Académique Documents

Professionnel Documents

Culture Documents

4342 Machining Milling 1

Transféré par

Shahrul AimanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

4342 Machining Milling 1

Transféré par

Shahrul AimanDroits d'auteur :

Formats disponibles

Manufacturing Processes lab I

Milling Machine- 1

Learning Objectives:

Describe how milling machines operate,

Identify the various types of milling machines,

Select the proper cutter for the job to be done,

Calculate cutting speeds and feeds.

Milling Machine:

A milling machine is a power-driven machine used for the comple shaping of

metal parts.

Its basic form is that of a rotating cutter or endmill which rotates about the spindle

ais !similar to a drill", and a movable table to which the wor#piece is affied.

Milling products

$illing machines may be operated manually or under computer numerical control

!C%C".

Types of Milling Machines:

&here are two main types of mill' the vertical mill and the hori(ontal mill.

)ori(ontal machine

*ertical machine

Vertical Mill:

In the vertical mill the spindle ais is vertically oriented !$illing cutters are held in

the spindle and rotate on its ais".

&he spindle can generally be etended !or the table can be raised+lowered, allowing

plunge cuts and drilling.

Horizontal Mill:

A hori(ontal mill has the same sort of x,y table, but the cutters are mounted on a

hori(ontal arbor across the table. A majority of hori(ontal mills also feature a -./+-

./ degree rotary table that allows milling at shallow angles.

0lain mills are used to shape flat surfaces. Special cutters can also cut grooves,

bevels, radii, or indeed any section desired. &hese specialty cutters tend to be

epensive.

Simple mills have one spindle, and duple mills have two.

It is also easier to cut gears on a hori(ontal mill.

arious Parts of the Horizontal Mill:

Types of Move!ents:

Types of Milling Machines:

Column and 1nee Column guides the #nee in vertical !2 ais" Direction.

1nee provides the 3 and 4 movements for the table.

"ubcategories of ertical Milling:

&here are several subcategories of vertical mills' the bedmill and the &urret mill.

&urret mills, are generally smaller than bedmills, but are more versatile. In a turret

mill the spindle remains stationary during cutting operations and the table is moved

both perpendicular to and parallel to the spindle ais to accomplish cutting.

In the bedmill, however, the table moves only perpendicular to the spindle5s ais,

while the spindle itself moves parallel to its own ais.

Types of Milling Machines:

A more comple form of the milling machine is the 6niversal milling machine, in

which the rotating cutter can be oriented vertically or hori(ontally, increasing the

fleibility of the machine tool.

&he table of the universal machine can be swiveled through a small angle !up to

about ./ degrees", enabling tapered cuts to be made over the length of the table.

Typical Milling Operations:

Plain Milling :

0lain milling is the milling of a flat surface with the ais of the cutter parallel to the

machining surface. It can be carried out either on a hori(ontal machine or a vertical

machine as shown here.

Typical Milling Operations:

#n$ Milling

7nd $illing is the milling of a flat surface with the ais of the cutter perpendicular

to the machining surface as shown here.

Typical Milling Operations:

%ang Milling

8ang milling is a hori(ontal milling operation that utili(es three or more milling

cutters grouped together for the milling of a comple surface in one pass.

Different type and si(e of cutters should be selected for achieving the desire profile

on the wor#piece.

"tra$$le Milling

In straddle milling, a group of spacers is mounted in between two side and face

milling cutters on the spindle arbor as shown, for the milling of two surfaces

parallel to each other at a given distance.

&lassification of Milling:

Slab milling !the milled surface is generated by teeth located on the periphery of

the cutter body. &he ais of cutter rotation is generally in a plane parallel to the

wor#piece surface to be machined",

9ace milling !the cutter is mounted on a spindle having an ais of rotation

perpendicular to the wor#piece surface. &he milled surface results from the action

of cutting edges located on the periphery and face of the cutter ",

7nd $illing !&he cutter in end milling generally rotates on an ais vertical to the

wor#piece. It can be tilted to machine tapered surfaces. Cutting teeth are located on

both the end face of the cutter and the periphery of the cutter body".

Metho$s of Milling:

1' (p !illing:

)'*o+n !illing:

Metho$s of !illing !achine control:

$anual' $ovements are made by hand lever control".

Semi-automatic' $ovements are controlled by hand and+or power feeds".

9ully automatic' A comple hydraulic feed arrangement that follows : or ;

dimensional templates.

C%C' $achining coordinates are entered into a master computer or computer

on the machine, using a special programming language.

&utting Tools:

Cutting tools for hori(ontal milling'

a. Slab $ills

9or heavy cutting of large and flat surfaces.

b. Side and 9ace Cutters

&his type of cutter has cutting edges on the periphery and sides of the teeth

for cutting shoulders and slots.

c. Slitting Saws

9or cutting deep slots or for parting off.

&utting Tools:

Cutting tools for vertical milling'

a' #n$ Mills

Commonly used for facing, slotting and profile milling.

b' ,ough &ut #n$ Mills

9or rapid metal removal

c' "lot *rills

9or producing poc#ets without drilling a hole before hand.

$' -ace Milling &utters

9or heavy cutting.

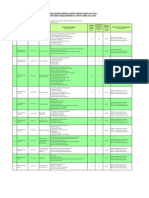

"pin$le "pee$ :

<0$

-ee$ ,ate:

Tool

Material

High "pee$ "teel &arbi$e

Material

&utting

"pee$

-ee$

.f/

&utting

"pee$

-ee$

.f/

Mil$ "teel )0 1'12 111 1'10

3lu!inu! 111 1'10 011 1'4

Har$ene$

"teel

--- --- 01 1'1

Cutting speed and feed rate depend on the material to be cut and tool material

and also type of operation=

Test yourself:

Is this up milling or down milling>

6p milling

Is this up milling or down milling>

Up milling

?hich one is the vertical milling and which one the hori(ontal one>

Vertical milling

Horizontal milling

"pecify the 56 7 an$ 8 $irections:

@abel each of the milling operations below. Choose from 9ace milling, 7nd

milling and Slab milling.

Slab milling 9ace milling 7nd milling

Are these tools for vertical or hori(ontal milling> @abel them using' Side and

face cutter, slitting saws and slab mills.

Slab $ills

Side and 9ace Cutters

Slitting Saws

Horizontal !illing:

Specify the following vertical mill cutting tools !choose from slot drill, end mill,

face milling cutter and rough cut end mill".

7nd mill

9ace milling cutter

Determine the approimate cutting speed and feed for a AB !./: mm" diameter side

cutter !)igh Speed Steel or )SS" with .A teeth, when milling free cutting steel.

Consider the cutting speed for free cutting steel :CC fpm. &he feed rate for free

cutting steel for side cutter is between C.CC/ to C.C.. inches. Consider the midpoint

in range.

Have a loo9 at this site:

http'++www.metalwor#ing.com+tutorials+A<$4-&C-D-/:E+chF.pdf

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- ABAHKAU2 WafretfDocument2 pagesABAHKAU2 WafretfShahrul AimanPas encore d'évaluation

- Application For Any Position at Your CompanyDocument1 pageApplication For Any Position at Your CompanyShahrul AimanPas encore d'évaluation

- Group Discussion 1: Engineering Mathematics 4Document1 pageGroup Discussion 1: Engineering Mathematics 4Shahrul AimanPas encore d'évaluation

- Result N Datasdfgdsf FSDFSDGDFHDFH J Erterter Etter TerteryeuDocument2 pagesResult N Datasdfgdsf FSDFSDGDFHDFH J Erterter Etter TerteryeuShahrul AimanPas encore d'évaluation

- SMK Permatang Tok Jaya (Model Khas Pulau Pinang) Sekolah Kluster KecermelanganDocument2 pagesSMK Permatang Tok Jaya (Model Khas Pulau Pinang) Sekolah Kluster KecermelanganShahrul AimanPas encore d'évaluation

- Coding AimnanDocument1 pageCoding AimnanShahrul AimanPas encore d'évaluation

- Muke Depan Machnics Muke DepanDocument3 pagesMuke Depan Machnics Muke DepanShahrul AimanPas encore d'évaluation

- Report Arc WeldingDocument3 pagesReport Arc WeldingShahrul AimanPas encore d'évaluation

- Jj104 - Workshop Technology 1 Milling Machine: Machanical Engineering DepartmentDocument2 pagesJj104 - Workshop Technology 1 Milling Machine: Machanical Engineering DepartmentShahrul AimanPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Subwork (Engineering)Document6 pagesSubwork (Engineering)shahid choudhuryPas encore d'évaluation

- EO and EO-2 Metric Bite Type FittingsDocument64 pagesEO and EO-2 Metric Bite Type FittingsCristianPas encore d'évaluation

- 8 Experiment Turning Full Procedure With ImageDocument28 pages8 Experiment Turning Full Procedure With ImageSiddiqui Adil AdnanPas encore d'évaluation

- Surface RoughnessDocument28 pagesSurface RoughnessNeelesh PatkiPas encore d'évaluation

- Short Term Courses Offered at Adtec Taiping 2014/2015Document2 pagesShort Term Courses Offered at Adtec Taiping 2014/2015Safar BrolyPas encore d'évaluation

- Single Point CuttingDocument35 pagesSingle Point CuttingCameron GrantPas encore d'évaluation

- Shapers, Planner and SlottersDocument121 pagesShapers, Planner and SlottersReyven ReconPas encore d'évaluation

- Refrigeretor and LatheDocument22 pagesRefrigeretor and LatheShreenivas ThakurPas encore d'évaluation

- BS 2782-4 Methods 430A To 430D-1983 - (2020-06-10 - 06-45-53 PM)Document12 pagesBS 2782-4 Methods 430A To 430D-1983 - (2020-06-10 - 06-45-53 PM)Yasmin LoperaPas encore d'évaluation

- Lecture-6: Fundamental of CuttingDocument38 pagesLecture-6: Fundamental of CuttingMuhammad IrfanPas encore d'évaluation

- Machining Fixture For Adaptive CNC Machining Process of Near-Net-Shaped Jet Engine BladeDocument18 pagesMachining Fixture For Adaptive CNC Machining Process of Near-Net-Shaped Jet Engine BladeJustformedia JustformediaPas encore d'évaluation

- Канавочные и отрезные резцы IscarDocument313 pagesКанавочные и отрезные резцы IscarstctoolPas encore d'évaluation

- 2023 Summer Question Paper (Msbte Study Resources)Document3 pages2023 Summer Question Paper (Msbte Study Resources)Piyush NikamPas encore d'évaluation

- HCN-5000 50 BrochureDocument3 pagesHCN-5000 50 Brochurevictor saenz100% (1)

- Retail Price List: Padi UnitDocument16 pagesRetail Price List: Padi Unitsalil kumar padhyPas encore d'évaluation

- Unit 4 Surface Texture: ObjectivesDocument23 pagesUnit 4 Surface Texture: ObjectivesApechRangerPas encore d'évaluation

- Classification of LatheDocument15 pagesClassification of LatheDamián G.S.Pas encore d'évaluation

- Broaching PDFDocument7 pagesBroaching PDFBalaji Karunakaran100% (1)

- Ncstudio Programming Manual-R5.08Document74 pagesNcstudio Programming Manual-R5.08kubik369100% (2)

- Assignment 6Document5 pagesAssignment 6Anonymous G6QkwTykKPas encore d'évaluation

- Protem Catalogue EDocument112 pagesProtem Catalogue EemadnaguibPas encore d'évaluation

- Bollhoff HeliCoil Plus Thread Repair KitsDocument40 pagesBollhoff HeliCoil Plus Thread Repair KitsAce Industrial SuppliesPas encore d'évaluation

- Machine Shop - SyllabusDocument4 pagesMachine Shop - SyllabusvirupakshaPas encore d'évaluation

- 8040 Aflex Cat 17 138Document1 page8040 Aflex Cat 17 138Nusrat IqbalPas encore d'évaluation

- Government Tool Room and Training CentreDocument24 pagesGovernment Tool Room and Training CentreNiranjan DsPas encore d'évaluation

- Suryadev T.S.for STRL FinalDocument46 pagesSuryadev T.S.for STRL Finalkrmcharigdc100% (1)

- ESPRIT Milling Tutorial 01Document24 pagesESPRIT Milling Tutorial 01Sandaruwan සුජීව100% (2)

- Lathe Machine Program Manual (C Type)Document259 pagesLathe Machine Program Manual (C Type)ダンハイソンPas encore d'évaluation

- Investigations On End Milling of CFRP Composite Using Router ToolsDocument14 pagesInvestigations On End Milling of CFRP Composite Using Router Tools18M232 Nanta gopal CPas encore d'évaluation

- Elements of Workshop Technology: U J I I IDocument357 pagesElements of Workshop Technology: U J I I IRaunak Gupta100% (1)