Académique Documents

Professionnel Documents

Culture Documents

EN

Transféré par

reacharunk0 évaluation0% ont trouvé ce document utile (0 vote)

19 vues1 pagePortlaucl cement, the latest (about IS-tS) of all these cements, is made from limestone and clay. The heaviest, considered the best in quality, weighs 110 lbs. To 112 lbs. Per striked bushel.

Description originale:

Titre original

EN(564)

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentPortlaucl cement, the latest (about IS-tS) of all these cements, is made from limestone and clay. The heaviest, considered the best in quality, weighs 110 lbs. To 112 lbs. Per striked bushel.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

19 vues1 pageEN

Transféré par

reacharunkPortlaucl cement, the latest (about IS-tS) of all these cements, is made from limestone and clay. The heaviest, considered the best in quality, weighs 110 lbs. To 112 lbs. Per striked bushel.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

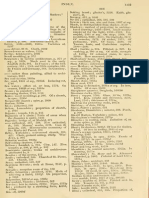

542

TIIHORY OF AKCIIITECTTTRE. Book II.

til in wliijh it absorlis more moisture. It answers well enough in dry situations. Vicat

formed a factitious Koinan cement ; but its efficacy was doubtful, though it had, for want

of a better substitute, been much employed at Paris.

,

1864. Portlaucl cement, the latest (about IS-tS) of all these cements, is made from

limestone and clay. The mud of the river Medway, corresponding to the argillo-

calcareous stone of Roman cement, is mixed with chalk and ashes from former makings,

and calcined at a heat amounting almost to that of vitrification. A larger quantity of

sand may be mixed with it than with Roman cement, to which it is> superior in colour

and hardness of setting. The heaviest, considered the best in quality, weighs 110 lbs.

to 112 lbs. per striked bushel.

18046. The distinguishing peculiarities which should render Portland cement a perraa-

ment substitute for Boman cement have been explained by a London manufacturer of both

materials {Builder, 1

863, p. 761).

It may be condensed into the statement

:

That the stone

from which Eoman cement is made, though composed of lime and the silicate of alumina,

yet the proportion of the latter preponderates t) such an extent as to prevent a perfect

amalgamation of the ingredients in burning. The result is a cement loose in its texture,

because containing inert foreign matter, which is retentive of moisture, and consequently

attackable by frost and vegetable growth. In Portland cement the case is otherwise. The

dose of lime to clay is in the ascertained correct proportion of two to one, and with this

condition there is the power thoroughly to combuie the ingredients by bui-ning, and thus

to give a density and compactness to the product which, in enabling it to resist water, frost,

and other decomposing agencies, are the elements of its durability and of its superiority

to the natural cements. Carelessness, or want of proper knowledge in its manufacture

;

an

improper mixture of the ingredients

;

an imperfect calcination

;

its bad manipulation

;

and

unfair handling when used as a cement, are all likely to result in disastrous effects on being

used. When employed as a mortar or as a concrete, it has seldom been known to fail.

1864(7. It is usual for the manufacturer to grind the cement after burning it. It i3

then placed in well-closed casks, which should not exceed 6 cvvt. each, when the cement

may be preserved for some time

;

but by contact with the atmosphere it is said to absirb

humidity and carbonic acid, and thus becomes deteriorated. It should be ground very

fine. For the sieve in sifting it, the French engineers required 185 meshes to the square

of 4 inches on a side. One-third of the volume of the cement for the quantity of water

is the best proportion, and the more that the cement is beaten up, the harder it becomes.

The best cement will harden in about five or six minutes, and under water in about an

hour; when mixed with sand it takes aklittle longer. When mixed with se.i-water, and

used in sea-water with a large quantity of sand, it may take even twenty-four hours

before setting. (See pars. 18626, c, and d.)

1864;^. The resistance to rupture of pure cement after 20 days' exposure to the air is

about 54 lbs. per inch square

;

if sand be added in the proportion of

i

to 1 of cement, it

falls to 37 lbs. ; and if it be in equal proportions, it falls to 27 lbs. The permanent load in

any large works should never be more than one-sixth of that required to produce rupture:

and if small materials be employed, only one-fifteenth should be calculated upon.

1864e. In testing Porcland cement, the Admiralty, at the Chatham Dockyard extension

works, f-pecified that samples would be taken from about one sack in ten, and gauged in

moulds, which, when set, would be placed in water and tested at the end of seven clear

days. Each must bear without breaking a weight of 650 lbs. upon the test- block of 1^ inches

square in section. In 1878 the Metropolitan Board of Works required the cement to be

of the best quality, ground so fine that it will pass through a sieve of fifty meshes to the

lineal inch. It must have a specific gravity of not less than 3'1, and weigh as delivered

114 lbs. or more to the imperial striked bushel. AVhen brought upon the works it is to

he put into dry sheds or buildings, which the contractor is to provide for the purpose,

having wooden floors and all necessary subdivisions. The cement is to be emptied out

upon this floor, every fifty bu'hel< being kept separate, and is not to be used until it has

been tested by samples taken out of every tenth sack. The samples to be gauged neat

in moulds, put into water 24 hours after the briquettes have been made, and remain till

tested, to bear without breaking a weight of 400 lbs. per square inch 7 d lys, and 600 lbs.

28 days after they have been made. The first to bo considered as preliminary, and the

second as decisive. Mr. John Grant's, C.E., specification is of a more extended character,

and includes the quality of sand. The briquettes with three of sand to bear a weight of

150 lbs. per square inch after 28 days.

1804/^. With cement at 112 lbs. per bushel, ,i cubic foot weighs 87'13 lbs., a cubic yard

2,352-6 lbs., and a ton occupies a space of

25'7 cubic feet.

1864^. With this cement, the ordinary proportions for walls may be 1 to 12 of gravel for

common, and 1 to 6 of slag and saudfor facing, concrete. A cubic yard of concrete takes

about Ig yard, or

31^

cubic f-^et, of loose gravel, exclusive of the cement, as made in a

gauge or measuring-box. One-twelfth of 31^

cubic feet, or a little more than

2|

feetcube,

goes to each sauge, and is easily calculated and prepared

;

or 218 11)S. by weight, if the

Cement weighs 112 lbs per bushel. For maki-^g good solid concrete, there should be

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Descreption of Cement TileDocument27 pagesDescreption of Cement TileAyoub L'voyPas encore d'évaluation

- BOQ For Block WorkDocument16 pagesBOQ For Block Workbaboonijj100% (1)

- Modeling The Prediction of Compressive Strength For Cement andDocument12 pagesModeling The Prediction of Compressive Strength For Cement andAnil Kumar Sharma100% (1)

- Cement Strength DevelopmentDocument6 pagesCement Strength DevelopmentMuhammadShoaib100% (1)

- Rate Analysis of Construction MaterialsDocument13 pagesRate Analysis of Construction MaterialsGino BrownPas encore d'évaluation

- English For Civil EngineersDocument41 pagesEnglish For Civil EngineersDANIEL STEVEN HERNANDEZ RODRIGUEZPas encore d'évaluation

- Report On Building Construction Summer TrainingDocument64 pagesReport On Building Construction Summer TrainingVkram Joshi100% (2)

- Prospekt BGF PDFDocument150 pagesProspekt BGF PDFreacharunkPas encore d'évaluation

- General Terms and Conditions of The Pzu NNW (Personal Accident Insurance Pzu Edukacja InsuranceDocument19 pagesGeneral Terms and Conditions of The Pzu NNW (Personal Accident Insurance Pzu Edukacja InsurancereacharunkPas encore d'évaluation

- Prospekt BGF PDFDocument150 pagesProspekt BGF PDFreacharunkPas encore d'évaluation

- Prospekt BGF PDFDocument150 pagesProspekt BGF PDFreacharunkPas encore d'évaluation

- Prospekt BGF PDFDocument150 pagesProspekt BGF PDFreacharunkPas encore d'évaluation

- Supplement To The Prospectuses and Summary Prospectuses For Investor Shares and Admiral™SharesDocument65 pagesSupplement To The Prospectuses and Summary Prospectuses For Investor Shares and Admiral™SharesreacharunkPas encore d'évaluation

- Supplement To The Prospectuses and Summary Prospectuses For Investor Shares and Admiral™SharesDocument65 pagesSupplement To The Prospectuses and Summary Prospectuses For Investor Shares and Admiral™SharesreacharunkPas encore d'évaluation

- En (1462)Document1 pageEn (1462)reacharunkPas encore d'évaluation

- NameDocument2 pagesNamereacharunkPas encore d'évaluation

- Emergency Response Quick Guide MY: 2014Document2 pagesEmergency Response Quick Guide MY: 2014reacharunkPas encore d'évaluation

- En (1463)Document1 pageEn (1463)reacharunkPas encore d'évaluation

- En (1461)Document1 pageEn (1461)reacharunkPas encore d'évaluation

- En (1464)Document1 pageEn (1464)reacharunkPas encore d'évaluation

- En (1460)Document1 pageEn (1460)reacharunkPas encore d'évaluation

- En (1459)Document1 pageEn (1459)reacharunkPas encore d'évaluation

- En (1452)Document1 pageEn (1452)reacharunkPas encore d'évaluation

- En (1457)Document1 pageEn (1457)reacharunkPas encore d'évaluation

- En (1453)Document1 pageEn (1453)reacharunkPas encore d'évaluation

- En (1458)Document1 pageEn (1458)reacharunkPas encore d'évaluation

- En (1455)Document1 pageEn (1455)reacharunkPas encore d'évaluation

- En (1456)Document1 pageEn (1456)reacharunkPas encore d'évaluation

- En (1454)Document1 pageEn (1454)reacharunkPas encore d'évaluation

- And Rome.: in Front of The Prostyle Existed atDocument1 pageAnd Rome.: in Front of The Prostyle Existed atreacharunkPas encore d'évaluation

- En (1451)Document1 pageEn (1451)reacharunkPas encore d'évaluation

- En (1450)Document1 pageEn (1450)reacharunkPas encore d'évaluation

- Mate The: (Fig. - VrouldDocument1 pageMate The: (Fig. - VrouldreacharunkPas encore d'évaluation

- En (1388)Document1 pageEn (1388)reacharunkPas encore d'évaluation

- En (1389)Document1 pageEn (1389)reacharunkPas encore d'évaluation

- En (1390)Document1 pageEn (1390)reacharunkPas encore d'évaluation

- En (1387)Document1 pageEn (1387)reacharunkPas encore d'évaluation

- Concrete: Building Technology 1: Div 03Document65 pagesConcrete: Building Technology 1: Div 03arki_37826160Pas encore d'évaluation

- PlasticDocument233 pagesPlasticaniruddhia4mPas encore d'évaluation

- Cement - Mortar: Material Testing EquipmentDocument49 pagesCement - Mortar: Material Testing EquipmentjohanPas encore d'évaluation

- Characterizing Curing-Cement Slurries by Permeability, Tensile Strength, and ShrinkageDocument6 pagesCharacterizing Curing-Cement Slurries by Permeability, Tensile Strength, and ShrinkageAry RachmanPas encore d'évaluation

- Properties of Concrete Incorporating Nano-SilicaDocument7 pagesProperties of Concrete Incorporating Nano-SilicaChan NovPas encore d'évaluation

- TRB Final MaterialDocument439 pagesTRB Final MaterialAnitha MuthukumaranPas encore d'évaluation

- Particle Packing TheoryDocument15 pagesParticle Packing Theorysrujan varma kaithojuPas encore d'évaluation

- Smeaton ProjectDocument18 pagesSmeaton ProjectNemesisRepublic@blogspot.comPas encore d'évaluation

- Mandatorystandards SlsDocument3 pagesMandatorystandards SlsBRGRPas encore d'évaluation

- The Use of Corn Cob Ash and Saw Dust Ash As Cement Replacement in Concrete WorksDocument8 pagesThe Use of Corn Cob Ash and Saw Dust Ash As Cement Replacement in Concrete WorksGener NavarroPas encore d'évaluation

- Specification Slag AggregatesDocument4 pagesSpecification Slag AggregatesAnuradhaPatraPas encore d'évaluation

- TK11 Draft Assignment1Document33 pagesTK11 Draft Assignment1Daun_ManggaPas encore d'évaluation

- 1 s2.0 S0950061819308888 MainDocument10 pages1 s2.0 S0950061819308888 MainDawit MogesPas encore d'évaluation

- Info On Paver BlocksDocument6 pagesInfo On Paver BlocksGaneshPas encore d'évaluation

- SECTION 03 30 00 Cast-In-Place ConcreteDocument36 pagesSECTION 03 30 00 Cast-In-Place ConcreteJuanPaoloYbañezPas encore d'évaluation

- Sonalac Paints and Coatings LimitedDocument8 pagesSonalac Paints and Coatings LimitedGaurav SinghPas encore d'évaluation

- Effect of Superplasticizers On Workability Retention and Initial Setting Time of Cement PastesDocument8 pagesEffect of Superplasticizers On Workability Retention and Initial Setting Time of Cement PastesShaiq Azizi100% (1)

- Martin Screw Conveyor and ElevatorDocument157 pagesMartin Screw Conveyor and ElevatorMohsen Ardestani100% (1)

- ECOFOR For Cement Mill - A Dose of Dry MedicineDocument4 pagesECOFOR For Cement Mill - A Dose of Dry MedicineAntonPas encore d'évaluation

- Magazine of Concrete ResearchDocument11 pagesMagazine of Concrete ResearchKathlene Lacosta LastimosaPas encore d'évaluation

- Planicrete NoRestrictionDocument4 pagesPlanicrete NoRestrictionFloorkitPas encore d'évaluation

- Fabrication and Properties of Redispersible Polymer Powder-Modified SystemsDocument18 pagesFabrication and Properties of Redispersible Polymer Powder-Modified SystemshPas encore d'évaluation

- Soil Stabilization With Using Waste Materials Against Freezing Thawing EffectDocument3 pagesSoil Stabilization With Using Waste Materials Against Freezing Thawing EffectArham SheikhPas encore d'évaluation