Académique Documents

Professionnel Documents

Culture Documents

4 2

Transféré par

dipali22290 évaluation0% ont trouvé ce document utile (0 vote)

21 vues8 pagesThe demand for petroleum products in India has been increasing at a very rapid rate. The methyl ester of water emulsified diesel oil is one such an alternative fuel which can be used as substitute to conventional petrodiesel. The engine was made semi-adiabatic by coating the piston crown with nickel chromium coating.

Description originale:

Titre original

4.2

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe demand for petroleum products in India has been increasing at a very rapid rate. The methyl ester of water emulsified diesel oil is one such an alternative fuel which can be used as substitute to conventional petrodiesel. The engine was made semi-adiabatic by coating the piston crown with nickel chromium coating.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

21 vues8 pages4 2

Transféré par

dipali2229The demand for petroleum products in India has been increasing at a very rapid rate. The methyl ester of water emulsified diesel oil is one such an alternative fuel which can be used as substitute to conventional petrodiesel. The engine was made semi-adiabatic by coating the piston crown with nickel chromium coating.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 8

Experimental Investigations on Semi-Adiabatic Diesel Engine Using Water Emulsified Diesel as Fuel

Proceedings of AECE-IRAJ International Conference, 14

th

J uly 2013, Tirupati, India, ISBN: 978-81-927147-9-0

105

EXPERIMENTAL INVESTIGATIONS ON SEMI-ADIABATIC DIESEL

ENGINE USING WATER EMULSIFIED DIESEL AS FUEL

1

P.S.BHARADWAJ,

2

B.VENKATESH

,

3

T.KARTHIKEYA SHARMA

1

Lecturer, Department of Mechanical Engineering, J NTUACE, Anantapur, India

2

Assistant professor, Department of Mechanical Engineering, Annamacharya Institute of Technology &science

(AUTONOMOUS,) Kadapa, Andhra Pradesh, India

3

Research Scholar, Department of Mechanical Engineering, NIT Warangal, A.P.India.

Abstract:- The demand for petroleum products in India has been increasing at a very rapid rate. Amongst various options

investigated for diesel fuel, biodiesel is one such initiative which is projected as an alternative to diesel fuel. The methyl

ester of water emulsified diesel oil is one such an alternative fuel which can be used as substitute to conventional petro-

diesel. The present work involves experimental investigation on the use of water emulsified diesel as fuel in conventional

diesel engine and semi-adiabatic diesel engine. The project aims at conducting analysis of diesel with water emulsified diesel

blends (10%, 20%, 30%) in conventional engine and semi-adiabatic engine. The engine was made semi adiabatic by coating

the piston crown with nickel chromium coating.

Keywords: coated piston, Diesel engine, Performance, water emulsified diesel.

I. INTRODUCTION

In this modern world of industries and

technology the diesel engine plays a major role in

various fields. It may be transportation (or)

production e.t.c., with the increase of various

applications to the diesel resources effects on the

environment leading to effect like green house.

Higher fuel efficiency in the diesel engine is achieved

due to the high compression ratios along with

relatively high oxygen concentration I the combustion

chamber. However, these same factors results in high

emission in diesel engine. The stringent emission

norms have been an important driving force to

develop the internal combustion engines more

environment friendly. The main pollutants from

diesel engines are Carbon Monoxide and Hydro

Carbons

This recommends the intensive studies on

the use of alternative fuels especially renewable ones

like vegetable oils and alcohols. The use of

vegetable oils as an alternative fuel for diesel engine

is not a new concept. Infact early engines were

demonstrated with vegetable oil. In a developing

country like India where mass transportation plays an

important role, the suitability of alternate fuels for a

diesel fuel engine application has to be thoroughly

investigated. Vegetable oils plays a prominent role in

substituting diesel, since they are renewable and are

easily produced in rural areas.

The inventor of diesel engine, Rudolph

diesel confidently predicted that plant oil would be

widely used to operate his engine. Rudolph diesel

used peanut oil as fuel in one of his engines at the

Paris exposition of 1900. But due to its high price

compared readily available petroleum products, the

use of vegetable oil based fuels was not explored.

But the fuel crisis of 1970s and 1980s focused the

attention on the desirability to develop alternative

fuels.

It is believed that vegetable oils can be used

diesel engines as an alternative to diesel with minimal

processing and preparation. However it is observed

by many researchers that while the diesel engines

operated satisfactorily on raw vegetable oils.

Combustion residues and deposits would quickly

cause problems with fuel injectors, Piston rings and

oil stability. Further their higher viscosity and higher

pour point compared to diesel, could affect the engine

operation in very cold climatic conditions. The

vegetable oils are more prone to oxidation and

polymerization than diesel and consequently the

engine oil becomes too thick.

Generally, the vegetable oils have

approximately 13% less energy than that of diesel

fuel. The loss of energy caused by the oxygen

content of vegetable oils is approximately 10%. They

have higher specific gravity which is approximately

0.88 compared to that of diesel. Whose specific

gravity is approximately 0.82. Hence the vegetable

oils regain some of the loss in energy on a mass basis

for an overall impact of approximately 7% loss in

energy per unit volume. Hence the use of vegetable

oils in diesel engine should experience a loss of fuel

economy of about 7% on an average.

The viscosity vegetable oils tend to alter the

injector spray pattern inside the engine causing the

fuel impingement on the piston on the other

combustion chamber surfaces. This leads the

formation of carbon deposits in the engine eventually

results in the problems such as stuck piston rings with

subsequent engine failure which would not occur

using diesel fuel.

The other important hurdle, for the use of

vegetable oils in diesel engines, is to control the

exhaust emissions, which is usually high in vegetable

oil operation. The main reason for the very high

Experimental Investigations on Semi-Adiabatic Diesel Engine Using Water Emulsified Diesel as Fuel

Proceedings of AECE-IRAJ International Conference, 14

th

J uly 2013, Tirupati, India, ISBN: 978-81-927147-9-0

106

emissions of the vegetable oil is the non optimized

injection system for the particular vegetable oil,

whose physical properties vary to a greater extent

when compared with diesel fuel.

The in efficiency of the non optimized

injection system can be compensated by hotter

combustion chamber which assists (vegetable oils)

spray atomization. Hence the vegetable oil operation

of the conventional engines is more efficient with low

emissions compared with vegetable oil operation of

the conventional engines. Because of the oxygen

content of the vegetable oils, CO emissions are

similar to the diesel operation or even lower in some

oils. The smoke and un-burned fuel emission levels

depend on the fuel spray. Characteristics and hence

the conventional engine configuration reduces them

to a greater extent.

Ultimately the disadvantages of vegetable

oils, which are the causes for poor performance and

heavy smoke can be overcome by the use of

vegetable oils in the conventional engine since the

gas temperatures are higher. Hence in the resent

work KARANJA OIL has been tested as fuel in the

conventional engine and semi adiabatic engine.

II. SEMI-ADIABATIC ENGINE

The trend of converting existing engine into

Semi-adiabatic diesel engines is to retain most of the

heat within and then convert it into useful work. It is

believed that through better design of the injection

system significant improvements in efficiency, speed

and smoothness of operation can be achieved. Further,

developments in the diesel engine appear to be in the

direction of detailed investigation of the losses in the

diesel engine and their control.

In the present day diesel engine, out of the

total heat energy supplied, only about one third of

supplied energy is converted to useful work at the

output shaft, one third is lost through exhaust gases

and the rest carried away by the cooling water.

Reducing the heat transfer to the coolant increases the

exhaust energy. One method of obtaining the above

condition is to thermally insulate the combustion

chamber converting it into an adiabatic engine. This

method insulates the combustion chamber, using high

temperature materials, which allow hot operation

near to adiabatic conditions. The hot or insulated high

temperature components include piston, cylinder head,

valves, cylinder liner and exhaust ports.

Further, the efficient combustion process in

Semi-Adiabatic engine will allow multi fuel

capability. The compact size and high power/weight

ratio of the semi - adiabatic engine will significantly

reduce the size and weight of the vehicle. In view of

the above, the present investigation aims at the

development of a Semi-Adiabatic engine with locally

available technologies. Attempts were also made to

solve the typical problems associated with Semi-

Adiabatic engine. Due consideration has been given

for the utilization of the energy from the high

temperature exhaust gases of the semi - adiabatic

engine.

Semi-Adiabatic engine is made with 50

microns of NiCrAl bond coat is used and the

experiments are conducted using Water emulsified

diesel biodiesel. The idea behind this is that for Semi-

Adiabatic engine at 50 microns of NiCrAl bond coat

creates a higher combustion chamber temperature that

may lead to the improvement in the combustion

characteristics of biodiesel, brake thermal efficiency

of the engine and reduction in the exhaust emissions.

The present work aims to develop a Semi-Adiabatic

engine using different techniques and improve its

performance, fuel economy, multi-fuel capability,

combustion characteristics by reducing frictional

power, increasing volumetric efficiency etc.

III. EXPERIMENTAL INVESTIGATION

The experiments were conducted by

considering various parameters. The tests were

conducted for Water emulsified diesel biodiesel with

Diesel at different proportions (10%, 20% and 30%)

for both conventional engine and coated piston

engine. The tests were conducted from no load to

maximum load conditions. The readings such as time

taken to consume 20cc of fuel consumption, speed of

the engine, temperatures, etc, were noted. The

observations were recorded in tabular column and

calculations are made using appropriate equations.

The experiments were conducted on a single

cylinder Alamgir four stroke diesel engine. The

general specifications of the engine are given in

Table-1. By taking the engine performance and plot

the graphs

ALAMGIR engines for generating sets are

fuel efficient, with the lube oil consumption less than

1% of S.C.F. lowest among the comparable brands.

They are equipped with heavy flywheels

incorporating 4% governing on the fuel injection

equipment. This complete avoids voltage functions.

In case of emergency, the unique overload stop

feature safeguards equipments by shutting down the

engine automatically

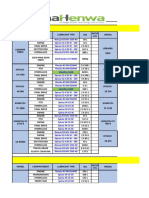

Table-1. Engine specifications.

Item Specifications

Engine power 6.6 kW

Cylinder bore 102 mm

Stroke length 110 mm

Connecting Rod Length 234 mm

Engine speed 1500 rpm

Compression ratio 17.5

Table 2: Properties of Diesel and Water emulsified

diesel biodiesel

Experimental Investigations on Semi-Adiabatic Diesel Engine Using Water Emulsified Diesel as Fuel

Proceedings of AECE-IRAJ International Conference, 14

th

J uly 2013, Tirupati, India, ISBN: 978-81-927147-9-0

107

Properties Diesel Water

emulsified

diesel

Biodiesel

Calorific

Value (kJ/kg)

43000 59835.82

Density

(kg/m3)

850

828

Flash point

(C)

40 175

Fire point (C) 42 185

An exhaust gas analyze was used to measure

CO, HC, CO2, O2, and NOx. The measuring range

and resolution are given in Table-2.

The water emulsified diesel fuel was prepared by

mixing 10%, 20% and 30% of distilled water with

90%, 80% and 70% of diesel by volume, respectively.

Polysorbate 20 was used as surfactant to prepare

emulsion. Polysorbate 20. (0.1%) is added with 100

ml and 200 ml distilled water and mixed with 900 ml

and 800 ml diesel to prepare D10 and D20 emulsified

diesel fuels, respectively. The mixer was stirred for 2-

3 minutes in an electrically operated agitator. The

experiments were performed at constant speed of

1500 rpm. The engine was loaded by electrical

dynamometer.

Table 3. Exhaust gas analyzer specifications

Measur

ing item

Measuring

method

Measur

ing Range

Resolut

ion

CO NDIR 0-

9.99%

0.01%

HC NDIR 0-

5000ppm

1ppm

CO

2

NDIR 0-20% 0.10%

O

2

Electrochem

ical

0-25% 0.01%

NO

X

Electrochem

ical

0-

5000ppm

1ppm

Fig:- Alamgir engine

Fig:- Load indicator

IV. RESULTS AND DISCUSSION

4.1 Indicated thermal efficiency:- Indicated thermal

efficiency indicates the output generated by an engine

with respect to heat supplied in the form of fuel in

modern engines an indicated thermal efficiency of

35%.

FIG1. Indicated Thermal Efficiency Vs Brake Power in

conventional engine

It is observed that Indicated thermal efficiency

increases as the load increases, and then decreases for

all fuel samples tested. From the Fig. 2 it is also

observed that maximum Indicated thermal efficiency

of 32.96% is obtained at 20% Water emulsified diesel

biodiesel blend with coated piston engine.. From the

Fig. 1 it is observed that maximum Indicated thermal

efficiency of 29.4% is obtained at 20% Water

emulsified diesel biodiesel blend with conventional

engine, which is less when compared to 32.96 % that

other blends of Water emulsified diesel biodiesel.

FIG2. Indicated Thermal Efficiency Vs Brake Power in semi-

adiabatic engine

Experimental Investigations on Semi-Adiabatic Diesel Engine Using Water Emulsified Diesel as Fuel

Proceedings of AECE-IRAJ International Conference, 14

th

J uly 2013, Tirupati, India, ISBN: 978-81-927147-9-0

108

4.2 Brake Thermal Efficiency:- Brake thermal

efficiency indicates the ability of the combustion

system to accept the experimental fuel, and provides

the comparable means for assessing how efficiently

the energy in the fuel was converted in to mechanical

efficiency.Fig3. and Fig4. Shows the variation of

brake thermal efficiency with brake power.

FIG3. Brake Thermal Efficiency Vs Brake Power in

Conventional engine

It is observed that brake thermal efficiency

increases as the load increases, and then decreases for

all fuel samples tested. From the Fig. 3 it is also

observed that maximum brake thermal efficiency of

20.08% is obtained at 20% Water emulsified diesel

biodiesel blend.. From the Fig. 4 it is observed that

maximum brake thermal efficiency of 20.28% is

obtained at 20% Water emulsified diesel biodiesel

blend, which is more when compared to 20.08% that

other blends of Water emulsified diesel biodiesel.

FIG4. Brake Thermal Efficiency Vs Brake Power in semi-

adiabatic engine

The reason for increase in efficiency at blend of 20%

Water emulsified diesel biodiesel may be the property

of blend, probably the lower viscosity of biodiesel

which helps in better atomization and effective

utilization of air resulting in increased efficiency. The

decrease in brake thermal efficiency for higher blends

may be due to the lower heating value and higher

viscosity of blends with a higher proportion of

biodiesel.

4.3 Brake Specific Fuel Consumption:- Fig. 5 and 6

shows the variation of brake specific fuel

consumption for Water emulsified diesel biodiesel

blends in conventional and semi adiabatic engine..

From the figure, it is observed that brake specific fuel

consumption is less in semi-adiabatic engine when

compared to conventional engine.

FIG5. Brake specific fuel consumption Vs Brake Power in

conventional engine

It is also observed that the difference in percentage

decrease in brake specific fuel consumption decreses

with increase in percentage of Water emulsified

diesel biodiesel in the blend. Also 20% Water

emulsified diesel biodiesel blend with nickel chrome

coated piston engine has minimum brake specific fuel

consumption when compared to other blends of

Water emulsified diesel biodiesel as shown in Fig. 5

and Fig. 6.

FIG6. Brake specific fuel consumption Vs Brake Power in

semi-adiabatic engine

4.4 Exhaust Temperature:- Fig. 7 and Fig. 8 show

the variation of exhaust gas temperature with brake

power for different blends of Water emulsified diesel

biodiesel in conventional and semi-adiabatic engine

respectively. The exhaust gas temperature increases

with increase in load. The exhaust gas temperature is

less at partial load for Water emulsified diesel

biodiesel blend than pure diesel.

FIG7. Exhaust temperature Vs Brake Power in conventional

engine

Experimental Investigations on Semi-Adiabatic Diesel Engine Using Water Emulsified Diesel as Fuel

Proceedings of AECE-IRAJ International Conference, 14

th

J uly 2013, Tirupati, India, ISBN: 978-81-927147-9-0

109

FIG8. Exhaust temperature Vs Brake Power in semi-adiabatic

engine

FIG9. Exhaust temperature Vs Load in conventional engine

FIG10. Exhaust temperature Vs Load in semi-adiabatic engine

4.5 Brake Specific Fuel consumption with Load:-

Fig. 11 and 12 shows the variation of brake specific

fuel consumption with load for Water emulsified

diesel biodiesel blends in conventional and semi

adiabatic engine. From the figure, it is observed that

brake specific fuel consumption is less in semi-

adiabatic engine when compared to conventional

engine

FIG11. Brake specific fuel consumption Vs Load in

conventional engine

It is also observed that the difference in percentage

decrease in brake specific fuel consumption increases

with increase in percentage of Water emulsified

diesel biodiesel in the blend. Also 20% Water

emulsified diesel biodiesel blend has minimum brake

specific fuel consumption when compared to other

blends of Water emulsified diesel biodiesel as shown

in Fig. 11 and Fig. 12.

FIG12. Brake specific fuel consumption Vs Load in semi-

adiabatic engine

4.6 Variation of mechanical efficiency with brake

power:- It can be observed from fig. 11, that the

maximum mechanical efficiency at 20% water

emulsified diesel blend full load is observed with

piston coated with nickel chromium. At full load the

mechanical efficiency with coated piston is found to

be 73.12%, with while the same is 71.38% with

conventional engine. The drop in mechanical

efficiency with normal piston can be attributed to the

higher coefficient of thermal expansion which results

in increase friction at elevated temperatures and

hence at high loads. By coating the piston with nickel

chromium, the mechanical efficiency is found to be

raised by 2.3%.

FIG13 and 14. Mechanical efficiency Vs Brake

power in conventional and Semi-adiabatic engine

FIG13. Mechanical efficiency Vs Load in conventional engine

FIG14. Mechanical efficiency Vs Brake power in semi-

adiabatic engine

4.7 Variation of volumetric efficiency with brake

power and load:- From fig. 15,16,17 and 18 it can be

found that at 20% water emulsified diesel blend at

full load the maximum volumetric efficiency is

obtained with piston coated with nickel chromium

Experimental Investigations on Semi-Adiabatic Diesel Engine Using Water Emulsified Diesel as Fuel

Proceedings of AECE-IRAJ International Conference, 14

th

J uly 2013, Tirupati, India, ISBN: 978-81-927147-9-0

110

while there is not much difference in volumetric

efficiency obtained with conventional engine. At full

load with coated engine the volumetric efficiencies

are found to be 67.86% with 20% water emulsified

diesel blend and with conventional engine it is found

to be 64.14% at 20% water emulsified diesel

blend .Thus volumetric efficiency is more with piston

coated with nickel chromium at full load.

FIG15. volumetric efficiency Vs Brake power in conventional

engine

FIG16. volumetric efficiency Vs Brake power in semi-adiabatic

engine

FIG17. volumetric efficiency Vs Load in conventional engine

FIG18. volumetric efficiency Vs Load in semi-adiabatic engine

4.8 Un-burnt Hydro Carbons:- Fig. 19 shows the

variation of hydrocarbon emission for different

blends of Water emulsified diesel biodiesel at full

load. It is observed that hydrocarbon emission

reduces with conventional engine decreases at 20 %

of klaranji biodiesel in blend. This may be due to

lesser amount of diesel present in higher percentage

blend. Lesser percentage of emission also indicates

complete combustion.

FIG19. HC Vs Load in conventional engine

Fig. 20 shows the variation of hydrocarbon emission

for different blends of Water emulsified diesel

biodiesel at full load. It is observed that hydrocarbon

emission reduces more with coated engine at 20 % of

klaranji biodiesel in blend. Lesser percentage of

emission also indicates complete combustion.

FIG20. HC Vs Load in coated engine

4.9 Carbon Monoxide:- The variation of carbon

monoxide emission in conventional engine at full

load for blends of Water emulsified diesel biodiesel is

as shown in Fig. 21. It is observed that emission of

carbon monoxide decreases up to 20% blend of Water

emulsified diesel biodiesel and increases for 10% and

30% blend. Lower percentage of carbon monoxide

emission indicates complete combustion. Increase in

carbon monoxide emission at 30% blend of Water

emulsified diesel biodiesel may be due to the

incomplete combustion.

FIG21. CO Vs Load in conventional engine

The variation of carbon monoxide emission in coated

engine at full load for blends of Water emulsified

diesel biodiesel is as shown in Fig. 22. It is observed

that emission of carbon monoxide decreases more

than conventional engine up to 20% blend of Water

emulsified diesel biodiesel and increases for 10% and

30% blend. Lower percentage of carbon monoxide

Experimental Investigations on Semi-Adiabatic Diesel Engine Using Water Emulsified Diesel as Fuel

Proceedings of AECE-IRAJ International Conference, 14

th

J uly 2013, Tirupati, India, ISBN: 978-81-927147-9-0

111

emission indicates complete combustion. Increase in

carbon monoxide emission at 30% blend of Water

emulsified diesel biodiesel may be due to the

incomplete combustion.

FIG22. CO Vs Load in semi-adiabatic engine

4.10 Carbon dioxide: - The variation of carbon

dioxide emission at full load for blends of Water

emulsified diesel biodiesel in conventional engine is

shown in Fig. 23. It is observed that percentage

emission of carbon dioxide increases with increase in

percentage of Water emulsified diesel biodiesel in

blend.

FIG23. CO2 Vs Load in conventional engine

The variation of carbon dioxide emission at full load

for blends of Water emulsified diesel biodiesel in

coated engine is shown in Fig. 24. It is observed that

percentage emission of carbon dioxide decreased than

in conventional engine.

FIG24. CO2 Vs Load in semi-adiabatic engine

4.11 Oxygen percentage:- The oxygen intake

percentage is increased with increase in blend

percentage in conventional engine and oxygen intake

is more for 20% water emulsified diesel blend in

coated engine. This shows that for semi adiabatic

(coated) engine the oxygen intake increases the

volumetric efficiency also increases which will

ensure complete combustion.

FIG25. O2 Vs Load in conventional engine

FIG26. O2 Vs Load in semi-adiabatic engine

CONCLUSION

It is observed that the semi-adiabatic engine

works with improved performance while running

with water emulsified diesel biodiesel blends

compared to biodiesel blends of conventional engine.

The blends of water emulsified diesel biodiesel with

diesel fuel can therefore be used as an alternative fuel

in existing diesel engine without modification of the

basic engine. It is observed that amongst the different

blends tested in the present work, 20% blend (diesel

80% & water emulsified diesel 20%) gives better

performance. Also compared to other blends tested

20% blend gave the best results. It was also observed

that the engine running with blends of water

emulsified diesel biodiesel with semi-adiabatic

engine gave better emission characteristics compared

to water emulsified diesel biodiesel blends with

conventional engine and also the mechanical

efficiency is better with nickel chromium coated

piston. The increase in mechanical efficiency is about

2,3% at full load. By using nickel chrome coated

piston brake specific fuel consumption is reduced

compare to conventional engine and is about 4.03%.

Thus it can be concluded that semi- adiabatic engine

will be used more efficiently for alternative fuels than

conventional engine.

REFERENCES

1. EkremBuyukkaya, Effects of thermal barrier coating on gas

emissions and performance of a LHR engine with different

injection timings and valve adjustments, Energy conversion

and management 47(2006)1298-1310.

Experimental Investigations on Semi-Adiabatic Diesel Engine Using Water Emulsified Diesel as Fuel

Proceedings of AECE-IRAJ International Conference, 14

th

J uly 2013, Tirupati, India, ISBN: 978-81-927147-9-0

112

2. Internal Combustion Engines Fundamentals by

J ohn.B.Heywood,McGrawHill(1988).

3. Thermal Engineering by R.K.Rajput

4. Internal combustion engines by V GANESAN

5. S.L. Ghodake, Prof.S.A.Pujari, Bio diesel - Fuel for

Automotives, Proceedings of the National Conference on

Biofuels for IC engines, March 23-25, 2006, NIT, Surathkal,

Karnataka-575 025

6. Ramesha D. K, G. Premakumara, Manjunath M. C, Honne

Gowda A study on effective use of Mahua methyl ester as

alternative to diesel, Proceedings of 21st National

conference on IC Engines & Combustion, Dec 10-12, pp 267-

279, 2009.

7. P.K. Devan and N.V. Mahalakshmi, A study of the

performance, emission and combustion characteristics of a

compression ignition engine using methyl ester of paradise

oileucalyptus oil blends, Applied Energy, Volume 86, Issue

5, pp 675-680, May 2009.

8. Dr. Syamasundar J oshi, Dr. Shantha J oshi, Simarouba

Glauca (Paradise tree), University of Agricultural Sciences,

GKVK Bangalore.

9. Tilman Altenburg, Hildegard Dietz, Matthias Hahl, Nikos

Nikolidakis, Christina Rosendahl, Kathrin Seelige, Biodiesel

policies for rural development in India- A report German

Development Institute, Bonn, May 2008.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- MP3 250 Workshop ManualDocument336 pagesMP3 250 Workshop ManualUdi Noam100% (5)

- APT Emulsion Fuels: Environmental Management PresentationDocument33 pagesAPT Emulsion Fuels: Environmental Management Presentationdipali2229Pas encore d'évaluation

- Reduction of Pollutants in CI Engine Using Emulsion Fuels To Reduce Overall Traffic-Induced EmissionsDocument7 pagesReduction of Pollutants in CI Engine Using Emulsion Fuels To Reduce Overall Traffic-Induced Emissionsdipali2229Pas encore d'évaluation

- Simple and Multiple Water Fuel Emulsions Preparation in Helical FlowDocument8 pagesSimple and Multiple Water Fuel Emulsions Preparation in Helical Flowdipali2229Pas encore d'évaluation

- Stability Behavior of Water-in-Diesel Fuel Emulsion: M. T. Ghannam and M. Y. E. SelimDocument16 pagesStability Behavior of Water-in-Diesel Fuel Emulsion: M. T. Ghannam and M. Y. E. Selimdipali2229Pas encore d'évaluation

- Direct Water Injection Cooling For Military E N G I N E S and Effects On The Diesel CycleDocument11 pagesDirect Water Injection Cooling For Military E N G I N E S and Effects On The Diesel Cycledipali2229Pas encore d'évaluation

- Applied Thermal Engineering: Görkem Kökkülünk, Güven Gonca, Vezir Ayhan, - Idris Cesur, Adnan ParlakDocument10 pagesApplied Thermal Engineering: Görkem Kökkülünk, Güven Gonca, Vezir Ayhan, - Idris Cesur, Adnan Parlakdipali2229Pas encore d'évaluation

- An Analysis of The Combustion Characters and The Mechanism of Oil-Consumption Economy For Diesel Engines Using Water-Blended OilDocument15 pagesAn Analysis of The Combustion Characters and The Mechanism of Oil-Consumption Economy For Diesel Engines Using Water-Blended Oildipali2229Pas encore d'évaluation

- Influence of Chosen Parameters of Water Fuel Microemulsion On Combustion Processes, Emission Level of Nitrogen Oxides and Fuel Consumption of Ci EngineDocument8 pagesInfluence of Chosen Parameters of Water Fuel Microemulsion On Combustion Processes, Emission Level of Nitrogen Oxides and Fuel Consumption of Ci Enginedipali2229Pas encore d'évaluation

- Foton Wheel LoaderDocument3 pagesFoton Wheel Loaderherwin100% (2)

- EN 4080 S 9 Elektr Schaltpl T4final A4Document50 pagesEN 4080 S 9 Elektr Schaltpl T4final A4Chris VerlindenPas encore d'évaluation

- 9852 0918 01a Setting COP 1238ME 07 Bench DrillingDocument1 page9852 0918 01a Setting COP 1238ME 07 Bench DrillingJehuty88Pas encore d'évaluation

- Gen00036-04 Wa600-6 Wheel LoaderDocument98 pagesGen00036-04 Wa600-6 Wheel LoaderJuan Araya BarrazaPas encore d'évaluation

- SM 34Document14 pagesSM 34Luis Oswaldo Roa PerezPas encore d'évaluation

- Sinotruk: Howo Hc16 Driving Axle Spare Parts CatalogDocument15 pagesSinotruk: Howo Hc16 Driving Axle Spare Parts CatalogSamuel Williams100% (1)

- Bendix Atr1dc Antilock Traction RelayDocument12 pagesBendix Atr1dc Antilock Traction RelayHenry NicaraguaPas encore d'évaluation

- Ecs Service Technical Handbook: Publ. No. 923862-0014 00-08Document31 pagesEcs Service Technical Handbook: Publ. No. 923862-0014 00-08Trần Quốc ĐôngPas encore d'évaluation

- 2021 Land CruiserDocument17 pages2021 Land CruiserariPas encore d'évaluation

- Marine Engine Programme 2014Document166 pagesMarine Engine Programme 2014Sebastian GeorgePas encore d'évaluation

- Wankel Engine MainDocument23 pagesWankel Engine MainAbhay MauryaPas encore d'évaluation

- DD15 MexicoDocument36 pagesDD15 MexicoElmer Tintaya Mamani50% (4)

- Darma Henwa Standard Lubricants Specifications - Mobile PlantDocument31 pagesDarma Henwa Standard Lubricants Specifications - Mobile PlantFahmi NurfaPas encore d'évaluation

- Ford Ever 23Document16 pagesFord Ever 23Huy ShallowPas encore d'évaluation

- Air Pressure Balance & Threshold Pressure Tests: Vehicle DataDocument4 pagesAir Pressure Balance & Threshold Pressure Tests: Vehicle DataZIBA KHADIBIPas encore d'évaluation

- UpRight LX-31-41-50Document148 pagesUpRight LX-31-41-50Lidia PopaPas encore d'évaluation

- FORScan ChangelogDocument58 pagesFORScan Changelogcici100% (1)

- LeafletDocument2 pagesLeafletYunendarPas encore d'évaluation

- Trsm0930en-Us 1219Document167 pagesTrsm0930en-Us 1219Juan Manuel GaloPas encore d'évaluation

- Catalogo Fan Clutch NPWDocument1 pageCatalogo Fan Clutch NPWpedro millanPas encore d'évaluation

- RenaultDocument97 pagesRenaultcostinel iordachescuPas encore d'évaluation

- Technical Specifications: 2019 FORD F-150Document9 pagesTechnical Specifications: 2019 FORD F-150AAAPas encore d'évaluation

- Automatic Transmission in Cars 4 WheelerDocument11 pagesAutomatic Transmission in Cars 4 WheelerSurendra Chaudhary100% (1)

- Ingersoll-Rand 231XP - 231XP-2 1-2 Drive Air Impact Wrench Repair PartsDocument2 pagesIngersoll-Rand 231XP - 231XP-2 1-2 Drive Air Impact Wrench Repair PartsPedro Samuel Brito Lopes100% (1)

- Cobra: Spare Parts ListDocument32 pagesCobra: Spare Parts ListGerwazy KufloweMocne MontanaPas encore d'évaluation

- PBM Assignment TemplateDocument20 pagesPBM Assignment TemplatesabarinathPas encore d'évaluation

- Exterior Colors Lineup: Unit: MMDocument4 pagesExterior Colors Lineup: Unit: MMVitorMelloPas encore d'évaluation

- 320 Parts Catalog 2245-, 5624Document563 pages320 Parts Catalog 2245-, 5624Галина КарташоваPas encore d'évaluation

- Daewoo K7C6F, K7CEFDocument364 pagesDaewoo K7C6F, K7CEFAtef KadhiPas encore d'évaluation