Académique Documents

Professionnel Documents

Culture Documents

Classic 2 Templates

Transféré par

Daniel GarfoDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Classic 2 Templates

Transféré par

Daniel GarfoDroits d'auteur :

Formats disponibles

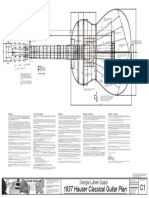

Sheet Number

Revisions:

Date: Feb. 2010

Unless Noted Otherwise,

These Plans Are Drawing

Full Scale. They Are

Labeled in mm and

Fractional Inches

This Drawing or Drawings Are To Used For One

Use Only And Not Reproduced For Any Other

Purpose Than Construction Of This Particular

Instrument, and a One Time Reproduction Only is

Allowed

Reproduction, Distribution or Sales For Any Other

Use Is Strictly Prohibitied And Falls Under U.S

Copyright Laws For Ultimate Guitar OnLine 2010

Use A Sharp Scratch All Or Other Sharp

Instrument And Mark All The Brace Ends.

These Are Shown With The Small Circle At

The Centerline Intersection

Drill Holes Through Brace End

Intersections - Be Precise

Once All The Holes Have Been Drilled,

Remove The Paper Protection From

The Plastic.

For The Brace Intersections, Take A

Sharp Pointed Tool, Like A Scratch Awl

And Mark The Centerline Of Each

Brace Clearly Into The Surface Of The

Plastic.

Top Thickness Allowance

Neck Thickness Only Is Shown (No

Fingerboard)

Headstock Trim Goes On Top Of

This Line

Notch For Nut Here

Allowance For Guitar Sides

To Slide Into Slots On Each

Side Of Neck Stock

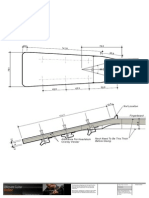

Neck Template

Cut This Template From The Sheet of Paper and Use Spray Adhesive

To Attach To A Piece Of Plexiglas or Lexan. (Keep Protection Paper On

The Plastic.) Cut Out The Top Outline Precicely To This Outline And

Sand To The Line Edge With A Spindle Sander If Available.

Next Use a Sharp Scratch All Or Other Sharp Instrucment And Mark All

Of the Brace Ends Clearly Into the Plastic.

Chuck Up A 1/16" Drill Bit In Your Drill Press And Carefully Drill A Hole

Through All Of the Brace Ends

With Brace Ends Dirlled And Brace Centers Scratched Into The Surface

Of The Plastic, You Now Have A Very Long-Lasting Top Template And

Top Brace Marking Template.

Knock-Off The Edges Of The Plastic Slightly To Prevent Injury And

Damage.

Note That The Lexan Will Be Harder To Sand And Will Scratch Easier,

But It Is Very Durable. Plexiglas Will Crack If Dropped On Your Shop

Floor.

Top & Brace Locator Template

3

6

8

.

5

2

3

0

.

1

6

3

.

5

5

2

.

4

5

4

.

0

5

8

.

0

7

8

.

5

3

8

.

0

5

0

.

8

5

3

.

2

16.4

128.6

39.7

1

0

5

.

2

1

0

2

.

0

9

4

.

0

2

.

2

1

0

.

2

41.3

9

8

.

4

5

.

0

4

.

5

7

.

5

1

2

.

0

385.3

4 224.7

1

6

.

0

6

.

0

29.2 120.0 29.2

178.3

4.3 112.8

117.1

1

6

.

0

1

6

.

0

4

.

5

1

1

.

5

5

.

0

3

.

0

2.0 243.4

26.5 98.3 26.5

151.3

26.5 144.2 26.5

197.1

5

.

0

3

.

0

26.5 157.1 26.5

210.1

3

.

0

5

.

0

26.5 171.7 26.5

5

.

0

26.5 198.8 26.5

5

.

0

224.7 251.7

26.5 112.6 26.5

5

.

0

26.5 152.7 26.5

5

.

0

205.7 165.6

3

.

0

3

.

0

3

.

0

3

.

0

26.5 64.2 26.5

117.1

1

9

2

.

3

23.4

8

.

0

1

.

0

5

.

1

7

.

9

1

4

.

0

8

.

0

9

5

.

2

7

.

9

1

4

.

0

8

.

0

1

.

0

5

.

2

7

.

8

1

4

.

0

8

.

0

1

.

8

5

.

2

7

.

0

1

4

.

0

82.3 199.7 82.3

364.3

364.3

58.3 160.2 58.3

276.8

4.4 268.0 4.4

276.8

257.3

3.1 251.3 3.1

257.5

59.0 139.5 59.0

59.0 159.1 59.0

277.2

9 275.5 9

277.2

36.3 75.0

32.7

5

2

.

4

6.8 2.4

2

.

1

5

.

1

4.8

27.6

65.0 82.7 114.0

660.0

3.4 162.2 2.6 203.1

277.1

6

.

0

7 275.7 7

4

.

5

1

1

.

5

52.8 171.5 52.8

277.1

178.3

151.3

197.1 210.1

55.3 120.4 55.5

2.4 226.4 2.4

231.3

10.7 106.8

4

.

5

105.1 10.7

4.8 373.3 7.2

385.3

4.8 49.2 59.8 54.1 51.6 111.7 46.9 7.2

2

8

2

.

0

20.8 4.8

1

5

.

9

7

.

9

29.1

85.7

12.7 1.2

37.0

34.9

34.9 21.8 20.8 4.8

1

5

.

9

7

.

9

6

5

.

1

7

3

.

0

103.2

660.0

4.8 660.0

21.0

129.6

19.0

7.9

1

9

.

1

34.9

34.9

43.0

177.6

1

4

.

5

6

.

3

37.0 35.0 33.0 31.1 29.4 27.8 26.2 24.7 23.3 22.0 20.8 19.6 18.5 17.5 16.5 15.6 14.7 13.9

330.0 43.5 30.7

37.0 35.0 258.0

494.4

37.0

72.0

105.0

136.2

165.6

193.3

219.5

244.2

267.6

289.6

310.4

330.0

348.5

366.0

382.5

398.1

412.8

426.7

1

7

.

9

6

.

3

60.0

27.0 6.0 27.0

1

7

.

9

6

.

3

28.6 6.0 28.6

35.5

R 12.0

R 4,686.3

R 42.1

R 36.8

R 38.7

R 181.4

1.77

1.77

85.00

4.28

!

"

#

$

$

!"#$

$

!

"

#

$

$

!"#$

$

!"#$$

!"#$$

!"#$$

Fret Wire Detail

Depth Of Holes For Rollers Can

Vary With Tuning Machine Mfr.

String Ramps

Re-Constituted Ivory Or Excellent Quality

Bone For the Nut.

Center Bridge Brace On

660mm Line For Scale

Length.

Certain Luthiers Tune The Top By Making The Top

Progressively Thinner As It Reaches The Guitar Edge

And Remain Full Thickness At The Top. If You Do

This Do Not Reduce The Edges Below 2.2mm And

Make The Center Slightly Thicker.

Re-Constituted Ivory Or Excellent Quality

Bone For the Nut.

This Light Line Is The Neck Splice

Joint. There Is A 8.13 Degree Angle

From The Neck To The Headpiece

The Top Trim For The Headstock Is Traditionally Made From

The Same Wood As The Back And Sides. It is Usually

Leftover Stock And Is About 2.2mm Thick. Glue Maple Or

Maple/Ebony Veneer Beneath For Additional Detail - This Is

A Personal Preference. Glue These Pieces Before Any

Headstock Work Is Started.

Many Classical Guitars Built In The Spanish

Tradition Shave The Bass Side Of The Fretboard

Down Gradually From The 12th Fret To The

Soundhole To Give The Bass Strings Additional

Room To Oscillate.

Shaping The "Foot" Of The Guitar Is One Of

The Most Demanding Operations. The Foot

Give The Neck And Body A Lot Of Structure

And This Joist Should Be As Perfect As

Possible.

Kerfed Lining Made From Either Basswood Or Cedar.

Many Spanish Classicals Use Solid Kerfing For The

Back Plate Attachment. If You Choose To Do That

Make Sure The Kerfing Is Pre-Bent Prior To Gluing. Do

Not Introduce Stress Into The Guitar

Note: Most Luthiers Make A Template From Either Wood Or

Plastic With The Neck Profile, Heal Shape And Interior Neck

Block And Foot Profile - All In One Template. Make Another Copy

Of This Plan To Make Your Own. Just Use Spray Adhesive To

Attach The Pattern And Cut It Out With Your Band Sand. Cut A

Little Big (Away From The Line) And Finish Sand With A Spindle

Sander Right Down To The Line

Back Braces - Vertical Grain Minimum 20 Grain/In.

Cedar Or Spruce #1 Quality. Cope Out Ends Of

Bracing And Fit Into Channels Cut Into The Lining (Do

Not Cut Through The Sides.

Side And Back Material: Many Different Woods Can Be

Used. For Bright Tones Go With One Of The

Rosewoods Such As Indian Rosewood or Brazialian

Rosewood. Koa Is Bright As Is Zircote And Madagascar

Rosewood. For Warm Tone Use Walnut. Most

Traditional Classical Guitars Are Constructed From

Indian Rosewood.

Back Block or Butt Block. Vertical Grain Cedar Or Spruce

Minimum 20 Grains/In. Some Luthiers Shave This Block or

Angle It Away From The Top As This Block Often Gives A

Guitar A "Hump" In The Top And Can Cause Cracking.

Drill These Holes Only After You Have

Purchased Your Tuning Machines. Make

Holes About 1mm Larger Than The Roller.

Drill These Holes First To Minimize Tear-Out

Of The Tuner Slots.

#1 Quality Cuban Mahogany Neck With

Ebony Reinforcement Strip Down Center

(See Detail Above). Select Only Vertical

Grain Wood For Your Neck.

Back Block or Butt Block. Vertical

Grain Cedar Or Spruce Minimum

20 Grains/In. Some Luthiers Shave

This Block or Angle It Away From

The Top As This Block Often Gives

A Guitar A "Hump" In The Top And

Can Cause Cracking.

Guitar Top Plate. Usually Braced Dead Level (No Arch) Use Only #1 or AAA Top Materials -

This Is The Single Most Important Piece Of Wood Used In A Guitar.

Materials Vary Quite A Bit, But Usually Consiste Of Spruce Or Cedar From Many Different

Regions. Spanish Cedar, Canadian Red Cedar And Many Others. Must Be Vertical Grain

Wood With No Run-out, Even Grain Across The Top And 20 Grain/In Minimum.

Top Thickness Varies As Well. From A Minimum of About 2.5 to 2.8mm Up To 3.5mm,

Depending On The Strength Of The Wood.

Kerfed Lining Made From Either Basswood Or Cedar.

Many Spanish Classicals Use Solid Kerfing For The

Back Plate Attachment. If You Choose To Do That

Make Sure The Kerfing Is Pre-Bent Prior To Gluing. Do

Not Introduce Stress Into The Guitar

Tone Bracing For Top. Spruce Or Cedar. Vertical

Grain, No Run-Out. Min. 20 Grains/Inch.

Classical Guitar Bridge Complete

With Tie Block, Saddle Channel And

Either Bone Or Ivory Saddle. Center

On 660mm Scale Length Both

Vertically and Horizontally.

The Soundhole Reinforcing Plate Is Made From The Same

Material As The Top Plate (i.e. Cedar) And Is Slightly

Larger Than The Rossette Size (About 1/8"). Glue It So

That The Grain Runs 90 Degrees To The Top. Fit It After

The Top Bracing Is In Place, To Fit It Perfectly Around The

Braces.

Side Braces. Set On Top Of Top Braces And Extend Down

Sides Of Guitar - See Latteral Section For Profile.

%&& ()* +,)-./

0$$ 123.

E

A B

F G

H J

K L

M

Back Block or Butt Block. Vertical Grain

Cedar Or Spruce Minimum 20 Grains/

In. Some Luthiers Shave This Block or

Angle It Away From The Top As This

Block Often Gives A Guitar A "Hump"

In The Top And Can Cause Cracking.

J

L

M

A

B

C

D

E

E

F

G

H

K

Classical Guitar Bridge Complete

With Tie Block, Saddle Channel And

Either Bone Or Ivory Saddle. Center

On 660mm Scale Length Both

Vertically and Horizontally.

Shaded Area Indicates 1/16" Cedar

Bridge Plate Glued To The Underside Of

The Top Place. Notch Fan Bracing Over

The Top Of The Bridge Plate.

Classical Guitar Bridge Complete

With Tie Block, Saddle Channel And

Either Bone Or Ivory Saddle. Center

On 660mm Scale Length Both

Vertically and Horizontally.

Brace Key Numbers. Refer To

Brace Diagram Plan For

Bracing Layouts

Laminate Cuban Cedar Left Overs From The

Neck Blank (Before You Rip The Blank Down The

Middle). Make Sure To Glue Enough For The

Continuous Neck Block And Foot At The Guitar

Interior As Well.

Either Extend The Back Material Over The Heel

Or Place A Piece Of Ebony Trim Over The Neck

Heal. Both Practices Are Used And Traditional.

Extension Of The Back Plate Over The Heals

Gives The Guitar Additional Strength.

Materials:

Assemble the proper materials before you begin your project. If you don't have your tone wood

already, there are several great suppliers including LMI (Luthier's Merchantile) which has a wide

range of top and back and side wood available. If this is your first guitar, you may want to try wood

that is a bit less expensive for your first try, such as mahogany for backs and sides or walnut, which

is about 50 to 33% of the cost of the Rosewoods etc. If you want an easy build guitar for your first

try, go with the Honduros Mahogany. It works easily, sands nicely, and finishes quite easily too. You

don't have to deal with exotic resins in the wood like you do with Rosewood, Cocobolo oand some

of the the other exotic woods.

When you order wood make sure you order wood that is at least 1" oversized in each direction so

you can eliminate splits etc. 2" is even better and quite often accomodated with tone wood. Make

sure the tops and backs are bookmatched for grain pattern.

Neck blanks can be Cuban Cedar. This is a very lightweight but very strong wood. Fretboards

should be clear Ebony, solid and you will have to buy 2 of them to allow you to add the Ebony

reinforcing to the center of the neck.

Most suppliers will have brace wood available, which is split from to log so there isn't any runout in

the wood - look for this in the literature.

You will also need additional wood to make up the purfling around he edges and you will need

maple or some other type of white wood if you want white stripping accents at your purflings. For

the dark wood use Rosewood veneer.

We did not get into the details of how purfling is put on this guitar as that is more of a construction

issue and not a guitar play issue. Any number of guitar construction books will guide you in the

proper techniques of installing purfling, where it should be and how to laminate it and bend it.

Buy good fret stock with at least 18% silver content. Steward MacDonald has a good assortment of

fretwire as does LMI.

Rossettes are best purchased already made unless you are determined to complete that difficult

operation. Many of the supply housed carry a great assortment of prefabricated rossettes.

Buy good tuning machines. Make sure they have good plating on them and the metal is a heavy

gauge. Buttons can be pearl, pearloid or ebony on many good quality machine heads.

Interior blocking for the butt blocks can be either Spruce or Cedar or even Mahogany or Cuban

Cedar. Just make sure it is free from knots and is striaght grained. Optain this at specialty lumber

yards or instrument supply shops.

Methods:

Start by sanding your top plate, back plate and sides to rough thickness (within 1mm of final

thickness). Carefully glue the center joints of the back and sides together. When gluing the back,

you will want to insert your decorative center strip at the same time. This should be pre-assembled

if you have multiple colors.

To prepare the joints, sand carefully with sandpaper glued to a perfectly straight edge. I like to use

adhesive backed sandpaper in rolls and stick it to the side of a 24" metal level. Trim the sandpaper

carefully. Use 120 grit paper and do not use a lot of force. The plates are joined most easily with a

cam-action jig while using a piece of wood on the top to keep things in alignment. Of course use

waxed paper wherever you risk having your wood stuck to the jig - or coat the jig with wax.

Once glued (If you use Rosewood, or one of the other exotic woods mentioned here, be sure to get

all of the resin out of the wood with acetone before you glue anything. Trace your top and back on

the wood - use a white pencil for dark wood. Then run the top and back through a wide stationary

belt sander - or use scrapers and hand sanding methods. Be careful with the use of acetone also.

Use rubber gloves and a resperator. You may also need to use a resperator for exotic wood dust as

many people have allergic reactions to the sanding dust (including myself).

When I started out making guitars, I couldn't afford all the expensive stationary sanders etc,,

that makes the work so simple now. I used to get one side of the plate completely flat, then I

would chuck up a small bit in the drill press and set it to stop at the desired thickness of my

plate. I would then drill dimples over the entire surface of the unfinished side and simply

sand until all of the dents were gone - pretty slick!

After you have your thickness completed on the top plates. trace the guitar contour and carefully cut

the outline out. Make the cut line at least 1/8" outside the line to give you some give.

Get your sides bent, either with a bending jig or on a bending iron. You can also boil the sides and

clamp them to an outside form for a few days to a week. Be sure to overbend a bit to allow for

springback.

While the sides are curing, rout the channel for the rossette and insert and glue that. I use a dremel

router with a steel stud sticking up through the center of the soundhold (the sound hole is not cut

out at this point. Once the rossette is installed, rout out the soundhole with the router too.

Now is the time to install all of your bracing on the top and back. As I mentioned I use a dowel jig. I

plan on detailing these jigs in an upcoming book on guitar construction, but do not have plans on

the jig at this point. It works fast and really secures the bracing evenly and uniform.

Now is the time to install all of your bracing on the top and back. As I mentioned I use a dowel jig. I

plan on detailing these jigs in an upcoming book on guitar construction, but do not have plans on

the jig at this point. It works fast and really secures the bracing evenly and uniform. It also gives you

a lot of fingerspace to allow gluing all of the braces in a single operation without a lot of clamps to

work around.

Typically the braces are only roughed-out for their final shaping is done after they are glued. After

the glue is mostly dry, remove the plate and get all of the glue squeeze out off the bracing and plate

with a sharp small chisel. The glue should be dry enough to not be liquid but not fully adhered to the

wood.

Once the braces have had at least a couple of hours to dry, shape them and round them with small

planes, finger planes, chisels and sanding sticks. Final shape and sand them with 220 sandpaper

until satin smooth.

Methods - Continued:

Now you should assemble the guitar neck. I recommed Cuban Cedar because it is light and strong.

Cut the Head scarf joint with a band saw first. Prepare this joint so it is perfectly tight. Next, cut the

blank to size and capture any blocks you can to glue to the heel/foot assembly. Now cut the neck

blank right down the center and flip the grain so it is opposed and working against each other. Slip a

6mm strip of Ebony between the halves and prepare all pieces in a similar manner to the plate

joints - or if you have a stationary drum sander, just run all the pieces through that. Prepare the

other half of the scarf joint so you will have a good joint for the headstock trim.

Glue the heel/foot block on the neck - all the while checking with your neck template. Once the neck

has dryed, do a final sanding on a stationary belt sander for the headstock and double-check the

thickness of the head. Now glue the headstock trim and purfling and set aside to dry.

Next rough-cut the heel and foot/endblock shape of the neck on the bandsaw, keeping things true

and plumb. Remember to always cut a bit outside the lines to allow for slight error. Now rough cut

the head after tracing with your headstock template. Sand the sides to final shape and size and drill

you machinehead roller holes of each side of the head. You can now drill your holes for the string

slots - being careful not to get any drill runout or tearout. Now cut the remainer of the slot out with

either a router or a jigsaw. Cut outside the line and finish the slots with sanding stick.

Cut your string ramps in the string grooves with a round rasp and finish with sandpaper wrapped

aroung a dowel. This can be a dowel section about 8" long with a slot cut in the end, right down the

center of the dowel for about 1/2 the dowel length. Insert the sandpaper in the slot and wrap around

the dowel.

Next rough-shape the neck with a 4-way rasp, using the rough cut blade. Get the neck to within

about 1/16" of final thickness and width. Now cut in the guitar side slots in the sides of the neck. Do

this very carefully and make sure you have good joints. I like to use dovetail saws for this operation

and g--o s--l--o--w. Thick the fitting often with your guitar sides clamped in the inside form.

Once the neck fits in the sides precisely, trim the butt joint of the sides and glue the butt block on

the bottom of the sides. Make sure to carefully fit the butt block the ot contour of the sides and

make sure the block is vertical grain. Once the butt block is in place, final fit and glue the neck. It is

essential that the side channels in the neck and the sides are trimed to match each other exactly.

Check the latteral and vertical positioning of the neck as this is extremely important at this time.

The foot and top of the block may need some additional trimming when the back and top are fit. You

also want to make sure that the sides are perfectly plumb in the form by using stretcher clamps.

With the sides rough-cut to contour, glue in the lining to receive the back plate. This lining can be

either kerfed lining or solid pre-bent lining. Glue with wooden clothespins with rubber bands

wrapped on them to strengthen their tension or use mini spring clamps. Make sure you have even

glue squeeze out and clean it up as you did on the braces. I like to elevate the lining slightly above

the sides while gluing (about 1/16" inch). This will allow you to easily sand down the lining only to

completely level the top.

Now fit the back to the sides and neck with the side following the contour of the inside form. Since

the braces for the back are slightly arched (about 1/8 to 1/4" ) carefully mark the trim marks for the

sides. This will vary with every aspect of the guitar beause the inherent nature of it's shape. Do

NOT glue the back on at this time. The top must be secured to the sides first.

Tips and Techniques:

Always make sure your tools are razor sharp and not dull. Buy good sharpening stones or

sharpening grinders such as the Tormek sharpener. It is also important to knock off the burr on your

chisels and other hand tools.

If you use stationary tools, make sure the blades on your bandsaw, tablesaw, jointer etc. are also

very sharp and you do not have to force wood through the machines. If given a choice, always use

carbide-tipped blades. Some of these hardwoods are tough to cut without a good carbide blade.

Setup of power tools is extremely important too - follow included direction or obtain good books on

proper setup of bandsaws, table saws etc. You can't believe what a difference this will make.

You can never have enough jigs, templates etc. in guitar-making. If you plan to continue beyond this

guitar and make several others, templates and jigs are a must more making your work a lot easier.

If you are starting from scratch, building guitars, make sure you make excellent quality forms for

your guitar. Both inside and outside forms for the body assembly. Look at LMI's side bending

machine. It works great and you can pump out a lot of bent sides in a short time.

Put together the templates we have shown here at a bare minimum. You should have a template to

trace your basic guitar boddy shape, your top and back brace locations, Your neck and foot profile

and the headstock layout, showning all the drilling locations for the tuning machine rollers and string

slots. Also it comes in handy to have back brace curvature templates, brace scalloping patterns, fret

slot location templates and bridge templates.

There are a lot of great little tools and gadgets available for Guitar Lutherie - Here are a few:

Thumb Planes - Available from Luthier supply houses - they are primarilary used for violins.

Spindle Sander - This is a tabletop stationary tool.

Dremel Router with roller bearing bushings - or other small hand-held mini-routher.

Note Stewmac has a lot of adapters available for the Dremel such as purfling routers, bits

etc.

Fret cutting jig - this is available from Stewmac also. Give you precise control over fret sawing.

Make a jig to glue your bracing. This consists of 2 plywood plates with dowel supports at each

corner. The braces are glued using bent dowels that span between the two plates.

Make sure your shop is held an a very constant humidity level all year long. Never vary more than

5% between 45 and 55%. This will minimize cracking, shrinkage and give overall durability to

guitars you plan to sell or gift.

Some of the other great little tools I love are:

Japanese Saws that cut both ways

Lots of the German Cam Clamps - both 6" and 8"

1" Spring Clamps - A whole 2# coffee can full of these

A great set of instrument maker's chisels in 1mm 2mm 4mm and 6mm sizes

Fret file, dovetail saws, fret end dressing tool, fret rocker etc. see my fret repair series for

detail on these and a lot more tools

Look at www.ultimate-guitar-online.com/woodworking-hand-tools.html for hand tools required and:

www.ultimate-guitar-online.com/woodworking-power-tools.html for stationary tools recommended.

Above all else make sure everything fits together perfectly before gluing. Do not force anything as

stress is a guitar ruins the tone. When in doubt take a few extra hours of sanding trimming and pre-

assembly to get everything as perfect as you can.

A

B

C

D

Side Reinforcing Braces. Profile, Size and

Amount Vary Greatly With Guitar Makers.

This One Sits On Top Of The Scalloped

Portion Of The Top Plate Braces And

Extends Down The Side About Half-Way.

They Are Typically Installed After The Top

Plate And The Sides Have Been Joined

Here Is A Much Easier Alternative To The Side

Bracing Shown On The Other Side Of This

Section. Space These Around The Sides Of The

Guitar Evenly (Between 6 and 8 Braces) The

Height Varies With The Sides. Place Them Into

Their Correct Location And Shape Them

Afterwards. They Are Glued In Place Just Before

Gluing The Back Plate To The Sides.

Butt The Rossette Reinforcing Plate

Into The Sides Of The Braces. Do Not

Extend Beneath Braces Or on Other

Side Of Braces

Optional Independent Side Braces - Refer To Latteral

Section For More Info. Spread Evenly Around The

Sides Of The Guitar. Refer To Section For The Exact

Profile. Usually Between 6 and 8 Are Used. These

Are Shaped Similar To A Brace Out Of The Same

Material As The Top Braces. Put In Place Just Prior

To Glueing The Back Plate To The Sides.

Optional Independent Side Braces - Refer To Latteral

Section For More Info. Spread Evenly Around The

Sides Of The Guitar. Refer To Section For The Exact

Profile. Usually Between 6 and 8 Are Used. These

Are Shaped Similar To A Brace Out Of The Same

Material As The Top Braces. Put In Place Just Prior

To Glueing The Back Plate To The Sides.

Rossette (Shaded) - Usually

Prefabricated. But You Can Make

Them Yourself.

C

D

Kerfed Lining Made From Either Basswood Or Cedar.

Many Spanish Classicals Use Solid Kerfing For The

Back Plate Attachment. If You Choose To Do That

Make Sure The Kerfing Is Pre-Bent Prior To Gluing. Do

Not Introduce Stress Into The Guitar.

Note: Bracing Shown Here Is The

Actual Placement Of The Bracing

On The Interior Side Of The Top

Plate. This Bracing Is Not Shown

In Xray Mode. Refer To Photograph

On Section Sheet.

Note: Bracing Shown Here Is The

Actual Placement Of The Bracing

On The Interior Side Of The Top

Plate. This Bracing Is Not Shown

In Xray Mode. Refer To Photograph

On Section Sheet.

1/16" (1.5mm) Cedar

Bridge Plate Glued To The Underside Of

The Top Place. Notch Fan Bracing Over

The Top Of The Bridge Plate.

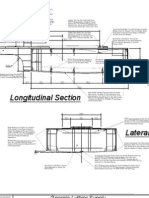

Lateral Section

5

/

8

"

5

/

1

6

"

1 15/32" 1 3/8" 1 3/8" 27/32" 13/16" 3/16"

1

4

1

/

2

"

9

1

/

1

6

"

5

/

8

"

5

/

1

6

"

2

9

/

1

6

"

13/16" 3/16"

1 5/32"

3 3/8"

1/2" 1/32"

2

3

/

3

2

"

13/16"

5 3/32"

3/4"

5/16"

4 1/16"

3

/

4

"

1 3/8"

1 3/8"

1 11/16"

7"

9

/

1

6

"

1

/

4

"

25 31/32"

4

5

/

3

2

"

3/16" 25 31/32"

4

1

/

3

2

"

3

1

1

/

1

6

"

1 21/32" 3

3

/

3

2

"

21/32"

1 5/8"

1 3/32"

1 7/16" 2 31/32"

3

/

3

2

"

1

3

/

3

2

"

2

"

1

1

/

2

"

13" 1 23/32" 1 7/32"

2 9/16" 3 1/4" 4 1/2"

2

1

/

2

"

2

1

/

1

6

"

2

1

/

8

"

2

9

/

3

2

"

184 1/2"

1 15/32" 1 3/8" 10 5/32"

2

7

/

8

"

5 1/16"

1 9/16"

1 17/32"

15/32"

1 15/32" 1 3/8" 1 5/16" 1 7/32" 1 5/32" 1 3/32" 1 1/32" 31/32" 29/32" 7/8" 13/16" 25/32" 23/32" 11/16" 21/32" 5/8" 19/32" 17/32"

3

7

/

8

"

1 7/16"

3

/

1

6

"

9

/

3

2

"

1

5

/

3

2

"

5

/

8

"

3

/

1

6

"

7

/

1

6

"

5

/

8

"

1

/

4

"

1 5/32" 4 23/32" 1 5/32"

7 1/32"

2 3/32" 6 3/4" 2 3/32"

10 29/32"

1

/

4

"

1/32" 10 27/32" 0" 1/32"

3/16" 1 15/16" 2 11/32" 2 1/8" 2 1/32" 4 13/32" 1 27/32" 9/32"

15 5/32"

3

/

1

6

"

7

/

1

6

"

5

/

8

"

3

/

1

6

"

1

/

8

"

1 1/32" 3 7/8" 1 1/32"

5 31/32"

1 1/32" 5 11/16" 1 1/32"

7 3/4"

3

/

1

6

"

1

/

8

"

1 1/32" 6 3/16" 1 1/32"

8 9/32"

1

/

8

"

3

/

1

6

"

1 1/32" 6 3/4" 1 1/32"

8 27/32"

3

/

1

6

"

1 1/32" 7 13/16" 1 1/32"

9 29/32"

3

/

1

6

"

1 1/32" 6" 1 1/32"

8 3/32"

3

/

1

6

"

1 1/32" 4 7/16" 1 1/32"

6 17/32"

3

/

1

6

"

1 1/32" 2 17/32" 1 1/32"

4 5/8"

1

/

8

"

1

/

8

"

1

/

8

"

3

/

1

6

"

1

/

8

"

7

9

/

1

6

"

29/32"

5

/

1

6

"

1

/

3

2

"

3

/

1

6

"

5

/

1

6

"

9

/

1

6

"

5

/

1

6

"

1

/

3

2

"

7

/

3

2

"

5

/

1

6

"

9

/

1

6

"

5

/

1

6

"

1

/

3

2

" 7

/

3

2

"

5

/

1

6

"

9

/

1

6

"

5

/

1

6

"

1

/

1

6

" 7

/

3

2

"

9

/

3

2

"

9

/

1

6

"

3 1/4" 7 7/8" 3 1/4"

14 11/32"

14 11/32"

2 9/32" 6 5/16" 2 9/32"

10 29/32"

3/16" 10 9/16" 3/16"

10 29/32"

2 5/16" 5 1/2" 2 5/16"

10 1/8"

1/8" 9 29/32" 1/8"

10 1/8"

2 5/16" 6 1/4" 2 5/16"

10 29/32"

1/32" 10 27/32" 1/32"

10 29/32"

2

5

/

3

2

"

2

1

/

1

6

"

1 9/32"

9/32" 3/32"

3

/

3

2

"

3

/

1

6

"

3/16"

10 29/32"

7 1/32"

5 31/32"

7 3/4" 8 9/32"

0" 8 27/32" 3/32" 9 19/32"

1/8" 6 3/8" 3/32" 8"

5/32" 4 7/16"

4 5/8"

13/32" 4 7/32"

4 1/8" 13/32"

2 3/16" 4 3/4" 2 3/16"

3

/

1

6

"

3/32" 8 29/32" 3/32"

9 3/32"

3/16" 14 11/16" 9/32"

15 5/32"

1

1

3

/

3

2

"

19 15/32"

Dashed Lines Indicate Outline Of

Neck Block Where It Meets The

Top.

25 31/32"

Dashed Line Indicates Rossette

Reinforcement Extends Beyond

Rossette Approx. 5mm.

Methods - Continued:

Now fit the top to the sides. Trim the top to fit exactly inside the inside form. Drop the sides on top

and glue the sides to the top with individual blocks. These should be about 1/2 to 3/4" long

depending of the contour they encounter and should be only set into place by hand and not

clamped as this adds undue stress to the guitar top plate. The line from the neck to the tip should

be perfectly level and even or you will be in trouble. Check, double check and triple check that the

neck centerline aligns with the top centerline before gluing. Get everything perfect at this point.

Now you can glue the back plate to the sides by using 3/4" elastic upholstery tape, rubber bands or

spindle clamps. Get even pressure, but DO NOT FORCE anything - no stress here either.

Next is the time to trim the plates, rout purfling groove around the edge of the guitar and fit the

purfling. With groove cleaned out, nice tight fit and everything cut to length, glue on the purfling.

Rough sand the sides, back and top plates and round the edge of the purfling.

Next sand the fingerboard to thickness, cut to correct width and final sand the edges on a stationary

belt sander. Cut the fret grooves and locate the fretboard on the neck. Lightly clamp it and drill 2

small holes down through the fret groove at the body and nut ends of the fretboard. Place small

locator nails in the holes and double check the fingerboard location before gluing. Double check all

the latteral and vertical locations with a precise straight edge. Glue the fret board in place.

Final shape the neck to the fretboard size, shape the heel and finish sand. Place a heel trim on the

bottom of the heel. Dry-fit the tuning machine and make any adjustments so there is no binding or

forcing in place. Fit the nut and bridge. Check the action, bridge location and after verifying glue the

bridge in place.

Give all wood surfaces a final sanding with 220 grit sandpaper, install the frets and prepare to install

the finish.

There are many different opionions on finish material from french polish to varnish to lacquers and

urethanes. Do your research and decide on what suite you best.

Finishing is a whole different operation in and of itself is too lengthy to discuse in this format. I

sugguest you get a good book on instrument finishing from one of the suppliers.

This was a quick overview of guitar construction and I have not had the room to go into any great

detail on anything. At Ultimate Guitar OnLine, we plan on publishing an ebook on guitar

construction in the near future, so watch for that.

Good Luck and most of all HAVE FUN!

Check Us Out At:

www.ultimate-guitar-online.com

http://ultimate-guitar-building.com

david@ultimate-guitar-online.com

Our sites have a LOT of tips on such things as fret installation, neck adjustments and

recommendations etc. Check out the articles and come back often as we are adding content all the

time.

Scale Length

Solid Ebony Fretboard.

Spanish Cedar Neck Material. Select

Vertical Grain - As Shown Here. Split

The Neck Blank Down The Middle

And Reverse The Grain So The Grain

Is Opposed - Gives Much Greater

Strength To Your Neck And Prevents

Warping.

Vertical Grain Ebony Center

Reinforcing Strip Down Center Of

Neck.

2

3

/

3

2

"

1

/

4

"

2 3/8"

1 1/16"

1/4"

1 1/16"

Brown Shaded Area Indicates Area

Of Head Block To Be Shaved Down

For Soundboard Thickness

2

3

/

3

2

"

1

/

4

"

Neck Section At

12th Fret

2 1/2"

1 1/8" 1/4" 1 1/8"

Guitar Sides "Let-in" Neck &

Head Block

Outline of "Foot"

Outline Of

Head Block

Dashed Lines Indicate Heel

Outline At Backplate

Side "Let-In" At Heel

Side "Let-In" At Top Of

Head Block

Guitar Sides "Let-in" Neck &

Head Block

7 5/32"

The Red Dashed Line

Indicates The Cut Of

A 10" Table Saw

Blade

Neck Section At 7th

Fret

Top of Head Block

Looking Down

Back Braces - Vertical Grain Minimum 20

Grain/In. Cedar Or Spruce #1 Quality.

Cope Out Ends Of Bracing.

Back Material: Many Different Woods Can

Be Used. For Bright Tones Go With One

Of The Rosewoods Such As Indian

Rosewood or Brazilian Rosewood. Koa Is

Bright As Is Zircote And Madagascar

Rosewood. For Warm Tone Use Walnut.

Most Traditional Acoustic Guitars Are

Constructed From Indian Rosewood Or

Mahogany.

Dark Line Indicates Outside

Perimeter of Guitar. Light Line Is

Inside Of Sides.

Back Block or Butt Block. Vertical Grain

Honduras Mahogany. Some Luthiers

Shave This Block or Angle It Away

From The Top As This Block Often

Gives A Guitar A "Hump" In The Top

And Can Cause Cracking.

Foot and Neck Block This Is A

Very Important Structural

Element. Construct From Vertical

Grain Cuban Cedar

A B

C D

Note How Sides Fit Into A 'Slot" In The Neck.

Forming This Slot Is One Of The More Difficult

Tasks In Classical Guitar Construction. The Slot

Follows The Profile Of The Heck/Heal All The Way

To The Fretboard. Also Notice How the Neck/Heal

Is One Piece.

This Is The Outline Of The Heal At The Back Plate

Of The Guitar.

Dashed Lines Indicate Back/

Side Lining. 2.4mm Wide. Bend

With a Side Bender To Match

Sides and Eliminate Stress.

Dashed Lines Indicate Back/

Side Lining. 2.4mm Wide. Bend

With a Side Bender To Match

Sides and Eliminate Stress.

Neck Block Profile At Top

Plate

Scallop The Brace Ends As Shown

This Is Not An Exact Science And Varies

Greatly From Luthier to Luthier.

To Cover Up The Center Seam Inside The

Guitar Body And Give The Joint Additional

Strength Use A Strip Of Maple 3mm Thick. Run

Betwen The Braces And Round-Off As Shown.

The Best Way To Install This Is As One Long

Piece And Carefully Cut And Chisel Out The

Channels For The Back Braces.

Arch The Back Of The Guitar For Sound

Reflectance Quality And To Allow Some

Tollerance For Humidity Changes. This Arch

Should Be Approximately 2mm to 3mm Across

The Wide Part Of The Back Plate

1 7/16"

Note: You Should Make All Your Bracing Longer Than It

Needs To Be, Or As Shown In The Bracing Diagrams Above.

Leave Each Brace At Least 3/8" Long And Trim Back During

Fitting Of The Back And Top Plates To The Guitar Sites.

Note: You Should Make All Your Bracing Longer Than It

Needs To Be, Or As Shown In The Bracing Diagrams Above.

Leave Each Brace At Least 3/8" Long And Trim Back During

Fitting Of The Back And Top Plates To The Guitar Sites.

Classical Back Arch Template

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29

30

1 2 3 4 5 6 7 8 9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29

30

Cut Slots Into Headstock After Drilling Holes For

Machine Head Rollers. Make A Template To

Locate Holes And Drile Precisely With A Drill

Press. Cut String Ramps In With A Round Rasp

and Final Shape With Sandpaper Wrapped Around

A Dowel.

Note: Be Sure To Check The Actual Roller Spacing

For Your Tuning Machines Before Making The

Template and Layout. They Vary Slightly From Mfr.

To Mfr.

Classical Side

Contour Template

Fret Layout Template

Back Plate Layout & Brace Layout

Longitudinal Section

Heel Contour

@ Body

6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

C

e

n

t

e

r

o

f

L

o

w

e

r

B

o

u

t

1 2 3 4 5

T

a

i

l

B

l

o

c

k

C

e

n

t

e

r

o

f

W

a

i

s

t

H

e

a

d

B

l

o

c

k

C

e

n

t

e

r

o

f

U

p

p

e

r

B

o

u

t

This point starts at the center of the tail block

for reference point one.

Center Template On Brace And Mark Out Contour.

Back Arch Contour

Note: The depth of this template represents the total depth of the guitar,

which includes the top and back plates. You should subract the dimensions

of these 2 plates from your template when you finalize the dimension or

your guitar will be deeper by that amount.

Each of these light lines represents a reference line

1" or 25.4mm apart

The dashed lined represents a straight line drawn from

The neck block to the tail block. As you can see, if you would trim

your guitar sides to this line you would have a lot of reforming to do.

3

6

8

.

5

2

3

0

.

1

6

3

.

5

5

2

.

4

5

4

.

0

5

8

.

0

7

8

.

5

3

8

.

0

5

0

.

8

5

3

.

2

16.4

128.6

39.7

1

0

5

.

2

1

0

2

.

0

9

4

.

0

2

.

2

1

0

.

2

41.3

9

8

.

4

5

.

0

4

.

5

7

.

5

1

2

.

0

385.3

4 224.7

1

6

.

0

6

.

0

29.2 120.0 29.2

178.3

4.3 112.8

117.1

1

6

.

0

1

6

.

0

4

.

5

1

1

.

5

5

.

0

3

.

0

2.0 243.4

26.5 98.3 26.5

151.3

26.5 144.2 26.5

197.1

5

.

0

3

.

0

26.5 157.1 26.5

210.1

3

.

0

5

.

0

26.5 171.7 26.5

5

.

0

26.5 198.8 26.5

5

.

0

224.7 251.7

26.5 112.6 26.5

5

.

0

26.5 152.7 26.5

5

.

0

205.7 165.6

3

.

0

3

.

0

3

.

0

3

.

0

26.5 64.2 26.5

117.1

1

9

2

.

3

23.4

8

.

0

1

.

0

5

.

1

7

.

9

1

4

.

0

8

.

0

9

5

.

2

7

.

9

1

4

.

0

8

.

0

1

.

0

5

.

2

7

.

8

1

4

.

0

8

.

0

1

.

8

5

.

2

7

.

0

1

4

.

0

82.3 199.7 82.3

364.3

364.3

58.3 160.2 58.3

276.8

4.4 268.0 4.4

276.8

257.3

3.1 251.3 3.1

257.5

59.0 139.5 59.0

59.0 159.1 59.0

277.2

9 275.5 9

277.2

36.3 75.0

32.7

5

2

.

4

6.8 2.4

2

.

1

5

.

1

4.8

27.6

65.0 82.7 114.0

660.0

3.4 162.2 2.6 203.1

277.1

6

.

0

7 275.7 7

4

.

5

1

1

.

5

52.8 171.5 52.8

277.1

178.3

151.3

197.1 210.1

55.3 120.4 55.5

2.4 226.4 2.4

231.3

10.7 106.8

4

.

5

105.1 10.7

4.8 373.3 7.2

385.3

4.8 49.2 59.8 54.1 51.6 111.7 46.9 7.2

2

8

2

.

0

20.8 4.8

1

5

.

9

7

.

9

29.1

85.7

12.7 1.2

37.0

34.9

34.9 21.8 20.8 4.8

1

5

.

9

7

.

9

6

5

.

1

7

3

.

0

103.2

660.0

4.8 660.0

21.0

129.6

19.0

7.9

1

9

.

1

34.9

34.9

43.0

177.6

1

4

.

5

6

.

3

37.0 35.0 33.0 31.1 29.4 27.8 26.2 24.7 23.3 22.0 20.8 19.6 18.5 17.5 16.5 15.6 14.7 13.9

330.0 43.5 30.7

37.0 35.0 258.0

494.4

37.0

72.0

105.0

136.2

165.6

193.3

219.5

244.2

267.6

289.6

310.4

330.0

348.5

366.0

382.5

398.1

412.8

426.7

1

7

.

9

6

.

3

60.0

27.0 6.0 27.0

1

7

.

9

6

.

3

28.6 6.0 28.6

35.5

R 12.0

R 4,686.3

R 42.1

R 36.8

R 38.7

R 181.4

1.77

1.77

85.00

4.28

!

"

#

$

$

!"#$

$

!

"

#

$

$

!"#$

$

!"#$$

!"#$$

!"#$$

Fret Wire Detail

Depth Of Holes For Rollers Can

Vary With Tuning Machine Mfr.

String Ramps

Re-Constituted Ivory Or Excellent Quality

Bone For the Nut.

Center Bridge Brace On

660mm Line For Scale

Length.

Certain Luthiers Tune The Top By Making The Top

Progressively Thinner As It Reaches The Guitar Edge

And Remain Full Thickness At The Top. If You Do

This Do Not Reduce The Edges Below 2.2mm And

Make The Center Slightly Thicker.

Re-Constituted Ivory Or Excellent Quality

Bone For the Nut.

This Light Line Is The Neck Splice

Joint. There Is A 8.13 Degree Angle

From The Neck To The Headpiece

The Top Trim For The Headstock Is Traditionally Made From

The Same Wood As The Back And Sides. It is Usually

Leftover Stock And Is About 2.2mm Thick. Glue Maple Or

Maple/Ebony Veneer Beneath For Additional Detail - This Is

A Personal Preference. Glue These Pieces Before Any

Headstock Work Is Started.

Many Classical Guitars Built In The Spanish

Tradition Shave The Bass Side Of The Fretboard

Down Gradually From The 12th Fret To The

Soundhole To Give The Bass Strings Additional

Room To Oscillate.

Shaping The "Foot" Of The Guitar Is One Of

The Most Demanding Operations. The Foot

Give The Neck And Body A Lot Of Structure

And This Joist Should Be As Perfect As

Possible.

Kerfed Lining Made From Either Basswood Or Cedar.

Many Spanish Classicals Use Solid Kerfing For The

Back Plate Attachment. If You Choose To Do That

Make Sure The Kerfing Is Pre-Bent Prior To Gluing. Do

Not Introduce Stress Into The Guitar

Note: Most Luthiers Make A Template From Either Wood Or

Plastic With The Neck Profile, Heal Shape And Interior Neck

Block And Foot Profile - All In One Template. Make Another Copy

Of This Plan To Make Your Own. Just Use Spray Adhesive To

Attach The Pattern And Cut It Out With Your Band Sand. Cut A

Little Big (Away From The Line) And Finish Sand With A Spindle

Sander Right Down To The Line

Back Braces - Vertical Grain Minimum 20 Grain/In.

Cedar Or Spruce #1 Quality. Cope Out Ends Of

Bracing And Fit Into Channels Cut Into The Lining (Do

Not Cut Through The Sides.

Side And Back Material: Many Different Woods Can Be

Used. For Bright Tones Go With One Of The

Rosewoods Such As Indian Rosewood or Brazialian

Rosewood. Koa Is Bright As Is Zircote And Madagascar

Rosewood. For Warm Tone Use Walnut. Most

Traditional Classical Guitars Are Constructed From

Indian Rosewood.

Back Block or Butt Block. Vertical Grain Cedar Or Spruce

Minimum 20 Grains/In. Some Luthiers Shave This Block or

Angle It Away From The Top As This Block Often Gives A

Guitar A "Hump" In The Top And Can Cause Cracking.

Drill These Holes Only After You Have

Purchased Your Tuning Machines. Make

Holes About 1mm Larger Than The Roller.

Drill These Holes First To Minimize Tear-Out

Of The Tuner Slots.

#1 Quality Cuban Mahogany Neck With

Ebony Reinforcement Strip Down Center

(See Detail Above). Select Only Vertical

Grain Wood For Your Neck.

Back Block or Butt Block. Vertical

Grain Cedar Or Spruce Minimum

20 Grains/In. Some Luthiers Shave

This Block or Angle It Away From

The Top As This Block Often Gives

A Guitar A "Hump" In The Top And

Can Cause Cracking.

Guitar Top Plate. Usually Braced Dead Level (No Arch) Use Only #1 or AAA Top Materials -

This Is The Single Most Important Piece Of Wood Used In A Guitar.

Materials Vary Quite A Bit, But Usually Consiste Of Spruce Or Cedar From Many Different

Regions. Spanish Cedar, Canadian Red Cedar And Many Others. Must Be Vertical Grain

Wood With No Run-out, Even Grain Across The Top And 20 Grain/In Minimum.

Top Thickness Varies As Well. From A Minimum of About 2.5 to 2.8mm Up To 3.5mm,

Depending On The Strength Of The Wood.

Kerfed Lining Made From Either Basswood Or Cedar.

Many Spanish Classicals Use Solid Kerfing For The

Back Plate Attachment. If You Choose To Do That

Make Sure The Kerfing Is Pre-Bent Prior To Gluing. Do

Not Introduce Stress Into The Guitar

Tone Bracing For Top. Spruce Or Cedar. Vertical

Grain, No Run-Out. Min. 20 Grains/Inch.

Classical Guitar Bridge Complete

With Tie Block, Saddle Channel And

Either Bone Or Ivory Saddle. Center

On 660mm Scale Length Both

Vertically and Horizontally.

The Soundhole Reinforcing Plate Is Made From The Same

Material As The Top Plate (i.e. Cedar) And Is Slightly

Larger Than The Rossette Size (About 1/8"). Glue It So

That The Grain Runs 90 Degrees To The Top. Fit It After

The Top Bracing Is In Place, To Fit It Perfectly Around The

Braces.

Side Braces. Set On Top Of Top Braces And Extend Down

Sides Of Guitar - See Latteral Section For Profile.

%&& ()* +,)-./

0$$ 123.

E

A B

F G

H J

K L

M

Back Block or Butt Block. Vertical Grain

Cedar Or Spruce Minimum 20 Grains/

In. Some Luthiers Shave This Block or

Angle It Away From The Top As This

Block Often Gives A Guitar A "Hump"

In The Top And Can Cause Cracking.

J

L

M

A

B

C

D

E

E

F

G

H

K

Classical Guitar Bridge Complete

With Tie Block, Saddle Channel And

Either Bone Or Ivory Saddle. Center

On 660mm Scale Length Both

Vertically and Horizontally.

Shaded Area Indicates 1/16" Cedar

Bridge Plate Glued To The Underside Of

The Top Place. Notch Fan Bracing Over

The Top Of The Bridge Plate.

Classical Guitar Bridge Complete

With Tie Block, Saddle Channel And

Either Bone Or Ivory Saddle. Center

On 660mm Scale Length Both

Vertically and Horizontally.

Brace Key Numbers. Refer To

Brace Diagram Plan For

Bracing Layouts

Laminate Cuban Cedar Left Overs From The

Neck Blank (Before You Rip The Blank Down The

Middle). Make Sure To Glue Enough For The

Continuous Neck Block And Foot At The Guitar

Interior As Well.

Either Extend The Back Material Over The Heel

Or Place A Piece Of Ebony Trim Over The Neck

Heal. Both Practices Are Used And Traditional.

Extension Of The Back Plate Over The Heals

Gives The Guitar Additional Strength.

Materials:

Assemble the proper materials before you begin your project. If you don't have your tone wood

already, there are several great suppliers including LMI (Luthier's Merchantile) which has a wide

range of top and back and side wood available. If this is your first guitar, you may want to try wood

that is a bit less expensive for your first try, such as mahogany for backs and sides or walnut, which

is about 50 to 33% of the cost of the Rosewoods etc. If you want an easy build guitar for your first

try, go with the Honduros Mahogany. It works easily, sands nicely, and finishes quite easily too. You

don't have to deal with exotic resins in the wood like you do with Rosewood, Cocobolo oand some

of the the other exotic woods.

When you order wood make sure you order wood that is at least 1" oversized in each direction so

you can eliminate splits etc. 2" is even better and quite often accomodated with tone wood. Make

sure the tops and backs are bookmatched for grain pattern.

Neck blanks can be Cuban Cedar. This is a very lightweight but very strong wood. Fretboards

should be clear Ebony, solid and you will have to buy 2 of them to allow you to add the Ebony

reinforcing to the center of the neck.

Most suppliers will have brace wood available, which is split from to log so there isn't any runout in

the wood - look for this in the literature.

You will also need additional wood to make up the purfling around he edges and you will need

maple or some other type of white wood if you want white stripping accents at your purflings. For

the dark wood use Rosewood veneer.

We did not get into the details of how purfling is put on this guitar as that is more of a construction

issue and not a guitar play issue. Any number of guitar construction books will guide you in the

proper techniques of installing purfling, where it should be and how to laminate it and bend it.

Buy good fret stock with at least 18% silver content. Steward MacDonald has a good assortment of

fretwire as does LMI.

Rossettes are best purchased already made unless you are determined to complete that difficult

operation. Many of the supply housed carry a great assortment of prefabricated rossettes.

Buy good tuning machines. Make sure they have good plating on them and the metal is a heavy

gauge. Buttons can be pearl, pearloid or ebony on many good quality machine heads.

Interior blocking for the butt blocks can be either Spruce or Cedar or even Mahogany or Cuban

Cedar. Just make sure it is free from knots and is striaght grained. Optain this at specialty lumber

yards or instrument supply shops.

Methods:

Start by sanding your top plate, back plate and sides to rough thickness (within 1mm of final

thickness). Carefully glue the center joints of the back and sides together. When gluing the back,

you will want to insert your decorative center strip at the same time. This should be pre-assembled

if you have multiple colors.

To prepare the joints, sand carefully with sandpaper glued to a perfectly straight edge. I like to use

adhesive backed sandpaper in rolls and stick it to the side of a 24" metal level. Trim the sandpaper

carefully. Use 120 grit paper and do not use a lot of force. The plates are joined most easily with a

cam-action jig while using a piece of wood on the top to keep things in alignment. Of course use

waxed paper wherever you risk having your wood stuck to the jig - or coat the jig with wax.

Once glued (If you use Rosewood, or one of the other exotic woods mentioned here, be sure to get

all of the resin out of the wood with acetone before you glue anything. Trace your top and back on

the wood - use a white pencil for dark wood. Then run the top and back through a wide stationary

belt sander - or use scrapers and hand sanding methods. Be careful with the use of acetone also.

Use rubber gloves and a resperator. You may also need to use a resperator for exotic wood dust as

many people have allergic reactions to the sanding dust (including myself).

When I started out making guitars, I couldn't afford all the expensive stationary sanders etc,,

that makes the work so simple now. I used to get one side of the plate completely flat, then I

would chuck up a small bit in the drill press and set it to stop at the desired thickness of my

plate. I would then drill dimples over the entire surface of the unfinished side and simply

sand until all of the dents were gone - pretty slick!

After you have your thickness completed on the top plates. trace the guitar contour and carefully cut

the outline out. Make the cut line at least 1/8" outside the line to give you some give.

Get your sides bent, either with a bending jig or on a bending iron. You can also boil the sides and

clamp them to an outside form for a few days to a week. Be sure to overbend a bit to allow for

springback.

While the sides are curing, rout the channel for the rossette and insert and glue that. I use a dremel

router with a steel stud sticking up through the center of the soundhold (the sound hole is not cut

out at this point. Once the rossette is installed, rout out the soundhole with the router too.

Now is the time to install all of your bracing on the top and back. As I mentioned I use a dowel jig. I

plan on detailing these jigs in an upcoming book on guitar construction, but do not have plans on

the jig at this point. It works fast and really secures the bracing evenly and uniform.

Now is the time to install all of your bracing on the top and back. As I mentioned I use a dowel jig. I

plan on detailing these jigs in an upcoming book on guitar construction, but do not have plans on

the jig at this point. It works fast and really secures the bracing evenly and uniform. It also gives you

a lot of fingerspace to allow gluing all of the braces in a single operation without a lot of clamps to

work around.

Typically the braces are only roughed-out for their final shaping is done after they are glued. After

the glue is mostly dry, remove the plate and get all of the glue squeeze out off the bracing and plate

with a sharp small chisel. The glue should be dry enough to not be liquid but not fully adhered to the

wood.

Once the braces have had at least a couple of hours to dry, shape them and round them with small

planes, finger planes, chisels and sanding sticks. Final shape and sand them with 220 sandpaper

until satin smooth.

Methods - Continued:

Now you should assemble the guitar neck. I recommed Cuban Cedar because it is light and strong.

Cut the Head scarf joint with a band saw first. Prepare this joint so it is perfectly tight. Next, cut the

blank to size and capture any blocks you can to glue to the heel/foot assembly. Now cut the neck

blank right down the center and flip the grain so it is opposed and working against each other. Slip a

6mm strip of Ebony between the halves and prepare all pieces in a similar manner to the plate

joints - or if you have a stationary drum sander, just run all the pieces through that. Prepare the

other half of the scarf joint so you will have a good joint for the headstock trim.

Glue the heel/foot block on the neck - all the while checking with your neck template. Once the neck

has dryed, do a final sanding on a stationary belt sander for the headstock and double-check the

thickness of the head. Now glue the headstock trim and purfling and set aside to dry.

Next rough-cut the heel and foot/endblock shape of the neck on the bandsaw, keeping things true

and plumb. Remember to always cut a bit outside the lines to allow for slight error. Now rough cut

the head after tracing with your headstock template. Sand the sides to final shape and size and drill

you machinehead roller holes of each side of the head. You can now drill your holes for the string

slots - being careful not to get any drill runout or tearout. Now cut the remainer of the slot out with

either a router or a jigsaw. Cut outside the line and finish the slots with sanding stick.

Cut your string ramps in the string grooves with a round rasp and finish with sandpaper wrapped

aroung a dowel. This can be a dowel section about 8" long with a slot cut in the end, right down the

center of the dowel for about 1/2 the dowel length. Insert the sandpaper in the slot and wrap around

the dowel.

Next rough-shape the neck with a 4-way rasp, using the rough cut blade. Get the neck to within

about 1/16" of final thickness and width. Now cut in the guitar side slots in the sides of the neck. Do

this very carefully and make sure you have good joints. I like to use dovetail saws for this operation

and g--o s--l--o--w. Thick the fitting often with your guitar sides clamped in the inside form.

Once the neck fits in the sides precisely, trim the butt joint of the sides and glue the butt block on

the bottom of the sides. Make sure to carefully fit the butt block the ot contour of the sides and

make sure the block is vertical grain. Once the butt block is in place, final fit and glue the neck. It is

essential that the side channels in the neck and the sides are trimed to match each other exactly.

Check the latteral and vertical positioning of the neck as this is extremely important at this time.

The foot and top of the block may need some additional trimming when the back and top are fit. You

also want to make sure that the sides are perfectly plumb in the form by using stretcher clamps.

With the sides rough-cut to contour, glue in the lining to receive the back plate. This lining can be

either kerfed lining or solid pre-bent lining. Glue with wooden clothespins with rubber bands

wrapped on them to strengthen their tension or use mini spring clamps. Make sure you have even

glue squeeze out and clean it up as you did on the braces. I like to elevate the lining slightly above

the sides while gluing (about 1/16" inch). This will allow you to easily sand down the lining only to

completely level the top.

Now fit the back to the sides and neck with the side following the contour of the inside form. Since

the braces for the back are slightly arched (about 1/8 to 1/4" ) carefully mark the trim marks for the

sides. This will vary with every aspect of the guitar beause the inherent nature of it's shape. Do

NOT glue the back on at this time. The top must be secured to the sides first.

Tips and Techniques:

Always make sure your tools are razor sharp and not dull. Buy good sharpening stones or

sharpening grinders such as the Tormek sharpener. It is also important to knock off the burr on your

chisels and other hand tools.

If you use stationary tools, make sure the blades on your bandsaw, tablesaw, jointer etc. are also

very sharp and you do not have to force wood through the machines. If given a choice, always use

carbide-tipped blades. Some of these hardwoods are tough to cut without a good carbide blade.

Setup of power tools is extremely important too - follow included direction or obtain good books on

proper setup of bandsaws, table saws etc. You can't believe what a difference this will make.

You can never have enough jigs, templates etc. in guitar-making. If you plan to continue beyond this

guitar and make several others, templates and jigs are a must more making your work a lot easier.

If you are starting from scratch, building guitars, make sure you make excellent quality forms for

your guitar. Both inside and outside forms for the body assembly. Look at LMI's side bending

machine. It works great and you can pump out a lot of bent sides in a short time.

Put together the templates we have shown here at a bare minimum. You should have a template to

trace your basic guitar boddy shape, your top and back brace locations, Your neck and foot profile

and the headstock layout, showning all the drilling locations for the tuning machine rollers and string

slots. Also it comes in handy to have back brace curvature templates, brace scalloping patterns, fret

slot location templates and bridge templates.

There are a lot of great little tools and gadgets available for Guitar Lutherie - Here are a few:

Thumb Planes - Available from Luthier supply houses - they are primarilary used for violins.

Spindle Sander - This is a tabletop stationary tool.

Dremel Router with roller bearing bushings - or other small hand-held mini-routher.

Note Stewmac has a lot of adapters available for the Dremel such as purfling routers, bits

etc.

Fret cutting jig - this is available from Stewmac also. Give you precise control over fret sawing.

Make a jig to glue your bracing. This consists of 2 plywood plates with dowel supports at each

corner. The braces are glued using bent dowels that span between the two plates.

Make sure your shop is held an a very constant humidity level all year long. Never vary more than

5% between 45 and 55%. This will minimize cracking, shrinkage and give overall durability to

guitars you plan to sell or gift.

Some of the other great little tools I love are:

Japanese Saws that cut both ways

Lots of the German Cam Clamps - both 6" and 8"

1" Spring Clamps - A whole 2# coffee can full of these

A great set of instrument maker's chisels in 1mm 2mm 4mm and 6mm sizes

Fret file, dovetail saws, fret end dressing tool, fret rocker etc. see my fret repair series for

detail on these and a lot more tools

Look at www.ultimate-guitar-online.com/woodworking-hand-tools.html for hand tools required and:

www.ultimate-guitar-online.com/woodworking-power-tools.html for stationary tools recommended.

Above all else make sure everything fits together perfectly before gluing. Do not force anything as

stress is a guitar ruins the tone. When in doubt take a few extra hours of sanding trimming and pre-

assembly to get everything as perfect as you can.

A

B

C

D

Side Reinforcing Braces. Profile, Size and

Amount Vary Greatly With Guitar Makers.

This One Sits On Top Of The Scalloped

Portion Of The Top Plate Braces And

Extends Down The Side About Half-Way.

They Are Typically Installed After The Top

Plate And The Sides Have Been Joined

Here Is A Much Easier Alternative To The Side

Bracing Shown On The Other Side Of This

Section. Space These Around The Sides Of The

Guitar Evenly (Between 6 and 8 Braces) The

Height Varies With The Sides. Place Them Into

Their Correct Location And Shape Them

Afterwards. They Are Glued In Place Just Before

Gluing The Back Plate To The Sides.

Butt The Rossette Reinforcing Plate

Into The Sides Of The Braces. Do Not

Extend Beneath Braces Or on Other

Side Of Braces

Optional Independent Side Braces - Refer To Latteral

Section For More Info. Spread Evenly Around The

Sides Of The Guitar. Refer To Section For The Exact

Profile. Usually Between 6 and 8 Are Used. These

Are Shaped Similar To A Brace Out Of The Same

Material As The Top Braces. Put In Place Just Prior

To Glueing The Back Plate To The Sides.

Optional Independent Side Braces - Refer To Latteral

Section For More Info. Spread Evenly Around The

Sides Of The Guitar. Refer To Section For The Exact

Profile. Usually Between 6 and 8 Are Used. These

Are Shaped Similar To A Brace Out Of The Same

Material As The Top Braces. Put In Place Just Prior

To Glueing The Back Plate To The Sides.

Rossette (Shaded) - Usually

Prefabricated. But You Can Make

Them Yourself.

C

D

Kerfed Lining Made From Either Basswood Or Cedar.

Many Spanish Classicals Use Solid Kerfing For The

Back Plate Attachment. If You Choose To Do That

Make Sure The Kerfing Is Pre-Bent Prior To Gluing. Do

Not Introduce Stress Into The Guitar.

Note: Bracing Shown Here Is The

Actual Placement Of The Bracing

On The Interior Side Of The Top

Plate. This Bracing Is Not Shown

In Xray Mode. Refer To Photograph

On Section Sheet.

Note: Bracing Shown Here Is The

Actual Placement Of The Bracing

On The Interior Side Of The Top

Plate. This Bracing Is Not Shown

In Xray Mode. Refer To Photograph

On Section Sheet.

1/16" (1.5mm) Cedar

Bridge Plate Glued To The Underside Of

The Top Place. Notch Fan Bracing Over

The Top Of The Bridge Plate.

Lateral Section

5

/

8

"

5

/

1

6

"

1 15/32" 1 3/8" 1 3/8" 27/32" 13/16" 3/16"

1

4

1

/

2

"

9

1

/

1

6

"

5

/

8

"

5

/

1

6

"

2

9

/

1

6

"

13/16" 3/16"

1 5/32"

3 3/8"

1/2" 1/32"

2

3

/

3

2

"

13/16"

5 3/32"

3/4"

5/16"

4 1/16"

3

/

4

"

1 3/8"

1 3/8"

1 11/16"

7"

9

/

1

6

"

1

/

4

"

25 31/32"

4

5

/

3

2

"

3/16" 25 31/32"

4

1

/

3

2

"

3

1

1

/

1

6

"

1 21/32" 3

3

/

3

2

"

21/32"

1 5/8"

1 3/32"

1 7/16" 2 31/32"

3

/

3

2

"

1

3

/

3

2

"

2

"

1

1

/

2

"

13" 1 23/32" 1 7/32"

2 9/16" 3 1/4" 4 1/2"

2

1

/

2

"

2

1

/

1

6

"

2

1

/

8

"

2

9

/

3

2

"

184 1/2"

1 15/32" 1 3/8" 10 5/32"

2

7

/

8

"

5 1/16"

1 9/16"

1 17/32"

15/32"

1 15/32" 1 3/8" 1 5/16" 1 7/32" 1 5/32" 1 3/32" 1 1/32" 31/32" 29/32" 7/8" 13/16" 25/32" 23/32" 11/16" 21/32" 5/8" 19/32" 17/32"

3

7

/

8

"

1 7/16"

3

/

1

6

"

9

/

3

2

"

1

5

/

3

2

"

5

/

8

"

3

/

1

6

"

7

/

1

6

"

5

/

8

"

1

/

4

"

1 5/32" 4 23/32" 1 5/32"

7 1/32"

2 3/32" 6 3/4" 2 3/32"

10 29/32"

1

/

4

"

1/32" 10 27/32" 0" 1/32"

3/16" 1 15/16" 2 11/32" 2 1/8" 2 1/32" 4 13/32" 1 27/32" 9/32"

15 5/32"

3

/

1

6

"

7

/

1

6

"

5

/

8

"

3

/

1

6

"

1

/

8

"

1 1/32" 3 7/8" 1 1/32"

5 31/32"

1 1/32" 5 11/16" 1 1/32"

7 3/4"

3

/

1

6

"

1

/

8

"

1 1/32" 6 3/16" 1 1/32"

8 9/32"

1

/

8

"

3

/

1

6

"

1 1/32" 6 3/4" 1 1/32"

8 27/32"

3

/

1

6

"

1 1/32" 7 13/16" 1 1/32"

9 29/32"

3

/

1

6

"

1 1/32" 6" 1 1/32"

8 3/32"

3

/

1

6

"

1 1/32" 4 7/16" 1 1/32"

6 17/32"

3

/

1

6

"

1 1/32" 2 17/32" 1 1/32"

4 5/8"

1

/

8

"

1

/

8

"

1

/

8

"

3

/

1

6

"

1

/

8

"

7

9

/

1

6

"

29/32"

5

/

1

6

"

1

/

3

2

"

3

/

1

6

"

5

/

1

6

"

9

/

1

6

"

5

/

1

6

"

1

/