Académique Documents

Professionnel Documents

Culture Documents

Anechoic Chambers A Fundamental Design and Specification Guide

Transféré par

eibygvTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Anechoic Chambers A Fundamental Design and Specification Guide

Transféré par

eibygvDroits d'auteur :

Formats disponibles

LLEUTHOMAGNLTIU

ANEUHOIUUHAMUEHU

IEEE Press

445 Hoes Lane, PO. Box 1331

Piscataway, NJ 08855-1331

IEEE Press Editorial Board

Stamatios V Kartalopoulos, Editor in Chief

M. Akay

!. B. Anderson

R. J. Baker

J. E. Brewer

M. Eden

M. E. El-Hawary

R. !. Herrick

R. Hoyt

D. Kirk

M. S. Newman

M. Padgett

W D. Reeve

. Zobrist

Kenneth Moore, Director of IEEE Press

Catherine Faduska, Senior Acquisitions Editor

Christina Kuhnen, Associate Acquisitions Editor

IEEE Electromagnetic Compatibil ity Society, Sponsor

EMC-S Liaison to IEEE Press, Mark Montrose

IEEE Antennas and Propagation Society, Sponsor

AP-S Liaison to IEEE Press, Robert J. Mailloux

Technical Reviewers

Mark Montrose, Santa Cl ara, CA

Stephen A. Sebo, Helsinki University ofTechnology

Hugh Denny, Decatur, GA

Livic Poles, Hanscom AFB, MA

00KS0Related Interest from IEEE Press

ENGINEERING ELECTROMATC COMPATBILITY SECOND EDIT ON

Prasad Kodali

2001 Hardcover 476 pp I SBN 0-780-34743-9

TME-HARONIC ELECTROMAGNETIC FELDS

Roger F Harrington

2001 Hardcover 496 pp I SBN 0-471-29806-X

FRONTIERS IN ELECTROMAGNETCS

Douglas H. Werner and Raj Mittra

1999 Hardcover 819 pp I SBN 0-780-34701-3

ELECTROMAGNETIC DSCHARGE AND ELECTRONIC EQUPMENT

Warren Boxleitner

1999 Paperback 128 pp ISBN 0-780-35388-9

LLLCTHOMAUNLTlC

ANLUHOlUUHAMULH

P UROBRBRBl BS@R

BDO Q0CCBIOD UO0

LELAND H. HEMMlNO

IEEE Electromagnetic Compatibility Society, oOn8Ot

IEEE Antennas and Propagation Society, bOn8Ot

I

|LLL Pr888

it

iutctuct

^ JOHN WILEY & SONS, INC., PUBLICATION

This text is printed on acid-free paper. Q

Copyright O 2002 by the Institute of Electrical and Electronics Engineers, Inc. All rights reserved.

Published simultaneously in Canada.

No part of this publication may be reproduced, stored in a retrieval system or transmitted in any

for or by any means, electronic, mechanical, photocopying, recording, scanning or otherise,

except as permitted under Section 107 or 108 of the 1976 United States Copyright Act, without

either the prior written perission of the Publisher, or authorization through payment of the

appropriate per-copy fee to the Copyright Clearance Center, 222 Rosewood Drive, Danvers, MA

01923, (978) 750-8400, fax (978) 750-4744. Requests to the Publisher for perission should be

addressed to the Permissions Deparment, John Wiley &Sons, Inc., 605 Third Avenue, New York,

NY10158-0012, (212) 850-6011, fax (212) 850-6008, E-Mail: PERMREQ@WILEY.COM.

For ordering and customer serice, caUI-800-CALL-WILEY

L6rcafCangressCctc/agngnPa6//cctan0ctcscvc//c6/e.

ISBN 0-471-20810-8

10 9 8 1 6 5 4 3 2 |

CONTENTS

Foreword

Preface

1 I ntroducti on

1 . 1 The Text Organization

References 2

2 Measurement Pri nci ples Perai ning to Anechoi c

Chamber Desi gn

2.1 Introduction 3

2.2 Measurement of Electromagnetic Fields 4

2. 2. 1 Introduction 4

2. 2. 2 Antennas 4

2. 2. 3 Radiated Emissions 7

2. 2. 4 Radiated Susceptibi lity 7

2. 2. 5 Military Electromagnetic Compatibilit

2. 2. 6 Antenna System Isolation

2. 2.7 Radar Cross Section 8

2. 3 Free-Space Test Requirements 8

2.3. 1 I ntroduction 8

2. 3. 2 Phase 9

2. 3. 3 Amplitde 1 1

2. 3.4 Polarization 1 2

8

8

xi i i

xv

1

3

V

V CONTENTS

2. 3. 5 The Fri is Transmission Formula 1 2

2. 4 Supporting Measurement Concepts 1 3

2. 4. 1 Introduction 1 3

2. 4. 2 Coordinate Systems and Device Positioners 1 3

2. 4. 3 Decibels 1 4

2. 4. 4 Efects of Refected Energy 1 5

2. 4. 5 Efects of Antenna Coupling 1 7

2. 5 Outdoor Measurement Facil ities 1 9

2. 5. 1 Introduction 1 9

2. 5. 2 Electromagnetic Design Considerations and Criteria 1 9

2. 5. 3 Elevated Outdoor Antenna Range 20

2. 5. 4 Ground Refection Antenna Range 2 1

2. 5. 5 Open-Area Test Sites (OATS) 23

References 24

3 El ectromagnetic Absorbi ng Materi al s

3 . 1 Introduction 27

3. 2 Microwave Absorbing Materials 28

3 . 2. 1 Pyramidal Absorber 28

3 . 2. 2 Wedge Absorber 35

3. 2. 3 Convoluted Microwave Absorber 35

3 . 2. 4 Multilayer Dielectric Absorber 37

3 . 2. 5 Hybrid Dielectric Absorber J

3. 2. 6 Walkway Absorber 39

3. 3 Low-Frequency Absorbing Material 40

3. 3. 1 Introduction 4 1

3. 3. 2 Ferrite Absorbers 4 1

3. 3. 3 Hybrid Absorbers 44

3 . 4 Absorber Modeling 44

3. 5 Absorber Testing 46

References 47

4 The Chamber Enclosure

4. 1 Introduction 49

4. 2 Electromagnetic Interference 50

4. 3 Control l ing the Environment 50

4. 4 Electromagnetic Shielding 50

4. 4. 1 Introduction 50

27

49

4. 4. 2 The Welded Shield 5 1

4. 4. 3 The Clamped Seam or Prefabricated Shield 5 1

4. 4. 4 The Single-Shield Systems 54

4. 5 Penetrations 54

4. 6 Performance Verification 54

4. 7 Shielded Enclosure Grounding 54

4. 8 Fire Protection 55

References 56

5 Anechoi c Chamber Design Techni ques

5 . 1 Introduction 57

5. 2 Practical Design Procedures 57

5 . 2. 1 Introduction 57

5. 2. 2 Quick Esti mate of Chamber Performance 58

5. 2. 3 Detai led Ray-Tracing Design Procedure 6 1

5. 3 Computer Modeling 67

5. 3. 1 Introduction 67

5. 3. 2 Ray Tracing 67

5. 3. 3 Finite-Diference Time-Domain Model 68

5 . 4 Other Techniques 69

5. 5 Antennas Used I n Anechoic Chambers 69

5. 5. 1 Introduction 69

5. 5. 2 Rectangular Chamber Antennas 70

5. 5. 3 Antenas for Tapered Chambers 70

5. 5. 4 EMI Chambers 7 1

References 7 1

b The Rectangul ar Chamber

6. 1 Introduction 73

6. 2 Antenna Testing 73

6. 2. 1 Introduction 73

6. 2. 2 Design Considerations 74

6. 2. 3 Design Exampl e 75

6. 2. 4 Acceptance Test Procedures

6. 3 Radar Cross-Section Testing 8 1

6. 3. 1 Design Considerations 8 1

6. 3. 2 Design Example 84

6. 3. 3 Acceptance Test Procedures

79

85

CONTENTS Vl

57

73

V CONTENTS

6. 4 Near-Field Testi ng 85

6. 4. 1 Introduction 85

6. 4. 2 Chamber Design Considerations 87

6. 4. 3 Design Example 88

6. 4. 4 Acceptance Test Procedure 89

6. 5 Electromagnetic Compatibil ity Testing 89

6. 5 . 1 Introduction 89

6. 5. 2 Chamber Design Considerations 90

6. 5. 3 Design Examples 90

6. 5. 4 Acceptance Test Procedures 92

6. 6 Immunity Testing 92

6. 6. 1 Introduction 92

6. 6. 2 Mode-Stirred Test Facility 92

6. 7 EM System Compatibil ity Testing 94

6. 7. 1 Design Considerations 94

6. 7. 2 Acceptance Testing 94

References 95

7 The Compact Range Chamber

7. 1 Introduction 97

7. 2 Antenna Testing 98

7. 2. 1 Prime Focus Compact Range 98

7. 2. 2 Dual Refector Compact Range 99

7. 2. 3 Shaped Refector Compact Range 1 01

7. 2. 4 Compact Antenna Range Absorber Layout 1 04

7. 2. 5 Acceptance Testing of the Compact Antenna

Anechoic Chamber 1 05

7. 3 Compact RCS Ranges 1 06

7. 3. 1 Introduction 1 06

7. 3. 2 Design Example 1 06

7. 3. 3 Acceptance Testing 1 08

References 1 08

97

8 I ncorporati ng Geometr in Anechoic Chamber Desi gn 109

8. 1 Introduction 1 09

8. 2 The Tapered Chamber 1 09

8.2. 1 Introduction 1 09

8. 2. 2 Antenna Testing III

8. 2. 3 Radar Cross-Section Measurements 1 23

8. 3 The Double Hom Chamber 1 23

8. 3 . 1 Introduction 1 23

8. 3. 2 Antenna Testing 1 23

8. 3. 3 Emissions and Immunit Testing 126

8. 4 The Missile Hardware-in-the-Loop Chamber 128

8. 4. 1 Introduction 1 28

8. 4. 2 Design Considerations 1 28

8. 4. 3 Design Example 1 29

8. 4. 4 Acceptance Test Procedures 1 30

8. 5 Consolidated Facilities 1 3 1

8. 5 . 1 Introduction 1 3 1

8. 5. 2 Design Considerations 1 3 1

8. 5. 3 Design Examples 133

8. 5. 4 Acceptance Test Procedures 1 33

8. 6 The TEM Cell 1 33

8. 6. 1 Introduction 1 33

8. 6. 2 TEM Principles of Operation 1 34

8. 6. 3 Typical Performance 1 34

References 1 36

9 Test Procedures

9. 1 Introduction 1 37

9. 2 Absorber Testing 1 37

9. 2. 1 Introduction 1 37

v.2.2 Testing of Microwave Absorber 1 38

9. 2. 3 Low-Frequency Testing 1 38

9. 2. 4 Compact Range Refector Testing 1 39

9. 2. 5 Fire-Retardant Testing 1 40

9. 3 Microwave Anechoic Chamber Test Procedures 1 42

9. 3 . 1 Introduction 1 42

9. 3. 2 Free-Space VSWR Method 142

9. 3. 3 Patter Comparison Method 1 48

9. 3. 4 7-Y Scanner Method 1 49

9. 3. 5 RCS Chamber Evaluation 1 53

9. 4 EMC Chamber Acceptance Test Procedures 1 53

9. 4. 1 Introduction 1 53

9. 4. 2 Volumetric Site Attenuation 153

CONTENTS X

1 37

X CONTENTS

9. 4. 3 Field Uniformity 1 56

9. 5 Shielding Efectiveness 1 58

References 1 58

1 0 Exampl es of I ndoor Electromagnetic Test Faci l ities 1 59

1 0. 1 Introduction 1 59

1 0. 2 Antenna Testing 1 59

1 0. 2. 1 Introduction 1 59

1 0. 2. 2 Rectangular Test Chamber 1 60

1 0. 2. 3 Tapered Anechoic Chamber 1 6 1

1 0. 2. 4 Compact Range Test Chamber 1 62

1 0. 2. 5 Near-Field Test Chamber 1 64

1 0. 3 Radar Cross-Section Testing 1 64

1 0. 3 . 1 Introduction 1 64

1 0. 3. 2 Compact Range Radar Cross-Section Faci l ities 1 65

1 0. 4 EMC Test Chambers 1 69

1 0. 4. 1 Introduction 1 69

1 0. 4. 2 Emission Test Chambers 1 70

1 0. 5 Electromagnetic System Compatibil ity Testing 1 74

1 0. 5 . 1 Introduction 1 74

1 0. 5. 2 Aircraft Systems 1 75

1 0. 5. 3 Spacecraf Test Faci l ities 1 77

References 1 79

Appendi x A Procedure for Determi ni ng the Area of

Specul ar Absorber Treatment

A. l I ntroduction 1 8 1

A. 2 Fresnel Zone Analysis 1 8 1

Appendix B Test Regi on Amplitude Taper

B. l Introduction 1 85

B. 2 Antenna Data 1 87

Appendi x C Design/Specification Checkl i sts

C. l Introduction 1 89

C. 2 The Rectangular Chamber 1 90

C. 2. 1 Introduction 1 90

C. 2. 2 Antenna Testing 1 90

1 81

1 85

1 89

CONTENTS Xl

Gl ossar

C. 2. 3 RCS Testing 1 92

C. 2. 4 Near-Field Testing 1 92

C. 2. 5 EMI Testing 1 93

C. 2. 6 Isolation Testing 1 94

C. 2. 7 Impedance Testing 1 94

C.3 Compact Range 1 95

C. 3. 1 Introduction 1 95

C. 3. 2 AntennaiRadome Testing 1 95

C. 3. 3 RCS Testing 1 95

C. 4 Shaped Chambers 1 95

C. 4. 1 Introduction 1 95

C. 4. 2 Tapered Chamber 1 96

C. 4. 3 Double Hom Chamber 1 96

C. 4. 4 Hardware-in-the-Loop Testing 1 97

C. 5 Shielding Design Checklist 1 98

C. 5. 1 Introduction 1 98

C. 5. 2 Checklist for Prefabricated Shielding 1 98

C. 5. 3 Checklist for Welded Enclosures 1 99

C. 5. 4 Checkl ist for Architectural Shielding 200

C. 5. 5 Conventional Construction 201

C. 5. 6 Fire Protection 202

References 202

Selected Bibliography

I ndex

About the Author

203

209

21 3

21 9

FOREWORD

At last, a handbook for electromagnetic anechoic chambers! A single source for

fndamentals, design, speci fication, and testing of anechoic chambers written by

one of the leading experts in anechoic chamber design and practice. Leland Hem

ming has brought together many disparate references to fill a void in the art of

electromagnetic measurement: the anechoic chamber.

This handbook presents all major tyes of anechoic chambers including: rec

tangular, tapered, and double hom. It includes all maj or measurement techniques

such as far-field, compact, and near-field testing. It also addresses all maj or types

of measurements, including: antenna, radar cross section, electromagnetic com

patibility, radiated susceptibility, and radiated emissions.

A key component of electromagnetic anechoic chambers is the materal used to

cover all interor surface of the chamber. The design of a chamber hinges on the

proper selection and placement of the absorber on the various surfaces of the

chamber, including the back wal l , the side-wall specular zones, the foor, and cor

ners of the chamber. The handbook includes in-depth discussion of the types of

absorber, the shapes of absorber, their refectivit properties, and the measure

ment techniques used to test the absorber.

Overlooked i ssues such as lighting, ventilation, f ire protection, high power

testing, and electromagnetic shielding are important in the final design and speci

fication of an anechoic chamber. This handbook supplies thi s information as well.

This handbook also includes the important topics of chamber test procedures

and acceptance testing. The testing techniques presented include: absorber test

ing, free space NbWK, patter comparison, 7-X scanner, and KLb evaluation.

The basis for each technique and the procedure to carry out each technique is pre

sented. I have found that without periodic testing and documentation, and subse

quent refrbishment, chamber performance can degrade significantly.

X

XV FOREWORD

I have become acutely aware of the scarci ty of i nformation regarding the de

sign, proper use, performance measurement and specification for anechoic cham

bers, in my teaching and research on antenna, radome and radar cross section

measurement techniques over the last 35 years. This is especially true for the new

er measurement techniques such as compact and near-field measurements per

formed in an anechoic chamber. It is with great pleasure that there is now an au

thoritatively written handbook that can supply the needed information for this

important part of electromagnetic measurement.

Hemming has chosen to include only the well-established time-tested tech

niques and information. I recommend this handbook to all students and practi

tioners of electromagnetic measurement.

LUwARU B. JOY

Pro/essorEmeritus

6eorgia|nstituteo/Iechnology

PREFACE

I first became involved in the design and/or procurement of anechoic chambers in

1 972 when I was responsible for procuring a dual-mode anechoic test facility. The

facility was designed to house a compact range for apertures up to 1 . 5 m and a

low-frequency tapered chamber that could operate down to 200 MHz. The physi

cal arrangement that we developed uti lized a common antenna test positioner lo

cated in the test region of the tapered chamber. The back wal l of the tapered

chamber was designed to open up and reveal the compact range refector. Si nce

that time, I have col lected materi al on anechoic materials and chambers. Subse

quently, I became chief designer for two diferent anechoic chamber manufactur

ers over a l O-year period. In 1 985, I returned to my primary career activity as an

antenna engineer. However, I have kept in touch with the anechoic chamber field

by working as a part-time consultant and have kept my fi les current on the tech

nology. This book is based on that experience.

The need for indoor testing of electromagnetic radiating devices, which began

in the early 1 950s [see Chapter 1 , Ref. 1 ] , has led to a number of companies pro

viding chambers and absorber products supporting a range of electromagnetic

testing requirements. The testing requirements range from hand-held telephone

antennas to whole vehicle testing of automobi les or aircraf. In recent years, the

prol i feration of portable electronic devices has led to the potential for extensive

electromagnetic interference beteen various products. Because of this potential

interference, various government agencies throughout the world have had to set

up emission and immunity test requirements. This has led to the extensive use of

indoor electromagnetic test faci l ities [see Chapter 2, Ref 2] . These facil ities, in

cluding the more conventional chambers used for testing of intentional radiators,

such as antennas, continue to add to the number of anechoic test chambers world-

XV

XV PREFACE

wide. In the aerospace industry, it i s common to test missiles, aircraf, or simi lar

weapons platforms for their radar cross-section in an attempt to reduce detectabil

ity by means of radar. All of these various testing requirements have led to a series

of specialized test faci l ities to accomplish the required testing. This book reviews

the current state of the art in indoor electromagnetic testing faci l ities and their de

sign and specification.

A glossary relating to electromagnetic measurements and anechoic chambers

is included at the back of the book, so that the reader will be able to fol low the ter

minology used in conj unction with a particular anechoic chamber design.

The purpose of this handbook i s to provide the designer/procurer of electro

magnetic chambers with a single source of practical information on the fll range

of anechoic chamber designs. Included are chapters on a large variety of anechoic

chambers used for a broad range of electromagnetic measurements that are com

monly conducted in indoor test faci l ities. Suficient information i s given on mea

surement theory to support the chamber design procedures provided in each of

the speci fic chamber designs. Test facilities for the measurement of antennas,

scattering (ReS, ) and electromagnetic compatibility are detailed for a variety of

anechoic chamber configurations. An extensive set of photographs i s provided

and demonstrates the broad range of anechoic test facil ities that have been built to

measure various types of equipment. A special color section is provided which

highl i ghts some of the more interesting anechoic test faci l ities that have been

built to solve various measurement problems. Final ly, designprocurement check

l i sts are provided for each of the various chamber configurations.

I am solely responsible for the technical information included in thi s hand

book. This information was solicited from the many suppliers who responded to

my request for detailed data on their absorber products and for pictures of their

anechoic chamber instal lations.

ACKNOWLEDGMENTS

I thank my wi fe, Valda, for her unending suppor during the three years it took to

complete this project. I am especially thankfl for the help provided by Donald J.

Martin, a co-worker at Boeing-Mesa, who processed all the artwork and pho

tographs into digital format and created many of the drawings. Many thanks go to

Edward Pelton, my former supervisor at McDonnell Douglas Technologies, who

proofread the final manuscript, and for his suggestions on some of the technical

and presentational issues. Final ly, my thanks to the volunteer reviewers for their

suggestions and recommendations on the various revisions of the book, to the

IEEE Press, and to the John Wiley & Sons staf who worked with me on the final

preparation and publication of this designprocurement guide.

Mesa, Arizona

May `00`

LLLANO H. HLMMiNC

ELbUTHOMAGNETIU

ANbUHOIUUHAMUbHU

CHAPTER T

INTRODUCTION

1 . 1 THE TEXT ORGANIZTI ON

Chapter 2 i s devoted to the principles of electromagnetic measurements that per

tain to anechoic chamber design. The .oncept of plane waves, uniform fi elds, and

uniform phase are given to establish the basis for determining the properties of a

radiating or scattering device in free space. Also discussed is the impact of the

measurement site itsel f on the accuracy of the measurements. For a later compari

son, the principles involved in the design of outdoor test ranges are described.

References specific to each chamber concept are included in the individual sec

tions. General references applicable to the general fiel d of electromagnetic test

faci lities are included in the Selected Bibliography.

Next, in Chapter 3, radio-frequency and microwave absorbing materials are de

scribed with detai led information on thei r performance and how they are used to

establ i sh control led electromagnetic test environments within an indoor test faci l

ity.

Chapter 4 provides information on the chamber enclosure. If electromagnetic

shielding is required, common available systems are described with references de

tai ling their construction.

Chapters 5 through 8 detail the designs of the various test faci lities broken down

by the geometry of the test facility. These include the rectangular chamber, the

compact range chamber, and those chambers where geometry is important in the

design, including the tapered chamber, the double hom chamber, and the TEM cell.

Chapter 9 summarizes all the test procedures associated with electromagnetic

acceptance testing of the various chambers and also the testing of absorber mate

rials used in the construction of the chambers.

T

2 I NTRODUCTI ON

Chapter 1 0 provides a summary of the types of indoor test facil iti es that have

been developed for the various electromagnetic measurements. These include

chambers for testing antennas, radar cross section, electromagnetic compatibility,

and electromagnetic systems. Extensive use of photographs has been used to i l

lustrate these various anechoic chambers. A special inser of fll-color pho

tographs has been included to highlight the design concepts used in anechoic

chamber design.

Appendix C provides a series of design and specification checklists for the var

ious types of anechoic chambers.

A selected bibliog

'

raphy is given in support of the content of the book.

An extensive index is provided so that convenient reference can be made to any

subject covered by the text

REFERENCES

I . W. H. Emerson, Electromagnetic Wave Absorbers and Anechoic Chambers Though

the Years, IEEE Transactions on Antennas and Prpagation, Vol. AP-2 1 , No. 4, July

1973.

2. B. F Lawrence, Anechoic Chambers, Past and Present, Conformit Vol . 6, No.4, pp.

54-56, April 2000.

3. IEEE Std 145-1983, IEEE Standard Defnitions of Terms for Antennas, IEEE Press,

New York, 1983.

4. ANSI C63.14: 1998, American National Staadard Dictionary for Techologies ofElec

tromagnetic Compatibility (EMC), Electromagnetic Pulse (EMP), and Electrostatic

Discharge (ESD).

5. IEEE 100, The Authoritative Dictionar of IEEE Standard Terms, 7t edition, IEEE

Press, New York, 2000.

CHAPTERZ

MEASUREMENT PRI NCI PLES PERTAI NI NG

TO ANECHOI C CHAMBER DESI GN

2.1 I NTRODUCTI ON

The purpose of the book i s to provide a guide on the design and performance

speci fication of electromagnetic anechoic chambers or indoor test faci l ities.

However, some knowledge of electromagnetic measurements is required to en

sure that all appl icable design factors have been applied in any given design situa

tion.

The measurement of electromagnetic waves involves a large number of elec

tronic devices. These devices can be categorized as i ntentional or unintentional

radiators. Measurement of intentional radiators (such as antenas) or the scatter

ing of electromagnetic energy, as in radar cross section, requires special ized test

ing faci l ities. Determining the level of radiation from unintentional radiators such

as digital devices or determining the level of i mmunity an electronic device has

with respect to an impinging electromagnetic wave also involves the measure

ment of el ectromagnetic waves in testing faci lities designed specifically for the

measurement to be performed.

El ectromagnetic waves result from the acceleration of electric charges. The

electric field due to an unaccelerated charge (one at rest or in uniform motion in a

straight line) is radially directed and decreases as the square of the distance from

the charge. However, the acceleration of the charge gives rise to a tangential com

ponent of the electric field, and this decreases linearly with distance [ 1 ] . This

time-varying electric field has associated with it a time varying magnetic field;

together, they comprise an electromagnetic field. An electromagnetic field that

decreases l inearly with distance represents an outward radiation.

3

4 MEASUREMENT PRI NCI PLES PERTAI NI NG TO ANECHOI C CHAMBER DESI GN

In practice, one is almost always concerned with macroscopic efects resulting

from acceleration of gross numbers of charges. On the macroscopic scale, the in

terrelationship between electric and magnetic fields is described mathematically

by Maxwel l 's equations [2, 3] . An additional set of equations called constittive

relationships [ 3, 4] specifies the characteristics of the medium in which the fiel d

exists.

The mathematics of electromagnetic fields and the associated media makes

use of vector and tensor analysis. The analysis can become very involved in

many problems, especially those involving propagation in nonisotropic, nonrec

iprocal, nonlinear, or nonhomogeneous media. Although certain problems in

electromagnetic measurements can require application of more detailed mathe

matics, only the relatively elementary aspects of vector analysis and electromag

netic theory are used in this book. The reader i s assumed to be fami liar with ba

sic vector operations and concepts of wave phenomena. Standard texts, such as

the references cited in this and subsequent chapters, should be consulted as

needed.

2.2 MEASUREMENT OF ELECTROMAGNETI C FI ELDS

2.2. 1 I ntroduction

The varety of electromagnetic field measurement techniques is fairly extensive.

The following examples represent a sampling of the most common types of

measurement and their parameters, which are afected by the testing environ

ment.

2.2.2 Antennas

2.2.2.1 Intrduction. Antenna measurements are extensively conducted

throughout industr and goverent test facilities. These measurements i nvolve

essentially two basic parameters. The first i s the distribution of the radiated ener

gy in space about the antenna or antenna patter and its associated gain. The sec

ond parameter i s how well the antenna is matched to the transmission line feeding

the antena or input impedance.

Z.Z.Z.Z RIBRR8 H8IIBNS. The energy radiated from an antenna is a three

dimensional problem. The pater shape can be nearly sphercal or all the energy

can be directed in one direction, such as that generated by a large refector anten

na. The facilities for measuring antennas vary greatly, depending on the purpose

of the antenna system and the type of pattern it generates. Low-gain or electrical

ly small antennas can be measured in simple rectangular chambers in the mi

crowave frequency range, but require specially designed chambers below 1 GHz,

due to the absorption properties of the anechoic material that must be used at the

l ower frequencies. High-gain antennas require very long length outdoor ranges or

2.2 MEASUREMENT OF ELECTROMAGNETI C FI ELDS 0

the use of compact antenna ranges indoors. Each of these diferent faci l ities ap

proximates the ideal test environent to varying degrees of performance. The dif

ferences will be discussed in the following chapters in conj unction with the de

sign of the particular facility. The following is general information that applies to

all facilities.

Figure 2. 1 depicts a generalized antenna patern. A maj or lobe i s shown with

its half-power beam width noted. The side lobe level s are also noted. The gain of

the antenna is referenced to the peak of the pater. The accuracy of the measured

patter i s a function of the level of extraneous energy existing in the test region of

the antenna test facility. If the extraneous level is -5 dB, then the 20-dB sidelobe

will have a I -dB uncertainty associated with the measurement. Figure 2. 2 is

used to evaluate the degree of uncerainty that applies to a given measurement,

knowing the level of extraneous energy that exists i n the test region and a given

pattern level .

2.2.2.3 Rf9RR8 8R. The IEEE Test Procedure for Antennas, Std- 1 49 [ 5] ,

defines the power gainof an antenna in a speci fied direction as 47 times the ratio

m

E

0

.

C

&

0

V

N

0

/

d

Ha||-p.wer

Deamwidth

Tenth-pOwer

Deamwidth

-

1

O0CO08

q

4

~q

v igia|

/\

|CDe

'

Nu|l

Deamwidth

`

~ ~1 1

Ang|einDegrees

Figure .1 Generalized antenna patter.

6 MEASUREMENT PRI NCI PLES PERTAI NI NG TO ANECHOI C CHAMBER DESI GN

O

1

0

310

C

`

:

20

.30

O

m

a.40

L

'50

60

8

`

`

` |

` `

` |

` `

"

" P

" ' h

" '

| h

"

"

'

` `

'

"

`

h

.T

`

D b

,

-

`

l

~

2

=

` l

h 2

~

` "

P

--

m

~

~

"

-

"

=

"

-

"

~ -

0.5 5

Peak to Peak Deviation (UJ

10 20 30 50 100

Figure 2.2 Pattern level uncertainty versus extraneous signal level .

of the power radiated per unit sol i d angle in that direction to the net power accept

ed by the antenna from its generator. This i s described mathematically by

G(4, |) 41<(4, |)/| (2-

1

)

where | is the power accepted by the antenna from its generator and 4(,1) i s

the radiation intensity (power radiated per uni t sol i d angle). Rewriting (2- 1 ) i n the

form

(2-2)

shows that the gain i s the ratio of the power radiated per steradian i n the specified

direction (4, |)to the power that would be radi ated per steradian by a lossless

isotropic antenna with the same input power | accepted at its terinal s. This

form gives a physical interpretation to the gain and also shows the relationship

between gain and directivity from the definition of the directivity

(2-3)

where | _ i s the power radiatedby the antenna.

Dividing (2-2) by (2-3) gives

(2-4)

Because the eficiency can never be as great as unity, the gain must always be less

than the directivity.

Techniques for measuring gain can be found in Ref. 5 .

2.2 MEASUREMENT OF ELECTROMAGNETI C FI ELDS 7

2.2.2.4 Antenna Impedance. The input impedance of an antenna is infu

enced by the physical environment adj acent to the antenna. Antennas radiate ener

gy; and i f the energy i s refected back into the antenna, then the apparent input

impedance changes. If the refecting object is greater than approximately one

wavelength away from the antenna, then the measurements are fai rly representa

tive of the actual i nput impedance. If the measurement is to be conducted within a

small RF absorber lined enclosure, then the refectivity of the absorber must be

selected careflly as pointed out in Chapter 3.

2.2.3 Radiated Emi ssi ons

The measurement of emissions from electronic devices has become a very impor

tant part of bringing an electronic device to market. Throughout the world gov

erent agencies now specify the maximum emissions that an electronic device

can radiate. The level s are very low due to the presence of so many devices i n a

given ofice environment. Carefl calibration of the measurement site is essential

because l arge errors could lead to expensive equipment fixes i f the specified lev

els of emissions are not met. Currently, these measurements are conducted on

open area test sites (OATS) or i n alterative indoor sites such as anechoic cham

bers. These measurements involve the measurement of the site atenuation-that

is, the propagation loss between the device under test and the measurement anten

na [6] . Knowing this loss and using a spectrum analyzer, the l evel of the emission

at a given distance can be determined. These measurements are general ly con

ducted at range lengths varying from 3 to 30 m. Anechoic chambers are common

ly used for the 3-m range length. Larger companies have built a number of 1 0-m

chambers [7] .

The measurement aspect that is most important in EMI anechoic design is the

degree to which the site attenuation is the same as measured on an OATS. Be

cause the facility i s confined within an enclosure, the repeatabi lity of the mea

surement within the test volume must also be verified. A third item common to al l

EMI measurements i s the uncertainty associated with the antennas used in the

measurements and how they are calibrated.

2.2.4 Radi ated Susceptibi l it

Radiated susceptibility requires the measurement to be conducted in a shielded

anechoic chamber because high l evel s of power are required to generate the

fields necessary to test the susceptibi lity of a device to various level s of electro

magnetic fields. Carefl design of these facilities is required to minimize uncer

tainty in the measurements. Detailed information is given on the design of these

specialized test faci l ities. The uniformity of the field i lluminating the device

under test (DUT) is the most critical parameter in susceptibility measurements

[6] .

8 MEASUREMENT PRI NCI PLES PERTAI NI NG TO ANECHOI C CHAMBER DESI GN

2.2.5 Mi l itar Electromagnetic Compatibi l ity

Military radiated electromagnetic measurements are conducted in shielded ane

choic enclosures using test procedures and absorber treatments specified i n MIL

STD-46 I E [ 8] .

2.2.6 Antenna System Isolation

Antenna system isolation measurements require a very low extraneous signal envi

ronment. A large clear area around the vehicle under test, i fl ocated outdoors, i s re

quired. A l arge test volume is required in an anechoic chamber. Indoors, the site

isolation is the sum of the two-way path loss to the wal l s plus the refectivity of the

absorber. The sum should be at least 6 dB greater than the system requirements to

provide an adequate signal-to-noise margin for the measurement. A special case of

this type of measurement is the measurement of passive intermodulation (PIM) [9] .

2.2.7 Radar Cross Secti on

The measurement of radar cross section has special test environment require

ments. These include ( I ) minimizing of forward scatter from the transmitter to the

test region, (2) minimizing extraneous energy refected from surrounding sur

faces, (3) uniform i llumination of the target, in phase and ampl i tude, and (4) the

ability to operate over very broad frequency ranges [ 1 0] . Each of these items is

discussed i n the sections describing a particular test chamber concept.

2.3 FREE-SPACE TEST REQUI REMENTS

2.3.1 I ntroduction

The radiation characteristics of an electronic device in spherical coordinates un

der a given set of conditions can be described by the fnctions

GI (4, e), G2(4, e)

&(4, e)

Z

(2-5)

where GI and G2 are the gain functions for two orthogonal polarizations, 0 i s the

phase angle between the output signals for the two polarizations, | is the eficien

cy ofthe device determined by its ohmic losses, and Z i s the impedance that the de

vice presents at its input terminals. These relationships are illustrated in Figure 2. 3.

Only i n the case of an intentional radiator, such as an antenna, are these para

meters easily determined. In addition, environmental factors must be considered

i n any electromagnetic measurement problem, and suitable allowance must be

made for their efects.

Z.3 FREE-SPACE TEST REQUI REMENTS 9

S1

Figure 2.3 Symbolic relationship of measured parameters.

Before proceeding to the speci fics of electromagnetic testing that is performed

in anechoic chambers, it is appropriate to review certain fndamental terms and

relations that are basic to electromagnetic measurements.

2.3.2 Phase

A commonly employed criterion for determining the minimum allowable separa

tion between the source antenna and the antenna under test is to restrict the phase

varation to be less than a maximum of 1/8 radian, or 22. 5 degrees [ I I ] .

Consider a source o f spherical waves and an antenna under test (AUT) located

at a distance K away from it as i llustrated in Figure 2. 4. The l argest phase difer-

Figure 2.4 Derivation of the far-field criteria.

1 0 MEASUREMENT PRI NCI PLES PERTAI NI NG TO ANECHOI C CHAMBER DESI GN

ence between the spherical wave and the ideal plane wave appears at the edges of

the AUT, which corresponds to the diference in the wave path lengths, o. Under

the common assumption, ko flfi l l s the requirement

ko : n/8 (2-6)

The diference in the wave path lengths, o, is determined by noticing that

(2-7)

The only physical solution of the above quadratic equation for o i s

(2-8)

The above is approxi mated by the use of the binomial expansion (the first two

terms only) as

o

R[(l + (Dmax/2R)2 1 ]

R[I + 1I2(Dmax/2R)2 - 1 ]

D

ax

/4R (2-9)

The mi nimum di stance from the source of the spherical wave is now deter

mined from the requirement in (2-6),

KDax/4R

(2n/A)(Dax/4R) : n/8 (2-10)

Under this condition,

(2-11)

If antenna measurements are made at this range length, then there wi l l be a mi

nor departure of the nulls of the radiation pattern and the location and l evel s of

the minor lobes from their infinite-range val ues.

Equation (2- 1 1 ) was derived as a guide to setting up an antenna measurement

range to accurately measure antenna radiation patterns. When conducting radar

cross-section (ReS) measurements, concerns are not the pattern of the source and

receive antenna, but i l lumination of the target. The primary requirement is that

the source antenna has rel atively constant ampl itude and phase characteristics, as

seen at the target.

These requirements can be achieved with the target closer to the antennas than

the value calculated by equation (2-11).

No published criterion is kown for determining exactly how close the target

should be to the source antenna. Some guidance was provided by Hu [ 1 2] , where

the phase within the 3-dB beamwidth is essentially the same as at infinity for a

distance of R/4 or 0.5D2/A. Equation (2- 1 1 ) can be general ized to

(2-12)

2.3 FREE-SPACE TEST REQUI REMENTS 1 1

When a target accuracy of 1 dB is required, Knott [ 1 3] has shown that Kshould

be between 2 and 10, depending on the target characteristics. The types of targets

that requi re a l arge value of Kare those i n which the edge scattering i s compara

ble to the specular-scatterng contribution. A convenient chart for determining the

target size as a fnction of Kis given in Figure 2. 5.

Radiated emission and susceptibility measurements are usually conducted for

both the near and far fields due to the broad frequency coverage and the distances

set by the testing requirements [ 1 4, 1 5] .

2.3.3 Ampl itude

For accuracy i n simulated far zone measurements, the i l l uminating field must be

suficiently constant i n amplitude both along the line of sight and i n planes nor

mal to the line of sight. If the field uniformity is not suficient along the axis, then

measurement errors will occur, especially in the minor lobes. If the amplitude ta

per across the aperture i s too great, then the measured patterns will vary signifi

cantly from free-space. For high-performance antenna ranges the taper is general

ly held to be less than 0. 25 dB, resulting in a measured gain error of less than 0. 1

dB [ I I ] . For a range length of R WI} [see equation (2- 1 2) ] , the source diam

eter would be restricted to

d : 0. 37 (2- 1 3)

where d is the diameter of the source antenna, Kis a constant, and D is the diam

eter of the AUT

!00

C

F !0

!

Tmsml

.

.

Antenna

.

u

.

. ~ >

a|Seometry

.

~

~

>

|

-

|

l

~

/< . .

> > . 1

.

- | -

X .

.

-

- . 7128

l

~

-~

~

u

l

.

> |

-

-

-

-

.

! !0 100 1000

3angeaj|requencySHzj

Figure 2.5 Test region size versus range length and frequency.

10000

1 2 MEASUREMENT PRI NCI PLES PERTAI NI NG TO ANECHOI C CHAMBER DESI GN

For most antenna measurements, i f the amplitude variation i s held to less than

I dB, then the error is usually acceptabl e.

2.3.4 Pol arization

At a large distance from a radiating antenna, the electric (E) and magnetic (H)

vectors of the radiated field are at right angles to each other and to the direction of

propagation. The two fields osci l l ate in time phase, and the ratio of their magni

tdes (E/H) i s a constant , the intrinsic impedance of free space, and has a value

of approximately 1 20' ohms.

The polarization of an electromagnetic fiel d is described i n terms of the direc

tion in space of the electric field [ I I ] . I f the vector, which describes the electric

fiel d at a point in space, is always directed along a line, which i s necessari ly nor

mal to the direction of propagation, the field is said to be lineauy polarized. In

general, however, the terminus of the electric vector describes an el l ipse, and the

field is said to be ellipticallypol arized.

Radiating devices exhibit polarization properties in rel ation to the fields they

radiate or receive. If an antenna is operated in the receiving mode, i t wi l l not in

general be polarzation-matched to the incident field. If it is polarization

matched, it will extract maximum power from the field and its polarization efi

ciency i s said to be unity. If its polarization is orthogonal to the field, it will ex

tract zero power, and its polarization eficiency i s consequently zero.

The polarization properties of fields and antennas are of primary focus in all

problems concerned with communication between antennas.

2.3.5 The Friis Transmi ssi on Formul a

I f it were necessary to determine the power transfer between two antennas by re

sorting to the basic processes that are defined by the fiel d equations and dif

fraction theory, the calculations would be virtual ly impossible for al l but the

simplest of antennas. The Fri i s transmission formula [ 1 6] permits the power

transfer to be determined from kowledge of the measured directive properties

and the dissipative attenuation of the antennas, i ndependent of their detailed de

SIgn.

P _ power received,

Po power transmitted,

(, |) transmit antenna gain in direction of other antenna,

(,|)

receive antenna gain in direction of other antenna,

A operating wavelength i n dimensions of R,

R range length in meters or feet or inches,

(2- 1 4)

polarization eficiency, a measure of how wel l the antennas, are po

l arization-matched.

2. 4 SUPPORTI NG MEASUREMENT CONCEPTS 1 3

2.4 SUPPORTI NG MEASUREMENT CONCEPTS

2.4. 1 I ntroduction

When conducting electromagnetic measurements it i s ofen requi red to establ i sh a

coordi nate system, because the measurements are general ly conducted in three di

mensions. Also, most electromagnetic measurements are conducted in decibels

(dB), because the dynamic range of the measurements ofen exceed a power ratio

of more than mi l l ion times or 60 dB. Another problem is that the measurements

are conducted near the earth or i n an enclosure, thus the problem of refected en

ergy must be addressed. These three general concepts are di scussed in the fol l ow

ing sections.

2.4.2 Coordinate Systems and Device Positioners

Almost all el ectromagnetic radiation measurement involves determination, in one

way or another, of signal levels as a function of position or direction in space,

usually the latter. Because of the nature of radiation, the spheri cal coordinate sys

tem (Fi gure 2.6) i s the system that is most often employed in electromagnetic

measurement problems. Ofen, the measurement of direction must be made to a

8-

J

O1nt (r,0}

Z

>

/

O:1ectiOn ,8

d- ;U`

+

;"

Figure 2.6 Spherical coordinates used in antenna measurements.

1 4 MEASUREMENT PRI NCI PLES PERTAI NI NG TO ANECHOI C CHAMBER DESI GN

high degree of precision because of the requirements of the operational system of

which the radiating device is a part.

Because of the relatively large distances that are often requi red between the de

vice under test and the source antenna or sampl i ng antenna (depending on

whether the device i s tested on receiving or transmitting), i t i s ofen not practical

to explore the radiation pattern of the device i n (<, 0)by movement of the device

or the antenna over a spherical surface. Instead, the line of sight between the test

devi ce and the measurement antena i s held fixed i n space, whi l e the device un

der test i s changed in orientation to simulate movement of the line of si ght over

the sphere. This requirement has led to the development of special-purpose posi

tioners, which are described for each test si tuation.

2.4. 3 Decibels

The use of decibels in calculations and measurements of radiation measurements

i s almost essential, due to the large dynamic range of the quantities described.

The decibel , abbrevi ated dB, i s a l ogarithmic unit and i s used to measure the ratio

between two amounts of power. By definition,

Number of dB = 1 0 log PtlP

2

(2- 1 5)

where PtlP

2

is a power rati o. When PtlP

2

is greater than unity, the number of dB

representing the rati o P/P2 i s positive. When P/P2 i s less than unity, the number

of dB representing P/P

2

i s negative. When the power ratio i s less than unity, the

fraction i s ofen inverted, and the ratio i s expressed as a decibel l oss.

Because power, voltage, and current are related by

P = |/K IK (2- 1 6)

we obtain

Number of dB = 20 logV/V2 = 20 log 1/12

The value of the use of decibels in electromagnetics is largely based upon

two factors. First, i f nt and n

2

are power ratios whose values i n dB are Nt and

N

2

, the product ntn2 i s represented by Nt + N

2

dB, and nt1n

2

i s represented by

Nt - N

2

dB. This permits the handling of products and quotients of large power

ratios simply by the operations of addition and subtraction. Second, the decibel

scale represents a compression of the power rati o scale, which permits the dis

play of large power ratios on a single graph, with equal resolution at all power

level s.

It i s convenient to convert the Fri i s transmi ssi on formula (2- 1 4) to decibel s i n

order to si mpli fy i ts appl icati on:

Z.4 SUPPORTI NG MEASUREMENT CONCEPTS T0

L

r =

L

a

+ g

(4

, |)+

g

'

(4

, |)- 20

1

0g(41RIA)

(2- 1 7)

where

L

r is the signal l evel at the output terminals of the receiving antenna in dBm,

L

a is the signal level at the i nput terminals of the transmitting antenna in dBm,

_i s the gain of the source antenna,

g

'

is the gain of the receive antenna,

g

(

1. |)

1 0 log (1. |).

g

'

(4

'

, |)= 1

0 log G

'

(4

, |).

and

R is the transmitter-receiver separation and A = wavelength.

Note: R and A must be in the same units (usually meters) of measure.

dBm is the signal level in power referenced to 1 m W

2.4.4 Efects of Reflected Energy

When two or more coherent electromagnetic signals combine in the test region of

an electromagnetic test facility, the fields i l l uminating the device under test are

distorted and the accuracy of the measurement is degraded.

The discussion here assumes a separation, R, between sources and receiving

antenna equal to or greater than 2D

2

/A (see Section 2. 3. 2), where D is the maxi

mum dimension of the receiving aperture. It i s frther assumed that the rati o DI R

is smal l in comparison with the half-power beamwidth of the source antenna's

pattern, so that plane wave approximations are meaningfl.

The mechani sm by which a refected signal interferes with the desired direct

path signal and distorts the incident field is demonstrated as follows. Consider the

case of a direct-path pl ane wave of amplitude ED that is normally incident on a

test aperture, as shown in Figure 2. 7. Let a refected pl ane wave of ampl itude ER

enter the aperture at an angle | from the normal . The radial l i ne defined by the

unit vector u is the intersection of the pl ane containing the directions of propaga

tion of the direct-path and refected signals and the pl ane containing the aperture.

The line having unit vector v is at some general angle D from u in the pl ane of the

test aperture. At any given time t,the phase of the direct wave is constant across

the aperture, and the magnitude of the direct-path field may be expressed in pha

sor notation as

(2- 1 8)

The phase of the postulated refected plane wave will vary across the aperture so

that the magnitude of the refected field along the line V or any l ine parallel to V is

given by

(2- 1 9)

In (2- 1 8) and (2- 1 9), and are constants, A is the wavelength, and l is a dis

tance measured along the radial line v or along some other line parallel to V. The

1 6 MEASUREMENT PRI NCI PLES PERTAI NI NG TO ANECHOI C CHAMBER DESI GN

'

I _,

l

|

l

\

|

a

~

|_

.

p

'

Figure 2.7 Summation of two coherent signals.

magnitude of the total fi eld measured as a function of distance along v wi l l be

proportional to

E(v) E E_sin(21/AI si n U COS o) (2-20)

The di stance between successive peaks of the resultant sinusoi dal fiel d i s

P = A/(sin U cos o) (2-2 1 )

This spatial period or pitch has a minimum value of

P __ = A/(si n 6) (2-22)

along the direction u, as shown in Figure 2. 8.

While the spatial periods of the measured fiel d fuctuations are fnctions of the

position of the radial l i ne in the aperture for which a recording of the fiel d i s

made using a field probe, the peak-to-peak amplitude of these fuctuations i s a

constant proportional to

(2-23)

? 4 SUPPORTI NG MEASUREMENT CONCEPTS 1 7

gW0v0l r00t

g W0v0fr00l8

l

Figure 2. 8 Vector addition of two coherent signals.

For typical logarithmic patterns, the ratio of ER and ED would be

(2-24)

where U i s the di ference in decibels between maxima and minima of the mea

sured pattern. A plot of ER/ED versus U i s given in Figure 2. 9.

The preceding example demonstrates the manner in which refected si gnals

would di stort an otherwise planar wave front. In a more realistic case, neither the

direct wave nor the refected wave would be strictly planar, and there would be

many sources of extraneous signals that could contribute to the total aperture

field. However, the simple model presented above is quite useful in interpreting

field probe data for the typical case where one refected signal i s somewhat

stronger than other signals that may be present. An al ternative method of per

forming the same analysis i s given i n Chapter v.

2.4.5 Efects of Antenna Coupli ng

At the lower frequenci es, the efects of inductive coupling between the source and

the test antenna must be considered [ 1 1 ] . The ratio of the ampl i tude of the induc

ti on field to that of the radiation field i s given as

(,

= A/(2TR)

If one assumes R - l OA, then 20 log

(,

) is -36 dB.

(2-25)

Mutual coupl ing due to scattering and reradiation of the energy by the test and

source antennas is also of concern. If coupl ing does occur, frequency pulling and

1 8 MEASUREMENT PRI NCI PLES PERTAI NI NG TO ANECHOI C CHAMBER DESI GN

I

E

O

T

E

9

O

m

O

0

|

L

m

O

0

I I

b

9

8

7

6

G

4

3

?

. 1

9

8

7

6

5

4

3

2

. 1

9

8

7

6

5

=

D

.

z

/

/

/

/

/

/

z

/

/

/

/

.

6b -55

=

4D

=

q

D

Figure 2.9 Plot of error versus extraneous signal level .

/

/

/

/

/

=

D

.5 OUTDOOR MEASUREMENT FACI LI TI ES 1 9

power l evel changes can be reduced by inserting an isolator or attenuator between

the source and its antenna.

2.5 OUTDOOR MEASUREMENT FACI LITI ES

2.5. 1 I ntroducti on

Before proceeding into the design of anechoic chambers, a brief review of out

door test ranges is required to set the stage.

The ideal test environment for determining far-zone perforance would pro

vide for a plane wave of uniform amplitude to illuminate the test aperture. Various

approaches to simulation of this ideal electromagnetic environment have led to

the evolution of two basic types of antenna test ranges: ( 1 ) free-space ranges and

(2) refection ranges.

Free-space ranges are those in which an atempt is made to suppress or remove

the efects of all surroundings, including the range surface or surfaces along the

wave front that i l luminates the test antenna. This suppression is sought through

one or more of such factors as

1 . Directivity and side lobe suppression of the source and test antenna

2. Clearance of the line of sight from the range surface

3. Redirection or absorption of energy reaching the range surface

4. Special signal processing techniques such as tagging by modulation of the

desired signal, gating of the signals, and time-domain techiques or by use

of shor pulses.

Typical geometries associated with the free-space approach include the elevat

ed range, the slant range, the rectangular anechoic chamber, the compact range,

and above cerain l imiting frequencies, the tapered anechoic chamber.

Refection ranges are designed to make use of energy that is reradiated from the

range surface(s) to create constructive interference with the direct-path signal in

the region about the test aperture. The geometry is controlled so that a symmetric

small amplitude taper is produced in the i lluminating field. The two maj or tes of

refection ranges in use are the ground refection range and for low frequencies, the

tapered anechoic chamber and the five-sided EMC emission chamber.

2.5.2 Electromagnetic Design Considerations and Criteria

For either basic type of range, the fndamental electromagnetic design criteria

deal with control of

1 . Inductive coupl ing between antennas

2. Phase curvature of the illuminating wave front

20 MEASUREMENT PRI NCI PLES PERTAI NI NG TO ANECHOI C CHAMBER DESI GN

J. Ampl itude taper of the i lluminating wave front

4. Spatial periodic variations i n the i l l uminating wave front caused by refec

tions

5. Interference from spurious radiating sources

Items through 4 primari ly establish the dimensional requirements on the range

design as wel l as l imiting the source-antenna directivity. Item 5 must be consid

ered in the overal l design.

2.5.3 El evated Outdoor Antenna Range

Elevated antenna range design proceeds as fol l ows (see Figure 2. 1 0) :

1 . Determine the minimum range length from the range equation,

(2-26)

2. Determine the maximum source antenna diameter where the ampl itude ta

per is l imited to 0. 25 dB,

where

d = source diameter

D test aperture

R range length

\= operating wavelength

SCUH|L

d = 0, 37 'RID

Figure 2. 10 Elevated antenna range.

(2-27)

1LS1

'

i

2. 5 OUTDOOR MEASUREMENT FACI LI TI ES 21

More general ly, for a range length R KD'/\, the source di ameter would be

restri cted to

d = 0. 37 KD (2-28)

Another criterion for el evated range design is given in Ref 1 1 , where

To ensure a good i l lumination taper and minimum range refections, check to

see that the first null of the source antenna pattern fal l s no lower than the base of

the test antenna tower. If further reduction of range refections i s needed, this can

be achieved by using range fences [ 1 1 ] . 2- 1 4

2.5.4 Ground Refl ection Antenna Range

2.5.4. 1 Introduction. The ground refection range design assumes that the

energy from the source antenna cannot be kept from reaching the surface of the

test range and refecting into the test aperture. At a fixed frequency the range pa

rameters can be adjusted so that the refecting energy is phased so as to create

constructive interference with the direct-path si gnal in the region of the test aper

tre.

2.5.4.2 Principles. The amplitude taper of the i l luminating field along a

horizontal line through the test aperture, normal to the l ine of sight, will be de

termined almost entirely by the source directivity, the apertre width, and the

range length, just as for elevated ranges. The taper along a vertical l ine through

the test aperture, however, i s virtually independent of the directivity of the

source antenna and depends almost entirely on the height of the center of the

test aperture above the range surface. This may be shown as di scussed in the fol

lowing paragraphs.

Consider test-range geometry as sketched in Fi gure 2. 1 1 . Set the phase refer

ence at zero for the di rect-path wave at the source antenna and neglect the slight

di ference in loss due to dispersion along the path lengths for the direct and re

fected waves. The phasor representing the amplitude of the field at points along a

vertical through the test apertre can then be written as

where the time dependence is suppressed. In this expression,

f 21/'

RD [R

2

+ (h - ht)

2

J

1

/

2

RR [R

2

' (h ' ht)

2

J l /

2

(2-29)

22 MEASUREMENT PRI NCI PLES PERTAI NI NG TO ANECHOI C CHAMBER DESI GN

TE5T

.

5URCE _ _

. >

h

' >

, .

R

Figure 2.1 1 Ground refection range.

ED = the direct-path field amplitude

ke-jq = an efective refection coeficient for the range surface

RD = direct path length

RR = refection path length

R range length

hI = height of transmit antenna

hr height of receive antenna

Assuming that the phase shift for typical ground refection geometr is nearly

equal to T radians and that the range length R i s large with respect to h_ the

height of the transmit source is given by approximately

(2-30)

When the first interference lobe is peaked at the test height, the fiel d variation

i s on the order of

(2-3 1 )

To ensure that the vertical amplitude variation across the test aperture o n a ground

refection range is suficiently fat, it is recommended that the test height hr be set

at [ 1 1 ]

(2-32)

. 5 OUTDOOR MEASUREMENT FACI LI TI ES Z

Z.0.9.d Contrl of Surace Refections in the Grund-Refection

Mode. Refections from a range surface may be classified into to general cat

egories, difse scatering and specular refection. The transition fom conditions

causing difse scattering to those producing essentially specular refection i s

gradual . Accordingly, criteria for specifing the boundaries and tolerances for the

refecting surfaces and other control led areas in the design of ground-refection

ranges are largely empirical.

For the range surface varations, it is suggested that peak-to-peak surface vari

ation be held to within [ 1 1 ]

`h A/(M sin )

where

A is the operating wavelength at the highest frequency of interest

Mis a smoothness factor between 8 and 32

arctan[(hr + h,)IR]

(2-33)

For the amount of range surface area t o be control led see the guidance given i n

Ref. 1 1 .

2.5.5 Open-Area Test Sites (OATS)

Z.0.0. I Intrduction. The Federal Communications Commission (FCC)

was given the authority to impose rules and regulations on industrial, commercial,

and consumer devices that may radiate electromagnetic energy under the Com

munications Act of 1 934. The commission adopted the open-area test site

(OATS), a specific form of ground refection range, as a convenient method of

standardizing emission measurements [ 1 7] .

The original specification specified that radiated emissions were t o be con

ducted on a ground plane using three range lengths: 3 m, 1 0 m, and 30 m. A suit

able site required that it be clear of obstructions such as trees, bushes, or metal

fences within an elliptical boundary. The site should also be wel l away from

buildings, parked automobiles, and the l ike. The suitability of the site is deter

mined by measuring the site attenuation [ 1 4] .

2.5.5.2 The Design of Open Ara Test Sites. Open-area test sites are

ground-refection ranges with specified range lengths and specified height ranges

for the scanning antennas that are used to measure the radiated emissions. The re

sult is that the sites have repeatable characteristics. Notably, the site attenuation,

which is defined as the propagation loss between the item under test and the mea

surement antenna, becomes a quantifiable parameter. Given the site attenuation

24 MEASUREMENT PRI NCI PLES PERTAI NI NG TO ANECHOI C CHAMBER DESI GN

the level of radiated emissions from a device under test can be calculated. This is

also tre for free-space and anechoic chamber test sites.

The design of open-area test sites is now specified by ANSI C63. 7- 1 992 [ 1 8] .

An extensive discussion i s given by Kodali [6] .

The validity of the test site is determined by measuring the site attenuation as

described in ANSI C63. 4 [ 1 4] .

REFERENCES

1 . J. D. Kraus, and D. A. Fleisch, Electromagnetics: With Applications, McGraw-Hi l l ,

New York, 1 998.

2. F T Ulaby, Fundamentals of Applied Electromagnetics. 1 999 edition, Prentice-Hall,

New York, 1 998.

3. C. T A. Johnk, Engineering Electromagnetic Fields and Waves. John Wiley & Sons,

New York, 1 975.

4. C. A. Balanis, Engineering Electromagnetics. John Wiley & Sons, New York,

1 989.

5. IEEE Std 1 49- 1 979, Standard Test Procedures for Antennas.

6. V Kodali, Engineering Electomagnetic Compatibilit. 2nd edition, IEEE Press,

200 1 .

7 . B. Lawrence, Anechoic Chambers, Past and Present, Conformit. Vol . 6, No. 4, pp.

5456, April 2000.

8. MIL-STD-461 E, Requirements for the Control ofElectrmagnetic Intererence Char

acteristics ofSubsystems and Equipment.

9. Special Session-Passive Intermodulation, Antenna Measurement Techniques Associ

ut/cn PrcceeJ/ngx, QQ. l +Zl J, Z.

1 0. E. F Knott, Radar Crss Section Measurements. Van Nostrand Reinold New York,

1 993.

1 1 . J. S. Hollis et aI . , Microwave Antenna Measurements. Scientific Atlanta, Inc. , 1 985

(available on CD from MI Technologies, Inc. , Norcross, GA).

1 2. Ming-Kuei Hu, Fresnel Region Field Distributions of Circular Apertures,

IEEE Transactions on Antennas and Prpagation. Vol . AP-8, pp. 344346, May

1 960.

1 3 . E. F Knott et aI . , How Far i s Far?, IEEE Transactions on Antennas and Prpagation.

Vol . AP-22, pp. 732-734, September 1 974.

14. American National Standard Institute (ANSI), C63. 4-2000: Standard for methods of

measurement of radio noise emissions from low-voltage electrical and electronic

equipment in the range of 9 kz to 40 GHz.

1 5. European standard, EN6 1 000-4-3 : 1 996, Electromagnetic Compatibility (EMC) Part

4-3 : Testing and measurement techniques-radiated, radio-frequency, electromagnet

ic field immunity test.

1 6. Harold 1 Fris, A Note on a simple Transmission Formula, Proceedings ofthe IRE.

Vol . 34, No. 5, p. 254, 1 937.

REFERENCES 25

1 7. Characteristics of Open Field Test Sites, Bulletin OST JJ, Federal Communica

tions Commission, Ofice of Science and Technology, Washington, D. C. , August

1 982.

1 8. ANSI C63. 7- 1 992, American National Standard for Construction of Open-Area Test

Sites for Performing Radiated Emission Measurements.

CHAPTERTHREE

ELECTROMAGNETI C

ABSORBI NG MATERI ALS

3.1 I NTRODUCTI ON

Electromagnetic absorbing material used in anechoic test facilities takes many

forms, depending on the purpose of the facility and fequency of operation. The

two most common are the dielectric absorbers used in the microwave fequency

range and the ferrite absorbers used in the lower fequency range. Dielectric ab

sorbers came about early in the devel opment of anechoic chambers during the

1 940s when indoor test faci l ities were first developed. These early chambers

were lined with matted "horse hair" that was impregnated with a conductive car

bon solution. In the 1 950s, urethane foam was found to be a good carrier for the

conductive solution, and the pyramidal-shaped absorber came into being. Wel l

i nto the 1 970s, this foam dielectric absorber was the primary product available

for anechoic chamber appl ications. Then a series of serious chamber fires oc

curred which caused the government to research the fire retardant properties of

absorbers and develop a new fire safety standard. The foam absorbers now mar

keted must meet the requirements of Naval Research Laboratory (NRL) 8093

[ 1 ] . This document specifies a series of laboratory tests to be performed to pro

vide a grade of absorber that is quite fire-resistant. For more details on the his

tory of anechoic chambers, refer to Refs. 2 and 3. In the l ate 1 980s, a market

developed for low-frequency testing within an indoor chamber. The first of these

facilities used the then avai lable material, which were large absorber pyramids

installed within shielded enclosures to establish an acceptable testing environ

ment. These faci l ities were very expensive, and only the l arger companies could

support the cost. As the demand for faci l ities rose, other solutions were devel -

27

28 ELECTROMAGNETI C ABSORBI NG MATERIALS

oped, and the ferrite-lined chamber came into commercial use. Today there are

several sources for the ferrite material. Most suppliers of anechoic faci l ities pro

vide designs for the fll range of materials. There are thousands of these cham

bers worldwide. A detailed history of EMI measurements is given in Chapter 1

of Ref. 4. In the 1 990s, chambers for testing wireless devices became the vogue,

and a variety of new chamber designs were developed [5] . All tes of absorb

ing material used in anechoic chambers are reviewed in this chapter. For conve

nience in presentation, the section i s broken down into two classes of material s,

those that are used above GHz (microwave) and those used below GHz (low

frequency).

3.2 MI CROWAVE ABSORBI NG MATERIALS

3.2.1 Prami dal Absorber

3.2. 1. 1 Sold Foam. Most of the electromagnetic anechoic chamber manu

facturers ofer a standard microwave absorber product that is pyramidal in shape.

The product is a solid carbon-loaded urethane foam absorber. To meet the current

fire retardancy requirements it is loaded with fire-retardant chemicals that are ei

ther mixed in with the carbon solution or added as a second treatment. The prima

ry application for this material i s in the construction of anechoic chambers, or for

covering test equipment within the chambers. Of all known absorbers, it provides

the highest broadband performance at both normal incidence and at wide inci

dence angles. It is primarily used for reducing forard scattering, but ofers good

back scattering properties as wel l , making it suitable for use in all locations with

in an anechoic chamber. It is available in a variet of thicknesses. It provides the

chamber designers with the opportunity to choose the right product for specific

frequencies and incidence angles.

The industry provides material as small as 5 . 1 cm (2 i n. ) high and as thick as

3. 7 m ( 1 2 f). The product generally comes in standard thicknesses. Special cuts

are ofen made for specific appl ications. Table 3 . 1 summaries common pyrami

dal materals available from the microwave materials industry. Two geometries

are available; the straight square pyramid shown in Figure 3 . 1 , and the twi sted

pyramid i l lustrated in Figure 3. 2. The latter i s used for the l arger pyramics

where the shoulders of the pyramids help carry the load of the cantileverea

geometry, i l lustrated in Figure 3. 3. The twisted pyramid i s commonly used in

the backwall of tapered chambers where the absorbers commonly used are up to

1 . 8 m (6 f) thick.

The product i s black when made and is usually painted with a blue l atex paint

to improve light refectance. At 95 GHz, the paint can degrade absorber refectiv

ity as much as 5 dB, so the tips are ofen lef unpainted in chambers where mi l

limeter measurements are to be conducted. It al so has been found that if the tips

are lef unpainted it minimizes tip breakage due to wear and tear found in normal

chamber operations. Foam absorber is not very robust and requires a high degree

3. 2 MI CROWAVE ABSORBI NG MATERIALS 29

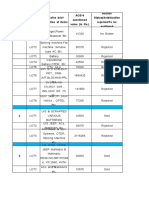

Table 3. 1 Pyramidal Absorber Performance

Height, Weight, Tips

Normal Incidence Refectivity, GHz

Type LU (in. } kg (Ib) per piece 0. 1 2 0. 3 0. 5 1 . 0 3. 0 6. 0 1 0. 0 1 8. 0 36 50

P-4 1 0. 9(4. 3) 1 .4(3) 1 44 30 35 42 50 50 50

P-6 1 5 . 2(6) 1 . 6(3. 5) 1 00 32 40 45 50 50 50

P-8 20. 3(8) 2. 0(4. 5) O 30 37 45 50 50 50 50

P- 1 2 30. 5( 1 2) 2. 7(6. 0) 36 35 40 45 50 50 50 50

P- 1 8 45. 7( 1 8) 5 . 4( 1 2) 1 6 30 37 40 45 50 50 50 >45

P-24 6 1 (24) 7. 7( 1 7) 9 30 35 40 45 50 50 50 50 >45

P-36 9 1 . 4(36) 1 0. 9(24) 4 35 37 42 50 50 50 50 50 >45

P-48 1 2 1 . 9(48) 1 7(38) 2 28 35 40 50 50 50 50 50 50 >45

P-72 1 82. 9(72) 23(50) 33 40 45 50 50 50 50 50 50 >45

Nole.Base dimensions are 0. 6 1 mZ(2 t). Power rating is 0.08 w/cm'(0. 5w/|n. ').

of maintenance. This is especially true in the vicinity of doors and other high-traf

fic areas.

Foam absorbers are general ly installed using pressure-sensitive adhesives. The

chamber surface is first painted with the adhesive, and then the back of the ab

sorber is coated. The adhesive is lef to fash of, and then the block is applied to

the surface. Several adhesive products on the market are used in these types of in

stallations. It is best to use the adhesives recommended by the absorber manufac

turer, because they have confirmed the compatibility of the adhesive with the

chemistry of the absorber material . If not properly applied, the adhesives tend to

lose their bonding power and the pyramids start to come loose from the walls and

especially the ceiling.

Figure 3.1 Geometry of the standard pyramid absorber. (Photograph courtesy

of Advanced ElectroMagnetics, Inc. , Santee, CA. )

30 ELECTROMAGNETI C ABSORBI NG MATERIALS

Figure 3.2 Geometry of the twisted pyramid absorber. (Photograph courtesy of

Advanced ElectroMagnetics, Inc. , Santee, CA. )

--[6h)

Figure 3.3 Stacking of twi sted pyramidal absorber.

3. ? MI CROWAVE ABSORBI NG MATERIALS 31

_

0

, .

5

4

. . ... .,... . ....... .. .. .. . .... . . . .,. . ,. . ,. ......,.....

48 -

:

'

-I

42

!

__

............ ..,. . ..

'

<

_

_

0

_

24

06

Figure 3.4 Normal incidence refectivity performance of pyramidal absorbers.

Pyramidal electromagnetic performance is specified as refectivity at normal

incidence and is stated i n -dB. Generally, this information is provided in tables of

absorber thickess versus frequency (see Table 3 . 1 [6]) over the decibel range of

-30 to -50. When the l oading is optimized and the material is on the order of one

wavelength thick, the refectivity is about -33 dB. At eight wavelengths, the re

fectivity is on the order of -5 1 dB. The numbers in the manufacturer's charts are

rounded of for convenience in specifying the products. Figure 3. 4 shows typical

performance of pyramidal material s. The slope of the curve i s approximately 6

dB per octave, the same as a one-section filter. It is also the same loss that is ex

perienced in free space by a wave front when the distance or frequency is dou

bled. When the absorber is less then one wavelength thick, the performance rol l s

of and approaches 0 dB very quickly. When the absorber is thick and large in

terms of wavelengths, the incident wave front begins to scatter and the absorber

refectivity performance drops of. The actual drop-of is a function of the aspect

ratio (heightlbase dimensions) and the nature of the conductive loading used in

the product to achieve the microwave loss properties. Experience has shown that

the curve in Figure 3 . 4 is achieved when the conductivity of the carbon loading is

optimal . If the conductivity is too great (i . e. , the carbon loading is high), then the

refectivity drops at the low end of the curve and peaks at the higher thicknesses

as shown i n Figure 3. 5. If the loading is too l ight, then the whole curve shifts to

*The curve was developed by the author in l V1J from published absorber performance tables. The

curve has been validated i n many measurements of pyramidal absorber materials.

32 ELECTROMAGNEI C ABSORBI NG MATERI ALS

O

_

| 8 0 8 B 8 B 8 0 OverOad| g

~NOrma|

+ + + Unde|LOadi ng

Z

N

N

N

N

N

#

= ,

:

'

. . . , _. . . . . . y. . . . . . . . . .. . . . . . . . , . . .. u,

. s

-

|

:

Z

3

J

f

;t

| . . . . . -- . . . . .,

1 Z

#

_ ' ` `

. u . .

#-

-

QQ

1 1 1 1

R| CKDSS | D VBV| D_RS

Figure 3. 5 Efect of carbon loading variations in the performance of pyramidal

absorbers.