Académique Documents

Professionnel Documents

Culture Documents

Napino File

Transféré par

Parveen JaatCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Napino File

Transféré par

Parveen JaatDroits d'auteur :

Formats disponibles

1.

1 OVERVIEW

A proud contributor to the progress of the Indian auto industry, the success of napino lies

in the ability of the organization to seamlessly adapt to the requirement of its clients

through aggressive development in technology and design.

Employing the most advanced equipment, napino auto & electronics offers technology

that is futuristic and cutting edge. Here efficiency is driven via significantly reducing the

cost of production without any compromise on quality .determination of the group to

bring about ethical conduct that is of the highest standards has led to a commitment that

assures wor environment that is synergistic in nature.

!ith success come greater challenges and as a "oint venture company and shindengen

electric manufacturing of #apan, !ho are world leaders in the field of power and auto

electronics products e$pectations, napino continues to focus on an increase in it adoption

for a considerable increase in production. Here, it aims at achieving ma$imum and

accomplishing what may seem beyond the grasp of their competitors.

1

%aintaining a safe and healthy wor environment for employees is apriority as they

continue to emphasize on complete transparency setting a bench mar for the industry as

they entered into second decade of the &'

st

century, there aim is to be recognized across

the globe as a leading manufacturer and supplier of high quality electric and electronics

components.

1.2 Achievements by napino auto &electronics ltd.

&(') *+% starts

&('& inauguration of design and development sector,'

&('& commenced operation at sector-. plant &((/ *0 '12/2 and I03 '/((

certification

&((. commenced operation at haridwar plant

&((4 3H0A0'.((' certification

&((/ certified for I03 '/((' 5environment managements system6

&(() 738 certification by H%98

&((& commenced operation at manser plant

&((' :0,2((( certification

'22. commenced production of 97I and ;E<=8A*3;>;E9*I?IE;

'22. collaboration with shindengen electric #apan

'22@ production of wiring harness

'22@ establishment of operations at udyog vihar.

1.3 ac!"round

*he history of the capacitor discharge ignition system can be traced bac to the '.2(As

when it is believed that Biola *esla was the first to propose such an ignition system.

*esla writes any suitable moving portion of the apparatus is caused to mechanically

control the charging of a condenser and its discharge through a circuit in inductive

relation to secondary circuit leading to the terminals between which the discharge is to

occur so that the desired intervals the condenser may be discharged through its circuit and

induces in the other circuit current of high potential

2

2.1 I#$RO%&'$IO# $O A&$O(O$IVE E)E'$RO#I'*

A=*3%3*ICE E8E9*;3BI90 are any electrically,generated systems used in road

vehicles, such asD carputers, telematics, in,car entertainment systems, etc.

Automotive electronics originated from the need to control engines. *he first electronic

pieces were used to control engine functions and were referred to as engine control units

5E9=6. As electronic controls began to be used for more automotive applications, the

acronym E9= too on the more general meaning of Eelectronic control unitE, and then

specific E9=Fs were developed. Bow, E9=Fs are modular. *wo types include engine

control modules 5E9%6 or transmission control modules 5*9%6.

A modern car may have up to '(( E9=Fs and a commercial vehicle up to /(.

2.1.1 En"ine electronics

3ne of the most demanding electronic parts of an automobile is the engine control unit.

Engine controls demand one of the highest real time deadlines, as the engine itself is a

very fast and comple$ part of the automobile. 3f all the electronics in any car the

computing power of the engine control unit is the highest, typically a )&,bit processor.

It controls such things asD

In a diesel engineD

?uel in"ection rate

Emission control, B3$ control

;egeneration of o$idation catalytic converter

*urbocharger control

9ooling system control

*hrottle

a gasoline engineD

3

8ambda control

3G7 53n,Goard 7iagnostics6

9ooling system control

Ignition system control

2.2 'har"in" system

*he basics of a motorcycle charging systemD,

3n almost every motorcycle you will find a battery, use for providing power for starting

the bie and for buffering an amount of electrical energy .the battery itself is charged by a

generator driven by an engine, and as long as the engine is running there will be current

flowing through the battery. *he no load voltage of a fully charged battery is about ')v

79 .for charging it the charging system should provide a voltage of about '/./ v 79 and

this should be constant voltage at all engine Hspeeds.

*he generator itself is located in pr on the engine, and on most of the bies there is a

separate regulator>rectifier unit located somewhere on the frame. *he reason for this is

that the almost all motorcycles are equipped with a three phase A.9 .generator, while the

electrical system on the bie is a 7.9. *he rectifier part inside the regulator taes care of

converting the A.9.,current

*o 7.9. Hcurrent the battery needs. *he three phase A.9. generator is used so often

because it is much more efficient and reliable then a dc generator. It can produce power

for charging battery even with the engine idly. *he regulator part of the regulator rectifier

is used to regulate the output Hvoltage 5to the battery6 '/./ v 7.9.

4

2.3 $he permanent ma"net "enerator system+,

A generator on the bie is producing this electric power because it has a copper wire

binding on the stator 5the static part of generator6 that is located inside the varying

magnetic fieldI the simplest generator uses a fly wheel that runs on a cran shift with

couple of magnets inside it. !e call this fly wheel with its built in magnets. *he magnet

themselves has north and 0outh +ole and file wheel is rotated around the stator. *he stator

is a metal core with a lot of metal poles that have winding of copper wire on them.

Gecause the fly wheel is rotating and there are north and south pole inside it, the winding

of stator are e$posed to first north pole, then south pole, then north pole again etc.. *his is

the varying magnetic field that is needed to let the winding itself produce ac current. *he

winding themselves are connected in a star 5one winding has two ends and three ends of

three different windings are connected together6 so the stator has only three output wires

emerging from it.

*his generator set up is called permanent magnet generator .this is because the fly wheel

contains magnet that are magnet all the time. *he output of a certain stator is depending

on the engine speed 2the higher the speed of engine the higher the stator output(, and the

force of magnetic field which is a constant. Gasically a stator produces a certain output at

certain ;.+.%.

*hen the ac current is lead through rectifier inside the regulator rectifier unit. *he

rectifiers convert the three ac phase to a single /./ v dc output, a ground and a positive.

Gecause the stator is producing power according to the engine speed the stator output is

too high all the time. *his would mean the output voltage of regulator rectifier is way

over '/./ v dc all the time, which would result in over charge battery and blowing

electrical components on the bie that were meant to run on voltage between '&,'4v dc.

8ucily there is regulator part inside a regulator rectifier the regulator loos at the 79 Hv

cross the battery Hterminal and short circuit .a certain amount of power that is produced

by a stator to go ground .this is regulated constantly, so the output voltage of regulator

rectifier 5which idly is the same as voltage across the battery terminals 6 stays at '/./v dc

5

all the time.yhe permanent magnet generator H setup is not very efficient is quite simple

and reliable .this e$plains why it is most commonly used system on the motor cycle . 3ne

of the problems with this system is the short circuiting of the e$cess power itself. *his is

done by regulator rectifier and this part has to dissipate the power that it shorts to ground,

meaning it will get very hot. *his is mostly because of the regulator and partly by the

rectifier, diodes themselves that get hot "ust because of the current flowing through it.

*he regulator rectifier internals need to be building so that the heat is transferred

efficiently from electronic components themselves to the housing of unit mostly equipped

with cooling fins. *his is the most important bit in designing a regulator rectifier in

designing a permanent magnet generator setup.

*he regulator part of the regulator rectifier needs to measure the dc voltage somewhere in

the system. 3n the cheapest built unit 5quit a lot of 3HE% ones6 this is not done by

measuring dc voltage in d c system, but by looing at ac voltage in between one stator

phase and the ground and sometimes e$cess power is shorted to the ground from "ust one

or two input phases instead of all input phase that are regulated. *he better built units

measure the output voltage of unit itself and regulate the input A.9. accordingly by

shorting more or less power to the ground, and equal amount of all the three phase.

6

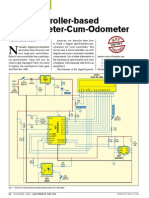

?igure & operations on machines

0ome units use an e$tra input wire to measure the dc voltage. *he wire normally is

connected up through the ignition switch and not straight to the battery. 0o there is only a

voltage on this lead if ignition is turned on. *his is done to mae up for a voltage drop

that occurs because of a bad connection in the leads from the regulator rectifier output to

the battery, terminals. *hese leads carry a high current and any bad connection here will

result in a lower voltage over the battery terminals.

*he e$tra lead carries a much lower current and the result of this setup is that the output

voltage of the rectifier will be higher, the same dc,voltage as the voltage Hdrop in the

high current leads plus '/./v dc. It has the disadvantage that the high current leads can

7

eventually burn out because of this, without the owner even noticing beforehand that

there is a problem in the circuit.

3ne thing to eep in mind is that the output Hpower provided by the stator Hwinding is

delivered I between the phases. *he ground in the charging system is the negative output

from the rectifier. *he ac part of the three phases system is the negative output from the

rectifier.tha ac part of the three phase system is the negative output from the rectifier. *he

ac part of the three phase system is floating from the ground. *his means that testing of

the c output needs to be done in between two of the three phases, and not from one phase

to ground.

2.2.3 $-E .IE)% 'O#$RO))E% /E#ER$AOR *0*$E(

*he other system used on motor cycles is the field,controlled generator. *he system itself

wors on the principles as a permanent magnet generator, the only big difference is that

there is no permanent magnet but instead there is an electromagnet that provides the

necessary magnetism 59alled as field6. *he electromagnet is a single big winding one

metal core that gets magnetized as soon as there is dc current flowing through the

winding supplied by the battery. A car generator basically uses the same system.

3n most of the field,controlled systems this metal core has claw poles and two slip

rings.thw whole thing rotates with the cranshaft, with the stator winding "ust lie the

permanent magnet stator6 around it. Imagine looing at the outer side of the rotor

sideways. Jou will see two pieces of metal pressed together with a winding in between

.when you apply battery Hvoltage across the slip rings, the rotor will behave lie a big

electromagnet, and the left hand side of the rotor will be say a north Hpole, then the right

Hhand side will be a south Hpole .in the middle you can see the pieces overlapping ,

meaning when the rotor rotates there first will be a south pole passing, then a north pole

,then a south pole etc. this is the needed varying magnetic field for generating ac,current

in the stator .the three phase ac output from the stator winding is led through a rectifier

2inside the regulator Hrectifier,unit( to convert it to dc for charging the battery.

;egulation is done by the regulator part of the regulator rectifier. It senses the voltage in

the bies electrical system and when the voltage is lower than '/./v dc it switches on the

8

field 5it switches a '&v dc supply across the slip rings6 then there is s a magnetic field, so

the stator will produce power. !hen the voltage in the bie system reaches over '/./v dc

the regulator senses that and "ust switches the field off. *he voltage drop will drop

because the stator doesnAt produce any power anymore. !hen the voltage drops below

app '/.& v, the regulator switchAs the field bac on.

*his is a constant process and the result of this is a constant voltage across the battery

terminals of ')./vdc. Gecause there is no e$cess power produced by the stator, this

system is very efficient. 9ounter side is that it is not as simple and small as a permanent

magnet generator. *he field winding normally has one side connected to the battery

positive through the ignition switch, so there is only power for the field when the ignition

is turned on. ;egulation is done through the regulator part of the regulator rectifier by

switching the ground for the field on or off. 3n some machines the setup is the other way

around, then one side of the field is connected to ground at all times, and the other side is

switched on or off to a positive feed 5through the ignition,switch 6by the regulator.

2.2.2 $-E (AI#$A#'E .REE .IE)% 'O#$RO))E% /E#ER$OR

0ome machines have a slightly different setup. *hen the stator is located inside a cover,

as well as the field winding in the middle of it. In between rotators an iron claw Hpole

driven by the engine. *he claw,pole gets magnetized by the field winding and the system

wors lie the field controlled ones as e$plained above. *he difference is that the field

does not rotate so it doesnAt need to be powered through slip,rings and brushes, which

maes it virtually maintenance Hfree. 9ounter side pf this setup is the e$tra air gap

between the field winding and the claw pole. Bormally you have every narrow air gap

between rotor and stator that is needed to let the rotor rotates freely. *his air gap needs to

be as small as possible, the smaller the air gap, the more efficient generator wors. 3n

this maintained free system there is e$tra air gap so this system is less efficient.

2.1.1 $-E &#I$ .IE)% 'O#$RO))E% /E#ER$OR

9

*he last variant of this system is an ac type generator that is bolted onto bie engine as a

single unit. It is driven by the engine itself and has a built in rectifier, and a built in

regulator in regulator, "ust lie a car generator. It is driven by the engine itself and has a

built in rectifier, and a built in regulator, "ust lie a car generator. *he only connections to

it are the positive output lead to the battery plus and a supply lead from the ignition

switch to the regulator inside ,so the regulator can be turned on and off when the engine

is not running and it can sense the voltage o the bies electrical system on this wire.

3.1 'A2A'I$OR %I*'-AR/E I/#I$OR 3'%I4

*he two wheelers industry comprised of scooters, motorcycles, commonly use an engine

ignition system based on capacitive discharge method. *he capacitive discharge ignition

system utilizes the energy transferred from magneto to a storage capacitor. !hen released

as a high voltage pulse via a step up transformer to a spar plug which ignites the fuel

mi$ture inside the cylinder. *he digital 97I allows the user to monitor the speed of the

engine to calculate the accurate timing for the spar which increases engine efficiency,

saves energy and reduces emissions.

10

?igure).' 97I

9apacitor discharge ignition 597I6 is a type of automotive electronic ignition system

which is widely used in outboard motors, motorcycles, lawn mowers, chainsaws, small

engines, turbine,powered aircraft, and some cars. It was originally developed to

overcome the long charging times associated with high inductance coils used in inductive

discharge ignition 5I7I6 systems, maing the ignition system more suitable for high

engine speeds 5for small engines, racing engine and rotator engine6. *he capacitive,

discharge ignition uses capacitor discharge current output to fire the spar plugs.

3.1 A*I' 2RI#'I2)E

%ost ignition systems used in cars are inductive discharge ignition 5I7I6 systems, which

are solely relying on the electric inductance at the coil to produce high,

voltage electricity to the spar plugs as the magnetic field collapses when the current to

the primary coil winding is disconnected 5disruptive discharge6. In a 97I system,

a charging circuit charges a high voltage capacitor, and at the instant of ignition the

system stops charging the capacitor, allowing the capacitor to discharge its output to the

ignition coil before reaching the spar plug.

11

?igure ).& woring of 97I

12

A typical 97I module consists of a small transformer, a charging circuit, a triggering

circuit and a main capacitor. ?irst, the system voltage is raised up to &4( to 1(( volts by a

power supply inside the 97I module. *hen, the electric current flows to the charging

circuit and charges the capacitor. *he rectifier inside the charging circuit prevents

capacitor discharge before the moment of ignition. !hen the triggering circuit receives

triggering signals, the triggering circuit stops the operation of the charging circuit,

allowing the capacitor to discharge its output rapidly to the low inductance ignition coil.

In a 97 ignition, the ignition coil acts as a pulse transformer rather than an energy

storage medium as it does in an inductive system. *he voltage output to the spar plugs is

purely dependent on the design of the 97 ignition. Coltages e$ceeding the insulation

capabilities of e$isting ignition components can lead to early failure of those components.

%ost 97 ignitions are made to give very high output voltages, but this is not always

beneficial. !hen thereFs no triggering signal, the charging circuit is re,connected to

charge the capacitor.

*he amount of energy the 97I system can store for the generation of a spar is dependent

on the voltage and capacitance of the capacitors used, but usually itFs around 4( m#, or

more. *he standard points>coil>distributor ignition, more properly called the inductive

discharge ignition system or Kettering ignition system, produces &4m# at low speed and

drops off quicly as speed increases.

%ost 97I modules are generally of two typesD

A9,97I , *he A9,97I module obtains its electricity source solely from

the alternating current produced by the alternator. *he A9,97I system is the most

basic 97I system which is widely used in small engines.

Bote that not all small engine ignition systems are 97I. 0ome older engines and engines

lie older Griggs and 0tratton use magneto ignition. *he entire ignition system, coil and

points, are under the magnetized flywheel.

Another sort of ignition system commonly used on small off,road motorcycles in the

'21(s and '2@(s was called Energy *ransfer. A coil under the flywheel generated a strong

79 current pulse as the flywheel magnet moved over it. *his 79 current flowed through

13

a wire to an ignition coil mounted outside of the engine. *he points sometimes were

under the flywheel for two,stroe engines, and commonly on the camshaft for four,stroe

engines. *his system wored lie all Kettering 5points>coil6 ignition systems... the

3pening points trigger the collapse of the magnetic field in the ignition coil, producing a

high voltage pulse which flows through the spar plug wire to the spar plug.

If the engine was rotated while e$amining the wave,form output of the coil with an

oscilloscope, it would appear to be A9. 0ince the charge,time of the coil corresponds to

much less than a full revolution of the cran, the coil really FseesF only 79 current for

charging the e$ternal ignition coil.

0ome electronic ignition systems e$ist that are not 97I. *hese systems use a transistor to

switch the charging current to the coil off and on at the appropriate times. *his eliminated

the problem of burned and worn points, and provided a hotter spar because of the faster

voltage rise and collapse time in the ignition coil.

79,97I , *he 79,97I module is powered by the battery, and therefore an

additional 79>A9 inverter circuit is included in the 97I module to raise the '& C

79 to /((,1((

79, maing the 97I modules slightly larger. However, vehicles that use 79,97I

systems have more precise.

3.2 A%VA#$A/E* A#% %I*A%VA#$A/E*

A 97I system has a short charging time, a fast voltage rise 5between ) L '( C>Ms6

compared to typical inductive systems 5)(( L 4(( C>Ms6 and a short spar duration

limited to about 4(,.( Ns. *he fast voltage rise maes 97I systems insensitive to shunt

resistance, but the limited spar duration can for some applications be too short to

provide reliable ignition. *he insensitivity to shunt resistance and the ability to fire

multiple spars can provide improved cold starting ability.

0ince the 97I system only provides a short spar, itFs also possible to combine this

ignition system with ionization measurement. *his is done by connecting a low voltage

14

5about .( C6 to the spar plug, e$cept when fired. *he current flow over the spar plug

can then be used to calculate the temperature and pressure inside the cylinder.

Advanta"es

*he main advantages of 0%* over the older through,hole technique areD

%uch higher component density 5components per unit area6 and many more

connections per component.

8ower initial cost and time of setting up for production.

?ewer holes need to be drilled.

0impler and faster automated assembly. 0ome placement machines are capable of

placing more than ')1,((( components per hour.

0mall errors in component placement are corrected automatically as the surface

tension of molten solder pulls components into alignment with solder pads.

9omponents can be placed on both sides of the circuit board.

8ower resistance and inductance at the connectionI consequently, fewer unwanted

;? signal effects and better and more predictable high,frequency performance.

Getter mechanical performance under shae and vibration conditions.

%any 0%* parts cost less than equivalent through,hole parts.

Getter E%9 performance 5lower radiated emissions6 due to the smaller radiation

loop area 5because of the smaller pacage6 and the smaller lead inductance.

15

%isadvanta"es

%anual prototype assembly or component,level repair is more difficult and

requires silled operators and more e$pensive tools, due to the small sizes and

lead spacing of many 0%7s.

0%7s cannot be used directly with plug,in breadboards 5a quic snap,and,play

prototyping tool6, requiring either a custom +9G for every prototype or the

mounting of the 0%7 upon a pin,leaded carrier. ?or prototyping around a specific

0%7 component, a less,e$pensive breaout board may be used.

Additionally, strip board style protoboards can be used, some of which include

pads for standard sized 0%7 components. ?or prototyping, Edead bugE bread

boarding can be used.

0%7sF solder connections may be damaged by potting compounds going through

thermal cycling.

0older "oint dimensions in 0%* quicly become much smaller as advances are

made toward ultra,fine pitch technology. *he reliability of solder "oints becomes

more of a concern, as less and less solder is allowed for each "oint. Coiding is a

fault commonly associated with solder "oints, especially when reflow a solder

paste in the 0%* application. *he presence of voids can deteriorate the "oint

strength and eventually lead to "oint failure.

0%* is unsuitable for large, high,power, or high,voltage parts, for e$ample in

power circuitry. It is common to combine 0%* and through,hole construction,

with transformers, heat,sined power semiconductors, physically large capacitors,

fuses, connectors, and so on mounted on one side of the +9G through holes.

0%* is unsuitable as the sole attachment method for components that are sub"ect

to frequent mechanical stress, such as connectors that are used to interface with

e$ternal devices that are frequently attached and detached.

16

Ignition timing and the engine can be started more easily when cold.

5.1 %E*I/# A#% A**E()0

7esign and assembly is a process by which products are designed with ease of assembly

in mind. If a product contains fewer pats it will tae less time to assemble, thereby

reducing assembly costs. In many companies 7?A is a corporate requirement and 7?A

software is continually being adopted by companyAs attempting to obtain greater control

over their manufacturing costs.

97I is also called thyristor ignition system. A 97I system with induction type pulse

generator contains a trigger bo$, a charging device, and a pulse shaping circuit and

ignition transformer. *he main components are

(A/#E$O+,

A small two,or four,stroe single or dual cylinder engine has a flywheel, incorporating

permanent magnets. *he rotor, consisting of a cooper coil, produces an ac voltage

between '((v to /((v, is proportional to the speed of the engine. After rectification, this

high dc voltage is applied to the capacitor portion. *he magneto is also nown as the

alternator.

2&)*ER+,

*he pulsar is a small coil mounted on the magneto that generates an alternating pulse

while the engine rotates. *hese pulses are induced from the two poles 5n and s( of the

magnetic plate that is mounted on the framewor of the magneto while it rotates and

passes the pulses coli. *he n and s pole induces a positive pulse followed by a negative

pulse that is typically &4 mechanical degrees apart. *he & degree is fi$ed by the length of

the magnetic plate. *he pea of the negative pulse is taen as the reference point, the top,

dead,centre of the piston. *herefore, the positive pulse leads the negative pulse by &4

mechanical degrees.

17

*2AR6 2)&/+,

*he spar plug is the final elements in the ignition chain. High engine efficiency and

complete gas combustion are lined to a good quality spar. <enerally, an estimated

minimum of &( mille,"oules is necessary at the spar plug to produce a sufficient spar.

18

?ig /.' machines

19

5.2 A**E()0 O. '%I

0teps in the manufacturing process of 97ID,

+rinted circuit board

+aste printer

9hip mounting

;eflow oven

97I 0%* visual

%anual 97I components insertion

!ave soldering

9ircuit tester

+9G panel cutting

;O section

Intermediate stage

7ata writing

%oulding

9uring oven

?inal testing

20

+;IB*E7 9I;9=I* G3A;7

*he raw material used in the assembly of 97I is printed circuit board. *he circuit

designed on the +9G. He circuit designed on the +9G is according to the company. After

this a semi,automatic machine which is the paste printer omara is used to paste

components on the +9G. *he solder paste is applied by the process of stenciling and

squeezing at the temperature less than &(c to only the areas where the components have

to be pasted.

9HI+ %3=B*IB<

*he components are pasted on the circuit with the help of a chip mounter. *he chip

mounter is the main machine which is used and which pastes the components precisely.

*his chip mounting is done using a method called surface mounting technology.

0=;?A9E %3=* *E9HB383<J

0%* 5surface mount technology6 component placement systems, commonly called pic,

and,place machines or +&+s, are robotic machines which are used to place surface,

mount devices 50%7s6 onto a printed circuit board 5+9G6. *hey are used for high speed,

high precision placing of broad range of electronic components,

lie capacitors, resistors, integrated circuits onto the +9Gs which are in turn used

in computers, consumer electronics as well as industrial, medical, automotive, military

and telecommunications equipment. 0urface,mount technology 50%*6 is a method for

producing electronic circuits in which the components are mounted or placed directly

onto the surface of printed circuit boards 5+9Gs6. An electronic device so made is called

a surface,mount device 50%76. In the industry it has largely replaced the through,hole

technology construction method of fitting components with wire leads into holes in the

circuit board. Goth technologies can be used on the same board for components not suited

to surface mounting such as large transformers and heat,sined power semiconductors

Re7lo8 oven

;eflow soldering is a process in which a solder paste 5a sticy mi$ture of powdered

solder and flu$6 is used to temporarily attach one or several electrical components to

21

their contact pads, after which the entire assembly is sub"ected to controlled haeat,which

melts the solder , permanently connecting the "oint . heating may be accomplished by

passing the assembly through a reflow oven.

;eflow soldering is the most common method of attaching surface mount components to

their a circuit board, although it can also be used for through, hole components by filling

the holes with solder paste and inserting the component leads through the paste. Gecause

wave soldering can be simpler and cheaper, reflow is not generally used on pure through,

hole boards. !hen used on boards contains a mi$ of 0%* and *H* components, through

Hhole reflows allows the wave soldering to be eliminated from the assembly process,

potentially reducing assembly costs.

*he goal of the reflow process is to melt the solder and heat the ad"oining surfaces,

without overheating and damaging the electrical components. In the conventional reflow

soldering process, there are usually four stages, called PzonesQ, each having a distinct

thermal profile, preheat, thermal soa, reflow and cooling.

;eflow oven

;eflow oven is a machine used primarily for reflow soldering of surface mount electronic

components to printed circuit boards. *his is an automatic machine which is operated at

high temperature s, the soldered paste over which the components are applied need to be

fitted to the +9G permanently. ?or this the +9G are inserted into reflow oven. *he reflow

oven is operated at different zones with different temperature.

9O#E $E(2ERA$&RE

Rone,' ')( degree c

Rone,& '/4 degree c

Rone,) '41 degree c

Rone,/ '14 degree c

Rone,4 '.4 degree c

Rone,1 &(( degree c

Rone,@ &.1 degree c

Rone,. &@' degree c

*able /.'

22

*he fan used to cool +9G paste wors at )(Hz. *here are & lanes in the reflow oven that

run simultaneously.

'ritical sta"e

In this stage the printed circuit board is checed by using a magnifier.

*he worer comes to now whether the components are now fi$ed in placed on the

circuit board. If by chance any component is out of place, the +9G is sent to the repair

station immediately where the components are fi$ed.

Bow they further sent to the IB circuit tester to chec whether the components are

woring properly or not. *his system is installed with programs which are used to chec

and tally the measurements of different components.

Intermediate sta"e

In this stage all the components are tested. If it does not clear this test, they are sent to the

motorcycle lie that, due to pollution and moistureI the components will definitely be

destroyed after a while. *hus for the protection of the components moulding is done.

(ouldin"

In this process of moulding, the components are covered by such materials which are not

affected by environment conditions lie rain. %oisture, pollution.

;esin and hardener are the ey components used in the moulding material. *he resin and

hardener are the ey components used in the moulding material .the resin and hardeners

are purchased from different company in cartons. *hey are mi$ed with the help of a

machine.

Epo$y stirring is done. +umping is done through house pipes. Bow the +9G is fitted in a

small container in which the mould is to be poured. A wall is provided to the socet so

that it does not get molded.

Bow there are containers with +9G and moulding material have to be inserted into the

curing oven so that the mould becomes strong enough and the components are safe.

23

Bow these sent for final testing. *he internal circuit is tested by inserting the socet in the

testing machine. Gy this we come to now whether all the components are woring

properly or not. If they wor properly they are placed inside the motorcycle.

?igureD , /.&

24

5.3. Assembly line 8ith *($ placement machines

?ig /.) %achine

!here components are to be placed, the printed circuit board normally has flat,

usually aluminum pads without holes, called solder pads. 0older paste, a sticy mi$ture

of flu$ and tiny solder particles, is first applied to all the solder pads with a stainless steel

or nicel stencil using a screen printing process. It can also be applied by a "et,printing

mechanism, similar to an in"et printer. After pasting, the boards then proceed to the pic,

and,place machines, where they are placed on a conveyor belt. *he components to be

25

placed on the boards are usually delivered to the production line in either paper>plastic

tapes wound on reels or plastic tubes. 0ome large integrated circuits are delivered in

static,free trays. Bumerical control pic,and,place machines remove the parts from the

tapes, tubes or trays and place them on the +9G.

*he boards are then conveyed into the reflow soldering oven. *hey first enter a pre,heat

zone, where the temperature of the board and all the components is gradually, uniformly

raised. *he boards then enter a zone where the temperature is high enough to melt the

solder particles in the solder paste, bonding the component leads to the pads on the circuit

board. *he surface tension of the molten solder helps eep the components in place, and

if the solder pad geometries are correctly designed, surface tension automatically aligns

the components on their pads. *here are a number of techniques for reflowing solder. 3ne

is to use infrared lampsI this is called infrared reflow. Another is to use hot

gas convection. Another technology which is becoming popular again is

special fluorocarbon liquids with high boiling points which use a method called vapor

phase reflow. 7ue to environmental concerns, this method was falling out of favor until

lead,free legislation was introduced which requires tighter controls on soldering.

9urrently, at the end of &((., convection soldering is the most popular reflow technology

using either standard air or nitrogen gas. Each method has its advantages and

disadvantages. !ith infrared reflow, the board designer must lay the board out so that

short components donFt fall into the shadows of tall components. 9omponent location is

less restricted if the designer nows that vapor phase reflow or convection soldering will

be used in production. ?ollowing reflow soldering, certain irregular or heat,sensitive

components may be installed and soldered by hand, or in large,scale automation, by

focused infrared beam 5?IG6 or localized convection equipment.

If the circuit board is double,sided then this printing, placement, reflow process may be

repeated using either solder paste or glue to hold the components in place. If a wave

soldering process is used, then the parts must be glued to the board prior to processing to

prevent them from floating off when the solder paste holding them in place is melted.

After soldering, the boards may be washed to remove flu$ residues and any stray solder

balls that could short out closely spaced component leads. ;osin flu$ is removed with

26

fluorocarbon solvents, high flash point hydrocarbon solvents, or low flash solvents

e.g. limonene 5derived from orange peels6 which require e$tra rinsing or drying cycles.

!ater soluble flu$es are removed with demonized water and detergent, followed by an air

blast to quicly remove residual water. However, most electronic assemblies are made

using a EBo,9leanE process where the flu$ residues are designed to be left on the circuit

board. *his saves the cost of cleaning, speeds up the manufacturing process, and reduces

waste. ?inally, the boards are visually inspected for missing or misaligned components

and solder bridging. If needed, they are sent to a rewor station where a human operator

repairs any errors. *hey are then usually sent to the testing stations 5in,circuit

testing and>or functional testing6 to verify that they operate correctly.

?igure /./ manufacturing process

27

'O#')&*IO#

*owards the completion of the training all the concepts get revised.

<et informed by management team about the final processes of manufacture

control.

Efficient utilisation of time and equipments.

*he wor and responsibilities as an electronics engineer in the particular firm.

9areer targeting approach towards an industry.

28

RE.ERE#'E*

Websites

www.ahu"a.com

www.napino.com

www.cdi.com

*tudy manual

0tudy material from industry

29

Vous aimerez peut-être aussi

- Sparkfun Electronics Stenciling: Materials by Bob Hunke & Linz CraigDocument33 pagesSparkfun Electronics Stenciling: Materials by Bob Hunke & Linz Craigblooper631Pas encore d'évaluation

- Obstacle Avoiding 4WD Arduino Robot Project ReportDocument12 pagesObstacle Avoiding 4WD Arduino Robot Project ReportLahmeen HaiderPas encore d'évaluation

- India Business Presentation - SharedDocument18 pagesIndia Business Presentation - SharedHelloPas encore d'évaluation

- ECE 513 Part1 ArduinoUnoFundamentals Ver1.2Document76 pagesECE 513 Part1 ArduinoUnoFundamentals Ver1.2Jecren Godinez BoocPas encore d'évaluation

- Renesas Flash Programmer Package V20401 FreeDocument19 pagesRenesas Flash Programmer Package V20401 FreeAnkit PrincePas encore d'évaluation

- Adafruit Motor Shield PDFDocument54 pagesAdafruit Motor Shield PDFRax ReyPas encore d'évaluation

- SOLDER PASTE STENCIL DESIGN GUIDEDocument17 pagesSOLDER PASTE STENCIL DESIGN GUIDEedwin100% (1)

- Civil Engineer ResumeDocument3 pagesCivil Engineer ResumeEr Sooraj KhewariyaPas encore d'évaluation

- PCB Presentation DraftDocument19 pagesPCB Presentation Draftsanjay sharma100% (1)

- The Past, Present and Future of Electronics: Origins, Benefits, Drawbacks and DevelopmentsDocument24 pagesThe Past, Present and Future of Electronics: Origins, Benefits, Drawbacks and DevelopmentsBrrijesh Yadav100% (1)

- Speedometer Cum OdometerDocument5 pagesSpeedometer Cum OdometerShashank ShekharPas encore d'évaluation

- What Is New in IPC 7351C - 7351004Document27 pagesWhat Is New in IPC 7351C - 7351004jagadees21Pas encore d'évaluation

- PCB Design in 45 MinutesDocument28 pagesPCB Design in 45 MinutesvinPas encore d'évaluation

- Assembly of Flexible Circuits With Lead - Free Solder AlloyDocument16 pagesAssembly of Flexible Circuits With Lead - Free Solder AlloyBorad AlpeshPas encore d'évaluation

- Adafruit Motor Shield v2 For ArduinoDocument47 pagesAdafruit Motor Shield v2 For ArduinoBrandon EricksonPas encore d'évaluation

- How To Build A 4WD Arduino Robot For BeginnersDocument18 pagesHow To Build A 4WD Arduino Robot For BeginnersRas TjandraPas encore d'évaluation

- IPC/industry Standard of PCB and PCBA?: PCB Fabrication Steps: (Presentation-How-To-Build-Pcb)Document3 pagesIPC/industry Standard of PCB and PCBA?: PCB Fabrication Steps: (Presentation-How-To-Build-Pcb)HenryPas encore d'évaluation

- ExarFunctionGeneratorDataBook TextDocument56 pagesExarFunctionGeneratorDataBook TextdPas encore d'évaluation

- PCB Assembly Business Setup GuideDocument11 pagesPCB Assembly Business Setup GuideAzeez BashaPas encore d'évaluation

- Build Arduino Robots and Devices GuideDocument10 pagesBuild Arduino Robots and Devices GuideSrinan MarvelPas encore d'évaluation

- Schematic Diagram OverviewDocument12 pagesSchematic Diagram Overviewalfredo_izquierdo_12Pas encore d'évaluation

- Saddam Hussain Latest Resume2Document3 pagesSaddam Hussain Latest Resume2Danish HPas encore d'évaluation

- Making of IR Sensor ModuleDocument18 pagesMaking of IR Sensor ModuleGhigoarta Sergiu DanielPas encore d'évaluation

- Anti Sleep Alarm RDocument31 pagesAnti Sleep Alarm RPrints Bindings100% (1)

- M. Tech. Smart Manufacturing (SMT) : TheoryDocument7 pagesM. Tech. Smart Manufacturing (SMT) : TheoryselvakumarPas encore d'évaluation

- EDJ16002 Lab 8 PCB Design & FabricationDocument26 pagesEDJ16002 Lab 8 PCB Design & FabricationpreethikaPas encore d'évaluation

- PIC18F97J60 Family Data SheetDocument476 pagesPIC18F97J60 Family Data SheetcoccomPas encore d'évaluation

- Gerber File CreationDocument44 pagesGerber File CreationBatka Shankar100% (2)

- Slua 125Document10 pagesSlua 125Anonymous RloUXGnmSWPas encore d'évaluation

- Schematic MPU 6050Document1 pageSchematic MPU 6050Nguyen HoaPas encore d'évaluation

- Semicounductors & Pn-Junction (Complete)Document47 pagesSemicounductors & Pn-Junction (Complete)Khalid AliPas encore d'évaluation

- ELEKTRONSKE KOMPONENTE - PASIVNEDocument131 pagesELEKTRONSKE KOMPONENTE - PASIVNECvetkovic IgorPas encore d'évaluation

- EXEMYS CatalogueDocument16 pagesEXEMYS CatalogueJorge_Andril_5370Pas encore d'évaluation

- Bicmos TechnologyDocument37 pagesBicmos TechnologyPriya SinghPas encore d'évaluation

- AMD RS785E DatabookDocument100 pagesAMD RS785E Databook1cvbnmPas encore d'évaluation

- Pioneer Plasma TV - ScanBoard & ICs Removal Re Installation GuideDocument12 pagesPioneer Plasma TV - ScanBoard & ICs Removal Re Installation GuideRagnar7052Pas encore d'évaluation

- 1.speed Synchronization of Multiple MotorsDocument89 pages1.speed Synchronization of Multiple MotorsBhanu TummalapalliPas encore d'évaluation

- PIC Single-Chip 4-Digit 99-Minute Timer: DiscussionDocument4 pagesPIC Single-Chip 4-Digit 99-Minute Timer: Discussionravikiran1955Pas encore d'évaluation

- PIFA Planar Inverted F AntennaDocument4 pagesPIFA Planar Inverted F AntennaAhsan AltafPas encore d'évaluation

- PCB History and Technology GuideDocument38 pagesPCB History and Technology GuideRajasekaran RPas encore d'évaluation

- PCB Design Guide Lines For 0.4mm Package-On-PackageDocument26 pagesPCB Design Guide Lines For 0.4mm Package-On-PackageElec 2PCBPas encore d'évaluation

- Control water pump with Arduino and SMSDocument6 pagesControl water pump with Arduino and SMSlena cpaPas encore d'évaluation

- EE 212 L Microprocessor and Microcontroller: Lab ManualDocument77 pagesEE 212 L Microprocessor and Microcontroller: Lab Manualrizwan900Pas encore d'évaluation

- HP Elite 7200 Series Microtower PCDocument3 pagesHP Elite 7200 Series Microtower PCChris TsitouridisPas encore d'évaluation

- PCB Design Guidelines For Reduced EMIDocument23 pagesPCB Design Guidelines For Reduced EMIEdgar Eduardo Medina CastañedaPas encore d'évaluation

- Electrical Plugs D7MOOCE-257160Document37 pagesElectrical Plugs D7MOOCE-257160Sergio Jr S FachinPas encore d'évaluation

- Simpson 260 8 Volt Ohm MilliammeterDocument33 pagesSimpson 260 8 Volt Ohm MilliammeterJuan Garcia HernandezPas encore d'évaluation

- FFUS2613LS4 Frigidaire Refrigerator Wiring 240389639Document2 pagesFFUS2613LS4 Frigidaire Refrigerator Wiring 240389639aderloch100% (1)

- PCB Lab Manual Iiisem Ece PDFDocument46 pagesPCB Lab Manual Iiisem Ece PDFkathirdcnPas encore d'évaluation

- 107 ConnectorsDocument28 pages107 ConnectorsJozo ĆurčićPas encore d'évaluation

- Controlled ImpedanceDocument44 pagesControlled ImpedanceMallappa Patil100% (1)

- SparkonixDocument16 pagesSparkonixBalvinder PrajapatiPas encore d'évaluation

- The Power of PCB PDFDocument70 pagesThe Power of PCB PDFAiman NabihahPas encore d'évaluation

- Diesel GeneratorDocument21 pagesDiesel GeneratoreiferjPas encore d'évaluation

- DYNA Power Control Manual For Plus 1, Plus 2, Plus 4 and Plus 6 Ft. Lb. SystemsDocument18 pagesDYNA Power Control Manual For Plus 1, Plus 2, Plus 4 and Plus 6 Ft. Lb. SystemsDavid Coronado100% (1)

- Changing From CH: - Traditional Charging TechniquesDocument2 pagesChanging From CH: - Traditional Charging Techniquesภูเก็ต เป็นเกาะPas encore d'évaluation

- Electrical System: Systems OperationDocument7 pagesElectrical System: Systems OperationTri WahyuningsihPas encore d'évaluation

- Generator and AlternatorDocument8 pagesGenerator and Alternatorvirgilio mercadoPas encore d'évaluation

- ADocument5 pagesAParveen JaatPas encore d'évaluation

- Customer Satisfaction PNBDocument55 pagesCustomer Satisfaction PNBParveen JaatPas encore d'évaluation

- Project Piyush - FINALDocument61 pagesProject Piyush - FINALParveen JaatPas encore d'évaluation

- Drill Powered Can Crusher Project ReportDocument1 pageDrill Powered Can Crusher Project ReportParveen JaatPas encore d'évaluation

- A Comparision of Marketing Strategies of Qualis, Versa, Scorpio, Safari'Document58 pagesA Comparision of Marketing Strategies of Qualis, Versa, Scorpio, Safari'Parveen JaatPas encore d'évaluation

- Can CrusherDocument42 pagesCan CrusherParveen Jaat100% (2)

- Minda Project Report - SaranDocument77 pagesMinda Project Report - SaranParveen JaatPas encore d'évaluation

- A Training Report ON Paper Technology AT Kuantum Paper LTD., Hosiarpur (Punjab)Document1 pageA Training Report ON Paper Technology AT Kuantum Paper LTD., Hosiarpur (Punjab)Parveen JaatPas encore d'évaluation

- Mutual FundDocument66 pagesMutual FundParveen JaatPas encore d'évaluation

- Done PriyankaDocument59 pagesDone PriyankaParveen JaatPas encore d'évaluation

- Drill Powered Can Crusher Project AcknowledgementDocument1 pageDrill Powered Can Crusher Project AcknowledgementParveen JaatPas encore d'évaluation

- ChapterDocument7 pagesChapterParveen JaatPas encore d'évaluation

- DataDocument35 pagesDataParveen JaatPas encore d'évaluation

- Appendix: CodingDocument6 pagesAppendix: CodingParveen JaatPas encore d'évaluation

- DDD DDDD CCCC CCCDocument17 pagesDDD DDDD CCCC CCCParveen JaatPas encore d'évaluation

- Embedded Systems Microcontroller 8051: Training ReportDocument10 pagesEmbedded Systems Microcontroller 8051: Training ReportParveen JaatPas encore d'évaluation

- DDD DDDD CCCC CCCDocument17 pagesDDD DDDD CCCC CCCParveen JaatPas encore d'évaluation

- Exp 1Document5 pagesExp 1Parveen JaatPas encore d'évaluation

- DDD DDDD CCCC CCCDocument17 pagesDDD DDDD CCCC CCCParveen JaatPas encore d'évaluation

- DDD DDDD CCCC CCCDocument17 pagesDDD DDDD CCCC CCCParveen JaatPas encore d'évaluation

- Ashutosh Synopsis Car ParkingDocument10 pagesAshutosh Synopsis Car ParkingParveen JaatPas encore d'évaluation

- Automotive Electronics Training Report for Bachelor's DegreeDocument1 pageAutomotive Electronics Training Report for Bachelor's DegreeParveen JaatPas encore d'évaluation

- Seminar ReportDocument16 pagesSeminar ReportParveen JaatPas encore d'évaluation

- Merged ReportDocument31 pagesMerged ReportParveen JaatPas encore d'évaluation

- Computer File B.edDocument43 pagesComputer File B.edParveen JaatPas encore d'évaluation

- KBC Quiz: Bachelor of Technology in Computer Science & EngineeringDocument7 pagesKBC Quiz: Bachelor of Technology in Computer Science & EngineeringParveen JaatPas encore d'évaluation

- Embedded Systems Microcontroller 8051: Training ReportDocument10 pagesEmbedded Systems Microcontroller 8051: Training ReportParveen JaatPas encore d'évaluation

- Book 1Document3 pagesBook 1Parveen JaatPas encore d'évaluation

- Ishp BelDocument29 pagesIshp BelParveen JaatPas encore d'évaluation

- High-Frequency Model of The Power Transformer Based On Frequency-Response MeasurementsDocument9 pagesHigh-Frequency Model of The Power Transformer Based On Frequency-Response MeasurementsFernando PaezPas encore d'évaluation

- IS:11592Document64 pagesIS:11592Santanu KararPas encore d'évaluation

- Physical Optics: 18 March 2021Document37 pagesPhysical Optics: 18 March 2021Luo MarkPas encore d'évaluation

- Plan For Today: Dry Friction Belt FrictionDocument17 pagesPlan For Today: Dry Friction Belt FrictionMr. JoestarPas encore d'évaluation

- Lab ManualDocument146 pagesLab Manualranjith krishnanPas encore d'évaluation

- Universal Law of Gravitation WorksheetDocument2 pagesUniversal Law of Gravitation WorksheetScionPas encore d'évaluation

- Power SystemDocument7 pagesPower Systemp09el860Pas encore d'évaluation

- ABB Instrument TransformersDocument64 pagesABB Instrument Transformersrajakprashant100% (3)

- 1fc6 5alternators PDFDocument40 pages1fc6 5alternators PDFRenato MatičevićPas encore d'évaluation

- Laser Physics Chapter 1Document49 pagesLaser Physics Chapter 1Alexander MintsPas encore d'évaluation

- Ecp Lab ManualDocument37 pagesEcp Lab ManualShah JainamPas encore d'évaluation

- Class 12 Physics Energy of Charged ParticlesDocument5 pagesClass 12 Physics Energy of Charged ParticlesCrazy about JunglesPas encore d'évaluation

- DUT HV Engineering Practical on Partial Discharge SimulationDocument3 pagesDUT HV Engineering Practical on Partial Discharge SimulationSibongiseni MasondoPas encore d'évaluation

- KBCC-240D: Chassis Mount Penta-DriveDocument2 pagesKBCC-240D: Chassis Mount Penta-DriveArkhamPas encore d'évaluation

- 01 Introduction Motor ProtectionDocument22 pages01 Introduction Motor ProtectionAndrés Felipe LeonPas encore d'évaluation

- Essential University Physics Volume II 3rd Edition Wolfson Solutions Manual Full Chapter PDFDocument48 pagesEssential University Physics Volume II 3rd Edition Wolfson Solutions Manual Full Chapter PDFTonyDonaldsonjmdye100% (11)

- GE MIC - Brochure465 PDFDocument2 pagesGE MIC - Brochure465 PDFAgung PrasetyoPas encore d'évaluation

- Experiment Manual 14thnov2011Document40 pagesExperiment Manual 14thnov2011Arpit AgrawalPas encore d'évaluation

- Rotor Bow CharacteristicsDocument3 pagesRotor Bow CharacteristicschdiPas encore d'évaluation

- Chapter Statics, Lecture Notes, Chapter 5Document74 pagesChapter Statics, Lecture Notes, Chapter 5RayanPas encore d'évaluation

- Contactors: Introduction - Contactors Power ContactorsDocument8 pagesContactors: Introduction - Contactors Power ContactorsBilal AhmadPas encore d'évaluation

- BioMechanics of Canine RetractionDocument113 pagesBioMechanics of Canine Retractionarshabharata100% (5)

- Formulas Physics B CH 11, 12, 22, 23, 24, 25 WavesDocument6 pagesFormulas Physics B CH 11, 12, 22, 23, 24, 25 WavesEpic WinPas encore d'évaluation

- Physics II ProblemsDocument1 pagePhysics II ProblemsBOSS BOSSPas encore d'évaluation

- Code MATH Course Details PDFDocument80 pagesCode MATH Course Details PDFAnees RahmanPas encore d'évaluation

- ILL-Dynamic vs. Quasi-Static Design of Catenary Mooring SystemDocument8 pagesILL-Dynamic vs. Quasi-Static Design of Catenary Mooring Systemmohdsolihat1Pas encore d'évaluation

- How ignition systems create sparks to light fuelDocument25 pagesHow ignition systems create sparks to light fuelNuno CunhaPas encore d'évaluation

- Ac TheoryDocument138 pagesAc TheoryHemraj Singh RautelaPas encore d'évaluation

- Assignment 2.2 ForcesDocument4 pagesAssignment 2.2 Forcespanghua tanPas encore d'évaluation