploration

We shall undertake the drilling of exploratory holes planned at the locations engineering

structures on-shore and off-shore.

The borehole locations and depths were planned for a good coverage at the area of

concern specifically at the proposed sites of the engineering structures.

On land drilling will be carried out at the sites of the powerhouse, cooling tower, chimney,

switchyard at the transformer location, tank farm for the fuel oil and the water tank

foundation. On the other hand, for off-shore drilling holes will be allocated at the sites the

pier and at alignment of sea water intake and discharge pipes.

The number and depth of holes will be determined after the plant layout and associated

structures shown on plans are available.

a. Soil Boring and Sampling with SPT

The boreholes shall be advanced using rotary techniques. In-situ density determinations

shall be undertaken at 1.0 meter interval regardless of strata employing Standard

Penetration Test (SPT). In the test, a split spoon sampler is advanced 45cm by blows from a

63.6kg trip hammer having a free fall of 76cm, the number of blows required for each

15cm penetration is recorded. The number of blows required for the last 30cm sampling is

the N-Value. When N-Value is equal or less than 8 (UDS) is undertaken using Shellby Tube.

Both ends of the tube shall be covered by paraffin wax.

Soil samples recovered from SPT shall be placed in jar or in zipped plastic bags to maintain,

if possible, the moisture content.

b. Core drilling in hard strata

i. Each hole will be drilled with standard diamond core drilling equipment using

suitable sized diamond core bits acceptable to the client representative at

the jobsite.

ii. Core drilling will be performed with clear water unless specifically authorized in

writing by the client duly authorized representative.

iii. Water table measurements shall be made in each borehole at the start of each

eight (8) hours shift of drilling operation for each day.

iv. The core drilling operations shall be carried out with utmost care to obtain a 100%

core recovery.

During the core drilling, an NX size diamond coring bit attached to a double tube or triple

tube core barrel shall be utilized for the better recoveries.

Core or rock samples shall be laid in core boxes with wood blocks as separator where the

length of run, core recovery and RQD expressed in percent shall be indicated.

Groundwater levels in boreholes shall be measured and recorded 24 hours after drilling

completion.

1.4 Transfer of Equipment from Hole to Hole

Transfer from hole to hole comprise of the actual transfer of a core drilling unit of

equipment, including attachments and accessories, from one drill hole to another after the

completion of all operations for drilling, water pressure testing and incidents to complete

the work in one hole.

1.5 Core Sample Box

The sample obtained shall be placed in covered PVC core boxes with standard

measurements of 1.10m x 0.60m with dividers for the lateral separation of the core samples.

Each core sample box shall be properly marked/labeled indicating the name of the

project, core box number, borehole number and location and extent of drilling.

Furthermore, each core box must be provided with wood spacers of about 5 cm long

whereby each depth advance, length of run, length of core and percentage of recovery

shall be reflected.

1.6 Permeability Test in Boreholes

a. Water Pressure Testing

Prior to water pressure test, the packer assembly together with the packer pipe shall be

calibrated at the ground surface preferably near the river bank. Procedure for packer

calibration is similar to the guidelines of water pressure testing using a single or double

packer assembly except that the testing or calibration is undertaken at the ground

surface.

b. Washing

Immediately before the pressure testing of each stage of any hole begins and at such

time as directed the hole shall be thoroughly washed if possible under pressure. All

intersected rock seams and crevices containing clay and other washable materials

shall be washed out as directed by introducing water into the holes. The holes shall be

washed at such time until the return water is clear and fracture filling is no longer

recovered. Before the start of the water pressure testing of the hole, the hole shall be

thoroughly washed for at least 10 minutes or as directed.

c. Time of Testing

Pressure testing shall be done immediately after completion of drilling the full depth of

a hole by using the double packer assembly or in sages as the hole is drilled using the

single packer assembly. When badly fractured or other unstable rock is encountered or

when the continuation of drilling will alter the structural condition of the rock, each

completed section of the hole in which tests are to be performed shall be pressure

tested before drilling is continued.

d. Section to be tested

All holes drilled at site as directed by the client shall be pressure tested at every 5.0m

length or 3.0m interval in fractured/jointed rock formation.

e. Testing Procedure

All testing shall be done under the supervision of the client duly authorized

representative at the jobsite. The static water level shall be determined before the start

of the test. Water level shall be measured inside the packer pipe after the packer has

been set.

Table 1: Specified Ratio of Pressure and Time for Each Step of a WPT

Step No. Pressure (P) Elapsed Time (min.)

1 P1 - 1/3 P3 5

2 P2 - 2/3 P3 5

3 P3 10

4 P4 - 2/3 P3 5

5 P5 - 1/2 P3 5

To start the test, the packer or packers are seated and the depth recorded. Hole and

equipment must be filled with water and begin pumping until pressure P1 is indicated on

the pressure gauge. Read the flow meter and start stopwatch for the first segments. At the

end of 5 minutes, increase pressure to P2 and read the flow meter. This is continued until all

five increments are completed.

Table 2 Specified Pressure

From To 1 & 5 2 & 4 P3

0 2 2 3 5

2 4 3 6 10

4 6 5 10 15

6 8 8 15 25

8 10 10 20 30

10 14 15 30 35

14 20 20 35 55

20 25 25 50 75

25 30 30 60 90

30 35 35 70 105

35 40 40 80 125

40 45 45 90 140

45 50 50 100 150

50 deeper 50 100 150

Vertical Depth of Packers

(m)

Specified Pressure for Test Stage

(psi)

The specified depth shall be the depth at the midpoint of the section tested.

If in any step, the specified pressure cannot be attained, run the pump at full speed and

recorded the highest steady pressure established and proceed with the test.

Between steps, the pressure shall not allowed to fall below the specified for the next step or

the step just completed.

f. Percolation Test

Permeability test by the open-end constant-head method shall be performed for

section which has not cemented yet or intensely weathered/or severly fractured

formation and overburden materials to which the packer cannot be installed

effectively.

When a hole has been drilled to the depth where the test is intended a casing shall be

installed for the full length of the hole. For tight contact of the casing with the deposits

in the surroundings the casing shall be installed.

1.7 Test Pitting

Test pits shall be dug manually using convenient hand tools. Minimum size of pit is 1.2m by

1.2m. Depth is 3.0 m but may vary depending on field conditions as certified by the client

duly authorized at the jobsite. Materials from the pits shall be removed by buckets

operated from a hoist, especially when depth is greater than 2.0m. During excavation, the

bottom of the hole should be kept fairly leveled and of full size so that each lift may

represent the corresponding portion of the deposit in quantity and quality. At the surface

the excavated material should be placed in an orderly manner around the pit and

marked stakes should be driven to indicate depth of the pit from which the material came

in order to facilitatelogging and ssampling. To avoid collapse of the pit walls, wooden cribs

shall be installed when necessary.

1.8 Laboratory Testing

Gathered representative soil and samples from boreholes shall be handled carefully

particularly the undisturbed samples in Shellby Tube to prevent them from jarring while in

transport to the laboratory.

Test to be conducted on representative soil and rock samples taken from boreholes are

shown below:

Soil Classification (USCS)

Grain Size Distribution with hydrometer test

Atterberg limit

Natural moisture content

Specific gravity

1. Soil

2. Rock

Unit Weight

1. Soil

2. Rock

Direct Shear Test (Soil Only)

Unconfined Compressive Strength Test

1. Soil

2. Rock

Consolidation Test (One Dimensional)

Determination of the number test shall be based on the boreholes drilled and on any

additional sub-surface exploration deemed necessary.

1.9 Factual Report

The report to be prepared by the contractor shall discuss the standard methods for

topographic and hydrographic survey, drilling and other associated in-situ tests

conducted. Procedures for gathering of disturbed and undisturbed samples shall also be

discussed.

The report shall include topographic and hydrographic plans and cross sections showing

also the borehole locations on on-shore and off-shore. Other enclosures that will form part

of report are the logs of boreholes normally prepared showing the layers of engineering

soils and results of the laboratory tests conducted on representative soils and rock samples.

1.10 Preparation of Geotechnical Report

Interpretation of results of drilling and laboratory testing and corresponding

recommendations shall be done by Geotechnical Engineering.

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Ashok B Lall - 1991 - Climate and Housing Form-A Case Study of New Delhi PDFDocument13 pagesAshok B Lall - 1991 - Climate and Housing Form-A Case Study of New Delhi PDFAkanksha SinghPas encore d'évaluation

- Zhejiang TelecomDocument4 pagesZhejiang TelecomShariffah Rekha Syed SalimPas encore d'évaluation

- How To Report On Cross Company Stock in Transit PDFDocument30 pagesHow To Report On Cross Company Stock in Transit PDFPatel BOPas encore d'évaluation

- Best Practice in Essbase Business Rule Writing-ManuskriptDocument5 pagesBest Practice in Essbase Business Rule Writing-Manuskriptsen2natPas encore d'évaluation

- Exercise Efficient and Effective Sustainable Practices in The Workplace PDFDocument4 pagesExercise Efficient and Effective Sustainable Practices in The Workplace PDFMa Joan Aguilar RodriguezPas encore d'évaluation

- Practices of A MultiplierDocument24 pagesPractices of A MultiplierBarry FeldmanPas encore d'évaluation

- Six Models of OrganizationDocument5 pagesSix Models of Organizationmh_sadri100% (1)

- Combinatorial Geometry PDFDocument2 pagesCombinatorial Geometry PDFLarryPas encore d'évaluation

- PGM and OUTPUTDocument52 pagesPGM and OUTPUTPushpavalli MohanPas encore d'évaluation

- (YDM) Ambo University Phy ExamDocument8 pages(YDM) Ambo University Phy ExamYdm DmaPas encore d'évaluation

- 20130222210228kuliah 1 - Falsafah MatematikDocument54 pages20130222210228kuliah 1 - Falsafah Matematikkharol1211100% (1)

- Wiegers Getting The Most Out of Requirements Management ToolDocument9 pagesWiegers Getting The Most Out of Requirements Management ToolAmreshPas encore d'évaluation

- 2 - SAP MM Level 1 TrainingDocument39 pages2 - SAP MM Level 1 TrainingkalykumPas encore d'évaluation

- ActuatorsDocument20 pagesActuatorsmohamedbadawyPas encore d'évaluation

- Mca AppDocument10 pagesMca Appvenkat6299Pas encore d'évaluation

- KABIR HASION CV Executive-1 PDFDocument2 pagesKABIR HASION CV Executive-1 PDFraiyanduPas encore d'évaluation

- 50 Affirmations For A Fertile Mind, Heart & SoulDocument104 pages50 Affirmations For A Fertile Mind, Heart & SoulKarishma SethPas encore d'évaluation

- Continuation Power Flow ExampleDocument7 pagesContinuation Power Flow ExampleSudheerKumarPas encore d'évaluation

- Dmitri Sorokin - Introduction To The Classical Theory of Higher SpinsDocument33 pagesDmitri Sorokin - Introduction To The Classical Theory of Higher SpinsKlim00Pas encore d'évaluation

- Rooms Division DepartmentDocument7 pagesRooms Division Departmentlil_jinkz09Pas encore d'évaluation

- Webmethods Flow Service Design and Practice PDFDocument11 pagesWebmethods Flow Service Design and Practice PDFJagadeeshwar ReddyPas encore d'évaluation

- AMJ Style GuideDocument4 pagesAMJ Style GuidepsmousePas encore d'évaluation

- 6 Feministic - Approach To AwoodDocument6 pages6 Feministic - Approach To AwoodbibaPas encore d'évaluation

- Brother Rice School Profile 2016-2017Document4 pagesBrother Rice School Profile 2016-2017brotherricePas encore d'évaluation

- Primary Prevention of HypertensionDocument7 pagesPrimary Prevention of HypertensioncinthyaaaPas encore d'évaluation

- African Handbook-TextDocument164 pagesAfrican Handbook-TextThe_Castle_Of_Letter100% (1)

- Marana Karaka SthanaDocument20 pagesMarana Karaka SthanaKamal RanathungaPas encore d'évaluation

- Correlation and Regression-1Document32 pagesCorrelation and Regression-1KELVIN ADDOPas encore d'évaluation

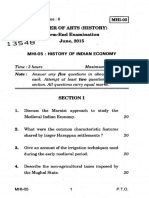

- Mhi 05 12Document6 pagesMhi 05 12aravPas encore d'évaluation

- Teaching PortfolioDocument25 pagesTeaching Portfolioazazel28Pas encore d'évaluation