Académique Documents

Professionnel Documents

Culture Documents

Aquaglide Brochure

Transféré par

Benicio Joaquín Ferrero Brebes0 évaluation0% ont trouvé ce document utile (0 vote)

92 vues2 pagesWorldwide presence of CLYDEUNION Pumps offers local service facilities in over 40 countries. Depending on your location we will provide either direct service support or support via our local authorised service partners. Component deliveries from as little as 24hrs on selected parts.

Description originale:

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentWorldwide presence of CLYDEUNION Pumps offers local service facilities in over 40 countries. Depending on your location we will provide either direct service support or support via our local authorised service partners. Component deliveries from as little as 24hrs on selected parts.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

92 vues2 pagesAquaglide Brochure

Transféré par

Benicio Joaquín Ferrero BrebesWorldwide presence of CLYDEUNION Pumps offers local service facilities in over 40 countries. Depending on your location we will provide either direct service support or support via our local authorised service partners. Component deliveries from as little as 24hrs on selected parts.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

Upgrades & Re-rates

Service & Overhaul

Installation & Commissioning

Technical Support

Inventory Management

3rd Party Equipment

Genuine High Quality

Original or upgraded specifcation spare parts, coupled with full engineering

design capability, enables longevity of reliable operation. Highly skilled

and experienced service engineers ensure accuracy in build and optimised

performance. The worldwide presence of CLYDEUNION Pumps offers local

service facilities in over 40 countries.

Service Solutions

CLYDEUNION Pumps is committed to supporting our installed base

wherever it may be. Depending on your location we will provide either

direct service support or support via our local authorised service partners.

Whichever option is provided, you can be assured of the best attention

from fully qualifed and experienced engineers.

Customer Satisfaction

Prompt and accurate quotation service and progress reporting during contract execution, facilitates

ease of doing business. Promise to deliver and accelerated service are recognised as key customer

requirements. We therefore offer a Rapid Response option with component deliveries from as little

as 24hrs on selected parts.

www.clydeunion.com

Copyright: CLYDEUNION Ltd, 2009 UK

We are constantly endeavouring to improve the performance of our equipment and as a result, we reserve

the right to make alterations from time to time, and equipment may differ from that detailed in this brochure.

Worldwide sales contacts

Sales:

Aftermarket:

Manufacturing:

(97) 12 631 1959 Tel: + (97) 12 635 1242 Fax: + uae@clydeunion.com Email: UAE:

(213) 21 69 2319 Tel: + (213) 21 69 3046 Fax: + algeria@clydeunion.com Email: Algeria:

(91) 120 4640 400 Tel: + (91) 120 4640 401 Fax: + newdelhi@clydeunion.com Email: New Delhi:

(86) 216 160 6969 Tel: + (86) 216 160 6968 Fax: + shanghai@clydeunion.com Email: Shanghai:

(65) 62 76 7117 Tel: + (65) 62 78 7117 Fax: + singapore@clydeunion.com Email: Singapore:

(86) 106 598 9500 Tel: + (86) 106 598 9505 Fax: + beijing@clydeunion.com Email: Beijing:

(1) 905 315 3800 Tel: + (1) 905 335 8262 Fax: + burlington@clydeunion.com Email: Burlington, ON:

(1) 403 236 8725 Tel: + (1) 403 236 7224 Fax: + calgary@clydeunion.com Email: Calgary, AB:

(1) 269 966 4600 Tel: + (1) 269 962 3534 Fax: + battlecreek@clydeunion.com Email: Battle Creek, MI:

(1) 562 622 2380 Tel: + (1) 562 622 2375 Fax: + downey@clydeunion.com Email: Downey, CA:

(1) 866 224 4787 Tel: + (1) 610 746 5907 Fax: + bethlehem@clydeunion.com Email: Bethlehem, PA:

(1) 225 775 2660 Tel: + (1) 225 778 0212 Fax: + batonrouge@clydeunion.com Email: Baton Rouge, LA:

Middle East / Africa

Asia

Europe

(1) 281 372 5040 Tel: + (1) 281 372 5042 Fax: + houston@clydeunion.com Email: Houston, TX:

(33) 45 005 5600 Tel: + (33) 45 005 5880 Fax: + annecy@clydeunion.com Email: Annecy:

(44) 122 676 3311 Tel: + (44) 122 676 6535 Fax: + penistone@clydeunion.com Email: Penistone, UK:

(44) 141 637 7141 Tel: + (44) 141 637 7358 Fax: + glasgow@clydeunion.com Email: Glasgow, UK:

(47) 815 310 02 Tel: + (47) 815 310 03 Fax: + nordic@clydeunion.com Email: Nordic countries:

(1) 801 292 7882 Tel: + (1) 801 292 7885 Fax: + saltlake@clydeunion.com Email: Salt Lake City, UT:

(7) 495 967 3453 Tel: + (7) 495 785 0636 Fax: + moscow@clydeunion.com Email: Moscow:

Americas

Union Pump

David Brown Pumps

DB Guinard Pumps

American Pump

Pumpline

* This is a heritage product acquired when the Weir Pumps business transferred to Clyde Pumps in May 2007

Weir Pumps

Mather & Platt

Drysdale

WH Allen

Girdlestone

Allen Gwynnes

Harland

CLYDEUNION Pumps - offers the following heritage products:

A Complete Aftermarket Service

Our customer focussed aftermarket organisation is positioned to provide comprehensive care for

our varied and diverse product lines. Heritage and obsolete products beneft from the same level

of attention and expertise in order that reliability and availability is maximised irrespective of

service length.

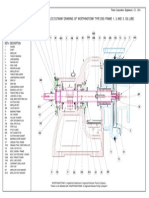

Range AQUA LIDE G

Large End Suction Water Pump

CU 12

Typical drawing only Copyright CLYDEUNION Ltd 2009

Range Coverage Charts

The CLYDEUNION Pumps Aquaglide range of high effciency large end

suction pumps has been developed for high capacity water pumping

applications. A range of material and coating options is available catering

for non-corrosive and corrosive applications including sea-water.

Range AQUA LIDE G

Specifcation

Applications:

Water supply & treatment

Water distribution

Water treatment

Irrigation

De-watering

Power/co-generation

Desalination

Mining

Metal manufacturing

Petrochemical

General industrial utility

Technical data:

Capacity: up to 10,000 m3/hr / 44,000 gpm

Delivery head: up to 100 m / 330 feet

Speed: up to 1,500 rpm

Temperature: up to 100 0C / 210 0F

Flange drilling: BS or ANSI

Sealing options:

Choice of sealing arrangements available as standard

Packed gland

Single spring mechanical seal

Single cartridge seal

Installation:

Horizontal

Vertical

Standard pump materials of construction:

(Casing Impeller)

Cast iron - Cast iron

Cast iron - Bronze

Cast iron - Stainless steel

Ni-resist - Stainless steel

Ni-resist - Duplex stainless steel

Stainless steel - Stainless steel

Large End Suction Water Pump

Minimum spares

Holding of shafts, seals, sleeves

& bearings. Modular construction

- fve standard shaft & bearing

housings to cover the entire

range.

Simplifed build

procedures

Self setting axial

clearance.

Optimum seal

Duty mechanical seal, packed

gland or cartridge seal options

available.

Reduced energy consumption

High effciency impeller design.

Allows pump effciencies

To be enhanced & as-new effciencies

are maintained through the operating

life of the pump. Effciency & protective

coatings available.

Allows pump effciency

to be maintained. Renewable casing

wear ring ftted as standard. Impeller

wear ring optional.

Increased shaft life

Dry shaft design.

Easily replaceable & reduces

maintenance costs

Shaft sleeve ftted as standard

on packed gland pump.

(Cartridge seal option shown)

Extended bearing life

Suitable for operation in high

ambient temperatures.

Generously rated thrust

bearings* - grease lubricated

as standard.

Reduced shaft defection

Leads to increased seal life-

minimum shaft overhang.

Reduced maintenance costs

Renewable back cover.

Increased bearing life

Impeller back vanes ftted where

required to reduce hydraulic

thrust.

The CLYDEUNION Pumps Aquaglide range

covers duties from 250 m/hr to 10,000

m/hr. The larger duties are covered by the

engineered range (please contact your local

representative for further details). For lower

fow duties please refer to the Isoglide range

of medium end suction pumps.

*Single or double bearing depending on frame size.

Vous aimerez peut-être aussi

- Clyde Aftermarket BrochureDocument2 pagesClyde Aftermarket BrochureglobalpumpsPas encore d'évaluation

- Clyde IsoglideDocument2 pagesClyde IsoglideShaisone ShoopPas encore d'évaluation

- Clyde Pumps WEIR API Brochures For Barrel Pumps EtcDocument22 pagesClyde Pumps WEIR API Brochures For Barrel Pumps EtcSSudhakarPas encore d'évaluation

- Emco API Couplers A4 Bro Low ResDocument4 pagesEmco API Couplers A4 Bro Low Resast654Pas encore d'évaluation

- Renold Sugar Chain 1007Document6 pagesRenold Sugar Chain 1007Omar Ahmed ElkhalilPas encore d'évaluation

- DESTACO Clamping Technologies CatalogDocument364 pagesDESTACO Clamping Technologies CatalogAnonymous oTrMzaPas encore d'évaluation

- Mining Product CatalogueDocument19 pagesMining Product CataloguefrancanPas encore d'évaluation

- Product Catalog: We Design, Manufacture, Specify, Service, Sell and RentDocument40 pagesProduct Catalog: We Design, Manufacture, Specify, Service, Sell and Rentjoana ramirezPas encore d'évaluation

- Global Gear Tuthill PDFDocument6 pagesGlobal Gear Tuthill PDFJose VargasPas encore d'évaluation

- Bailey Hydraulics Catalog 289 PDFDocument260 pagesBailey Hydraulics Catalog 289 PDFBrunex Choqueticlla100% (2)

- Gates Uk PDFDocument293 pagesGates Uk PDFZMCONTROLPas encore d'évaluation

- High Pressure Compressor Bellis Marcom-Serie - wh#1Document13 pagesHigh Pressure Compressor Bellis Marcom-Serie - wh#1cysauts100% (1)

- Johnson Pump 08 - Top GearDocument8 pagesJohnson Pump 08 - Top GearTejas MehtaPas encore d'évaluation

- Poclain Hydraulics Selection GuideDocument44 pagesPoclain Hydraulics Selection GuideM S GokulPas encore d'évaluation

- SP CBP 88Document6 pagesSP CBP 88mailme_vijuPas encore d'évaluation

- The Optimum Solution For Service and SupportDocument8 pagesThe Optimum Solution For Service and Supportzulu80Pas encore d'évaluation

- Paint Repair MaintenanceDocument6 pagesPaint Repair MaintenanceRajiv Kumar M100% (1)

- Conveyor Chain Design GuideDocument64 pagesConveyor Chain Design GuideAtacomaPas encore d'évaluation

- Deu BlinDocument58 pagesDeu Blinraghunath.psPas encore d'évaluation

- Cable Tray Catalogue WebDocument64 pagesCable Tray Catalogue Webshaaban2009Pas encore d'évaluation

- Product Catalogue For David BrownDocument12 pagesProduct Catalogue For David BrownIzdiharBinRosland0% (1)

- Norris Pro-Rod Coiled RodDocument8 pagesNorris Pro-Rod Coiled RodMohamed GhareebPas encore d'évaluation

- OzLinc Product CatalogueDocument192 pagesOzLinc Product CatalogueKarenPas encore d'évaluation

- Metalock Brochure May2013Document32 pagesMetalock Brochure May2013mjezeracPas encore d'évaluation

- Rainwater Systems: Design and Installation GuideDocument22 pagesRainwater Systems: Design and Installation GuideGELIGNITEPas encore d'évaluation

- 2008 3 65 PDFDocument10 pages2008 3 65 PDFLuisYFer1Pas encore d'évaluation

- Maypc 06 FullDocument156 pagesMaypc 06 FullIskconnickerie Sewraj100% (1)

- Hallite SealsDocument260 pagesHallite Sealssharafudheen_s100% (4)

- Plidco ClampDocument16 pagesPlidco ClampChooSK8850% (2)

- PFT Overview BrochureDocument25 pagesPFT Overview BrochureMohamed GuezguezPas encore d'évaluation

- Nitrogen BrochureDocument4 pagesNitrogen BrochureavarvanyPas encore d'évaluation

- Hydro Bond Engineering LTD Pressure Hull Glands & Outboard SystemsDocument3 pagesHydro Bond Engineering LTD Pressure Hull Glands & Outboard SystemsBharathidasan SugumaranPas encore d'évaluation

- CEMC Screw Conveyor Manual 2.20Document107 pagesCEMC Screw Conveyor Manual 2.20Angel Alvarez100% (7)

- Style 22 Vic-Ring Coupling: Product DescriptionDocument2 pagesStyle 22 Vic-Ring Coupling: Product DescriptionDante2500Pas encore d'évaluation

- 2010 KMT Waterjet PSC Catalog - LDocument39 pages2010 KMT Waterjet PSC Catalog - LaeradriPas encore d'évaluation

- Drilling Systems BrochureDocument8 pagesDrilling Systems BrochureBeniamine SarmientoPas encore d'évaluation

- Valve SelectDocument20 pagesValve SelectsajuherePas encore d'évaluation

- Autoborewelding vs. Hand WeldingDocument4 pagesAutoborewelding vs. Hand WeldingAntonius NataPas encore d'évaluation

- HDD Brochure FMCDocument2 pagesHDD Brochure FMCCesarPas encore d'évaluation

- MikroPul High Efficiency Cyclones 200511Document4 pagesMikroPul High Efficiency Cyclones 200511Zoran DanilovPas encore d'évaluation

- Full CatalogDocument92 pagesFull CatalogYip Ying MunPas encore d'évaluation

- Renold Couplings - 7th EditionDocument96 pagesRenold Couplings - 7th EditionGiancarlo MenachoPas encore d'évaluation

- F303EDocument2 pagesF303EswnjiopmyPas encore d'évaluation

- Geog OverviewDocument2 pagesGeog OverviewhjpbunoPas encore d'évaluation

- Rigole PDFDocument30 pagesRigole PDFmariuspiPas encore d'évaluation

- Oil States Corporate Overview 022020Document5 pagesOil States Corporate Overview 022020judsonlobPas encore d'évaluation

- Fan and Blower ApplicationsDocument2 pagesFan and Blower Applicationsanhntran4850Pas encore d'évaluation

- Marine Propulsion Engine: Powered by Your NeedsDocument2 pagesMarine Propulsion Engine: Powered by Your NeedsTran HanPas encore d'évaluation

- Manhole Price Catalogue (Web)Document28 pagesManhole Price Catalogue (Web)Marie Fe Fortuno BermidoPas encore d'évaluation

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!D'EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Évaluation : 5 sur 5 étoiles5/5 (2)

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Machines, Tools and Methods of Automobile ManufactureD'EverandMachines, Tools and Methods of Automobile ManufactureÉvaluation : 4 sur 5 étoiles4/5 (1)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerD'EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerÉvaluation : 5 sur 5 étoiles5/5 (1)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyD'EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyÉvaluation : 5 sur 5 étoiles5/5 (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideD'EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideÉvaluation : 4.5 sur 5 étoiles4.5/5 (8)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreD'EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreÉvaluation : 4.5 sur 5 étoiles4.5/5 (11)

- Building Honda K-Series Engine PerformanceD'EverandBuilding Honda K-Series Engine PerformanceÉvaluation : 5 sur 5 étoiles5/5 (2)

- Petroleum Refinery Relocation Projects: 5-Phases of Project ManagementD'EverandPetroleum Refinery Relocation Projects: 5-Phases of Project ManagementPas encore d'évaluation

- John Crane Acoplamientos Serie LDocument8 pagesJohn Crane Acoplamientos Serie LBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- Ensival Moret MP PumpsDocument6 pagesEnsival Moret MP PumpsBenicio Joaquín Ferrero Brebes100% (1)

- Pedrollo 2CPDocument8 pagesPedrollo 2CPBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- RuhrpumpenDocument2 pagesRuhrpumpenBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- Ensival Moret PRE Pumps (French-English)Document3 pagesEnsival Moret PRE Pumps (French-English)Benicio Joaquín Ferrero BrebesPas encore d'évaluation

- Ensival Moret MP PumpsDocument6 pagesEnsival Moret MP PumpsBenicio Joaquín Ferrero Brebes100% (1)

- Ensival Moret PumpsDocument5 pagesEnsival Moret PumpsBenicio Joaquín Ferrero Brebes0% (1)

- Manual Bomba Layne BowlerDocument21 pagesManual Bomba Layne BowlerBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- Catalogo Fire 2009Document7 pagesCatalogo Fire 2009Benicio Joaquín Ferrero BrebesPas encore d'évaluation

- RuhrpumpenDocument4 pagesRuhrpumpenBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- Aurora PumpsDocument14 pagesAurora PumpsBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- Viking Heavy Duty Pumps: SERIES 4193 AND 493 Steel ExternalsDocument12 pagesViking Heavy Duty Pumps: SERIES 4193 AND 493 Steel ExternalsBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- FPD 1034 e PDFDocument923 pagesFPD 1034 e PDFBenicio Joaquín Ferrero Brebes75% (4)

- DC9 65 A 356kVADocument2 pagesDC9 65 A 356kVABenicio Joaquín Ferrero BrebesPas encore d'évaluation

- Spec Sheet - JU6H-LS - C13556 - 04-05Document2 pagesSpec Sheet - JU6H-LS - C13556 - 04-05Benicio Joaquín Ferrero BrebesPas encore d'évaluation

- Screw Pump HC 232 - 80/2 / N: 1.0 Project DataDocument1 pageScrew Pump HC 232 - 80/2 / N: 1.0 Project DataBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- ISC2 SeriesDocument6 pagesISC2 SeriesBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- 6" Encapsulated Submersible Motors: Application DataDocument2 pages6" Encapsulated Submersible Motors: Application DataBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- Catalogo OMEGADocument20 pagesCatalogo OMEGABenicio Joaquín Ferrero BrebesPas encore d'évaluation

- Acoplamientos TSK PDFDocument4 pagesAcoplamientos TSK PDFBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- Red Title Here Proven Low-Flow, High-Head PerformanceDocument2 pagesRed Title Here Proven Low-Flow, High-Head PerformanceBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- RPH PDFDocument14 pagesRPH PDFBenicio Joaquín Ferrero BrebesPas encore d'évaluation

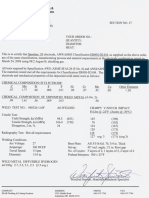

- Reference Numbers: Thelco Cutaway Drawing of Worthington® Type CNG Frame 1, 2, and 3, Oil LubeDocument1 pageReference Numbers: Thelco Cutaway Drawing of Worthington® Type CNG Frame 1, 2, and 3, Oil LubeBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- Nitobond SBR PDFDocument4 pagesNitobond SBR PDFhelloitskalaiPas encore d'évaluation

- Is 8224Document16 pagesIs 8224Ankit YadavPas encore d'évaluation

- List of Accredited List of Accredited EIA Consultant Organizations (As On March 05, 2015) Organizations - 170Document135 pagesList of Accredited List of Accredited EIA Consultant Organizations (As On March 05, 2015) Organizations - 170santhoshneo02@gmail.comPas encore d'évaluation

- Suelo, Agua Subterranea y Sedimento Norma CanadienseDocument40 pagesSuelo, Agua Subterranea y Sedimento Norma CanadiensehensilPas encore d'évaluation

- Tyvek CodeDocument1 pageTyvek CodeDaveCindy ShaferPas encore d'évaluation

- MSDSDocument13 pagesMSDSSehry SyedPas encore d'évaluation

- ASTM B188-2002 Tubos de CobreDocument10 pagesASTM B188-2002 Tubos de Cobrelinealmen100% (1)

- SunCoBe ShampooDocument24 pagesSunCoBe ShampooDong YulPas encore d'évaluation

- E Grout Mc050Document2 pagesE Grout Mc050Tori SmallPas encore d'évaluation

- Method Statement of Hydraulic Pressure Testing: 1. Machinery / Equipment and ToolsDocument9 pagesMethod Statement of Hydraulic Pressure Testing: 1. Machinery / Equipment and Toolskevin JiaoPas encore d'évaluation

- ASTM Method D5134-92Document1 pageASTM Method D5134-92Sylab InstrumentsPas encore d'évaluation

- DesalinationTechnologiesforDevelopingCountriesAReview PDFDocument22 pagesDesalinationTechnologiesforDevelopingCountriesAReview PDFlebob12Pas encore d'évaluation

- Stainless EnstainlessDocument27 pagesStainless EnstainlessVinaya Almane DattathreyaPas encore d'évaluation

- Nitrogen, Total, TNT, 0 To 25.0, Persulfate Digestion Method 10071Document9 pagesNitrogen, Total, TNT, 0 To 25.0, Persulfate Digestion Method 10071Dwiyana YogasariPas encore d'évaluation

- Hemodialysis Medical Supply and MedicationDocument10 pagesHemodialysis Medical Supply and Medicationsiuagan.jayveePas encore d'évaluation

- Brass PPTDocument41 pagesBrass PPTAbhiram shuklaPas encore d'évaluation

- Experiments 11 15 NotesDocument16 pagesExperiments 11 15 Notesforisko05Pas encore d'évaluation

- 5MF 10MFDocument8 pages5MF 10MFRodrigo Pessoa VespaPas encore d'évaluation

- Iron Oxide NanoparticlesDocument25 pagesIron Oxide NanoparticlesGöksun GüvenPas encore d'évaluation

- Bab 4 ObjektifDocument9 pagesBab 4 ObjektifFida NordinPas encore d'évaluation

- Description and Solubility - MTZDocument6 pagesDescription and Solubility - MTZPityu PíPas encore d'évaluation

- Experimental Detemination of Crystal StructureDocument40 pagesExperimental Detemination of Crystal StructureAASHIR AHMAD JASKANIPas encore d'évaluation

- Major Intermediates in Organophosphate Synthesis (PCL, Pocl, PSCL, and Their Diethyl Esters) Are Anticholinesterase Agents Directly or On ActivationDocument7 pagesMajor Intermediates in Organophosphate Synthesis (PCL, Pocl, PSCL, and Their Diethyl Esters) Are Anticholinesterase Agents Directly or On ActivationYancy JuanPas encore d'évaluation

- Technological Advancements in The Drying of Fruits and Vegetables: A ReviewDocument14 pagesTechnological Advancements in The Drying of Fruits and Vegetables: A ReviewMaria MadanPas encore d'évaluation

- Data Correction and Copper Mass Balance Before Evaluation of Copper Solvent Extraction PerformanceDocument52 pagesData Correction and Copper Mass Balance Before Evaluation of Copper Solvent Extraction Performancejoseph kafumbila100% (2)

- Experilab Breinwave: Bubble BlowersDocument4 pagesExperilab Breinwave: Bubble BlowersHirenkumarPas encore d'évaluation

- Oisd 142Document55 pagesOisd 142sandeep MPas encore d'évaluation

- Ramabulana Et Al. 2021 MN and MetPA - Chemical Space of Four Momordica Plant SpeciesDocument15 pagesRamabulana Et Al. 2021 MN and MetPA - Chemical Space of Four Momordica Plant SpeciesFernanda SantosPas encore d'évaluation

- Urea UV Freeze DriedDocument1 pageUrea UV Freeze DriedJanos ImrePas encore d'évaluation

- ESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root GapDocument1 pageESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root Gapalok987Pas encore d'évaluation