Académique Documents

Professionnel Documents

Culture Documents

Catalog

Transféré par

Zaid MajedCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Catalog

Transféré par

Zaid MajedDroits d'auteur :

Formats disponibles

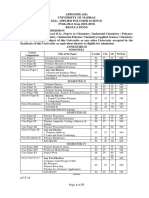

Thermal Analysis & Thermophysical Properties

DSC/TGA 4-5

Thermomechanical Analysis TMA 6-7

Simultaneous Thermal Analysis STA 8-9

High Temperature DSC / DTA 10-11

Ditaltometry DIL 12-15

Differential Scanning Calorimeter DSC 16-17

Gasanalysis / Couplings EGA 18-19

Thermal Diffusivity / Thermal Conductivity 20-21

Software 22-23

3

Since 1957 Linseis Corporation deliveres outstanding ser-

vice, know how and leading innovative products in the feld

of thermal analysis and thermal physical properties.

We are driven by innovation and customer satisfaction.

Customer orientation, innovation, fexibility and last but

not least highest quality are what Linseis stands for from the

very beginning. Thanks to these fundamentals our company

enjoys an exeptional reputation among the leading scientifc

and industrial companies. Linseis is since many years offe-

ring benchmark products in highly innovative branches.

The Linseis business unit thermal analysis encounters the

complete range of thermoanalytical equipment for R&D and

quality control in sectors such as polymers, chemical in-

dustry, inorganic building materials as well as environmental

analytics. Furthermore thermophysical properties of solids,

liquids and smelts can be analyzed.

Our thrive is technological leadership. We develop and

manufacture thermoanalytic and thermophysical testing

equipments up to the highest standard and precision. Due

to our innovative drive and ultimate precision we are a lea-

ding manufacturer of Thermal Analysis equipment.

The development of thermoanalytical testing machines

requires signifcant research and a high degree of precision;

for Linseis this is normal for the beneft of our customers.

Claus Linseis

Managing Director

TGA PT1000

The Linseis TGA PT1000 is a toploading Thermobalance,

which offers a highly userfriendly design. Even at a sample

weight of up to10g the tara is done electronically. The spe-

cially designed furnaces allow fast heating and cooling rates

as well as a highly precise temperature control. The system

can be optionally equipped with a coupling device for EGA

(Evolved Gas Analysis). The instrument is highly suitable for

thermal composition, thermal stability and oxidation studies.

Thermogravimetry TG

Temperature range: RT up to 1000C

Sample mass: up to 10g

Resolution: 0.5 ug / 0.1 ug

Vacuum: 10E

-2

mbar

Automatic evacuation: optional

Gas control box: optional

Cool down speed: < 15min (1000 100C)

DTA Calc. Optional

Upgrade to: TG-DTA/DSC

DSC PT10

This is the most common thermal analysis method due to

its wide range of information provided. The system works

after the heat fux principle. The highest resolution sensor

guarantees superior resolution, baseline stability, shortest

time constant and a condensation free sample chamber.

Common application areas are polymers, food, pharmaceu-

ticals, inorganic chemistry, metals and many more.

Temperature range: -150 up to 700C

Heating/cooling rates: 0.01 up to 100C

Resolution: 0.125 uW

Cooling options: Air/LN2/Intracooler

Gas control box: optional

Automatic evacuation: optional

TGA PT 1000

Differential Scanning Calorimenter - DSC

5

DSC PT 10

Thermomechanical analysis (TMA) measures linear or volu-

metric changes in the dimensions of a sample as a function

of time, temperature and force in a controlled atmosphere.

7

TMA PT1000

The Thermomechanical Analyzers TMA PT1000 and

TMA PT1000 EM uniquely combine the fexibility of several

measurement procedures under changing requirements.

The instrument can measure expansion and deformation at

highest precision.

Thermomechanical Analysis TMA

Model TMA PT1000 EM TMA PT1000

Temperature range: (-150-1000C) (-150-1000C)

Cryo option: available available

Force: 1/5.7N 1/5.7/20N

Frequency: 1/5Hz

Resolution: 0.125nm 0.125nm

Atmospere: inert, oxid inert, oxid

red., vac. red., vac.

Vacuum: 10E

-5

mbar 10E

-5

mbar

TMA PT1600

The TMA PT1600 offers a broad temperature range (RT

up to 1600C) for all kinds of thermomechanical investiga-

tions.

Model: TMA PT1600

Temperature range: -150 up to 500C

RT up to 1600C

Force: 1N

Frequency: 1Hz

Resolution: 0.125nm

Atmospere: inert, oxid

red., vac.

Vacuum: 10E

-5

mbar

TMA PT 1000

TMA PT 1600

Simultaneous TGA-DTA/DSC measures both heat fow and

weight changes in a material as a function of temperature

or time in a controlled atmosphere. Simultaneous measure-

ment of these two material properties not only improves pro-

ductivity but also simplifes interpretation of the results. The

complimentary information obtained allows differentiation

between endothermic and exothermic events which have no

associated weight loss (e.g., melting and crystallization) and

those which involve a weight loss (e.g., degradation).

9

STA PT1000

The Linseis STA PT1000 is a toploadindg Thermobalance,

which offers a highly userfriendly design. Even at a sample

weight of up to 10g the Tara is done electronically. The spe-

cially designed furnaces allow fast heating and cooling rates

as well as a highly precise temperature control. Exchanging

the different TGA, DTA or DSC measuring systems is only a

question of minutes.

STA PT1600

The STA PT1600 is the high end Simultaneous Thermoba-

lance from Linseis. The system offers unparalelled TG and

DSC resolution in combination with highest vacuum capabi-

lities and TG drift stability.

The system is modular due to fve exchangeable furnaces,

many different measuring systems and crucibles. The coup-

ling ability and many other optional acessories guarantee

the perfect setup for whatever application.

Simultaneous Thermal Analysis (STA) TGA DTA DSC

STA PT 1000 STA PT 16000

Temperature range: RT up to 1100C -150 up to 500C,

RT up to 1400/1500/1600/1750C

RT up to 2000/2400C

Sample mass: 10g 10g

Resolution: 0.5ug 0.5ug

Mesysteme: E/K/S E/K/S/B

Atmospere: inert, oxid., red., vac. Inert, oxid., red., vac.

Vacuum: 10E

-2

mbar 10E

-5

mbar

Preasure: optional 2/5 bar

Sample Carriers: TG DTA/DSC TG DTA/DSC

DSC measuring systems: E/K/S E/K/S/B

STA PT 1000

STA PT 1600

Differential Scanning Calorimetry (DSC) is most popular

thermal analysis technique it measures endothermic and

exothermic transitions as a function of temperature

- Endothermic = heat fows into a sample

- Exothermic = heat fows out of the sample

Linseis offers a unique line of high temperature DTA and

DSC systems.

11

This is the most common thermal analysis method due

to its wide range of information provided. The Linseis high

temperature DTA/DSC are desighned to deliver highest

calorimetric sensitivity, short time constants and a conden-

sation free sample chamber. These features guarantee su-

perior resolution, baseline stability over the entire instrument

lifetime. Thus providing a indispensable tool for material

development, R&D and quality control.

The modular concept of the DSC and DTA systems allows

the use of different furnaces with a temperature range from

-150 up to 2400C, different measuring systems for DSC

and DTA as well as many different crucibles. The vacuum

tight design enables quantitiative enthalpy and Cp (Specifc

Heat) determination under cleanest atmosperes as well as

under vacuum 10E-5mbar. Additionaly the systems can be

coupled to a MS or FTIR.

Hochtemperatur DTA

Temperature range: -150 up to 500C

RT up to 1400C

RT up to 1500C

RT up to 1600C

RT up to 1650C

RT up to 1750C

RT up to 2000C

RT up to 2400C

Sensors: different sensors

Vacuum: 10

-5

mbar

Atmospheres: inert, oxid., red., vac.

High Temperature DSC DSC PT1600

Temperature range: -150 up to 500C

RT up to 1400C

RT up to 1500C

RT up to 1600C

RT up to 1650C

RT up to 1750C

Sensors: E / K / S / B

DSC- Cp, DSC, DTA

Vacuum: 10

-5

mbar

Atmospheres: inert, oxid., red., vac.

High Temperature DSC / DTA

DSC/DTA PT 1600

Dilatometry (DIL) is a technique in which a dimension of a

substance under negligible load is measured as a function of

temperature while the substance is subjected to a controlled

temperature program in a specifed atmosphere.

13

DIL L76PT

The Linseis Dilatometer series L76 PT combines user

friendliness high modularity to different applications and out-

standing performance in one system. The low cost dilato-

meter series is especially suitable for the veramics and glass

industry.

DIL L75

DIL L76

Temperature range: RT up to 1000/1400/1600C

Resolution: 1.25 nm/digit

Sample length: 25 / 50 mm

Sample diameter: 7 / 14 / 20 mm < Vakuumnicht mglich

Sample number: Single or differential measuring system

Atmosphere: inert, oxid.

Sample holders: Fused Silica, Al

2

O

3

, Sappire

The high end pushrod dilatometer solves all measurement

tasks when it comes to determining the thermal length

change of solids, powders or pasts. The horizontal / vertical

design as single or differential system provides the perfect

solution for any type of expansion coeffcient and material

characteristica.

All models rely on a LVDT displacement sensor with almost

indefnite resilition, furthermore the thermostacaly controled

housing and perfect measuring design allow highest precission

and resolution measurments as well as long term drift stability.

Model L75 PT Horizontal L75 PT Vertical

Temperature range : -150 up to 500C -150 up to 500C

RT up to 1000/1400/1600/2000C RT up to 1000/1400/1600

1750/2000/2400/2800C

Resolution: 0.125 nm/digit 0.125 nm/digit

Sample length: 25/50 mm 25/50 mm

Sample diameter: 7/14/20 mm 7/14 mm

Sample number: Single or differential Single, differential or Quattro

Atmosphere: inert, oxid., red., vac. inert, oxid., red., vac.

Sample holders: Fused Silica, Al

2

O

3

, Fused Silica, Al

2

O

3

,

Sapphire, Graphite Sapphire, Graphite

Ditaltometry DIL

DIL L75PT Horizontal /Vertical opperation mode

14

Laser Dilatometer

The next step in expansion measurements. The L75 Laser

Dilatometer outperforms any conventional pushrod dilato-

meter by offering a 33 times higher resolution. The measure-

ment principle is based on a Michelson interferometer thus

eliminating all mechanical errors. This outstanding patented

measurement principle can cope with latest high tech ultra

low expansion (ULE) materials. Linseis has put much em-

phasis in the system design to secure a handling which is as

easy as with our conventional type of dilatometers.

Sample preperation does not require any special prepera-

tion it is as simple as with any conventional dilatometer. Any

kind of sample geometry can be measured as long as it fts

into the maximum sample dimesions.

Applications

Highest precission expansion measurements of materials

such as:

Carbon, Graphite, Composit materials, Glass, Alumina,

Fused Silica, Substrates, semiconductor material, etc

Quality and entry control of materials with problematic

expansions characteristics like, glass, bimetals, precission

electronics components, etc.

DIL L75 Laser

Specifcations

Method : Laser Dilatometer Michelson Prinzip

Temperature range: -180 up to 500C

RT up to 1000C

Sample length: up to 20 mm

Sample diameter: up to 7 mm

Resolution: 0.3 nm

Atmospere: inert, oxid., red., vac.

Vacuum: 10E

-5

mbar

Sample preperation: same as conventional dilatometer

15

L78 RITA Quenching Dilatometer

The Quenching Dilatometer L78 RITA is especially sui-

table for the determination of TTT, CHT and CCT diagrams.

The special induction furnace enables heating and cooling

speeds in excess of 400C/s. The system complies with

ASTM A1033.

All critical parametes such as heat up and cool down

speed, gas control and saftey features are software control-

led. The professional 32-bit software Linseis TA-WIN oppe-

rates exclusivly under the Microsoft operation system. All

routine (creation of CHT/CCT/TTT diagrams) and demanding

applications are solved by the unique Software package

which comes with the instrument.

Certainly export functions in ASCII-format as well as gra-

phic output is possible.

L 78 RITA

Specifcations

Temperature range: RT up to 1000C

RT up to 1600C

Heating / cooling rates: up to 400C/s for solid samples

Hollow samples even faster

Sample holders: Fused Silica, Al

2

O

3

Sample lengtth: 10 mm

Sample diameter: 6-7 mm

Atmospere: inert, oxid., red, vac.

Vacuum: 10E

-5

mbar (with turbomolecular pump)

Bild Dr. Sommer Werkstofftechnik GmbH, Issum

Differential Scanning Calorimetry (DSC) is most popular

thermal analysis technique it measures endothermic and

exothermic transitions as a function of temperature

- Endothermic = heat fows into a sample

- Exothermic = heat fows out of the sample

The instrument is used to characterize polymers, pharma-

ceuticals, foods/biologicals, organic chemicals and inorga-

nics. Transitions measured include Tg, melting, crystalliza-

tion, curing and cure kinetics, onset of oxidation and

heat capacity.

17

DSC PT 10

The DSC PT10 comprises the advantages of latest techno-

logy, highest resolution and a robust easy to use instrument

design. The measurement priciple of heat fux allows ulti-

mate measurement precission. The used sensor has a very

high resolution and can be calibrated very accuratly.

The optional software controled gas box enables Oxidati-

on Induction Time (OIT) measurements. The Kinetic software

and many other features provide the perfect solution for any

calorimetric experiment.

Temperature range: -150 up to 700C

Heating and cooling rates: 0.01 up to 100C/min

Resolution: 0.125 uW

Cooling: Air, LN2, intracooler

Gas control box: up to 4 gases

Atmosphere: inert, oxid., red.

Differential Scanning Calorimeter DSC

Food

The three evaluated substances (Fructose,Glucose and

Saccharose) show distinctive melting points. These melting

points can be precisely determined by means of Diffe-

rentialScanning Calorimetry (DSC). For this the analytical

method is frequently used for the determination of unknown

substances. Even mixtures with identical molecular weight

such as Fructose and Glucose can thus be recognized.

Thermoplasts

PolyEthylenTherephtalat (PET) shows a signifcant endo-

thermic glass point at about 77C, which is quite special

for partly crystalline thermoplasts. The relation between the

exothermal cold crystallization at 131C and the endother-

mic melting peak is a measure for the degree of crystalliza-

tion of the material. In the case of (PET) the crystalline part

is very small which results in a good transparency of the

material.

DSC PT 10

When couppling a Thermal Analyzer with a Quadrupole

Massspectrometer (QMS) or FTIR (Fourier Transformed

Infrared Spectrometer) out gassing products can be determi-

ned and identifed. The siglal can then be timewise correla-

ted with the signals received by the Thermal Analyzer.

With the optional Pulse Analysis the outgasings can be

quatifed when using a QMS as well as a FTIR.

19

Gasanalysis / Couplings

The combination of a Linseis Thermal Analyzer with a FTIR

(Fourier Tranformed Infrared Spectrometer) is especially

interesting in felds such as polymers, chemical and pharma-

ceutical industry. The coupling is more than the sume of the

seperate parts. Beneft from Linseis couplig knowledge and

integrated hard- and software concept.

Gasanalysis / Couplings

MS coupling

Massnumbers: 100/200/300 amu

Detector: Faraday and SEV (Channeltron)

Vacuum system: Turbomolecular and Diaphragm pump (oil free)

Heating: Adapter, heated capillary and QMS

Couplings: DSC, TGA, STA, DIL by heated capillary

FTIR coupling

Wave numbers: 7500 cm-1 370 cm-1

Resolution: 1 cm-1

Heating: Transfer line and adapter

Material transfer line: stainless steel (exchangeable)

Option Pulse-Analysis

The Pulse-Analysis injects a exactly predetermined

amount of liquid or gas into the Thermobalance (TGA) or

Simultaneous Thermal Analyzer (STA). This enhances the

measurement possibilities signifcantly: the MS or FTIR can

now be calibrated. Out gassings can be quantifed precisely

with this method.

Purge Gas

Injected Gas

Pulse Gas Box TG-DSC Gas Analysis

A

P

P

L

I

C

A

T

I

O

N

S

T

H

E

R

M

A

L

D

I

F

F

U

S

I

V

I

T

Y

/

T

H

E

R

M

A

L

C

O

N

D

U

C

T

I

V

I

T

Y

The sample is positioned horizontaly on a sample robot,

located in a furnace. The furnace is then held at a prede-

termined temperature. At this temperature the sample bot-

tom is then irradiated with a programmed energy pulse (laser

or xenon fash). This energy pulse results in a homogeneous

temperature rise at the sample top. The resulting tempera-

ture rise of the sample top is measured by a high speed

IR detector and thermal diffusivity values are computed

from the temperature rise versus time data. The resulting

measuring signal computes the thermal diffusivity, and in

most cases the specifc heat (Cp) data. If the density (r) is

identifed, the thermal conductivity can be calculated:

l(T)=a(T)cp(T)r(T)

Graphite

Copper & Aluminum

21

highly modular design allows upgrade to the LFA 1000 the

high end system whenever the measurement requires or the

budget allows it. The LFA 1000 provides unbeaten sampling

rates, up to 6 samples at the same measurement cycle, hig-

hest modularity, three different user exchangable furnaces

(-125 up to 1600C) and two detectors as well as a high

vacuum design (10E

-5

mbar).

System Design

Linseis is offering an unparalleled modular system desig

for this Thermophysical properties Analyzer. It is possible

to upgrade the temperature range (exchangeable fur-

naces/measuring system) and the detector (InSb/MCT).

This enables the user to start with a cost effective solution

and upgrade the system whenever the budget allows or the

measurement task requires it.

Correspondence with International Standards The LINS-

EIS LFA and XFA operate in agreement with national and

international standards such as ASTM E-1461, DIN 30905

and DIN EN 821.

LINSEIS offers a variety of instruments to measure the

Thermal Diffusivity. The XFA 500 provides a cost effective

solution for the temperaure range RT up to 500C. The

Thermal Diffusivity / Thermal Conductivity

XFA 500/LFA 1000

Thermal Diffusivity / Thermal Conductivity

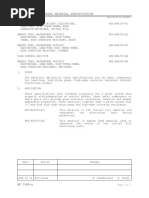

Model XFA 500 LFA 1000

Sample dimensions: 10 mm, 0.1 to 6 mm thick 10 mm, 0.1 to 6 mm thick

12.7 mm, 0.1 to 6 mm thick 12.7 mm, 0.1 to 6 mm thick

25.4 mm, 0.1 to 6 mm thick 25.4 mm, 0.1 to 6 mm thick

10x10 mm, 0.1 to 6mm thick 10x10 mm, 0.1 to 6mm thick

Max. Sample number: Up to 6 samples 12,7mm round Up to 6 samples 12,7mm round

Up to 3 samples 25,4mm round Up to 3 samples 25,4mm round

Temperature range: RT up to 500 -125 up to 500C

RT up to 1250/1600C

Vacuum: 10E

-5

mbar 10E

-5

mbar

Atmosphere: inert, oxidizing or reducing inert, oxidizing or reducing

Measuring range:

Thermal Diffusivity 0,01 up to 1000 mm

2

/s 0,01 up to 1000 mm

2

/s

Thermal Conductivity 0.1 W/(mK) to 2000 W/(mK) 0.1 W/(mK) to 2000 W/(mK)

Pulse source: Xenon Flash Nd: YAG Laser

Pulse energy: 10J/pulse 25J/pulse

All thermo analytical devices of LINSEIS are PC controlled

the individual software modules exclusively run under Micro-

soft operating systems. The complete software consists of

3 modules: temperature control, data acquisition and data

evaluation. The Linseis 32 bit software encounters all es-

sential features for measurement preparation, execution and

evaluation. Due to our specialists and application experts

LINSEIS was able to develop this easy understandable and

highly practical software.

23

LINSEIS TA-WIN

Features -Software:

User-friendly

Multi-methods analysis (DSC TG, TMA, DIL, etc.)

Zoom function

Online help menu

Report generator

Data export to MS Excel

Export and import of data ASCII

Program capable of text editing

Data security in case of power failure

Thermocouple break protection

Repetition measurements with minimum parameter

input

Evaluation of current measurement

Curve comparison up to 32 curves

Storage and export of evaluations

Programmable gas control

Statistical evaluation package

Smoothing of total or partial measurement

Tangent intersection determination (automatic or

manual)

Free scaling

The information of a thermo analytical measurement can

be increased when using the broad range of specialized

Software.

Software Options

Specifc Heat determination (Cp)

Rate Controlled Sintering (RCS)

Calculated-DTA

Quenching Dilatometer Software

CHT / CCT / TTT Diagrams

Thermo Kinetics Software

Software

LINSEIS GmbH

Vielitzerstr. 43

95100 Selb

Germany

Tel.: (+49) 9287880 - 0

Fax: (+49) 928770488

E-mail:info@linseis.de

LINSEIS Inc.

20 Washington Road

P.O.Box 666

Princeton-Jct. NJ 08550

Tel.: (609) 7996282

Fax: (609) 7997739

E-mail: info@linseis.com

www.linseis.com

Products: DIL, TG, STA, DSC, HDSC, DTA, TMA, MS/FTIR, Laser Flash

Services: Service Lab, Calibration Service

Vous aimerez peut-être aussi

- 2010 - Bayram Ercikdi - Utilizationofwaterreducingadmixturesincementedpast (Retrieved 2017-09-27)Document7 pages2010 - Bayram Ercikdi - Utilizationofwaterreducingadmixturesincementedpast (Retrieved 2017-09-27)Zaid MajedPas encore d'évaluation

- 2010 - Bayram Ercikdi - Effectofnaturalpozzolansasmineraladmixtureontheper (Retrieved 2017-09-27) PDFDocument6 pages2010 - Bayram Ercikdi - Effectofnaturalpozzolansasmineraladmixtureontheper (Retrieved 2017-09-27) PDFZaid MajedPas encore d'évaluation

- Soil Swell PropertiesDocument15 pagesSoil Swell Propertiesvasudeva yasasPas encore d'évaluation

- Underground MiningDocument45 pagesUnderground MiningZaid MajedPas encore d'évaluation

- Standard Test Method For Determination of The Proportion of Phases in Portland Cement and Portland-Cement Clinker Using Xray Powder Diffraction AnalysisDocument10 pagesStandard Test Method For Determination of The Proportion of Phases in Portland Cement and Portland-Cement Clinker Using Xray Powder Diffraction AnalysisZaid MajedPas encore d'évaluation

- TG and DTG Curves of Control Paste at 28 Days' Curing TimeDocument27 pagesTG and DTG Curves of Control Paste at 28 Days' Curing TimeZaid MajedPas encore d'évaluation

- Thermal Analysis of Cement Paste Partially ReplacedDocument5 pagesThermal Analysis of Cement Paste Partially ReplacedZaid MajedPas encore d'évaluation

- Evaluation of Relationship Between Water Absorption and Durability of Concrete Materials PDFDocument9 pagesEvaluation of Relationship Between Water Absorption and Durability of Concrete Materials PDFZaid MajedPas encore d'évaluation

- 2015-Specimen Size Effect On Strength Behavior of Cemented Paste BackfillsDocument11 pages2015-Specimen Size Effect On Strength Behavior of Cemented Paste BackfillsZaid MajedPas encore d'évaluation

- Documents - MX Geotech Considerations in Mine Back Filling in AustraliaDocument8 pagesDocuments - MX Geotech Considerations in Mine Back Filling in AustraliaZaid MajedPas encore d'évaluation

- Mine Wastes ManagementDocument13 pagesMine Wastes ManagementOolasyar KhattakPas encore d'évaluation

- Underground MiningDocument45 pagesUnderground MiningZaid MajedPas encore d'évaluation

- 97 FullDocument5 pages97 FullZaid MajedPas encore d'évaluation

- Dissertation ScheduleDocument1 pageDissertation SchedulerishaanjeffriPas encore d'évaluation

- A Side Effect Was The Formation of A Gypsum Layer On Some of The SpecimensDocument9 pagesA Side Effect Was The Formation of A Gypsum Layer On Some of The SpecimensZaid MajedPas encore d'évaluation

- Lec 9-Impacts of CC On Hydrological Variables DistributionsDocument37 pagesLec 9-Impacts of CC On Hydrological Variables DistributionsZaid MajedPas encore d'évaluation

- Study On Surface Permeability of Concrete Under ImmersionDocument11 pagesStudy On Surface Permeability of Concrete Under ImmersionZaid MajedPas encore d'évaluation

- ContentDocument30 pagesContentZaid MajedPas encore d'évaluation

- Collection Solid WasteDocument33 pagesCollection Solid WasteZaid MajedPas encore d'évaluation

- CHEM 3440: Thermal MethodsDocument7 pagesCHEM 3440: Thermal Methodstieuca08Pas encore d'évaluation

- Adressing The Climate Adressing The Climate Change Threat Change Threat Change Threat Change ThreatDocument27 pagesAdressing The Climate Adressing The Climate Change Threat Change Threat Change Threat Change ThreatZaid MajedPas encore d'évaluation

- Thermal AnalysisDocument37 pagesThermal AnalysisZaid Majed100% (1)

- 17 Chapter 10 GeochemistryDocument55 pages17 Chapter 10 GeochemistryZaid MajedPas encore d'évaluation

- Matl RecycleDocument61 pagesMatl RecycleZaid MajedPas encore d'évaluation

- Briefing Paper Conversion TechnologiesDocument5 pagesBriefing Paper Conversion TechnologiesZaid MajedPas encore d'évaluation

- 4139 LandfillzzzzzzDocument123 pages4139 LandfillzzzzzzZaid MajedPas encore d'évaluation

- Series AR712/722 Gas Chromatograph: Analysis of Impurities in ArgonDocument2 pagesSeries AR712/722 Gas Chromatograph: Analysis of Impurities in ArgonZaid MajedPas encore d'évaluation

- Barrier Systems For Waste Disposal FacilitiesDocument20 pagesBarrier Systems For Waste Disposal FacilitiesZaid Majed0% (1)

- Barrier Systems For Waste Disposal FacilitiesDocument20 pagesBarrier Systems For Waste Disposal FacilitiesZaid Majed0% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Facility Evs30-5830703Document17 pagesFacility Evs30-5830703yogendra49Pas encore d'évaluation

- E487-14 Standard Test Method For Constant-TemperatDocument4 pagesE487-14 Standard Test Method For Constant-Temperatouari.ouariPas encore d'évaluation

- Astm E1860 - 1 (En)Document3 pagesAstm E1860 - 1 (En)JOHOPas encore d'évaluation

- Thermal AnalysisDocument8 pagesThermal AnalysisHafsa QasimPas encore d'évaluation

- CO Oxidation Over Alumina Monolith Impregnated With Oxides of CopperDocument10 pagesCO Oxidation Over Alumina Monolith Impregnated With Oxides of CopperNickly NickPas encore d'évaluation

- Comprehensive VivaDocument9 pagesComprehensive VivaSAURABH KUMAR PANDEY Research Scholar, Chemical Engg. & Technology , IIT(BHU)Pas encore d'évaluation

- Thermoanalytical Instruments ListDocument2 pagesThermoanalytical Instruments ListHui Yuan YeonPas encore d'évaluation

- AstmDocument18 pagesAstmar_kedarPas encore d'évaluation

- SDocument594 pagesSDavid Fernando Urrelo RodriguezPas encore d'évaluation

- Evaluation and Interpretation of Peak Temper-Atures of DSC Curves. Part 1: Basic PrinciplesDocument5 pagesEvaluation and Interpretation of Peak Temper-Atures of DSC Curves. Part 1: Basic PrinciplesUnknownPas encore d'évaluation

- Catalogue Industrial Laboratory Solutions SDDocument84 pagesCatalogue Industrial Laboratory Solutions SDAs Des As BenedictionPas encore d'évaluation

- Mechanical Engineering CAD Cam ProjectDocument15 pagesMechanical Engineering CAD Cam ProjectJayant ShrotePas encore d'évaluation

- Lamara2018 PDFDocument13 pagesLamara2018 PDFUmer HayatPas encore d'évaluation

- Modified M.SC SyllabusDocument27 pagesModified M.SC SyllabusAbhishekBanerjeePas encore d'évaluation

- 1 Page Synopsis ECU CasingDocument2 pages1 Page Synopsis ECU CasingIliyas InamdarPas encore d'évaluation

- A Review On Recent Developments in The Determination of Residual Solvents by Gas ChromatographyDocument9 pagesA Review On Recent Developments in The Determination of Residual Solvents by Gas ChromatographychiralicPas encore d'évaluation

- C3. Paint Specification (WSS-M64J39-A1) v1Document7 pagesC3. Paint Specification (WSS-M64J39-A1) v1Chandrajeet ShelkePas encore d'évaluation

- Thermal Fatigue Monitoring GuidelinesDocument104 pagesThermal Fatigue Monitoring Guidelinesvarunsuri8100% (2)

- Evaluating Nonmetallic Materials For Oxygen ServiceDocument26 pagesEvaluating Nonmetallic Materials For Oxygen Servicevuqar0979Pas encore d'évaluation

- Esther's WorkDocument26 pagesEsther's WorkMudassir Adam MuhammadPas encore d'évaluation

- (Ebook) - Thermal Analysis TechniquesDocument21 pages(Ebook) - Thermal Analysis Techniquesiordache0% (1)

- Thermal Analysis Application Brief TGADocument3 pagesThermal Analysis Application Brief TGAZeemam Abdur RehmanPas encore d'évaluation

- Andrey Tarasov Thermal Analysis 121026Document48 pagesAndrey Tarasov Thermal Analysis 121026e582099Pas encore d'évaluation

- Centralized Resource Laboratories, University of Peshawar: S.No Name of Equipment Status Particulars of The TestsDocument2 pagesCentralized Resource Laboratories, University of Peshawar: S.No Name of Equipment Status Particulars of The TestsAliPas encore d'évaluation

- Lecture 1backupDocument16 pagesLecture 1backupZUL KAMARUDDINPas encore d'évaluation

- Thermophysical Properties of Tussar SilkDocument7 pagesThermophysical Properties of Tussar SilkAmruta Vishwaradhya PuranikmathPas encore d'évaluation

- Astm For RealDocument4 pagesAstm For RealDeepakPas encore d'évaluation

- Behavior of Impregnated Activated Carbons Heated To The Point of OxidationDocument10 pagesBehavior of Impregnated Activated Carbons Heated To The Point of Oxidation43Pas encore d'évaluation

- Optimizing Exhaust Manifold Design Using SimulationDocument11 pagesOptimizing Exhaust Manifold Design Using SimulationAltemir Manzanete100% (2)

- Model Free Kinetics: Thermal Analysis Application No. UC 212Document4 pagesModel Free Kinetics: Thermal Analysis Application No. UC 212Martin CelestinoPas encore d'évaluation