Académique Documents

Professionnel Documents

Culture Documents

2H + O ® 2H O + 2e: Fuel Cell Basics

Transféré par

Ram Mohan Rao MakineniTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

2H + O ® 2H O + 2e: Fuel Cell Basics

Transféré par

Ram Mohan Rao MakineniDroits d'auteur :

Formats disponibles

Solid Oxide Fuel Cells

by

Earnest Garrison

This is an introductory to advanced lesson on Solid Oxides Fuel Cells. I decided the Solid Oxide was the

best option in that there werent expensive electrodes and the electrolyte was solid.

The purpose of this Web page is to introduce alternate energy sources that are now available. The fuel cell is

currently In use at small building sites around the world.

Basic Reactions

2H

2

+O

2

2H

2

O +2e

-

Fuel Cell Basics

What is a fuel cell?

A fuel cell is a device that generates electricity by a chemical reaction. Every fuel cell has two electrodes, one

positive and one negative, called, respectively, the cathode and anode. The reactions that produce electricity

take place at the electrodes.

Every fuel cell also has an electrolyte, which carries electrically charged particles from one electrode to the

other, and a catalyst, which speeds the reactions at the electrodes.

Hydrogen is the basic fuel, but fuel cells also require oxygen. One great appeal of fuel cells is that they

generate electricity with very little pollutionmuch of the hydrogen and oxygen used in generating electricity

ultimately combine to form a harmless byproduct, namely water.

One detail of terminology: a single fuel cell generates a tiny amount of direct current (DC) electricity. In

practice, many fuel cells are usually assembled into a stack. Cell or stack, the principles are the same.

How do fuel cells work?

The purpose of a fuel cell is to produce an electrical current that can be directed outside the cell to do work,

such as powering an electric motor or illuminating a light bulb or a city. Because of the way electricity

behaves, this current returns to the fuel cell, completing an electrical circuit.

There are several kinds of fuel cells, and each operates a bit differently. But in general terms, hydrogen atoms

enter a fuel cell at the anode where a chemical reaction strips them of their electrons. The hydrogen atoms are

now ionized, and carry a positive electrical charge. The negatively charged electrons provide the current

through wires to do work. If alternating current (AC) is needed, the DC output of the fuel cell must be routed

through a conversion device called an inverter.

Oxygen enters the fuel cell at the cathode and, in some cell types (like the one illustrated above), it there

combines with electrons returning from the electrical circuit and hydrogen ions that have traveled through the

electrolyte from the anode. In other cell types the oxygen picks up electrons and then travels through the

electrolyte to the anode, where it combines with hydrogen ions.

The electrolyte plays a key role. It must permit only the appropriate ions to pass between the anode and

Solid Oxide Fuel Cells http://mypages.iit.edu/~smart/garrear/fuelcells.htm

1 of 8 7/18/2014 9:32 AM

cathode. If free electrons or other substances could travel through the electrolyte, they would disrupt the

chemical reaction.

Whether they combine at anode or cathode, together hydrogen and oxygen form water, which drains from the

cell. As long as a fuel cell is supplied with hydrogen and oxygen, it will generate electricity.

Even better, since fuel cells create electricity chemically, rather than by combustion, they are not subject to

the thermodynamic laws that limit a conventional power plant. Therefore, fuel cells are more efficient in

extracting energy from a fuel. Waste heat from some cells can also be harnessed, boosting system efficiency

still further.

So why cant I go out and buy a fuel cell?

The basic workings of a fuel cell may not be difficult to illustrate. But building inexpensive, efficient, reliable

fuel cells is a far more complicated business.

Scientists and inventors have designed many different types and sizes of fuel cells in the search for greater

efficiency, and the technical details of each kind vary. Many of the choices facing fuel cell developers are

constrained by the choice of electrolyte. The design of electrodes, for example, and the materials used to

make them depend on the electrolyte. Today, the main electrolyte types are alkali, molten carbonate,

phosphoric acid, proton exchange membrane (PEM) and solid oxide. The first three are liquid electrolytes;

the last two are solids.

The type of fuel also depends on the electrolyte. Some cells need pure hydrogen, and therefore demand extra

equipment such as a reformer to purify the fuel. Other cells can tolerate some impurities, but might need

higher temperatures to run efficiently. Liquid electrolytes circulate in some cells, which requires pumps. The

type of electrolyte also dictates a cells operating temperaturemolten carbonate cells run hot, just as the

name implies.

Each type of fuel cell has advantages and drawbacks compared to the others, and none is yet cheap and

efficient enough to widely replace traditional ways of generating power, such coal-fired, hydroelectric, or

even nuclear power plants.

The following list describes the five main types of fuel cells. More detailed information can be found in those

specific areas of this site.

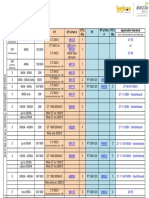

Different types of fuel cells.

Solid Oxide Fuel Cells http://mypages.iit.edu/~smart/garrear/fuelcells.htm

2 of 8 7/18/2014 9:32 AM

Drawing of an alkali cell.

Alkali fuel cells operate on compressed hydrogen and oxygen. They generally use a solution of potassium

hydroxide (chemically, KOH) in water as their electrolyte. Efficiency is about 70 percent, and operating

temperature is 150 to 200 C, (about 300 to 400 F). Cell output ranges from 300 watts (W) to 5 kilowatts

(kW). Alkali cells were used in Apollo spacecraft to provide both electricity and drinking water. They require

pure hydrogen fuel, however, and their platinum electrode catalysts are expensive. And like any container

filled with liquid, they can leak.

Drawing of a molten carbonate cell

Molten Carbonate fuel cells (MCFC) use high-temperature compounds of salt (like sodium or magnesium)

carbonates (chemically, CO

3

as the electrolyte. Efficiency ranges from 60 to 80 percent, and operating

temperature is about 650 C (1,200 F). Units with output up to 2 megawatts (MW) have been constructed,

and designs exist for units up to 100 MW. The high temperature limits damage from carbon monoxide

"poisoning" of the cell and waste heat can be recycled to make additional electricity. Their nickel electrode-

catalysts are inexpensive compared to the platinum used in other cells. But the high temperature also limits

the materials and safe uses of M C F C sthey would probably be too hot for home use. Also, carbonate

ions from the electrolyte are used up in the reactions, making it necessary to inject carbon dioxide to

compensate.

Phosphoric Acid fuel cells (PAFC) use phosphoric acid as the electrolyte. Efficiency ranges from 40 to 80

percent, and operating temperature is between 150 to 200 C (about 300 to 400 F). Existing phosphoric acid

Solid Oxide Fuel Cells http://mypages.iit.edu/~smart/garrear/fuelcells.htm

3 of 8 7/18/2014 9:32 AM

cells have outputs up to 200 kW, and 11 MW units have been tested. P A F C s tolerate a carbon monoxide

concentration of about 1.5 percent, which broadens the choice of fuels they can use. If gasoline is used, the

sulfur must be removed. Platinum electrode-catalysts are needed, and internal parts must be able to withstand

the corrosive acid.

drawing of how both phosphoric acid and

PEM fuel cells operate

Drawing of how both phosphoric acid and PEM fuel cells operate.

Proton Exchange Membrane (PEM) fuel cells work with a polymer electrolyte in the form of a thin,

permeable sheet. Efficiency is about 40 to 50 percent, and operating temperature is about 80 C (about 175

F). Cell outputs generally range from 50 to 250 kW. The solid, flexible electrolyte will not leak or crack, and

these cells operate at a low enough temperature to make them suitable for homes and cars. But their fuels

must be purified, and a platinum catalyst is used on both sides of the membrane, raising costs.

Drawing of a solid oxide cell

Solid Oxide fuel cells (SOFC) use a hard, ceramic compound of metal (like calcium or zirconium) oxides

(chemically, O

2

) as electrolyte. Efficiency is about 60 percent, and operating temperatures are about 1,000 C

(about 1,800 F). Cells output is up to 100 kW. At such high temperatures a reformer is not required to extract

hydrogen from the fuel, and waste heat can be recycled to make additional electricity. However, the high

temperature limits applications of SOFC units and they tend to be rather large. While solid electrolytes cannot

leak, they can crack.

Let's see what you have learned.

Solid Oxide Fuel Cells http://mypages.iit.edu/~smart/garrear/fuelcells.htm

4 of 8 7/18/2014 9:32 AM

To go to Testing Page, click here.

These are the results from an research done this year at Northwestern University on solid oxide electrolyte .

The electrolyte usually CaO or ZrO and operates at about 1000 C. The operational efficiency is about 60 %

and output is about 100 kWh.

Simultaneously optimizing electrical performance and mechanical strength

Minimizing electrical losses

Tight gas seals to prevent fuel and oxidant mixing

Manufacturability

Scalability

Solid Oxide Fuel Cells http://mypages.iit.edu/~smart/garrear/fuelcells.htm

5 of 8 7/18/2014 9:32 AM

Relatively high conductivity of CSZ substrate at high T shunting current

Difficulty of patterning deposits using e.g. slurry coating and EVD

Patterning around full width of tube easier with flat surfaces

Large cell widths (1 cm) can lead to resistive losses

Good mechanical properties

Solid Oxide Fuel Cells http://mypages.iit.edu/~smart/garrear/fuelcells.htm

6 of 8 7/18/2014 9:32 AM

Uses porous supports

High resistance

Eliminates high resistance pressure contacts between SOFC and IC plates

Flattened tube geometry easy to process

Small cells more tolerant of thin electrolyte defects

Small (1-2 mm) cells minimize electrode current paths, resistance losses

Current flow along surface instead of between separate pieces

Since plates arent in contact, manufacturing tolerances eased

Eliminates interconnects and reduces number of flow fields by 2 (relative to planar SOFC

Flattened tubes allow high volume density, minimize sealing problems

Compare ISOFC losses with 10 cm 10 cm planar stack SOFC

(Assumptions: 0.5 W/cm 2 at 0.7 V, 0.2 contact resistance)

PSZ: TCE close to YSZ

relatively low ionic conductivity

Solid Oxide Fuel Cells http://mypages.iit.edu/~smart/garrear/fuelcells.htm

7 of 8 7/18/2014 9:32 AM

high fracture toughness

conductivity, TCE (13.5 10

xx

)

Possible techniques for patterned deposition

Easy to align shadow masks over planar substrates

Easy to make 0.1 mm features. Consistent with 1 2 mm wide cells

Mask alignment needed if pieces are removed between depositions (e.g. for sintering

Back to the SMART index page.

Solid Oxide Fuel Cells http://mypages.iit.edu/~smart/garrear/fuelcells.htm

8 of 8 7/18/2014 9:32 AM

Vous aimerez peut-être aussi

- How Fuel Cells WorkDocument18 pagesHow Fuel Cells Work70 Kabir JainPas encore d'évaluation

- Fuel Cell 2Document10 pagesFuel Cell 2Aravind KumarPas encore d'évaluation

- Large Scale Power Generation Using Fuel CellDocument6 pagesLarge Scale Power Generation Using Fuel CellsrilakshmisiriPas encore d'évaluation

- Fuel BatteryDocument17 pagesFuel BatteryHarsha Vardhan SakalaPas encore d'évaluation

- A Paper Prasentation On FUEL CELL1Document10 pagesA Paper Prasentation On FUEL CELL1kalyanjammulaPas encore d'évaluation

- Presentation Fuel Cell Presentation 1509777151 19748Document39 pagesPresentation Fuel Cell Presentation 1509777151 19748Krishna Pavan KPas encore d'évaluation

- How Fuel Cells WorkDocument58 pagesHow Fuel Cells Workwhcallegari100% (1)

- Application of Fuel CellsDocument28 pagesApplication of Fuel CellsKhirad JagarwalPas encore d'évaluation

- Lecture 21: Alternative Energy Resources - The Fuel CellDocument6 pagesLecture 21: Alternative Energy Resources - The Fuel CellIjazzzAliPas encore d'évaluation

- Electricity Generation ResearchDocument35 pagesElectricity Generation ResearchlightrocketPas encore d'évaluation

- Lecture Sheet PDFDocument65 pagesLecture Sheet PDFFaruk abdullahPas encore d'évaluation

- Seminar ON Fuel Cells::Anirudh Gupta: Electrometallurgy and Corrosion.: 902 2011Document15 pagesSeminar ON Fuel Cells::Anirudh Gupta: Electrometallurgy and Corrosion.: 902 2011Devashish JoshiPas encore d'évaluation

- General Fuel Cell PresentationDocument35 pagesGeneral Fuel Cell PresentationMukhtiar Hussain100% (1)

- Fuels & Combustion: Fuel Cells ExplainedDocument26 pagesFuels & Combustion: Fuel Cells ExplainedHomesick TutorsPas encore d'évaluation

- Renewable Energy Systems2Document7 pagesRenewable Energy Systems2ARVINDPas encore d'évaluation

- The Promise of Hydrogen as a Clean Fuel of the FutureDocument15 pagesThe Promise of Hydrogen as a Clean Fuel of the FutureAbhinav GuptaPas encore d'évaluation

- Hydrogen Fuel Cell Technology: Will It Contribute To Energy Independence?Document44 pagesHydrogen Fuel Cell Technology: Will It Contribute To Energy Independence?sagarsawhneyPas encore d'évaluation

- Lecture9 - Energy StorageDocument47 pagesLecture9 - Energy StorageTze Long GanPas encore d'évaluation

- SeminarDocument17 pagesSeminarAbhi s. patelPas encore d'évaluation

- Fuel Cells: Done By: Arvind SDocument28 pagesFuel Cells: Done By: Arvind SJoyPas encore d'évaluation

- Harnessing Hydrogen For Power: Hydrogen Cars: Sunny Saini Branch: M.EDocument18 pagesHarnessing Hydrogen For Power: Hydrogen Cars: Sunny Saini Branch: M.ELuis NunesPas encore d'évaluation

- Hydrogen Fuel Cell Tech ExplainedDocument61 pagesHydrogen Fuel Cell Tech ExplainedSyed Ñąveed HąįdeŕPas encore d'évaluation

- Design and Operation of Solid Oxide Fuel Cells: The Systems Engineering Vision for Industrial ApplicationD'EverandDesign and Operation of Solid Oxide Fuel Cells: The Systems Engineering Vision for Industrial ApplicationPas encore d'évaluation

- Fuel Cell Modeling and Simulation: From Microscale to MacroscaleD'EverandFuel Cell Modeling and Simulation: From Microscale to MacroscalePas encore d'évaluation

- Metal-Hydrogen Systems: Proceedings of the Miami International Symposium on Metal-Hydrogen Systems, 13-15 April 1981, Miami Beach, Florida, U.S.A.D'EverandMetal-Hydrogen Systems: Proceedings of the Miami International Symposium on Metal-Hydrogen Systems, 13-15 April 1981, Miami Beach, Florida, U.S.A.Pas encore d'évaluation

- Solar-Driven Green Hydrogen Generation and StorageD'EverandSolar-Driven Green Hydrogen Generation and StorageRohit SrivastavaPas encore d'évaluation

- Green Carbon Dioxide: Advances in CO2 UtilizationD'EverandGreen Carbon Dioxide: Advances in CO2 UtilizationGabriele CentiPas encore d'évaluation

- Municipal Solid Waste to Energy Conversion Processes: Economic, Technical, and Renewable ComparisonsD'EverandMunicipal Solid Waste to Energy Conversion Processes: Economic, Technical, and Renewable ComparisonsPas encore d'évaluation

- Bolts in TensionDocument20 pagesBolts in TensionshingkeongPas encore d'évaluation

- Operations Intelligence Complete Self-Assessment GuideD'EverandOperations Intelligence Complete Self-Assessment GuidePas encore d'évaluation

- Water and Thermal Management of Proton Exchange Membrane Fuel CellsD'EverandWater and Thermal Management of Proton Exchange Membrane Fuel CellsPas encore d'évaluation

- One-dimensional Nanostructures for PEM Fuel Cell ApplicationsD'EverandOne-dimensional Nanostructures for PEM Fuel Cell ApplicationsPas encore d'évaluation

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationD'EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationPas encore d'évaluation

- Solar Tower TechnologyDocument29 pagesSolar Tower Technologysanjana16dec100% (1)

- Hidrogeno Revision PDFDocument6 pagesHidrogeno Revision PDFtunja1Pas encore d'évaluation

- Solar Hydrogen ProyectDocument19 pagesSolar Hydrogen ProyectCamilo Ig GoarPas encore d'évaluation

- Global hydrogen trade to meet the 1.5°C climate goal: Part III – Green hydrogen cost and potentialD'EverandGlobal hydrogen trade to meet the 1.5°C climate goal: Part III – Green hydrogen cost and potentialPas encore d'évaluation

- Modeling, Assessment, and Optimization of Energy SystemsD'EverandModeling, Assessment, and Optimization of Energy SystemsPas encore d'évaluation

- Renewable Energy Engineering: Solar, Wind, Biomass, Hydrogen and Geothermal Energy SystemsD'EverandRenewable Energy Engineering: Solar, Wind, Biomass, Hydrogen and Geothermal Energy SystemsPas encore d'évaluation

- AC-DC Converters For Electrolyzer Applications StaDocument30 pagesAC-DC Converters For Electrolyzer Applications StaAudaPas encore d'évaluation

- Electricity Supply Industry Performance Report 2018Document54 pagesElectricity Supply Industry Performance Report 2018African Centre for Media ExcellencePas encore d'évaluation

- Fuel Cell AssignmentDocument13 pagesFuel Cell AssignmentChetanPrajapati100% (1)

- Fuel Cell DevelopmentDocument3 pagesFuel Cell DevelopmentDivij KishalPas encore d'évaluation

- Books: Cryogenic Engineering, 2 Edition Distillation Theory and Its Application To Design of Separation UnitsDocument1 pageBooks: Cryogenic Engineering, 2 Edition Distillation Theory and Its Application To Design of Separation UnitsRaul tejadaPas encore d'évaluation

- Case Story DK - Green Methanol - Web 1Document4 pagesCase Story DK - Green Methanol - Web 1Pao M. MorenoPas encore d'évaluation

- New Model For Predicting Thermal Radiation From Flares and High Pressure Jet Fires For Hydrogen and SyngasDocument15 pagesNew Model For Predicting Thermal Radiation From Flares and High Pressure Jet Fires For Hydrogen and Syngasthlim19078656Pas encore d'évaluation

- Chemical Energy in The Fuel To Electrical Energy With Efficiencies of Up To 60%. No Carbon Dioxide EmissionsDocument13 pagesChemical Energy in The Fuel To Electrical Energy With Efficiencies of Up To 60%. No Carbon Dioxide EmissionsyashvantPas encore d'évaluation

- Evaluation of Separators For Use in Li-Ion BatteriesDocument7 pagesEvaluation of Separators For Use in Li-Ion BatteriesVNPas encore d'évaluation

- Translating Grades into Danish Grading SystemDocument4 pagesTranslating Grades into Danish Grading SystemRam Mohan Rao MakineniPas encore d'évaluation

- Nonlinear Control For Mitigation of Second-Order Harmonic Ripple Problem in Grid ConvertersDocument5 pagesNonlinear Control For Mitigation of Second-Order Harmonic Ripple Problem in Grid ConvertersRam Mohan Rao MakineniPas encore d'évaluation

- Adopting Mbse and Sysml For Design of Electric Vehicle: Dassault Systemes India Pvt. LTDDocument3 pagesAdopting Mbse and Sysml For Design of Electric Vehicle: Dassault Systemes India Pvt. LTDRam Mohan Rao MakineniPas encore d'évaluation

- Aauthoring: by Company Secondary Research SourcesDocument1 pageAauthoring: by Company Secondary Research SourcesRam Mohan Rao MakineniPas encore d'évaluation

- Annual Instalment Request with Expenditure StatementDocument2 pagesAnnual Instalment Request with Expenditure StatementRam Mohan Rao MakineniPas encore d'évaluation

- FAQ On CoWIN For CitizensDocument5 pagesFAQ On CoWIN For CitizensYakifePas encore d'évaluation

- ECE Graduate Courses - 1 - 0Document4 pagesECE Graduate Courses - 1 - 0Ram Mohan Rao MakineniPas encore d'évaluation

- Power Purchase Agreement For Procurement of Solar Power On Long Term Basis Under PM-KUSUM Component-A Scheme BetweenDocument33 pagesPower Purchase Agreement For Procurement of Solar Power On Long Term Basis Under PM-KUSUM Component-A Scheme BetweenRam Mohan Rao MakineniPas encore d'évaluation

- 272 504 GSDocument1 page272 504 GSRam Mohan Rao MakineniPas encore d'évaluation

- Vikash Singh: Experience LanguagesDocument2 pagesVikash Singh: Experience LanguagesRam Mohan Rao MakineniPas encore d'évaluation

- Form Rdc/1A: (Please Identify Key Issues/problems To Be Addressed)Document5 pagesForm Rdc/1A: (Please Identify Key Issues/problems To Be Addressed)Alemayehu DargePas encore d'évaluation

- EncoderDocument4 pagesEncoderRam Mohan Rao MakineniPas encore d'évaluation

- Aauthoring: by Company Secondary Research SourcesDocument1 pageAauthoring: by Company Secondary Research SourcesRam Mohan Rao MakineniPas encore d'évaluation

- University Selection Post GRE Draft List of Universities 454538 1613474763Document48 pagesUniversity Selection Post GRE Draft List of Universities 454538 1613474763Ram Mohan Rao MakineniPas encore d'évaluation

- Documents PDFDocument18 pagesDocuments PDFRam Mohan Rao MakineniPas encore d'évaluation

- Indian Institute of Technology Jodhpur Power Electronics and Electric Vehicle Laboratory (Peevl)Document4 pagesIndian Institute of Technology Jodhpur Power Electronics and Electric Vehicle Laboratory (Peevl)Ram Mohan Rao MakineniPas encore d'évaluation

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word DocumentRam Mohan Rao MakineniPas encore d'évaluation

- Research ProposalDocument6 pagesResearch ProposalRam Mohan Rao MakineniPas encore d'évaluation

- Instructions To Candidates: Attempt Any Five QuestionsDocument2 pagesInstructions To Candidates: Attempt Any Five QuestionsRam Mohan Rao MakineniPas encore d'évaluation

- SopDocument2 pagesSopRam Mohan Rao MakineniPas encore d'évaluation

- Review of Techniques for Mitigating Second-order Harmonic Ripple in Single-phase InvertersDocument36 pagesReview of Techniques for Mitigating Second-order Harmonic Ripple in Single-phase InvertersRam Mohan Rao MakineniPas encore d'évaluation

- OPAL-RT How-To Video and Quick Start Guide Links (Updated Feb 2019)Document5 pagesOPAL-RT How-To Video and Quick Start Guide Links (Updated Feb 2019)Ram Mohan Rao MakineniPas encore d'évaluation

- Converters CiruitDocument1 pageConverters CiruitRam Mohan Rao MakineniPas encore d'évaluation

- Course Rev Asscessment Worksheet CO2 3EE1A EDC (4.2)Document2 pagesCourse Rev Asscessment Worksheet CO2 3EE1A EDC (4.2)Ram Mohan Rao MakineniPas encore d'évaluation

- Course Rev Asscessment Worksheet CO1 3EE1A EDC (4.1)Document13 pagesCourse Rev Asscessment Worksheet CO1 3EE1A EDC (4.1)Ram Mohan Rao MakineniPas encore d'évaluation

- Course Rev Asscessment Worksheet CO2 3EE1A EDC (4.2)Document2 pagesCourse Rev Asscessment Worksheet CO2 3EE1A EDC (4.2)Ram Mohan Rao MakineniPas encore d'évaluation

- Course Rev Asscessment Worksheet CO2 3EE1A EDC (4.2)Document2 pagesCourse Rev Asscessment Worksheet CO2 3EE1A EDC (4.2)Ram Mohan Rao MakineniPas encore d'évaluation

- Form A & B For DSTDocument10 pagesForm A & B For DSTRam Mohan Rao MakineniPas encore d'évaluation

- Energy Recycler FanDocument11 pagesEnergy Recycler FanRam Mohan Rao MakineniPas encore d'évaluation

- Government of Rajasthan DST ProjectDocument14 pagesGovernment of Rajasthan DST ProjectRam Mohan Rao MakineniPas encore d'évaluation

- ACI 229 Enhanced CLSM 20160415 PDFDocument30 pagesACI 229 Enhanced CLSM 20160415 PDFerosPas encore d'évaluation

- Altronics DD Annunciator BLLTN 07-1996 PDFDocument4 pagesAltronics DD Annunciator BLLTN 07-1996 PDFSMcPas encore d'évaluation

- Smiflexi en PDFDocument44 pagesSmiflexi en PDFLacosteiq6 HhPas encore d'évaluation

- Master Plan For Delhi: Dr. Mayank MathurDocument40 pagesMaster Plan For Delhi: Dr. Mayank MathurJay PrakashPas encore d'évaluation

- FEED Deliverables ListDocument3 pagesFEED Deliverables ListS.KAMBANPas encore d'évaluation

- Came 1998Document18 pagesCame 1998pradeepsmart1988100% (1)

- FMC Product OverviewDocument32 pagesFMC Product OverviewGustavoSilvinoSilvinoPas encore d'évaluation

- BA L M EPA Carb4 PDFDocument83 pagesBA L M EPA Carb4 PDFCristiTancuPas encore d'évaluation

- Kumera Helical and Bevel Gear Units PDFDocument136 pagesKumera Helical and Bevel Gear Units PDFanto starlinPas encore d'évaluation

- Solar Project REPORTDocument15 pagesSolar Project REPORTismailPas encore d'évaluation

- Earthing: To The 16th Edition IEE RegulationsDocument3 pagesEarthing: To The 16th Edition IEE RegulationsRakesh Kumar VermaPas encore d'évaluation

- Compare Energy Sources & Their Environmental EffectsDocument2 pagesCompare Energy Sources & Their Environmental Effectsamit shuklaPas encore d'évaluation

- Transient Stability Improvement of Power System Using UpfcDocument18 pagesTransient Stability Improvement of Power System Using UpfcMuhammadWaqarPas encore d'évaluation

- Thermal Pocket Guide / Infrared ThermographyDocument56 pagesThermal Pocket Guide / Infrared Thermographymdbeukel100% (4)

- Lzdzmobmvrtpctpfnstcm 0616 eDocument2 pagesLzdzmobmvrtpctpfnstcm 0616 eMomo1010Pas encore d'évaluation

- Smoke Control: Section 4/chapter 12Document12 pagesSmoke Control: Section 4/chapter 12Ramyaa LakshmiPas encore d'évaluation

- Cgb-2 K Cgw-2 Cgs-2 Csz-2 GBDocument24 pagesCgb-2 K Cgw-2 Cgs-2 Csz-2 GBFlorin StanciuPas encore d'évaluation

- Background Study: SCBA) Shown in Figure 2Document11 pagesBackground Study: SCBA) Shown in Figure 2Miza AneesaPas encore d'évaluation

- CT/PT Selection Chart: Applicable Standard (A) (V) CT's Qty PT PT's Part # PT's Qty Service Size CT CT's Part # PhaseDocument1 pageCT/PT Selection Chart: Applicable Standard (A) (V) CT's Qty PT PT's Part # PT's Qty Service Size CT CT's Part # PhasePrabakar PPas encore d'évaluation

- Enigma Motors: Mobility Company That Sticks To GrassrootsDocument14 pagesEnigma Motors: Mobility Company That Sticks To GrassrootsUmangPas encore d'évaluation

- Cat Marine Engine ProgramDocument4 pagesCat Marine Engine ProgramRobert BeddingfieldPas encore d'évaluation

- Totse Knowledge Thread 4Document14 pagesTotse Knowledge Thread 4negzPas encore d'évaluation

- 301 Basic Mechanics Course DescriptionDocument2 pages301 Basic Mechanics Course DescriptionAnonymous q9eCZHMuSPas encore d'évaluation

- Thermochemistry Practice ProblemsDocument3 pagesThermochemistry Practice ProblemsElla BombergerPas encore d'évaluation

- 308.8515.3.4-4 Serie 9 ENDocument40 pages308.8515.3.4-4 Serie 9 ENСергій БоженкоPas encore d'évaluation

- Sennheiser Digital 9000 System Manual 2017 ENDocument126 pagesSennheiser Digital 9000 System Manual 2017 ENAnder APas encore d'évaluation

- Chapter 3 - Work Energy and PowerDocument22 pagesChapter 3 - Work Energy and PowerKenny Jay LabianoPas encore d'évaluation

- MS - Tank Cleaning and DesludgingDocument7 pagesMS - Tank Cleaning and DesludgingkoyahassanPas encore d'évaluation

- Egypowpd Module3Document52 pagesEgypowpd Module3Jas PayaPas encore d'évaluation