Académique Documents

Professionnel Documents

Culture Documents

372 Syllabus Summer 2013

Transféré par

Kristan Tybuszewski0 évaluation0% ont trouvé ce document utile (0 vote)

22 vues4 pagesThis document outlines the syllabus for an undergraduate materials selection course taught over the summer. The course will cover topics related to mechanical behavior of engineering materials including deformation, fracture, fatigue and materials selection for design. It will be taught via video lectures with in-person labs. Grading will be based on homework assignments, lab reports, and four exams. The objective of the course is to provide students with knowledge of materials properties and failure analysis to enable selection of materials for safe and reliable mechanical designs.

Description originale:

372 Syllabus Summer 2013

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document outlines the syllabus for an undergraduate materials selection course taught over the summer. The course will cover topics related to mechanical behavior of engineering materials including deformation, fracture, fatigue and materials selection for design. It will be taught via video lectures with in-person labs. Grading will be based on homework assignments, lab reports, and four exams. The objective of the course is to provide students with knowledge of materials properties and failure analysis to enable selection of materials for safe and reliable mechanical designs.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

22 vues4 pages372 Syllabus Summer 2013

Transféré par

Kristan TybuszewskiThis document outlines the syllabus for an undergraduate materials selection course taught over the summer. The course will cover topics related to mechanical behavior of engineering materials including deformation, fracture, fatigue and materials selection for design. It will be taught via video lectures with in-person labs. Grading will be based on homework assignments, lab reports, and four exams. The objective of the course is to provide students with knowledge of materials properties and failure analysis to enable selection of materials for safe and reliable mechanical designs.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

EMAE/EMSE 372

RELATION OF MATERIALS TO DESIGN (4 Cr)

SUMMER 2013

Instructor: Professor John J. Lewandowski

Room: 522/520 - White Bldg.

Phone: 368-4234

Email: JJL3@case.edu

Fax: 368-3209

Office Hours: W 2:00-4:00 p.m. Call/E-mail First!

Class Meetings: Class Will be Offered Via Mediavision Access via laptop/computer

Labs will be conducted in person at CWRU

Textbooks Required: Mechanical Behavior of Materials, NE Dowling, 3

rd

Edition.

Prentice-Hall, Inc., New York, NY 2007

On Reserve in Library: Deformation and Fracture of Engineering Materials,

RW Hertzberg Wiley, 1987.

Mechanical Metallurgy, GE Dieter, 3

rd

Edition,

McGraw Hill Book Company, 1986.

Elementary Engineering Fracture Mechanics, D Broek,

Martinue Nighoff, 1982.

Mechanical Behavior of Materials, TH Courtney,

McGraw Hill Book Company, 1990.

The New Science of Strong Materials: JE Gordon

Structures, or Why Things Dont Fall Down: JE Gordon

Materials Selection and Design: ASM Handbook, Volume 20

Selection and Use of Eng. Matls: JA Charles, FAA Crane, JAG Furness

Materials Selection in Mechanical Design: MF Ashby

SOFTWARE: CES Edupack (Download ONCE from CWRU Software Library)

LAB: Dates/Times TBD

EMAE/EMSE 372

TENTATIVE COURSE OUTLINE

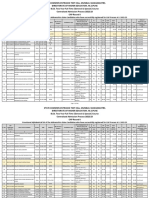

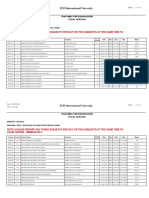

DATE TOPIC READING DATE TOPIC READING

Wk 1 (6/3)

Introduction/

Overview

D-1,2

Wk 1

Structure and

Deformation

D-2

Read Petroski

HW#1-out

7/2 Wk 5

Fracture: Charpy

Impact Energy

D-8

Wk 1

DiscussPetroski,

Survey Eng

Matls-Design

D-3

Lab#1:Matl

Selection

7/3

FractureCracked

Members - K,

Toughness

D-8

Wk 1/2

Survey Eng

Matls - Steels

D-3

7/5

Applications of

Fracture

Toughness

D-8

HW#5 - due

HW#6 out

6/10

Survey Eng

Matls Non-

ferrous metals

D-3

HW#1 due

HW#2 - out

Wk 6

Fatigue: Stress-

BasedApproach,

Tests-Mean

D-8,9

Wk 2

Survey Eng

Matls - Polymer

D-3

7/10

Fatigue: Stress-

BasedApproach,

Multiaxial

D-8,9

HW#6 due

6/14

Survey Eng

Matls - Ceramic

& Composites

D-3

HW#2 - due

7/12

Design for

Multiple

Constraints

D-3

Lab#3 due

6/17

EXAM I

(Chap 1,2,3)

D-4

HW#3-out

7/15

EXAM III

(Chap 8,9)

D-10

HW#7 out

Lab#4:Toughness

6/18

Mech Testing:

Tension Tests

D-4

Lab#1- due

Lab#2:Tension

7/17 Wk 7

Fatigue: Notch

Effects

D-10

Wk 3

Mech Testing:

Charpy Impact

D-4

Wk 3

Mech Testing:

Bending/Torsion

D-4

7/19

Fatigue:Notched

Estimate Life

D-10,11

HW#7 due

HW#8 - out

6/21

Mech Testing:

Compression,

Hardness

D-4

HW#3 due

HW#4 - out

7/22 Wk 8

Fatigue Crack

Growth-Intro

D-11

Wk 4

Stress-Strain

Relations-

Models

D-5

7/24

Fatigue Crack

Growth: Paris

Regime

D-11

HW#8 due

Lab#4 due

6/26

Stress-Strain

Relations-Elastic

D-5

HW#4 - due

7/26

EXAM IV

(Chap 10,11)

Lab#4 due

6/28

Stress-Strain:

D-5

Lab#2 due

7/1

EXAM II

(Chap 4,5)

D-8

HW#5 - out

Lab#3: Charpy

Objective: Designing machines, vehicles, and structures that are safe, reliable,

and economical requires both efficient use of materials and

assurance that structural failure will not occur. This course

considers the role of material selection in the design of mechanical

and structural elements with respect to static failure, elastic

stability, residual stresses, stress concentrations, impact, fatigue,

creep, and environmental conditions on the mechanical behavior of

engineering materials (metals, polymers, ceramics, composites).

The professional and ethical responsibility of the engineer in this

context will be considered where appropriate.

Ultrastructural and microstructural aspects of materials are

reviewed in terms of how they influence mechanical properties.

Mechanical test methods are reviewed. Models for deformation

behavior of isotropic and anisotropic materials are considered.

Methods to analyze static and fatigue fracture properties are

considered. Rational approaches to materials selection for new and

existing designs of structures are examined. Failure analysis

methods of failed structures are considered. Failure analysis

examples of actual failed structures will be discussed and the

professional and ethical responsibility of the engineer will be

considered.

Laboratories: There will be 4 mandatory laboratories. Times and locations will

be arranged as everyone will have to do the lab at the same time.

Each laboratory will require at least 1 hour of preparation prior to

the lab meeting to organize procedures and expected results. FOR

SAFETY REASONS, STUDENT ARRIVING AT THE

LABORATORY TIME UNPREPARED OR WEARING

INAPPROPRIATE CLOTHING WILL NOT BE ALLOWED

TO OPERATE EQUIPMENT AND MAY BE DENIED

ENTRANCE TO THE LABORATORY. A report will be part

of each lab. Group Lab reports will be prepared, with different

group leads assigned for each lab.

Homework: Homework problems are to be worked on individually, unless

otherwise specified. Homework assignments will be given

approximately once a week. Homework is due on the date shown

by 5PM. BECAUSE OF THE SHORT SUMMER TERM, NO

LATE HOMEWORK WILL BE ACCEPTED.

Grading Criteria:

Homework 20%

Lab reports 20%

Exam 1 15%

Exam 2 15%

Exam 3 15%

Exam 4 15%

Assessment: The homework assignments will be utilized to assess the students

ability to apply their knowledge of mathematics, science and

engineering to solve formulate and solve problems. The

homework assignments will also be utilized to assess the students

ability to consider materials selection in the design components or

systems to meet a specific design rationale. The Laboratory

reports will be utilized to assess the students ability to design and

conduct experiments and to analyze and interpret data. Laboratory

Reports will be utilized to assess the students ability to

communicate effectively in written format. The Exams will be

used to assess the students ability to synthesize and appropriately

apply the concepts concerning materials selection and deformation,

fracture and fatigue of materials learned in class.

Vous aimerez peut-être aussi

- Metallurgical Failure Analysis: Techniques and Case StudiesD'EverandMetallurgical Failure Analysis: Techniques and Case StudiesÉvaluation : 3 sur 5 étoiles3/5 (1)

- Cae 315Document4 pagesCae 315draqbhattiPas encore d'évaluation

- Materials: Engineering, Science, Processing and DesignD'EverandMaterials: Engineering, Science, Processing and DesignPas encore d'évaluation

- AE310 Syllabus Schedule 2013Document4 pagesAE310 Syllabus Schedule 2013Christopher DanielPas encore d'évaluation

- ME 3217 Meta CuttingDocument6 pagesME 3217 Meta CuttingscribbyscribPas encore d'évaluation

- ENG1050Lecture1 S1 2014Document38 pagesENG1050Lecture1 S1 2014powerangers8903Pas encore d'évaluation

- CE 431 Construction Materials Laboratory - 3Document5 pagesCE 431 Construction Materials Laboratory - 3Hasib DoskePas encore d'évaluation

- 1 - 2 Definitions and Modes of FailureDocument10 pages1 - 2 Definitions and Modes of FailureAhmed AymanPas encore d'évaluation

- RMD2508Document5 pagesRMD2508ismail douidiPas encore d'évaluation

- CE6315-Strength of Materials LabDocument43 pagesCE6315-Strength of Materials LabkattabommanPas encore d'évaluation

- Coursework TwoDocument5 pagesCoursework TwoPa1 Kumar MPas encore d'évaluation

- MECH421 Outline 2017Document5 pagesMECH421 Outline 2017mralex11Pas encore d'évaluation

- Electronica-Potencia-Prof. Mack Grady PDFDocument206 pagesElectronica-Potencia-Prof. Mack Grady PDFGabrielPas encore d'évaluation

- 92-311-Course Syllabus - Fall 20130Document12 pages92-311-Course Syllabus - Fall 20130Muhammad Hamish Khan NiaziPas encore d'évaluation

- Grady UT Austin EE462L Fall 2010Document206 pagesGrady UT Austin EE462L Fall 2010Chetan KotwalPas encore d'évaluation

- Ensc1002 2015 Sem-1 CrawleyDocument4 pagesEnsc1002 2015 Sem-1 CrawleyDoonkiePas encore d'évaluation

- ME 2256 - Strength of Materials - Lab ManualDocument36 pagesME 2256 - Strength of Materials - Lab ManualMohan Prasad.M100% (22)

- MECE 2420U: Solid Mechanics: Faculty of Engineering and Applied ScienceDocument5 pagesMECE 2420U: Solid Mechanics: Faculty of Engineering and Applied ScienceMadison BratinaPas encore d'évaluation

- Me770, Me770a - Course OutlineDocument3 pagesMe770, Me770a - Course OutlinePrakhar GuptaPas encore d'évaluation

- Aircraft StructuresDocument7 pagesAircraft StructuresKamran KhanPas encore d'évaluation

- General Laboratory InstructionsDocument11 pagesGeneral Laboratory InstructionsREX IAN BONGALESPas encore d'évaluation

- Syllabus For Che 3400Document4 pagesSyllabus For Che 3400ssavage03Pas encore d'évaluation

- CIVL3206 2014 Semester 2 StudentDocument4 pagesCIVL3206 2014 Semester 2 StudentApril IngramPas encore d'évaluation

- CS CH CH141.91. Diaz - J A 2017 1Document4 pagesCS CH CH141.91. Diaz - J A 2017 1Jiara MontañoPas encore d'évaluation

- 221 Outline-Fall 2014Document4 pages221 Outline-Fall 2014vince273Pas encore d'évaluation

- MECH344 Course Ouline Winter 2012-13Document3 pagesMECH344 Course Ouline Winter 2012-13bookdigitPas encore d'évaluation

- Course DescDocument4 pagesCourse DescadauPas encore d'évaluation

- Section 12: Student Evaluation and Pre-LabsDocument26 pagesSection 12: Student Evaluation and Pre-Labschrist9088Pas encore d'évaluation

- SyllabusDocument4 pagesSyllabusHamza FayyazPas encore d'évaluation

- Strength of Material SugDocument8 pagesStrength of Material Sugspraveen123Pas encore d'évaluation

- Fall 2011 EM 319 Syllabus - Nanshu Lu - v2.0Document6 pagesFall 2011 EM 319 Syllabus - Nanshu Lu - v2.0Ciara Mae WaldronPas encore d'évaluation

- Synthesis of A Correcting Equation For 3 Point Bending Test DataDocument16 pagesSynthesis of A Correcting Equation For 3 Point Bending Test DataÖmer faruk SilPas encore d'évaluation

- SR61 78Document165 pagesSR61 78Ajit PatilPas encore d'évaluation

- MECH 411 Course Outline - Fall 2016Document4 pagesMECH 411 Course Outline - Fall 2016JohnPas encore d'évaluation

- 5 2 1 Material TestingDocument2 pages5 2 1 Material Testingapi-261511055Pas encore d'évaluation

- Instruction Plans: InstructionsDocument20 pagesInstruction Plans: InstructionsDivy GuptaPas encore d'évaluation

- Foundry and Forging Laboratory ManualDocument110 pagesFoundry and Forging Laboratory Manualvampiredraak2712Pas encore d'évaluation

- Design of Machine Elements (MCT 3214)Document20 pagesDesign of Machine Elements (MCT 3214)Abdin YousifPas encore d'évaluation

- EEE 3308C Electronics I Laboratory ManualDocument18 pagesEEE 3308C Electronics I Laboratory Manualluceo00Pas encore d'évaluation

- ME 499 Syllabus - Fatigue AnalysisDocument3 pagesME 499 Syllabus - Fatigue AnalysisJack JPas encore d'évaluation

- MDP408a Syllabus FA20Document6 pagesMDP408a Syllabus FA20Hazem MahmoudPas encore d'évaluation

- Studyguide Ead 410 2013Document29 pagesStudyguide Ead 410 2013Herless FloresPas encore d'évaluation

- Material and Processing Basics Through Reverse EngineeringDocument15 pagesMaterial and Processing Basics Through Reverse EngineeringAhmed HamoudaPas encore d'évaluation

- Strength of Materials Lab Manual - MechanicalDocument41 pagesStrength of Materials Lab Manual - MechanicalNallappan Rajj A100% (2)

- Syllabus - Chem 2211 - Fall 2016Document6 pagesSyllabus - Chem 2211 - Fall 2016Rishab ChawlaPas encore d'évaluation

- Diploma Program: Contact HoursDocument11 pagesDiploma Program: Contact HoursayariseifallahPas encore d'évaluation

- Strength of Materials Laboratory ManualDocument33 pagesStrength of Materials Laboratory ManualRock Man100% (1)

- MatE195 Syllabus Fall2000Document5 pagesMatE195 Syllabus Fall2000conn76Pas encore d'évaluation

- Che 413Document6 pagesChe 413Charlie GalanPas encore d'évaluation

- CEE 586 - Rock Mechanics & Behavior: Course SyllabusDocument3 pagesCEE 586 - Rock Mechanics & Behavior: Course Syllabusrivai sargawiPas encore d'évaluation

- 2015 Spring MSE2001 Syllabus ScheduleDocument6 pages2015 Spring MSE2001 Syllabus ScheduleSamuel DiazPas encore d'évaluation

- Syllabus 2013Document2 pagesSyllabus 2013Ronaldo MenezesPas encore d'évaluation

- Ensayos No DestructivosDocument2 pagesEnsayos No DestructivosOneill Vasquez AmayaPas encore d'évaluation

- EGRB 102 Syllabus (Spring 2015)Document6 pagesEGRB 102 Syllabus (Spring 2015)unknown racerx50Pas encore d'évaluation

- MATSCEN 5952 BasicDocument2 pagesMATSCEN 5952 BasicEmmanuel Kwesi ArthurPas encore d'évaluation

- Introduction To Experimental MethodsDocument13 pagesIntroduction To Experimental Methodsmariostructural2010Pas encore d'évaluation

- Syllabus For IEE 572 Fall 2011Document5 pagesSyllabus For IEE 572 Fall 2011zazaidiPas encore d'évaluation

- 2b.course Delivery Plan - SampleDocument11 pages2b.course Delivery Plan - SampleArunkuma81Pas encore d'évaluation

- MATS1192 Course Outline - T1 2021Document11 pagesMATS1192 Course Outline - T1 2021Henok GirmaPas encore d'évaluation

- Breathless Rough DraftDocument5 pagesBreathless Rough DraftKristan TybuszewskiPas encore d'évaluation

- Exposition Universelle de 1889Document28 pagesExposition Universelle de 1889Kristan Tybuszewski100% (1)

- Solutions Practice Exam 2Document6 pagesSolutions Practice Exam 2Kristan TybuszewskiPas encore d'évaluation

- "Le Cadavre Exquis Boira Le Vin Nouveau.": - Andre BretonDocument7 pages"Le Cadavre Exquis Boira Le Vin Nouveau.": - Andre BretonKristan TybuszewskiPas encore d'évaluation

- EMAE 360 SyllabusDocument5 pagesEMAE 360 SyllabusKristan TybuszewskiPas encore d'évaluation

- Mach No Figures D WilsonDocument3 pagesMach No Figures D WilsonKristan TybuszewskiPas encore d'évaluation

- Practice Exam III 2011Document2 pagesPractice Exam III 2011Kristan TybuszewskiPas encore d'évaluation

- EECS 246 Syllabus HandoutDocument2 pagesEECS 246 Syllabus HandoutKristan TybuszewskiPas encore d'évaluation

- EMAE 360 SyllabusDocument5 pagesEMAE 360 SyllabusKristan TybuszewskiPas encore d'évaluation

- DWG SpecsDocument11 pagesDWG SpecsFrank SandorPas encore d'évaluation

- Argumentative Essay A Good Education Is The Only Path To SuccessDocument2 pagesArgumentative Essay A Good Education Is The Only Path To SuccessSandra Ati AcherPas encore d'évaluation

- Barcelona Objectives - Childcare Facilities For Young Children in EuropeDocument48 pagesBarcelona Objectives - Childcare Facilities For Young Children in EuropeAntonio PortelaPas encore d'évaluation

- Essay WritingDocument18 pagesEssay Writing3kkkishore3Pas encore d'évaluation

- Fisher Divorce Adjustment Scale - Scoring GuideDocument7 pagesFisher Divorce Adjustment Scale - Scoring GuidecioconabegailPas encore d'évaluation

- USYD Subject ReviewsDocument133 pagesUSYD Subject Reviewsaucyaucy123Pas encore d'évaluation

- Alphabetic List (Maharashtra State) - Round 2Document994 pagesAlphabetic List (Maharashtra State) - Round 2Mysha ZiaPas encore d'évaluation

- RPH PlantsDocument10 pagesRPH PlantsMOHD HASRUL ASRAF BIN OTHMAN MoePas encore d'évaluation

- RGSMC Learning Packet Week 1 P.E 9 UpdatedDocument4 pagesRGSMC Learning Packet Week 1 P.E 9 UpdatedAizel Nova Fermilan ArañezPas encore d'évaluation

- Vietnam - Introduce Tekla Open APIDocument34 pagesVietnam - Introduce Tekla Open API김성곤Pas encore d'évaluation

- Chapter 02Document20 pagesChapter 02jeremyPas encore d'évaluation

- Lars2 AnswersDocument14 pagesLars2 Answersyusuf ceribasPas encore d'évaluation

- EDTL3026 - Guidelines For The Action Research StudyDocument5 pagesEDTL3026 - Guidelines For The Action Research StudyShellsia St JustePas encore d'évaluation

- Research2 Module 1 Quarter 2Document3 pagesResearch2 Module 1 Quarter 2Aldrin M. Obias100% (1)

- National Level Science Fair For Young Children 2018.6 SJKT Mukim PundutDocument5 pagesNational Level Science Fair For Young Children 2018.6 SJKT Mukim PundutsjktmplPas encore d'évaluation

- Jeffrey K. Sexton: E C Wake Forest University, Winston-Salem, NCDocument2 pagesJeffrey K. Sexton: E C Wake Forest University, Winston-Salem, NCJeff SextonPas encore d'évaluation

- Final - BcsiDocument3 pagesFinal - Bcsiphython 1109Pas encore d'évaluation

- Nelson Mandela University PDFDocument115 pagesNelson Mandela University PDFCarlos Chafla100% (1)

- Mba Finance CourseworkDocument7 pagesMba Finance Courseworkbcrqs9hr100% (2)

- امتحان اللغه الانجليزيه الصف الاول الثانوي= نموذج الاجابهDocument5 pagesامتحان اللغه الانجليزيه الصف الاول الثانوي= نموذج الاجابهretaj AhmedPas encore d'évaluation

- Tamil-Nadu ArchitectDocument8 pagesTamil-Nadu Architectaman3327100% (1)

- INSTRUCTIONS Discussion Assignment InstructionsDocument2 pagesINSTRUCTIONS Discussion Assignment InstructionsMeriam AbrahamPas encore d'évaluation

- Transcript Not Official Unless Delivered Through Parchment ExchangeDocument1 pageTranscript Not Official Unless Delivered Through Parchment ExchangealesyPas encore d'évaluation

- Iuiu Family Law 1 OutlineDocument26 pagesIuiu Family Law 1 Outlinenansubuga salaamaPas encore d'évaluation

- Inoue TetsujiroDocument37 pagesInoue Tetsujirojeanettelunas.babasaPas encore d'évaluation

- Cognition PDFDocument38 pagesCognition PDFHEMA CHANDRANPas encore d'évaluation

- Cyclothymia, A Circular Mood Disorder by Ewald Hecker Introduction by Christopher Baethge, A, B Paola Salvatoreb, C and Ross J. BaldessarinibDocument15 pagesCyclothymia, A Circular Mood Disorder by Ewald Hecker Introduction by Christopher Baethge, A, B Paola Salvatoreb, C and Ross J. Baldessarinibrustycarmelina108Pas encore d'évaluation

- The Mystery of The Missing Footbal CupDocument10 pagesThe Mystery of The Missing Footbal CupJose LuisPas encore d'évaluation

- GRADE 10 MAPEH 1st Monthly ExaminationDocument2 pagesGRADE 10 MAPEH 1st Monthly ExaminationHoward AranetaPas encore d'évaluation

- A Case Study of A Child Age 17Document23 pagesA Case Study of A Child Age 17api-385551553Pas encore d'évaluation

- Domicile Under International LawDocument11 pagesDomicile Under International LawLEX 4790% (10)

- How to Teach Nature Journaling: Curiosity, Wonder, AttentionD'EverandHow to Teach Nature Journaling: Curiosity, Wonder, AttentionÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- A-level Biology Revision: Cheeky Revision ShortcutsD'EverandA-level Biology Revision: Cheeky Revision ShortcutsÉvaluation : 5 sur 5 étoiles5/5 (5)

- Quantum Physics for Beginners: Simple Illustrated Guide to Discover with Practical Explanations the Paradoxes of the Life and Universe Reconsidering RealityD'EverandQuantum Physics for Beginners: Simple Illustrated Guide to Discover with Practical Explanations the Paradoxes of the Life and Universe Reconsidering RealityÉvaluation : 2 sur 5 étoiles2/5 (1)

- Lower Secondary Science Workbook: Stage 8D'EverandLower Secondary Science Workbook: Stage 8Évaluation : 5 sur 5 étoiles5/5 (1)

- Interactive Science Notebook: The Human Body WorkbookD'EverandInteractive Science Notebook: The Human Body WorkbookÉvaluation : 4 sur 5 étoiles4/5 (2)

- STEM Labs for Physical Science, Grades 6 - 8D'EverandSTEM Labs for Physical Science, Grades 6 - 8Évaluation : 3.5 sur 5 étoiles3.5/5 (6)

- How Do Cell Phones Work? Technology Book for Kids | Children's How Things Work BooksD'EverandHow Do Cell Phones Work? Technology Book for Kids | Children's How Things Work BooksPas encore d'évaluation

- Nature-Based Learning for Young Children: Anytime, Anywhere, on Any BudgetD'EverandNature-Based Learning for Young Children: Anytime, Anywhere, on Any BudgetÉvaluation : 5 sur 5 étoiles5/5 (1)

- Nature Preschools and Forest Kindergartens: The Handbook for Outdoor LearningD'EverandNature Preschools and Forest Kindergartens: The Handbook for Outdoor LearningÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- A-Level Chemistry Revision: Cheeky Revision ShortcutsD'EverandA-Level Chemistry Revision: Cheeky Revision ShortcutsÉvaluation : 4 sur 5 étoiles4/5 (5)

- Workbook to Accompany Maintenance & Reliability Best PracticesD'EverandWorkbook to Accompany Maintenance & Reliability Best PracticesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookD'EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookPas encore d'évaluation

- Interactive Notebook: Life Science, Grades 5 - 8D'EverandInteractive Notebook: Life Science, Grades 5 - 8Évaluation : 5 sur 5 étoiles5/5 (4)

- Creative Investigations in Early Engineering and TechnologyD'EverandCreative Investigations in Early Engineering and TechnologyPas encore d'évaluation

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsD'EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsÉvaluation : 4 sur 5 étoiles4/5 (11)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)D'EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Évaluation : 4 sur 5 étoiles4/5 (12)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookD'EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookPas encore d'évaluation

- Nature Play Workshop for Families: A Guide to 40+ Outdoor Learning Experiences in All SeasonsD'EverandNature Play Workshop for Families: A Guide to 40+ Outdoor Learning Experiences in All SeasonsÉvaluation : 4 sur 5 étoiles4/5 (4)