Académique Documents

Professionnel Documents

Culture Documents

Erection of Steel Structures Rev 0A

Transféré par

pigfly2012100%(1)100% ont trouvé ce document utile (1 vote)

312 vues13 pagesThe document provides engineering specifications for the erection of steel structures for Husky's Western Canada Upstream projects. It outlines requirements for codes and standards, documentation, materials, design, handling and storage, erection, inspection and testing, and clean-up. The contractor must submit erection drawings and plans for review and gain approval before starting work. Temporary bracing, supports and guys must be designed and installed to safely support the structure during erection.

Description originale:

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe document provides engineering specifications for the erection of steel structures for Husky's Western Canada Upstream projects. It outlines requirements for codes and standards, documentation, materials, design, handling and storage, erection, inspection and testing, and clean-up. The contractor must submit erection drawings and plans for review and gain approval before starting work. Temporary bracing, supports and guys must be designed and installed to safely support the structure during erection.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

312 vues13 pagesErection of Steel Structures Rev 0A

Transféré par

pigfly2012The document provides engineering specifications for the erection of steel structures for Husky's Western Canada Upstream projects. It outlines requirements for codes and standards, documentation, materials, design, handling and storage, erection, inspection and testing, and clean-up. The contractor must submit erection drawings and plans for review and gain approval before starting work. Temporary bracing, supports and guys must be designed and installed to safely support the structure during erection.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 13

ENGINEERING SPECIFICATIONS

Erection of Steel Structures

DS-CS-03

Rev Date Description Author

Checked

By

Approval

Technical

Approval

Management

0 2007/08/24 Issued for Use J G KD J G RS

0A 2011/05/17 Issued for Review D.McIntosh G. Salamanca

ENGINEERING SPECIFICATIONS

Erection of Steel Structures

DS-CS-03

Rev. 0A

Page 2 of 13

Contents

1.0 Scope 3

2.0 Codes and Standards 3

3.0 Documentation 4

4.0 Definitions 5

5.0 Materials 6

6.0 Design 6

7.0 Handling and Storage 6

8.0 Erection 7

9.0 Inspection and Testing 11

10.0 Clean-Up 12

Appendix A Revision History 13

ENGINEERING SPECIFICATIONS

Erection of Steel Structures

DS-CS-03

Rev. 0A

Page 3 of 13

1.0 Scope

1.1 This specification covers the general requirements for erection of steel structures and their components

for Huskys Western Canada Upstream Business Units projects including Tucker Lake, Rainbow

Lake, and Pikes Peak Facilities.

2.0 Codes and Standards

2.1 The erection of steel structures shall be in accordance with the latest edition of following codes,

specifications, and standards. Whenever a conflict exists between the referenced codes, standards,

specifications and other referenced documents, the more stringent shall apply unless specifically noted

in the project documents. Huskys E&PM Technical Services Mechanical/Civil Group shall be

consulted for conflict resolution.

Canadian Standards Association (CSA)

B167

Travelling Cranes Design, inspection, maintenance, and safe operation

G40.20/G40.21

General Requirements for Rolled or Welded Structural Quality Steel/Structural Quality Steel

S16

Design of steel Structures

S136

Design of Cold-formed Steel Structural Members

W47.1

Certification of Companies for Fusion Welding of Steel Structures

W48

Filler Metals and Allied Metals for Metal Arc Welding

W59

Welded Steel Construction (Metal Arc Welding)

W178.1

Certification of Welding Inspection

W178.2

Certification of Welding Inspectors

Z259.2.16

Design of active fall-protection systems

National Research Council of Canada (NRCC)

National Building Code of Canada (NBC)

Provincial Building Code where applicable

American National Standards Institute (ANSI) / American Society of Safety Engineers (ASSE)

ANSI/ASSE Z359.1

Safety Requirements for Personal Fall Systems, Subsystems and Components

ENGINEERING SPECIFICATIONS

Erection of Steel Structures

DS-CS-03

Rev. 0A

Page 4 of 13

American Society for Testing and Materials (ASTM)

A307

Standard Specification for Carbon Steel Bolts and Studs; 60,000 psi Tensile Strength

A325

Standard Specification for Structural Bolts, Steel, Heat Treated, 120/105 ksi Minimum Tensile Strength

A490

Standard Specification for Structural Bolts, Alloy Steel, Heat Treated, 150 ksi Minimum Tensile

Strength

A578/A578M

Standard Specification for Straight-Beam Ultrasonic Examination of Rolled Steel Plates for Special

Applications

A786/A786M

Standard Specification for Hot-Rolled Carbon, Low-Alloy, High Strength Low Alloy, and Alloy Steel

Floor Plates

Occupational Health and Safety

Provincial Occupational Health and Safety Act and Regulations

Canadian Institute of Steel Construction (CISC)

CISC Handbook of Steel Construction

Related Husky Specifications

DS-CS-01

Structural Engineering Design Criteria

DS-CS-02

Supply and Fabrication of Structural Steel

DS-CS-05

Grout

PS-MW-05

Paint

3.0 Documentation

3.1 Drawings shall conform to the requirements of Section 4 of CSA Standard S16-09.

3.2 At least two (2) weeks prior to the job start date; the Contractor shall submit the following to Husky for

review and approval:

Erection drawings showing all temporary bracing, supports, and guys necessary for the erection of

the structures.

Erection plans, including a detailed description of proposed erection methods, sequence, and

equipment.

3.3 Review and approval of the Contractors drawings by Huskys Engineer does not relieve the Contractor

of responsibility for completeness, accuracy, details, and conformance with codes and standards.

ENGINEERING SPECIFICATIONS

Erection of Steel Structures

DS-CS-03

Rev. 0A

Page 5 of 13

3.4 If welding is involved in the erection of steel structures, the Contractor shall submit a copy of the

following certificates or qualifications to Huskys Inspector for review and approval at least two (2)

weeks before the start of welding:

1. Canadian Welding Bureau (CWB) certification for all welders, including company, engineer(s),

and Quality Assurance (QA) personnel in accordance with CSA W47.1 Division 1 or 2.

2. Welding procedure specifications, welding procedure qualification record, and welding

consumable control procedure.

3. Canadian Welding Bureaus qualification test record(s) of the welder(s) or operator(s) as per CSA

W47.1.

4. Quality Assurance Program and inspection test.

3.5 The Contractor shall give Huskys Inspector at least seven (7) days notice before the planned start of

erection work to allow inspection of the preparation work.

3.6 Drawings shall show the extent of fireproofing required on the structure.

3.7 Where required by code or local jurisdiction, design documentation including calculations and

drawings required for construction shall be stamped and signed by a Professional Engineer registered in

the respective province where the project is being constructed.

3.8 Where connections are designed by the Contractor the shop and erection drawings shall bear the seal of

a Professional Engineer registered in the province where the project is being constructed.

3.9 The shop and erection drawings shall provide:

Details of all members and their splices and connections,

Connection design details providing information for the preparations of shop detailing and

fabrication,

The marking and position of each member, including any temporary bracing and connections

required for the erection.

4.0 Definitions

4.1 Husky means Husky Oil Operations Ltd. or its designated representatives.

4.2 Huskys Engineer means the Engineer responsible for the design of the structural steel. This could

be an EPCM consultant working on behalf of Husky.

4.3 Contractor means the entity that supplies and fabricates the structural steel including all sub-

contractors.

4.4 Huskys Inspector means the person authorized for inspection on behalf of Husky.

4.5 Huskys Representative means the person at the construction site or Contractors yard that represents

Huskys interests.

ENGINEERING SPECIFICATIONS

Erection of Steel Structures

DS-CS-03

Rev. 0A

Page 6 of 13

5.0 Materials

5.1 All materials and coating of materials to be incorporated into the permanent steel structures shall be

new stock unless noted otherwise in the project specific documentation.

5.2 Welding electrodes shall be low hydrogen electrodes meeting the requirements of CSA W48.1, Class

E49XX.

5.3 Grout for structural base plates shall be as specified on the drawings and shall conform to Huskys

Specification DS-CS-05, Grout.

5.4 Coatings for structural shall be as specified on the drawings and shall conform to Huskys

Specifications DS-CS-02, Supply and Fabrication of Structural Steel and PS-MW-05, Paint.

6.0 Design

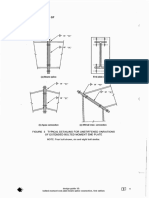

6.1 Design Requirements for Module Design, Assembly, and Transportation

6.1.1 The Contractor shall design, fabricate and supply all temporary bracing, temporary transverse

transportation beams and blocking or any other supports and guys or tie downs necessary for safe

assembly and transportation in accordance with the requirements of the National Building Code, and

Huskys Specification DS-CS-01, Structural Engineering Design Criteria.

6.2 Design Requirements for Erection

6.2.1 All temporary bracing, supports and guys shall be designed and erected by the Contractor to resist all

loads to which the structure may be subjected during erection. Such bracing, supports or guys shall be

left in place as long as required for safety.

7.0 Handling and Storage

7.1 All structural steel products shall be clearly stamped in accordance to the erections drawings and

shipping list. The markings shall remain legible until installation.

7.2 Each individual structure shall have its own number system in order that items at the project site can

clearly be identified in relation to the structure it belongs to.

7.3 All items associated with a specific structure shall, as practically as possible, be shipped together.

7.4 All materials shall be packed, crated, blocked, and transported in a manner so that no damage occurs

during loading, transportation, and unloading.

7.5 All materials will be stored on site in such a manner so that no damage or deterioration occurs due to

exposure to weather or damaging physical contact. Structural steel shall be blocked off the ground.

7.6 Coated surfaces shall not be stacked face-to-face. Non-abrasive materials shall be used to separate

sections or components.

7.7 All materials shall be handled during installation as specified on the erection drawings. Care shall be

taken so that damage due to exposure to weather or damaging physical contact does not occur.

ENGINEERING SPECIFICATIONS

Erection of Steel Structures

DS-CS-03

Rev. 0A

Page 7 of 13

7.8 In the event of damage, repairs or replacements of materials shall be made expeditiously by the

Contractor and to the approval of Husky. The repairs and replacements will be completed at the

expense of the Contractor.

8.0 Erection

8.1 Preparation for Erection

8.1.1 The Contractor shall verify the locations and elevations of the as-built foundations, anchor bolts and

other relevant items before erecting the steel structures. Husky shall be notified immediately of any

non-conformances or discrepancies.

8.1.2 The Contractor shall check the minimum grout thickness for steel structure base plates before erecting

the columns. The minimum grout thickness shall be as specified in Huskys Specification DS-CS-05,

Grout.

8.1.3 The Contractor shall provide all necessary protection to adjoining existing facilities to prevent damage

during the erection of steel structures. Adjacent painted or coated steel surfaces, including those

underneath the spots to be welded, shall be properly covered during welding to prevent damages to the

coating or paint.

8.2 General Erection

8.2.1 Erection of structural and miscellaneous steel shall conform to CSA S16.

8.2.2 The erection of steel structures shall commence only when shims and anchor rods are in a condition

that they can adequately support or resist all the loads subjected to them.

8.2.3 Provisions shall be made for all erection loads and sufficient temporary bracing to maintain the

structure in a safe, stable, and plumb manner and in true alignment until erection has been completed.

8.2.4 Each part of a structure shall be properly aligned before completing field connections. All members in

completed frames shall be true to line and free from bends, twists, and open joints.

8.2.5 Generally, all field connections shall be bolted. Field welded connections shall be made only where

specified on the design drawings.

8.2.6 Fitting-up bolts and drift pins shall not be used to bring improperly fabricated or aligned members and

parts into place thus causing a strain on bolts in finished work. Drift pins shall not be driven with such

force as to damage adjacent metal. No packing, shimming or wedging shall be permitted to correct

faulty work.

8.2.7 Holes not furnished by the structural steel fabricator but required for erection shall be field drilled. The

use of a torch may not be used to make or enlarge holes.

8.2.8 The Contractor shall not cut, drill or otherwise alter the steel structures or the work of others to

accommodate other trades or the Contractors own work, unless such cutting, drilling or alteration is

specified clearly in the project documents or approved by Huskys Engineer.

8.2.9 Minor misfitting, which can be remedied by a moderate amount of reaming and slight cutting and/or

grinding, may be permitted when approved in writing by Huskys Engineer.

ENGINEERING SPECIFICATIONS

Erection of Steel Structures

DS-CS-03

Rev. 0A

Page 8 of 13

8.2.10 All shop errors shall be reported to the Huskys Representative immediately upon discovery.

8.2.11 Fastening of splices for compression members shall be done after abutting surfaces have been brought

completely into contact. Splices shall be permitted only where indicated on the design drawings or shop

drawings.

8.2.12 Erection bolts used in welded construction shall be tightened securely and left in place, or removed

with the holes plug welded, ground smooth and coated with the same system as the adjacent steel.

8.2.13 The structure shall be plumbed in accordance with CSA S16. In addition, columns higher than 9 m

shall not exceed 1/1000 from vertical unless approved in writing by Huskys Engineer.

8.2.14 Contractor shall ensure the structure is in a safe condition prior to allowing general loading of the

structure.

8.2.15 All ragged or sharp edges as well as protruding bolts or other fasteners that might cause injury to

personnel shall be avoided. If these are unavoidable, they shall be ground smooth.

8.3 Safety Fall Arrest

8.3.1 Engineered permanent safety fall arrest systems shall be provided for pipe racks and other structures

where workers will have exposure to potential falls greater than 3 m (10 ft) or where a fall from a

height of less than 3 m involves a risk of injury greater than the risk of injury from the impact on a flat

surface.

8.3.2 Permanent anchors shall be provided for use with retractable lifelines and shall comply with all

manufacturers instructions and regulations for the safety fall arrest system.

8.3.3 The safety fall arrest system shall comply with the following standards:

CSA Z259.2.16

ANSI/ASSE Z359.1

Provincial Occupational Health and Safety Act and Regulations

8.3.4 The fall arrest anchors shall be designed for a minimum load of 22 kN per support.

8.4 Installation of Base Plates and Grouting

8.4.1 Base plates shall be set and shimmed to the correct positions and elevations, as shown on the design

drawings. The final position of each plate shall be subject to the inspection and approval of Huskys

Inspector.

8.4.2 Following erection of the first lift of steel structure and unless clause 8.4.3 applies, grout shall be

placed under all column base plates in accordance with the design drawings or other project documents.

8.4.3 Where engineered shims are provided to withstand the load of the completed structure or part thereof,

grout may be installed after the structure or part thereof has been erected.

8.4.4 Following the installation and curing of grout, anchor rods shall be brought to a snug tight condition.

8.5 Installation of Bolted Connections

ENGINEERING SPECIFICATIONS

Erection of Steel Structures

DS-CS-03

Rev. 0A

Page 9 of 13

8.5.1 When assembled, all joint surfaces, including those adjacent to the bolt heads, nuts, or washers, shall be

free of blurs, dirt, and other foreign material that would prevent solid seating of parts.

8.5.2 For joints with a large number of bolts in several rows, a sequential tightening of all bolts, working

from the middle of the bolt group outward, shall be employed.

8.5.3 All standard bolts and high strength bolts shall be installed to a snug-tight condition except in slip-

critical connections where high strength bolts tightened by turn of nut are required as per sections

8.5.4 and 8.5.5.

8.5.4 Unless otherwise specified in the project documents or drawings, all bolted joints using high strength

bolts shall be bearing-type connections. Slip critical connections shall only be used on crane supports

and locations where vibratory loading, dynamic loading, fatigue, or reversal loading occurs.

8.5.5 Methods employed to install high-strength bolts in slip critical connections shall conform to the

requirements of CSA S16 and the following:

High strength bolts shall be installed by the turn-of-nut method.

Tightening of high strength bolts by means of direct tension indicator shall not be permitted

without the prior written approval of Huskys Engineer.

For the turn-of-nut method, the outer face of the nut shall be match-marked with the bolt point

immediately after the bolts have been brought to the snug-tight condition to provide the Inspector a

visual means of verifying nut rotation after final tightening. Bolts shall be tightened beyond the

snug-tight condition by the applicable amount of relative rotation given in CSA S16.

8.5.6 When high strength bolts are used as fit-up bolts in connections and are not tightened to the specified

minimum tension, bolts may be left in place, and subsequently tightened as permanent bolts.

8.5.7 Plain (un-coated) high strength bolts that have been installed by the turn of nut method may be

loosened and re-tightened one additional time, provided that the nut can be turned freely by hand for

the full length of the threads. Coated high strength bolts that have been tightened by the turn of nut

method shall not be reused.

8.5.8 Welding on connection bolts or nuts shall not be permitted. Welding on anchor rods may be acceptable

with written approval from Huskys Engineer.

8.6 Field Welding

8.6.1 The company and the welder(s) undertaking welding shall be currently certified by the Canadian

Welding Bureau, and shall meet the requirements of CSA W47.1, Division 1 or 2.

8.6.2 All welding shall be performed using procedures approved by the Canadian Welding Bureau.

8.6.3 All welding shall be in accordance with CSA W47.1, CSA W59 and CSA S16-09.

8.6.4 All weld testing shall be in accordance with the requirements of CSA W59.

8.6.5 All ragged edges or welds that might cause injury to personnel shall be avoided, or if not avoidable,

ground smooth.

8.7 Installation of Crane Runway

ENGINEERING SPECIFICATIONS

Erection of Steel Structures

DS-CS-03

Rev. 0A

Page 10 of 13

8.7.1 Rail joints shall be tight and shall provide a smooth transfer of the crane wheel from one rail to another.

8.7.2 Erection tolerances shall be in accordance with CSA S16, and the following, or the crane vendor

tolerance if more stringent:

Crane rails shall be centered on crane girders, which shall be properly aligned before hand. In no

case shall the rail eccentricity be greater than three-fourths of the thickness of the girder web.

8.7.3 The rails for crane runways shall not be supported by structural members that may experience

differential horizontal deflection. For example, if one rail is supported on a building column and the

other rail is supported on a pipe rack the differential movement between the two supports may result in

binding of the trolley.

8.8 Installation of Floor Plates

8.8.1 All penetrations not dimensioned on drawings or not furnished by the steel Fabricator shall be field cut

and suitably banded with toe plates.

8.8.2 Field installed and removable floor plates shall be secured in place with 12 mm cadmium plated, steel

countersunk, self-tapping head bolts, at 300 mm centers.

8.8.3 Non-removable floor plates shall be welded to the supporting members with 6 mm fillet welds that are

40 mm in length at 300 mm centers.

8.8.4 All floor plates shall sit flat on supporting steel without any raised edges that could cause a tripping

hazard.

8.8.5 The Contractor shall ensure that the structure is in a safe condition prior to allowing general access to

the structure.

8.9 Installation of Floor Gratings

8.9.1 All cutouts for columns, bracing connections, and other openings in floor gratings shall be banded with

toe plates, and bars at least equivalent to the grating bars.

8.9.2 Field installed and removable floor gratings shall be secured in place with removable saddle clip

anchors fastened to supporting steel. There shall be a minimum of two (2) fasteners per section at each

support, with a minimum of four (4) anchors per grating panel.

8.9.3 The Contractor shall ensure that the structure is in a safe condition prior to allowing general access to

the structure.

8.10 Installation of Handrails

8.10.1 Installation of handrails shall be in accordance with Huskys Specification DS-CS-02, Supply and

Fabrication of Structural Steel.

8.10.2 Handrails shall be provided around all platforms, permanent floors, and openings in platforms,

walkways and stairways and shall be bolted to supporting members unless noted otherwise on the

drawings.

8.10.3 Unless noted otherwise on the drawings, the maximum spacing of handrail posts shall be 1800 mm,

except on stairs where the maximum shall be 1200 mm.

ENGINEERING SPECIFICATIONS

Erection of Steel Structures

DS-CS-03

Rev. 0A

Page 11 of 13

8.10.4 Hinged, self closing safety gates shall be located across all ladder access locations that create an

opening in the handrailing.

8.11 Installation of Ladders

8.11.1 Installation of ladders shall be in accordance with Huskys Specification DS-CS-02, Supply and

Fabrication of Structural Steel.

8.12 Field Coating

8.12.1 After completion of erection, steel surfaces where coating was omitted for field welding or field bolting

and all areas damaged subsequent to shop coating shall be prepared, cleaned and coated with the same

coating system as the original shop coat.

8.12.2 All steel surfaces designated to be galvanized shall be covered with zinc-rich coatings at least

equivalent to the shop galvanizing.

8.12.3 After cleaning and preparation, all surfaces to be field painted or coated shall be inspected by Huskys

Inspector prior to painting or coating.

8.12.4 During painting or coating, the Contractor shall protect all adjacent sections, structures, equipment and

facilities from over spray or spatter of paint.

8.12.5 The Contractor shall remove all masking or cover materials after completion of the job. A daily

cleanup of the work area shall be made to remove cartons, cans, and other discarded containers or

equipment.

8.12.6 Field coating shall meet the requirements given in Huskys Specification DS-CS-02, Supply and

Fabrication of Structural Steel and Huskys Specification PS-MW-05, Paint.

8.13 Field Fireproofing

8.13.1 After erection or assembly completion, all structural steel connections where fireproofing was omitted,

shall be prepared, cleaned and fireproofed with the same fireproofing system as the original shop

fireproofing.

8.13.2 Where the lower transverse beam of a module has been used to support the module during

transportation and the fireproofing has been blocked out at point of support at the underside of the

bottom flange of the transport beam so as not to damage the fireproofing and to allow direct bearing on

steel, these locations shall be prepared, cleaned and fireproofed with the same fireproofing system as

the original shop fireproofing.

9.0 Inspection and Testing

9.1 Huskys Inspector shall inspect the erected steel work and workmanship for conformance with the

requirements of this specification, including but not limited to, checking for alignment, plumbness,

high strength bolting, field welds, and touch-up coating if required.

9.2 The Contractor shall provide facilities including platforms, ladders, tools, and calibration for Huskys

Inspector to carry out the inspections during the work.

ENGINEERING SPECIFICATIONS

Erection of Steel Structures

DS-CS-03

Rev. 0A

Page 12 of 13

9.3 The Contractor shall rectify all deficiencies using Husky approved methods and materials, at no

additional cost to the Husky.

9.4 All weld testing shall be in accordance with standards listed in Section 6.2 of Huskys Specification,

DS-CS-02, Supply and Fabrication of Structural Steel, and Section 3.4 of this specification.

10.0 Clean-Up

10.1 At the completion of Work, the Contractor shall remove from site all tools, equipment, surplus

materials and debris resulting from the Contractors operations and shall leave the site in a clean and

acceptable condition.

ENGINEERING SPECIFICATIONS

Erection of Steel Structures

DS-CS-03

Rev. 0A

Page 13 of 13

Appendix A Revision History

Rev Date Description Author Checked

By

Approval

Technical

Approval

Management

0 2007/08/24 Issued for Use J G KD J G RS

0A 2011/05/17 Issued for Review with the following

revisions:

Format revised to meet new

standard.

References revised for accuracy

and completeness.

Documentation Section revised to

include more complete welding

and documentation requirements.

Fall arrest code references

updated in Section 8.

Field welding requirements

updated.

D. McIntosh G. Salamanca

Vous aimerez peut-être aussi

- Structural Steel Erection Method Statement .Document6 pagesStructural Steel Erection Method Statement .Mohamed Elarabi0% (1)

- Codes Standards For Structural Steel Fabrication ErectionDocument7 pagesCodes Standards For Structural Steel Fabrication Erectionelangorenga67% (3)

- Steel Detailing Practices in The Philippines - GuerreroDocument11 pagesSteel Detailing Practices in The Philippines - GuerreroRichard Fallega100% (1)

- Steel Structure ErectionDocument33 pagesSteel Structure ErectionAhmed ImranPas encore d'évaluation

- Method Statement of Steel FabricationDocument14 pagesMethod Statement of Steel FabricationKhyle Laurenz Duro100% (4)

- 24.1.2 Steel Erection PlanDocument5 pages24.1.2 Steel Erection PlanEdgelle EjercitoPas encore d'évaluation

- Erection Method For Pre Engineered Steel StructureDocument17 pagesErection Method For Pre Engineered Steel StructureKvn Kvt100% (1)

- Peb Steel Structures Tolerance Table As Per Aisc: Builtup/ Hotroll BeamsDocument2 pagesPeb Steel Structures Tolerance Table As Per Aisc: Builtup/ Hotroll BeamsSamsuPas encore d'évaluation

- Anchor Bolt MSDocument7 pagesAnchor Bolt MSGaneshPas encore d'évaluation

- Annexure-5-Technical Specification For Structural Steel WorksDocument20 pagesAnnexure-5-Technical Specification For Structural Steel WorksGarapati Bala KrishnaPas encore d'évaluation

- Qcs 2010 Part 8.06 Metal WorksDocument10 pagesQcs 2010 Part 8.06 Metal WorksRotsapNayrbPas encore d'évaluation

- v4 Structural Steelwork Fabrication and Erection Ts 2Document21 pagesv4 Structural Steelwork Fabrication and Erection Ts 2Farid RezaeianPas encore d'évaluation

- Is Standard ListDocument5 pagesIs Standard ListbalramkinagePas encore d'évaluation

- Kirby Erection ManualDocument42 pagesKirby Erection ManualAburvaraj100% (1)

- Steel Erection 1Document154 pagesSteel Erection 1Ranjit KumarPas encore d'évaluation

- Steel Erection 6512Document63 pagesSteel Erection 6512brenstagPas encore d'évaluation

- Structural Steel PTD ModuleDocument91 pagesStructural Steel PTD ModulefaridPas encore d'évaluation

- Team Leader - Senior Checker For Structural Steel Detailing - Delhi - Delhi - Simsona Technology Pvt. Ltd. - 3 To 6 Years of Experience PDFDocument3 pagesTeam Leader - Senior Checker For Structural Steel Detailing - Delhi - Delhi - Simsona Technology Pvt. Ltd. - 3 To 6 Years of Experience PDFDeepankar ChoudhuryPas encore d'évaluation

- Introduction To The New Subpart R: Prepared by The U.S. Department of Labor, OSHADocument45 pagesIntroduction To The New Subpart R: Prepared by The U.S. Department of Labor, OSHAVirgilio Calizo Sr.Pas encore d'évaluation

- Structural Steel ErectionDocument8 pagesStructural Steel Erectionbratishkaity100% (1)

- G05.4 - Civil WorksDocument107 pagesG05.4 - Civil WorksLandon Mitchell100% (1)

- Section 05120 Structural Steel Part 1Document43 pagesSection 05120 Structural Steel Part 1jacksondcplPas encore d'évaluation

- Steel ErectDocument63 pagesSteel ErectEssam Abdelmonem Mohamed Pmp100% (1)

- Shop Fabrication of Structural SteelDocument12 pagesShop Fabrication of Structural SteelAris WicaksonoPas encore d'évaluation

- Structural SteelDocument30 pagesStructural Steelnandi_scr100% (1)

- Steel Fabrication Method StatementDocument13 pagesSteel Fabrication Method StatementAfiq JamalPas encore d'évaluation

- Steel Structure SpecsDocument61 pagesSteel Structure SpecstOMPas encore d'évaluation

- Interview Questions For Structural EngineersDocument8 pagesInterview Questions For Structural EngineersPml PrasadPas encore d'évaluation

- Structural Steel Design ChecklistDocument2 pagesStructural Steel Design Checklistmassive85100% (3)

- Guidelines On Fabrication of Steel Structure ofDocument3 pagesGuidelines On Fabrication of Steel Structure ofsamirbendre1Pas encore d'évaluation

- Fabrication of Structural Steel WorkDocument16 pagesFabrication of Structural Steel WorkyogeswaranPas encore d'évaluation

- Structural Steel: Steel Shape Profile Cross Section Chemical Composition Standards I-Beams Second Moments of AreaDocument10 pagesStructural Steel: Steel Shape Profile Cross Section Chemical Composition Standards I-Beams Second Moments of AreaAnonymous nABFA4lPas encore d'évaluation

- Method Statement For PRE-ENGINEERED BUILDING ASSEMBLYDocument39 pagesMethod Statement For PRE-ENGINEERED BUILDING ASSEMBLYStephanie EmersonPas encore d'évaluation

- Erection of Steel Structures PDFDocument76 pagesErection of Steel Structures PDFUmar MohammadPas encore d'évaluation

- Basic Rules For Steel ErectionDocument71 pagesBasic Rules For Steel Erectionfoller2Pas encore d'évaluation

- Method Statement For Fabrication Works Structural SteelDocument13 pagesMethod Statement For Fabrication Works Structural SteelRohit SharmaPas encore d'évaluation

- Steel Erection MethodologyDocument26 pagesSteel Erection MethodologyLiniel de JesusPas encore d'évaluation

- Specification For Supply and Fabrication of Steel Structure-Gas de FranceDocument18 pagesSpecification For Supply and Fabrication of Steel Structure-Gas de Francehappale2002Pas encore d'évaluation

- Techinical Specifications Welcome To NescoDocument54 pagesTechinical Specifications Welcome To NescotejzabPas encore d'évaluation

- STEEL Structures in GeneralDocument11 pagesSTEEL Structures in GeneralsbunPas encore d'évaluation

- Pre-Engineered Steel BuildingsDocument40 pagesPre-Engineered Steel BuildingsThilan SenarathnePas encore d'évaluation

- Structural Steel PresentationDocument91 pagesStructural Steel PresentationP SHANKAR BABU75% (4)

- Technical Submittal BunaDocument17 pagesTechnical Submittal Bunazaid khanPas encore d'évaluation

- Fabrication Division QMDDocument11 pagesFabrication Division QMDRakesh RanjanPas encore d'évaluation

- Nelson Stud Welding - CJL Reduced Base StudsDocument1 pageNelson Stud Welding - CJL Reduced Base StudsStefan IonitaPas encore d'évaluation

- Steel Stairs, Ladders and Platforms - MSTDocument13 pagesSteel Stairs, Ladders and Platforms - MSTwafikmh4Pas encore d'évaluation

- ZS PEB Maintenance ManualDocument4 pagesZS PEB Maintenance Manualakarsh ePas encore d'évaluation

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Anonymous 0x2pwMCWgjPas encore d'évaluation

- ERECTION METHOD STATEMENT Rev01 ERECTIONDocument32 pagesERECTION METHOD STATEMENT Rev01 ERECTIONMohamedPas encore d'évaluation

- Engineering Encyclopedia: Structural Steel Codes and StandardsDocument27 pagesEngineering Encyclopedia: Structural Steel Codes and Standardsbth8320100% (1)

- Steel Erection Checklist: DrawingsDocument2 pagesSteel Erection Checklist: DrawingsALPHYL BALASABASPas encore d'évaluation

- Transmission Tower RCFoundation ACI318 14Document19 pagesTransmission Tower RCFoundation ACI318 14mirfanjpcgmailcomPas encore d'évaluation

- 01 Procedure For Structural SteelDocument9 pages01 Procedure For Structural Steelpunitg_2Pas encore d'évaluation

- Steel Erection Safety Program One ManualDocument82 pagesSteel Erection Safety Program One ManualHardeep SinghPas encore d'évaluation

- DS-CS-08 - Steel Buildings Rev 0Document12 pagesDS-CS-08 - Steel Buildings Rev 0pigfly2012Pas encore d'évaluation

- Welding of Structural Steel: The Following Was Submitted by Member Phil Nolan of Structureall LTDDocument3 pagesWelding of Structural Steel: The Following Was Submitted by Member Phil Nolan of Structureall LTDaxl_calin82Pas encore d'évaluation

- 02 SpecificationsDocument194 pages02 SpecificationsNabeel Adeeb Alshare100% (1)

- TS2 - Structural Steelwork Fabrication and ErectionDocument16 pagesTS2 - Structural Steelwork Fabrication and ErectionmojgfdPas encore d'évaluation

- 05 12 00 Structural Steel FramingDocument15 pages05 12 00 Structural Steel FramingAbdul RafiquePas encore d'évaluation

- Part 1 GeneralDocument6 pagesPart 1 GeneralCamilo Eduardo Celis MeloPas encore d'évaluation

- Protopren 103 SprayDocument1 pageProtopren 103 SprayNovingroupPas encore d'évaluation

- Case Study Shanghai TowersDocument1 pageCase Study Shanghai TowersShinde ShubhamPas encore d'évaluation

- HE7200A-BB2327 Structural Install DiagramDocument2 pagesHE7200A-BB2327 Structural Install DiagramHozyaPas encore d'évaluation

- MTC's ARAMCODocument17 pagesMTC's ARAMCOMotahar NajiPas encore d'évaluation

- LED Street Light - Luminhome Lighting LH-T1A SeriesDocument8 pagesLED Street Light - Luminhome Lighting LH-T1A SeriesLuminhomeLightingPas encore d'évaluation

- Cmci Cmci: Epoxy Grout System For Equipment BasesDocument2 pagesCmci Cmci: Epoxy Grout System For Equipment Basespravi3434Pas encore d'évaluation

- Lec2 CIVE1144 2013Document36 pagesLec2 CIVE1144 2013Joe TangPas encore d'évaluation

- Second Floor Beams Top Tie BeamsDocument1 pageSecond Floor Beams Top Tie Beamsሳምሶን ወርቁPas encore d'évaluation

- Dinding Penahan TanahDocument36 pagesDinding Penahan TanahMifthah Reino AnantaPas encore d'évaluation

- Operating, Installation & Maintenance Manual FOR Series 210 MK - Ii Sample ProbeDocument44 pagesOperating, Installation & Maintenance Manual FOR Series 210 MK - Ii Sample ProbeSenterver Equipos IndustrialesPas encore d'évaluation

- Sesión 3 - Metso Outotec Filtros PFDocument82 pagesSesión 3 - Metso Outotec Filtros PFEyner GonzalesPas encore d'évaluation

- Compression of Granular Materials: Gholamreza Mesri and Barames VardhanabhutiDocument24 pagesCompression of Granular Materials: Gholamreza Mesri and Barames VardhanabhutiRat Jaga CivilPas encore d'évaluation

- Form WorksDocument13 pagesForm Worksmaryeonee12Pas encore d'évaluation

- p400 BoltedDocument24 pagesp400 BoltedCIMARTEC TECNICOSPas encore d'évaluation

- Plasco Overview by Plasco LTD - Mwanza PresentationsDocument28 pagesPlasco Overview by Plasco LTD - Mwanza PresentationsSaravanan100% (1)

- L RFD Bridge Design ManualDocument969 pagesL RFD Bridge Design ManualNguyễn Văn CôngPas encore d'évaluation

- A Study On Causes of Accident and Prevention inDocument10 pagesA Study On Causes of Accident and Prevention inYOLO crapperPas encore d'évaluation

- Shear Key Grout ComparisonDocument3 pagesShear Key Grout ComparisonsulingPas encore d'évaluation

- 006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapDocument20 pages006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapEko Budi HartantoPas encore d'évaluation

- Module 7 (Maintenance Practices) Sub Module 7.15 (Welding, Brazing, Soldering and Bonding) PDFDocument14 pagesModule 7 (Maintenance Practices) Sub Module 7.15 (Welding, Brazing, Soldering and Bonding) PDFAamir JavaidPas encore d'évaluation

- Slope Deflection Assignment - 2023Document2 pagesSlope Deflection Assignment - 2023Andrew ChikuselaPas encore d'évaluation

- 2022 Quoted Jobs NO. Company AmountDocument6 pages2022 Quoted Jobs NO. Company AmountRichard KankamPas encore d'évaluation

- Optimization of Piping Layout With Respect To Pressure and Temperature Using Caeser-IiDocument6 pagesOptimization of Piping Layout With Respect To Pressure and Temperature Using Caeser-IichabibPas encore d'évaluation

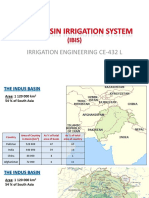

- Irrigation Engineering Ce-432 LDocument18 pagesIrrigation Engineering Ce-432 LAhmed FiazPas encore d'évaluation

- Bending Stress CalculationsDocument4 pagesBending Stress Calculationsschaali100% (5)

- A Brief Presentation On Shoe-Sole MakingDocument15 pagesA Brief Presentation On Shoe-Sole MakingTahmidPas encore d'évaluation

- Tabelat Thermal Comfort IndexDocument17 pagesTabelat Thermal Comfort IndexoutmatchPas encore d'évaluation

- Trusses ExamplesDocument13 pagesTrusses ExamplesShaikh Yaseen MehmoodPas encore d'évaluation

- Geotechnical Interpretative Report - 29+959Document17 pagesGeotechnical Interpretative Report - 29+959Navarun VashisthPas encore d'évaluation

- Design of A Landfill Final Cover SystemDocument9 pagesDesign of A Landfill Final Cover SystemWagner TeixeiraPas encore d'évaluation