Académique Documents

Professionnel Documents

Culture Documents

Science 2014 Rausch 1326 30

Transféré par

overlordalexTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Science 2014 Rausch 1326 30

Transféré par

overlordalexDroits d'auteur :

Formats disponibles

DOI: 10.1126/science.

1257443

, 1326 (2014); 345 Science

et al. Benjamin Rausch

redox mediator in water splitting

Decoupled catalytic hydrogen evolution from a molecular metal oxide

This copy is for your personal, non-commercial use only.

clicking here. colleagues, clients, or customers by

, you can order high-quality copies for your If you wish to distribute this article to others

here. following the guidelines

can be obtained by Permission to republish or repurpose articles or portions of articles

): September 11, 2014 www.sciencemag.org (this information is current as of

The following resources related to this article are available online at

http://www.sciencemag.org/content/345/6202/1326.full.html

version of this article at:

including high-resolution figures, can be found in the online Updated information and services,

http://www.sciencemag.org/content/suppl/2014/09/11/345.6202.1326.DC1.html

can be found at: Supporting Online Material

http://www.sciencemag.org/content/345/6202/1326.full.html#ref-list-1

, 7 of which can be accessed free: cites 38 articles This article

http://www.sciencemag.org/cgi/collection/chemistry

Chemistry

subject collections: This article appears in the following

registered trademark of AAAS.

is a Science 2014 by the American Association for the Advancement of Science; all rights reserved. The title

Copyright American Association for the Advancement of Science, 1200 New York Avenue NW, Washington, DC 20005.

(print ISSN 0036-8075; online ISSN 1095-9203) is published weekly, except the last week in December, by the Science

o

n

S

e

p

t

e

m

b

e

r

1

2

,

2

0

1

4

w

w

w

.

s

c

i

e

n

c

e

m

a

g

.

o

r

g

D

o

w

n

l

o

a

d

e

d

f

r

o

m

o

n

S

e

p

t

e

m

b

e

r

1

2

,

2

0

1

4

w

w

w

.

s

c

i

e

n

c

e

m

a

g

.

o

r

g

D

o

w

n

l

o

a

d

e

d

f

r

o

m

o

n

S

e

p

t

e

m

b

e

r

1

2

,

2

0

1

4

w

w

w

.

s

c

i

e

n

c

e

m

a

g

.

o

r

g

D

o

w

n

l

o

a

d

e

d

f

r

o

m

o

n

S

e

p

t

e

m

b

e

r

1

2

,

2

0

1

4

w

w

w

.

s

c

i

e

n

c

e

m

a

g

.

o

r

g

D

o

w

n

l

o

a

d

e

d

f

r

o

m

o

n

S

e

p

t

e

m

b

e

r

1

2

,

2

0

1

4

w

w

w

.

s

c

i

e

n

c

e

m

a

g

.

o

r

g

D

o

w

n

l

o

a

d

e

d

f

r

o

m

o

n

S

e

p

t

e

m

b

e

r

1

2

,

2

0

1

4

w

w

w

.

s

c

i

e

n

c

e

m

a

g

.

o

r

g

D

o

w

n

l

o

a

d

e

d

f

r

o

m

(20). In a hollow lattice, the nodes are constrained

only by the shell walls, which has a detrimental

effect on strength and stiffness because load trans-

fer at the nodes occurs via shell wall bending. This,

together with the sharp angles between the tubes,

leads to an uneven distribution of stress and

induces large stress concentrations in the vicin-

ity of the nodes (Fig. 1, B and E). Bending of the

tubes also causes large deflections and addi-

tional ovalization at the nodes, which further

increases the compliance and stress concentra-

tions. In situ experiments and postcompression

analysis revealed that most of the deformation

is localized to the nodes (Figs. 2, Dand E, and 3J),

which implies that improving nodal strength is a

critical factor in enhancing the scaling of strength

and stiffness with density.

We demonstrated the creation of ultralight

hollow ceramic nanolattices that absorb energy,

recover after significant compression, and reach

an untapped strength and stiffness material prop-

erty space. This is achieved using high-strength

ALDalumina engineered into a thin-walled nano-

lattice that is capable of deforming elastically via

shell buckling. The ultralight ceramic nanolattices

represent the concept of materials by design, where

it is possible totransforma stronganddense brittle

ceramic into a strong, ultralight, energy-absorbing,

and recoverable metamaterial. These results

serve to emphasize the critical connectionbetween

material microstructure, hierarchical architecture,

and mechanical properties at relevant length

scales.

REFERENCES AND NOTES

1. D. Jang, L. R. Meza, F. Greer, J. R. Greer, Nat. Mater. 12,

893898 (2013).

2. J. R. Greer, J. T. M. De Hosson, Prog. Mater. Sci. 56, 654724

(2011).

3. X. W. Gu, Z. Wu, Y.-W. Zhang, D. J. Srolovitz, J. R. Greer, Nano

Lett. 13, 57035709 (2013).

4. D. Z. Chen et al., Nano Lett. 13, 44624468 (2013).

5. J. Rys et al., Adv. Eng. Mater. 16, 889896 (2014).

6. L. R. Meza, J. R. Greer, J. Mater. Sci. 49, 24962508 (2014).

7. X. Zheng et al., Science 344, 13731377 (2014).

8. J. Bauer, S. Hengsbach, I. Tesari, R. Schwaiger, O. Kraft,

Proc. Natl. Acad. Sci. U.S.A. 111, 24532458 (2014).

9. A. G. Evans, J. Am. Ceram. Soc. 73, 187206 (1990).

10. I.-W. Chen, L. A. Xue, J. Am. Ceram. Soc. 73, 25852609

(1990).

11. P. F. Becher, J. Am. Ceram. Soc. 74, 255269 (1991).

12. D. C. Hofmann et al., Nature 451, 10851089 (2008).

13. E. Munch et al., Science 322, 15161520 (2008).

14. J. C. Weaver et al., J. Struct. Biol. 158, 93106 (2007).

15. C. E. Hamm et al., Nature 421, 841843 (2003).

16. M. A. Meyers, J. McKittrick, P.-Y. Chen, Science 339, 773779

(2013).

17. L. J. Gibson, M. F. Ashby, Cellular Solids: Structure and

Properties (Cambridge Univ. Press, Cambridge, ed. 2, 1999).

18. V. S. Deshpande, M. F. Ashby, N. A. Fleck, Acta Mater. 49,

10351040 (2001).

19. S. Pellegrino, C. R. Calladine, Int. J. Solids Struct. 22, 409428

(1986).

20. V. S. Deshpande, N. A. Fleck, M. F. Ashby, J. Mech. Phys. Solids

49, 17471769 (2001).

21. T. A. Schaedler et al., Science 334, 962965 (2011).

22. L. C. Montemayor, L. R. Meza, J. R. Greer, Adv. Eng. Mater. 16,

184189 (2014).

23. See the supplementary materials.

24. M. D. Groner, F. H. Fabreguette, J. W. Elam, S. M. George,

Chem. Mater. 16, 639645 (2004).

25. Y. K. Akimov, Instrum. Exp. Tech. 46, 287299 (2003).

26. L. Valdevit, A. J. Jacobsen, J. R. Greer, W. B. Carter, J. Am.

Ceram. Soc. 94, s15s34 (2011).

27. M. Berdova et al., Acta Mater. 66, 370377 (2014).

28. H. G. Allen, P. S. Bulson, Background to Buckling (McGraw-Hill,

Berkshire, UK, 1980).

29. G. Ju, S. Kyriakides, Int. J. Solids Struct. 29, 11431171

(1992).

30. A. Torrents, T. A. Schaedler, A. J. Jacobsen, W. B. Carter,

L. Valdevit, Acta Mater. 60, 35113523 (2012).

31. L. Valdevit, S. W. Godfrey, T. Schaedler, A. J. Jacobsen,

W. B. Carter, J. Mater. Res. 28, 24612473 (2013).

32. K. J. Maloney et al., APL Mater. 1, 022106 (2013).

ACKNOWLEDGMENTS

The authors gratefully acknowledge the financial support from the

Defense Advanced Research Projects Agency under the Materials

with Controlled Microstructure and Architecture program managed

by J. Goldwasser (contract no. W91CRB-10-0305) and to the Institute

for Collaborative Biotechnologies through grant W911NF-09-0001

from the U.S. Army Research Office. The content of the information

does not necessarily reflect the position or the policy of the

government, and no official endorsement should be inferred. The

authors are grateful to the Kavli Nanoscience Institute at Caltech

for the availability of critical cleanroom facilities, and to R. Liontas

and C. Garland for TEM assistance. Part of this work was carried

out in the Lewis Group facilities at Caltech.

SUPPLEMENTARY MATERIALS

www.sciencemag.org/content/345/6202/1322/suppl/DC1

Materials and Methods

Figs. S1 to S6

Table S1

Reference (33)

Movies S1 to S3

12 May 2014; accepted 11 August 2014

10.1126/science.1255908

WATER SPLITTING

Decoupled catalytic hydrogen evolution

from a molecular metal oxide redox

mediator in water splitting

Benjamin Rausch, Mark D. Symes, Greig Chisholm, Leroy Cronin*

The electrolysis of water using renewable energy inputs is being actively pursued as a

route to sustainable hydrogen production. Here we introduce a recyclable redox mediator

(silicotungstic acid) that enables the coupling of low-pressure production of oxygen

via water oxidation to a separate, catalytic hydrogen production step outside the

electrolyzer that requires no post-electrolysis energy input. This approach sidesteps the

production of high-pressure gases inside the electrolytic cell (a major cause of membrane

degradation) and essentially eliminates the hazardous issue of product gas crossover at

the low current densities that characterize renewables-driven water-splitting devices. We

demonstrated that a platinum-catalyzed system can produce pure hydrogen over 30

times faster than state-of-the-art proton exchange membrane electrolyzers at equivalent

platinum loading.

H

ydrogen is vital for the production of com-

modity chemicals such as ammonia and

has great potential as a clean-burning fuel

(1, 2). However, currently around 95%

(~15 trillion mol year

1

) of the worlds sup-

ply of H

2

is obtained by reforming fossil fuels (3),

a process that is both unsustainable and leads to

a net increase in atmospheric CO

2

levels. Of the

alternative methods for H

2

production that are

not linked to fossil resources, the electrolysis of

water stands out as a mature, scalable technol-

ogy for which the only required inputs are water

and energy (in the formof electricity) (4). Hence,

if the energy source is renewable, H

2

can be

produced sustainably from water using electrol-

ysis (5, 6).

Renewable energy inputs tend to be sporadic

and fluctuating, and thus the systems that are

developed to harness this energy and convert it

to H

2

[such as proton exchange membrane elec-

trolyzers (PEMEs) (7), solar-to-fuels systems (8),

and artificial leaves (9)] must be able to deal with

varying energy inputs effectively and have rapid

startup times. At the low power loads that are

characteristic of renewable power sources, the

rate at which H

2

and O

2

are produced may in

fact be slower than the rate at which these gases

permeate the membrane (10). At the very least,

this will severely affect the amount of hydrogen

that can be harvested fromsuch devices (11), and

in extreme cases could give rise to hazardous

O

2

/H

2

mixtures. The PEME is the most mature

technology citedfor renewables-to-hydrogencon-

version, but prevention of such gas crossover at

lowcurrent densities remains a challenge. PEMEs

use nontrivial amounts of precious metal catalysts

and so tend to operate at high current densities

(1 A cm

2

or above) and high pressure, where the

cost of their components can be offset to some

extent (7). However, these optimal conditions may

be hard to maintain in all cases of renewables-

driven electrolysis (for example, in small-scale

facilities), where less-expensive and lower-power

devices would therefore be beneficial. Meanwhile,

the high-pressure and high-current-density condi-

tions under which PEMEs work most effectively

are also not without drawbacks: These condi-

tions can also lead to gas crossover through the

membrane, and the coexistence of H

2

, O

2

and

catalyst particles produces reactive oxygen species

1326 12 SEPTEMBER 2014 VOL 345 ISSUE 6202 sciencemag.org SCIENCE

RESEARCH | REPORTS

WestCHEM, School of Chemistry, University of Glasgow,

University Avenue, Glasgow G12 8QQ, UK.

*Corresponding author. E-mail: lee.cronin@glasgow.ac.uk

(ROS) that degrade the membrane and shortenits

lifetime (12, 13). There is thus a need to develop

newelectrolyzer systems that canprevent product

gases from mixing over a range of current den-

sities and that make more effective use of the

precious metal catalysts they employ, in order to

make renewables-to-hydrogenconversionbothprac-

tically and economically more attractive.

Previously, we introduced the concept of the

electron-coupled proton buffer (ECPB), which

can act to decouple electrolytic H

2

and O

2

pro-

duction, producing these gases at separate times

(14, 15). Here we describe a redox mediator that

can be reversibly reduced in an electrolytic cell

(as water is oxidized at the anode) and then

transferred to a separate chamber for sponta-

neous catalytic H

2

evolution, without the need

for additional energy input after reduction of the

mediator (Fig. 1). This approach leads to a device

architecture for electrolyzers that has several im-

portant advantages. First, it allows the electro-

chemical step to be performed at atmospheric

pressure, while potentially permitting H

2

to be

evolved at elevated pressure in a distinct com-

partment. Second, virtually no H

2

is produced in

the electrolytic cell itself, which (taken with the

feature above) obviates the need to purge H

2

from the anode side of the cell and could signif-

icantly reduce ROS-mediated membrane degra-

dationandthe possibility of explosive gas mixtures

forming at low current densities or upon mem-

brane failure. Third, H

2

evolution from such a

systemis no longer directly coupled to the rate of

water oxidation, and thus the decoupled H

2

pro-

duction step can be performed a rate per milli-

gram of catalyst that is over 30 times faster than

that for state-of-the-art PEMEs (movie S1). Finally,

the hydrogen produced has the potential to have

an inherently low O

2

content, both on account of

its production in a separate chamber from water

oxidation and by virtue of the fact that the re-

duced mediator reacts rapidly with O

2

in solution.

This final point could render the H

2

produced

suitable for applications requiring high-purity H

2

such as fuel cells (16) or the Haber-Bosch process

(17), without the need for post-electrolysis purifi-

cation or built-in recombination catalysts.

The redox mediator investigated in this work

was silicotungstic acid (H

4

[SiW

12

O

40

]), the cyclic

voltammogram (CV) of which on a glassy car-

bon electrode in aqueous solution is shown in

Fig. 2A (black line). H

4

[SiW

12

O

40

] was chosen

for investigation on account of its high solubil-

ity in water (up to 0.5 M), in which solvent it is

a strong acid (18). H

4

[SiW

12

O

40

] has reversible

one-electron redox waves centered at +0.01 V

(wave I) and 0.22 V [wave II; all potentials are

versus the normal hydrogen electrode (NHE)],

the positions of which are critical to the follow-

ing discussion (18). Also shown in Fig. 2A are

reductive scans taken at a similar pH in the ab-

sence of H

4

[SiW

12

O

40

] on carbon and Pt electro-

des (red and green lines, respectively). Given

that the onset of H

2

evolution on Pt occurs at es-

sentially the same potential as the first reduc-

tion of H

4

[SiW

12

O

40

], but that H

2

evolution on

carbon is not appreciable above 0.6 V, we hy-

pothesized that the reduction of H

4

[SiW

12

O

40

]

at a carbon electrode at potentials slightly more

positive than 0.6 V would give the two-electron

reduced form (H

6

[SiW

12

O

40

]) without any com-

peting H

2

evolution. If H

6

[SiW

12

O

40

] were then

exposed to Pt, it should spontaneously evolve H

2

until equilibrium between H

2

and the reduced

mediator was reached, whichFig. 2Asuggests will

correspond to a mixture of H

4

[SiW

12

O

40

] and the

one-electron reduced form, H

5

[SiW

12

O

40

].

To test this hypothesis, an airtight electrolysis

cell was constructed with a Pt mesh or carbon

felt anode (for water oxidation) and a carbon felt

cathode (for H

4

[SiW

12

O

40

] reduction), as shown

in fig. S1. Reduction of the mediator and conco-

mitant water oxidation were performed, and the

composition of the gases in the separated head-

spaces was monitored by gas chromatographic

headspace analysis (GCHA). Full faradaic effi-

ciency for O

2

evolution could be observed (using

SCIENCE sciencemag.org 12 SEPTEMBER 2014 VOL 345 ISSUE 6202 1327

RESEARCH | REPORTS

Fig. 1. A schematic of silicotungstic acidmediated H

2

evolution from water. At the anode, H

2

O

is split into O

2

, protons, and electrons, while the mediator is reversibly reduced and protonated at the

cathode in preference to direct production of H

2

. The reduced H

6

[SiW

12

O

40

] (dark blue) is then

transferred to a separate chamber for H

2

evolution over a suitable catalyst and without additional energy

input after two-electron reduction of the mediator to H

6

[SiW

12

O

40

].

Fig. 2. Performance of silicotungstic acid as an electrochemical mediator for water splitting.

(A) Reductive CVs under Ar and at room temperature: black, H

4

[SiW

12

O

40

] in water (0.5 M, pH 0.5), at a

glassy carbon working electrode (area = 0.071 cm

2

); red, 1 M H

3

PO

4

(pH = 1.0) on a glassy carbon

working electrode; green, 1 M H

3

PO

4

(pH = 1.0) on a Pt disc working electrode (area = 0.031 cm

2

). A Pt-

mesh counterelectrode and Ag/AgCl reference electrode were used at a scan rate of 0.1 V s

1

. (B)

Comparison of the rate of H

2

production possible using electrolysis mediated by silicotungstic acid

(this work) and a selection of state-of-the-art electrolyzers from recent years. Square symbols

indicate data obtained for a mediated system in this paper. Red data (left-hand y axis): the rate of H

2

production per milligram of Pt. Blue data (right-hand y axis): the absolute rate of H

2

production

determined for H

2

production from H

6

[SiW

12

O

40

] (this work, squares) and the various literature

electrolyzer systems. Dashed lines are provided solely as guides to the eye. Code for literature data is as

follows: pentagons, reference (30); stars, reference (26); triangles, reference (31); dots, reference (32).

This comparison does not include the time taken to reduce the mediator to H

6

[SiW

12

O

40

]. For more

details on how these metrics were obtained, see table S1.

Pt anodes), whereas complete two-electron re-

duction of the mediator could be achieved with

only trace H

2

being evolved [see supplemen-

tary materials (SM) section SI-4 and figs. S2 and

S3]. This two-electron reduced H

6

[SiW

12

O

40

]

could then be stored without significant spon-

taneous H

2

evolution (<0.002%loss of H

2

per hour;

fig. S3). Taken together, these data suggest that

O

2

evolution and H

2

evolution can be effectively

decoupled from each other using H

4

[SiW

12

O

40

],

potentially allowing the O

2

produced during

electrolysis to be vented to the atmosphere with-

out the need for additional H

2

removal pro-

cesses (19).

The two-electron reduced mediator could then

be removed from the electrolysis cell and intro-

duced into sealed reaction flasks under an atmo-

sphere of Ar. The addition of various metal foils

to this solution catalyzed H

2

evolution, with Pt

exhibiting the best performance (SM section SI-5

and fig. S4A). Powdered samples of MoS

2

(20, 21)

and Ni

2

P (22) were also found to be effective cat-

alysts for H

2

evolution from H

6

[SiW

12

O

40

] (fig.

S4B). However, by far the greatest rate of H

2

evolution was found when using precious metal

catalysts supported on carbon. Figure 2B shows

that per milligram of Pt used, the rate of H

2

production from H

6

[SiW

12

O

40

] exceeds the rate

of H

2

evolution possible using a state-of-the-art

PEME by a factor of 30 (red data). This more

effective use of the precious metal H

2

evolution

catalyst could be a result of the better disper-

sion of catalyst that is possible when it is not

confined to an electrode.

The kinetics of H

2

evolution from solutions of

H

6

[SiW

12

O

40

] as a function of time and catalyst

are examined in Fig. 3A. Based on the volume of

mediator solution used in these experiments, full

conversion of two-electron reduced H

6

[SiW

12

O

40

]

to one-electron reduced H

5

[SiW

12

O

40

] would be

expected to liberate 122.4 ml of H

2

, whereas com-

plete reversion to H

4

[SiW

12

O

40

] would release

244.7 ml of H

2

(SM section SI-6). In practice,

somewhat more than 122.4 ml of H

2

were liber-

ated in under 30 min with all the catalysts ex-

amined in Fig. 3A, suggesting complete and rapid

transformation of H

6

[SiW

12

O

40

] to H

5

[SiW

12

O

40

],

followed by limited further conversion (10 to

36%) of H

5

[SiW

12

O

40

] to H

4

[SiW

12

O

40

] under these

conditions.

Initial rates were then extrapolated to rates of

H

2

produced per milligramof precious metal per

hour (Table 1 and table S2), giving a maximum

rate of 2861 mmol of H

2

mg

1

hour

1

when using

low loadings of Pt/C. The rate of H

2

evolution

decays from the initial value in Fig. 3B on ac-

count of the process H

6

[SiW

12

O

40

] H

5

[SiW

12

O

40

]

being 80% complete within 30 s for all the Pt/C

loadings shown. Hence, in a continuous flow

system, it should be possible to achieve rates very

similar to the initial rate measured here for as

long as the flowof H

6

[SiW

12

O

40

] is maintained(the

mediator could then be recycled to the cathode

for recharging). Table 1 compares the rate of H

2

production by the mediator-based system with

that achieved by a selection of state-of-the-art

PEMEs from the recent literature (a more ex-

tensive comparison can be found in table S1).

With PEMEs, the rate of H

2

production is nec-

essarily coupled to the rate of water oxidation

occurring at the anode. Ina mediated electrolysis

cell, the rates of water oxidation and mediator

reduction are coupled, but the rate of H

2

produc-

tion depends on the availability of the reduced

mediator. This allows a mediated systemto make

more effective use of the H

2

evolution catalyst,

as illustrated by Table 1. The time required to

reduce the mediator is not included in the

calculations for Table 1: Only the rate of H

2

production (and hence how long it would take

to obtain all the H

2

from the mediator for com-

pression and/or storage) is considered. Details

on mediator reduction can be found in the

1328 12 SEPTEMBER 2014 VOL 345 ISSUE 6202 sciencemag.org SCIENCE

RESEARCH | REPORTS

Fig. 3. Catalytic H

2

evolution from H

6

[SiW

12

O

40

] when in contact with various catalysts. (A) Rate

of H

2

production from a 20-ml sample of 0.5 M H

6

[SiW

12

O

40

] under an Ar atmosphere. (B) Magnification

of the first 2 min of the H

2

evolution process from H

6

[SiW

12

O

40

] in the presence of 50 mg Pt/C (5, 3,

and 1 weight %). Dashed lines indicate the derived initial rates. (C) A typical apparatus configuration for

determining volumes of H

2

evolved when H

6

[SiW

12

O

40

] was exposed to powdered catalysts. Reduced

mediator in the upper flask (blue circle in left-hand photograph) is allowed to flow into the lower chamber

containing catalyst (blue circle in middle photograph), and H

2

is rapidly evolved and collected (as

indicated by the red arrows). A movie showing rapid H

2

evolution (movie S1) and full experimental

details can be found in the supplementary materials (SM section SI-6).

Table 1. Comparison of the rate of H

2

production possible with silicotungstic acidmediated elec-

trolysis and a selection of leading PEMEs from the current literature. Literature values are based

on the highest rate of H

2

production reported in those works. A table with more examples and a full

description of how these metrics were calculated can be found in the supplementary materials.

H

2

evolution catalyst

Amount of

powder/size

of electrode

Total catalyst

used (mg)

H

2

production

rate (mmol

hour

1

mg

1

)

Reference

Pt/C (0.5 mg of Pt cm

2

) 9 100 cm

2

450 22 (33)

Pt/C (0.4 mg of Pt cm

2

) 5 cm

2

2 47 (26)

Pt/C (0.7 mg of Pt cm

2

) 7 cm

2

4.9 53 (31)

Pt/C (0.3 mg of Pt cm

2

) 20 cm

2

6 93 (32)

Pd/C 10% 50 mg 5 143 This work

Rh/C 5% 50 mg 2.5 241 This work

Pt/C 5% 50 mg 2.5 368 This work

Pt/C 3% 50 mg 1.5 423 This work

Pt/C 1% 50 mg 0.5 1275 This work

Pt/C 1% 25 mg 0.25 1336 This work

Pt/C 1% 10 mg 0.1 2861 This work

supplementary materials (SM sections SI-3

and SI-7).

Next, we examined the purity of the H

2

that

was produced by this silicotungstic acidmediated

method. GCHA indicated that the level of

electrolysis-derived O

2

in this H

2

was below de-

tectable limits (T0.08%; SM sections SI-4 and

SI-6). Moreover, if 10% O

2

were deliberately in-

troduced into the headspace of the vessel con-

taining H

6

[SiW

12

O

40

], this extraneous O

2

was

completely removed by reaction with H

6

[SiW

12

O

40

]

(% O

2

in the headspace was only 0.04% after

30 min), ultimately producing water and reoxi-

dized mediator (23) and further guaranteeing

that the H

2

evolved is O

2

-free (SM section SI-9

and fig. S9). This has obvious implications for

electrolyzer safety, because gaseous mixtures of

H

2

and O

2

on the cathode side are now pre-

cluded by the reduced mediators rapid reaction

with O

2

. This reaction is spontaneous and does

not require any precious metalbased recom-

bination catalysts such as those often employed

in PEMEs.

As noted earlier, a primary mode of degrada-

tion of the perfluorinated membranes used in

PEMEs is attack by ROS (12). These ROS form

in the presence of O

2

, H

2

, and precious metals (in-

cluding the catalytic recombination layers that are

designedtoprevent mixtures of O

2

andH

2

forming

in electrolysis product streams). Moreover, recom-

bination of H

2

and O

2

is an exothermic process

that causes local heating, damaging the membrane

through mechanical means; this route is especially

prevalent at Pt sites on the cathode (24, 25). The

use of a mediator can help to mitigate against

membrane degradation in three ways. First, the

amount of H

2

produced in the electrolyzer itself is

vastly diminished, removing the need to purify the

O

2

product stream and preventing ROS forma-

tion on the anode side of the cell. Second, on the

cathode side, the reduced mediator reacts rap-

idly with any O

2

present to produce water, and

any peroxy species that do formwill do so in bulk

solution far from the membrane and will them-

selves rapidly react with reduced mediator to

form water (23). Finally, the catalyst is now iso-

lated in a second chamber and is not in contact

with the membrane, lessening local heating

effects. Hence, using a mediator could potentially

allow increased lifetimes for the membranes

used in such electrolyzers relative to the life span

of similar membranes in PEMEs.

The efficiency of the electrochemical process

to produce O

2

fromwater and H

6

[SiW

12

O

40

] from

H

4

[SiW

12

O

40

] was calculated and compared to

equivalent systems that wouldproduce H

2

and O

2

directly by electrolysis (SM section SI-7 and fig.

S6). In comparison to a systemthat uses a carbon

cathode to reduce protons and a Pt anode to

oxidize water, the mediated systemwas 16%more

efficient, with an overall energy efficiency of 63%.

A standard electrolysis system for direct O

2

and

H

2

production from water, in which both electro-

des are Pt, was found to have an efficiency of 67%

[which agrees well with the efficiency of room-

temperature PEMEs reported in the literature

(26)]. Hence, given the potential for lower load-

ings of precious metal and high initial purity of

the product gases whenusingmediatedelectrolysis

(and other possible technoeconomic advantages;

SM section SI-12), we believe that such systems

will be competitive with PEMEs in terms of cost-

efficiency metrics.

The redox reactions of silicotungstic acid are

summarized in fig. S10A. Starting from fully re-

duced H

6

[SiW

12

O

40

], H

2

evolution in the pres-

ence of a catalyst such as Pt/C is rapid, leading

to the one-electron reduced species H

5

[SiW

12

O

40

].

This process can be reversed by electro-reducing

H

5

[SiW

12

O

40

] at a carbon cathode. Alterna-

tively, starting from the fully oxidized species

H

4

[SiW

12

O

40

], the one-electron reduced species

can be accessed either by electrochemical reduc-

tion or by reaction with H

2

in the presence of a

suitable catalyst such as Pt/C (SM section SI-8

and fig. S8). Likewise, if one-electron reduced

H

5

[SiW

12

O

40

] is placed in a sealed reaction vessel

under Ar in the presence of Pt/C, H

2

evolves

slowly into the headspace, as gauged by GCHA

(fig. S7). This behavior implies that there exists

an equilibriumbetween H

2

and H

4

[SiW

12

O

40

] on

one hand and the one-electron reduced mediator

(H

5

[SiW

12

O

40

]) on the other in the presence of

catalysts such as Pt/C.

Overall faradaic efficiencies for the roundtrip

process were gauged by fully reducing a sample

of H

4

[SiW

12

O

40

] to H

6

[SiW

12

O

40

] with coulometry.

Pt/C was then added to this H

6

[SiW

12

O

40

], and

H

2

was evolved. At the cessation of spontaneous

H

2

evolution, an amount of H

2

corresponding to

68% of the charge passed in reducing H

4

[SiW

12

O

40

]

to H

6

[SiW

12

O

40

] was obtained. In a cyclic system,

any one-electron reduced H

5

[SiW

12

O

40

] could sim-

ply be returned to the electrolyzer for re-reduction

to H

6

[SiW

12

O

40

]. However in this case, once H

2

evolution had ceased, the Pt/C catalyst was re-

moved by filtration under Ar, and the result-

ing Pt-free mediator solution was titrated with

an Fe(III) source in order to oxidize all remain-

ing H

5

[SiW

12

O

40

] to colorless H

4

[SiW

12

O

40

] and

thus ascertain the amount of H

5

[SiW

12

O

40

] still

present at the cessation of H

2

evolution (SM

section SI-10). This value, when combined with

the electrons already accounted for by the amount

of H

2

evolved, gave a faradaic yield in excess

of 98% for the roundtrip H

4

[SiW

12

O

40

]

H

6

[SiW

12

O

40

] H

4

[SiW

12

O

40

].

The stability of the mediator to several cycles

of oxidation and reduction was probed both elec-

trochemically (by comparing the charges passed

in oxidizing the reducing the mediator over a

series of cycles, SM section SI-13) and by com-

paring ultraviolet-visible spectra of fresh and

cycled samples and of reduced samples that were

reoxidized by exposure to air (SM section SI-14).

Figure S11A shows that 98% of the charge passed

in fully reducing the mediator by one electron

could be retrieved by reoxidation over nine full

one-electron reduction-oxidation cycles, with no

apparent degradation of the mediator. Figure

S11B shows the stability of the mediator to four

consecutive cycles of reduction to 80% of the max-

imum for full two-electron reduction, followed

by reoxidation to 20% of this maximum. This

experiment was designed to mimic the condi-

tions under which the mediator would have to

operate in a continuous-flow system. The data

in fig. S11B suggest that there is no decay in the

amount of charge that can be stored in the me-

diator (which would signal irreversible decom-

position) within these bounds over the number

of cycles probed. Similarly, fig. S12, A and B,

show that a sample of silicotungstic acid sub-

jected to 20 consecutive two-electron reduction

and reoxidation cycles has an ultraviolet-visible

spectrum indistinguishable from that of a fresh

sample of silicotungstic acid. Taken together,

these data suggest that the mediator is stable to

redox cycling under these conditions and that

H

4

[SiW

12

O

40

] might thus be suitable as a me-

diator in a continuous-flow system.

Because of the high molecular weight of

H

4

[SiW

12

O

40

], it does not constitute an especially

effective static storage medium for H

2

(or H

2

equivalents). Clearly, lowermolecular-weight me-

diators, or systems capable of storing more elec-

trons, would therefore be at a practical advantage

(15), allowing greater buffering capacity to be built

into the systemand providing more flexibility with

regard to the temporal separation of water oxida-

tion and H

2

generation. We are currently pursuing

the identification of such mediators, and we see

great potential for optimized mediator systems to

be combined with other recent breakthroughs in

catalysis (27, 28) and device design (9, 29), facil-

itating the use of low-power inputs (or those sub-

ject to large fluctuations) inrenewables-to-hydrogen

conversion.

REFERENCES AND NOTES

1. A. Le Goff et al., Science 326, 13841387 (2009).

2. N. Armaroli, V. Balzani, ChemSusChem 4, 2136 (2011).

3. U.S. Department of Energy Hydrogen Analysis Resource

Center, Hydrogen Production, Worldwide Refinery Hydrogen

Production Capacities (2012), http://hydrogen.pnl.gov/

cocoon/morf/hydrogen/article/706.

4. J. D. Holladay, J. Hu, D. L. King, Y. Wang, Catal. Today 139,

244260 (2009).

5. F. M. Toma et al., Nat. Chem. 2, 826831 (2010).

6. D. Gust, T. A. Moore, A. L. Moore, Acc. Chem. Res. 42,

18901898 (2009).

7. M. Carmo, D. L. Fritz, J. Mergel, D. Stolten, Int. J. Hydrogen

Energy 38, 49014934 (2013).

8. Y. Tachibana, L. Vayssieres, J. R. Durrant, Nat. Photonics 6,

511518 (2012).

9. S. Y. Reece et al., Science 334, 645648 (2011).

10. F. Barbir, Sol. Energy 78, 661669 (2005).

11. A. Berger, R. A. Segalman, J. Newman, Environ. Sci. 7,

14681476 (2014).

12. L. Ghassemzadeh, K.-D. Kreuer, J. Maier, K. Mller, J. Phys.

Chem. C 114, 1463514645 (2010).

13. V. Prabhakaran, C. G. Arges, V. Ramani, Proc. Natl. Acad. Sci.

U.S.A. 109, 10291034 (2012).

14. M. D. Symes, L. Cronin, Nat. Chem. 5, 403409 (2013).

15. B. Rausch, M. D. Symes, L. Cronin, J. Am. Chem. Soc. 135,

1365613659 (2013).

16. International Organization for Standardization, ISO 14687-

2:2012, Hydrogen fuel - Product specification - Part 2: Proton

exchange membrane (PEM) fuel cell applications

for road vehicles, www.iso.org/iso/home/store/catalogue_ics/

catalogue_detail_ics.htm?csnumber=55083 (2012).

17. N. Wiberg, E. Wiberg, A. F. Holleman, in Inorganic Chemistry

(Academic Press, San Diego, CA, 2001), vol. 1.

18. B. Keita, L. Nadjo, J. Electroanal. Chem. 217, 287304

(1987).

19. S. A. Grigoriev et al., Int. J. Hydrogen Energy 34, 59865991

(2009).

20. H. I. Karunadasa et al., Science 335, 698702 (2012).

SCIENCE sciencemag.org 12 SEPTEMBER 2014 VOL 345 ISSUE 6202 1329

RESEARCH | REPORTS

21. D. Merki, S. Fierro, H. Vrubel, X. Hu, Chem. Sci. 2, 12621267

(2011).

22. E. J. Popczun et al., J. Am. Chem. Soc. 135, 92679270 (2013).

23. A. Hiskia, E. Papaconstantinou, Inorg. Chem. 31, 163167 (1992).

24. A. B. LaConti, H. Liu, C. Mittelsteadt, R. C. McDonald,

ECS Trans. 1, 199219 (2006).

25. A. S. Aric et al., J. Appl. Electrochem. 43, 107118 (2013).

26. N. Mamaca et al., Appl. Catal. B 111112, 376380 (2012).

27. T. W. Kim, K.-S. Choi, Science 343, 990994 (2014).

28. Z. Han, F. Qiu, R. Eisenberg, P. L. Holland, T. D. Krauss, Science

338, 13211324 (2012).

29. K. S. Joya, Y. F. Joya, K. Ocakoglu, R. van de Krol, Angew.

Chem. Int. Ed. 52, 1042610437 (2013).

30. J. Xu, G. Liu, J. Li, X. Wang, Electrochim. Acta 59, 105112

(2012).

31. P. Millet et al., Int. J. Hydrogen Energy 35, 50435052

(2010).

32. C. Xu, L. Ma, J. Li, W. Zhao, Z. Gan, Int. J. Hydrogen Energy 37,

29852992 (2012).

33. S. Siracusano et al., Int. J. Hydrogen Energy 37, 19391946

(2012).

ACKNOWLEDGMENTS

This work was supported by the Engineeering and Physical

Sciences Research Council (UK). L.C. thanks the Royal Society/

Wolfson Foundation for a Merit Award. M.D.S. thanks the University

of Glasgow for a Lord Kelvin Adam Smith Research Fellowship.

We are grateful to J. Liddell (University of Glasgow) for production

of the H cells used in this work. Supplementary materials

are available, which include full experimental details for

electrochemical procedures, GCHA, and catalytic H

2

evolution,

as well as a movie showing the H

2

evolution step (movie

S1). The advances presented in the work form part of a

patent filing.

SUPPLEMENTARY MATERIALS

www.sciencemag.org/content/345/6202/1326/suppl/DC1

Supplementary Text Sections SI-1 to SI-14

Figs. S1 to S12

Tables S1 and S2

References (3442)

Movie S1

16 June 2014; accepted 6 August 2014

10.1126/science.1257443

BLACK HOLE PHYSICS

Rapid growth of seed black holes

in the early universe by

supra-exponential accretion

Tal Alexander

1

* and Priyamvada Natarajan

2

Mass accretion by black holes (BHs) is typically capped at the Eddington rate, when

radiation's push balances gravity's pull. However, even exponential growth at the

Eddington-limited e-folding time t

E

~ few 0.01 billion years is too slow to grow

stellar-mass BH seeds into the supermassive luminous quasars that are observed when

the universe is 1 billion years old. We propose a dynamical mechanism that can trigger

supra-exponential accretion in the early universe, when a BH seed is bound in a star cluster

fed by the ubiquitous dense cold gas flows. The high gas opacity traps the accretion

radiation, while the low-mass BH's random motions suppress the formation of a slowly

draining accretion disk. Supra-exponential growth can thus explain the puzzling emergence

of supermassive BHs that power luminous quasars so soon after the Big Bang.

O

ptically bright quasars powered by accre-

tion onto black holes (BHs) are now de-

tected at redshifts as high as z ~ 7, when

the universe was 6% of its current age (<1

billion years) (1). Their luminosities imply

supermassive BHs (SMBHs) with the mass of the

BH (M

) 10

9

solar masses (M

) (2). The main

obstacles to assembling such SMBHs so rapidly

are the lowmasses of the hypothesizedinitial seed

BHs, born of first-generation (Pop III) stars, cou-

pled with the maximal growth rate for radiative-

ly efficient accretion, the Eddington limit (35).

Proposed ways to circumvent these limitations

invoke super-Eddington accretion for brief pe-

riods of time (6); the ab initio formation of more-

massive BH seeds (710) from the direct collapse

of self-gravitating pre-galactic gas disks at high

redshifts (1114); and the formation of a very mas-

sive star from runaway stellar mergers in a dense

cluster (15, 16). Discriminating between these

scenarios is challenging, because seed formation

redshifts (z > 10) are observationally inaccessible.

Current data require finely tuned, continuous

early BH growth and massive initial BH seeds

(1720). Recent results from high-resolution sim-

ulations of early star formation at z 15 to 18

exacerbate the problem by indicating that effi-

cient fragmentation and turbulence (2125) lead

to the efficient formation of stellar clusters em-

bedded in the flow, which prevents the forma-

tion of massive seeds (>>10 M

) by limiting the

mass of their potential Pop III progenitor stars.

On the other hand, theoretical and numerical

results on larger scales suggest that ubiquitous

dense cold gas flows (26) stream in along fila-

ments and feed protogalactic cores (27, 28).

Adaptive mesh refinement simulations track the

fate of these sites (collapsed 10

7

M

dark-matter

halos) from1 Mpc scale at z ~ 21 with resolutions

as low as ~ 2 10

10

pc in the central regions.

These simulations find isothermal density cusps

that reach extreme central densities, with an av-

erage density of r

10

16

g cm

3

(10

8

cm

3

for

pure H) on 0.1 pc scales (29). They also reveal a

marginally unstable central gas reservoir of

few10

5

M

in the inner fewparsecs (30), where

the dynamical time scale is ~10

6

years. Although

these simulations are somewhat idealized, we

adopt the properties of this high-density envi-

ronment as the initial conditions for the model

presented here.

We consider a scenario in which a low-mass

Pop III remnant BH remains embedded in a

nuclear star cluster fed by dense cold gas flows

(26) (Fig. 1 and Table 1). The stars and gas are

virialized in the cluster potential, and the BHis

initially a test particle in equipartition with the

stars. Gas within the accretion (capture) radius

of the BH, r

a

= [2c

2

/(c

2

+v

2

)]r

g

, is dynamically

bound to it, where r

g

= G M

/c

2

is the gravita-

tional radius of the BH; c

is the gas sound

speed in the cold flowfar fromthe BH, which is

a measure of the depth of the cluster's gravita-

tional potential; and v

is the BHvelocity relative

to the gas. Gas bound to the BH inside r

a

is not

necessarily accreted by it. Prompt accretion re-

quires gas toflowfromr

a

intothe BHonaplunging

trajectory with low specific angular momentum

j < j

ISO

4r

g

c, through the innermost stable

periapse distance r

ISO

. It is this angular momen-

tum barrier, rather than the Eddington limit,

that is the main obstacle to supra-exponential

growth.

The BH is more massive than a cluster star,

so v

2

< c

2

, and the accretion flow is quasi-

spherical. In the idealized case where the flow

is radial and adiabatic, it is described by the

Bondi solution (31),

M

B

p=

2

p

r

2

a

r

(adia-

batic index G = 4/3 assumed), which can be

written compactly in terms of m = M

/M

i

, where

M

i

is the initial BHmass, as m m

2

=t

B

, with time

scale t

B

= c

3

/ 2

3/2

pG

2

M

i

r

. The stronger-than-

linear dependence of the accretion rate on the

BH mass leads to a solution that diverges supra-

exponentially in a finite time t

B

as m(t) = 1/(1 t/t

B

).

Physical flows, where gravitational energy is re-

leased as radiation, are not strictly adiabatic. As

the mass accretion rate grows, the local luminos-

ity can far exceed the Eddington luminosity L

E

=

4pcG M

/k =

M

E

c

2

(k is the gas opacity), for

which radiation flux pressure balances gravity.

However, radiation produced inside the photon-

trapping radius r

g

~

M=

M

E

r

g

is carried with the

flow into the BH, because the local optical depth

t(r) ~ kr(r)r makes photon diffusion outward

slower than accretion inward (32) [which is a

manifestation of the Ov=c effect of relativistic

beaming (33)]. The luminosity L

that escapes

to infinity from r r

g

translates to a lowered ra-

diative efficiency h

g

= L

/

Mc

2

~ min(r

g

/r

g

,r

g

/r

ISO

),

so it does not exceed ~L

E

, thereby allowing supra-

exponential Bondi mass accretion rates (34). De-

tailed calculations show that L

0.6 L

E

(35).

1330 12 SEPTEMBER 2014 VOL 345 ISSUE 6202 sciencemag.org SCIENCE

RESEARCH | REPORTS

1

Department of Particle Physics and Astrophysics, Weizmann

Institute of Science, Rehovot 76100, Israel.

2

Department of

Astronomy, Yale University, 260 Whitney Avenue, New

Haven, CT 06511, USA.

*Corresponding author. E-mail: tal.alexander@weizmann.ac.il

Vous aimerez peut-être aussi

- Solar-Hydrogen Energy Systems: An Authoritative Review of Water-Splitting Systems by Solar Beam and Solar Heat: Hydrogen Production, Storage and UtilisationD'EverandSolar-Hydrogen Energy Systems: An Authoritative Review of Water-Splitting Systems by Solar Beam and Solar Heat: Hydrogen Production, Storage and UtilisationPas encore d'évaluation

- Sarafian 2014Document5 pagesSarafian 2014mariano totoPas encore d'évaluation

- 50 Science 306 666 669 2004Document5 pages50 Science 306 666 669 2004Arturo CamachoPas encore d'évaluation

- Science 1257158Document4 pagesScience 12571581592162022Pas encore d'évaluation

- International Conference, GrdsDocument36 pagesInternational Conference, GrdsGlobal Research and Development ServicesPas encore d'évaluation

- 623 FullDocument5 pages623 Fullmariano totoPas encore d'évaluation

- Thermally Stable Single-Atom Platinum-On-Ceria Catalysts Via Atom TrappingDocument6 pagesThermally Stable Single-Atom Platinum-On-Ceria Catalysts Via Atom Trappingsergioodin4851Pas encore d'évaluation

- A PaperDocument7 pagesA Paperweererw12Pas encore d'évaluation

- Degradation Patterns in Water and Oxygen of An Inverted Polymer Solar CellDocument10 pagesDegradation Patterns in Water and Oxygen of An Inverted Polymer Solar CellFirmino ViseuPas encore d'évaluation

- CarbonDocument4 pagesCarbonRijy LorancePas encore d'évaluation

- BindingDocument6 pagesBindingalgorithm123Pas encore d'évaluation

- 2PA CdSe-ZnSDocument4 pages2PA CdSe-ZnSlabasvisogeroPas encore d'évaluation

- Electrical Energy Storage For The Grid: A Battery of ChoicesDocument8 pagesElectrical Energy Storage For The Grid: A Battery of ChoicesAneesh ChandPas encore d'évaluation

- High-Throughput Synthesis of Zeolitic Imidazolate Frameworks and Application To CO2 Capture (DRX)Document6 pagesHigh-Throughput Synthesis of Zeolitic Imidazolate Frameworks and Application To CO2 Capture (DRX)Annaíres AlmeidaPas encore d'évaluation

- Electronic Dura Mater For Long-Term Multimodal Neural InterfacesDocument6 pagesElectronic Dura Mater For Long-Term Multimodal Neural InterfacesNatalia Lizana GarciaPas encore d'évaluation

- Selected Nanotechnologies For Renewable Energy Applications: Samuel S. Mao and Xiaobo ChenDocument18 pagesSelected Nanotechnologies For Renewable Energy Applications: Samuel S. Mao and Xiaobo ChenIvana Titana DrivePas encore d'évaluation

- Fibers Do The Twist: Science February 2014Document4 pagesFibers Do The Twist: Science February 2014Sarah MendesPas encore d'évaluation

- Literature Review CapacitorDocument6 pagesLiterature Review Capacitorafdtsebxc100% (1)

- Zinc Glycolate: A Precursor To Zno: Jaykrushna Das, Ivana R. Evans, and Deepa KhushalaniDocument3 pagesZinc Glycolate: A Precursor To Zno: Jaykrushna Das, Ivana R. Evans, and Deepa KhushalanijeffersonPas encore d'évaluation

- Tao Et Al. (2010)Document5 pagesTao Et Al. (2010)mateus_rocha0% (1)

- Analysis of Thermal Degradation of Organic Light-EDocument10 pagesAnalysis of Thermal Degradation of Organic Light-ESyahirah SalimPas encore d'évaluation

- Structure-Performance Correlations in Vapor Phase Deposited Self-Assembled Nanodielectrics For Organic Field-Effect TransistorsDocument11 pagesStructure-Performance Correlations in Vapor Phase Deposited Self-Assembled Nanodielectrics For Organic Field-Effect TransistorsKomodoDSPas encore d'évaluation

- Josh Vura-Weis Et Al - Geometry and Electronic Coupling in Perylenediimide Stacks: Mapping Structure-Charge Transport RelationshipsDocument2 pagesJosh Vura-Weis Et Al - Geometry and Electronic Coupling in Perylenediimide Stacks: Mapping Structure-Charge Transport RelationshipsGomsajPas encore d'évaluation

- Impact of P3HT Materials Properties and Layer Architecture On OPV DeviceDocument17 pagesImpact of P3HT Materials Properties and Layer Architecture On OPV DeviceFab AstroPas encore d'évaluation

- Letters To Nature: Low-Temperature Processing of Baroplastics' by Pressure-Induced FlowDocument5 pagesLetters To Nature: Low-Temperature Processing of Baroplastics' by Pressure-Induced Flowfrox123Pas encore d'évaluation

- Sara A. DiBenedetto Et Al - Charge Conduction and Breakdown Mechanisms in Self-Assembled Nano DielectricsDocument11 pagesSara A. DiBenedetto Et Al - Charge Conduction and Breakdown Mechanisms in Self-Assembled Nano DielectricsGomsajPas encore d'évaluation

- 18 - Ok Water Metamaterial For Ultra-Broadban and Wide Angle AbsorptionDocument8 pages18 - Ok Water Metamaterial For Ultra-Broadban and Wide Angle Absorptionflavio silvaPas encore d'évaluation

- Synthesis and Characterization of Cufe2O4 Nano/Submicron Wire-Carbon Nanotube Composites As Binder-Free Anodes For Li-Ion BatteriesDocument51 pagesSynthesis and Characterization of Cufe2O4 Nano/Submicron Wire-Carbon Nanotube Composites As Binder-Free Anodes For Li-Ion BatteriesKepoin yukPas encore d'évaluation

- Siegfried 2004Document4 pagesSiegfried 2004Colín Poblete BaezaPas encore d'évaluation

- Journal of Energy and Power Engineering-2012.01Document160 pagesJournal of Energy and Power Engineering-2012.01Raquel GardePas encore d'évaluation

- 2005 NatureDocument5 pages2005 NaturecrackintheshatPas encore d'évaluation

- 1 s2.0 S0038092X15001139 Main PDFDocument19 pages1 s2.0 S0038092X15001139 Main PDFMuhammad Bilal QadirPas encore d'évaluation

- 1 s2.0 S0038092X23006321 MainDocument27 pages1 s2.0 S0038092X23006321 MainGasht 22Pas encore d'évaluation

- Nanoscale Tunable Reduction of Graphene Oxide For Graphene ElectronicsDocument6 pagesNanoscale Tunable Reduction of Graphene Oxide For Graphene Electronicsadrianoreis1Pas encore d'évaluation

- Expanding The Fluorine Chemistry of Living Systems Using Engineered Polyketide Synthase PathwaysDocument7 pagesExpanding The Fluorine Chemistry of Living Systems Using Engineered Polyketide Synthase PathwaysJunia Alfa NessaPas encore d'évaluation

- C Improving Photosynthesis and Crop Productivity byDocument7 pagesC Improving Photosynthesis and Crop Productivity bymiguelPas encore d'évaluation

- Asymmetric Supercapacitor Electrodes and Devices: Advanced Materials February 2017Document31 pagesAsymmetric Supercapacitor Electrodes and Devices: Advanced Materials February 2017miliPas encore d'évaluation

- OE2011 Wetzel WavelengthStableRareEarthFreeGreenLEDEnergyEfficiency, Wetzel Detchprohm, OpticsExpress19 (S4) A962 (2011)Document10 pagesOE2011 Wetzel WavelengthStableRareEarthFreeGreenLEDEnergyEfficiency, Wetzel Detchprohm, OpticsExpress19 (S4) A962 (2011)Pawan KumarPas encore d'évaluation

- Science 2012 Yu 566 9Document5 pagesScience 2012 Yu 566 9Ligia MoreiraPas encore d'évaluation

- Decarbonizing The Energy System Using Decentralized Energy GenerationDocument8 pagesDecarbonizing The Energy System Using Decentralized Energy GenerationFlaviaPas encore d'évaluation

- Banks-Leite Et Al 2014 - 0Document6 pagesBanks-Leite Et Al 2014 - 0Amanda AlvesPas encore d'évaluation

- Dissertation Fuel CellDocument5 pagesDissertation Fuel CellWhereCanIFindSomeoneToWriteMyCollegePaperUK100% (1)

- PHD Thesis Energy StorageDocument4 pagesPHD Thesis Energy Storagelodyicxff100% (2)

- 2007 Hydrogen EnergyDocument15 pages2007 Hydrogen EnergyWilliam ChangPas encore d'évaluation

- CO2 Science 2012Document7 pagesCO2 Science 2012f20212955Pas encore d'évaluation

- Afsar 2019Document42 pagesAfsar 2019Kaustav LahiriPas encore d'évaluation

- Wells To Wire: Sarah Marie JordaanDocument124 pagesWells To Wire: Sarah Marie JordaanJohn Bender100% (1)

- Electroactive Polymer Composites FutureDocument5 pagesElectroactive Polymer Composites FutureDr. Stan Wardel BA, MA, MChem, MBA, DPhil, DSc.Pas encore d'évaluation

- A Perspective On Solar-Driven Water Splitting With All-Oxide Hetero-NanostructuresDocument11 pagesA Perspective On Solar-Driven Water Splitting With All-Oxide Hetero-NanostructuresgonelgoktugPas encore d'évaluation

- 09 - 2016 - Optics Express - Experimental and Theoretical Investigations of An Air-Slot Coupler Between Dielectric and Plasmonic WaveguidesDocument6 pages09 - 2016 - Optics Express - Experimental and Theoretical Investigations of An Air-Slot Coupler Between Dielectric and Plasmonic WaveguidesRami WahshehPas encore d'évaluation

- Seismic Design of Buried and Offshore PipelinesDocument384 pagesSeismic Design of Buried and Offshore PipelinesÁngel CamposPas encore d'évaluation

- Issue 8, 2013 Journal of Civil Engineering and ArchitectureDocument146 pagesIssue 8, 2013 Journal of Civil Engineering and ArchitectureJCEAJournalPas encore d'évaluation

- 2010-Building A Better BatteryDocument2 pages2010-Building A Better BatteryJunro YoonPas encore d'évaluation

- El Kady2012Document6 pagesEl Kady2012Magdiel SchmitzPas encore d'évaluation

- ElectrolysisDocument300 pagesElectrolysisberbouPas encore d'évaluation

- Thesis Perovskite Solar CellDocument4 pagesThesis Perovskite Solar CellBuyingEssaysOnlineNewark100% (2)

- 250-Operating Conditions of Batteries in Off-Grid RESDocument17 pages250-Operating Conditions of Batteries in Off-Grid RESFikri Al-MubarokPas encore d'évaluation

- Energy Harvesting From Water Distribution Systems: Journal of Energy Engineering March 2012Document12 pagesEnergy Harvesting From Water Distribution Systems: Journal of Energy Engineering March 2012raja manePas encore d'évaluation

- Chapter 1 IntroductionDocument11 pagesChapter 1 IntroductionJoseph Israel BagasinaPas encore d'évaluation

- University of BahrainDocument35 pagesUniversity of Bahrainapi-291560513Pas encore d'évaluation

- A First Etymological Dictionary of BasquDocument29 pagesA First Etymological Dictionary of BasquDaily MailPas encore d'évaluation

- Energy BodiesDocument1 pageEnergy BodiesannoyingsporePas encore d'évaluation

- 2011 Burris CatalogDocument56 pages2011 Burris CatalogMario Lopez100% (1)

- DLL Drafting 7Document4 pagesDLL Drafting 7Ram Dacz100% (3)

- Solutions of Inverse Geodetic Problem in Navigational Applications PDFDocument5 pagesSolutions of Inverse Geodetic Problem in Navigational Applications PDFLacci123Pas encore d'évaluation

- Lub OIl Flushing Procedure PDFDocument44 pagesLub OIl Flushing Procedure PDFSubrahmanyam100% (1)

- The Data Driven AuditDocument34 pagesThe Data Driven AuditMon compte Mon comptePas encore d'évaluation

- How To Install 64 Bits IDES On 32 Bits OSDocument1 pageHow To Install 64 Bits IDES On 32 Bits OSMuhammad JaveedPas encore d'évaluation

- SD-NOC-MAR-202 - Rev00 Transfer of Personnel at Offshore FacilitiesDocument33 pagesSD-NOC-MAR-202 - Rev00 Transfer of Personnel at Offshore Facilitiestho03103261100% (1)

- Pamphlet 89 Chlorine Scrubbing SystemsDocument36 pagesPamphlet 89 Chlorine Scrubbing Systemshfguavita100% (4)

- Evidence MODULE 1 Evidence DefinitionDocument8 pagesEvidence MODULE 1 Evidence Definitiondave BarretoPas encore d'évaluation

- Ib Psychology - Perfect Saq Examination Answers PDFDocument2 pagesIb Psychology - Perfect Saq Examination Answers PDFzeelaf siraj0% (2)

- Practicewith Argument Athletesas ActivistsDocument30 pagesPracticewith Argument Athletesas ActivistsRob BrantPas encore d'évaluation

- Handbook On National Spectrum Management 2015Document333 pagesHandbook On National Spectrum Management 2015Marisela AlvarezPas encore d'évaluation

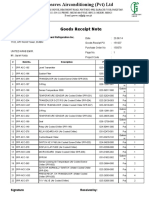

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocument4 pagesGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanPas encore d'évaluation

- WSI - Catalogue of O-Ring PDFDocument37 pagesWSI - Catalogue of O-Ring PDFyearetg100% (1)

- DAY 3 STRESS Ielts NguyenhuyenDocument1 pageDAY 3 STRESS Ielts NguyenhuyenTĩnh HạPas encore d'évaluation

- Dredge Yard Gate Valve BrochureDocument5 pagesDredge Yard Gate Valve BrochureFederico BabichPas encore d'évaluation

- (Word 365-2019) Mos Word MocktestDocument4 pages(Word 365-2019) Mos Word MocktestQuỳnh Anh Nguyễn TháiPas encore d'évaluation

- Harriet Tubman Lesson PlanDocument7 pagesHarriet Tubman Lesson PlanuarkgradstudentPas encore d'évaluation

- Dayco-Timing Belt Training - Entrenamiento Correa DentadaDocument9 pagesDayco-Timing Belt Training - Entrenamiento Correa DentadaDeiby CeleminPas encore d'évaluation

- Practice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDDocument8 pagesPractice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDMarc Stanley YaoPas encore d'évaluation

- HP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningDocument2 pagesHP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningParesh BabariaPas encore d'évaluation

- Optimizing Stata For Analysis of Large Data SetsDocument29 pagesOptimizing Stata For Analysis of Large Data SetsTrần Anh TùngPas encore d'évaluation

- Summative Test in Foundation of Social StudiesDocument2 pagesSummative Test in Foundation of Social StudiesJane FajelPas encore d'évaluation

- Sop GC6890 MS5973Document11 pagesSop GC6890 MS5973Felipe AndrinoPas encore d'évaluation

- Kat-A 4102 Rotovalve Edition3!12!02-2013 enDocument4 pagesKat-A 4102 Rotovalve Edition3!12!02-2013 enWalter PiracocaPas encore d'évaluation

- Unit 7 ActivitiesDocument8 pagesUnit 7 ActivitiesleongeladoPas encore d'évaluation

- Green ThumbDocument2 pagesGreen ThumbScarlet Sofia Colmenares VargasPas encore d'évaluation

- Managing Markets Strategically: Professor Noel CaponDocument49 pagesManaging Markets Strategically: Professor Noel CaponChristiandeuxPas encore d'évaluation

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyD'EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansD'EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)D'EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Pas encore d'évaluation

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsD'EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsPas encore d'évaluation

- To Engineer Is Human: The Role of Failure in Successful DesignD'EverandTo Engineer Is Human: The Role of Failure in Successful DesignÉvaluation : 4 sur 5 étoiles4/5 (138)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeD'EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeÉvaluation : 4.5 sur 5 étoiles4.5/5 (59)

- Skyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownD'EverandSkyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownPas encore d'évaluation

- Troubleshooting and Repair of Diesel EnginesD'EverandTroubleshooting and Repair of Diesel EnginesÉvaluation : 1.5 sur 5 étoiles1.5/5 (2)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetD'EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Structural Cross Sections: Analysis and DesignD'EverandStructural Cross Sections: Analysis and DesignÉvaluation : 4.5 sur 5 étoiles4.5/5 (19)

- Geotechnical Engineering Calculations and Rules of ThumbD'EverandGeotechnical Engineering Calculations and Rules of ThumbÉvaluation : 4 sur 5 étoiles4/5 (17)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesD'EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesPas encore d'évaluation

- Structural Analysis 1: Statically Determinate StructuresD'EverandStructural Analysis 1: Statically Determinate StructuresPas encore d'évaluation

- Summary of Taiichi Ohno's Taiichi Ohno's Workplace ManagementD'EverandSummary of Taiichi Ohno's Taiichi Ohno's Workplace ManagementPas encore d'évaluation

- Rock Fracture and Blasting: Theory and ApplicationsD'EverandRock Fracture and Blasting: Theory and ApplicationsÉvaluation : 5 sur 5 étoiles5/5 (2)

- CAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementD'EverandCAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementPas encore d'évaluation