Académique Documents

Professionnel Documents

Culture Documents

NOM 007 SECRE 2010 Eng

Transféré par

Alfredo Bautista HernándezDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

NOM 007 SECRE 2010 Eng

Transféré par

Alfredo Bautista HernándezDroits d'auteur :

Formats disponibles

7.6.

1 When the minimum depth requirements cannot be met or where external loads are

excessive,thepipelinemustbejacketed,ordesignedtowithstandanticipatedexternalload.

Inareaswheretherecanbecarriedoutagriculturalactivitiesthatrequiredeepplowing,inareas

subject to erosion, or in areas where it is planned the construction of roads, railroads, among

others,itshouldbeconsideredadditionalprotectionorburythepipelinedeeper.

7.6.2 The pipes to be installed in a navigable river or body of water or in a seaport must have a

minimumcoverof120cminnormalsoiland60cminconsolidatedrock.However,inthesecasesa

minimumcoverisallowedthatislowertheestablishedinaccordancewiththeprecedingsection.

A.Designformulaforsteelpipe

7.7 Thickness of the Pipe.The calculation of the thickness of the steel pipe that transports gas is

determinedinaccordancewiththefollowingformula:

t=

PxD

2xSxFxExT

Where:

t = minimum wall thickness required in cm. The additional wall thickness required for external

loadingwillbedeterminedtakingintoaccounttheprovisionsofsection7.2.

P=designpressure,inkilopascals(kPa).

S=minimumyieldstrengthinkilopascals(kPa)

D=specifiedoutsidediameterofthepipeline,incm.

F=designfactordeterminedinaccordancewiththeprovisionsofsection7.10.(Table2)

E=efficiencyfactoroflongitudinaljointdeterminedasprovidedundersection7.11(Table3)

T=correctionfactorfortemperaturedeterminedasprovidedinsection7.12.(Table4)

7.7.1 Limiting values in piping design. The design pressure of a steel pipe is limited to 75 %

(seventyfivepercent)ofthevaluedeterminedinaccordancewiththeprovisionsofsection7.7,if

it has been subjected to cold expansion to meet the MPA and its was subsequently heated to a

temperature exceeding, at some point, 755 K or if the pipe has been maintained for more than

onehouratatemperatureabove589K,unlessthisheatwasbyweldingorstressrelieved.

7.8 Minimum yield strength or MPA for steel pipes. The MPA will be established in the

specificationofthepipeline.

7.9 Specified Thickness. The specified thickness should not be reduced in any part of the tube

beyondthetolerancesofthethicknesscontainedintheinternationallyrecognizedpractice.

7.10 Design Factor (F) for steel pipe. The factor used in the design formula in section 7.7 is

determinedasdescribedinTable2,exceptasprovidedinsubsections(a),(b)and(c)below:

Table2.Designfactorbypopulationdensity

Location Rock

Centimeters(tothetopofthepipe)

locationclass1,2

locationclass3y4

Intersectionswithroadsandsewerfringesinpublicroads

Intersectionswithrailroads

60

75

90

120

45

60

60

120

locationclass Designfactor(F)

1 0.72

2 0.60

3 0.50

4 0.40

a)Inthedesignformulaofsection7.7inlocationclass1,itshouldbeusedadesignfactorof0.60

orlowerforpipelinesthat:

Crossoverwithoutjacketedapublicroadoranunpavedroad;

Crossoverwithoutjacketedorinvadeinparalleltherightofwayofroads,highways,streets

orrailroadtracks;

Arelocatedonvehicular,pedestrian,railorpipelinebridges,or

Use manufactured assemblies, including accessories for separators, assemblies of valve

heads, cross connections, heads in river crossings, among others or that are used at a

distance smaller than five diameters pipeline of any accessory of the manufactured

assembly,exceptfromsometransientoranelbowpieceusedinabendofthepipelinethat

isnotassociatedwiththeassembly.

b)Inlocationclass2,itshouldbeusedadesignfactor(F)equaltoorlessthan0.50intheformula

in section 7.7, for the unjacketed steel pipeline crossing the right of way of a paved road,

highway,publicstreetorrailroadtrack;

c)Inlocationclasses1and2,itshouldbeusedadesignfactor(F)equaltoorlessthan0.50inthe

designformulainsection7.7for:

Ductsinacompression,regulatingormeteringstationand

Pipelines,whichincludeanascendingpipeplacedinnavigablewaters.

7.11Efficiencyfactorofthelongitudinaljoint(E)forsteelpipes.Thelongitudinaljointfactorused

intheformulainsection7.7,isdeterminedinaccordancewithfollowingTable3:

Table3.Efficiencyfactoroftheweldedlongitudinaljoint(E)

Specification Tubeclass Factorofthe

longitudinal

joint(E)

ASTMA53 Seamless

Weldedbyelectricresistance

Buttweldedinoven.Continuouswelding

1.00

1.00

0.60

ASTMA106 Seamless 1.00

ASTMA135 Weldedbyelectricresistance 1.00

ASTMA139 Weldedbyelectricfusion 0.80

ASTMA211 Helicalwelding 0.80

ASTMA333 Seamless

Weldedbyelectricresistance

1.00

1.00

ASTMA381 Weldedwithdoublesubmergedarc 1.00

ASTMA671 Weldedbyelectricfusion

Classes13,23,33,43and53

Classes12,22,32,42and52

0.80

1.00

ASTMA672 Weldedbyelectricfusion

Classes13,23,33,43and53

Classes12,22,32,42ad52

0.80

1.00

API5L Seamless

Weldedbyelectricresistance

Weldedbyelectricflashing

Weldedwithsubmergedarc

Buttweldedinoven

1.00

1.00

1.00

1.00

0.60

Otherspecification

orunknown

specification

Pipe with nominal diameter equal to or greater

than101.6mm(4")

0.80

Otherspecification

orunknown

specification

Pipe with nominal diameter lower than 101.6 mm

(4")

0.60

7.12Correctionfactorfortemperature(T)forsteelpipes.Thetemperaturecorrectionfactortobe

usedinthedesignformulaofsection7.7,isdeterminedinaccordancewithTable4below:

Table4.Temperaturecorrectionfactor(T)

Gastemperature(K) T

400olower 1.000

*420 0.967

*450 0.933

*480 0.900

*500 0.867

(*)Forintermediategastemperatures,thetemperaturecorrectionfactorisdeterminedbydirect

interpolation.

B.Componentsofthepipe

7.13 Technical specifications and safety requirements. This section B establishes the technical

specifications and the minimum safety requirements to be met by the components of the

transportation system. It also establishes the requirements for protection against accidental

overpressureandprovides:

a)Specificationsandselectionofpartsandaccessoriesoftheconveyingpipelines;

b)Appropriatemethodsfortheconnectionsofthebranches;

c)Considerationsrelatingtotheeffectsofchangesintemperatureand

d)Appropriatemethodsforsupportingandanchoringthepipelines,whetherexposedorburied.

Vous aimerez peut-être aussi

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerD'EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerÉvaluation : 5 sur 5 étoiles5/5 (1)

- BD 8200Document19 pagesBD 8200JosephChongPas encore d'évaluation

- All-in-One Manual of Industrial Piping Practice and MaintenanceD'EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceÉvaluation : 5 sur 5 étoiles5/5 (1)

- Storm DrainageDocument8 pagesStorm DrainageEphrem GizachewPas encore d'évaluation

- Culvert ThicknessDocument23 pagesCulvert ThicknessNilaAbubakarPas encore d'évaluation

- MH1.1 Jul02 V8Document2 pagesMH1.1 Jul02 V8Katracho2Pas encore d'évaluation

- Square and Round Concrete PilesDocument14 pagesSquare and Round Concrete PilesngumbanPas encore d'évaluation

- Strom DrainageDocument16 pagesStrom DrainageammarrafeiPas encore d'évaluation

- Pipe Culvert: by Ch. VenkataramaiahDocument12 pagesPipe Culvert: by Ch. VenkataramaiahveevimalPas encore d'évaluation

- Subsoil Drainage Detailed DesignDocument4 pagesSubsoil Drainage Detailed Designbirajr78Pas encore d'évaluation

- B Paper IESLDocument21 pagesB Paper IESLJanaka DineshPas encore d'évaluation

- Subsoil DrainageDocument11 pagesSubsoil DrainageRachel IngramPas encore d'évaluation

- 33 05 23.16 Pipe JackingDocument3 pages33 05 23.16 Pipe JackingisaacalvareztejanoPas encore d'évaluation

- 02720Document9 pages02720uddinnadeemPas encore d'évaluation

- 22 14 00 - Facility Storm Drainage PDFDocument6 pages22 14 00 - Facility Storm Drainage PDFsyed0% (1)

- Culvculvculvculvculv Ererererer T Uset Uset Uset Uset Use, Installa, Installa, Installa, Installa, InstallaDocument16 pagesCulvculvculvculvculv Ererererer T Uset Uset Uset Uset Use, Installa, Installa, Installa, Installa, InstallaAffan Abu MaulikhaPas encore d'évaluation

- Vertical Alignment (Profiles) .: A. Cover Over PipelineDocument5 pagesVertical Alignment (Profiles) .: A. Cover Over Pipelinerathod.sanju8Pas encore d'évaluation

- Pipe CulvertDocument12 pagesPipe CulvertveevimalPas encore d'évaluation

- Pipe Culvert: by Ch. VenkataramaiahDocument12 pagesPipe Culvert: by Ch. VenkataramaiahsudhajagannathanPas encore d'évaluation

- Pipe Culvert: by Ch. VenkataramaiahDocument12 pagesPipe Culvert: by Ch. VenkataramaiahrajPas encore d'évaluation

- Pipe CulvertDocument12 pagesPipe CulvertDrainage Division CHIRALAPas encore d'évaluation

- Pipe Culvert: by Ch. VenkataramaiahDocument12 pagesPipe Culvert: by Ch. VenkataramaiahRaMmy RockPas encore d'évaluation

- Pipe CulvertDocument12 pagesPipe CulvertveevimalPas encore d'évaluation

- Pipe Culvert: by Ch. VenkataramaiahDocument12 pagesPipe Culvert: by Ch. Venkataramaiahkutticute_877110165Pas encore d'évaluation

- Pipe Culvert: by Ch. VenkataramaiahDocument12 pagesPipe Culvert: by Ch. VenkataramaiahamanPas encore d'évaluation

- Technical Commentary Standard Plan B-10.20: For Catch Basin Type 2Document3 pagesTechnical Commentary Standard Plan B-10.20: For Catch Basin Type 2Sabina ShresthaPas encore d'évaluation

- Concrete Encased Duct Bank PDFDocument8 pagesConcrete Encased Duct Bank PDF101079Pas encore d'évaluation

- 33 05 13 Manholes and Structures 10Document4 pages33 05 13 Manholes and Structures 10Mohammed AlkhateebPas encore d'évaluation

- Engineering Standards Manual: Code of Practice For City Infrastructure & Land DevelopmentDocument13 pagesEngineering Standards Manual: Code of Practice For City Infrastructure & Land DevelopmentAther Hussain MoverPas encore d'évaluation

- 1169 - USA - 49 CFR 192 - Eff 03 2016Document21 pages1169 - USA - 49 CFR 192 - Eff 03 2016Enoch TwumasiPas encore d'évaluation

- Minimum Design Criteria For The Permitting of Gravity SewersDocument2 pagesMinimum Design Criteria For The Permitting of Gravity SewerslaikienfuiPas encore d'évaluation

- Selection of Pipe Material.: A. GeneralDocument4 pagesSelection of Pipe Material.: A. GeneralalkhiatPas encore d'évaluation

- Standard Practice For The Design and Construction of Reinforced Concrete Storm Sewer Pipe (RCP) Part 1: GeneralDocument23 pagesStandard Practice For The Design and Construction of Reinforced Concrete Storm Sewer Pipe (RCP) Part 1: GeneralAnony MousPas encore d'évaluation

- Design Water Network For StormDocument22 pagesDesign Water Network For Stormsaidelsayed2012Pas encore d'évaluation

- TN27 Australian Standard For Precast BC and HeadwallDocument8 pagesTN27 Australian Standard For Precast BC and HeadwallgemotorresPas encore d'évaluation

- Section 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery ExtensionDocument3 pagesSection 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery Extensionery achjariPas encore d'évaluation

- Code of Practice For Laying of Cast Iron Pipes: Indian StandardDocument15 pagesCode of Practice For Laying of Cast Iron Pipes: Indian StandardgavallapalliPas encore d'évaluation

- Design PipelineDocument9 pagesDesign Pipelineengr_asad364Pas encore d'évaluation

- Construction and Materials Manual: 5.50.1 Culvert Pipe ListDocument4 pagesConstruction and Materials Manual: 5.50.1 Culvert Pipe Listt_aligPas encore d'évaluation

- SpecificationsDocument44 pagesSpecificationssofianina05Pas encore d'évaluation

- 33 05 13 Manholes and Structures 10Document4 pages33 05 13 Manholes and Structures 10salamPas encore d'évaluation

- Drain PipeDocument4 pagesDrain PipeNur HaryatiPas encore d'évaluation

- For Pipeline Route SelectionDocument11 pagesFor Pipeline Route SelectionGalymzhan Botabayev100% (1)

- Section 6 WaterDocument3 pagesSection 6 WaterBabiker ElrasheedPas encore d'évaluation

- Cement-Mortar Lined & Coated Steel PipeDocument5 pagesCement-Mortar Lined & Coated Steel Pipenay denPas encore d'évaluation

- Clarifier Tank Part 1 - GeneralDocument4 pagesClarifier Tank Part 1 - Generalfiddy_ftPas encore d'évaluation

- Section 9.0 - CulvertsDocument11 pagesSection 9.0 - CulvertsOMANAKUTTAN100% (1)

- dm43 Apr09 V8Document2 pagesdm43 Apr09 V8Katracho2Pas encore d'évaluation

- FAA APPROVED: November 15, 1988Document4 pagesFAA APPROVED: November 15, 1988Imam Arif RahmanPas encore d'évaluation

- Water Tank SpecificationDocument28 pagesWater Tank Specificationdan20000Pas encore d'évaluation

- 3.2 Design Standards and ConsiderationsDocument19 pages3.2 Design Standards and ConsiderationsAjay SinghPas encore d'évaluation

- Culvculvculvculvculv Ererererer T Uset Uset Uset Uset Use, Installa, Installa, Installa, Installa, InstallaDocument16 pagesCulvculvculvculvculv Ererererer T Uset Uset Uset Uset Use, Installa, Installa, Installa, Installa, Installaralfaro2288Pas encore d'évaluation

- Church of Jesus Christ of Latter Day Saints Mabvuku Tafara-Civils BriefDocument14 pagesChurch of Jesus Christ of Latter Day Saints Mabvuku Tafara-Civils BriefTrevor T ParazivaPas encore d'évaluation

- 6 Ten States Standards 2004 - Chapter 30 - Design of SewersDocument12 pages6 Ten States Standards 2004 - Chapter 30 - Design of SewersCowbeak7959Pas encore d'évaluation

- Pipeline Crossings and Clearances.: A. GeneralDocument7 pagesPipeline Crossings and Clearances.: A. GeneralSuhas NatuPas encore d'évaluation

- Scope of Work:: Gail (India) LimitedDocument8 pagesScope of Work:: Gail (India) LimitedAnonymous sdMq4MSPas encore d'évaluation

- Pipeline Stream Crossings.: A. GeneralDocument8 pagesPipeline Stream Crossings.: A. GeneralAlejandro GuerreroPas encore d'évaluation

- Sewage Disposal Works: Their Design and ConstructionD'EverandSewage Disposal Works: Their Design and ConstructionPas encore d'évaluation

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsD'EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsPas encore d'évaluation

- CV 41Document2 pagesCV 41Alfredo Bautista HernándezPas encore d'évaluation

- 1045-BB1-ME-CAL-001 - A ScopeDocument187 pages1045-BB1-ME-CAL-001 - A ScopeAlfredo Bautista HernándezPas encore d'évaluation

- 1042 BB1 Me Cal 001 - 0Document108 pages1042 BB1 Me Cal 001 - 0Alfredo Bautista HernándezPas encore d'évaluation

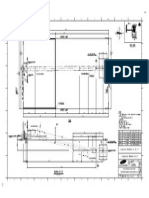

- 3.3 2586-4-Pi-Ga-301 - Ag Piping Plan For Interconnection Zone (1 - 4) - Rev 4 - Ifc-2Document1 page3.3 2586-4-Pi-Ga-301 - Ag Piping Plan For Interconnection Zone (1 - 4) - Rev 4 - Ifc-2Alfredo Bautista HernándezPas encore d'évaluation

- Mss sp-44 1996Document28 pagesMss sp-44 1996DsokasPas encore d'évaluation

- Removing of Major PartsDocument7 pagesRemoving of Major PartsAlfredo Bautista HernándezPas encore d'évaluation

- US-106911-01-IP-100-001 P4 - REV B-ModelDocument1 pageUS-106911-01-IP-100-001 P4 - REV B-ModelAlfredo Bautista HernándezPas encore d'évaluation

- LeanDesign 1clickDocument3 pagesLeanDesign 1clickPallab DasguptaPas encore d'évaluation

- B.E. Mech PDFDocument113 pagesB.E. Mech PDFarulmuruguPas encore d'évaluation

- Agathiyan Angamuthu - OriginalDocument3 pagesAgathiyan Angamuthu - OriginalQatar Pride 2022Pas encore d'évaluation

- Volume 2 Building Works Ss R 2012Document262 pagesVolume 2 Building Works Ss R 2012bbaplPas encore d'évaluation

- 18 Dwelling House PlanDocument25 pages18 Dwelling House PlanAh Chhun'y Seng100% (1)

- HPS Catalog Dry-Type Medium VoltageDocument15 pagesHPS Catalog Dry-Type Medium VoltageEmilio SalazarPas encore d'évaluation

- Pages From KERPEN CableDocument2 pagesPages From KERPEN CablerelaxjackPas encore d'évaluation

- Impact FactorDocument13 pagesImpact FactorNindy SabrinaPas encore d'évaluation

- DBR-HVAC Rev 0Document16 pagesDBR-HVAC Rev 0psjjoshiPas encore d'évaluation

- Civils SpecDocument135 pagesCivils SpecNafnaf Troop100% (2)

- Cooling Tower FundamentalsDocument117 pagesCooling Tower FundamentalsСергій ГейкоPas encore d'évaluation

- First Semester 2010-2011 - Schedue of Classes - As of May 11, 2010Document54 pagesFirst Semester 2010-2011 - Schedue of Classes - As of May 11, 2010xerexoxPas encore d'évaluation

- IS550 MidTerm Spring 2015 SolutionDocument7 pagesIS550 MidTerm Spring 2015 Solutionaboaziz2130Pas encore d'évaluation

- JD - Biomedical TechnicianDocument4 pagesJD - Biomedical TechnicianMohammad BerroPas encore d'évaluation

- Profile of Dr. Premanand ShenoyDocument1 pageProfile of Dr. Premanand ShenoyPremanand ShenoyPas encore d'évaluation

- Digital System Design HomeworkDocument5 pagesDigital System Design HomeworkHassanNajjarPas encore d'évaluation

- Midterm EV407 May 2017Document4 pagesMidterm EV407 May 2017khalil AlwastiPas encore d'évaluation

- Precast Piles For Route 40 Bridge in Virginia Using Concrete Filled FRP TubesDocument14 pagesPrecast Piles For Route 40 Bridge in Virginia Using Concrete Filled FRP TubesmarkicivanPas encore d'évaluation

- Multi Choice Tech 1 AnswerDocument20 pagesMulti Choice Tech 1 AnswerquyennqPas encore d'évaluation

- Staad Load Combinations With Notional LoadsREV3Document6 pagesStaad Load Combinations With Notional LoadsREV3ramonortiz55Pas encore d'évaluation

- This Part Describes Preliminary and Basic Services Which An Architect Will Normally ProvideDocument9 pagesThis Part Describes Preliminary and Basic Services Which An Architect Will Normally ProvidedodsmPas encore d'évaluation

- 610 SullivanDocument19 pages610 SullivanJhon GreigPas encore d'évaluation

- Project Title: Design 2B Final Project ReportDocument3 pagesProject Title: Design 2B Final Project ReportÚt MậnPas encore d'évaluation

- Dse7560 Data Sheet PDFDocument2 pagesDse7560 Data Sheet PDFGeorge AniborPas encore d'évaluation

- Establishment ListDocument3 pagesEstablishment ListRiya100% (1)

- Method of Compensation: Standard of Professional Practice (SPP) On Post-Construction Services SPP Document 205Document3 pagesMethod of Compensation: Standard of Professional Practice (SPP) On Post-Construction Services SPP Document 205Michael RuñaPas encore d'évaluation

- John Ngaya Mukabi, PHD Full CV 23NOV09Document104 pagesJohn Ngaya Mukabi, PHD Full CV 23NOV09John Ngaya MukabiPas encore d'évaluation

- 1 and 2 HR Wall Assemblies PDFDocument9 pages1 and 2 HR Wall Assemblies PDFaPas encore d'évaluation

- Concrete Fail in Compressive Strength Cube 368Document11 pagesConcrete Fail in Compressive Strength Cube 368talatzahoorPas encore d'évaluation

- London AmbulanceDocument22 pagesLondon AmbulanceRafiqul IslamPas encore d'évaluation