Académique Documents

Professionnel Documents

Culture Documents

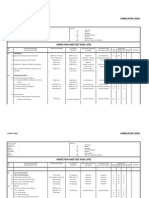

ITP Mechanical Fabrication Piping and Structure

Transféré par

Adiguna Dhana0 évaluation0% ont trouvé ce document utile (0 vote)

681 vues7 pagesList for Inspection Test Plan about fabrication of piping and structure

Copyright

© © All Rights Reserved

Formats disponibles

XLSX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentList for Inspection Test Plan about fabrication of piping and structure

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme XLSX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

681 vues7 pagesITP Mechanical Fabrication Piping and Structure

Transféré par

Adiguna DhanaList for Inspection Test Plan about fabrication of piping and structure

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme XLSX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 7

DESCRIPTION NO.

INSPECTION AND TEST PLAN

MECHANICAL FABRICATION PIPING AND STRUCTURE

DOC NO: ///..//.

Prepared by, Reviewed by,

AGUS SUTRISNO

QA/QC TAR QA/QC Lead

IRWAN SIMANJUNTAK

TURNAROUND AND CONSTRUCTION PROJECT 2014

INSPECTION AND TEST PLAN

MECHANICAL FABRICATION PIPING AND STRUCTURE

DOC NO: ///..//.

PROJECT TITLE :

CONSTRUCTION, ELECTRICAL, MECHANICAL

CONSTRUCTION, ELECTRICAL, MECHANICAL

PAINTING

PACKAGING AND DELIVERY

HOOK UP / INSTALLATION

DOCUMENTATION

ABREVIATION

7.

8.

9.

10.

DESCRIPTION

DOCUMENT REVIEW

MATERIAL RECEIVING

WELDING

INSPECTION

HYDROSTATIC TEST

1.

2.

3.

4.

5.

6.

NO.

DESCRIPTION

NSD TEAM LEADER

INSPECTION AND TEST PLAN

MECHANICAL FABRICATION PIPING AND STRUCTURE

DOC NO: ///..//.

ANGGIT SANTIA

Reviewed by, Approved by,

QA/QC Lead

IRWAN SIMANJUNTAK MOHAMMAD ABDURRAFIQ

TAR TEAM LEADER

Approved by,

TURNAROUND AND CONSTRUCTION PROJECT 2014

INSPECTION AND TEST PLAN

MECHANICAL FABRICATION PIPING AND STRUCTURE

DOC NO: ///..//.

PAINTING

PACKAGING AND DELIVERY

HOOK UP / INSTALLATION

DOCUMENTATION

ABREVIATION

DESCRIPTION

DOCUMENT REVIEW

MATERIAL RECEIVING

WELDING

INSPECTION

HYDROSTATIC TEST

Date Issue : .-.-..

Revision : 0

Page : 1 of 18

Date Issue : .-.-..

Revision : 0

Page : 2 of 18

DESCRIPTION

QA/QC CERTIFICATION

RICHARD H. SINAGA M. SYAFEI LUBIS

FAB TEAM LEADER

INSPECTION AND TEST PLAN

MECHANICAL FABRICATION PIPING AND STRUCTURE

DOC NO: ///..//.

PAGE

Approved by,

TURNAROUND AND CONSTRUCTION PROJECT 2014

INSPECTION AND TEST PLAN

MECHANICAL FABRICATION PIPING AND STRUCTURE

DOC NO: ///..//.

Approved By

of

of

18 of

of

of

of

18

18

18

18

18

of

of

of

of 18

18

18

18

PAINTING

PACKAGING AND DELIVERY

HOOK UP / INSTALLATION

DOCUMENTATION

ABREVIATION

3

3

4

6

17

7

8

9

10

15

DESCRIPTION

DOCUMENT REVIEW

MATERIAL RECEIVING

WELDING

INSPECTION

HYDROSTATIC TEST

PAGE

Client : PHE ONWJ Date Issue : .-.-..

Project : Revision : 0

Location : Offshore North West Java Page : 3 of 18

FAB/CAT/GRP NDT TEAM PHE QC QPS MIGAS

1 Document Review

- WPS & PQR - ASME Section IX - - WPS & QPR - ASME Section IX P R

- Welder Certificate - ASME Section IX - Welder Certificate - ASME Section IX P R

- Fabrication Procedure - ASME Section IX - Manufacture Data Report - ASME Section IX P W/I

- Hydrostatic Procedure - ASME Section V / Spec ARII - Spesification/Procedure P W/I

- Quality Assurance Manual (if any) - ARII-GS-105 - - Quality Manual (if any) - Specification/Pricedure/ISO P R

- Purchasing Order - Procedure Specification - Purchasing Order/Work Order - Purchasing Order P R

- NDE Procedure - ASME Section V NDE Procedure P R

- NDE Personnel Certificate - ASME Section V - NDE Personnel Certificate - ASME Section IX P R

- Painting Procedure - PHEONWJ-F-PRC-007 - - Painting Procedure - PHEONWJ-F-PRC-0007 P R

- Mill Certificate - ASME Section II - Mill Certificate - ASME Section II P R

- Inspection Report - ASME Section V - Inspection & Test Report - ASME Section V P R

- AFC Drawing - PHEONWJ-X-DSH-0001

2 Material Receiving

- Verification Material

- Visual Material (take photoraphs) - Purchasing/Work Order - - Test Report, Inspection Report - ASME Section II P V/W

- PHEONWJ-S-SPE-0101

- Identification Material - Mill Certificate - - Mill Certifiate - ASME Section II P W/I

- PHEONWJ-M-SPE-0023

- PHEONWJ-M-SPE-0025

- Heat Number Transfer - Purchasing Order/Work Order - - Test Report & Inspection Report - ASME Section II P V/W

- PHEONWJ-M-SPE-0023

- PHEONWJ-M-SPE-0025

- Stamping Identification - Drawing - - Name Plate/Stamp Odentification - ASTM, MSS 44, 45 P V/W

- Specification/Procedure - Manufacture Data Report - PHEONWJ-X-DSH-0001

- ASME Section II - Inspection Report Heat Number

- ASTM, MSS 44/ 55 Transfer

- Dimensional - ASTM - - Report of Dimensional - Procedure P V/W

- ASME B16.5 - Report Inspection - ASTM/MSS SP 44/55

- ASME B16.47 A/B - Mill Certificate - ASME B16.5

- API 5L - Purchasing Order/Work Order - ASME B16.47 A/B

- ASTM / MSS 44/ 45 - PHEONWJ-M-SPE-0023

- PHEONWJ-M-SPE-0025

- Material Handling - ASTM - - Mill Certificate - Procedure/Specification P V/R

- MSS 44/55 - Procedure/Specification

- Procedure/Specification

All welding activities shall be comply with

WPS/QPR approved by authorized parties/Migas

All of document shall be review by PHE ONWJ

prior to used in project execution

All of document shall be refers to PHE ONWJ

Spesification and International Code/Standard

Inspection

H = Hold Point, W= Witness Point, R = Review, P = Perform/ Provide, M = Monitor, S = Spot, V = Verify, I = Inspection

Verified Document Acceptance Crtiretia Note No Activity Reference Document

DOC NO: ///..//.

INSPECTION AND TEST PLAN

..

Acceptance Norm

Material to be received in good condition c/w

MTO and mill certificate and other documentation

Material to be identified one by one with

accurately, againt with the mill certificate

Heat number shall be transfer from the originally

plate sheet or piping to the cutet pieces plate

sheet or piping (if any)

Material to be identified one by one with

accurately, againt with the mill certificate

All material received will be dimensional as per

PHE ONWJ specification and international

standard code

Material to be handled and storage refer to

warehouse manual handling procedure

CONSTRUCTION, ELECTRICAL, MECHANICAL

Vous aimerez peut-être aussi

- Itp For Tank Fabrication & Installation Work1 - Rev02Document22 pagesItp For Tank Fabrication & Installation Work1 - Rev02mister pogi100% (3)

- ITP Format For New PVDocument8 pagesITP Format For New PVDavid LambertPas encore d'évaluation

- Itp VesselDocument4 pagesItp VesselHakim BaihaqiPas encore d'évaluation

- Itp PipingDocument4 pagesItp Pipingerdemlix100% (2)

- Tank Erection Itp & Org ChartDocument34 pagesTank Erection Itp & Org Charthasan_676489616100% (2)

- Piping Release Report (Spool For Paint)Document2 pagesPiping Release Report (Spool For Paint)Siddiqui Abdul Khaliq100% (1)

- ITP - Erection of Static EquipmentDocument4 pagesITP - Erection of Static Equipmentbhct1987Pas encore d'évaluation

- Daily Welding Progress ReportDocument1 pageDaily Welding Progress ReportManoj KumarPas encore d'évaluation

- Inspection Test Plan - Piping FabricationDocument5 pagesInspection Test Plan - Piping Fabricationhassan_ndt80% (5)

- Welding Quality Control and Inspection FormDocument1 pageWelding Quality Control and Inspection FormJuli Agus100% (2)

- Inspection and Test Plan For Pipe Line Works Rev 0Document1 pageInspection and Test Plan For Pipe Line Works Rev 0CrstnScribidPas encore d'évaluation

- Weld Map & NDE Extent of Pressure VesselDocument32 pagesWeld Map & NDE Extent of Pressure VesselMahesh Kumar100% (2)

- Daily ReportDocument4 pagesDaily ReportfasihaiderPas encore d'évaluation

- 5 Material and Traceability RecordDocument6 pages5 Material and Traceability RecordEdha Ali100% (1)

- Itp For Installation of Pressurization UnitDocument1 pageItp For Installation of Pressurization UnitvictorPas encore d'évaluation

- Inspection and Test PlanDocument58 pagesInspection and Test PlanTouil Houssem100% (1)

- Sample Template Itp For Piping Fabrication and InstallationDocument16 pagesSample Template Itp For Piping Fabrication and InstallationEyoh EffiongPas encore d'évaluation

- ITP For Piping WorksDocument3 pagesITP For Piping WorksOrlando1949100% (3)

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96Pas encore d'évaluation

- Material Inspection Report: Project Name Date InspDocument22 pagesMaterial Inspection Report: Project Name Date InspRafiqKuPas encore d'évaluation

- Fabrication Erection and Installation Procedure For PipingDocument36 pagesFabrication Erection and Installation Procedure For PipingMuzaffar Hussain100% (3)

- Procedure Fabrikasi TankiDocument10 pagesProcedure Fabrikasi TankiMuhammad Yunus NurdinPas encore d'évaluation

- Ug PipingDocument1 pageUg PipingVinoth KumarPas encore d'évaluation

- Welding Consumable and Storage ProcedureDocument10 pagesWelding Consumable and Storage Procedurehasan_676489616100% (1)

- Equipment Erection, Static and RotaryDocument8 pagesEquipment Erection, Static and RotaryHamada ELaraby60% (5)

- Piping Erection ItpDocument22 pagesPiping Erection ItpHaythem Ben Zid100% (1)

- 033-Itp For Piping Installation Ag and Ug PDFDocument13 pages033-Itp For Piping Installation Ag and Ug PDFKöksal Patan75% (4)

- DAILY WELD FIT-UP and PRODUCTION REPORT (Field Weld) - PIPELINE-SATR-W-2007Document2 pagesDAILY WELD FIT-UP and PRODUCTION REPORT (Field Weld) - PIPELINE-SATR-W-2007smdriyazbashaPas encore d'évaluation

- Welding Report For PipingDocument1 pageWelding Report For PipingRifki HasyaPas encore d'évaluation

- Piping Welding Daily Quality Control and Inspection Report FormDocument1 pagePiping Welding Daily Quality Control and Inspection Report Formenels77100% (5)

- A Prior To Erection (Rotating Equipments) : 2 Calibration of Testing / Checking EquipmentsDocument4 pagesA Prior To Erection (Rotating Equipments) : 2 Calibration of Testing / Checking EquipmentsGaapchu100% (2)

- ITP-000 Piping FabricationDocument5 pagesITP-000 Piping FabricationNatraji100% (1)

- 10) Itp - Tank Fabrication PDFDocument6 pages10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- Piping Daily Fit Up Quality Control and Inspection Report FormDocument1 pagePiping Daily Fit Up Quality Control and Inspection Report FormSamer Bayati83% (6)

- Hydrostatic and Settlement Tests ProcedureDocument12 pagesHydrostatic and Settlement Tests Procedureツ ツ100% (1)

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyPas encore d'évaluation

- Itp TankDocument4 pagesItp TankAmber Chavez100% (2)

- ITP Static EquipmentDocument12 pagesITP Static Equipmentaamirapi100% (3)

- Itp - Tanks - 01Document10 pagesItp - Tanks - 01ravigurajapuPas encore d'évaluation

- Line History SheetDocument46 pagesLine History SheetBhanu Pratap Choudhury33% (3)

- (A358) Inspection Test Plan - Rev.d - 130514Document5 pages(A358) Inspection Test Plan - Rev.d - 130514Ronny AjaPas encore d'évaluation

- Sample Itp For VesselDocument10 pagesSample Itp For VesselWijayanto BekasiPas encore d'évaluation

- Sample - Template - Itp For Piping Fabrication and InstallationDocument2 pagesSample - Template - Itp For Piping Fabrication and Installationmohd as shahiddin jafriPas encore d'évaluation

- Rotating Itp 1Document4 pagesRotating Itp 1abdul aziz100% (1)

- FInal QAP HDPE WeldingDocument2 pagesFInal QAP HDPE Weldingkannagi198Pas encore d'évaluation

- Inspection Test Plan: 1 QA/QC Document Submission & ApprovalDocument1 pageInspection Test Plan: 1 QA/QC Document Submission & Approvalmohd as shahiddin jafri100% (2)

- ITP ManifoldDocument7 pagesITP ManifoldvinothPas encore d'évaluation

- ITP AllDocument1 pageITP AllMuhammadIqbalMughalPas encore d'évaluation

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Document28 pagesField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciPas encore d'évaluation

- Pressure Test & Test Pack ManagementDocument43 pagesPressure Test & Test Pack ManagementStanley Alex100% (4)

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimPas encore d'évaluation

- Checlist Kelompok Pressure VesselDocument8 pagesCheclist Kelompok Pressure VesselerniPas encore d'évaluation

- Msog-m1611-Qaqc-gp-002 - Code 2 - Itp Piping and StructuresDocument5 pagesMsog-m1611-Qaqc-gp-002 - Code 2 - Itp Piping and StructuresMohd SaffririzalPas encore d'évaluation

- ITP Piping Nitrogen SystemDocument48 pagesITP Piping Nitrogen Systemmohd as shahiddin jafriPas encore d'évaluation

- ITP Mechanical Fabrication Piping and StructureDocument7 pagesITP Mechanical Fabrication Piping and Structurenadeem.ahmad45897Pas encore d'évaluation

- Inspection and Test Plan: On-Shore Pipeline CertificationDocument2 pagesInspection and Test Plan: On-Shore Pipeline CertificationKayra Riri Chirul100% (1)

- 011 Itp Culvert Works 1Document3 pages011 Itp Culvert Works 1MikiRoniWijayaPas encore d'évaluation

- ITP For Inspection Fin-Fan Cooler 03-E-2A (1 & 2) B1CDocument2 pagesITP For Inspection Fin-Fan Cooler 03-E-2A (1 & 2) B1CAmel Rayhan Aira100% (5)

- Inspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Document7 pagesInspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Akhilesh KumarPas encore d'évaluation

- ITP Crane - Pertamina EPDocument14 pagesITP Crane - Pertamina EPAry Putra100% (4)

- Receiving Materials & Equipment InspectDocument26 pagesReceiving Materials & Equipment InspectAdiguna Dhana86% (7)

- NOHSC 1015-2001 Storage - HandlingDocument54 pagesNOHSC 1015-2001 Storage - HandlingAdiguna DhanaPas encore d'évaluation

- Flange Joint Bolt Tightening ProcedureDocument37 pagesFlange Joint Bolt Tightening ProcedureAdiguna Dhana91% (11)

- NOHSC 2011-1994 Preparation MSDSDocument97 pagesNOHSC 2011-1994 Preparation MSDSAdiguna DhanaPas encore d'évaluation

- NOHSC 1005-1994 Hazardous Substances Model RegsDocument23 pagesNOHSC 1005-1994 Hazardous Substances Model RegsAdiguna DhanaPas encore d'évaluation

- NOHSC 1006-2001 Cert Users Industrial EquipDocument230 pagesNOHSC 1006-2001 Cert Users Industrial EquipAdiguna DhanaPas encore d'évaluation

- Simulation of Dynamic Behaviour of A FPSO CraneDocument17 pagesSimulation of Dynamic Behaviour of A FPSO CraneAdiguna DhanaPas encore d'évaluation

- Sea Loads On Ships and Offshore StructuresDocument166 pagesSea Loads On Ships and Offshore Structurestamalingga100% (1)

- Airgap Prediction From Second-Order Diffraction and StokesDocument5 pagesAirgap Prediction From Second-Order Diffraction and StokesAdiguna DhanaPas encore d'évaluation

- Distillation Column PipingDocument57 pagesDistillation Column PipingKaran Singh92% (13)

- Reliability Engineering PrinciplesDocument8 pagesReliability Engineering PrinciplesAdiguna Dhana100% (1)

- Lifting Equipment OperationDocument37 pagesLifting Equipment OperationHuget St100% (1)

- Anchor ManualDocument168 pagesAnchor ManualAdiguna DhanaPas encore d'évaluation

- Sni Iso 9001-2008Document28 pagesSni Iso 9001-2008Adiguna DhanaPas encore d'évaluation

- MasonryDocument8 pagesMasonryMarito da Silva Alves0% (1)

- A082 PDFDocument4 pagesA082 PDFManuel ContrerasPas encore d'évaluation

- The Need of AutomationDocument25 pagesThe Need of AutomationSanjaya Kumar SahooPas encore d'évaluation

- MultistoreybuildingDocument43 pagesMultistoreybuildingmohan890100% (1)

- Abhi ResumeDocument4 pagesAbhi Resumeajay_davimPas encore d'évaluation

- Draft PSG For The Bachelor of Science in Civil Engineering BSCE Effective AY 2018 2019Document22 pagesDraft PSG For The Bachelor of Science in Civil Engineering BSCE Effective AY 2018 2019Mico CruzadoPas encore d'évaluation

- HC 200Document11 pagesHC 200Abu BiduPas encore d'évaluation

- 1 s2.0 S2212827121004091 MainDocument6 pages1 s2.0 S2212827121004091 MainZakirUllahPas encore d'évaluation

- Software Quality: SE6121102 Pengantar Rekayasa Perangkat LunakDocument43 pagesSoftware Quality: SE6121102 Pengantar Rekayasa Perangkat LunaktumramPas encore d'évaluation

- Factsheet Straw BaleDocument2 pagesFactsheet Straw BaleBiogasDudePas encore d'évaluation

- Integrated Boiler Tube Failure Reduction/Cycle Chemistry Improvement ProgramDocument96 pagesIntegrated Boiler Tube Failure Reduction/Cycle Chemistry Improvement ProgramOwais MalikPas encore d'évaluation

- Control System Engineer Role - MultiserveDocument76 pagesControl System Engineer Role - Multiserveahmed hamdyPas encore d'évaluation

- Ce5610 Assignment-2017-18 - Ce5610Document8 pagesCe5610 Assignment-2017-18 - Ce5610Fayaz HabeebPas encore d'évaluation

- 6th Sem Milling MachineDocument41 pages6th Sem Milling MachineIshan VermaPas encore d'évaluation

- Failure Analysis Master Course V1Document21 pagesFailure Analysis Master Course V1manu6969aPas encore d'évaluation

- Rate Analysis Multi - Drift 30-05-2022 - R2Document8 pagesRate Analysis Multi - Drift 30-05-2022 - R2Rajat SharmaPas encore d'évaluation

- Design CriteriaDocument4 pagesDesign CriteriaEdmond Dellomas TulipanPas encore d'évaluation

- 7UT512Document2 pages7UT512Farhan Shah0% (1)

- Low Temperature District Heating Systems - PHD Defence - Hakan İbrahim TolDocument64 pagesLow Temperature District Heating Systems - PHD Defence - Hakan İbrahim TolHakan TolPas encore d'évaluation

- Real and Reactive Power Flow Control With Upfcconnected To A Transmission LineDocument7 pagesReal and Reactive Power Flow Control With Upfcconnected To A Transmission LineSravan GuptaPas encore d'évaluation

- Yousef Motivation Letter Final-1Document10 pagesYousef Motivation Letter Final-1yousef shabanPas encore d'évaluation

- Mechanics of SolidsDocument9 pagesMechanics of SolidsSrikanth GogineniPas encore d'évaluation

- Pump Foundation Plan Pump Foundation Plan: NotesDocument1 pagePump Foundation Plan Pump Foundation Plan: NotesamitPas encore d'évaluation

- I2MTC-2019 Program FINAL Ad PDFDocument104 pagesI2MTC-2019 Program FINAL Ad PDFmrme44Pas encore d'évaluation

- BoschRexroth MTTFD PaperDocument12 pagesBoschRexroth MTTFD PaperLizardladPas encore d'évaluation

- Tekla Structures Functionality Configurations enDocument2 pagesTekla Structures Functionality Configurations enmixi1978Pas encore d'évaluation

- Ashrae Standard: Ashrae Standard Energy Standard For Buildings Except Low-Rise Residential BuildingsDocument16 pagesAshrae Standard: Ashrae Standard Energy Standard For Buildings Except Low-Rise Residential BuildingsDhayanandh MuruganPas encore d'évaluation

- CAPdoDocument5 pagesCAPdoPauloanDiasPas encore d'évaluation

- J-L Tripoint Company ProfileDocument19 pagesJ-L Tripoint Company ProfileMavic Escuadro LaraPas encore d'évaluation

- Final 2011 CV - FuadDocument3 pagesFinal 2011 CV - FuadNil SabbirPas encore d'évaluation