Académique Documents

Professionnel Documents

Culture Documents

200DLC

Transféré par

Gopal Sudhir100%(1)100% ont trouvé ce document utile (1 vote)

27 vues16 pagesThe 200D and 200D LC deliver more swing torque, drawbar pull, and lift capability. Fuel-efficient Tier 3 emission-certified PowerTech (tm) diesel delivers power without compromise in all conditions. Redesigned cab combines more legroom and tinted glass for unsurpassed comfort and visibility.

Description originale:

Titre original

200DLC[1]

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe 200D and 200D LC deliver more swing torque, drawbar pull, and lift capability. Fuel-efficient Tier 3 emission-certified PowerTech (tm) diesel delivers power without compromise in all conditions. Redesigned cab combines more legroom and tinted glass for unsurpassed comfort and visibility.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

27 vues16 pages200DLC

Transféré par

Gopal SudhirThe 200D and 200D LC deliver more swing torque, drawbar pull, and lift capability. Fuel-efficient Tier 3 emission-certified PowerTech (tm) diesel delivers power without compromise in all conditions. Redesigned cab combines more legroom and tinted glass for unsurpassed comfort and visibility.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 16

D

EXCAVATORS

2 0 M E T R I C T O N

200D | 200D LC

DKAX200DLC Page 1

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

When youre ready to take aim at your bottom line,

arm yourself with the standard-undercarriage 200D

or long-undercarriage 200D LC. Stronger and faster

than before, this 20-metric-ton excavator is loaded

with enhancements that not only increase produc-

tivity and uptime, but lower daily operating costs,

too. A high-efciency on-demand cooling system,

Tier 3 PowerTech

E diesel engine, advanced multi-

function monitor, and more spacious cab with 47-

percent more tinted glass headline the long list of

advances. Delivering the power, smoothness, and

control you expect from a J ohn Deere, the 200D

and 200D LC come with everything you need to

get more done.

PAGES

23

Arm yourself to

get more done.

Arm yourself to

get more done.

Arm yourself to

get more done.

DKAX200DLC Page 2

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

The 200D and 200D LC deliver more swing torque, drawbar

pull, and lift capability, with less emissions and noise.

Extended engine and hydraulic uid service intervals increase

uptime and reduce daily operating costs.

Redesigned cab combines more legroom and tinted glass for

unsurpassed comfort and visibility.

Powerwise III

engine/hydraulic management system

maximizes power output, saves fuel, and delivers smooth

multifunction hydraulic operation.

Hydraulically driven fan runs only as needed, reducing noise,

fuel consumption, and operating costs. Reversing option auto-

matically back-blows cooler cores to reduce debris buildup.

Fuel-efcient Tier 3 emission-certied PowerTech E diesel

delivers power without compromise in all conditions.

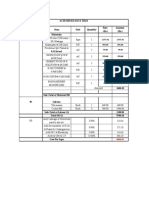

Specications 200D 200D LC

Net Power . . . . . . . . . . . 159 hp 159 hp

Operating Weight . . . . . 48,617 lb. 49,940 lb.

Lift Capacity . . . . . . . . . . 13,223 lb. 14,248 lb.

Digging Depth . . . . . . . . 21 ft. 11 in. 21 ft. 11 in.

Arm Breakout Force . . . 22,924 lb. 22,924 lb.

DKAX200DLC Page 3

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

Noise levels and operator fatigue have been

signicantly reduced. Variable-speed fan, dual-

pass mufer, and isochronous high-idle speed

help quiet things down.

Additional hydraulic capability a necessity? Two

factory-installed high-pressure, high-ow auxiliary

hydraulic packages enable you to meet the need.

Who says you cant always get what you want?

Choose from a variety of track widths, arm

lengths, buckets, and other options.

Changing hydraulic ow is pushbutton easy

through the monitor. Accommodates a wide vari-

ety of attachment needs, right from the seat.

1. Powerwize III perfectly balances engine

performance and hydraulic ow for

smooth multifunction operation and fast

cycles. One work mode makes it easy to

be productive in any application.

2. Generous hydraulic ow combined with

increased swing torque help you load

more trucks or open more trench.

3. For nesse work like setting pipe, the

200D and 200D LCs best-in-class meter-

ing and smooth multifunction operation

give you the precise, predictable control

you need.

4. When the digging gets tough, simply

press the power-boost button for

additional hydraulic muscle.

1

2

4 3

DKAX200DLC Page 4

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

PAGES

45

The 200D and 200D LC will satisfy your appetite.

Faster hydraulics combined with increased lift capac-

ity, swing torque, and drawbar pull enable you to pile

more work on your plate. Youll enjoy typical J ohn

Deere nesse, thanks to the Powerwise III engine/

hydraulic management system that delivers pinpoint

metering and predictable smooth-as-silk low-effort

control. And with numerous noise-reducing features,

the 200D and 200D LC quietly go about the business

of making you more productive. Dig in!

Hungry for

productivity?

Hungry for

productivity?

Hungry for

productivity?

DKAX200DLC Page 5

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

PAGES

67

Want your operators to be more productive? Put

them in their place behind the controls of a

200D or 200D LC. Their spacious well-appointed

interior boasts more of everything. A wider

expanse of tinted glass for virtually unrestricted

visibility. More peace and quiet. Substantially

more legroom. And numerous creature comforts

and conveniences including automatic climate

control, AM/FM radio, ample storage, and avail-

able heated air-suspension seat. The 200D and

200D LC deliver more of everything your opera-

tors need to do their best.

More room.

More comfort.

More done.

More room.

More comfort.

More done.

More room.

More comfort.

More done.

DKAX200DLC Page 6

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

Deluxe-suspension multi-position seat has 10 inches of

travel, sliding together or independent of the control console.

So it wont cramp an operators style.

Ergonomically designed short-throw pilot levers provide

smooth, predictable ngertip control with less movement

and effort.

Go from backhoe- to SAE-style controls with just a twist of

your wrist. Optional lockable control pattern selector valve

comes factory-installed.

Pushbuttons in the right lever allow ngertip control of

auxiliary hydraulic ow for operating attachments.

Convenient 12-volt port powers cell phones and other

electronic devices.

Redesigned cab isnt just roomier, its also noticeably quieter

and more comfortable. Silicone-lled cab mounts effectively

isolate operators from noise and vibration.

1. Forty-seven-percent more glass, narrow

front cab posts, large tinted overhead

hatch, and numerous mirrors provide

virtually unobstructed all-around visibility.

2. No shortage of storage in here. Theres a

place for a cooler, cup holders, and even

a hot/cold box that keeps refreshments at

just the right temperature.

3. Automatic, high-velocity bi-level climate-

control system with automotive-style

adjustable louvers helps keep the glass

clear and the cab comfortable.

4. Intuitive, multi-language monitor with

four-color LCD screen provides a wealth

of info and control. Displays operating,

diagnostic, and maintenance data with

easy-on-the-eyes clarity.

2

3

1

4

DKAX200DLC Page 7

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

Optional reversing fan automatically back-blows

cooler cores to reduce debris buildup. Its a

welcome addition that will increase uptime.

Graphite-iron wet-sleeve cylinder liners, mono-steel

pistons, and large-diameter connecting rods ensure

long-term engine durability.

Oil-impregnated bushings enhance durability and

extend grease intervals to 500 hours (100 hours

for the bucket joint). Reinforced resin thrust plates

increase boom lube intervals to 500 hours.

Welded bulkheads within the boom resist torsional

stress. Boom, arms, and mainframe are so tough,

theyre warranted for three years or 10,000 hours.

Tungsten-carbide coating creates an extremely

wear-resistant surface to protect the all-important

bucket-to-arm joint.

1. With large idlers, rollers, and strutted

links, the 200D and 200D LCs sealed and

lubricated undercarriage delivers long and

reliable performance.

2. Rigid, reinforced D-channel side frames

resist impact, providing maximum cab

and component protection.

3. Perforations in the hood and side shields

serve as a rst lter, preventing trash

entry. Anything that passes through will

also clear the cooler cores.

4. Box-section track frames, thick-plate

single-sheet mainframe, and large swing

bearing deliver rock-solid durability.

1

2

3 4

DKAX200DLC Page 8

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

PAGES

89

Unlike some excavators that scream for attention,

the 200D and 200D LCs hydraulically driven on-

demand fan runs only as needed, reducing noise

and fuel consumption. The highly efcient system

keeps things running cool, even in high-trash envi-

ronments and high altitudes. A direct-drive fan is

optional. Other traditional J ohn Deere durability fea-

tures include tungsten-carbide thermal-coated arm

surfaces, oil-impregnated bushings, and welded-

boom bulkheads. For maximum uptime, shift after

productive shift, month after month. When you

know how theyre built, youll run a Deere.

Nothing runs

like a Deere,

because nothing

is built like one.

Nothing runs

like a Deere,

because nothing

is built like one.

Nothing runs

like a Deere,

because nothing

is built like one.

DKAX200DLC Page 9

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

Machine Information Center

(MIC) captures and stores

vital machine performance

and utilization data to help

improve uptime, productivity,

and prot.

Auto-idle automatically

reduces engine speeds when

hydraulics arent in use,

making the most of every

precious drop of fuel.

Large, easy-to-open doors

provide quick access to ser-

vice items. Lube banks, lters,

and checkpoints are grouped

for added convenience.

Large fuel tank and 500-

and 5,000-hour engine and

hydraulic oil-service intervals

enable the 200D LC to work

longer between stops for

service.

Fluid-level sight gauges are

conveniently located and

can be checked at a glance.

PAGES

1011

DKAX200DLC Page 10

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

1. Vertical spin-on engine oil and fuel/water

lters in the right rear compartment allow

ground-level servicing.

4. Fresh-air cab lter is quickly serviced from

outside the cab where its more likely to

get done.

2. Easy-to-navigate LCD color monitor tracks

up to 14 maintenance intervals and lets an

operator check any of 32 machine operating

parameters at the touch of a button.

5. Wide-n spacing lets trash easily pass

through cores to resist plugging. Hinged,

swing-out coolers provide additional access.

3. Centralized lube banks place difcult-to-lube

zerks within easy reach, for faster greasing

with less mess.

6. Remote diagnostic and uid-sample ports

located in the pump compartment help speed

preventative maintenance and troubleshooting.

1

As with all J ohn Deere machines, the 200D and

200D LC are loaded with features that make them

hassle free to service and low cost to maintain.

Large, easy-to-open service doors and easy-

access service points make quick work of the

daily routine. Remote-mounted vertical oil and

fuel lters and extended engine and hydraulic oil-

change intervals minimize maintenance, too. Plus

the Machine Information Center, a state-of-the-art

LCD color monitor, and uid-sample ports help you

make timely decisions about machine upkeep

and maximize uptime, productivity, and prots.

4

2 3

5 6

Uncover new ways to

keep costs down.

Uncover new ways to

keep costs down.

Uncover new ways to

keep costs down.

DKAX200DLC Page 11

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

PAGES

1213

Specifications

Specifications

Specifications

Engine 200D / 200D LC

Manufacturer and Model . . . . . . . . . . . . . . . . . . . . . . J ohn Deere 6068H

Non-Road Emission Standards . . . . . . . . . . . . . . . . . . certified to EPA Tier 3 emissions

Net Power (ISO 9249) . . . . . . . . . . . . . . . . . . . . . . . . . 159 hp (119 kW) @ 2,000 rpm

Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414 cu. in. (6.8 L)

Off-Level Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . 100% (45 deg.)

Aspiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . turbocharged, air-to-air charge air cooler

Cooling

Cool-on-demand hydraulic-driven, suction-type fan with remote-mounted drive

Powertrain

Maximum Travel Speed

Low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 mph (3.5 km/h)

High. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.4 mph (5.5 km/h)

Hydraulics

Open center, load sensing

Main Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 variable-displacement axial-piston pumps

Maximum Rated Flow . . . . . . . . . . . . . . . . . . . . . 2 x 56.0 gpm (2 x 212 L/m)

Pilot Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . one gear

Maximum Rated Flow . . . . . . . . . . . . . . . . . . . . . 7.9 gpm (30 L/m)

Pressure Setting . . . . . . . . . . . . . . . . . . . . . . . . . 580 psi (3999 kPa)

System Operating Pressure

Implement Circuits . . . . . . . . . . . . . . . . . . . . . . . 4,980 psi (34 336 kPa)

Travel Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,980 psi (34 336 kPa)

Swing Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,980 psi (34 336 kPa)

Power Boost . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5,270 psi (36 335 kPa)

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pilot levers, short stroke, low effort; hydraulic pilot controls with shutoff lever

Cylinders

Heat-treated, chrome-plated, polished cylinder rods; hardened-steel (replaceable bushings) pivot pins

Bore Rod Diameter Stroke

Boom (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.72 in. (120 mm) 3.35 in. (85 mm) 49.61 in. (1260 mm)

Arm (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.31 in. (135 mm) 3.74 in. (95 mm) 58.07 in. (1475 mm)

Bucket (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.53 in. (115 mm) 3.15 in. (80 mm) 41.73 in. (1060 mm)

Electrical

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 x 12 volt

Reserve Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . 440 min.

Alternator Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 amp

Work Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 halogen (one mounted on boom, one mounted on frame)

Undercarriage 200D 200D LC

Planetary final drives with axial-piston motors

Carrier Rollers (per side) . . . . . . . . . . . . . . . . . . . . . . 2 2

Track Rollers (per side) . . . . . . . . . . . . . . . . . . . . . . . 7 8

Shoes (per side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 49

Drawbar Pull . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45,620 lb. (20 711 kg) 45,620 lb. (20 711 kg)

Track

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hydraulic hydraulic

Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . center center

Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . sealed and lubricated sealed and lubricated

DKAX200DLC Page 12

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

Swing Mechanism 200D / 200D LC

Swing Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.3 rpm

Swing Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50,662 lb.-ft. (68 900 Nm)

Ground Pressure 200D 200D LC

Triple Semi-Grouser Shoes

24 in. (600 mm) . . . . . . . . . . . . . . . . . . . . . . . . . 6.90 psi (47.6 kPa) 6.87 psi (47.4 kPa)

28 in. (700 mm) . . . . . . . . . . . . . . . . . . . . . . . . . 6.10 psi (42.1 kPa) 6.08 psi (41.9 kPa)

32 in. (800 mm) . . . . . . . . . . . . . . . . . . . . . . . . . 5.30 psi (36.5 kPa) 5.30 psi (36.5 kPa)

Serviceability 200D / 200D LC

Refill Capacities

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106 gal. (400.0 L)

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . 27.6 qt. (26.1 L)

Engine Oil with Filter . . . . . . . . . . . . . . . . . . . . . . 24 qt. (23.0 L)

Hydraulic Tank . . . . . . . . . . . . . . . . . . . . . . . . . . 36 gal. (135.0 L)

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . 63.4 gal. (240.0 L)

Gearbox

Propel (each) . . . . . . . . . . . . . . . . . . . . . . . . . 7.2 qt. (6.8 L)

Swing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.0 qt. (6.2 L)

Pump Drive . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1 qt. (1.0 L)

Operating Weights 200D 200D LC

With Full Fuel Tank; 175-lb. (79 kg) Operator;

42-in. (1065 mm), 1.19-cu.-yd. (0.91 m

3

),

1,951-lb. (886 kg) Heavy-Duty Bucket; 9-ft.

7-in. (2.91 m) Arm; 10,463-lb. (4750 kg)

Counterweight; and 32-in. (800 mm) Triple

Semi-Grouser Shoes . . . . . . . . . . . . . . . . . . . . . . 48,617 lb. (22 072 kg) 49,940 lb. (22 673 kg)

Optional Components

Undercarriage with Triple Semi-Grouser Shoes

24 in. (600 mm) . . . . . . . . . . . . . . . . . . . . . . . . . 14,873 lb. (6752 kg) 16,196 lb. (7353 kg)

28 in. (700 mm) . . . . . . . . . . . . . . . . . . . . . . . . . 15,733 lb. (7143 kg) 17,056 lb. (7743 kg)

32 in. (800 mm) . . . . . . . . . . . . . . . . . . . . . . . . . 16,381 lb. (7437 kg) 17,704 lb. (8038 kg)

One-Piece Boom (with arm cylinder) . . . . . . . . . . . . . 3,815 lb. (1732 kg) 3,815 lb. (1732 kg)

Arm with Bucket Cylinder and Linkage

7 ft. 11 in. (2.42 m) . . . . . . . . . . . . . . . . . . . . . . . 2,044 lb. (928 kg) 2,044 lb. (928 kg)

9 ft. 7 in. (2.91 m) . . . . . . . . . . . . . . . . . . . . . . . . 2,181 lb. (990 kg) 2,181 lb. (990 kg)

Boom Lift Cylinders (2) Total Weight . . . . . . . . . . . . . 750 lb. (341 kg) 750 lb. (341 kg)

42-in. (1065 mm), 1.19-cu.-yd. (0.91 m

3

) Heavy-

Duty Bucket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,951 lb. (886 kg) 1,951 lb. (886 kg)

Counterweight (standard) . . . . . . . . . . . . . . . . . . . . . . 10,463 lb. (4750 kg) 10,463 lb. (4750 kg)

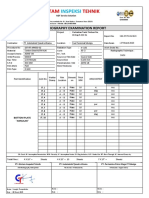

Operating Dimensions 200D 200D LC

Arm Length Arm Length Arm Length Arm Length

7 ft. 11 in. (2.42 m) 9 ft. 7 in. (2.91 m) 7 ft. 11 in. (2.42 m) 9 ft. 7 in. (2.91 m)

Arm Force with 42-in. (1065 mm) Heavy-Duty

Bucket with Power Boost . . . . . . . . . . . . . . . . . . . 27,877 lb. (124.0 kN) 22,924 lb. (102.0 kN) 27,877 lb. (124.0 kN) 22,924 lb. (102.0 kN)

Bucket Digging Force with 42-in. (1065 mm)

1.19-cu.-yd. (0.91 m

3

) Heavy-Duty Bucket

with Power Boost. . . . . . . . . . . . . . . . . . . . . . . . . 29,099 lb. (129.4 kN) 29,099 lb. (129.4 kN) 29,099 lb. (129.4 kN) 29,099 lb. (129.4 kN)

Lifting Capacity Over Front at Ground Level

20-ft. (6.1 m) Reach with Power Boost . . . . . . . . 14,607 lb. (6632 kg) 13,223 lb. (6003 kg) 14,533 lb. (6598 kg) 14,248 lb. (6469 kg)

A Maximum Reach . . . . . . . . . . . . . . . . . . . . . . . . 30 ft. 11 in. (9.43 m) 32 ft. 7 in. (9.92 m) 30 ft. 11 in. (9.43 m) 32 ft. 7 in. (9.92 m)

A

|

Maximum Reach at Ground Level . . . . . . . . . . . 30 ft. 4 in. (9.25 m) 32 ft. 0 in. (9.75 m) 30 ft. 4 in. (9.25 m) 32 ft. 0 in. (9.75 m)

B Maximum Digging Depth . . . . . . . . . . . . . . . . . . 20 ft. 3 in. (6.18 m) 21 ft. 11 in. (6.68 m) 20 ft. 3 in. (6.18 m) 21 ft. 11 in. (6.68 m)

B

|

Maximum Digging Depth at 8-ft. (2.44 m)

Flat Bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 ft. 6 in. (5.95 m) 21 ft. 4 in. (6.50 m) 19 ft. 6 in. (5.95 m) 21 ft. 4 in. (6.50 m)

C Maximum Cutting Height . . . . . . . . . . . . . . . . . . 31 ft. 9 in. (9.67 m) 32 ft. 11 in. (10.04 m) 31 ft. 9 in. (9.67 m) 32 ft. 11 in. (10.04 m)

D Maximum Dumping Height . . . . . . . . . . . . . . . . . 22 ft. 5 in. (6.83 m) 23 ft. 7 in. (7.18 m) 22 ft. 5 in. (6.83 m) 23 ft. 7 in. (7.18 m)

E Minimum Swing Radius . . . . . . . . . . . . . . . . . . . 10 ft. 9 in. (3.28 m) 10 ft. 5 in. (3.18 m) 10 ft. 9 in. (3.28 m) 10 ft. 5 in. (3.18 m)

F Maximum Vertical Wall . . . . . . . . . . . . . . . . . . . 17 ft. 5 in. (5.30 m) 19 ft. 8 in. (5.99 m) 17 ft. 5 in. (5.30 m) 19 ft. 8 in. (5.99 m)

G Tail Swing Radius . . . . . . . . . . . . . . . . . . . . . . . 9 ft. 0 in. (2.75 m) 9 ft. 0 in. (2.75 m) 9 ft. 0 in. (2.75 m) 9 ft. 0 in. (2.75 m)

C

E

N

T

E

R

L

I

N

E

O

F

S

W

I

N

G

GROUND LINE

G

E

C D

B B

A

A

F

DKAX200DLC Page 13

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

PAGES

1415

Machine Dimensions 200D 200D LC

Arm Length Arm Length Arm Length Arm Length

7 ft. 11 in. (2.42 m) 9 ft. 7 in. (2.91 m) 7 ft. 11 in. (2.42 m) 9 ft. 7 in. (2.91 m)

A Overall Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 ft. 6 in. (9.60 m) 31 ft. 3 in. (9.53 m) 31 ft. 6 in. (9.60 m) 31 ft. 3 in. (9.53 m)

B Overall Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 ft. 5 in. (3.18 m) 9 ft. 8 in. (2.95 m) 10 ft. 5 in. (3.18 m) 9 ft. 8 in. (2.95 m)

C Rear-End Length/Swing Radius . . . . . . . . . . . . . . . 9 ft. 0 in. (2.75 m) 9 ft. 0 in. (2.75 m)

D Distance Between Idler/Sprocket Centerline . . . . . 11 ft. 0 in. (3.35 m) 12 ft. 0 in. (3.67 m)

E Undercarriage Length . . . . . . . . . . . . . . . . . . . . . . 13 ft. 8 in. (4.17 m) 14 ft. 8 in. (4.46 m)

200D / 200D LC

F Counterweight Clearance . . . . . . . . . . . . . . . . . . . 3 ft. 5 in. (1031 mm)

G Upperstructure Width . . . . . . . . . . . . . . . . . . . . . . 8 ft. 11 in. (2.71 m)

H Cab Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 ft. 8 in. (2.95 m)

I Track Width with Triple Semi-Grouser Shoes . . . . 24 in. (600 mm) /

28 in. (700 mm) /

32 in. (800 mm)

J Gauge Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 ft. 10 in. (2.39 m)

K Ground Clearance . . . . . . . . . . . . . . . . . . . . . . . . . 18 in. (450 mm)

L Overall Width with Triple Semi-Grouser Shoes

24 in. (600 mm) . . . . . . . . . . . . . . . . . . . . . . . 9 ft. 10 in. (2.99 m)

28 in. (700 mm) . . . . . . . . . . . . . . . . . . . . . . . 10 ft. 2 in. (3.09 m)

32 in. (800 mm) . . . . . . . . . . . . . . . . . . . . . . . 10 ft. 6 in. (3.19 m)

Lift Charts

Boldface italic type indicates hydraulic-limited capacities; lightface type indicates stability-limited capacities, in lb. (kg). Ratings are at bucket lift hook, using 1.12-cu.-yd. (0.86 m

3

)

bucket; standard counterweight, situated on firm, level, uniformsupporting surface. Figures do not exceed 87 percent of hydraulic capacity or 75 percent of weight needed to tip machine.

Load Point 10 ft. (3.05 m) 15 ft. (4.57 m) 20 ft. (6.10 m) 25 ft. (7.62 m)

Height Over Front Over Side Over Front Over Side Over Front Over Side Over Front Over Side

200D with 9- ft. 7- in. (2.91 m) arm and 28- in. (700 mm) triple semi- grouser shoes

20 ft. (6.10 m) 8,048 (3651) 8,048 (3651)

15 ft. (4.57 m) 8,970 (4069) 8,970 (4069) 8,574 (3889) 6,523 (2959)

10 ft. (3.05 m) 13,847 (6281) 13,847 (6281) 10,757 (4879) 9,161 (4155) 9,329 (4232) 6,290 (2853)

5 ft. (1.52 m) 18,108 (8214) 13,135 (5958) 12,766 (5791) 8,578 (3891) 9,515 (4316) 6,004 (2723)

Ground Line 20,308 (9212) 12,435 (5640) 13,103 (5943) 8,139 (3692) 9,255 (4198) 5,765 (2615)

5 ft. (1.52 m) 14,425 (6543) 14,425 (6543) 20,412 (9259) 12,245 (5554) 12,866 (5836) 7,925 (3595) 9,120 (4137) 5,641 (2559)

10 ft. (3.05 m) 23,940 (10 859) 23,940 (10 859) 18,971 (8605) 12,337 (5596) 12,873 (5839) 7,931 (3597) 9,183 (4165) 5,699 (2585)

15 ft. (4.57 m) 20,943 (9500) 20,943 (9500) 15,628 (7089) 12,683 (5753) 11,249 (5102) 8,204 (3721)

200D with 9- ft. 7- in. (2.91 m) arm and 32- in. (800 mm) triple semi- grouser shoes

20 ft. (6.10 m) 8,048 (3651) 8,048 (3651)

15 ft. (4.57 m) 8,970 (4069) 8,970 (4069) 8,574 (3889) 6,581 (2985)

10 ft. (3.05 m) 13,847 (6281) 13,847 (6281) 10,757 (4879) 9,237 (4190) 9,329 (4232) 6,348 (2879)

5 ft. (1.52 m) 18,108 (8214) 13,244 (6007) 12,766 (5791) 8,653 (3925) 9,603 (4356) 6,062 (2750)

Ground Line 20,308 (9212) 12,545 (5690) 13,223 (5998) 8,214 (3726) 9,344 (4238) 5,822 (2641)

5 ft. (1.52 m) 14,425 (6543) 14,425 (6543) 20,412 (9259) 12,354 (5604) 12,985 (5890) 8,001 (3629) 9,209 (4177) 5,698 (2585)

10 ft. (3.05 m) 23,940 (10 859) 23,940 (10 859) 18,971 (8605) 12,446 (5645) 12,992 (5893) 8,007 (3632) 9,272 (4206) 5,756 (2611)

15 ft. (4.57 m) 20,943 (9500) 20,943 (9500) 15,628 (7089) 12,792 (5802) 11,249 (5102) 8,279 (3755)

200D LC with 7- ft. 11- in. (2.42 m) arm and 32- in. (800 mm) triple semi- grouser shoes

20 ft. (6.10 m) 9,001 (4083) 9,001 (4083)

15 ft. (4.57 m) 11,212 (5086) 11,212 (5086) 9,795 (4443) 9,795 (4443) 9,278 (4208) 7,199 (3265)

10 ft. (3.05 m) 15,341 (6959) 15,341 (6959) 11,500 (5216) 10,132 (4596) 9,847 (4467) 7,008 (3179)

5 ft. (1.52 m) 13,340 (6051) 9,589 (4349) 10,677 (4843) 6,755 (3064)

Ground Line 20,586 (9338) 14,165 (6425) 14,533 (6592) 9,216 (4180) 10,682 (4845) 6,557 (2974)

5 ft. (1.52 m) 20,010 (9076) 14,109 (6400) 14,669 (6654) 9,073 (4115) 10,607 (4811) 6,488 (2943)

10 ft. (3.05 m) 20,215 (9169) 20,215 (9169) 18,022 (8175) 14,284 (6479) 13,444 (6098) 9,153 (4152)

15 ft. (4.57 m) 17,763 (8057) 17,763 (8057) 13,813 (6265) 13,813 (6265)

200D LC with 9- ft. 7- in. (2.91 m) arm and 24- in. (600 mm) triple semi- grouser shoes

20 ft. (6.10 m) 8,048 (3651) 8,048 (3651)

15 ft. (4.57 m) 8,970 (4069) 8,970 (4069) 8,574 (3889) 7,158 (3247)

10 ft. (3.05 m) 13,847 (6281) 13,847 (6281) 10,757 (4879) 10,049 (4558) 9,329 (4232) 6,922 (3140)

5 ft. (1.52 m) 18,108 (8214) 14,549 (6599) 12,766 (5791) 9,454 (4288) 10,309 (4676) 6,632 (3008)

Ground Line 20,308 (9212) 13,829 (6273) 14,248 (6463) 9,007 (4086) 10,390 (4713) 6,389 (2898)

5 ft. (1.52 m) 14,425 (6543) 14,425 (6543) 20,412 (9259) 13,633 (6184) 14,529 (6590) 8,789 (3987) 10,251 (4650) 6,263 (2841)

10 ft. (3.05 m) 23,940 (10 859) 23,940 (10 859) 18,971 (8605) 13,728 (6227) 14,028 (6363) 8,795 (3989) 10,316 (4679) 6,321 (2867)

15 ft. (4.57 m) 20,943 (9500) 20,943 (9500) 15,628 (7089) 14,083 (6388) 11,249 (5102) 9,073 (4115)

L

B

A

K

J

G

I

H

C

F

D

E

DKAX200DLC Page 14

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

m

3

)

chine.

Side

2959)

2853)

2723)

2615)

2559)

2585)

2985)

2879)

2750)

2641)

2585)

2611)

3265)

3179)

3064)

2974)

2943)

3247)

3140)

3008)

2898)

2841)

2867)

F

Lift Charts (continued) 200D / 200D LC

Boldface italic type indicates hydraulic-limited capacities; lightface type indicates stability-limited capacities, in lb. (kg). Ratings are at bucket lift hook, using 1.12-cu.-yd. (0.86 m

3

)

bucket; standard counterweight, situated on firm, level, uniformsupporting surface. Figures do not exceed 87 percent of hydraulic capacity or 75 percent of weight needed to tip machine.

Load Point 10 ft. (3.05 m) 15 ft. (4.57 m) 20 ft. (6.10 m) 25 ft. (7.62 m)

Height Over Front Over Side Over Front Over Side Over Front Over Side Over Front Over Side

200D LC with 9- ft. 7- in. (2.91 m) arm and 28- in. (700 mm) triple semi- grouser shoes

20 ft. (6.10 m) 8,048 (3651) 8,048 (3651)

15 ft. (4.57 m) 8,970 (4069) 8,970 (4069) 8,574 (3889) 7,288 (3306)

10 ft. (3.05 m) 13,847 (6281) 13,847 (6281) 10,757 (4879) 10,221 (4636) 9,329 (4232) 7,052 (3199)

5 ft. (1.52 m) 18,108 (8214) 14,799 (6713) 12,766 (5791) 9,625 (4366) 10,309 (4676) 6,762 (3067)

Ground Line 20,308 (9212) 14,079 (6386) 14,248 (6463) 9,178 (4163) 10,593 (4805) 6,519 (2957)

5 ft. (1.52 m) 14,425 (6543) 14,425 (6543) 20,412 (9259) 13,883 (6297) 14,751 (6691) 8,960 (4064) 10,455 (4742) 6,393 (2900)

10 ft. (3.05 m) 23,940 (10 859) 23,940 (10 859) 18,971 (8605) 13,978 (6340) 14,028 (6363) 8,966 (4067) 10,316 (4679) 6,451 (2926)

15 ft. (4.57 m) 20,943 (9500) 20,943 (9500) 15,628 (7089) 14,334 (6502) 11,249 (5102) 9,244 (4193)

200D LC with 9- ft. 7- in. (2.91 m) arm and 32- in. (800 mm) triple semi- grouser shoes

20 ft. (6.10 m) 8,048 (3651) 8,048 (3651)

15 ft. (4.57 m) 8,970 (4069) 8,970 (4069) 8,574 (3889) 7,389 (3352)

10 ft. (3.05 m) 13,847 (6281) 13,847 (6281) 10,757 (4879) 10,353 (4696) 9,329 (4232) 7,152 (3244)

5 ft. (1.52 m) 18,108 (8214) 14,992 (6800) 12,766 (5791) 9,758 (4426) 10,309 (4676) 6,862 (3113)

Ground Line 20,308 (9212) 14,272 (6474) 14,248 (6463) 9,310 (4223) 10,750 (4876) 6,619 (3002)

5 ft. (1.52 m) 14,425 (6543) 14,425 (6543) 20,412 (9259) 14,076 (6385) 14,751 (6691) 9,092 (4124) 10,612 (4814) 6,493 (2945)

10 ft. (3.05 m) 23,940 (10 859) 23,940 (10 859) 18,971 (8605) 14,171 (6428) 14,028 (6363) 9,098 (4127) 10,316 (4679) 6,552 (2972)

15 ft. (4.57 m) 20,943 (9500) 20,943 (9500) 15,628 (7089) 14,527 (6589) 11,249 (5102) 9,376 (4253)

Buckets

A full line of buckets is offered to meet a wide variety of applications. Digging forces are with power boost. The buckets have an adjustable bushing for side clearance, with the exception

of the ditching bucket. Tooth selection inclused either the J ohn Deere Tanggs, Standard, Tiger, Twin Tiger, Abrasion panel or Flare tooth or the ESCO(Vertalok) Standard, TIger, Twin Tiger

or Flare tooth. Replaceable cutting edges are available through J ohn Deere parts. Optional side cutters add 6 inches (150 mm) to bucket widths. Capacities are SAE heaped ratings.

Bucket Bucket Bucket Arm Dig Force Arm Dig Force Bucket

Type Bucket Width Capacity Weight Dig Force 7 ft. 11 in. (2.42 m) 9 ft. 7 in. (2.91 m) Tip Radius No. Teeth

in. mm cu. yd. m

3

lb. kg lb. kN lb. kN lb. kN in. mm

General-Purpose 30 760 0.79 0.60 1,432 650 28,904 128.6 27,806 123.7 22,873 101.7 58.00 1473 4

High Capacity 36 915 1.00 0.76 1,621 736 28,904 128.6 27,806 123.7 22,873 101.7 58.00 1473 5

42 1065 1.22 0.93 1,790 813 28,904 128.6 27,806 123.7 22,873 101.7 58.00 1473 5

48 1220 1.43 1.09 1,976 897 28,904 128.6 27,806 123.7 22,873 101.7 58.00 1473 6

Heavy Duty 24 610 0.52 0.40 1,197 543 29,099 129.4 27,877 124.0 22,924 102.0 57.61 1463 4

30 760 0.71 0.54 1,369 622 29,099 129.4 27,877 124.0 22,924 102.0 57.61 1463 4

36 915 0.90 0.69 1,559 708 29,099 129.4 27,877 124.0 22,924 102.0 57.61 1463 5

42 1065 1.09 0.83 1,731 786 29,099 129.4 27,877 124.0 22,924 102.0 57.61 1463 5

48 1220 1.29 0.99 1,921 872 29,099 129.4 27,877 124.0 22,924 102.0 57.61 1463 6

Heavy-Duty 24 610 0.56 0.43 1,424 646 28,904 128.6 27,806 123.7 22,873 101.7 58.00 1473 4

High Capacity 30 760 0.76 0.58 1,593 723 28,904 128.6 27,806 123.7 22,873 101.7 58.00 1473 4

36 915 0.97 0.74 1,782 809 28,904 128.6 27,806 123.7 22,873 101.7 58.00 1473 5

42 1065 1.19 0.91 1,951 886 28,904 128.6 27,806 123.7 22,873 101.7 58.00 1473 5

Ditching 60 1524 1.14 0.87 1,271 577 40,279 179.2 31,133 138.5 25,271 112.4 41.62 1057 0

Bucket Selection Guide*

3.0

(2.3)

2.0

(1.5)

2,000 2,200 2,600 3,200 lb./ cu. yd.

kg/ m

3

B

U

C

K

E

T

S

I

Z

E

c

u

.

y

d

.

(

m

3

)

1,600 3,400

1.0

(0.8)

1.5

(1.0)

2.5

(1.9)

3.5

(2.7)

1,200 1,400 1,800 2,400 2,800 3,000 3,600

W

e

t

P

e

a

t

T

o

p

s

o

i

l

C

o

a

l

C

a

l

i

c

h

e

S

h

a

l

e

D

r

y

S

a

n

d

D

r

y

C

l

a

y

L

i

m

e

s

t

o

n

e

W

e

t

E

a

r

t

h

W

e

t

C

l

a

y

,

G

r

a

n

i

t

e

M

o

i

s

t

S

a

n

d

W

e

t

S

a

n

d

W

e

t

S

a

n

d

,

G

r

a

v

e

l

1300

Contact your J ohnDeeredealer for optimumbucket andattachment selections. Theserecommendations arefor general conditions andaverageuse. Does not includeoptional

equipment suchas thumbs or couplers. Larger buckets maybepossiblewhenusinglight materials, for flat andlevel operations, less compactedmaterials, andvolumeloading

applications suchas mass excavationapplications inideal conditions. Smaller buckets arerecommendedfor adverseconditions suchas off-level applications, rocks, anduneven

surfaces. Bucket capacityindicatedis SAEheaped.

*

700 800 900 1000 1100 1200 2000 1400 1500 1600 1700 1800 1900 2100

Deere 7- ft. 11- in. (2.42 m) Arm

Deere 9- ft. 7- in. (2.91 m) Arm

DKAX200DLC Page 15

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

DKAX200DLC Litho in U.S.A. (08-07)

200D / LC Engine

Certified to EPA Tier 3 emissions

Auto-idle system

Automatic belt tension device

Batteries (two 12 volt), 440-min. reserve capacity

Coolant recovery tank

Dual-element dry-type air filter

Electronic engine control

Enclosed fan guard (conforms to SAE J 1308)

Engine coolant to 34F (37C)

Fuel filter with water separator

Full-flow oil filter

Turbocharger with charge air cooler

Muffler, under hood, with vertical curved end

exhaust stack

Cool-on-demand hydraulic-driven fan

500-hour engine oil-change interval

100% (45 deg.) off-level capability

Engine-oil-sampling valve

Hydraulic fan reverser

Engine coolant heater

Direct-drive fan

Hydraulic System

Reduced-drift valve for boom down, arm in

Auxiliary hydraulic valve section

Spring-applied, hydraulically released automatic

swing brake

Auxiliary hydraulic-flow adjustments through

monitor

Auto power lift

5,000-hour hydraulic oil-change interval

Hydraulic-oil-sampling valve

Auxiliary hydraulic lines

Auxiliary pilot and electric controls

Hydraulic filter restriction indicator kit

Load-lowering control device

Single-pedal propel control

Control pattern-change valve

Undercarriage

Planetary drive with axial piston motors

Propel motor shields

Spring-applied, hydraulically released automatic

propel brake

Track guides, front idler and center

Two-speed propel with automatic shift

Upper carrier rollers (2)

Sealed and lubricated track chain

200D / LC Undercarriage (continued)

Triple semi-grouser shoes, 24 in. (600 mm)

Triple semi-grouser shoes, 28 in. (700 mm)

Triple semi-grouser shoes, 32 in. (800 mm)

Upperstructure

Right- and left-hand mirrors

Vandal locks with ignition key: Cab door / Fuel

cap / Service doors / Toolbox

Debris-screening side panel

Remote-mounted engine oil and fuel filters

Front Attachments

Centralized lubrication system

Dirt seals on all bucket pins

Less boom and arm

Oil-impregnated bushings

Reinforced resin thrust plates

Tungsten carbide thermal coating on arm-to-

bucket joint

Arm, 7 ft. 11 in. (2.42 m)

Arm, 9 ft. 7 in. (2.91 m)

Attachment quick-couplers

Boom cylinder with plumbing to mainframe for

less boom and arm

Buckets: Ditching / Heavy duty / Heavy-duty

high capacity / Side cutters and teeth

Material clamps

Super-long fronts

Operators Station

Adjustable independent control positions (levers-

to-seat, seat-to-pedals)

AM/FM radio

Auto climate control/air conditioner, 20,000

Btu/hr. (5.9 kW), with heater and pressurizer

Built-in operators manual storage compartment

and manual

Cell-phone power outlet, 12 volt, 60 watt, 5 amp

Coat hook

Deluxe suspension cloth seat with 4-in. (100 mm)

adjustable armrests

Floor mat

Front windshield wiper with intermittent speeds

Gauges (illuminated): Engine coolant / Fuel

Horn, electric

Hour meter, electric

Hydraulic shutoff lever, all controls

Hydraulic warm-up control

200D / LC Operators Station (continued)

Interior light

Large cup holder

Machine Information Center (MIC)

Mode selectors (illuminated): Power modes

three / Travel modes two with automatic shift /

Work mode one

Multifunction, color LCD monitor with: Diagnostic

capability / Multiple-language capabilities / Main-

tenance tracking / Clock / System monitoring

with alarm features: Auto-idle indicator, engine

air cleaner restriction indicator light, engine

check, engine coolant temperature indicator light

with audible alarm, engine oil pressure indicator

light with audible alarm, low-alternator-charge

indicator light, low-fuel indicator light, fault-code

alert indicator, fuel-rate display, wiper-mode

indicator, work-lights-on indicator, and work-

mode indicator

Monitor system with alarm features: Hydraulic

oil filter restriction indicator light

Motion alarm with cancel switch (conforms to

SAE J 994)

Power-boost switch on right console lever

Auxiliary hydraulic control switches in right con-

sole lever

SAE two-lever control pattern

Seat belt, 2 in. (51 mm), retractable

Seat belt, 3 in. (76 mm), non-retractable

Tinted glass

Transparent tinted overhead hatch

Hot/cold beverage compartment

Air-suspension heated seat

24- to 12-volt D.C. radio convertors, 10 amp

Circulation fan

Protection screens for cab front, rear, and side

Window vandal protection covers

Electrical

80-amp alternator

Blade-type multi-fused circuits

Positive terminal battery covers

Cab extension wiring harness

J DLink

TM

wireless communication system

Lights

Work lights: Halogen / One mounted on boom /

One mounted on frame

200D / 200D LC EXCAVATORS

Key: St a nda r d equi pment Opt i ona l equi pment *See your J ohn Deere dealer for further information.

CONTROL OWNING AND OPERATING COSTS

Customer Personal Service (CPS) is part of J ohn Deeres proactive, fix-before-fail strategy on

machine maintenance that will help control costs, increase profits, and reduce stress. Included

in this comprehensive lineup of ongoing programs and services are:

Fluid analysis program tells you whats going on inside all of your machines major com-

ponents so youll know if theres a problembefore you see a decline in performance. Fluid analysis

is included in most extended coverage and preventive-maintenance agreements.

Component life- cycle data gives you vital information on the projected life span of com-

ponents and lets you make informed decisions on machine maintenance by telling you approxi-

mately how many hours of use you can expect froman engine, transmission, or hydraulic pump.

This information can be used to preempt catastrophic downtime by servicing major components

at about 80 percent of their life cycle.

Preventive Maintenance (PM) agreements give you a fixed cost for maintaining a machine

for a given period of time. They also help you avoid downtime by ensuring that critical maintenance

work gets done right and on schedule. On-site preventive maintenance service performed where

and when you need it helps protect you fromthe expense of catastrophic failures and lets you

avoid waste-disposal hassles.

Extended coverage gives you a fixed cost for machine repairs for a given period of time

so you can effectively manage costs. Whether you work in a severe-service setting or just want

to spread the risk of doing business, this is a great way to custom-fit coverage for your operation.

And an extended coverage contract also travels well because its backed by J ohn Deere and is

honored by all Deere construction dealers.

Customer Support Advisors (CSAs) Deere believes the CSA programlends a personal

quality to Customer Personal Service (CPS). Certified CSAs have the knowledge and skills for

helping make important decisions on machine maintenance and repair. Their mission is to help

you implement a plan thats right for your business and take the burden of machine maintenance

off your shoulders.

Net engine power is with standard equipment including air

cleaner, exhaust system, alternator, and cooling fan at test

conditions per ISO9249. Noderatingis requiredupto10,000-ft.

(3050 m) altitude.

Specifications and design subject to change without notice. Wherever applicable, specifications are in accordance with SAE stan-

dards. Except whereotherwisenoted, thesespecifications arebasedonunits with 9-ft. 7-in. (2.91 m) arms; 42-in. (1065 mm),

1.19-cu. yd. (0.91 m

3

), 1,951-lb. (886 kg) heavy-dutybuckets; 10,463-lb. (4750 kg) counterweights; full fuel tanks; and 175-lb.

(79 kg) operators; and a 200DLCunit with32-in. (800 mm) triplesemi-grouser shoes.

DKAX200DLC Page 16

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan Magenta Yellow Black

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hiab 320Document152 pagesHiab 320Jasbir Jammu Repairing & Maintence LLCPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- R070T Parts ManualDocument43 pagesR070T Parts ManualDieselkPas encore d'évaluation

- The Attached Excerpted Resource Materials Have Been Made Available For Use Within ACI UniversityDocument11 pagesThe Attached Excerpted Resource Materials Have Been Made Available For Use Within ACI Universityguillemir100% (2)

- Rate AnalysisDocument190 pagesRate AnalysisKeshava Murthy89% (27)

- Civil Works-Rate AnalysisDocument122 pagesCivil Works-Rate Analysisraghacivil96% (23)

- Rate AnalysisDocument19 pagesRate AnalysisNikhil63% (8)

- Rate AnalysisDocument19 pagesRate AnalysisNikhil63% (8)

- Rate AnalysisDocument19 pagesRate AnalysisNikhil63% (8)

- Rate AnalysisDocument19 pagesRate AnalysisNikhil63% (8)

- Unfired Pressure VesselDocument30 pagesUnfired Pressure VesselSrinivasan RajenderanPas encore d'évaluation

- EASA Piston Engine Module Tutorial QuestionsDocument19 pagesEASA Piston Engine Module Tutorial QuestionsJoseph Timoney100% (5)

- Despiese Bomba de Direccion D8TDocument3 pagesDespiese Bomba de Direccion D8TEliecer godoyPas encore d'évaluation

- Is 1343 1980 PDFDocument68 pagesIs 1343 1980 PDFpriyankaPas encore d'évaluation

- Material RequiredDocument2 pagesMaterial RequiredNikhil88% (8)

- Material RequiredDocument2 pagesMaterial RequiredNikhil88% (8)

- Post-tensioned slab design criteriaDocument3 pagesPost-tensioned slab design criteriaShamim Ahsan Zubery100% (1)

- Cement Concrete Technology PDFDocument155 pagesCement Concrete Technology PDFArun VyasPas encore d'évaluation

- Renault Master BrochureDocument37 pagesRenault Master BrochureAdriano Freire SilvaPas encore d'évaluation

- GARLOCK Gasket SheetsDocument59 pagesGARLOCK Gasket SheetsdanianishPas encore d'évaluation

- Final ReviewDocument104 pagesFinal Reviewzhou wangchaoPas encore d'évaluation

- KALMAR DRS 4531 - S5 Pareparts - PEÇAS Merge PDFDocument610 pagesKALMAR DRS 4531 - S5 Pareparts - PEÇAS Merge PDFBreno Cambraia Lanznaster100% (5)

- Kumera-848027c - Installation and Maintenance - en - 2015-08 PDFDocument40 pagesKumera-848027c - Installation and Maintenance - en - 2015-08 PDFgilbertogatoPas encore d'évaluation

- Construction Systems - CCANZ CH 15 - FormworkDocument14 pagesConstruction Systems - CCANZ CH 15 - FormworkGopal SudhirPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument16 pagesDisclosure To Promote The Right To InformationGopal SudhirPas encore d'évaluation

- Bar Bending Shape Codes As Per Bs 8666: Structural Engineering & Geospatial ConsultantsDocument7 pagesBar Bending Shape Codes As Per Bs 8666: Structural Engineering & Geospatial ConsultantsGopal SudhirPas encore d'évaluation

- Pricing The Priceless: PaintingsDocument6 pagesPricing The Priceless: PaintingsGopal SudhirPas encore d'évaluation

- Pricing The Priceless: PaintingsDocument6 pagesPricing The Priceless: PaintingsGopal SudhirPas encore d'évaluation

- Sree Vishnu Sahasra Nama Stotram - Kannada Lyrics (Text)Document20 pagesSree Vishnu Sahasra Nama Stotram - Kannada Lyrics (Text)HarshithaShrinathPas encore d'évaluation

- Area and FormulasDocument14 pagesArea and FormulasAbdiqani Muse EngsaabirPas encore d'évaluation

- 20 Tiling Floors PDFDocument10 pages20 Tiling Floors PDFGopal SudhirPas encore d'évaluation

- Pricing The Priceless: PaintingsDocument6 pagesPricing The Priceless: PaintingsGopal SudhirPas encore d'évaluation

- Acid TilesDocument6 pagesAcid TilesGopal SudhirPas encore d'évaluation

- Acid Resistance TilesDocument1 pageAcid Resistance TilesGopal SudhirPas encore d'évaluation

- Acid Resistance TilesDocument1 pageAcid Resistance TilesGopal SudhirPas encore d'évaluation

- 201302261950270.1, Construcation of Flag Post For Rajaram College KolhapurDocument10 pages201302261950270.1, Construcation of Flag Post For Rajaram College KolhapurGopal SudhirPas encore d'évaluation

- Acid TilesDocument6 pagesAcid TilesGopal SudhirPas encore d'évaluation

- Er. Kashmir Dass: Prepared byDocument32 pagesEr. Kashmir Dass: Prepared byZamadagniNippuPas encore d'évaluation

- Material Testing Lab - ManualDocument28 pagesMaterial Testing Lab - ManualtonydisojaPas encore d'évaluation

- Articulated Trucks: Tam Thoi Gui Bo Ve Cac Thiet Bi Xay Dung. Mai Con Se Gui Bo Ve Thiet Bi Va .N TaiDocument40 pagesArticulated Trucks: Tam Thoi Gui Bo Ve Cac Thiet Bi Xay Dung. Mai Con Se Gui Bo Ve Thiet Bi Va .N TaiGopal SudhirPas encore d'évaluation

- SP46Document213 pagesSP46Gopal SudhirPas encore d'évaluation

- 1.5 Concrete IDocument10 pages1.5 Concrete IdsmnnangPas encore d'évaluation

- Pt. Gintam Tehnik: InspeksiDocument5 pagesPt. Gintam Tehnik: Inspeksirizky youlandaPas encore d'évaluation

- Chief Engineer's Standing Instructions.Document3 pagesChief Engineer's Standing Instructions.prashant manhasPas encore d'évaluation

- Biffi IS2000Document16 pagesBiffi IS2000Kolbert ArpadPas encore d'évaluation

- Trilectron DAC900 TMEverestDocument394 pagesTrilectron DAC900 TMEverestVictory GSEPas encore d'évaluation

- USE of Evans & Duncans ChartDocument39 pagesUSE of Evans & Duncans ChartAsif Mostafa AnikPas encore d'évaluation

- Fluid Mechanics Test and Exam DetailsDocument8 pagesFluid Mechanics Test and Exam DetailsDiego FungPas encore d'évaluation

- Self-Check 1-1: Submitted by On 3/9/2012 5:21:18 PMDocument219 pagesSelf-Check 1-1: Submitted by On 3/9/2012 5:21:18 PMblue4882Pas encore d'évaluation

- ASTM A153 Guide for Galvanized Hardware & FastenersDocument5 pagesASTM A153 Guide for Galvanized Hardware & FastenersMekhmanPas encore d'évaluation

- Amblygon Ta 15-2: Product InformationDocument2 pagesAmblygon Ta 15-2: Product InformationGregory Alan Francisco IIPas encore d'évaluation

- Experiment No. 3 Measurement of Specific Weight and Pressure Intensity of LiquidsDocument4 pagesExperiment No. 3 Measurement of Specific Weight and Pressure Intensity of LiquidsChristine KimPas encore d'évaluation

- Mechanical Vibration and Oscillation in Transmission LinesDocument27 pagesMechanical Vibration and Oscillation in Transmission LinesChhatrapal SinghPas encore d'évaluation

- DIB - Generators & MotorsDocument6 pagesDIB - Generators & MotorsDeepen SharmaPas encore d'évaluation

- PSXX OMR0002 PDFDocument64 pagesPSXX OMR0002 PDFLupePas encore d'évaluation

- JC GGC 2011 Catalogue Low ResDocument52 pagesJC GGC 2011 Catalogue Low ResgaluPas encore d'évaluation

- Me6302 - Manufacturing Technology - I: Iii Semester Mechanical EngineeringDocument69 pagesMe6302 - Manufacturing Technology - I: Iii Semester Mechanical EngineeringamdevaPas encore d'évaluation

- Probset4. EnergybalancesDocument4 pagesProbset4. EnergybalancesUmmu Qurratul Aini MansorPas encore d'évaluation

- Brixton BX-125 Motorcycle User ManualDocument49 pagesBrixton BX-125 Motorcycle User ManualCARLOS GONZALEZPas encore d'évaluation

- HP Valve PDFDocument48 pagesHP Valve PDFTuanTu NguyenTranPas encore d'évaluation

- Cia 1 Paper 2022-23Document3 pagesCia 1 Paper 2022-23veerendra kumarPas encore d'évaluation