Académique Documents

Professionnel Documents

Culture Documents

Solving Vessel Equations PDF

Transféré par

Naturasfera Suplementos AlimenticiosDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Solving Vessel Equations PDF

Transféré par

Naturasfera Suplementos AlimenticiosDroits d'auteur :

Formats disponibles

C

alculating the volume of a liquid

in a vessel of a complex shape

is a common task for chemical

engineers. However, there are

several difficulties associated with ac-

curately carrying out this calculation.

In my own experience as a chemi-

cal engineer, I have become familiar

with the complexities of calculations

related to determining the volume of

a liquid contained in a vessel with an

irregular shape.

Precise volume-determination equa-

tions are readily available for common

vessel shapes. But what if you are

using a vessel that is a vertical cyl-

inder with a hemispherical top and

bottom? Or, what if you are working

with a horizontal elliptical vessel with

concave heads? No matter the type of

vessel you are working with, chemical

engineers need to account for the liq-

uids within these irregular shapes to

calculate the volume properly.

Vessel-calculation challenges

Lets begin with an example scenario.

Suppose a chemical engineer works

at a pharmaceutical facility that pro-

duces cough syrup. In that capacity,

the engineer may have to prepare a

solution in a 1,000-gal vessel or tank

with an irregular shape. To prepare

the proper concentration of cough

syrup, he or she may need to add 50

pounds of an active pharmaceutical

ingredient into sugar syrup.

Before adding anything to this liquid

base to prepare the proper concentra-

tion, the exact fluid volume must be

known. One option is to measure the

volume using a meter pump, but this

method will not produce an accurate

result. The alternative is to verify the

exact amount of liquid needed by cal-

culating the volume of this irregularly

shaped vessel based on the liquid level.

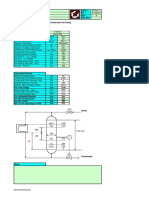

In this scenario, suppose that the

vessel in question is a vertical cylindri-

cal vessel comprised of a conical bottom

and elliptical top. The elliptical portion

of the vessel is partially filled with liq-

uid, while the cylindrical and conical

portions are fully filled (Figure 1). What

should be the approach to calculating

the portion that is partially filled?

To calculate the total volume, you

need to combine the different equa-

tions one for each of these three

basic shapes of the vessel: the conical

bottom, the elliptical top and the verti-

cal cylinder.

At this point, two complexities arise.

Engineers are forced to search through

databases and manuals for the equa-

tions that are appropriate for the ir-

regular parts of the tank, and then cal-

culate the volume using some kind of

calculation software. While many en-

gineers favor Microsoft Excel as their

calculation software of choice, keep in

mind that the program was not spe-

cifically designed for entering complex

equations. As a result, this process for

calculating the volume of a particular

vessel can be a time-consuming and

inefficient process. Engineers cannot

afford to waste time they need reli-

able equations and quick calculations.

In a similar scenario (depicted in

Figure 1), the author and colleagues

first either found and verified, or de-

rived equations, in some instances

using integrals, for each shape in-

volved. Glancing through a reliable en-

Feature Report

30 CHEMICAL ENGINEERING WWW.CHE.COM JUNE 2013

Cover Story

Solving Vessel Equations:

A Better Way

V R h

where R

D

c c

2

2

:=

:=

t

h

b

D

H

Volume of vertical cylindrical shell:

Shell diameter D := 50 in.

Volume of

conical bottom:

Bottom height b := 30 in.

Volume of

elliptical top:

Conditions:

Top height t := 10 in.

Shell height H := 150 in.

Liquid level h := 150 in.

V

R

b

h

b

3 b

:=

2

3

V

R

t

h

t

3

3t

2

h

t

2

:=

2

t

2

h

c

:= if

(

H+bh

) (

h>b

)

V := if

(

hb

)

V

b

else

if h

(

H + b

)

V

c

+ V

b

else

V

c

+ V

b

+ V

t

h b

else

0

<

h

t

:= if

(

h>(H+b)

)

h H b

else

0

h

b

:= if

(

h<b

)

h

else

b

FIGURE 1. Calculating the volume of a liquid in an irregularly shaped vessel in-

volves combining equations for the various portions of the vessel, such as a cylinder

portion, a conical portion and an elliptical portion, in this case

Sasha Gurke

Knovel Corp.

Irregularly shaped vessels

present challenges

for determining

liquid volumes.

New tools can help

gineering book, such as Perrys Chem-

ical Engineers Handbook, revealed

nothing useful for this problem.

We had better luck conducting In-

ternet-based research, but it was not

until poring through many search

results that we came across the fol-

lowing article by Dan Jones Cal-

culating Tank Volume (http://www.

webcalc.com.br/blog/Tank_Volume.

pdf). Also see (Chem. Eng., Sept. 2011,

pp 5563).

Using the equations provided in

Jones article for practical calcula-

tions proved to be a problem in itself.

First, the equations had to be as-

sembled in a sensible way to account

for all the shapes containing liquid in

the vessel. In addition, depending on

the level of the liquid you are working

with, there are different equations

that have to be used.

Another common frustration for

chemical engineers is that the data

found online must be validated as well.

Often with research conducted online,

the reliability and validity of the the in-

formation found is not clear or defined.

Checking the validity of the equations

that are found can be complicated. To

be sure that an equation is validated,

engineers may need to recalculate ev-

erything from scratch which we did

CHEMICAL ENGINEERING WWW.CHE.COM JUNE 2013 31

The Tafel equation is an equation in electrochemical

kinetics relating the rate of an electrochemical reaction to

the overpotential. The Tafel equation was first deduced

experimentally and was later shown to have a theoretical

justification. The equation is named after Swiss chemist

Julius Tafel (1862-1918)

Tafel equation

GENERAL Tafel equation

Tafel Equation

+

x

010

101

if

for line while

Arithmetic

Matrices

Boolean

Functions

Plot

Programming

Symbols

Plot

V is the overpotential, V

A is the so-called Tafel slope, V

i is the current denisity, A/m

2

and

i

0

is the so called exchange current density

Calc 1

NEW UPLOAD DOWNLOAD

Tafel diagram n vs log i

2

1

log i

0

log i

0

1

10

6

1

10

5

1

10

4

0.001

+

x x Calc 2 x Calc 3 x

V A

i

i

=

ln

0

f

x

contributed by Jane Chemist

references Publication One, Publication Two is Longer

citations Electrochemical Methods, Fundementals and Applications

FIGURE 3. Cloud-based calculation tools can improve engineering workfow

Time

Concept

development

High-level

requirements

Detailed

requirements

High-level

design

Detailed

design

Scale-up, inte-

gration and testing

Implementation

Subystem

verification

Acceptance

Operation and

maintenance

Part/unit replacement

and

process improvements

Initial design stages:

sizing, conceptualizing,

material selection

Equation library

(corporate/Wiki)

Databases

(materials/components)

Life engineering calculation tools (SMath-based)

Optional PLM integration layer

via API

Codes and

standards FIGURE 2. A Web-based equation li-

brary can help in vessel calculations

in this case and of course, it ended

up costing us even more time.

Once we found and validated the

equations and vessel dimensions, the

next step was to use a calculation tool

that is easy to integrate with the data.

We first turned to Microsoft Excel,

probably the most-often-used tool in

many engineers toolboxes. For most

calculations and analyses, an Excel

spreadsheet would suffice. Several

generations of engineers now have

grown up using Excel its a common,

inexpensive software that is readily

available on most desktops and lap-

tops. In addition to its familiarity, its

relatively easy to input large amounts

of data into Excel.

However, in this case of calculating

volume in an irregularly shaped ves-

sel, it was not. It became clear that it

would become an exceedingly time-

consuming process just to enter the

equations and variables.

Other reasons why Excel was not the

right calculation tool in this case is that

programming is required with external

data. Second, all calculations must be

performed in a consistent system of

units with conversion factors embed-

ded in equations. This is because Excel

does not automatically understand the

units of measurement and does not

support calculations in different unit

systems unless additional program-

ming is introduced. Third, we planned

to create a browser-based application,

but the Internet version of Excel has

exhibited performance issues and is

not highly rated by many users.

Beyond Excel, there are engineer-

ing calculation tools available such

as PTCs (Needham, Mass.; www.ptc.

com) Mathcad, which has automatic

unit conversion and can check equa-

tions for mathematical errors. How-

ever, a browser version of Mathcad is

not available, and that limits its use-

fulness in cloud-based applications.

SMath

To calculate the volume of a liquid in a

vessel of a complex shape, a task that

should take only minutes, we tested

a tool that is readily available online

and that could integrate our data. We

found an engineering desktop calcu-

lation tool that is both powerful and

distributed free of charge SMath

Studio (http://en.smath.info/forum/

yaf_topics12_Download-SMath-Stu-

dio.aspx).

SMath has a browser version called

SMath Live. While it is function-

ally similar to the desktop version, it

needs further development. SMath,

developed specifically for engineering

calculations, is now used by thousands

of engineers and engineering students

around the world.

This tool consists of a powerful math

engine core, user-friendly worksheet-

based graphical user interface (GUI)

and plug-ins some of which are

open source software that connect

the core with GUI. SMath has the fol-

lowing features:

The ability to handle numeric and

symbolic calculations

Capabilities for 2-D and 3-D graphs

Software versions designed for differ-

ent platforms and operating systems

Partial support of Mathcad files

(*.xmcd)

The ability to use mathematical units

(either built-in or user defined)

Multi-language worksheets

Multi-language interface (28 lan-

guages)

The capacity to use programming

functions directly on the worksheet

Infrastructure to support third-

party plug-ins

An auto-complete feature with de-

scription of all supported entries

The ability to use the tool in collabo-

ration (via server)

Equation snippets

Improved volume calculations

The tools chemical engineers have at

their disposal are critical for main-

Cover Story

32 CHEMICAL ENGINEERING WWW.CHE.COM JUNE 2013

FIGURE 4. (AH) Various standard shapes that can be combined include

cylinders, cones, ellipsis and hemispherical. The diagrams and equations

show some of the possible situations for volume measurement that engi-

neers might face

V Hh+ R

h h

H

D

2

3H

:=

where R :=

2

2

A. Conical top:

H

h

D

V

b

h

H

6 R

3 Rh :=

2

B. Elliptical head:

D

2

where R :=

h

H

D

R

C. Elliptical bottom:

V h

3

H

D

R

3 Hh :=

2

2

2

2

where R :=

h

H

D

R

Note: := means

is defined to be

H

h

W

L

D. Horizontal elliptical vessel:

V L (hb) (hb)

hb a

b

:=

b asin

2

2 2

+ b

b

2

+ b

2

H

2

b :=

W

2

where a :=

Note: := means

is defined to be

taining high levels of productivity. Ide-

ally, engineers should use tools that

are seamless, can save time, and avoid

costly errors in the workflow. One way

to accomplish this is through cloud

computing, where software programs

and data that have traditionally re-

sided on company servers are now lo-

cated on a third partys remote servers

and are accessed via the Web.

Cloud computing assures todays en-

gineers quick and easy access to data

from anywhere on a variety of devices.

It also allows engineers to easily share

data with their peers across the globe.

Fortunately, as technology continues

to move into the cloud, engineers will

have more effective and reliable tools

to integrate data, such as equations

with calculation software, into their

design and workflow.

Currently in the early stages of de-

velopment, there is an engineering

cloud-based productivity tool (Figure

2) comprising of SMath Live inte-

E. Hemispherical head:

V

b h

6

(1.5

Dh)

:=

2

h

D

F. Hemispherical top:

h

D

V h

3

(D+h)

:=

2

3

4

D

2

D

G. Horizontal cylinder:

D

R

L

h

V L

Rh

:=

R

acos (Rh)

2 2

R

D

2

where R :=

2

hh

H. Horizontal hemicylindtrical top:

R

L

h

V L

h

:=

R

acos h

2 2 2 2

R

R h 0.5

R

CHEMICAL ENGINEERING WWW.CHE.COM JUNE 2013 33

Circle 11 on p. 56 or go to adlinks.che.com/45773-11

WHY MONITOR POWER INSTEAD OF JUST AMPS?

NO LOAD NO LOAD

Power is Linear-Equal Sensitivity

at Both Low and High Loads

No Sensitivity

For Low Loads

FULL LOAD FULL LOAD

P

O

W

E

R

A

M

P

S

WWW.LOADCONTROLS.COM

CALL NOW FOR YOUR FREE 30-DAY TRIAL 888-600-3247

PROTECT PUMPS

DRY RUNNING CAVITATION BEARING FAILURE OVERLOAD

MONITOR PUMP POWER

Best Sensitivity

Digital Display

TWO ADJUSTABLE SET POINTS

Relay Outputs

Adjustable Delay Timers

4-20 MILLIAMP ANALOG OUTPUT

COMPACT EASY MOUNTING

Only 3.25" x 6.25" x 2"

Starter Door Panel

Raceway Wall

UNIQUE RANGE FINDER SENSOR

Works on Wide-range of Motors

Simplies Installation

PUMP POWER

PUMPING

VALVE CLOSING

VALVE OPENING

NO FLUID

Cover Story

34 CHEMICAL ENGINEERING WWW.CHE.COM JUNE 2013

grated with a searchable and brows-

able library of common engineering

equations, including those for par-

tially filled shapes, that could help

you calculate liquid volume as a func-

tion of liquid level much faster than

before. A chemical engineer could

use this cloud-based product to find

shapes and assemble them in any

reasonable combination to calculate

the volume of liquid in any partially

filled vessel. Such a product will be

useful when integrated into engineer-

ing workflow as an early-stage design

tool. The stages of a typical engineer-

ing workflow where this tool can be

integrated can be seen in Figure 3.

This type of Web-based product

would enable users to find and select

equations for various shapes and then

assemble them like Lego blocks onto

an SMath Live worksheet. If you are

working with any unusually shaped

shells, bottoms or heads, you can build

any vessel from them using smaller

pieces (Figure 4). You can continue

to build up to more complex shapes

and calculate the volume of the entire

shape or the volume of liquid in par-

tially filled shape. The same approach

could be used for calculating the vol-

ume of dry particulates, suspensions

and so on.

Initial results are encouraging and

can be seen in Figure 1, which shows

an example of a calculation for a verti-

cal cylindrical vessel with conical bot-

tom and elliptical top. This example

was assembled from calculations for

three basic shapes: cone bottom, el-

liptical top and vertical cylinder. Each

calculation contains limiting condi-

tions and validation routines, as well

as graphic representation of a shape.

These conditions and validation rou-

tines are easily adoptable for the ves-

sel shown in the example.

A prototype of this cloud-based

calculation tool is now underway. We

believe that the future of engineer-

ing will be characterized by tools

that integrate data and calculation

software and are available in the

cloud. Development and deployment

of these sophisticated tools will be

critical for maintaining high levels

of engineering productivity in the

chemical industry.

Edited by Scott Jenkins

Author

Sasha Gurke is engineer-

ing technical fellow at Knovel

Corp. (240 West 37th Street,

New York, NY 10018; Email:

sgurke@knovel.com; Phone:

617-803-8344). A chemist and

chemical engineer, Gurke has

more than 30 years of experi-

ence in the technical infor-

mation field. He co-founded

Knovel in 1999 and as senior

vice president, he was actively

involved in product development and manage-

ment. Knovel was acquired by Elsevier in 2012,

and Gurke continues to play an important role

in new product development and strategy. Prior

to Knovel, he spent 15 years with Chemical Ab-

stracts Service/American Chemical Society in

product development and editorial positions.

His industrial experience includes working as a

chemist at water treatment and paint manufac-

turing plants. Gurke holds a masters degree in

chemical technology from St. Petersburg State

University of Technology and Design.

2

Register early to increase your

chances of winning a FREE registration.

Register April 2 and be entered into the rst of many

drawings to win a complimentary full conference

WEFTEC registration. Subsequent drawings

will be made each month through

July. The sooner you register, the

greater your chances of winning!

WEFTEC is the largest annual water

and wastewater conference and

exhibition in the world offering the

most comprehensive water-quality

education, training, and technology

available.

Mark your

calendars for the

single greatest

opportunity

to grow your

professional

network and

your mind!

86th Annual Water Environment Federation

Technical Exhibition and Conference

McCormick Place South, Chicago, Illinois | October 5 9

Visit www.weftec.org for details.

N

E

W

fo

r

W

E

F

T

E

C

2

0

1

3

R

E

D

U

C

E

D

registration fees

Access to the technical

exhibition at N

O

C

H

AR

G

E

w

hen you register online

com

plim

ents of W

EF and

the W

EFTEC

Exhibitors.

Circle 19 on p. 56 or go to adlinks.che.com/45773-19

Vous aimerez peut-être aussi

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979D'EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonPas encore d'évaluation

- Handbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28D'EverandHandbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28Pas encore d'évaluation

- Emergency ShutingdownDocument11 pagesEmergency ShutingdownOsama OmayerPas encore d'évaluation

- Emergency Shutdown System or ESD SystemDocument3 pagesEmergency Shutdown System or ESD Systemkamala 123Pas encore d'évaluation

- Flame Arrestor White Paper en 5364202Document15 pagesFlame Arrestor White Paper en 5364202ksvvijPas encore d'évaluation

- Energy Optimization Using Pinch Analysis: Practical ConsiderationsDocument10 pagesEnergy Optimization Using Pinch Analysis: Practical ConsiderationsconfyPas encore d'évaluation

- Impact of Emergency Shutdown Devices On Relief System Sizing and Design PDFDocument21 pagesImpact of Emergency Shutdown Devices On Relief System Sizing and Design PDFB rgPas encore d'évaluation

- PSSCV ZixxingDocument2 pagesPSSCV ZixxingShashi Kant KumarPas encore d'évaluation

- GoyalDocument3 pagesGoyalVan LePas encore d'évaluation

- 36 PSV 8001 Thermal ExpansionDocument4 pages36 PSV 8001 Thermal Expansionwinlugue3059Pas encore d'évaluation

- Tube Rupture. Dynamic SimulationDocument5 pagesTube Rupture. Dynamic SimulationAbbasPas encore d'évaluation

- Instrument Alarms, Trips and Set Points List: 0 1980 RPM 1980 RPM VAIDocument1 pageInstrument Alarms, Trips and Set Points List: 0 1980 RPM 1980 RPM VAInastyn-1Pas encore d'évaluation

- Petrochemical Feedstock by Thermal Cracking of Plastic WasteDocument6 pagesPetrochemical Feedstock by Thermal Cracking of Plastic WasteWindi SetianyPas encore d'évaluation

- E PR 460Document37 pagesE PR 460khorzooPas encore d'évaluation

- Process Engineering Services: Feasibility Studies and Conceptual DesignDocument18 pagesProcess Engineering Services: Feasibility Studies and Conceptual DesignDuy TùngPas encore d'évaluation

- Chemsep Tutorial: Distillation With Hypothetical ComponentsDocument25 pagesChemsep Tutorial: Distillation With Hypothetical ComponentsErving MJPas encore d'évaluation

- Consider Bottom Venting For Reactive LiquidDocument10 pagesConsider Bottom Venting For Reactive LiquidAndri SaputraPas encore d'évaluation

- Flare Sweep GasDocument5 pagesFlare Sweep GasChem.EnggPas encore d'évaluation

- Page 1 of 5 Compressor Blocked Discharge - Chemical EngineersDocument5 pagesPage 1 of 5 Compressor Blocked Discharge - Chemical EngineersKarthikeyan SivaPas encore d'évaluation

- CompressorDocument6 pagesCompressorAbdul MalikPas encore d'évaluation

- 14 Hot Oil Systems v3Document14 pages14 Hot Oil Systems v3sssss100% (1)

- Pro II Faq From Simsci SiteDocument9 pagesPro II Faq From Simsci SiteNareshPas encore d'évaluation

- Steam Tracing AppendixDocument13 pagesSteam Tracing AppendixAmin BagheriPas encore d'évaluation

- Aspen Dynamics DIERS BenchmarksDocument9 pagesAspen Dynamics DIERS BenchmarksAmir JoonPas encore d'évaluation

- How To Calculate Vessel Depressurization Time With QuickDocument4 pagesHow To Calculate Vessel Depressurization Time With Quickhgandhi02Pas encore d'évaluation

- Simulation, System and Analytical: Lainnya Blog Berikut Buat Blog MasukDocument8 pagesSimulation, System and Analytical: Lainnya Blog Berikut Buat Blog MasukIkhsanudin AbdullahPas encore d'évaluation

- For Exchanger Tube Rupture PDFDocument3 pagesFor Exchanger Tube Rupture PDFNikhil DivatePas encore d'évaluation

- Process Safeguarding - PSE02Document2 pagesProcess Safeguarding - PSE02Sarfraz AliPas encore d'évaluation

- 15-501-EP-RP-003 - Rev.3 (Blowdown and Vent Study)Document238 pages15-501-EP-RP-003 - Rev.3 (Blowdown and Vent Study)Umair A. KhanPas encore d'évaluation

- Compare Vapor Pressures of Hydrogen, Methane, Ethylene and Ethane in Aspen PlusDocument10 pagesCompare Vapor Pressures of Hydrogen, Methane, Ethylene and Ethane in Aspen Plusmukeshg108Pas encore d'évaluation

- HP Heat Exchanger Tube Rupture and Metal EmbrittlmentDocument6 pagesHP Heat Exchanger Tube Rupture and Metal Embrittlmentaegean227100% (1)

- Phast: Tutorial ManualDocument42 pagesPhast: Tutorial ManualNitesh KirnakePas encore d'évaluation

- Group C: Benefits and ConsequencesDocument16 pagesGroup C: Benefits and ConsequencesMohamad IbrahimPas encore d'évaluation

- Nioec SP 47 27Document29 pagesNioec SP 47 27sgh1355Pas encore d'évaluation

- Evaporative Rates of A SpillDocument3 pagesEvaporative Rates of A SpillkurtbkPas encore d'évaluation

- CMPAPPP Separator Vessel and Filter Design GuideDocument18 pagesCMPAPPP Separator Vessel and Filter Design GuideJWilson73Pas encore d'évaluation

- WP UniSim Design Blowdown Utility PDFDocument21 pagesWP UniSim Design Blowdown Utility PDFMinh Hoàng NguyễnPas encore d'évaluation

- Heat-Exchanger Bypass Control: William L. LuybenDocument9 pagesHeat-Exchanger Bypass Control: William L. LuybenYu Hui100% (1)

- Heat-Exchanger Bypass Control: William L. LuybenDocument9 pagesHeat-Exchanger Bypass Control: William L. LuybenHens Christian FuentesPas encore d'évaluation

- HP-LP Flare KO Drum SizingDocument2 pagesHP-LP Flare KO Drum SizingmadithakPas encore d'évaluation

- Training CaseDocument15 pagesTraining CaseThái Xuân QuangPas encore d'évaluation

- Manuale Sicurezza - 1000-MU-2005 - E - 0Document48 pagesManuale Sicurezza - 1000-MU-2005 - E - 0anghel_florin82Pas encore d'évaluation

- Ethylene PipesDocument8 pagesEthylene Pipesingbarragan87Pas encore d'évaluation

- PSV SlidesDocument47 pagesPSV SlidesAhmed sohaibPas encore d'évaluation

- Steam Condensate Pot Sizing PDFDocument1 pageSteam Condensate Pot Sizing PDFjittshong8072Pas encore d'évaluation

- NGL SeparationDocument6 pagesNGL SeparationhoustonmathPas encore d'évaluation

- Gas Blowby - An Overview - ScienceDirect TopicsDocument15 pagesGas Blowby - An Overview - ScienceDirect TopicsWin Thi HaPas encore d'évaluation

- Acentric Factor EoSDocument10 pagesAcentric Factor EoSdesertflowPas encore d'évaluation

- XFH 9Document33 pagesXFH 9haosfPas encore d'évaluation

- Volume and Wetted Area of Partially Filled Horizontal VesselsDocument11 pagesVolume and Wetted Area of Partially Filled Horizontal VesselsMelvin MagbanuaPas encore d'évaluation

- Flarenet Data Import From ExcelDocument15 pagesFlarenet Data Import From ExcelAbhay BhoirPas encore d'évaluation

- High Integrity Protective SystemsDocument9 pagesHigh Integrity Protective SystemsAbhiyan Anala ArvindPas encore d'évaluation

- Filtration and SeparationDocument2 pagesFiltration and SeparationantoniojaviermaciasPas encore d'évaluation

- Dynamic Modeling of Heat Exchanger Tube RaptureDocument20 pagesDynamic Modeling of Heat Exchanger Tube RaptureRajesh NimmakayalaPas encore d'évaluation

- Dynamic Depressuring PDFDocument16 pagesDynamic Depressuring PDFAsimPas encore d'évaluation

- Workbook For Chemical Reactor Relief System SizingDocument123 pagesWorkbook For Chemical Reactor Relief System SizingRicardo BecPas encore d'évaluation

- Statistics for Process Control Engineers: A Practical ApproachD'EverandStatistics for Process Control Engineers: A Practical ApproachPas encore d'évaluation

- Vapor-Liquid Equilibria Using Unifac: A Group-Contribution MethodD'EverandVapor-Liquid Equilibria Using Unifac: A Group-Contribution MethodPas encore d'évaluation

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7D'EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Pas encore d'évaluation

- Structured What If Technique A Complete Guide - 2020 EditionD'EverandStructured What If Technique A Complete Guide - 2020 EditionPas encore d'évaluation

- Modicon M580 Quick Start - v1.0 - Training ManualDocument169 pagesModicon M580 Quick Start - v1.0 - Training Manualaryan_iust0% (1)

- Uvod PDFDocument13 pagesUvod PDFbarbara5153Pas encore d'évaluation

- Things To Remember When Writing Your Conference Proposal AbstractDocument2 pagesThings To Remember When Writing Your Conference Proposal AbstractBalizkoa BadaezpadakoaPas encore d'évaluation

- SajaneDocument6 pagesSajaneJoshua AbordoPas encore d'évaluation

- 1) Two Vectors A, B Are Orthogonal IfDocument9 pages1) Two Vectors A, B Are Orthogonal IfRamesh MallaiPas encore d'évaluation

- DSP Manual Autumn 2011Document108 pagesDSP Manual Autumn 2011Ata Ur Rahman KhalidPas encore d'évaluation

- Labacha CatalogueDocument282 pagesLabacha CatalogueChaitanya KrishnaPas encore d'évaluation

- Community Service - Group 3 - Project 2Document24 pagesCommunity Service - Group 3 - Project 2rofiq wibawantoPas encore d'évaluation

- Conceptualizing Teacher Professional LearningDocument33 pagesConceptualizing Teacher Professional LearningPaula Reis Kasmirski100% (1)

- Chemical EngineeringDocument26 pagesChemical EngineeringAnkit TripathiPas encore d'évaluation

- Evidence DoctrinesDocument5 pagesEvidence DoctrinesChezca MargretPas encore d'évaluation

- Fruits Basket - MemoryDocument1 pageFruits Basket - Memorywane10132100% (1)

- Finding The Right Place On The Map: Central and Eastern European Media Change in A Global PerspectiveDocument306 pagesFinding The Right Place On The Map: Central and Eastern European Media Change in A Global PerspectiveIntellect BooksPas encore d'évaluation

- Taylor Linker ResumeDocument2 pagesTaylor Linker ResumeTaylor LinkerPas encore d'évaluation

- Feedback For Question 1-MIDTERM 2 AFM 451Document2 pagesFeedback For Question 1-MIDTERM 2 AFM 451jason fPas encore d'évaluation

- CT Analyzer Whats New V4 52 ENUDocument6 pagesCT Analyzer Whats New V4 52 ENUSivakumar NatarajanPas encore d'évaluation

- 20 Issues For Businesses Expanding InternationallyDocument24 pages20 Issues For Businesses Expanding InternationallySubash RagupathyPas encore d'évaluation

- Permutation Vs CombinationDocument4 pagesPermutation Vs CombinationSaleh RehmanPas encore d'évaluation

- UgvDocument24 pagesUgvAbhishek MatPas encore d'évaluation

- Review of Cyborg BabiesDocument3 pagesReview of Cyborg BabiesNate GreenslitPas encore d'évaluation

- O.E.Lab - Docx For Direct Shear TestDocument14 pagesO.E.Lab - Docx For Direct Shear TestAmirah SyakiraPas encore d'évaluation

- Ubd Food ChainDocument5 pagesUbd Food Chainapi-313687749Pas encore d'évaluation

- Part 1 - Install PfSense On ESXi - Calvin BuiDocument8 pagesPart 1 - Install PfSense On ESXi - Calvin Buiandrei2andrei_3Pas encore d'évaluation

- Savoldi-SIM and USIM File System - A Forensics PerspectiveDocument24 pagesSavoldi-SIM and USIM File System - A Forensics PerspectiveAntonio SavoldiPas encore d'évaluation

- Types of WomanDocument16 pagesTypes of Womanveerendra75% (4)

- Tga Kinetic ValueseDocument3 pagesTga Kinetic ValueseCarlos ChavezPas encore d'évaluation

- A Wish Poetry Analysis Long Bond Paper PrintDocument2 pagesA Wish Poetry Analysis Long Bond Paper PrintJosephine OngPas encore d'évaluation

- Retail Analysis WalmartDocument18 pagesRetail Analysis WalmartNavin MathadPas encore d'évaluation

- Probability Form 4Document10 pagesProbability Form 4Deen ZakariaPas encore d'évaluation

- LodhaDocument3 pagesLodhaSohil Kisan0% (1)