Académique Documents

Professionnel Documents

Culture Documents

Selection and Integration of Positive Displacement Motors Into Di - 2

Transféré par

MostafaSouag0 évaluation0% ont trouvé ce document utile (0 vote)

69 vues24 pagesUniversity of Tennessee honors Program 5-2004 Selection and Integration of Positive Displacement Motors into directional drilling systems Kirk Townsend lowe. Tis is brought to you for free and open access by the University of Tennessee honors Program at Trace: Tennessee research and Creative Exchange.

Description originale:

Titre original

Selection and Integration of Positive Displacement Motors Into Di_2

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentUniversity of Tennessee honors Program 5-2004 Selection and Integration of Positive Displacement Motors into directional drilling systems Kirk Townsend lowe. Tis is brought to you for free and open access by the University of Tennessee honors Program at Trace: Tennessee research and Creative Exchange.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

69 vues24 pagesSelection and Integration of Positive Displacement Motors Into Di - 2

Transféré par

MostafaSouagUniversity of Tennessee honors Program 5-2004 Selection and Integration of Positive Displacement Motors into directional drilling systems Kirk Townsend lowe. Tis is brought to you for free and open access by the University of Tennessee honors Program at Trace: Tennessee research and Creative Exchange.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 24

University of Tennessee, Knoxville

Trace: Tennessee Research and Creative

Exchange

University of Tennessee Honors Tesis Projects University of Tennessee Honors Program

5-2004

Selection and Integration of Positive Displacement

Motors into Directional Drilling Systems

Kirk Townsend Lowe

University of Tennessee - Knoxville

Follow this and additional works at: htp://trace.tennessee.edu/utk_chanhonoproj

Tis is brought to you for free and open access by the University of Tennessee Honors Program at Trace: Tennessee Research and Creative Exchange. It

has been accepted for inclusion in University of Tennessee Honors Tesis Projects by an authorized administrator of Trace: Tennessee Research and

Creative Exchange. For more information, please contact trace@utk.edu.

Recommended Citation

Lowe, Kirk Townsend, "Selection and Integration of Positive Displacement Motors into Directional Drilling Systems" (2004).

University of Tennessee Honors Tesis Projects.

htp://trace.tennessee.edu/utk_chanhonoproj/763

UNIVERSITY HONORS

SENIOR PROJECT - APPROVAL

N ame: _________________ _

College: .... Department: \S:6.-J .. cJ

Faculty Mentor: _-,D=--:..t'"_, __ ..

PROJECT TITLE: __ _ __ ',-' ..J_-<-

I have reviewed this completed senior honors thesis with this student and certify that it is a

urate wit h 0 level undergra.duate research in this field.

Signed: ---Ir-+----'''---''<II---'l:t--'''-----''------''I:-----' Faculty Mentor

Date (\.1 "'tJ 6 J UJ () 3,

Comments (Optional):

b",

"\;jVJ w-P J +v

0) {)0VVl

+-

Selection and Integration of Positive Displacement

Motors into Directional Drilling Systems

By: Kirk Lowe

Faculty Advisor: Dr. Don Dareing

University of Tennessee, Knoxville

Department of Mechanical, Aerospace, and Biomedical Engineering

May 7,2003

Motivation

The positive displacement motor (PDM) has been used in directional drilling now for

several years and is a key component in bottom hole drilling assemblies. These

downhole drilling motors, coupled with Measurements While Drilling (MWD) tools and

proper stabilization allow directional wells to be drilled with one bottom hole assembly,

eliminating costly mUltiple drillstring tripping, which in the past was necessary for

surveying, hole corrections, and stabilized assemblies.

2

A key issue in designing bottom-hole assemblies for specific directional drilling

situations is the selection and operation of the "best" positive displacement motor (PDM)

for the application. A part of this decision is the integration into the total drilling system,

paying close attention to the hydraulic horsepower at the bottom of the drillstring for

powering the motor and for cleaning the drill bit. This decision is compounded

somewhat by the many possible choices ofPDM's available on the market. PDM's are

available in various sizes, rotor/stator lobes, etc., each having their own set of

performance characteristics.

This paper presents a logical methodology for predicting general performance of PDMs

and shows how to use this performance information to come to a logical basis for

choosing a best motor for a given set of operating conditions.

Background

In the early part of the twentieth century, directional drilling was becoming a main stay in

offshore drilling. Economics did not allow for multiple platforms to be built in order to

recover more oil and gas from the reservoirs. The industry had to come up with new

ways to drill multiply holes off of one production platform.

To accomplish this task, operators found that if they could divert the bit at an angle, then

they could stabilize the drillstring in this orientation and drill in another direction besides

straight down. Early attempts at this method included Whipstock wedges that would be

oriented in the bottom of the hole and direct the bit in a predetermined path. The

drillstring would then be pulled out and stabilizers that held the bottom hole assembly at

a fixed curvature would be attached. This process was the standard practice until bent

subs became more widely used. The bent sub was a fixed bend installed near the bit that

would offset the direction of the drilling when employed. The bent sub replaced the

Whipstock wedge. Once the initial kick off angle was established, the operators would

trip out the drillstring and replace the bent sub with stabilizers as they did with the

wedges and continue drilling. These methods resulted in wells that had an average radius

of curvature of about 1500 feet. Platforms today typically have around forty directional

wells stemming off of them.

As one can imagine this process was slow and costly. By the 1960's and 1970's

downhole motors started to make headway in the drilling market [7]. One advantage that

these downhole motors possessed was the fact that it created one bottom hole assembly.

The operators no longer had to trip the drillstring in and out to change out bottom hole

assemblies. The downhole motors had bent subs and stabilizers built into them so that

the entire process could be accomplished in one pass. In today's competitive industry,

downhole motors are allowing operators to develop directional wells quicker and with

more precision. Though the average well curvatures are still around 1500 - 2000 ft,

some downhole motors combined with other technologies can create directional wells

with curvatures around 200 feet. This reduction in curvature allows for operators to

economically create horizontal wells, which offer many advantages including faster

drilling.

3

Several types of downhole power units exist. In the past, electric motors have been

evaluated; today however, downhole power units are typically positive displacement or

turbines. The earliest power unit in this class is the Turbodrill; the first patent credited to

C. G. Cross in 1873 [7]. It operates like a generator in that there are turbines contained in

a sleeve fixed to a central axis. When the drilling mud or other hydraulic fluid is pumped

through the motor the turbines rotate causing axial motion for the bit. The turbine power

units are generally characterized by their high speed and torque capabilities. Their

addition to the bit power is in the range of 250 hp. This addition is considerable when the

power supplied to the bit by traditional rotary drilling methods is only around 23 hp

(1500 ft-lbs & 80 rpm).

Another type of downhole power unit is the positive displacement motor (PDM). The

first idea of this concept dates back to Rene Moineau, a French inventor who in the

1930's designed pumps and compressors that used a powered rotor/stator device to move

fluids. Later that decade T. Hudson and W. Gerber reversed Moineau's concept and let

the moving fluid tum the rotor thus converting hydraulic power into mechanical power.

Throughout the mid 1900's, this idea underwent several revisions until in 1957 Wallace

Clark patented the first industrial PDM the "Dyna-Drill." Since the original invention,

many companies have invested in developing this tool. Eastman-Whipstock, Baker

Hughes INTEQ, Dyna-Drill, Drilex, Schlumberger, and Sperry-Sun all have variations of

a PDM with different rotor/stator relationships and performance characteristics [7].

PDMs come in a wide variety of classifications. Some are made for high torque

applications and others for high speed. These characteristics are dependent on the

rotor/stator relationship which will later be discussed. PDMs' contribution to bit power is

in the range of 150 hp. Even though this addition is not as much as the turbine power

units, positive displacement motors offer several advantages. Turbine power units have

to be operated at a specified rotational speed in order to achieve the level of power

mentioned previously. This window of operation is much smaller than a PDM operating

range. For the specified rotation to be achieved a downhole tachometer, a MWD tool, is

necessary. PDMs do not require these MWD tools for operation. With the wide variety

of performance abilities, a positive displacement motor exists for almost every

application. This fact makes PDMs economical and ideal for retrofitting into existing

production platform setups.

4

Components of Positive Displacement Motors (PDMs)

A positive displacement motor is made up of four basic components: a bent sub or

adjustable housing, rotor/stator power section, bearing assembly, and a transmission unit.

A surface pump on the drilling platform or ground moves the drilling mud through the

drillstring to the PDM. This pump can provide the mud at varying flow rates and

pressures. The fluid then moves into the power section of the motor.

RolDr I Stator

Figure 1- Basic units of a PDM [1]

~ S d The rotor and stator act in a helical motion creating

chambers in which the fluid pressure causes

rotation in the rotor and thus rotation at the bit.

More discussion on the kinematics of this

relationship will follow. The bent sub can be

located either before or after the power unit. Baker

Hughes, manufacturer of the Navi-Drill, advocates

the use of the bent sub after the power unit. In this

geometry the offset between the bit and the axis of

the drillstring is smaller which imposes less stress

and wear on the motor as a whole. These bent subs

allow for the PDM to change the direction of the

drillstring.

The transmission unit in early models was a series

of universal joints and rigid links to transfer the

rotation and thus power to the bit. More recent

motors employ the technology of flexible shafts in

Figure 2 - PDM with a dump sub order to accomplish the same goal with less

[6] moving parts. Many PDMs also have a dump sub

above the power unit. This dump sub allows for

the drilling mud to bypass the motor when tripping the motor in and out of the hole. The

PDM does not allow for drilling fluid to move through the motor under hydrostatic

conditions. If the dump sub did not exist the PDM would trip out wet and trip in partially

dry. Another way to let fluid move in and out of the bottom hole assemble during

tripping is to install ajet nozzle in the rotor [1]. In this case the rotor has a hollow core

so that fluid can pass not only through the rotor/stator power unit but also through the

rotor center. Several restrictions apply to this technology, but it is useful when operating

at high flow rates. The dump sub also can be a safety device. If the motor were to stall

out, the dump sub would act as a pressure relief valve preventing serious damage to the

PDM. Stall out will be discussed later in more detail.

5

The rotor and stator have a unique relationship in that the rotor has one less lobe than the

stator. This geometric relationship is necessary to satisfy the fundamental gear tooth law.

Manufacturers of the motors make sure that the design provides the smoothest rotation

for the rotor around the stator. In this relationship it is important to note that the offset

axial rotation creates vibration normal to the axial direction. This vibration can be

minimized by proper gear design to aid in decreasing wear on the motor. Below are

pictures of the original patent filed by Moineau for this concept and of common

configurations that are currently being used in the industry today.

Do.. 27, 9 ~ It. J. L. MOINEAU 1,892,217

5:6 6:7 7:8 8:9 9:10

Figure 3 - Rotor/stator relationships [6]

Figure 4 - Original patent showing the

concept of the helical gearing system [4]

One main advantage of a PDM over the turbodrills is that their performance can be

predicted and monitored without the use of measurement while drilling devices, MWD's

for short. Through motor theory and analysis of performance data provided by

manufacturers, the affects of the addition of a positive displacement motor on the drilling

system as a whole can be accurately estimated. Furthermore the parameters for

idealization of the drilling system can be discovered.

PDM Motor Theory

Because of the geometric relationship between the rotor and stator, correlations can be

drawn between pressure, flow rate, rotational speed, and torque. The following analysis

combines fluid mechanics and kinematic relationships to form useful equations for

PDMs. One note about the following analysis is that friction and leakage through the

motor are ignored. These factors can be sizeable; however, if operation of the PDM is

within defined limits, the following procedure gives practical predictions of the

performance. Efficiencies can always be added to correct for the leakage if necessary.

In general the power produced by the drilling mud is proportional to the pressure and

flow rate.

Phyd = pQ (1)

The pressure can be observed from the standpipe pressure and the flow rate is known.

The mechanical power produced at the bit is:

P

mech

= TN (2)

Where the torque and rotation speed can be determined either by downhole devices or

theoretically with other motor design parameters. As written these equations have no

conversion factors however if

p = psi

Q=gpm

T = ft-Ibf

N=rpm

Then P _ Q 144in

2

ft3 hp s min - pQ h

hyd - P ft2 7.477 gaZ 550ft .Zbf 60s - 1714 P (1 a)

And P = TN 27C min hp . s = TN h (2a)

mech rev 60s 550ft Zbf 5252 P

6

As the fluid moves through the motor, it experiences a pressure drop. This drop can be

observed from the standpipe. When the BHA is just shy of the bottom of the hole and the

pump is providing enough pressure to cause the PDM to rotate the observed pressure is

called the off-bottom pressure. The pressure that occurs when weight or torque is applied

to the BRA by making contact with the hole is the on-bottom pressure. The difference in

on and off-bottom pressures is the pressure drop across the motor [7]. This differential

pressure is proportional to the weight on the bit or applied torque. The more WOB the

larger the differential pressure because the motor must create more torque to overcome

the applied load. The hydraulic power consumed by the PDM then becomes;

PPDM= ~ p hp

1714

(3)

A point exists where the WOB exceeds the motor's power producing capacity. This

point is referred to as stall out. At this point the mud's flow rate and pressure can no

longer create enough torque to overcome the applied load and the rotor stops with mud

being forced between it and the stator. Stall causes detrimental damage to the stator

elastomer and the motor as 100% leakage occurs. Safety devices such as dump subs, by-

pass valves, and jet nozzles help to save the motors as discussed previously. It is best,

though, to not operate near stall out conditions in order to avoid this situation. Many

manufacturers list maximum operating conditions that already have a safety factor built

in and are below stall out conditions.

Rotational Output of PDM

As mentioned the parameters T and N can be determined analytically. The rotational

output speed has a direct relationship with the flow rate and can be written as:

N=CQ (4)

In many cases, the output speed and flow rate are known from experimentation.

Experimentally it is common to test PDM's on test stands and collect data for rotational

speeds at varying flow rates. If Nand Q are known to correlate to one another, the

constant can be solved for directly. In the case of the Navi-Drills and also PDMs

manufactured by Sperry-Sun, the constant can be found by correlating output speed to

flow rates.

Table 1 - Motor Performance Data [1 & 6]

Navi-Drill Sperry-Sun

61/2" M1X 63/4" M4XL 61/2" 6 3/4"

Rotor/stator 5/6 1/2 4/5 1/2

flow-rate (GPM) 265-660 265-530 300-600 200-500

output speed (RPM) 90-220 450-900 150-300 200-500

C (rev/gal) 0.3365* 1.698 0.5 1

* some values C for mlU and max differ and recorded C IS an average.

This calculated C would be valid for all performance data when an efficiency is added

into it because as will be shown C depends solely on geometric parameters. Leakage in

the motor can cause the constants to vary a little between the minimum and maximum

operating conditions.

Analytically C can be calculated from equation 4 to:

C=nlq

n = unit output shaft rotation

q = volume thru one stator stage of the motor

In order to further develop this equation, several schemes need to be considered. First,

the output rotation needs to be related to known parameters. Second, the volume of the

motor needs to be found.

7

In looking at the output rotation consider the example of a planetary gear system. In this

case the outside shell is the stator and remains stationary. The rotor is represented by the

inside gear and is connected to an input shaft with a linkage. The linkage and input shaft

are taking the place of the fluid which actual turns the rotor. Universal joints connect the

rotor to the output shaft. In more modem PDM's the universal joint setup is replaced by

a flexible shaft.

Figure 5 - Scheme for calculating output rotation of motor

output

bI }'---__ T

r lInPUlshafl

c=:=:!]

joints

a - pitch radius of stator (# of lobes)

b - pitch radius of rotor (# of lobes)

8

For this case consider counterclockwise (CCW) motion as negative and clockwise(CW)

motion as positive. If the input shaft makes one complete rotation CCW, then the linkage

arm would have one complete rotation CCW. The arms rotation causes the rotor gear to

rotate CW while the rotor center moves with the linkage in a CCW motion. The output

shaft is attached to the rotor and consequently rotates CWo

Table 2 - Rotation table for Figure 5

Stator Rotor Output Arm

Arm -1 -1 -1 -1

Rei to Arrr 1 alb alb 0

Total 0 alb-1 a/b-1 -1

The relative motion of the rotor to the arm is the gear ratio alb where a and b also

represent the number of lobes on the stator and rotor, respectively. The total output of the

shaft is the same sign and magnitude as the total rotation of the rotor which coincides

with earlier statements. The output rotation will in this set up always be clockwise

because the ratio of alb > O.

Applying the results of this example to C=n1q produces

C= .:....%.:::...b_-_

I

q

To evaluate the volume of the stator stage, consider the second scheme. If the top of the

rotor and stator are held rigid and the output shaft turns alb-I times, the stator would

"untwist". The rotor would be reduced to one pitch. In the power unit, the rotor has two

pitches per stator stage. The volume would be conserved as the "untwisting" occurred.

Figure 6 - Scheme for calculating volume of motor stage

T

Ls

Let A = the difference in cross-sectional area of the stator and rotor

Ls = the length of one stator stage

9

Then the volume of one stage of the motor q = AL

s

. Substituting this fact into C results

in:

a-b

C=--

bAL

s

Recognizing that a-b=1 for all cases in Moineau motor geometry:

Combining 4 and 5

1

C=--

bALs

(5)

(6)

Under the same flow rate conditions, changing the volume of the PDM or the rotor/stator

ratio can alter the rotational speed. If the volume is also held constant a motor with 1:2

ratio would operate at a higher speed than a 5:6 or a 9: 10 motor. Generally it can be seen

from the motor data in Table 1 that the 1:2 motors operate between 200 and 900 rpm,

which at the bottom end of their performance is still rotating at the top end of the 4:5 and

5:6 motors' performance.

From equation 6 the volume per stage of the motor can also be determined. The Sperry-

Sun 6 %" motor has a 1:2 rotor/stator relationship. The volume of a stage length of this

particular motor would be:

500(21t) = 500/(1 * ALs)

ALs = .159 gals

This value could also be found from the constants in table 1 by applying equation 5.

10

Table 3 - Stage volumes of sample motors

Navi-Drill Sperry-Sun

61/2" M1X 63/4" M4XL 61/2" 6 3/4"

Ie (rev/gal) 0.3365 1.698 0.5 1

IALs (gal) 0.0945 0.0937 0.0796 0.159

In general, as the flow rate increases the rotational speed increases. If fitting a motor to

an existing drilling system, equation 6 is useful to find out how fast the PDM will rotate

with the given surface pump. On the design side, equation 6 is useful in determining the

volumes and rotor/stator relationships for the given design parameters.

Another essential relationship for determining the performance of PDMs is the way

torque is related to pressure.

Output Torque of PDM

The output torque will be discussed in terms of a 1:2 motor configuration. The simplest

derivation of output torque is through the equation of energy balance between output

mechanical energy per rotation of the output shaft and hydraulic energy taken from the

fluid over the length of a motor stage. Consider a motor that is 100% efficient.

TN =flpQ

The unit of time cancels between flow rate and speed. For one rotation of 21t and a

volume of ALs for one revolution of the motor, the result would be:

(7)

This gives an expression for output torque [2 & 3].

It is also useful to derive the output torque expression from a force balance consideration.

The analytical derivation for the output torque stems from the analysis of the cross-

sections in figures 7 and 8. Figure 7 is a diagram of two rotor stages and one stator

stage. Fluid enters the top section at PI and moves through the motor. The fluid exits at

P2. The pressure drop across the motor can be observed from the standpipe, i.e. the

difference in on and off-bottom pressures. PI is greater than P2; otherwise the drilling

mud would flow backwards through the PDM.

From figure 7, the source of the work can be inferred. Let the stator stage be considered

as the control volume. Even though the rotor in the stator is moving, the actual volume

between the two is constant. Refer to the scheme presented for deriving the output

rotation to understand this concept more clearly. The work for a control volume is

W = J v . dp. From the figure, it shows no pressure change over the control volume

making dp = 0 and thus the work within an entire stator stage is zero. If the control

volume is changed to the last rotor stage, it is apparent that work is being done because a

11

change in pressure is present. The magnitude of this work is not as apparent. To obtain

an expression for the work refer to figure 8.

3

r .. , ..... PI

TIl'"

~

I

z+

_-.-i-

I

iLs

'-'r'-'-'"

I

"'..-

.....

i,1 ... /.

......

. _. _. t ~ ~ _. _. _. _. _. _. _. _. _. _. _. _ ...

""'.. .J

....................

Figure 7 - Rotor and Stage Lengths Figure 8 - Cross-section of rotor and stator

rotation

Figure 8 is useful to visualize the relative motion between the rotor and stator by fixing

the centers Os and Or of each. The relative motion between rotor and stator remain the

same as in the planetary motion arrangement. The circular cross-section of the rotor is

captured in a typical angular position defined by <I> while the angular position of the stator

is defined by 8. Note that in this case <I> = 28. In figure 8, P represents the force

produced by the pressure difference across the rotor cross-section. F is the reaction of the

rotor against the side of the stator cavity.

The figure cross-section can be understood in two ways. The first is as cross-sections of

the rotor and stator taken at different distances Z from the top of the power unit. Position

1 would represent Z = 0 and Z = Lr. Position 2 would represent Z = Lr/4 and 5Lr/4, and

position 3 would represent Z = Lr/2 and 3Lr/2. Remember that the stator and rotor both

have a helical shape.

The other way to interpret the figure is to think of it as the position of the top of the rotor

as the stator rotates and the bottom of the rotor is fixed. Position 1 would be e = 0, 180,

and 360. Position 2 would be where e = 45 and 225, and position 3 would be where

e = 90 and 270.

1

The motion of the rotor can be modeled as a sliding mass that is attached to a two bar

linkage. One link is fixed between the centers of the stator and rotor circles. The

distance between the centers is e. The distance d that the rotor center is from the center

of the stator circle is

~ ...............

e

d = 2ecos e

...... , ...... e

e

Figure 9 - dimensions of linkage from figure 8

The free-body diagram shows the torque about the center of the stator circle is

T = 2Fecos e (8a)

F

Figure 10 - Free-body of linkage assemble

Because equation 8a would hold true for all differential elements, it is better to express

equation 8a as:

dT = 2 dF ecos e

From the geometry of the diagram:

F

tan8=-

p

F=Ptane

(8b)

(9a)

Again it is more appropriate to express this equation in differential form:

dF = dp tan e (9b)

Combining equations 8b and 9b results in

dT = 2e dP sin e

12

Where dP, the force due to pressure, is ~ p ) d Z . The sum of all reactionary torques then

will be equal to the torque on the output shaft. Thus the differential unit of torque is

Ie

i

I

dT = 2eilp(sin 8)odZ

Z

In order to get the equation in terms of Z use the fact that theta is by ratio 21tZILs. This

relationship is coherent with the fundamental gear tooth law in that the ratio of the

rotation of the rotor and the stator is a constant.

dT = 2eilp(sin 21tZlL

s

)8dZ

J dT = 2eilp8 L'y (sin 21tZILs) dZ

o

T

_ 4eilp8Ls

- 21t

o

(10)

13

The limit LJ2 is the length of one rotor stage. Note that if the integrand were from 0 to

Ls then the result would be O. This derivation supports the previous discussion about the

work done in the control volumes. The result implies that no torque or work is achieved

over a whole stator stage. Thus just the first and last half stages or one whole stage of the

rotor produce the work to rotate the bit. Despite this fact, most motors are made up of

several stages. The extra stages act as a dynamic seal against leakage. The more stages

the better the seal, but this number is limited by the resulting increase in friction due to

the extra stages. Most motors range from 3-5 stages.

The cross-sectional area of the stator is 4e8. Substituting into equation 10 yields:

(7)

Equation 6 and equation 7 can predict the performance of a PDM. By observing the

standpipe pressure, the torque can be monitored. Likewise the flow rate can be used to

monitor the bit speed. These equations do not take into affect the leakage or internal

friction in the mud motor, but they still provide a good means of approximating PDM

performance. Actual performance can only be established through testing and on site

monitoring.

14

Analytical Prediction of PDM Performance

The results of stand tests provide data on PDM performance. In typical testing a PDM is

attached to a dynamometer. Pressure differentials for various torque settings are recorded

at constant flow rates. Corresponding applied torques and rotational speeds are also

recorded. This information is included in motor handbooks that are published by the

manufacturer. One way the information is presented is in graphical form. Figure 11

shows the general relationship that torque and rotational speed have for a constant flow

rate.

Figure 11 - General performance curve of PDM

Stall Out

f------\...- Maximum Operating Pressure

Q = constant

Rotational Speed - RPM

When no torque from the dynamometer is applied the rotational speed is at its maximum.

At this point the differential pressure over the motor is just large enough to overcome the

friction with in the power unit. This point is the smallest differential pressure or no-load

pressure for the motor. As the torque is increased with the dynamometer, the rotational

speed begins to drop off because of leakage through the motor. The increase in torque

also causes the differential pressure to increase. The point at which the maximum torque

and minimum speed occur is the stall out point where 100% leakage occurs through the

motor. The conditions and consequences for stall have already been discussed. In order

to avoid stall conditions, a general rule of thumb is to operate around two-thirds of the

maximum.

A similar performance curve for the 6 1f2 " MIX Navi-Drill is shown in figure 12. The

ratings and information that the manufacturers provide generally correspond to about ten

percent leakage through the motor. Although this fact means that PDMs do not truly

behave according to theory, the analysis presented in the paper is accurate enough for

practical field applications as long as the motors are being operated within the

recommended pressure and flow rate ranges.

4500

4000

3500

3000

(J)

~ 2500

,

(])

:::>

E! 2000

~

1500

1000

500

15

Figure 12 - Performance curve for Navi-Drill MIX

Stall Torque

l:l p = 465 psi

QmID = 660 GPM

Qmin = 265 GPM

50 100 150 200 250 300 350 400

Rotational Speed - RPM

The maximum operating differential pressure creates a torque that is roughly two-thirds

of the stall torque. Calculated from the information provided by the manufacturer, the

constant from equation 4 is 0.3365 for this specific motor. At the minimum flow rate, the

power unit rotates at 90 R P ~ at its maximum flow rate, the unit rotates at 220 RPM.

These values are obtained from equation 4 or by correlating the manufacturer's

performance data in table 1. From equation 2a, the maximum mechanical power

produced by this motor would then be:

p = 2202690 = 113h

mech 5252 P

From equation 3, the power consumed be the motor under the maximum operating

conditions above would be:

P. = 465 660 = 179 h

hyd 1714 P

The overall efficiency of this motor would be:

11 = P

mech

= 63%

P

hyd

The same process can be applied to the other motors presented in the paper given their

operating differential pressures. Efficiencies cover a large spectrum depending on the

geometries and the age of the motor. As motors age the elastomer stator wears down

which can allow more leakage than a new motor would permit. This leakage would

reduce the overall efficiency of the motor. Yet for new motors, efficiencies can reach 80-

85%.

16

System Analysis

In order to optimize the operating parameters of a PDM, an understanding of available

power must be understood. At the surface of the drilling operation the surface pump

supplies drilling mud through the drill string to the PDM. The mud pump operates on a

curve that balances flow rate for pressure. The pumps can operate at high pressures but

low flow rates or at high flow rates and low pressures. Replacing the liners in the pumps

can alter the pump's performance. Smaller liners would produce higher pressures and

larger ones would produce larger flow rates. For example, a 1500 hp pump would have a

performance curve similar to the one in figure 13. Even though the pump might max out

at in the 10000 psi range most operators will run the pump at half or less in order to

expand the life of the pump.

Figure 13 - Surface Pump Performance

8ooo.,..------.--,..-------r-------,,------

7000

6000

_ 5000

(I)

0.

4000

(I)

(I)

0.. 3000 __ ----''''

2000

1000

Flow Rate - GPM

For example, a 1500 hp pump operating at 3000 psi can deliver the fluid at this pressure

up to a maximum flow rate of 857 gpm.

The power that this fluid possesses is dictated by equation 1. In an average drilling

situation, a surface pump maintains around 3000 psi in the standpipe. The fluid at this

pressure can be delivered at different flow rates. As the fluid progresses through the

drilling system, pressure is lost. This lost is referred to as parasitic pressure loss. The

parasitic pressure is a summation of the pressure loss due to friction in the drill stem,

friction in the annulus, and debris in the annulus. Experimentally it has been found that

this loss is proportional to Q1.86. The difference in the surface pump power and the

parasitic power loss is the power available for driving the PDM and cleaning the bit (see

Figure 14). The pressure and power loss here is based on a 5 W' drillstring and a 97/8"

wholelbit diameter for drilling mud with a density of 12 Ibm/gal [5]. In general at the

point of maximum available power the parasitic pressure losses will be approximately

one-third of the supplied pressure from the surface pump [8].

where Pp = ppQ = constQ2

086

Setting the derivative to zero gives the Q at which P

max

occurs.

O=Ps - 2.86*constQ1.86 (11)

or substituting the definition of Pp back in results in:

(12)

Figure 14 - Hydraulic losses in system

4000

om

0. Surface Pump

:;,

2000

(])

a: 1000

1000

u

:s

(IJ

-a 500

200 400 600 800

./"

"

Surface Pump System .

,/'

200 400 600 800

Flow Rate - GPM

1000

1000

17

In general drilling conditions without a PDM, most operators try to maintain a flow rate

at the point where maximum power is available at the bit for cleaning. By inspection this

is around 600 GPM. Analytically this flow rate can be determined from equation 12.

[

P

]

><'86

Q_ s

2.86 canst

(13)

An appropriate PDM for this available power curve would be one that operates in the

range of 400 to 700 GPM. The Navi-Drill MIX operates from 265-660 GPM; a good fit

for the available power.

18

By adding the PDM perfonnance curve to this chart, the operating range becomes

obvious. The PDM curve is determined by the pressure drop data provided by the PDM

manufacturers. The manufacturers also supply the minimum and maximum operating

flow rates.

0..

I

700

600

500

.!'! 400

3

~

1:>

f 300

200

100

Figure 15 - PDM Hydraulic Power usage

Available

Qmax

o ~ ~ ~ ~ ~ L L ~

200 400 600 800 1000

Flow Rate - GPM

From this point the other restraints become guess and check. The motor must operate in

a range where a minimum annular velocity can be maintained. There must also be

enough power left to allow an adequate pressure drop across the bit for hole cleaning.

This parameter can be checked and results in a total flow area for the bit.

Next, the flow rate at which a minimum annular flow can be maintained needs to be

found. Annular flow rates general run between 50 ft/min and 200 ft/min. A common

maintainable annular velocity is around 120 ftlmin. This rate provides adequate flow to

move the cuttings away from the bit but not so much flow that it would erode the hole

wall and enlarge the annulus.

Dh = hole diameter

4Q

Va = (D 2 D 2)

1t h - s

Ds = drillstring diameter

Va = annular velocity

Q = flow rate

(11)[5]

The bit size range and thus hole size range for the motors under consideration is 7-7/8" to

9-7/8". From equation 11, the annular flow rates for a 9-7/8" hole would be:

By comparing these values to the flow rate range of the motors in chart 1, the annular

velocity constraints on the PDM become evident. With the PDM usage shown, operating

at maximum hydraulic horsepower would provide ample flow to maintain the annular

velocity.

19

The last restraint of fitting a PDM into an existing drilling system is the nozzle selection.

The available hydraulic power for the bit is the difference between the PDM curve and

available hydraulic power curve. If the pump operates at 600 GPM, the PDM consumes

163 hp out of the 683 hp available. This leaves 520 hp for the bit. This power correlates

to a pressure drop across the bit of 1485 psi per equation (la). The total flow area for the

bit can be found from:

TFA=1[ p.Q

[

2 ]112

where p = 12 Ibm/gal

Q=600GPM

Pb = 1485 psi

4 6700 ilPb

TFA = .518 in

2

(12)[5]

This same procedure can be repeated in a more general manner by using graphs that plot

TFA against varying flow rates. The chart would also show the annular velocity as a

function of flow rate. By setting limits on the chart, the operating Q, Va, and TF A can be

found.

For the MIX to operate in a 97/8" hole with 5 W' drill pipe with a surface pump capacity

of 3000 psi and 600 gpm, the bit would need to have a TF A of .518 in

2

in order to use the

most power that the pump is providing. This process could be repeated for any system

and any PDM configuration. The total process is a balancing act between flow rate,

system losses, bit size, and nozzle size

Conclusions

Downhole motors and more specifically positive displacement motors are essential tools

in bottom hole assemblies in drilling today. PDMs add a power boost or act as the sole

means of rotation for the bit. They generally contribute 100-150 extra horsepower

compared to the 23 hp generated by tradition drill string rotation.

PDMs come in a variety of configurations making retrofitting one into existing situations

confusing without proper knowledge of how to evaluate a PDM's performance.

Performance in general terms:

Rotational speed is proportional to its flow rate. It can be increased by

reducing the number of lobes on the rotor, increasing flow rate, or decreasing

the volume per stage of the motor.

Torque is proportional to the pressure drop across the motor. Torque can be

increased by increasing the differential pressure, increasing the volume of the

stage, or increasing the number of lobes on the rotor.

20

The mechanical power produced it proportional to rotational speed and torque.

It can be increased by increasing either rotational speed or torque.

PDMs with a greater number of lobes generally produce more torque but

operated a slower speeds than motors with just 1 or 2 lobes on the rotor. The

power produced by the motors cannot be generalized in terms of rotor/stator

configuration and is specific to each case.

Efficiency drops with larger lobe configurations because of friction and fluid

slippage.

Before a motor can be chosen, the hydraulic power available must be

calculated. The maximum available power is approximately two-thirds of the

power initially supplied by the surface pump. The best motor makes optimal

use of the available hydraulic horsepower

As a rule of thumb when deciding the flow rate at which to operate the PDM, it

ought to consume near one-third of the hydraulic power available. This flow

rate needs to be checked against the annular velocity to make sure it is large

enough to provide adequate bit cleaning but not so large that it will erode the

hole wall.

The last step in fitting the PDM into the existing system is to chose an

appropriate size bit nozzle. If the size nozzle turns out to be too large based on

available equipment, try increasing the operational flow rate. If the size is still

too large, the hole size may need to be decreased or a different PDM may need

to be considered.

Be careful not to operate the PDM outside of the manufacturer recommended

operating conditions. Operating beyond these suggested limits puts the BHA at

risk for stall out and thus detrimental damage. Also operating outside these

limits decreases the accuracy of the equations presented.

All equations assume 100% efficiency and no leakage. Although this is not

realistic, it gives a good prediction and analysis of a PDM's performance in

normal operating conditions.

The processes presented in this paper are general and can be applied to any drilling

situation and any PDM. It is essential to understand the performance possibilities and

system limitations in order to truly incorporate the best PDM into an existing drilling

system.

Nomenclature

A = cross-sectional area of void in power unit

a = # lobes on stator

b = # lobes on rotor

BHA = bottom hole assembly

Dh = hole diameter

Ds = drill string diameter

e = distance between the center of the stator and rotor circles

Ls = length of stator stage

MWD = measurement while drilling

N = rotational speed

n = unit output shaft rotation

PDM = positive displacement motor

P

b

= power at bit

Pp = power parasitic (power loss)

P

s

= power from surface pump

p = pressure

Pb = pressure across bit

p = mud density

Q = flow rate

q = volume thru one stator stage of the motor

T = torque

TFA = Total flow area across bit

Va = annular velocity

WOB = weight on bit

21

22

References

1. Baker-Hughes INTEQ. "Navi-Drill Motor Handbook." 8 ed. Baker Hughes Inc.,

1998.

2. Cohen, John, Maurer, William, Evans, Charles, & Westcott, Paul. "High-Power

Downhole Motor." American Society of Mechanical Engineers, 1995. vol. 65:

265-271.

3. Delpassand, Majid. "Stator Life of a Positive Displacement Down-hole Drilling

Motor." ASME Energy Sources Technology Conference, 1999.

4. Moineau, Rene. "Gear Mechanism." US Patent #1,892,217 Dec 27,1932

5. Schuh, Frank. "Petroleum Engineer's Equations & Rules-of-Thumb: Drilling

Equations." Petroleum Engineer Publishing 1977.

6. Sun-Sperry Drilling Services. "Sun Drill Technical Information Handbook." 2

ed. Halliburton Energy Services Inc, 2000.

7. Tiraspolsky, Wladimir. "Hydraulic Downhole Drilling Motors." Gulf Publishing:

Houston, 1985.

8. Ed. Whittaker, Alun. "Theory and Application of Drilling Fluid Hydraulics."

International Human Resources Development: Boston, 1985.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- SEW Line Machine Checksheet DDocument7 pagesSEW Line Machine Checksheet DMURALIDHRAPas encore d'évaluation

- Amsco 400 Series Medium Steam Sterilizers: ApplicationDocument8 pagesAmsco 400 Series Medium Steam Sterilizers: ApplicationMiloven WongPas encore d'évaluation

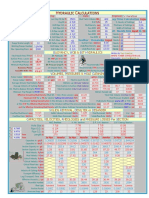

- Hydraulic Calculations MudpumpDocument1 pageHydraulic Calculations MudpumpSudish BhatPas encore d'évaluation

- Relief Valve (Cushion Crossover) Relief Valve Operation: SMCS Code: 5111 5454Document15 pagesRelief Valve (Cushion Crossover) Relief Valve Operation: SMCS Code: 5111 5454Sam SungPas encore d'évaluation

- Smartroc T45: Surface Drill Rig For Quarrying and ConstructionDocument5 pagesSmartroc T45: Surface Drill Rig For Quarrying and ConstructionSerkanAlPas encore d'évaluation

- Pump Installation Do's and Don'TsDocument62 pagesPump Installation Do's and Don'Tsdieguineo100% (1)

- Actuators Structure of DiscussionDocument13 pagesActuators Structure of DiscussionMr.M. ArivalaganPas encore d'évaluation

- Automation of Die Cutting MachineDocument34 pagesAutomation of Die Cutting Machinesyed ebadPas encore d'évaluation

- Equipos para La Estacion de BomberosDocument35 pagesEquipos para La Estacion de BomberosCarlos JavierPas encore d'évaluation

- Warnings and Cautions Views and Hydraulic Schematic: Hydraulic Ultra-High Pressure Test Pump User's ManualDocument2 pagesWarnings and Cautions Views and Hydraulic Schematic: Hydraulic Ultra-High Pressure Test Pump User's ManualfranciscoPas encore d'évaluation

- Liebherr Hs 8130 HD Duty Cycle Crawler Crane Technical Data Sheet Spec Specifications 16224 0 2Document12 pagesLiebherr Hs 8130 HD Duty Cycle Crawler Crane Technical Data Sheet Spec Specifications 16224 0 2JusmaWahidahPas encore d'évaluation

- Genie Energetique SyllabusDocument166 pagesGenie Energetique SyllabusEsteban hubertPas encore d'évaluation

- SPAN Approval 2018 - Sludge Pump (Lampiran A)Document9 pagesSPAN Approval 2018 - Sludge Pump (Lampiran A)Syed IhyaPas encore d'évaluation

- BPR ControlsDocument7 pagesBPR ControlssssydorenkoPas encore d'évaluation

- Centrifugal Pumps Problem SolvingDocument1 pageCentrifugal Pumps Problem SolvingKamal UddinPas encore d'évaluation

- Displacement Manual PDFDocument29 pagesDisplacement Manual PDFAngel Schettino Villalba100% (1)

- Leak DetectionDocument41 pagesLeak DetectionZsuzsanna Tamásiné Horváth100% (1)

- PowerTech 4.5L &6.8L Diesel Engines - Level 12 Electronic Fuel System-Stanadyne DE10 Pump-CTM331Document550 pagesPowerTech 4.5L &6.8L Diesel Engines - Level 12 Electronic Fuel System-Stanadyne DE10 Pump-CTM331grand fir100% (40)

- Fan and Pump Motor Energy Savings Guide: Year 1 Year 2Document14 pagesFan and Pump Motor Energy Savings Guide: Year 1 Year 2sakshi_nittPas encore d'évaluation

- Electrical Eng GDocument47 pagesElectrical Eng GHtet lin AgPas encore d'évaluation

- Hydrotec SKM DDocument8 pagesHydrotec SKM DkulilistrikPas encore d'évaluation

- 2.5 Fuel Oil SystemDocument14 pages2.5 Fuel Oil SystemDangolPas encore d'évaluation

- Ebsray Pumps: G SeriesDocument4 pagesEbsray Pumps: G Seriesmartin.rubenPas encore d'évaluation

- 5.5 Thing Power Plant Need To Know About PumpsDocument4 pages5.5 Thing Power Plant Need To Know About Pumpsfirdausshukri14Pas encore d'évaluation

- Condensate Cycle SystemDocument26 pagesCondensate Cycle SystemBhumit Sagathiya100% (2)

- Refinery Operating Procedure PDFDocument48 pagesRefinery Operating Procedure PDFMohamed67% (3)

- P1PD Medium Pressure Axial Piston Pumps-HY28-2665-01 - P1 - ENDocument68 pagesP1PD Medium Pressure Axial Piston Pumps-HY28-2665-01 - P1 - ENGilson RodriguesPas encore d'évaluation

- Piaggio Beverly 250 USA (EN)Document308 pagesPiaggio Beverly 250 USA (EN)ManuallesPas encore d'évaluation

- Conf 2000B FlucomDocument6 pagesConf 2000B FlucomPietro RosataPas encore d'évaluation

- Sandvik DL431 TS2-274 - 03Document4 pagesSandvik DL431 TS2-274 - 03Anonymous UXEtI80kPas encore d'évaluation