Académique Documents

Professionnel Documents

Culture Documents

10.eoin O Brien WTG Foundations2010

Transféré par

Bogdan Constantin-Babii0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues18 pagesasd

Titre original

10.Eoin O Brien WTG Foundations2010

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentasd

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues18 pages10.eoin O Brien WTG Foundations2010

Transféré par

Bogdan Constantin-Babiiasd

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 18

ElecTEC 10 11 June 2010 1

Wind Turbine Foundations

Risk Mitigation of Foundation Problems in the Industry

ElecTEC 10 11 June 2010 2

Content

Background WTG Foundations Industry Problems

Causes Identified and Solutions in Place

Additional requirement for larger WTG

ElecTEC 10 11 June 2010 3

ElecTEC 10 11 June 2010 4

CAN Supplied by some WTG Manufacturers for installation in

foundations by others

Interface issues

ElecTEC 10 11 June 2010 5

Steady Increase in size of machine over the last 8 Years:

WTG Increase 850 kW to 3 MW

Rotor Diameter 52 m to 90 m

Hub Height 50 m to 90 m

Loads Increase from 20,000 kNm to 90,000 kNm

ElecTEC 10 11 June 2010 6

ElecTEC 10 11 June 2010 7

TOWER

FOUNDATION

Voids

Voids

ElecTEC 10 11 June 2010 8

ElecTEC 10 11 June 2010 9

Foundation Problems the Causes

Generally at the mechanical/civil interface i.e CAN

Design

fatigue of concrete

7,000,000 cycles/Year;

Typical Bridge 500,000 cycles/Year

poor detailing congested rebar difficult to compact concrete

Quality Control - Long pours c 500 m3 concrete over 9 hours often

starting at 5 am

ElecTEC 10 11 June 2010 10

Foundation Problems and Solutions

Poor Detailing/Quality Control

Design of two stage Concrete pour foundation

Reduced congestion of rebar

Reduced time for concrete pour around CAN (9 hrs to 3 hrs)

fatigue in concrete

Eurocode 2 Structural Design

Quality Control - Training of onsite construction workforce

ElecTEC 10 11 June 2010 11

Design Standards/Documents

Guidelines for the Certification of Wind Turbines - GL Renewables

Certification Guidelines, 2003;

Wind Turbine Foundation Behaviour and Design Considerations -

Morgan, Ntambakwa, - Garrad Hassen, AWEA 2008;

Design of concrete structures - BS EN 1992-1-1:2004 Eurocode 2:

Wind Turbines Part 1: Design Requirements - BS EN 61400-1:2005

Load/Technical Specification WTG Supplier

ElecTEC 10 11 June 2010 12

Design Information Loads

Load factors vary from 0.9 (favourable) to 1.5 (unfavourable)

Wind loads

Permanent loads

Extreme loads

Fatigue loads

Foundation/Soil Interface

Rotational Stiffness Rotating Spring rate

Bearing pressure

Dynamic analysis - eigenfrequency

ElecTEC 10 11 June 2010 13

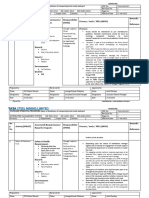

Picture Area

One Stage Pour -

Can Placed in Bottom Concrete

Workmanship and Detailing Problems

Very Congested Rebar

Quality control Difficult (9 hour pour)

One Stage Pour -

Can Placed in Pedestal Pour

Less congestion of Rebar

Better Quality Control (3 hour pour)

ElecTEC 10 11 June 2010 14

ElecTEC 10 11 June 2010 15

ElecTEC 10 11 June 2010 16

Solutions - Keeping up with new

Developments

Attendance at industry forums (European/UK/Ireland)

Contact with other developers/designers/contractors

Attendance at WTG Supplier information forums

ElecTEC 10 11 June 2010 17

New Problems

2.5MW+ WTG

Known foundation problems

Various site in Ireland/UK/Europe

Design issues EC2

Fatigue design to EC2

Load transfer from CAN to concrete

Are there other problems in the industry we dont know about?

CAN or bolts Which is better?

ElecTEC 10 11 June 2010 18

Going forward

Properly designed and detailed HD bolts

Finite Element Analysis And Design for fatigue

Dynamic analysis of Ground, Foundation and Tower

Details to reflect design assumptions

Control of quality on site essential

User Friendly Two Pours, Space for compaction

Vous aimerez peut-être aussi

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Ncma Tek 2008Document4 pagesNcma Tek 2008azizahnur381Pas encore d'évaluation

- Metallic Materials - Selected Standards: ManualDocument102 pagesMetallic Materials - Selected Standards: ManualThiruppathirajanPas encore d'évaluation

- A Guide to Ship Repair Estimates in Man-hoursD'EverandA Guide to Ship Repair Estimates in Man-hoursÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Cement Factory Design CriteriaDocument13 pagesCement Factory Design CriteriaUzair Maqbool Khan100% (2)

- Pipelines - M. AmeriniDocument150 pagesPipelines - M. Amerinihenry ardiyanto50% (2)

- Substation Construction MethodologyDocument23 pagesSubstation Construction Methodologyhusktech67% (15)

- LNG Import Terminal Cost and Schedule BasicsDocument23 pagesLNG Import Terminal Cost and Schedule Basicsjomafeba100% (3)

- Bendix Airbrake General CatalogueDocument132 pagesBendix Airbrake General CatalogueKOKPas encore d'évaluation

- Welding Personal Protection and Safety Equipment: Expert GuideDocument15 pagesWelding Personal Protection and Safety Equipment: Expert GuidedokundotPas encore d'évaluation

- Pipeline Installation, Manufacturing, Welding and NDTDocument102 pagesPipeline Installation, Manufacturing, Welding and NDTIfenna Obele100% (4)

- Structural DetailDocument13 pagesStructural DetailSyedAbdulSafi100% (1)

- Primavera Manual PDFDocument445 pagesPrimavera Manual PDFsajeevPas encore d'évaluation

- Design of Pad Foundations According To EC2Document84 pagesDesign of Pad Foundations According To EC2Chuksbozment78% (9)

- A State-of-the-Art Guide for Post-Installed ReinforcementD'EverandA State-of-the-Art Guide for Post-Installed ReinforcementPas encore d'évaluation

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesD'EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesÉvaluation : 4.5 sur 5 étoiles4.5/5 (16)

- CIVL4150 Engineer Practice Unit Resource Project - Aurecon: University of Western AustraliaDocument8 pagesCIVL4150 Engineer Practice Unit Resource Project - Aurecon: University of Western AustraliaKreen132Pas encore d'évaluation

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeD'EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticePas encore d'évaluation

- 4 Standards and Preliminary Design of Bridges 23Document26 pages4 Standards and Preliminary Design of Bridges 23Praveen BhandariPas encore d'évaluation

- Global Partner Program - Training and Certification - Learning Path OptionsDocument51 pagesGlobal Partner Program - Training and Certification - Learning Path OptionsFabioPas encore d'évaluation

- ERP RevlonDocument21 pagesERP RevlonZerin BariPas encore d'évaluation

- FC-WCJ-18016-CSW6ST101-001 Cal - PDFDocument205 pagesFC-WCJ-18016-CSW6ST101-001 Cal - PDFSaravanan SKPas encore d'évaluation

- Construction of Telicom Towers Quality and Productivity ImprovementDocument49 pagesConstruction of Telicom Towers Quality and Productivity ImprovementPrabhakara BychappaPas encore d'évaluation

- Endo MetricsDocument36 pagesEndo MetricsBogdan Constantin-BabiiPas encore d'évaluation

- Technical Standards Training Nov01Document83 pagesTechnical Standards Training Nov01Monish KrishnaPas encore d'évaluation

- Monthly Report-21-December To 20-January 20 11Document46 pagesMonthly Report-21-December To 20-January 20 11ringlove97Pas encore d'évaluation

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringD'EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringÉvaluation : 4 sur 5 étoiles4/5 (5)

- Introduction To Eurocodes 3Document30 pagesIntroduction To Eurocodes 3Halina HamidPas encore d'évaluation

- 3 Overhead Line and Substation Construction MethodologyDocument34 pages3 Overhead Line and Substation Construction MethodologyNurul Islam Faruk100% (4)

- IEC61400 1 2005 GL ExperienceDocument24 pagesIEC61400 1 2005 GL ExperienceSunli Karla Sivincha Romero100% (1)

- Abutment Design To BD 30 and en 1997Document109 pagesAbutment Design To BD 30 and en 1997Premanand Shenoy100% (1)

- SPATA Intro To Eurocode 2 Part 3 Tanks 4 Oct 2012Document14 pagesSPATA Intro To Eurocode 2 Part 3 Tanks 4 Oct 2012Cristian BarbulescuPas encore d'évaluation

- Module Lifting Supervisor (BI)Document170 pagesModule Lifting Supervisor (BI)shahrul azharPas encore d'évaluation

- Design Standards For Box CulvertsDocument4 pagesDesign Standards For Box CulvertsCT0011Pas encore d'évaluation

- Bca Design Standards For Box CulvertsDocument3 pagesBca Design Standards For Box CulvertsNguyễn Văn BanPas encore d'évaluation

- Poduri Structuri Compozite - EC3, EC4Document191 pagesPoduri Structuri Compozite - EC3, EC4florincinciPas encore d'évaluation

- Cad & Bim:: Is There A Free Pass? A Report On Graphisoft Archicad'S DWG WorkflowDocument32 pagesCad & Bim:: Is There A Free Pass? A Report On Graphisoft Archicad'S DWG WorkflowAndreia RocaPas encore d'évaluation

- Fleet Parts StorekeeperDocument2 pagesFleet Parts StorekeeperBright Edward NasamuPas encore d'évaluation

- Self-Compacting Concrete GuidelinesDocument68 pagesSelf-Compacting Concrete GuidelinesJim Jackofalltrades Heffernan100% (1)

- CEE+3348+8+ +Lesson+Eight+ +Term+Project+OverviewDocument12 pagesCEE+3348+8+ +Lesson+Eight+ +Term+Project+OverviewChachi CPas encore d'évaluation

- Fabricacion Tanques A PresionDocument22 pagesFabricacion Tanques A PresionJhonny AlvarezPas encore d'évaluation

- 1 Introduction To EurocodesDocument27 pages1 Introduction To EurocodesSuhaidi AliasPas encore d'évaluation

- BST PresentationDocument11 pagesBST PresentationBurhanPas encore d'évaluation

- SPATA Intro To Eurocode 2 4 Oct 2012Document14 pagesSPATA Intro To Eurocode 2 4 Oct 2012izyannn8950Pas encore d'évaluation

- ABC by 2010: How Have We Done?Document21 pagesABC by 2010: How Have We Done?Percy Arana PumaPas encore d'évaluation

- A5 - Martin Sigrist & Chris Wilson - Project Engineering A Major Electrification ProjectDocument35 pagesA5 - Martin Sigrist & Chris Wilson - Project Engineering A Major Electrification Projectbasel baransiPas encore d'évaluation

- Griders HarshalDocument6 pagesGriders HarshalPrince GorePas encore d'évaluation

- Prestressed Concrete PolesDocument4 pagesPrestressed Concrete Polesabajifar2004Pas encore d'évaluation

- MSY Lecture1 - Introduction To ECDocument46 pagesMSY Lecture1 - Introduction To ECMohamad Salleh YassinPas encore d'évaluation

- Name Forename Date Place of Birth Family Situation: Married (One Child in Charge)Document6 pagesName Forename Date Place of Birth Family Situation: Married (One Child in Charge)MOKRANIPas encore d'évaluation

- Tilt Up Concrete Construction To Prefabricated Concrete Elements The Changes To AS3850 With NotesDocument47 pagesTilt Up Concrete Construction To Prefabricated Concrete Elements The Changes To AS3850 With NotesMuhammad SafdarPas encore d'évaluation

- MME501 Tutorial Topic1 v1.2Document49 pagesMME501 Tutorial Topic1 v1.2Zain KhanPas encore d'évaluation

- GopiDocument8 pagesGopirfvz6sPas encore d'évaluation

- 0 Ali - Amjid@ymail - Com CV AmjidAli - 00Document3 pages0 Ali - Amjid@ymail - Com CV AmjidAli - 00Amjid AliPas encore d'évaluation

- Lectures 1Document23 pagesLectures 1sunder kumawatPas encore d'évaluation

- 0061 BSC Bridges and Related Structures - 00 PDFDocument5 pages0061 BSC Bridges and Related Structures - 00 PDFInês FerrazPas encore d'évaluation

- CV-Harsha D (Structural Engg - CEng)Document6 pagesCV-Harsha D (Structural Engg - CEng)Samantha HartPas encore d'évaluation

- CV ExampleDocument16 pagesCV ExampleNagaraju SeelamPas encore d'évaluation

- Chapter 10 Foundations and Equipment PadsDocument30 pagesChapter 10 Foundations and Equipment PadsNyan LinPas encore d'évaluation

- Eurocodes TurkeyDocument23 pagesEurocodes TurkeyjadrichemPas encore d'évaluation

- Abhi SeminarDocument15 pagesAbhi SeminarAbhimanyu Khardia100% (1)

- PP - FP - 2004 - 008 - Eng - 02-EURO RESEARCH IMPROV FATIGA RESISTANCEDocument23 pagesPP - FP - 2004 - 008 - Eng - 02-EURO RESEARCH IMPROV FATIGA RESISTANCEJean PierrePas encore d'évaluation

- Đuro ĐakovićDocument16 pagesĐuro Đakovićclaude.bouillot3566Pas encore d'évaluation

- ECEPP SI - 08a Qualification Forms PER-2Document20 pagesECEPP SI - 08a Qualification Forms PER-2woopPas encore d'évaluation

- Latest Development in Concrete Code 2004 (Oct 2011)Document38 pagesLatest Development in Concrete Code 2004 (Oct 2011)Zhe ZhaoPas encore d'évaluation

- CV Rachid BEN AISSA - English 2019Document10 pagesCV Rachid BEN AISSA - English 2019Mohammed H SaeedPas encore d'évaluation

- Final Exam August 16, 2014Document9 pagesFinal Exam August 16, 2014mulkeab11Pas encore d'évaluation

- Steel Structures Design Based on Eurocode 3D'EverandSteel Structures Design Based on Eurocode 3Évaluation : 3 sur 5 étoiles3/5 (1)

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresD'EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresPas encore d'évaluation

- X M8H Data Sheet PDFDocument6 pagesX M8H Data Sheet PDFBogdan Constantin-BabiiPas encore d'évaluation

- Analysis and Design of A Continuous Reinforced Concrete Raker Beam For Stad PDFDocument13 pagesAnalysis and Design of A Continuous Reinforced Concrete Raker Beam For Stad PDFBogdan Constantin-BabiiPas encore d'évaluation

- Direct Analysis Method WhitepaperDocument9 pagesDirect Analysis Method WhitepaperBogdan Constantin-BabiiPas encore d'évaluation

- Carte LemnDocument104 pagesCarte LemnBogdan Constantin-BabiiPas encore d'évaluation

- (12020ZSt1 - R1en) 1st Revision - Summary of Static Calculation - 3Document3 pages(12020ZSt1 - R1en) 1st Revision - Summary of Static Calculation - 3Bogdan Constantin-BabiiPas encore d'évaluation

- Faza / Phase: PTH: Armare Pilot Pile ReinforcementDocument1 pageFaza / Phase: PTH: Armare Pilot Pile ReinforcementBogdan Constantin-BabiiPas encore d'évaluation

- Sil SystemDocument3 pagesSil SystemBogdan Constantin-BabiiPas encore d'évaluation

- Technical Manual - Alligator CouplersDocument10 pagesTechnical Manual - Alligator CouplersBogdan Constantin-BabiiPas encore d'évaluation

- Cario 7Document9 pagesCario 7Bogdan Constantin-BabiiPas encore d'évaluation

- Lect 6Document12 pagesLect 6Bogdan Constantin-BabiiPas encore d'évaluation

- Crane DictionaryDocument15 pagesCrane DictionarySandeep SolankiPas encore d'évaluation

- CNC Lathe Machine Technician and ProgrammerDocument16 pagesCNC Lathe Machine Technician and ProgrammermanjuPas encore d'évaluation

- Summary Sheet For VariationDocument6 pagesSummary Sheet For VariationKaran KumarPas encore d'évaluation

- Drain Tech Valve Box SizesDocument5 pagesDrain Tech Valve Box SizesbltzkrigPas encore d'évaluation

- Course Outline - Fall 2022 Advanced Manufacturing ProcessesDocument5 pagesCourse Outline - Fall 2022 Advanced Manufacturing ProcessesAbuzar AliPas encore d'évaluation

- 1-GNZS594 Shale Shaker and Mud CleanerDocument6 pages1-GNZS594 Shale Shaker and Mud CleanerGeorgePas encore d'évaluation

- Furniture Making WAEC/SSCEDocument5 pagesFurniture Making WAEC/SSCEIfiokobong AkpanPas encore d'évaluation

- Shopping Cart Report PDFDocument15 pagesShopping Cart Report PDFapi-367155741Pas encore d'évaluation

- Ba Ecotron GBDocument52 pagesBa Ecotron GBdj_nerminPas encore d'évaluation

- D1, L9 Solving Linear Programming ProblemsDocument16 pagesD1, L9 Solving Linear Programming ProblemsmokhtarppgPas encore d'évaluation

- Unit 6 PDFDocument32 pagesUnit 6 PDFFany Zanuar Rachmadi100% (1)

- ATMS MDCBP Method Statement For Masonry Works CHB Laying Plastering TB OnlyDocument8 pagesATMS MDCBP Method Statement For Masonry Works CHB Laying Plastering TB OnlycuanicochorielynjuviPas encore d'évaluation

- Mini SSR 2023-24Document66 pagesMini SSR 2023-24kadapaPas encore d'évaluation

- SOP For Breakdown of Vehicle - 17. Rev-2Document3 pagesSOP For Breakdown of Vehicle - 17. Rev-2syed aquibPas encore d'évaluation

- Quality Assurance in Textile EducationDocument7 pagesQuality Assurance in Textile Educationandrei_bertea7771Pas encore d'évaluation

- Automating A Purchase Requisition Process With BPMDocument2 pagesAutomating A Purchase Requisition Process With BPMakashvarmaPas encore d'évaluation

- Rubberdam YOOIL BrochureDocument10 pagesRubberdam YOOIL BrochureAbhishek RajputPas encore d'évaluation

- Pany ProfileDocument31 pagesPany ProfilehungletePas encore d'évaluation

- DeadlockansDocument11 pagesDeadlockansshini s gPas encore d'évaluation

- Siemens RD in China Final enDocument9 pagesSiemens RD in China Final enKarol MisztalPas encore d'évaluation