Académique Documents

Professionnel Documents

Culture Documents

A TRIAC-Dimmable LED Lamp Driver With Wide

Transféré par

Musthafa KadershaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

A TRIAC-Dimmable LED Lamp Driver With Wide

Transféré par

Musthafa KadershaDroits d'auteur :

Formats disponibles

1434 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 29, NO.

3, MARCH 2014

A TRIAC-Dimmable LED Lamp Driver With Wide

Dimming Range

Ruihong Zhang, Student Member, IEEE, and Henry Shu-hung Chung, Senior Member, IEEE

AbstractLED light bulbs are becoming increasingly popular

as they consume much less power than traditional incandescent

lamps. To enable full compatibility with incandescent lamps, apart

fromdelivering the same light output andquality, they are expected

to be operable with standard TRIAC-based light dimmers. How-

ever, the input current of the LED light bulbs at dimming could

fall below the holding current of the TRIAC, resulting in limited

dimming range and lamp ickering. This paper presents a TRIAC-

dimmable LED lamp driver allowing wide dimming range. The

concept is based on controlling the input reactive power, so that

the input current is increased to a level higher than the holding

current of the TRIAC, while the LED array power is regulated.

The driver consists of two power conversion stages, including a

four-quadrant acdc converter for shaping the input current and

a resonant converter for regulating the output power to the LED

array. The two converters share the same switching network. Mod-

eling, analysis, and design of the driver will be presented. An LED

prototype has been built and evaluated. Experimental results re-

veal that the true ring angle of the TRIAC can be adjusted down

to 172

, and the lamp power can be dimmed from 7.2 to 0.3 W

linearly.

Index TermsFull bridge, LED driver, resonant converter,

TRIAC dimmer.

I. INTRODUCTION

W

ITH recent development in solid-state lighting technol-

ogy, LEDreplacement light bulbs are quickly becoming

available for general illumination as they have higher luminous

efcacy and longer life expectancy than traditional incandescent

lamp bulbs [1]. To enable full compatibility, the operational fea-

tures of LED lamps are always expected to exhibit similar to or

better than that of the incandescent lamps. Among them, com-

patibility of the LED lamps with TRIAC-based light dimmers

has attracted much research interest, since many TRIAC-based

light dimmers had been installed in various places, originally

for controlling incandescent lamps. However, the evolvement

of a technology that allows LED lamps to perform wide range

dimming is still less impressive. The main difculty arises from

the low LED lamp input current, and the high and diversied

Manuscript received October 6, 2012; revised February 5, 2013 and March 29,

2013; accepted May 14, 2013. Date of current version September 18, 2013. This

work was supported by e.Energy Lighting Limited through Project 9231038.

Recommended for publication by Associate Editor C. A. Canesin.

The authors are with the Centre for Smart Energy Conversion and Uti-

lization, City University of Hong Kong, Kowloon, Hong Kong (e-mail:

eerhzhang@gmail.com; eeshc@cityu.edu.hk).

Color versions of one or more of the gures in this paper are available online

at http://ieeexplore.ieee.org.

Digital Object Identier 10.1109/TPEL.2013.2263935

Fig. 1. Typical circuit of the TRIAC-based light dimmer.

magnitude of the TRIAC holding current. Practically, the hold-

ing current of TRIAC ranges from 20 to 80 mA while the input

current of LED lamps can be less than 60 mA, hindering the

compatibility of LED lamps with different TRIAC-based light

dimmers. For the same lamp brightness, the input current of LED

lamps is only one-tenth of the incandescent lamps, and its mag-

nitude is too small to hold the TRIAC in the conduction state

after the TRIAC is latched. Thus, existing TRIAC-dimmable

LED lamp drivers cannot provide a very wide dimming range.

For example, a 15-WLEDlamp driver using a yback converter

with primary-side regulation to control the LED current is pro-

posed in [2] and [3]. The adjustable dimming range reported is

from 35

to 150

. In [4], an active damper circuit together with

the primary-side regulation method is proposed. It provides suf-

cient turn-on input current with smaller power consumption, as

compared with the passive damper circuit, in order to latch the

conduction state of the TRIAC. However, the effect of the hold-

ing current of the TRIAC on the dimming range has not been

addressed. The maximum dimming range reported is around

130

. Thus, challenges will appear if the dimmed power level is

further reduced.

Fig. 1 shows the typical circuit of the TRIAC-based light

dimmer. The resistors R

1

and R

2

and capacitor C form an RC

network. R

1

is used to adjust the phase and the voltage across C.

When the voltage across the capacitor C reaches the breakdown

voltage of DIAC, a gate signal will be applied to the TRIAC.

The control knob of R

1

can thus control the ring angle (turn-on

time) of the TRIAC and lamp power. Fig. 2 shows the typical

waveforms of the line voltage v

in

and the input current i

in

of

the lamp controlled by a TRIAC. The angles and ( ) are

the ring angle and extinction angle of the TRIAC, respectively.

The TRIAC is turned OFF naturally at ( ) when i

in

is less

than the holding current I

h

.

Fig. 3 shows the minimumlamp power P

min

against the ring

angle with holding current ranging from 20 to 80 mA under

the condition that the conduction time of the TRIAC is not less

than 30

and the load is purely resistive. Generally, the higher

0885-8993 2013 IEEE

ZHANG AND CHUNG: TRIAC-DIMMABLE LED LAMP DRIVER WITH WIDE DIMMING RANGE 1435

Fig. 2. Typical waveforms with resistive load [Case IIi

in

is in phase with

v

in

( = 0

)].

Fig. 3. Minimum lamp power against the ring angle.

the holding current, the higher the minimum lamp power. For

example, at =10

, P

min

=10 Wwhen I

h

=20 mA, and P

min

= 40 W when I

h

= 80 mA. Detailed derivations of the curves

will be given in Section II. Thus, the curves can explain why

low-power LED lamps have limited dimming range. Moreover,

at large ring angle, lamps could icker easily at the frequency

of 100 or 120 Hz, namely invisible icker. Although the invis-

ible icker cannot be easily seen by human eyes, it will cause

possible health problems, like brain damaging, headaches, eye

strain, and so on [5].

The previous problem can be lessened by adding a resistor,

namely bleeding circuit [6], [7], in the lamp driver in order to

consume minimum power. However, this will introduce extra

power loss in the whole driver. In [8], a TRIAC-dimmable LED

driver that does not require any bleeding circuit is proposed. The

concept is based on reducing the conduction time of the TRIAC

when the ring angle is large. It allows the dimmer to turn off

if the input current is lower than the holding current. Thus, the

input current is pulsating. In [9], the circuit is extended from the

ballast for compact uorescent lamps. It consists of a capacitor

network for increasing the input current and thus maintaining

the TRIAC conduction. However, the LED current is pulsating

and the reported maximum dimming is about 10%.

A TRIAC-dimmable LED lamp driver allowing wide dim-

ming range is presented. It consists of two power conversion

stages. The rst stage controls the active and reactive power

drawn from the line, so that the input current is programmed

to satisfy the minimum holding current requirement. The lamp

can thus exhibit a wide dimming range. The second stage is an

isolated resonant converter for regulating the LEDarray current.

The lamp power is controlled to be in linear relationship with

the ring angle. The two converters share the same switching

network, which is in variable frequency and variable duty cy-

cle control [10], [11]. The function of the variable frequency

control is used to remove the line frequency ripple in the LED

current and regulate the output LED lamp power. The function

of the variable duty cycle control is used to shape the input

current. An LED driver prototype has been built and evaluated.

The lamp power can be adjusted from full power of 7.2 to 0.3 W

with the true ring angle down to 172

. Section II describes the

operating principles of the proposed driver. Section III gives a

set of design procedure. Section IV will show the experimental

verication. The conclusions follow in the last section.

II. OPERATING PRINCIPLES OF THE PROPOSED LED DRIVER

Fig. 4 shows the circuit schematic of the proposed driver,

which consists of two power conversion stages. The rst stage

is a four-quadrant acdc converter and the second stage is an

LLC resonant converter. The two converters share the switches

S

1

S

4

. Fig. 5 shows the equivalent circuit model of the power

stage. The ac side of the switching network is represented by

a voltage source v

AB

, which is composed of a low-frequency

component v

AB,L

and a high-frequency component v

AB,H

. The

secondary side of the transformer T

r

is referred to the primary

side and is modeled by an equivalent resistor R

eq

.

A. First StageFour-Quadrant ACDC Converter

The four-quadrant acdc converter which adopts the full-

bridge topology can be capable of operating in all four quad-

rants of the i

in

v

in

plane and regenerate the energy back to

the grid [12], [13]. It can also be considered as a bidirectional

converter that can perform bidirectional power ow [14]. The

four-quadrant acdc converter is composed of an input lter

formed by the inductor L

in

and the capacitor C

in

, inductors

L

s1

and L

s2

, switches S

1

S

4

, and dc-link capacitor C

dc

. It is

connected to the output stage through the nodes A and B.

The input current i

in

is programmed to be lagging, in-phase,

or leading the input voltage v

in

, so that the active and reactive

power drawn from v

in

are controlled and i

in

is kept higher than

the holding current of the TRIAC on dimming.

As the voltage waveformacross the capacitor C

in

is nearly the

same as the dimmer output voltage v

in

, the input lter formed

by the inductor L

in

and the capacitor C

in

is excluded in Fig. 5,

for the sake of simplicity in the analysis.

Let the lamp power P

LED

vary linearly with the ring angle

. P

LED

is expressed as

P

LED

() =

_

P

r

, < 0

P

r

_

1

_

, 0 <

(1)

where P

r

is the rated lamp power.

1436 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 29, NO. 3, MARCH 2014

Fig. 4. Circuit schematic of the proposed TRIAC-dimmable LED driver.

Fig. 5. Equivalent circuit model of the power stage.

The voltages v

in

, v

in

, and the current i

in

are expressed as

v

in

(t) = V

m

sin t (2)

v

in

(t) =

_

0, t <

V

m

sin t, t < +

(3)

i

in

(t) =

_

0, t <

I

m

sin(t ), t < +

(4)

where V

m

and I

m

are the amplitude of the input voltage v

in

and

input current i

in

, respectively, is the angular line frequency,

and is the phase difference between v

in

and i

in

.

There are three possible operational cases. They are Case I

i

in

leads v

in

(i.e., < 0

), Case IIi

in

is in phase with v

in

(i.e., = 0

) , and Case IIIi

in

lags v

in

(i.e., > 0

). The

three cases are illustrated in Figs. 6, 2, and 7, respectively. Case

I is operated when is small. can be negative, zero, or pos-

itive with different TRIAC holding currents. Their waveforms

are shown in Fig. 6(a)(c). Case III is operated when is large.

Since is operating-point dependent, there will have three pos-

sible scenarios in Case III, including < , = , and > .

Their waveforms are shown in Fig. 7(a)(c), respectively.

The average input active power P

avg

in all three cases is

expressed as

P

avg

(, , ) =

1

2

__

+

V

m

I

m

sin sin( )d

+

_

2+

+

V

m

I

m

sin sin( )d

_

=

V

m

I

m

2

[( +) cos

+ sin( + ) cos( )]. (5)

Consider the critical condition that the input current at the

extinction angle equals I

h

:

I

h

= I

m

sin . (6)

To ensure stable operation, i

in

should not be less than I

h

over

the TRIAC conduction time. Thus, when TRIAC is turned ON

at t = , based on (4)

I

m

sin( ) I

h

. (7)

By substituting (6) into (7)

. (8)

The curves shown in Fig. 3 are obtained by using (5) and (6),

and putting = 0, = for /36 5/12, and putting

= 0, = + / 6 for 5/12 < .

Then, assume that the system efciency is 100%, P

avg

=

P

LED

. By putting (1) and (6) into (5)

P

r

_

1

_

=

V

m

I

h

2 sin

[( +) cos

+ sin( + ) cos( )]. (9)

ZHANG AND CHUNG: TRIAC-DIMMABLE LED LAMP DRIVER WITH WIDE DIMMING RANGE 1437

Fig. 6. Case Ii

in

leads v

in

( < 0

). (a) < 0

. (b) = 0

. (c) > 0

.

The rms value of the input voltage v

in

, V

rms

, is

V

rms

=

V

m

2

. (10)

The rms value of the input current i

in

, I

rms

, is as shown (11)

at the bottom of the page.

The apparent input power S is

S(, , ) = V

rms

I

rms

=

V

m

I

m

2

_

1

[( +) + sin( + ) cos( )].

(12)

Fig. 7. Case IIIi

in

lags v

in

( > 0

). (a) < . (b) = . (c) > .

By using (5) and (12), the input power factor PF is

PF(, , ) =

P

avg

S

=

( +) cos + sin( + ) cos( )

_

[( +) + sin( + ) cos( )]

.

(13)

Equation (13) gives the input power factor with different val-

ues of , , and that can satisfy the required power level given

in (9). Thus, PF can be maximized by changing . Fig. 8 illus-

trates the maximum achievable power factor with different val-

ues of and I

h

ranging from 20 to 80 mA, and the required val-

ues of for giving the maximum power factor. The parameters

I

rms

(, , ) =

1

2

__

+

[I

m

sin( )]

2

d +

_

2+

+

[I

m

sin( )]

2

d

_

= I

m

_

1

2

[( +) + sin( + ) cos( )] (11)

1438 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 29, NO. 3, MARCH 2014

Fig. 8. Maximum achievable power factor against ring angle with the re-

quired phase shift.

TABLE I

SPECIFICATIONS OF THE PROTOTYPE

Fig. 9. Actual power factor against ring angle with the simplied phase shift

control.

used in the analysis are given in Table I, in which the rated

power is 7.2 W. However, according to Fig. 8, the phase shift

has to be varied with and I

h

. This is impractical as the

holding current of a TRIAC is difcult to be determined. Thus,

a xed relationship between and is designed by linearizing

the curve when the holding current is 80 mA in Fig. 8.

It is given in Fig. 9. This is the worst case of all the situations

in Fig. 8. In other words, the LED driver will operate normally

Fig. 10. Waveform of v

AB

.

with TRIAC having holding current below 80 mA. When <

0, is constant and equals the phase shift till = 0. When 0

<

1

, is negative and reduces linearly with . When

1

<

<

2

, is positive and increases linearly with . When

2

< < 172

, is positive and reduces linearly with .

1

and

2

are chosen by considering the PF curve in Fig. 8 under

the maximum holding current (i.e., I

h

= 80 mA) at which

= 0

and is maximum for i

in

lags v

in

, respectively.

1

=

60

and

2

= 105

are chosen in Fig. 9. Although the resulting

power factor with the simplied phase-shift control is slightly

different from the maximum achievable power factor, it is still

acceptable in practice.

The voltage between nodes A and B, v

AB

, is

v

AB

=

_

+v

dc

, when S

1

and S

4

are ON , and S

2

and S

3

are OFF

v

dc

, when S

2

and S

3

are ON , and S

1

and S

4

are OFF .

(14)

Fig. 10 shows the waveform of v

AB

. Based on Fig. 5, the

voltage across the equivalent inductor L

s

= L

s1

+L

s2

, v

Ls

, is

v

Ls

=

_

0, t <

L

s

I

m

cos(t ), t < +.

(15)

v

AB,H

in Fig. 5 is neglected in the following analysis as the

high-frequency impedance of L

s

is large. Thus, consider the

low-frequency component of v

AB

, v

AB,L

v

AB,L

= v

dc

d(t) v

dc

[1 d(t)]

= v

dc

[2d(t) 1] (16)

where d(t) is the duty cycle of S

1

and S

4

. The duty cycle of S

2

and S

3

thus equals 1 d(t).

By applying KVL

v

AB,L

= v

in

v

Ls

=

_

0, t <

V

m

sin t L

s

I

m

cos(t ), t < +.

(17)

ZHANG AND CHUNG: TRIAC-DIMMABLE LED LAMP DRIVER WITH WIDE DIMMING RANGE 1439

Fig. 11. Variation of d(t) over a line cycle at different ring angle. (a) =

0

. (b) = 45

. (c) = 90

. (d) = 145

.

By putting (17) into (16)

d(t)

=

_

_

1

2

, t <

1

2

+

_

V

2

m

2V

m

I

m

L

s

sin +

2

L

2

s

I

2

m

2v

dc

sin(t ),

t < +

(18)

where = tan

1 L

s

I

m

cos

V

m

L

s

I

m

sin

.

Based on (18), the minimum and maximum duty cycles, d

min

and d

max

, are

d

max

=

_

_

1

2

+

_

V

2

m

2V

m

I

m

L

s

sin +

2

L

2

s

I

2

m

2v

dc

,

2

+

max

__

1 d

_

+

__

, d

_

_

_

,

>

2

+

(19)

d

min

= 1 d

max

. (20)

Figs. 11(a)(d) show the variations of d(t) over a line cycle

at = 0

, 45

, 90

, and 145

, respectively.

B. Second StageLLC Resonant Converter

The LLC resonant converter is composed of the switches

S

1

S

4

, inductor L

r

, capacitor C

r

, transformer T

r

, output l-

ter, and LED array. The resonant path is formed by L

r

, magne-

tizing inductance L

m

of the transformer T

r

, and C

r

. The LLC

resonant converter has many advantages over conventional res-

onant converters, as it can regulate the output over wide input

and load ranges with zero-voltage switching and a relatively

small variation of the switching frequency [15], [16]. As de-

scribed in (18), the duty cycles of the switches vary with the

line frequency. v

AB,L

in Fig. 5 will have small effect on the

output, as the impedance of C

r

is very high. Thus, only the

high-frequency component of v

AB

, v

AB,H

is considered in the

following discussion. Let K

v

be the ratio between the rms val-

ues of the voltage across R

eq

, v

R

, (|v

R

|), and v

AB,H

(|v

AB,H

|).

Referring to Fig. 5

K

v

_

r

_

=

|v

R

|

|v

AB,H

|

=

|R

eq

//j

s

L

m

|

R

eq

//j

s

L

m

+j

s

L

r

+

1

j

s

C

r

=

m

_

r

_

2

_

mQ

r

_

1

_

r

_

2

__

2

+

_

(m+ 1)

_

r

_

2

1

_

2

(21)

where Q =

Z

r

R

e q

is the quality factor, Z

r

=

_

L

r

C

r

is the

characteristic impedance, m =

L

m

L

r

,

s

= 2f

s

, and f

s

is the

switching frequency, and

r

=

1

L

r

C

r

is the angular resonant

frequency.

Fig. 12 shows the relationships between K

v

and

s

/

r

with

different combinations of the values of Qand m. K

v

is sensitive

to Q and is less sensitive to m for m > 1.

The waveform of v

AB

shown in Fig. 10 is even symmetrical.

For the sake of simplicity in the analysis, only the fundamen-

tal frequency component is considered in the following analy-

sis. Based on Fourier analysis, the fundamental component of

v

AB,H

, v

F

AB,H

is

v

F

AB,H

(t) = V

F

AB,H

(v

dc

, d) cos(

s

t)

=

4v

dc

sin[d(t)] cos(

s

t) (22)

where V

F

AB,H

(v

dc,

d) =

2

T

s

_ T s

2

T s

2

v

AB

(t) cos

s

tdt =

4v

d c

sin

[d(t)].

Thus, the lamp power can be expressed as

P

LED

() =

K

2

v

_

r

_

v

F

AB,H

(t)

2

R

eq

()

=

8v

2

dc

K

2

v

_

r

_

sin

2

[d(t)]

2

R

eq

()

(23)

where |v

F

AB,H

| =

V

F

A B , H

2

is the rms value of v

F

AB,H

.

The equivalent load resistance R

eq

at different LED current

can be expressed in terms of the LED array voltage as

R

eq

() =

2n

2

v

LED

i

LED

()

. (24)

Detailed proof of (24) is given in the Appendix.

By putting (24) into (23)

v

dc

=

nv

LED

2K

v

_

r

_

sin[d(t)]

. (25)

According to Fig. 12, in order to ensure that the resonant cir-

cuit operates in the inductive mode,

s

r

> 1. K

v

will then be less

than unity. Since the minimum value of the term sin[d(t)] in

1440 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 29, NO. 3, MARCH 2014

Fig. 12. Relationships between K

v

and

s

/

r

. (a) m = 0.5. (b) m = 1. (c) m = 2. (d) m = 2.5. (e) m = 3.

the denominator of (25) is sin[ d

max

] or sin[ d

min

], the min-

imum value of v

dc

required, v

dc,min

, is determined by putting

K

v

_

r

_

= 1 into (25). Thus

v

dc,min

=

nv

LED

2 sin[d

max

]

=

nv

LED

2 sin[d

min

]

. (26)

By putting (26) into (19) with v

dc

= v

dc,min

, the following

implicit function for d

max

can be obtained:

d

max

=

_

_

1

2

+

sin[d

max

]

_

V

2

m

2V

m

I

m

L

s

sin +

2

L

2

s

I

2

m

nv

LED

,

2

+

max

__

1 d

_

+

__

, d

_

_

_

,

>

2

+

(27)

where d

_

+

_

and d

_

_

are obtained by (18).

For a given ring angle , all parameters, except d

max

, in

(27) are known. d

max

is determined by an iterative method.

v

dc,min

is then obtained by putting the determined d

max

into

(26). Hence, the relationships between v

dc,min

and shown in

Fig. 13 are obtained by repeating the previous analysis method

with different values of .

By substituting (18) into (25) with v

dc

=v

dc,min

, Fig. 14 shows

the variation of K

v

over one line cycle at different ring angle of

the TRIAC, in which the minimum value of K

v

, K

v,min

occurs

when sin[d(t)] = 1. Thus

K

v,min

=

nv

LED

2v

dc,min

. (28)

Fig. 15 shows the variation of K

v,min

against .

C. Control Method

The controller shown in Fig. 4 regulates the lamp power at

different ring angles by sensing the voltage v

in

, input cur-

rent i

in

, dc-link voltage v

dc

, and LED array current i

LED

, and

controlling both the duty cycle and switching frequency of the

switches. The purpose of adjusting the duty cycle is to perform

the input current shaping while the purpose of adjusting the

ZHANG AND CHUNG: TRIAC-DIMMABLE LED LAMP DRIVER WITH WIDE DIMMING RANGE 1441

Fig. 13. v

dc, min

against .

switching frequency is to regulate the lamp power so that the

line-frequency harmonics are removed. The control method is

described as follows.

The ring angle is rst detected by the sensed v

in

. It will be

used to derive the reference dc-link voltage V

dc,ref

, based on the

curve v

dc,min

depicted in Fig. 13. The actual dc-link voltage

v

dc

will be compared with the reference dc-link voltage V

dc,ref

,

and their error v

dc

will be passed to a PI controller, namely

PI-1, to derive the reference input current i

in,ref

, which will be

in the form of

i

in,ref

=

_

0, t <

I

m,ref

sin(t ), t < +

(29)

where I

m,ref

is the amplitude of the reference input current

i

in,ref

.

The actual input current i

in

will be compared with the ref-

erence input current i

in,ref

, and their error i

in

will be passed

to a PI controller, namely PI-2, to derive the modulating signal

v

m

for the PWM modulator. The gate signals for S

1

S

4

are

derived by comparing v

m

with the carrier signal v

tri

. In (29),

is determined by considering the ring angle, as depicted in

Fig. 9. The amplitude I

m,ref

is determined by the output of PI-1.

Thus, the duty cycles of the switches are controlled through this

control mechanism.

The switching frequency is controlled as follows. After deter-

mining the ring angle, a reference LED array current, i

LED,ref

,

is derived as follows:

i

LED,ref

=

P

LED

()

v

LED

. (30)

The actual LEDarray current i

LED

will be compared with the

reference LED array current i

LED,ref

and their error i

LED

will

be passed to a PI controller, namely PI-3, to vary the frequency

of the carrier signal v

tri

. It should be noted that the previous

controls are all performed on a microcontroller.

III. DESIGN PROCEDURE

The values of L

s1

= L

s2

= L

s

/2, L

in

, C

in

, n, L

r

, C

r

, L

m

,

C

dc

, L

o

, and C

o

are determined by considering the following

parameters:

1) P

r

: Rated lamp power;

2) V

m

: Amplitude of the voltages v

in

and v

in

expressed in

(2) and (3);

3) f

s,min

: Minimum switching frequency of the switches;

4) i

s

: The ripple current through the inductors L

s1

and L

s2

when the switching frequency is the minimum;

5) I

h,max

: Maximum designed holding current of the

TRIAC;

6)

0

: Introduced phase shift when = 5

shown in Fig. 9;

7) v

dc,r

: v

dc

at the rated lamp power;

8) v

dc,r

: peak-to-peak ripple voltage on v

dc

at the rated

lamp power;

9) i

Lo

: The ripple current through the inductor L

o

when

the switching frequency is the minimum.

Step 1: The amplitude of i

in

, I

m

, is determined by using (6).

That is

I

m

=

I

h,max

sin(

0

0

)

. (31)

L

s

is then determined by considering that the switching fre-

quency is the lowest. The duty cycle of S

1

and S

4

, d, should

be maximum. Based on (16) and (17), v

in

should be maximum

when d is maximum, so v

Ls

is neglected for the sake of sim-

plicity in calculation. By substituting (16) into (17)

d

max

=

v

in

+v

dc

2v

dc

(32)

L

s

i

s

d

max

(1/f

s,min

)

= v

dc

v

in

. (33)

By substituting (32) into (33)

L

s

=

d

max

(v

dc

v

in

)

f

s,min

i

s

=

(v

2

dc,r

v

2

m

)

2v

dc

f

s,min

i

s

(34)

where i

s

is taken to be 40% of I

m

when the switching fre-

quency is the lowest.

Therefore

L

s1

= L

s2

=

L

s

2

. (35)

Step 2: L

in

and C

in

are determined by considering that

the high-frequency ripple current through L

s1

and L

s2

ows

through C

in

at f

s,min

. Assume that the impedance of L

in

is

larger than three times the impedance of C

in

at f

s,min

. Thus

2f

s,min

L

in

> 3

1

2f

s,min

C

in

L

in

C

in

>

3

4

2

f

2

s,min

. (36)

1442 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 29, NO. 3, MARCH 2014

Fig. 14. Variation of K

v

over one line cycle at different ring angle. (a) = 0

. (b) = 45

. (c) = 90

. (d) = 145

.

Fig. 15. Variation of K

v , min

against .

Step 3: The value of n is determined by (26)

n =

2v

dc,r

v

LED

sin(d

max

) =

2v

dc,r

v

LED

sin(d

min

). (37)

Step 4: With = 0

, based on (24), R

eq

(0) equals

R

eq

(0) =

2n

2

v

2

LED

P

r

. (38)

If the quality factor Qat the rated power is Q

r

, the character-

istic impedance Z

r

is equal to

Z

r

= Q

r

R

eq

(0). (39)

Fig. 16. Trajectories of K

v , min

against

s

r

for different lamp power and

m = 2.5.

Thus, based on Fig. 12, Fig. 16 shows the trajectories of

K

v,min

against

s

r

for different lamp power and m = 2.5. It can

be observed from the trajectories that:

1) if Q

r

is small, for example, Q

r

= 2, there is considerable

variation of the switching frequency from the rated power

to the dimmed power;

2) if Q

r

is large, for example, Q

r

= 20, the lamp power is

too sensitive to the variation to the switching frequency.

ZHANG AND CHUNG: TRIAC-DIMMABLE LED LAMP DRIVER WITH WIDE DIMMING RANGE 1443

Thus, it can be observed that Q

r

= 5 gives the compromise

between the previous two considerations. Thus, based on (38)

and (39)

Z

r

=

_

L

r

C

r

= 5R

eq

(0)

L

r

=

100n

4

v

4

LED

P

2

r

C

r

. (40)

Based on (21), the resonant frequency is designed at f

s,min

.

Thus

f

s,min

=

1

2

L

r

C

r

. (41)

Thus, by solving (40) and (41) for L

r

and C

r

, it can be shown

that

L

r

=

5n

2

v

2

LED

P

r

f

s,min

(42)

C

r

=

P

r

20n

2

v

2

LED

f

s,min

. (43)

The value of L

m

is chosen by taking m = 2.5. Thus, based

on (21)

L

m

= mL

r

=

12.5n

2

v

2

LED

P

r

f

s,min

. (44)

Step 5: For the sake of simplicity in the design, the value of

C

dc

is designed by assuming that the input current is in phase

with the supply voltage at the rated power condition

P

r

=

1

2

_

2

0

V

m

I

m

sin

2

tdt

=

V

m

I

m

2

. (45)

C

dc

absorbs the difference between the input power and the

average lamp power. Thus, the maximumvariation of the energy

E

C

stored in the capacitor is

E

C

=

P

r

. (46)

Assume that v

dc

varies between v

dc,r

and v

dc,r

+ v

dc,r

, and

v

dc,r

<< v

dc,r

1

2

C

dc

(v

dc,r

+ v

dc,r

)

2

1

2

C

dc

v

2

dc,r

=

P

r

C

dc

=

P

r

v

dc,r

v

dc,r

. (47)

Step 6: The value of L

o

is designed by considering the ripple

current i

Lo

through it. Based on (A.9) given in the Appendix,

the RMS value of voltage v

R

, | v

R

|in Fig. 4, is

| v

R

| =

2v

LED

. (48)

So, the voltage v

R

is

v

R

= 2v

LED

|sin

s

t| (49)

TABLE II

COMPONENT VALUES USED IN THE EXPERIMENTAL PROTOTYPE

L

o

i

L

o

t

= v

R

v

LED

L

o

=

(2

3

2

3

)v

LED

2f

s,min

i

L

o

. (50)

The value of C

o

is estimated by cutoff frequency f

o

of the

lter formed by L

o

and C

o

being

f

o

=

1

2

L

o

C

o

C

o

=

1

4

2

f

2

o

L

o

. (51)

IV. IMPLEMENTATION OF THE TRIAC-DIMMABLE

LED DRIVER

An experimental 110 V/60 Hz prototype has been built and

tested. The rated power is 7.2 W. It is based on the requirements

given in Table I. Based on the design method given in Section III,

the component values are given in Table II. The microcontroller

used is MC9S08QE128. The lamp can be dimmed from 7.2 to

0.3 W with a TRIAC dimmer. Fig. 17 shows the waveforms of

the input voltage v

in

, input current i

in

, and LED array current

i

LED

. The average current and peak-to-peak ripple current of the

LED are measured. Fig. 17(a) shows the waveforms when the

lamp is connected to the ac mains without TRIAC. It can be seen

that the input current is in phase with the voltage. Fig. 17(b)(f)

shows the corresponding waveforms when the ring angle is

25

, 45

, 90

, 145

, and 172

, respectively. The LED array

current ripples in all cases are found to be less than 25%. The

phase of the input current varies with the ring angle, so as

to introduce the required reactive power and thus maintain the

conduction state of the TRIAC.

Fig. 18 shows the theoretical and measured switching fre-

quencies of the switches versus the lamp power. Both of them

are in close agreement. The measured output power P

LED

and

efciency against the ring angle are given in Fig. 19. The

output power and the ring angle are in linear relationship, con-

rming the proposed driving method. The highest efciency is

found to be 80%when the ring angle is 0

, i.e., the rated condi-

tion. The efciency performance of the prototype is comparable

1444 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 29, NO. 3, MARCH 2014

Fig. 17. Experimental results of the prototype (v

in

: 250 V/div, i

in

: 500 mA/div, i

LED

: 200 mA/div, Timebase: 4 ms/div). (a) Without TRIAC and P

LED

=

7.2 W. (b) = 25

and P

LED

= 7.2 W. (c) = 45

and P

LED

= 5.4 W. (d) = 90

and P

LED

= 3.6 W. (e) = 145

and P

LED

= 1.4 W. (f) = 172

and P

LED

= 0.3 W.

Fig. 18. Switching frequency f

S

versus the lamp power P

LED

.

Fig. 19. Measured lamp power P

LED

and efciency versus ring angle .

ZHANG AND CHUNG: TRIAC-DIMMABLE LED LAMP DRIVER WITH WIDE DIMMING RANGE 1445

Fig. 20. Photographs of the prototype driver. (a) Top view. (b) Side view.

to the yback-type structure given in [7]. The lowest efciency

is found to be 52% when the ring angle is 172

. Fig. 13 shows

the experimental results of v

dc

versus the ring angle. Its prole

is similar to the theoretical prediction.

Fig. 20 shows the prototype driver for a 7-W LED lamp.

In terms of physical size, the present design can be optimized

further. For example, the circuitry can be further reduced as the

four switches and their corresponding drivers can be integrated

with current semiconductor packaging technologies.

V. CONCLUSION

A TRIAC-dimmable LED lamp driver that can provide wide

dimming range for extremely low-power operation without dis-

sipative bleeding circuit has been presented. By introducing the

reactive power control, the input current can be increased while

the active power is regulated. The concept has been demon-

strated on a 7.2 W prototype, which can be dimmed down to

0.3 W. Experiments reveal that the current ripple of the LED

is small. The output power of LED can be controlled in linear

relationship with the ring angle of the TRIAC. The theoret-

ical predictions and experimental measurements are in close

agreement.

APPENDIX

PROOF OF (24)

The high-frequency component of v

AB

, v

AB,H

, is only con-

sidered here as the low-frequency component is blocked by the

capacitor C

r

. In Fig. 5, the magnetizing inductance of the trans-

former L

m

is much larger than the equivalent resistance R

eq

at

high-frequency switching. Thus, L

m

is neglected in the analysis.

The phasor for representing v

F

AB,H

in (22) v

F

AB,H

is

v

F

AB,H

=

4v

dc

2

sin[d(t)]0

. (A.1)

The current i

p

owing through L

r

and C

r

is

i

p

=

i

LED

()

2n

(A.2)

where is the phase difference between v

F

AB,H

and i

p

.

So, the output power transferred to the secondary side of

transformer is

P = v

AB,H

i

p

cos()

=

2v

dc

i

LED

()

n

sin[d(t)] cos . (A.3)

Thus,

cos =

nP

2v

dc

i

LED

() sin[d(t)]

. (A.4)

The voltages across L

r

, v

Lr

, and C

r

, v

Cr

, are

v

L

r

=

i

p

s

L

r

90

=

i

LED

()

s

L

r

n

(90

) (A.5)

v

C

r

=

i

p

s

C

r

90

=

i

LED

()

n

s

C

r

(90

). (A.6)

Based on KVL, the voltage across R

eq

, v

R

, is

v

R

= v

F

AB,H

v

L

r

v

C

r

. (A.7)

R

eq

is approximated by assuming that the imaginary part of

v

R

in (A.7) is negligible. Thus, by considering the real part of

(A.7) and substituting (A.1), (A.5), and (A.6) into (A.7)

R

eq

= Re[

v

R

i

p

] =

2n

2

v

LED

i

LED

()

(A.8)

| v

R

| = |

i

p

|R

eq

=

2nv

LED

. (A.9)

REFERENCES

[1] D. Rand, B. Lehman, and A. Sheynberg, Issues, models, and solutions for

TRIAC modulated phase dimming of LED lamps, in Proc. IEEE Power

Electron. Spec. Conf., Jun. 2007, pp. 13981404.

[2] J. Zhang, H. Zhong, and T. Jiang, A primary-side control scheme for

high-power-factor LED driver with TRIAC dimming capability, IEEE

Trans. Power Electron., vol. 27, no. 11, pp. 46194629, Nov. 2012.

[3] T. Jiang, H. Zeng, J. Zhang, and Z. Qian, Aprimary side feedforward con-

trol scheme for low power LED driver compatible with TRIAC dimmer,

in Proc. 27th Appl. Power Electron. Conf. Expo., Feb. 2012, pp. 963968.

[4] H. Eom, C. Lee, T. Yang, and S. Yang, Design optimization of TRIAC-

dimmable AC-DC converter in LED lighting, in Proc. 27th Appl. Power

Electron. Conf. Expo., Feb. 2012, pp. 831835.

[5] A. Wilkins, J. Veitch, and B. Lehman, LED lighting icker and poten-

tial health concerns: IEEE standard PAR1789 update, in Proc. Energy

Convers. Congr. Expo., Sep. 2010, pp. 171178.

1446 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 29, NO. 3, MARCH 2014

[6] A. Shteynberg, H. Rodriguez, D. Zhou, and B. M. Lehman, Adap-

tive current regulation for solid state lighting, U.S. Patent Application

2010/0213859, Aug. 26, 2010.

[7] LM3445-120VAC, 8W Isolated Flyback LED Driver, Texas Instruments,

Dallas, TX, USA, AN-2034, Sep. 22, 2010.

[8] L. Yan, B. Chen, and J. Zheng, A new TRIAC dimmable LED driver

control method achieves High-PF and quality-of-light, in Proc. 27th

Appl. Power Electron. Conf. Expo., Feb. 2012, pp. 969974.

[9] A. Tjokrorahardjo, Simple TRIAC dimmable compact uorescent lamp

ballast and light emitting diode driver, in Proc. 25th IEEE Appl. Power

Electron. Conf. Expo., 2010, pp. 13521357.

[10] K. Mitsuyuki, M. Takumi, A. Keizo, and Y. Hirokazu, Power adjust-

ment with variable frequency and duty-cycle control for induction heating

apparatus, U.S. Patent Application 4 147 910, Apr. 3, 1979.

[11] C. Chakraborty, S. Dalapati, and S. Bhattacharya, Variable frequency

variable duty cycle operation of the controlled capacitor charging (CCC)

type inverter, presented at the 31st Annu. Conf. IEEE Ind. Electron. Soc.,

Raleigh, NC, USA, Nov. 2005.

[12] R. Garcia-Gil, J. M. Espi, E. J. Dede, and E. Sanchis-Kilders, A bidi-

rectional and isolated three-phase rectier with soft-switching operation,

IEEE Trans. Ind. Electron., vol. 52, no. 11, pp. 765773, Jun. 2005.

[13] N. Mohan, T. Undeland, and W. Robbins, Power Electronics: Converters,

Applications, and Design, 3 rd ed. New York, NY, USA: Wiley, 2003,

pp. 202210.

[14] D. Dong, F. Luo, D. Boroyevich, and P. Mattavelli, Leakage current

reduction in a single-phase bidirectional ACDC full-bridge inverter,

IEEE Trans. Power Electron., vol. 27, no. 10, pp. 42814291, Oct. 2012.

[15] R. Beiranvand, B. Rashidian, M. R. Zolghadri, and S. M. H. Alavi, A

design procedure for optimizing the LLC resonant converter as a wide

output range voltage source, IEEE Trans. Power Electron., vol. 27, no. 8,

pp. 37493763, Aug. 2012.

[16] H. Choi, Analysis and design of LLC resonant converter with integrated

transformer, in Proc. 22nd Appl. Power Electron. Conf. Expo., Feb. 2007,

pp. 16301635.

Ruihong Zhang (S12) received the B.Eng. degree

in computer science and the M.Eng. degree in elec-

trical engineering, both from the Harbin Institute of

Technology, Harbin, China, in 2005 and 2008, re-

spectively. She is currently working toward the Ph.D.

degree in electrical engineering from the City Uni-

versity of Hong Kong, Kowloon, Hong Kong.

Her current research interests include the light-

ing system, power-factor-correction, resonant con-

verters, ac/dc, dc/dc converters, and energy-recycling

techniques.

Henry Shu-hung Chung (M95SM03) received

the B.Eng. degree, in 1991, and the Ph.D. degree in

electrical engineering, in 1994, both fromHong Kong

Polytechnic University, Kowloon, Hong Kong.

Since 1995, he has been with the City University

of Hong Kong, Kowloon. He is currently a Profes-

sor in the Department of Electronic Engineering, and

the Director of the Centre for Smart Energy Conver-

sion and Utilization Research. He has authored six

research book chapters, and more than 300 technical

papers including 140 refereed journal papers in his

research areas, and holds 26 patents. His research interests include time- and

frequency-domain analysis of power electronic circuits, switched-capacitor-

based converters, random-switching techniques, control methods, digital audio

ampliers, soft-switching converters, and electronic ballast design.

Dr. Chung is currently the Chairman of Technical Committee on High-

Performance and Emerging Technologies of the IEEE Power Electronics Soci-

ety, and an Associate Editor of the IEEE TRANSACTIONS ON POWER ELECTRON-

ICS, IEEE TRANSACTIONS ON CIRCUITS AND SYSTEMS, PART I: FUNDAMENTAL

THEORY AND APPLICATIONS, and the IEEE JOURNAL OF EMERGING AND SE-

LECTED TOPICS IN POWER ELECTRONICS.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Multy User Mobile Bluetooth Two Way Text ChatDocument9 pagesMulty User Mobile Bluetooth Two Way Text ChatfahadPas encore d'évaluation

- Visually Gesture Recognition For An Interactive Robot Grasping ApplicationDocument8 pagesVisually Gesture Recognition For An Interactive Robot Grasping ApplicationMusthafa KadershaPas encore d'évaluation

- Manet SessionsDocument8 pagesManet SessionsMusthafa KadershaPas encore d'évaluation

- Automatic Punching ConveyorDocument5 pagesAutomatic Punching ConveyorMusthafa KadershaPas encore d'évaluation

- PWM Based Three Phase Induction Motor Speed ControllerDocument4 pagesPWM Based Three Phase Induction Motor Speed ControllerMusthafa KadershaPas encore d'évaluation

- A.8 Automatic ParkingDocument30 pagesA.8 Automatic ParkingMusthafa KadershaPas encore d'évaluation

- 06297976Document13 pages06297976Musthafa KadershaPas encore d'évaluation

- A.8 Automatic ParkingDocument30 pagesA.8 Automatic ParkingMusthafa KadershaPas encore d'évaluation

- VLSIDocument2 pagesVLSIMusthafa KadershaPas encore d'évaluation

- An Online RFID and Zigbee Based Manufacturing Monitoring System Using ARM7 Micro ControllerDocument5 pagesAn Online RFID and Zigbee Based Manufacturing Monitoring System Using ARM7 Micro ControllerMusthafa KadershaPas encore d'évaluation

- A.8 Automatic ParkingDocument30 pagesA.8 Automatic ParkingMusthafa KadershaPas encore d'évaluation

- Modernized Vechicle Control System With Alcohol DetectionDocument2 pagesModernized Vechicle Control System With Alcohol DetectionMusthafa KadershaPas encore d'évaluation

- Development of A Robotic Arm For Dangerous Object DisposalDocument3 pagesDevelopment of A Robotic Arm For Dangerous Object DisposalMusthafa KadershaPas encore d'évaluation

- Power SupplyDocument4 pagesPower SupplyMusthafa KadershaPas encore d'évaluation

- Polyline To Polygon MatchingDocument22 pagesPolyline To Polygon MatchingSoundar MsrPas encore d'évaluation

- Suganya ADocument2 pagesSuganya AMusthafa KadershaPas encore d'évaluation

- Library Management SystemDocument95 pagesLibrary Management SystemMusthafa Kadersha0% (1)

- Image Features Extraction and Fusion Based On Joint Sparse RepresentaionDocument9 pagesImage Features Extraction and Fusion Based On Joint Sparse RepresentaionMusthafa KadershaPas encore d'évaluation

- Non-Orthogonal View Iris Recognition SystemDocument18 pagesNon-Orthogonal View Iris Recognition SystemMusthafa KadershaPas encore d'évaluation

- Need ProjectDocument1 pageNeed ProjectMusthafa KadershaPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Catalog LivingDocument120 pagesCatalog LivingTeodora AtomeiPas encore d'évaluation

- Draft 1 - Lampiran 2 Perbup TPPNSDocument40 pagesDraft 1 - Lampiran 2 Perbup TPPNSIvani Amelia CitraPas encore d'évaluation

- KatalogDocument50 pagesKatalogAnonymous Vrndt2Pas encore d'évaluation

- AUGUST 2022 Ecolum Price ListDocument8 pagesAUGUST 2022 Ecolum Price ListDream BuilderPas encore d'évaluation

- ATBMDocument4 pagesATBMBastian NovaPas encore d'évaluation

- Staray - Price ListDocument37 pagesStaray - Price Listf136495Pas encore d'évaluation

- The OSRAM Vintage Edition 1906. New For Over 100 YearsDocument28 pagesThe OSRAM Vintage Edition 1906. New For Over 100 YearsVela RibaPas encore d'évaluation

- LEDL057 GE LED 14W Value Type A LED Glass Tubes Spec SheetDocument2 pagesLEDL057 GE LED 14W Value Type A LED Glass Tubes Spec SheetAldyPratamaPas encore d'évaluation

- Experiment 3: Illumination Design of Dental Clinic: B. Lighting StandardDocument16 pagesExperiment 3: Illumination Design of Dental Clinic: B. Lighting StandarderizaPas encore d'évaluation

- Lighting Online Catalogue V6 2018 PDFDocument151 pagesLighting Online Catalogue V6 2018 PDFFgp MalangPas encore d'évaluation

- Elumanation - SlimCab Elevator LED Light Panel Fixture - ELP-SF30 - Specification GuideDocument2 pagesElumanation - SlimCab Elevator LED Light Panel Fixture - ELP-SF30 - Specification GuideReeta SelvaPas encore d'évaluation

- Research Paper On Led LightingDocument8 pagesResearch Paper On Led Lightingk0wyn0tykob3100% (1)

- LED Product ReckonerDocument12 pagesLED Product ReckonerShray GuptaPas encore d'évaluation

- DLP TVLDocument2 pagesDLP TVLPhiw TabuzoPas encore d'évaluation

- Philips ProductCatalogue 2011 en PDFDocument171 pagesPhilips ProductCatalogue 2011 en PDFMohammed Jahir HusainPas encore d'évaluation

- Tender For Supply LED Fixtures - T35Document42 pagesTender For Supply LED Fixtures - T35Balamurugan ArumugamPas encore d'évaluation

- O25011v78 SU 1 KNX - Data SheetDocument2 pagesO25011v78 SU 1 KNX - Data SheetGilbert GivaryPas encore d'évaluation

- PUBLIC LIGHTING CONTROL SYSTEM GENERAL TECHNICAL DESCRIPTION - Rev. 06 1203Document12 pagesPUBLIC LIGHTING CONTROL SYSTEM GENERAL TECHNICAL DESCRIPTION - Rev. 06 1203Sanela BeganovicPas encore d'évaluation

- Tech Specs of LED FittingsDocument10 pagesTech Specs of LED FittingsSr. DEEPas encore d'évaluation

- PH Ue Ledtube Uet8 Leaflet A4 q3 2023 LRDocument2 pagesPH Ue Ledtube Uet8 Leaflet A4 q3 2023 LRcandidodealmeida10Pas encore d'évaluation

- Topas Led SeriesDocument6 pagesTopas Led SeriesViktorasPas encore d'évaluation

- MT7626Document6 pagesMT7626Vishal dtuPas encore d'évaluation

- DIN Rail Universal Dimmer Installation & Operation Guide: Description Important Notes Hardware Hookup Set The Net IDDocument2 pagesDIN Rail Universal Dimmer Installation & Operation Guide: Description Important Notes Hardware Hookup Set The Net IDKhaliun BoldbaatarPas encore d'évaluation

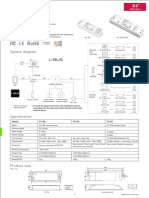

- LED Wireless Driver: System DiagramDocument2 pagesLED Wireless Driver: System Diagrammauro zaratePas encore d'évaluation

- LED Light Bulb Brightness Scale & Color Charts - Bulb GuideDocument8 pagesLED Light Bulb Brightness Scale & Color Charts - Bulb GuidechichavlajaPas encore d'évaluation

- 2ZL 4ZL Brochure PDFDocument2 pages2ZL 4ZL Brochure PDFali zeidPas encore d'évaluation

- Americanlite Ul Led TubesDocument33 pagesAmericanlite Ul Led TubesOscar DavilaPas encore d'évaluation

- N Y VMVFXNJ epjvbmd7IHTl20v9eiaxtY3GMxOPFp0rbYwwZAxVGFZuGfgt8K65IxqZK5eZq6YzP1tPnr0Q7cg - aTFQA G1kuw9WsqJyiqRI1Xxo7UMt - U3f 02TS6Q1 i5g3wSHSgstLDocument25 pagesN Y VMVFXNJ epjvbmd7IHTl20v9eiaxtY3GMxOPFp0rbYwwZAxVGFZuGfgt8K65IxqZK5eZq6YzP1tPnr0Q7cg - aTFQA G1kuw9WsqJyiqRI1Xxo7UMt - U3f 02TS6Q1 i5g3wSHSgstLIlyas Amiri Year 10Pas encore d'évaluation

- 2019 - BMC - Automated TentsDocument13 pages2019 - BMC - Automated TentsVictor DeleclozPas encore d'évaluation

- Visum II Product BrochureDocument4 pagesVisum II Product BrochureGreg Whitwham0% (1)