Académique Documents

Professionnel Documents

Culture Documents

Hot Work: Standard Operating Procedures

Transféré par

droffilcz270 évaluation0% ont trouvé ce document utile (0 vote)

133 vues4 pagesMOD

Titre original

12-352MOD_5G

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentMOD

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

133 vues4 pagesHot Work: Standard Operating Procedures

Transféré par

droffilcz27MOD

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

Committed to Excellence in Mining Safety

Last Modied: Page:

JAN 2013 1 of 5

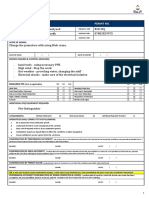

STANDARD OPERATING PROCEDURES

Hot Work

MODULE 5

www.coresafety.org

(CONT.)

Hot Work

I PURPOSE

This standard was established for the purpose of ensuring and taking all necessary

precautions to prevent accidents caused by any activity that generates spark, ame or

ignition sources.

2 SCOPE

This procedure applies to all functional areas, operations, projects, ofces, employees and

contractors.

3 DEFINITIONS AND ACRONYMS

Denitions

Combustible, Flammable or Explosive Materials are resources such as wood, plastic,

rubber, paint, oil, grease, solvent, compresses gas, powdered metal, volatile fumes or gas,

and explosives, which could ignite or explode when exposed to heat or ame.

Designated Hot Work Areas are places such as in shops where ammable and

combustible materials have been removed, compressed gas cylinders are secured and

located at least 15 feet away from the actual hot work, ventilation considerations have been

made, re extinguishing equipment is available, welding screens, where applicable, are in

place to protect other workers in the area, and the area has been posted as a hot work area

by management.

Fire Watch is a person positioned at the job site and designated to monitor the area until the

hot work is completed and the area has been secured from any potential re hazards.

Hot Work is any work that creates enough heat from spark, molten metal, torches, etc. to

ignite combustible or ammable material. Grinding, cutting and welding are all considered

types of hot work.

Acronyms

HMR HSLP Management Representative

HSLP Health, Safety and Loss Prevention

PPE Personal Protective Equipment

Committed to Excellence in Mining Safety

Last Modied: Page:

JAN 2013 2 of 5

www.coresafety.org

MODULE 5

(CONT.) Hot Work

4 ROLES AND RESPONSIBILITIES

Document Owner

HMR

Responsible Roles and Position-Holders

Contractors/Vendors are businesses performing a service for the COMPANY. They are

responsible for ensuring their employees working on COMPANY sites have completed the

required permit as specied in this procedure and that their employees understand and

comply with the requirements as outlined in this procedure.

Employee and Contracted Employees all employees in any position whether COMPANY

or contracted employees working on any COMPANY site. They are responsible for complying

with the requirements as outlined in this procedure and ensure that the required permits

completed.

HSLP is any COMPANY employee working under and including the Regional Director of

HSLP. They are responsible for periodically auditing for compliance to this procedure. They

provide advice regarding the standards governing the performance of hot work and check

compliance with these standards on a random and sufciently frequent basis.

A Supervisor/Foreman or Designee can be a COMPANY employee or a contractor/

vendor working or traveling on any COMPANY site. They are responsible for ensuring

that the permit is completed correctly and enforcing all hot work requirements, rules, and

established guidelines as outlined in this procedure. They ensure personnel are provided with

the needed resources to properly carry out the requirements of this procedure and that they

are adequately trained, and understand the provisions outlined in the hot work procedure.

They inspect the location where the hot work will be performed and review information on

the permit ensuring that the precautions and descriptions of work are on the permit before

signing it.

5 DIRECTION

All employees, vendors, contractors, and visitors traveling/working on site shall comply with

and ensure personnel accountable to them comply with the following requirements of this

procedure.

General Rules

All Employees shall:

a Keep their work area free of any re hazards (accumulation of combustible,

ammable, or explosive material).

b Know the location of reghting equipment, re alarm pull stations,

communication systems etc. and how to use them.

c Inspect their equipment before starting any hot work to ensure it is free from

defects and safe to use.

Committed to Excellence in Mining Safety

Last Modied: Page:

JAN 2013 3 of 5

www.coresafety.org

MODULE 5

(CONT.) Hot Work

d Correctly use the appropriate Personal Protective Equipment, bearing in

mind the provisions set forth in this document.

e Obtain authorization to carry out hot work before starting to work. Notify

their immediate supervisor before carrying out any hot work.

When hot work is to be performed outside of designated hot work areas the appropriate

supervisor or designee will issue a hot work permit only after:

a The re watch person has inspected the area and removed all combustible,

ammable, and explosive materials within a minimum radius of 60 feet, or

b When removal is not possible the material shall be protected with re

resistant material such as re blankets or welding screens and this

information shall be noted on the permit.

The work area and equipment being utilized must be inspected before, during and after the

performance of work, in order to detect any substandard condition.

No hot work shall take place unless the Fire Watch is present and all safety precautions have

been taken (an exception to the Fire Watch requirement is in pit areas where there are no

combustible materials within 40 feet of the hot work e.g. welding on open buckets).

The Fire Watch must have a re extinguisher in operating condition, which must be within at

least 6 feet of the work being performed. The Fire Watch person must position themselves so

they can extinguish a re from the upwind side of the re.

The completed Hot Work Permit Form must be displayed in a visible place in the work area.

All hot work must be suspended if the conditions under which the permit was issued change.

Example: Gas leak, fuel spill, adverse weather conditions etc.

When hot work is suspended due to changing conditions, the work can be resumed only

when the safety conditions are re-established and a new Hot Work Permit is issued.

Fire Watch

Shall be familiar with the location and use of re alarms, re-ghting equipment, rst-aid

equipment, radios and telephones for emergency cases.

Inspect the hot work area prior to performing any hot work.

Remove all combustible and ammable materials from the work area. A distance of 40 feet

should be used as a minimum guideline.

Fill out the hot work permit listing all pertinent safety precautions, get signatures, and then

post it in the hot work area.

Properly use the appropriate PPE, bearing in mind the provisions set forth in this document

and those outlined in the permit.

Ensure an adequate re extinguisher or water hose is at hand, the permit is posted in the area,

observe the hot work activity as it progresses and extinguish any res resulting from the hot

work.

Committed to Excellence in Mining Safety

Last Modied: Page:

JAN 2013 4 of 5

www.coresafety.org

MODULE 5

Hot Work

Inspect the area 30 minutes after the hot work has been completed to ensure no re has

started.

Oxygen Acetylene Cutting Operation

Gages and regulators used with oxygen or acetylene cylinders shall be kept clean and free

of oil or grease.

To prevent accidental release of gases from hoses and torches attached to oxygen and

acetylene cylinders, valves shall be closed when:

The cylinders are moved;

The torch and hoses are left unattended: or

The task or series of tasks is completed.

The oxygen and acetylene cylinders and hoses must be located in such a manner to protect

them from possible damage due to the hot work.

Torches shall be attended at all times while lit.

Cutting torches must be equipped with anti-ame back ash valves in both hoses going to the

cylinder.

Regarding the cylinders, the provisions set forth in the Compressed Gas Standards of the

COMPANY must be complied with.

Safety Considerations when lling out the permit.

Air quality must always be considered and when necessary, ventilation systems must

be utilized.

Use of welding screens and blankets is mandatory when other personnel will be in the vicinity

of the hot work.

Evaluate barricading and posting of the area to keep personnel away from the hot work when

necessary.

Additional Personal Protective Equipment such as welding leathers, gloves, respirators and fall

protection should be specied on the permit as conditions dictate.

When hot work is carried out at heights or within conned spaces, the relevant COMPANY

procedures must be complied with.

Before starting any hot work in tanks, ponds, containers or pipes that have contained fuel or

ammable liquids, the appropriate steps must be taken to ensure that they are empty and that

they have been properly drained, ventilated and washed.

Welding Operation

Welding machines must be properly grounded.

Welding operations must be shielded when performed at locations where

arc ash could be hazardous to persons.

Hearing protection is required while air arcing.

Vous aimerez peut-être aussi

- Lockout-Tagout ProcedureDocument17 pagesLockout-Tagout ProcedureshaikhbwcPas encore d'évaluation

- Work Order Standard Operating ProcedureDocument10 pagesWork Order Standard Operating ProcedureJemar B. BagnatePas encore d'évaluation

- Disciplinary Action FormDocument2 pagesDisciplinary Action Formbirender_kumarPas encore d'évaluation

- Daily Hse Report Job Safety Analysis MakcoDocument14 pagesDaily Hse Report Job Safety Analysis MakcoSafety Mohini100% (2)

- VR-ForM-F06.10 (Hot Work Permit Request Form)Document1 pageVR-ForM-F06.10 (Hot Work Permit Request Form)imtz2013Pas encore d'évaluation

- 7.electrical LOTO Check List InspectionDocument1 page7.electrical LOTO Check List Inspectionfitri widyaPas encore d'évaluation

- Work PermitDocument17 pagesWork PermitRiccar303Pas encore d'évaluation

- General work permitDocument1 pageGeneral work permitgurvinder singhPas encore d'évaluation

- 18A - FO - Permit To Work LogDocument2 pages18A - FO - Permit To Work Lograjesh_rathPas encore d'évaluation

- PLTG 75 MW PAYA PASIR MEDAN PTW RequestDocument2 pagesPLTG 75 MW PAYA PASIR MEDAN PTW RequestDimas Dwi SwarnaPas encore d'évaluation

- PTW No.: - : Excavation PermitDocument1 pagePTW No.: - : Excavation PermitbhaskarPas encore d'évaluation

- First Aid Box Treatment & Inspection Register TemplateDocument1 pageFirst Aid Box Treatment & Inspection Register TemplateSn Ahsan100% (1)

- Personal Protective Equipment (P.P.E) RegisterDocument2 pagesPersonal Protective Equipment (P.P.E) RegistermarvinPas encore d'évaluation

- Job Safety Analysis: JSA Reference #: DateDocument3 pagesJob Safety Analysis: JSA Reference #: DateLi QiPas encore d'évaluation

- Permit To Work ProceduceDocument4 pagesPermit To Work ProceduceQuý Hoàng ChuPas encore d'évaluation

- Tool Box TalkDocument2 pagesTool Box TalkTwin BullsPas encore d'évaluation

- Site Specific Safety OrientationDocument39 pagesSite Specific Safety OrientationBernard AmooPas encore d'évaluation

- Powder Actuated ToolsDocument1 pagePowder Actuated ToolsJayvee Baradas ValdezPas encore d'évaluation

- Health and Safety Induction ChecklistDocument2 pagesHealth and Safety Induction ChecklistYathawan Nair ThamutharamPas encore d'évaluation

- Health and Safety Induction SampleDocument5 pagesHealth and Safety Induction SampleMohamad Hafiz100% (1)

- Chemical Spill Procedure: 1. PurposeDocument2 pagesChemical Spill Procedure: 1. PurposeWalter A. Mustafa Takeo100% (1)

- R-16 Safety Management Review MeetingDocument2 pagesR-16 Safety Management Review MeetingSandeep Kumar100% (1)

- Integrated Management System Work Permit ProceduresDocument2 pagesIntegrated Management System Work Permit ProceduresKishan MauryaPas encore d'évaluation

- Permit To Work ProceduresDocument3 pagesPermit To Work ProceduresREBAA HatemPas encore d'évaluation

- List of Operational Control ProcedureDocument1 pageList of Operational Control ProcedureRam Naidu PenPas encore d'évaluation

- Ppe Training Record: Department Occupation Type of Ppe Make/Model Name InitialsDocument3 pagesPpe Training Record: Department Occupation Type of Ppe Make/Model Name Initialsvlad100% (1)

- OCP - 21 - Safe Use of HelmetDocument2 pagesOCP - 21 - Safe Use of HelmetNagendra Kumar SinghPas encore d'évaluation

- Lockout Tagout ProcedureDocument7 pagesLockout Tagout ProcedureKadesh Hanah McCarthyPas encore d'évaluation

- Contractor - Permit To Work in Occupied Areas: (Select All That Apply)Document2 pagesContractor - Permit To Work in Occupied Areas: (Select All That Apply)AAT SupplyPas encore d'évaluation

- Safety Health Emergency Response ProcedureDocument2 pagesSafety Health Emergency Response Procedurearjuna rahmat100% (1)

- EHS Training Attendance SheetDocument2 pagesEHS Training Attendance SheetTwin BullsPas encore d'évaluation

- HSE Hot Work PermitDocument3 pagesHSE Hot Work PermitCSD shakthiPas encore d'évaluation

- Inspection Form Lockout TagoutDocument4 pagesInspection Form Lockout TagoutCarina Kouamé100% (1)

- HSE-P-07 Work Permit Procedure Issue 2.1Document30 pagesHSE-P-07 Work Permit Procedure Issue 2.1eng20072007100% (1)

- PPE Hazard Assessment FormDocument3 pagesPPE Hazard Assessment FormeastPas encore d'évaluation

- Permit To Work Policy ProcedureDocument7 pagesPermit To Work Policy ProcedureChristian Auditor RiveraPas encore d'évaluation

- First Aid Cases RecordDocument1 pageFirst Aid Cases RecordFrancis Enriquez TanPas encore d'évaluation

- Electrical Safe Work PracticesDocument1 pageElectrical Safe Work PracticesjesusbarajasPas encore d'évaluation

- Jsa PDFDocument5 pagesJsa PDFVAMSIPas encore d'évaluation

- STA Audit Format-EditableDocument1 pageSTA Audit Format-EditableDeepu ChandranPas encore d'évaluation

- HSE-201-PR - Form 1 - Toolbox Meeting FormDocument1 pageHSE-201-PR - Form 1 - Toolbox Meeting FormCobbinah MarkPas encore d'évaluation

- Permit To WorkDocument1 pagePermit To WorkMohammed KadhimPas encore d'évaluation

- Fall Protection Plan: QPS Services - Occupational Health and Safety Management System Fall Protection Plan Page 1 of 8Document8 pagesFall Protection Plan: QPS Services - Occupational Health and Safety Management System Fall Protection Plan Page 1 of 8HeleenPas encore d'évaluation

- HSE Operational Control Procedure For Electrical WorkDocument3 pagesHSE Operational Control Procedure For Electrical Workalit2Pas encore d'évaluation

- 015 CH 10 Tool InspectionDocument3 pages015 CH 10 Tool InspectionLinda BooysenPas encore d'évaluation

- Hazard Communication Program 1Document4 pagesHazard Communication Program 1myo lwinPas encore d'évaluation

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaPas encore d'évaluation

- 2014 Energized Electrical Work Permit - ByU-IdahoDocument2 pages2014 Energized Electrical Work Permit - ByU-Idahocarrot123456Pas encore d'évaluation

- Training Matrix SampleDocument4 pagesTraining Matrix SampleMaurice Avicor CoccusPas encore d'évaluation

- 3 SPS Sop RCC FullDocument14 pages3 SPS Sop RCC FullDwitikrushna RoutPas encore d'évaluation

- Safe Work Permit Rev. 06: BASF Corporation Title: Beaumont Site Function: Health & Safety Procedure No.: Page: 1 ofDocument22 pagesSafe Work Permit Rev. 06: BASF Corporation Title: Beaumont Site Function: Health & Safety Procedure No.: Page: 1 ofIvan BaracPas encore d'évaluation

- Aerial Lift Inspection FormsDocument15 pagesAerial Lift Inspection FormsianPas encore d'évaluation

- Control MeasuresDocument4 pagesControl MeasuresCharlie Dela RosaPas encore d'évaluation

- Hot Work at Height and From Scaffolding Presents Special Hazards. Additional Requirements Are NeededDocument2 pagesHot Work at Height and From Scaffolding Presents Special Hazards. Additional Requirements Are Neededテレブリコ ジェファーソンPas encore d'évaluation

- Job Hazard Analysis Form (Shutdown Activites)Document4 pagesJob Hazard Analysis Form (Shutdown Activites)MARK ARQUE LACANARIA100% (1)

- Work Permit for Working at HeightDocument2 pagesWork Permit for Working at HeightVipul BansalPas encore d'évaluation

- Hot Work Permit ChecklistDocument3 pagesHot Work Permit ChecklistUmair KhanPas encore d'évaluation

- 6.DOSH Reporting An Accident 17Document1 page6.DOSH Reporting An Accident 17alexcus1539Pas encore d'évaluation

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerPas encore d'évaluation

- Confined Space (Permit Required) AttendentsDocument41 pagesConfined Space (Permit Required) Attendentsdroffilcz27Pas encore d'évaluation

- CS Rescue Awareness: Objectives, Hazards, Techniques & EquipmentDocument50 pagesCS Rescue Awareness: Objectives, Hazards, Techniques & EquipmentHtin Lin Aung100% (5)

- Introduction To Confined Space SafetyDocument32 pagesIntroduction To Confined Space Safetydroffilcz27Pas encore d'évaluation

- Fall Hazards2Document78 pagesFall Hazards2Rakesh KumarPas encore d'évaluation

- Chemical Waste Management Refresher TrainingDocument42 pagesChemical Waste Management Refresher TrainingenvsandyPas encore d'évaluation

- JSA Amp Risk AssessmentDocument19 pagesJSA Amp Risk Assessmentdroffilcz27Pas encore d'évaluation

- Behavior of Fuel: (Incident Command & Control)Document16 pagesBehavior of Fuel: (Incident Command & Control)droffilcz27Pas encore d'évaluation

- Basic Rigging Training (BRT)Document38 pagesBasic Rigging Training (BRT)droffilcz27100% (1)

- Surface Condenser: Applications of Surface Condensers and Requirement of Surface CondenserDocument17 pagesSurface Condenser: Applications of Surface Condensers and Requirement of Surface Condenserdroffilcz27100% (1)

- Compressed Gas SafetyDocument28 pagesCompressed Gas SafetyDiaa Gab-AllahPas encore d'évaluation

- What Is An Accident?Document15 pagesWhat Is An Accident?amol31179Pas encore d'évaluation

- Piping Fundamentals for Beginners: A Guide to Piping Systems, Components, and DesignDocument29 pagesPiping Fundamentals for Beginners: A Guide to Piping Systems, Components, and DesignManoj Pratap SinghPas encore d'évaluation

- 5S - House KeepingDocument20 pages5S - House KeepingRawinder100% (2)

- 1 Hsef-101Chemistry of FireDocument15 pages1 Hsef-101Chemistry of Firedroffilcz27Pas encore d'évaluation

- 4 Special Fire Hazards and PreventionDocument22 pages4 Special Fire Hazards and Preventiondroffilcz27100% (1)

- Industrial Fire Hazards and Risk Management StrategiesDocument18 pagesIndustrial Fire Hazards and Risk Management Strategiesdroffilcz27Pas encore d'évaluation

- 43 Safe BehaviorsDocument11 pages43 Safe Behaviorsdroffilcz27Pas encore d'évaluation

- OSHADocument37 pagesOSHAdroffilcz27Pas encore d'évaluation

- Safety checklist for abrasive wheel grindersDocument1 pageSafety checklist for abrasive wheel grindersJohn Vem BansagPas encore d'évaluation

- Construction Site Safety: ©consultnet LTDDocument19 pagesConstruction Site Safety: ©consultnet LTDdroffilcz27Pas encore d'évaluation

- OSHA 501 Subpart J Confined SpacesDocument109 pagesOSHA 501 Subpart J Confined Spacesdroffilcz27Pas encore d'évaluation

- Worker Safety Policy ExampleDocument4 pagesWorker Safety Policy ExampleDhadendra LalPas encore d'évaluation

- 5 Personal Protective EquipmentDocument45 pages5 Personal Protective Equipmentdroffilcz27100% (1)

- Preliminary Hazard Analysis GuideDocument40 pagesPreliminary Hazard Analysis Guidedroffilcz27100% (2)

- BASIC FIRST AID GUIDEDocument37 pagesBASIC FIRST AID GUIDEdroffilcz27100% (1)

- Basic Behavior Based SafetyDocument7 pagesBasic Behavior Based Safetydroffilcz27Pas encore d'évaluation

- Brief Idea of HAZOPDocument8 pagesBrief Idea of HAZOPdroffilcz27Pas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- JSA Amp Risk AssessmentDocument19 pagesJSA Amp Risk Assessmentdroffilcz27Pas encore d'évaluation

- Introduction to LOPA for Process Safety Risk AssessmentDocument5 pagesIntroduction to LOPA for Process Safety Risk Assessmentdroffilcz2750% (2)

- The Relevance of Vivekananda S Thought IDocument16 pagesThe Relevance of Vivekananda S Thought IJaiyansh VatsPas encore d'évaluation

- AS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDocument31 pagesAS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDuy PhướcPas encore d'évaluation

- Digital B&W Copiers (D154/D155-NA) Parts CatalogDocument118 pagesDigital B&W Copiers (D154/D155-NA) Parts Catalogkhoi vuPas encore d'évaluation

- Retired Car Jacker Screen PlayDocument4 pagesRetired Car Jacker Screen Playapi-633948182Pas encore d'évaluation

- EM-CABLE Product CatalogDocument96 pagesEM-CABLE Product Catalogm00h00Pas encore d'évaluation

- BMW Mini COoper Installation InstructionsDocument1 pageBMW Mini COoper Installation InstructionsEdiJonPas encore d'évaluation

- Nitocote WP DDocument4 pagesNitocote WP DdaragPas encore d'évaluation

- Cooling System Exhaust System: RadiatorDocument2 pagesCooling System Exhaust System: RadiatorMd ShPas encore d'évaluation

- Digestion Unit 1 QDocument15 pagesDigestion Unit 1 QKajana Sivarasa ShenthanPas encore d'évaluation

- A Feature Selection Based On The Farmland Fertility Algorithm For Improved Intrusion Detection SystemsDocument27 pagesA Feature Selection Based On The Farmland Fertility Algorithm For Improved Intrusion Detection SystemsRashed ShakirPas encore d'évaluation

- Tap Yourself FreeDocument134 pagesTap Yourself Freenguyenhavn100% (2)

- NitrocelluloseDocument7 pagesNitrocellulosejumpupdnbdjPas encore d'évaluation

- JSW Energy Plant Maintenance BBPDocument46 pagesJSW Energy Plant Maintenance BBPSandeep Kumar PraharajPas encore d'évaluation

- Standardization Parameters For Production of Tofu Using WSD-Y-1 MachineDocument6 pagesStandardization Parameters For Production of Tofu Using WSD-Y-1 MachineAdjengIkaWulandariPas encore d'évaluation

- Gante Iris PPT Pe p006Document20 pagesGante Iris PPT Pe p006Donna Ville GantePas encore d'évaluation

- Coloi Eeml Disease: Original ArticlesDocument67 pagesColoi Eeml Disease: Original ArticlesLuisAngelPonceTorresPas encore d'évaluation

- Forklift Truck Risk AssessmentDocument2 pagesForklift Truck Risk AssessmentAshis Das100% (1)

- History: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHDocument3 pagesHistory: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHPatrizio MassaroPas encore d'évaluation

- CLIC Catalogue PDFDocument28 pagesCLIC Catalogue PDFsangram patilPas encore d'évaluation

- 4 Ideal Models of Engine CyclesDocument23 pages4 Ideal Models of Engine CyclesSyedPas encore d'évaluation

- 500 Important Spoken Tamil Situations Into Spoken English Sentences SampleDocument7 pages500 Important Spoken Tamil Situations Into Spoken English Sentences SamplerameshdurairajPas encore d'évaluation

- Surface Hardening enDocument20 pagesSurface Hardening engtm1207Pas encore d'évaluation

- G 26 Building Using ETABS 1673077361Document68 pagesG 26 Building Using ETABS 1673077361md hussainPas encore d'évaluation

- CH 10Document125 pagesCH 10Lisset Soraya Huamán QuispePas encore d'évaluation

- Shapes FlashcardsDocument5 pagesShapes FlashcardsHome Organising by JRPas encore d'évaluation

- Heradesign Brochure 2008Document72 pagesHeradesign Brochure 2008Surinder SinghPas encore d'évaluation

- Schroedindiger Eqn and Applications3Document4 pagesSchroedindiger Eqn and Applications3kanchankonwarPas encore d'évaluation

- Lab Manual Cape Bio Unit 1 2023Document37 pagesLab Manual Cape Bio Unit 1 2023drug123addict25Pas encore d'évaluation

- Print Date:: Container No NO Size Seal No Seal Party Supplier Status Movement TypeDocument3 pagesPrint Date:: Container No NO Size Seal No Seal Party Supplier Status Movement TypeYudha PermanaPas encore d'évaluation

- EiaDocument14 pagesEiaRamir FamorcanPas encore d'évaluation