Académique Documents

Professionnel Documents

Culture Documents

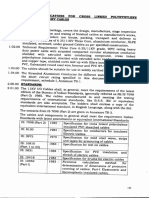

1.9.6 Cables Specifications (Type Designation-HT)

Transféré par

anurag_pugaliaa0 évaluation0% ont trouvé ce document utile (0 vote)

43 vues2 pagesCables shall have the following specifications: S.No Description CableHT-1 1. Voltage grade and type 2. No. Of cores 3. IS Reference IS: 7098(Part-"), IS: 8130, IS:5831 4. Conductor Stranded, round aluminium conductor class 2 to IS:8130 with maximum operating temperature 90 0 C 5. Conductor screen Extruded, semi-conducting thermo-setting material manufactured by triple extrusion technique.

Description originale:

Titre original

11kv

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentCables shall have the following specifications: S.No Description CableHT-1 1. Voltage grade and type 2. No. Of cores 3. IS Reference IS: 7098(Part-"), IS: 8130, IS:5831 4. Conductor Stranded, round aluminium conductor class 2 to IS:8130 with maximum operating temperature 90 0 C 5. Conductor screen Extruded, semi-conducting thermo-setting material manufactured by triple extrusion technique.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

43 vues2 pages1.9.6 Cables Specifications (Type Designation-HT)

Transféré par

anurag_pugaliaaCables shall have the following specifications: S.No Description CableHT-1 1. Voltage grade and type 2. No. Of cores 3. IS Reference IS: 7098(Part-"), IS: 8130, IS:5831 4. Conductor Stranded, round aluminium conductor class 2 to IS:8130 with maximum operating temperature 90 0 C 5. Conductor screen Extruded, semi-conducting thermo-setting material manufactured by triple extrusion technique.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

2X18 MWCPp

Tender Call No.:RSWM-200SlEPCIM01 Section-VI(B) Technical Specifications

Electrical, Instrumentation & Control

1.9.6 CablesSpecifications (TypeDesignation-HT)

Cables shall have the following specifications:

S.No Description

CableHT-1

1.

Voltage grade and type

11 kV (UE) grade XLPE Power Cables

2.

No. of cores

Single

3.

IS Reference

IS: 7098(Part-"), IS: 8130, IS:5831

4.

Conductor

Stranded, round aluminium conductor class 2

to IS:8130 with maximum operating

temperature 90

0

C

5.

Conductor screen

Extruded, semi-conducting thermo-setting

material manufactured by triple extrusion

technique.

6.

Insulation

Dry cured cross linked polyethylene (XLPE) as

per IS: 7098 (Part-II) 1985

7.

Insulation screen

Extruded, semi-conducting compound for core

shielding followed by copper tape screening

and core identification tape protected by inner

sheath of PVC type ST -2 capable of

continuously operating with conductor at 900C

without deteriorating, removable without

applicable of heat and manufactured by triple ' I.

extrusion technique

i \

Extruded PVC Type ST-2

8.

i

Inner sheath and filler

9.

Armouring

Hard drawn aluminium wire/flat

10.

J acket or outer sheath

Extruded FRLS PVC Anti termite and anti

rodent Type ST-2 compound type capable of

passing factor tests specified below

, I

11.

Factory tests i.

Type test certificate as per IS:7098

(Part-II) including

Dielectric power factory test

ii. Acceptance tests in respect of each lot

of cable as per IS:7098 (Part-It)

iii. '. Routine tests in respect of each piece

of cable as per IS:7098 (Part-II)

fCCSL, 86 of 137

2 X18 MWCPP

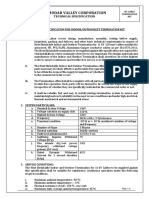

Tender Calf No.:RSWM-200SIEPCIM01

Section-VI(S) Technical Specifications

Electrical, Instrumentation & Control

12. Marking

13.

Guarantee

i

S.No

Description

1.

Voltage grade and type

2.

No. of cores

3.

IS Reference

4~

Conductor

5.

Conductor screen

6.

Insulation

7.

Insulation screen

tV.

Flammability test : The cables should

pass the requirement of IEEE 383 in

this regard

v. Smoke Generation test for sheath

under fire:

When tested as per ASTM D2843 the

cable shall meet the requirement of

minimum 40% light transmittance.

However, preference shall be given for

higher values

vi.

Oxygen Index test: The oxygen index

when tested under ASTM D2863 shall

be minimum 29

vii.

Acid Gas Generation test:

When tested as per IEC 754-1 the

maximum acid gas generated should

not be more than 20% byweight

marking on length of the cable shall be at

every meter interval on the outer most PVC

sheath of cable

Cable shall be guaranteed to safely withstand

continuous conductor temperature of 90C and

shall also safely withstand conductor

temperature upto 130C for duration of 100 '

I , t

hours per year

\ \

Cable HT-2

11kV (UE) grade XLPE Power Cables

Three

IS: 7098(Part-II), IS:8130, IS: 5831, IS:3975

Stranded. round aluminium conductor class 2

to IS: 8130 with maximum operating

temperature 90C

Extruded, semi-conducting thermo-setting

material manufactured by triple extrusion

technique.

Dry cured cross linked polyethylene (XLPE) as

per IS: 7098 (Part-II) 1985

Extruded, semi-conducting compound for core

shielding followed by copper tape screening

ICCSL,

870f137

Vous aimerez peut-être aussi

- Tech - Spec.-Aerial Bunched Cable-XLPE Insulated H.T. Cable.Document6 pagesTech - Spec.-Aerial Bunched Cable-XLPE Insulated H.T. Cable.Bilal AhmadPas encore d'évaluation

- IS-7098 PT - 1.Document17 pagesIS-7098 PT - 1.Rishi PalPas encore d'évaluation

- 11kv CablesDocument46 pages11kv CablesS.k. RathPas encore d'évaluation

- B-09 HT Power CablesDocument8 pagesB-09 HT Power Cablesrahul patraPas encore d'évaluation

- B-03 LT Power CablesDocument8 pagesB-03 LT Power Cablesrahul patraPas encore d'évaluation

- Technical SpecificationDocument7 pagesTechnical SpecificationrohitctppPas encore d'évaluation

- Technical Specifications For Aerial BunchedDocument5 pagesTechnical Specifications For Aerial BunchedNazriPas encore d'évaluation

- BESCOM Technical-Specification-HT-UG-CablesDocument15 pagesBESCOM Technical-Specification-HT-UG-Cablesಪರಮಮಿತ್ರಸಂಪತ್ಕುಮಾರ್ಶೆಟ್ಟಿPas encore d'évaluation

- Cables Specifications VFDocument13 pagesCables Specifications VFraiutkarshPas encore d'évaluation

- Section-6 Chapter-1 Part-I Technical Specification For 66 KV (Cross Linked Polyethylene Insulated Power Cable: 1.1 SCOPEDocument5 pagesSection-6 Chapter-1 Part-I Technical Specification For 66 KV (Cross Linked Polyethylene Insulated Power Cable: 1.1 SCOPESandeep SharmaPas encore d'évaluation

- Industrialnet Category 6 S/FTP Copper Cable: SpecificationsDocument2 pagesIndustrialnet Category 6 S/FTP Copper Cable: SpecificationsCarlos SalcedoPas encore d'évaluation

- Teldor PN 8bdp112109Document1 pageTeldor PN 8bdp112109Codigo de BarrasPas encore d'évaluation

- Is 7098 Part I 1998Document17 pagesIs 7098 Part I 1998Sanjeev DhariwalPas encore d'évaluation

- LV Power Cable Specification - 06.11.2009Document10 pagesLV Power Cable Specification - 06.11.2009ErAkashAryanPas encore d'évaluation

- Technical Specification For 3C XPLE CableDocument9 pagesTechnical Specification For 3C XPLE Cableramana3339Pas encore d'évaluation

- TECHNICAL SPECIFICATION - INSTRUMENT & CONTROL CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022Document9 pagesTECHNICAL SPECIFICATION - INSTRUMENT & CONTROL CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022nnPas encore d'évaluation

- Msedcl Ts LT CablesDocument41 pagesMsedcl Ts LT CablesAshish bhattPas encore d'évaluation

- Technical Specifications and GTP For 11KV XLPE Cable SP 574Document13 pagesTechnical Specifications and GTP For 11KV XLPE Cable SP 574hafizrahimmitPas encore d'évaluation

- Opgw SpecificDocument21 pagesOpgw SpecificASH TVPas encore d'évaluation

- Technical Specification: 2Cx16+25 SQ - MM LT Xlpe Ab CableDocument9 pagesTechnical Specification: 2Cx16+25 SQ - MM LT Xlpe Ab CableRamesh Arjun TPas encore d'évaluation

- CSC 115R 1Document15 pagesCSC 115R 1walid kawsarPas encore d'évaluation

- Cross-Linked Polyethylene Insulated Thermoplastic Sheathed Cables-SpecificationDocument22 pagesCross-Linked Polyethylene Insulated Thermoplastic Sheathed Cables-SpecificationSuresh SharmaPas encore d'évaluation

- OPGW Specifications: GeneralDocument18 pagesOPGW Specifications: GeneralMubashir HussainPas encore d'évaluation

- ANNEX E - Amended - Technical Specs of L.T TWISTED INSULATED CABLEDocument7 pagesANNEX E - Amended - Technical Specs of L.T TWISTED INSULATED CABLEsajjad_pirzadaPas encore d'évaluation

- ALC ElectricalDocument8 pagesALC ElectricalmarckalhiPas encore d'évaluation

- 06-POWER AND CONTROL CABLE - Rev5 PDFDocument14 pages06-POWER AND CONTROL CABLE - Rev5 PDFSanjay RoutPas encore d'évaluation

- Technical Specification For Cross Linked Polyethylene Insulated 3 Core 11kv CablesDocument13 pagesTechnical Specification For Cross Linked Polyethylene Insulated 3 Core 11kv CablesNarendra SinghPas encore d'évaluation

- TS-OPGW 1.4 9feb2017Document18 pagesTS-OPGW 1.4 9feb2017asim204Pas encore d'évaluation

- Cable Selection Guide Gtc020212Document4 pagesCable Selection Guide Gtc020212MEGA_ONEPas encore d'évaluation

- Chapter 20: Technical Specification For Xlpe Cable With TerminationDocument46 pagesChapter 20: Technical Specification For Xlpe Cable With TerminationSristi MitraPas encore d'évaluation

- TS For 4Cx10 SQ - MM Armoured CableDocument8 pagesTS For 4Cx10 SQ - MM Armoured CableAshish bhattPas encore d'évaluation

- Cap Ngam 24KV-1x500mm2Document10 pagesCap Ngam 24KV-1x500mm2Minh VienPas encore d'évaluation

- 4x2x16 AWG XLPE FUTP 600V Instrumentation Cable With PVC Jacket - 8A61004101Document2 pages4x2x16 AWG XLPE FUTP 600V Instrumentation Cable With PVC Jacket - 8A61004101AndresPas encore d'évaluation

- Technical SpecificationDocument7 pagesTechnical Specificationshivam dwivediPas encore d'évaluation

- Draft Test Report - 4 C X 300 Sq. MM A2XFY FRLSDocument11 pagesDraft Test Report - 4 C X 300 Sq. MM A2XFY FRLSShara LogisticPas encore d'évaluation

- HT Cable RFQ Specifications PDFDocument7 pagesHT Cable RFQ Specifications PDFAshil ThomasPas encore d'évaluation

- Cap Ngam 240mm2 Cach Dien Xlpe Hay EprDocument7 pagesCap Ngam 240mm2 Cach Dien Xlpe Hay EprMinh VienPas encore d'évaluation

- Instrument Cable SpecificationDocument12 pagesInstrument Cable Specificationfloreda100% (1)

- XLPE Power Cable 11 & 33 KVDocument9 pagesXLPE Power Cable 11 & 33 KVArjun M KumarPas encore d'évaluation

- Arial Bunch ConductorDocument10 pagesArial Bunch Conductorbbakari2000Pas encore d'évaluation

- Tech Spec For DC String CablesDocument6 pagesTech Spec For DC String CablesPaari BPas encore d'évaluation

- Sheet L 1 of 11: CH 24: LT Control CablesDocument11 pagesSheet L 1 of 11: CH 24: LT Control CablesSudipto MajumderPas encore d'évaluation

- 15 Sec Technical Rev 0Document13 pages15 Sec Technical Rev 0mohanksebPas encore d'évaluation

- LT Aerial Bunch Cable (3C X 95 SQMM)Document541 pagesLT Aerial Bunch Cable (3C X 95 SQMM)Biju100% (5)

- Cable Selection Guide: Gai-Tronics®Document4 pagesCable Selection Guide: Gai-Tronics®Vicente HdezPas encore d'évaluation

- Technical Description Td-95/3 400 KV, 30 Mvar or 50 Mvar or 60 Mvar Shunt ReactorsDocument25 pagesTechnical Description Td-95/3 400 KV, 30 Mvar or 50 Mvar or 60 Mvar Shunt ReactorsK Vijay Bhaskar ReddyPas encore d'évaluation

- Ab Cable GTPDocument17 pagesAb Cable GTPNaresh Ch MahapatraPas encore d'évaluation

- 600 V Multiconductor: Power CableDocument1 page600 V Multiconductor: Power Cablecesar1023Pas encore d'évaluation

- 66 KV Cable and AccessoriesDocument4 pages66 KV Cable and AccessoriesSandip AhirePas encore d'évaluation

- DesignVerification SYS1Document20 pagesDesignVerification SYS1Geir Arne HagbyPas encore d'évaluation

- Negotino Cable Factory CatalogueDocument125 pagesNegotino Cable Factory CatalogueRejnald ZyfiPas encore d'évaluation

- XLPE Cable 33KV - Rev 2 PDFDocument12 pagesXLPE Cable 33KV - Rev 2 PDFRatul ChakrabortyPas encore d'évaluation

- SX6X04ATL-LED Technical DataDocument2 pagesSX6X04ATL-LED Technical DataJosé Santiago Miranda BernaolaPas encore d'évaluation

- HT Cable Termination Kit 14.3.22Document8 pagesHT Cable Termination Kit 14.3.22JIGSPas encore d'évaluation

- Is 1554 1 1988Document26 pagesIs 1554 1 1988karthikraja21Pas encore d'évaluation

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsD'EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsPas encore d'évaluation

- Marine Electrical Practice: Marine Engineering SeriesD'EverandMarine Electrical Practice: Marine Engineering SeriesÉvaluation : 4 sur 5 étoiles4/5 (8)

- Circuit Breaker IMS - 50 - 05 - FOR - 78 (Half Yearlyshutdown)Document2 pagesCircuit Breaker IMS - 50 - 05 - FOR - 78 (Half Yearlyshutdown)anurag_pugaliaaPas encore d'évaluation

- LA Leakage Current Testing (With Graphs) - 2014Document28 pagesLA Leakage Current Testing (With Graphs) - 2014anurag_pugaliaaPas encore d'évaluation

- LA Leakage Current Testing (With Graphs) PDFDocument15 pagesLA Leakage Current Testing (With Graphs) PDFanurag_pugaliaaPas encore d'évaluation

- Shree Cement LTD, Bangurcity Battery Charger & Battery BankDocument3 pagesShree Cement LTD, Bangurcity Battery Charger & Battery Bankanurag_pugaliaaPas encore d'évaluation

- 132 KV Thermography - 2014Document1 page132 KV Thermography - 2014anurag_pugaliaaPas encore d'évaluation

- Check List ShcduleDocument3 pagesCheck List Shcduleanurag_pugaliaaPas encore d'évaluation

- 220 KV Thermography - 2014Document1 page220 KV Thermography - 2014anurag_pugaliaaPas encore d'évaluation

- ActivityDocument4 pagesActivityanurag_pugaliaaPas encore d'évaluation

- Prsentation On Soft Starter FDocument27 pagesPrsentation On Soft Starter Fanurag_pugaliaaPas encore d'évaluation

- Confirmation of Contract Labour Engagement Purely On Temporary Jobs DepartmentDocument1 pageConfirmation of Contract Labour Engagement Purely On Temporary Jobs Departmentanurag_pugaliaaPas encore d'évaluation

- Sil 10042014Document1 pageSil 10042014anurag_pugaliaaPas encore d'évaluation

- Improvement Jobs FormatDocument5 pagesImprovement Jobs Formatanurag_pugaliaaPas encore d'évaluation

- Pre Test PDFDocument6 pagesPre Test PDFanurag_pugaliaaPas encore d'évaluation

- Repair ChecklistDocument1 pageRepair Checklistanurag_pugaliaaPas encore d'évaluation

- Activity AssociationDocument9 pagesActivity Associationanurag_pugaliaaPas encore d'évaluation

- New Microsoft Office Excel WorksheetDocument1 pageNew Microsoft Office Excel Worksheetanurag_pugaliaaPas encore d'évaluation

- Asset (P-Elec.)Document342 pagesAsset (P-Elec.)anurag_pugaliaaPas encore d'évaluation

- 220kV Cable Accessory Technical SpecificationDocument9 pages220kV Cable Accessory Technical Specificationanurag_pugaliaaPas encore d'évaluation

- 11kV 1xC XLPEDocument1 page11kV 1xC XLPEanurag_pugaliaaPas encore d'évaluation

- Sop TurbineDocument4 pagesSop Turbineanurag_pugaliaaPas encore d'évaluation

- 220kV RRVPNL Cable SpecificationDocument22 pages220kV RRVPNL Cable Specificationanurag_pugaliaaPas encore d'évaluation

- 1 - DG Fault EngDocument5 pages1 - DG Fault Engspk53Pas encore d'évaluation

- 259Document5 pages259anurag_pugaliaaPas encore d'évaluation

- Power - Aug'13 To July'14Document393 pagesPower - Aug'13 To July'14anurag_pugaliaaPas encore d'évaluation

- Near Miss Incident Form Annex-29Document1 pageNear Miss Incident Form Annex-29anurag_pugaliaaPas encore d'évaluation

- Abt ManualDocument39 pagesAbt ManualAbhinav Tewari100% (1)

- 3-Power Circuit Breaker69kvDocument6 pages3-Power Circuit Breaker69kvanurag_pugaliaaPas encore d'évaluation

- High Voltage Circuit Breaker PDFDocument4 pagesHigh Voltage Circuit Breaker PDFA.K.A. HajiPas encore d'évaluation

- Monthly Major HighlightsDocument1 pageMonthly Major Highlightsanurag_pugaliaaPas encore d'évaluation

- Yuzu InstallerDocument3 pagesYuzu InstallerJohnnel PrietosPas encore d'évaluation

- 2015 Grade 4 English HL Test MemoDocument5 pages2015 Grade 4 English HL Test MemorosinaPas encore d'évaluation

- Supreme Court Case Analysis-Team ProjectDocument5 pagesSupreme Court Case Analysis-Team ProjectJasmineA.RomeroPas encore d'évaluation

- July 2014Document56 pagesJuly 2014Gas, Oil & Mining Contractor MagazinePas encore d'évaluation

- Diagnostic Test Everybody Up 5, 2020Document2 pagesDiagnostic Test Everybody Up 5, 2020George Paz0% (1)

- Dr. Babasaheb Ambedkar Technological UniversityDocument3 pagesDr. Babasaheb Ambedkar Technological UniversityalfajPas encore d'évaluation

- Al-Farabi Fusul Al MadaniDocument107 pagesAl-Farabi Fusul Al MadaniDaniel G.G.100% (1)

- Unit 6B - PassiveDocument18 pagesUnit 6B - PassiveDavid EstrellaPas encore d'évaluation

- Recognition AND AmbivalenceDocument350 pagesRecognition AND AmbivalenceFrederic ValPas encore d'évaluation

- Boeing SWOT AnalysisDocument3 pagesBoeing SWOT AnalysisAlexandra ApostolPas encore d'évaluation

- Sample Paper Book StandardDocument24 pagesSample Paper Book StandardArpana GuptaPas encore d'évaluation

- Data Mining For Business Analyst AssignmentDocument9 pagesData Mining For Business Analyst AssignmentNageshwar SinghPas encore d'évaluation

- Qualification of Class Y Flip Chip Cga Package Technology For SpaceDocument8 pagesQualification of Class Y Flip Chip Cga Package Technology For SpacePepe ChorizoPas encore d'évaluation

- (Biophysical Techniques Series) Iain D. Campbell, Raymond A. Dwek-Biological Spectroscopy - Benjamin-Cummings Publishing Company (1984)Document192 pages(Biophysical Techniques Series) Iain D. Campbell, Raymond A. Dwek-Biological Spectroscopy - Benjamin-Cummings Publishing Company (1984)BrunoRamosdeLima100% (1)

- Skills Check Extra 2ADocument1 pageSkills Check Extra 2AVishmi JayawardenePas encore d'évaluation

- Communication MethodDocument30 pagesCommunication MethodMisganaw GishenPas encore d'évaluation

- NHD Process PaperDocument2 pagesNHD Process Paperapi-122116050Pas encore d'évaluation

- 3114 Entrance-Door-Sensor 10 18 18Document5 pages3114 Entrance-Door-Sensor 10 18 18Hamilton Amilcar MirandaPas encore d'évaluation

- The Evolution of Knowledge Management Systems Needs To Be ManagedDocument14 pagesThe Evolution of Knowledge Management Systems Needs To Be ManagedhenaediPas encore d'évaluation

- Digital Signatures: Homework 6Document10 pagesDigital Signatures: Homework 6leishPas encore d'évaluation

- Vietnamese Alphabet and PronounDocument10 pagesVietnamese Alphabet and Pronounhati92Pas encore d'évaluation

- Isaiah Chapter 6Document32 pagesIsaiah Chapter 6pastorbbPas encore d'évaluation

- Brochure - Actiwhite PWLS 9860.02012013Document12 pagesBrochure - Actiwhite PWLS 9860.02012013J C Torres FormalabPas encore d'évaluation

- F. Moyra Allen: A Life in Nursing, 1921-1996: Meryn Stuart, R.N., PH.DDocument9 pagesF. Moyra Allen: A Life in Nursing, 1921-1996: Meryn Stuart, R.N., PH.DRose Nirwana HandayaniPas encore d'évaluation

- Demand, Supply, and Market EquilibriumDocument15 pagesDemand, Supply, and Market EquilibriumAnonymous HBQ86kPas encore d'évaluation

- B1 Editable End-of-Year TestDocument6 pagesB1 Editable End-of-Year TestSyahira Mayadi50% (2)

- Fabric DefectsDocument30 pagesFabric Defectsaparna_ftPas encore d'évaluation

- Case Studies InterviewDocument7 pagesCase Studies Interviewxuyq_richard8867100% (2)

- Pinterest or Thinterest Social Comparison and Body Image On Social MediaDocument9 pagesPinterest or Thinterest Social Comparison and Body Image On Social MediaAgung IkhssaniPas encore d'évaluation

- 1.12 Properties of The Ism - FlexibilityDocument4 pages1.12 Properties of The Ism - FlexibilityyomnahelmyPas encore d'évaluation