Académique Documents

Professionnel Documents

Culture Documents

Bit 3251

Transféré par

Paulo Roberto s freireDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bit 3251

Transféré par

Paulo Roberto s freireDroits d'auteur :

Formats disponibles

B i T E K

DCC CONTROLLED

May 16, 2007

Beyond Innovation Technology Co., Ltd. BIT3251

2006/7/7 Confidential, for authorized user only page 1 of 7

DOC NO.W-DS-0034

BIT3251

Low Cost PWM Controller

Version: A0

Please read the notice stated in this preamble carefull y

before accessing any contents of the document attached.

Admission of BiTEKs statement therein is presumed once

the document is released to the receiver.

B i T E K

DCC CONTROLLED

May 16, 2007

Beyond Innovation Technology Co., Ltd. BIT3251

2006/7/7 Confidential, for authorized user only page 2 of 7

DOC NO.W-DS-0034

Notice:

Firstly, the information furnished by Beyond Innovation Technology Co. Ltd. (BiTEK) in this document is believed to be

accurate and reliable and subject to BiTEKs amendment without prior notice. And the aforesaid information does not

form any part or parts of any quotation or contract between BiTEK and the information receiver.

Further, no responsibility is assumed for the usage of the aforesaid information. BiTEK makes no representation that

the interconnect of its circuits as described herein will not infringe on exiting or future patent rights, nor do the descriptions

contained herein imply the granting of licenses to make, use or sell equipment constructed in accordance therewith.

Besides, the product in this document is not designed for use in life support appliances, devices, or systems where

malfunction of this product can reasonably be expected to result in personal injury. BiTEK customers using or selling this

product for use in such applications shall do so at their own risk and agree to fully indemnify BiTEK for any damage

resulting from such improper use or sale.

At last, the information furnished in this document is the property of BiTEK and shall be treated as highly

confidentiality; any kind of distribution, disclosure, copying, transformation or use of whole or parts of this document

without duly authorization from BiTEK by prior written consent is strictly prohibited. The receiver shall fully compensate

BiTEK without any reservation for any losses thereof due to its violation of BiTEKs confidential request. The receiver is

deemed to agree on BiTEKs confidential request therein suppose that said receiver receives this document without making

any expressly opposition. In the condition that aforesaid opposition is made, the receiver shall return this document to

BiTEK immediately without any delay. -Version A4

B i T E K

DCC CONTROLLED

May 16, 2007

Beyond Innovation Technology Co., Ltd. BIT3251

2006/7/7 Confidential, for authorized user only page 3 of 7

DOC NO.W-DS-0034

Features:

Voltage Mode PWM Controller

Low 0.2V reference Voltage

330KHz Operation

Over Voltage Protection

Internal Soft-Start

Internal UVLO (Under Voltage Lock Out)

Limited Output Duty Cycle

Low Shutdown current (0.1uA)

CMOS Totem Pole Output

SOP-8 Package

General Description:

The BIT3251 is a high frequency PWM controller

integrates required functions for boost conversion in a

small SOP-8 package. A low 0.2V feedback voltage

and over voltage protection make the BIT3251 be an

ideal controller for LED backlight supplies. CMOS

process greatly reduces the operating current when

comparing to similar products.

Pin Layout:

Absolute Ratings: (if Ta=25)

VDD...-0.3 ~ +8 V

GND..0.3 V

Input Voltage....-0.3 ~ VDD+0.3 V

Operating Ambit Temperature.0 ~ 70

Extreme Operating Ambient Temp-40 ~ 85 ***

Operating Junction Temperature..+150

Storage Temperature...-55~ 150

Recommended Operating Condition:

Supply Voltage.4~ 8 V

Operating Frequency..330KHz

Operating Ambient Temperature...0 ~ 70

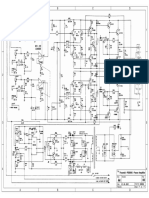

Functional Block Diagram:

6.75K 7.05K

RAMP

+

-

+

-

+

-

+

-

0.45K

0.75K

Band Gap

Voltage

References

Ramp Wave

Generator

EA

HV

0.2V

INN

EAN

3.6V

EA

HV

EHV

1.8V

CMP VDD

ERR_OVP

Error Amplifier

0.308V

4.0V

VDD = 4.0V ~ 8.0V

BIT3251

OVPN

EHV

OVPN

UVLO

LATCH

PWMOUT

ERR_OVP

BUFFER

OUT

1.5V

1.75V

RAMP

CMP

Digital

Control

Circuit

PWM Comparator

GND OVP EA

*** For Extreme Operating Ambient Temperature, the supply voltage should be limited. The recommended voltage range is

from 4.5V to 7.5V.

4 5

8 1

VDD

EA

CMP

INN

OUT

GND

NC

OVP

B i T E K

DCC CONTROLLED

May 16, 2007

Beyond Innovation Technology Co., Ltd. BIT3251

2006/7/7 Confidential, for authorized user only page 4 of 7

DOC NO.W-DS-0034

Pin Description:

Pin No. Names Description

1 VDD Supply voltage input.

2 EA Enable Control Pin

3 CMP The output of the error amplifier. CMP is force to low when VDD < 3.6V.

4 INN

PWM controller input, the inverting input of error amplifier. INN is pulled high to

reduce the CMP when VDD < 3.6V

5 OVP Over Voltage detection pin

6 NC No Connection

7 GND Ground

8 OUT Output pin

Function Description:

The PWM Controller: The pulse width modulation

control circuit includes a ramp wave generator, an error

amplifier and a comparator. These devices provide

the required active components for the PWM feedback

control application. The inverting input of the error

amplifier is pulled high to reduce its output CMP when

VDD<3.6V. The maximum duty cycle of the PWM

controller is limited to 93%

The Over Voltage Protection: The converter output

voltage will boost too high when the LEDs are

disconnected from the circuit or fail open. The BIT3251

will latch off the output if the OVP pin senses a voltage

that is larger than 1.5V. The latched off status can be

reset by reducing the supply voltage to lower than 3.6V.

UVLO: The Under-Voltage-Lock-Out circuit turns the

output driver off when supplying voltage drops to less

than 3.6V

Enable Control: When V(EA) is1.2V, the BIT3251 is

enabled. When V(EA) is0.8V, the BIT3251 enter into

shutdown mode operation. The BIT3251 has an

internal 80K15% ohm pull low resistor on the EA pin,

thus the device is normally in the OFF state or

shutdown mode operation.

Initial Setting: System will have a fast transition

response by setting a suitably initial voltage. The

BIT3251 will set an initial voltage of Vinn and Vcmp

under below conditions.

Table 1. Initial setting Voltage

Voltage Setting(@5V) VEA VDD VOVP

VINN =0.68V, VCMP =0.53V VEA > 1.2V VDD < 3.6V VOVP < 1.5V

VINN =0.68V, VCMP =0.53V VEA < 0.8V VDD > 4.0V VOVP < 1.5V

VINN =0.68V, VCMP =0.53V VEA > 1.2V VDD > 4.0V VOVP > 1.5V

Setting Equation

VINN =0.68V+0.12V*(VDD-5) (1)

VCMP =0.53V+0.08V*(VDD-5) (2)

Figure 1. Initial transition response

(VDD=5V, VINN =0.68V, VCMP =0.53V)

Vinn

Vinn=0.2V

Vcmp

Vcmp

Initial start up time

B i T E K

DCC CONTROLLED

May 16, 2007

Beyond Innovation Technology Co., Ltd. BIT3251

2006/7/7 Confidential, for authorized user only page 5 of 7

DOC NO.W-DS-0034

DC/AC Characteristics:

Parameter Test Conditions Min. Typ.(Limits) Max. Unit

Reference Voltage

Output voltage

Measured with shorted

INN CMP pins

VDD=5V, Ta=25C

0.194 0.2 0.206 V

Line regulation VDD=4 ~ 8V, Ta=25C 2 20 mV

Under Voltage Look Out

Upper threshold voltage 3.6 3.8 4.0 V

Hysteresis

Ta=25C

Note2

0.1 0.2 0.3 V

Ramp Wave Generator

Frequency 300 330 360 KHz

Output peak (Internal ) 1.7 1.8 1.9 V

Output valley (Internal)

Note 1

0.25 0.308 0.35 V

Error Amplifier

Open loop gain 60 80 dB

Unit gain band width

Note 1

1 1.5 MHz

Over Voltage Protection

OVP threshold voltage VDD=5V, Ta=25C 1.45 1.55 1.65 V

Enable Control

Turn on Threshold 1.2 V

Turn off Threshold

VDD=5V, Note 1

0.8 V

Output

CMOS output impedance Note 1, Note 2 50

Maximum Duty Cycle

VDD=5V, Ta=25C,

330KHz.

90 93 95 %

Rising Time 65.5 ns

Falling Time

VDD=5V, 1000pF load,

Note 1, Note 2 88.5 ns

Ta: ambient temperature.

Note 1. Only guaranteed by simulation or sampled evaluation during 40~+85C. Not 100% tested.

Note 2. The voltages of the output drivers are pulled to GND in each off states.

Layout Notice:

Some of the pins are very sensitive to noise. Please follow the bellowing guideline to make the layout:

Note 1. Please keep the capacitor between VDD and GND as close as possible. Noisy IC VDD may trigger UVLO.

Note 2. Figure 2 is an example of making shortest traces between VDD and GND. The layout traces are under the IC.

Figure 2

4 5

8 1

VDD

EA

CMP

INN

OUT

GND

NC

OVP

B i T E K

DCC CONTROLLED

May 16, 2007

Beyond Innovation Technology Co., Ltd. BIT3251

2006/7/7 Confidential, for authorized user only page 6 of 7

DOC NO.W-DS-0034

Soldering Information

Reflow Soldering:

The choice of heating method may be influenced by plastic QFP package). If infrared or vapor phase heating is

used and the package is not absolutely dry (less than 0.1% moisture content by weight), vaporization of the small

amount of moisture in them can cause cracking of the plastic body. Preheating is necessary to dry the paste and

evaporate the binding agent. Preheating duration: 45 minutes at 45 C.

Reflow soldering requires solder paste (a suspension of fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stenciling or pressure-syringe dispensing before package placement.

Several methods exist for reflowing; for example, convection or convection/infrared heating in a conveyor type oven.

Throughput times (preheating, soldering and cooling) vary between 100 and 200 seconds depending on heating

method.

Typical reflow peak temperatures range from 215 to 270 C depending on solder paste material. The top-surface

temperature of the packages should preferable be kept below 245 C for thick/large packages (packages with a

thickness 2.5 mm or with a volume 350 mm

3

so called thick/large packages). The top-surface temperature of

the packages should preferable be kept below 260 C for thin/small packages (packages with a thickness < 2.5 mm

and a volume < 350 mm

3

so called thin/small packages).

Stage Condition Duration

1st Ram Up Rate max3.0+/-2/sec -

Preheat 150~200 60~180 sec

2nd Ram Up max3.0+/-2/sec -

Solder Joint 217 above 60~150 sec

Peak Temp 260 +0/-5 20~40 sec

Ram Down rate 6/sec max -

Wave Soldering:

Conventional single wave soldering is not recommended for surface mount devices (SMDs) or printed-circuit

boards with a high component density, as solder bridging and non-wetting can present major problems.

Manual Soldering:

Fix the component by first soldering two diagonally-opposite end leads. Use a low voltage (24 V or less) soldering

iron applied to the flat part of the lead. Contact time must be limited to 10 seconds at up to 300 C. When using a

dedicated tool, all other leads can be soldered in one operation within 2 to 5 seconds between 270 and 320 C.

Time(sec)

Temp ()

60~150 60~180

25

RT

200

217

260

150

B i T E K

DCC CONTROLLED

May 16, 2007

Beyond Innovation Technology Co., Ltd. BIT3251

2006/7/7 Confidential, for authorized user only page 7 of 7

DOC NO.W-DS-0034

Order Information:

BI T3251- SO

SO: SOP

Part number

Beyond Innovation Technology Co., Ltd.

Package Information :

Unit: mm

SOP type :

Vous aimerez peut-être aussi

- Bit 3713Document11 pagesBit 3713Jan RiskenPas encore d'évaluation

- Datasheet Bit3715 PMW Monitor LCD AcerDocument11 pagesDatasheet Bit3715 PMW Monitor LCD AcershibatoyanPas encore d'évaluation

- Bit 3715Document11 pagesBit 3715Rocko RattPas encore d'évaluation

- BIT3251 Datasheet PDFDocument7 pagesBIT3251 Datasheet PDFElectronica Libra Libra100% (1)

- BIT3252ADocument8 pagesBIT3252ASiva Anand.PPas encore d'évaluation

- DatasheetDocument3 pagesDatasheetlzrd88Pas encore d'évaluation

- BD9275FDocument5 pagesBD9275Fproctep100% (1)

- 9623 BIT3251 DatasheetDocument7 pages9623 BIT3251 Datasheet81968Pas encore d'évaluation

- BD9893FDocument5 pagesBD9893FAriel NavarretePas encore d'évaluation

- EN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated InductorDocument16 pagesEN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated Inductorcatsoithahuong84Pas encore d'évaluation

- Features General Description: HT7L4813 Non-Isolation Buck LED Lighting Driver With Active PFCDocument10 pagesFeatures General Description: HT7L4813 Non-Isolation Buck LED Lighting Driver With Active PFCEnéas BaronePas encore d'évaluation

- Two-Phase Brushless Fan Motor Driver: 3098B-DIP10SDocument5 pagesTwo-Phase Brushless Fan Motor Driver: 3098B-DIP10Smax_speed45Pas encore d'évaluation

- PD Derated at 8.5mW/ For Temperature Above Ta 25 (When Mounted On A PCB 70.0mm×70.0mm×1.6mm)Document5 pagesPD Derated at 8.5mW/ For Temperature Above Ta 25 (When Mounted On A PCB 70.0mm×70.0mm×1.6mm)Osama YaseenPas encore d'évaluation

- Bp3102 - Ds - Rev 1.0 en Led DriverDocument10 pagesBp3102 - Ds - Rev 1.0 en Led DriverTheodoradrianPas encore d'évaluation

- Ir1161lpbf - Infineon Solutions For Transportation 24V To 60VDocument25 pagesIr1161lpbf - Infineon Solutions For Transportation 24V To 60VAnonymous R0s4q9X8Pas encore d'évaluation

- Over Voltage, Over Current, Transient Voltage & Reverse Polarity Protection Circuit Using RT1720 Hot Swap Controller With Fault TimerDocument10 pagesOver Voltage, Over Current, Transient Voltage & Reverse Polarity Protection Circuit Using RT1720 Hot Swap Controller With Fault TimerKoushik MaityPas encore d'évaluation

- 74VHC14 Hex Schmitt Inverter: Features General DescriptionDocument8 pages74VHC14 Hex Schmitt Inverter: Features General DescriptionAriel NavarretePas encore d'évaluation

- OB2269Document12 pagesOB2269Juan Ballon100% (1)

- RT9202Document16 pagesRT9202bachet56Pas encore d'évaluation

- 500V / 7A Switching Regulator Applications: Data SheetDocument4 pages500V / 7A Switching Regulator Applications: Data SheetFlorin RaduPas encore d'évaluation

- NSS12201L DDocument5 pagesNSS12201L DjamesabowdenPas encore d'évaluation

- 1.5A USB-Friendly Li-Ion Battery Charger and Power-Path Management ICDocument33 pages1.5A USB-Friendly Li-Ion Battery Charger and Power-Path Management ICanarchie2008Pas encore d'évaluation

- MAX77680 Datasheet and Technical InfoDocument9 pagesMAX77680 Datasheet and Technical InfojackPas encore d'évaluation

- SA5888Document8 pagesSA5888albinicue1Pas encore d'évaluation

- HT7 L4815 V 100Document9 pagesHT7 L4815 V 100Enéas BaronePas encore d'évaluation

- LV47002PDocument9 pagesLV47002PchichedemorenoPas encore d'évaluation

- Datasheet PDFDocument8 pagesDatasheet PDFmcr16986Pas encore d'évaluation

- MTC 2 eDocument8 pagesMTC 2 eravikumarrkPas encore d'évaluation

- UP220-AE-A Power SupplyDocument8 pagesUP220-AE-A Power SupplyAndy WilsonPas encore d'évaluation

- TDA8139Document5 pagesTDA8139cosdeaPas encore d'évaluation

- HT7L4811 Non-Isolation Buck LED Lighting Driver With Active PFCDocument12 pagesHT7L4811 Non-Isolation Buck LED Lighting Driver With Active PFCEnéas BaronePas encore d'évaluation

- MP3389 r1.04Document16 pagesMP3389 r1.04Andres Alegria100% (1)

- Kps 2222aDocument3 pagesKps 2222apruebapreuba2015Pas encore d'évaluation

- UTC Unisonic Tech UT3232G S16 R - C84913Document7 pagesUTC Unisonic Tech UT3232G S16 R - C84913KURALMOZHI RAMESHPas encore d'évaluation

- BC 171Document4 pagesBC 171Beniamin Vasile ChetranPas encore d'évaluation

- Ta 8050 PDocument9 pagesTa 8050 PJuan Alamada Reynoso100% (1)

- Wide Bandwidth Dual Bipolar Operational Amplifier: DescriptionDocument10 pagesWide Bandwidth Dual Bipolar Operational Amplifier: DescriptionAlexander MasiasPas encore d'évaluation

- Datasheet - HK rt8110 7327105 PDFDocument14 pagesDatasheet - HK rt8110 7327105 PDFLuis CarlosPas encore d'évaluation

- Circuito Integrado TA8207KDocument11 pagesCircuito Integrado TA8207KIberê CamposPas encore d'évaluation

- Low Frequency Power Amplifier: FeaturesDocument10 pagesLow Frequency Power Amplifier: FeaturesgusguicorPas encore d'évaluation

- WT7520Document9 pagesWT7520Inajá FerreiraPas encore d'évaluation

- Data SheetDocument7 pagesData Sheetitamar_123Pas encore d'évaluation

- Uc 2710Document6 pagesUc 2710pic18f4550Pas encore d'évaluation

- Color TV Horizontal Deflection Output Applications: Package Dimensions FeaturesDocument4 pagesColor TV Horizontal Deflection Output Applications: Package Dimensions FeaturesJosue Benjamin Puc CohuoPas encore d'évaluation

- T370HW02 Ve - 20081113Document29 pagesT370HW02 Ve - 20081113Tran Van Thien0% (1)

- YP47LPBD - SPEC-120927 (47' Slim) PDFDocument13 pagesYP47LPBD - SPEC-120927 (47' Slim) PDFautreraPas encore d'évaluation

- 1P MMBT 2222A-1 FairchildDocument5 pages1P MMBT 2222A-1 FairchildgaryzherePas encore d'évaluation

- FZT651Document7 pagesFZT651Olga PlohotnichenkoPas encore d'évaluation

- Cxa3834am PDFDocument28 pagesCxa3834am PDFaldo_suviPas encore d'évaluation

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsD'EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsÉvaluation : 3.5 sur 5 étoiles3.5/5 (6)

- Analog Circuit Design Volume Three: Design Note CollectionD'EverandAnalog Circuit Design Volume Three: Design Note CollectionÉvaluation : 3 sur 5 étoiles3/5 (2)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsD'EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsPas encore d'évaluation

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Pas encore d'évaluation

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Évaluation : 2.5 sur 5 étoiles2.5/5 (3)

- Beginning Digital Electronics through ProjectsD'EverandBeginning Digital Electronics through ProjectsÉvaluation : 5 sur 5 étoiles5/5 (1)

- 3.3-V/5-V Input, 6-A, D-Cap+ Mode Synchronous Step-Down Integrated Fets Converter With 2-Bit VidDocument35 pages3.3-V/5-V Input, 6-A, D-Cap+ Mode Synchronous Step-Down Integrated Fets Converter With 2-Bit VidPaulo Roberto s freirePas encore d'évaluation

- Green-Mode PWM Controller With Frequency Swapping and Audio Noise PreventionDocument18 pagesGreen-Mode PWM Controller With Frequency Swapping and Audio Noise PreventionPaulo Roberto s freirePas encore d'évaluation

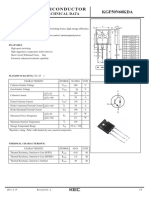

- Semiconductor KGF50N60KDA: Technical DataDocument8 pagesSemiconductor KGF50N60KDA: Technical DataPaulo Roberto s freirePas encore d'évaluation

- 12204-1 BottomDocument1 page12204-1 BottomPaulo Roberto s freirePas encore d'évaluation

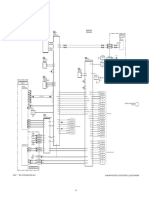

- 12 Block Diagram: 12.1. Servo & System ControlDocument18 pages12 Block Diagram: 12.1. Servo & System ControlPaulo Roberto s freirePas encore d'évaluation

- SMK0460I: Switching Regulator ApplicationsDocument8 pagesSMK0460I: Switching Regulator ApplicationsPaulo Roberto s freirePas encore d'évaluation

- Digital Controller: E5AK/E5EKDocument37 pagesDigital Controller: E5AK/E5EKPaulo Roberto s freirePas encore d'évaluation

- 111Db 192Khz 24-Bit 2ChDocument26 pages111Db 192Khz 24-Bit 2ChPaulo Roberto s freirePas encore d'évaluation

- Multi-Channel Power Supply IC For Car Audio Systems: DatasheetDocument44 pagesMulti-Channel Power Supply IC For Car Audio Systems: DatasheetPaulo Roberto s freirePas encore d'évaluation

- FSCQ1565RT: Green Mode Fairchild Power Switch (FPS) For Quasi-Resonant Switching ConverterDocument25 pagesFSCQ1565RT: Green Mode Fairchild Power Switch (FPS) For Quasi-Resonant Switching ConverterPaulo Roberto s freirePas encore d'évaluation

- SR302 - SR306: Not Recommended For New Designs, Use Sb3X0 SeriesDocument2 pagesSR302 - SR306: Not Recommended For New Designs, Use Sb3X0 SeriesPaulo Roberto s freirePas encore d'évaluation

- For New Designs: AOZ1033AIDocument15 pagesFor New Designs: AOZ1033AIPaulo Roberto s freirePas encore d'évaluation

- FSQ0365RN, FSQ0265RN, FSQ0165RN, FSQ311 Green Mode Fairchild Power Switch (FPS™) For Quasi-Resonant OperationDocument19 pagesFSQ0365RN, FSQ0265RN, FSQ0165RN, FSQ311 Green Mode Fairchild Power Switch (FPS™) For Quasi-Resonant OperationPaulo Roberto s freirePas encore d'évaluation

- Philips FX30X PDFDocument51 pagesPhilips FX30X PDFCarlos Roberto AlvesPas encore d'évaluation

- TB1240ANDocument85 pagesTB1240ANPaulo Roberto s freirePas encore d'évaluation

- Irfp7530pbf PDFDocument10 pagesIrfp7530pbf PDFPaulo Roberto s freirePas encore d'évaluation

- Pyramid - PB300G - Power AmplifierDocument1 pagePyramid - PB300G - Power AmplifierPaulo Roberto s freirePas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Social Media Landscape in India and Future OutlookDocument5 pagesSocial Media Landscape in India and Future Outlookpriyaa2688Pas encore d'évaluation

- Mid Term Test - Group 1 An and yDocument18 pagesMid Term Test - Group 1 An and yAprieza NurizkiPas encore d'évaluation

- IBM System Storage DS3950 Storage Subsystem Injstallation, Users's and Maintenance GuideDocument252 pagesIBM System Storage DS3950 Storage Subsystem Injstallation, Users's and Maintenance GuideAntonio A. BonitaPas encore d'évaluation

- Excel Spreadsheets - How To Ensure 21 CFR Part 11 ComplianceDocument8 pagesExcel Spreadsheets - How To Ensure 21 CFR Part 11 ComplianceComplianceOnline75% (4)

- Powerscale Hardware Installation: Participant GuideDocument96 pagesPowerscale Hardware Installation: Participant GuideLadislauPas encore d'évaluation

- Basic Concepts and Definitions: CE6011 Smart Buildings and Automation 2013-2014Document29 pagesBasic Concepts and Definitions: CE6011 Smart Buildings and Automation 2013-2014RK MEHTAPas encore d'évaluation

- PHP App To Call c4c APIDocument20 pagesPHP App To Call c4c APISerendipity SeyaPas encore d'évaluation

- Hertz v. Pike Holdings Et. Al.Document5 pagesHertz v. Pike Holdings Et. Al.PriorSmartPas encore d'évaluation

- School Communication PlanDocument4 pagesSchool Communication PlanRESTTIE DAGUIOPas encore d'évaluation

- Kontakt 7 6 Manual enDocument273 pagesKontakt 7 6 Manual enAlin Bâte ABPas encore d'évaluation

- Enroll. No. - : Marwadi UniversityDocument4 pagesEnroll. No. - : Marwadi UniversityRudrik BhattPas encore d'évaluation

- System 20: Inline Sensors & MonitorsDocument6 pagesSystem 20: Inline Sensors & MonitorsJaimeEnriquePadillaPobletePas encore d'évaluation

- Gate Qs PapersDocument481 pagesGate Qs PapersSoumyabrataPas encore d'évaluation

- Notes-Ch 10. Sinusoidal Steady-State Analysis PDFDocument39 pagesNotes-Ch 10. Sinusoidal Steady-State Analysis PDFnanekPas encore d'évaluation

- Pega CLSA Office Hour Note 1651953783Document21 pagesPega CLSA Office Hour Note 1651953783Chinmayee ParijaPas encore d'évaluation

- RsyslogDocument329 pagesRsyslogPichai Ng-arnpairojhPas encore d'évaluation

- The Future Evolution of High-Performance Microprocessors: Norm Jouppi HP LabsDocument57 pagesThe Future Evolution of High-Performance Microprocessors: Norm Jouppi HP LabsronnmacPas encore d'évaluation

- Computing Fundamentals AssignmentDocument11 pagesComputing Fundamentals AssignmentMary Jane Evardone EspinoPas encore d'évaluation

- Simplex Method (Chapter 4) : MSCI 603 Section 1 Instructor: Mehrdad PirniaDocument27 pagesSimplex Method (Chapter 4) : MSCI 603 Section 1 Instructor: Mehrdad PirniaMridul GuptaPas encore d'évaluation

- EcoTank L3151 Datasheet PDFDocument2 pagesEcoTank L3151 Datasheet PDFIce BibovskiPas encore d'évaluation

- Technological Institute of The Philippines: College of Information Technology EducationDocument10 pagesTechnological Institute of The Philippines: College of Information Technology EducationGio RocaPas encore d'évaluation

- Facebook Marketing 101 EbookDocument114 pagesFacebook Marketing 101 EbookestrategonlinePas encore d'évaluation

- iVMS-4200 Quick Start GuideDocument23 pagesiVMS-4200 Quick Start GuideVlatko BoskoskiPas encore d'évaluation

- Mech FRACTAL ROBOTSDocument22 pagesMech FRACTAL ROBOTSIndu priya VPas encore d'évaluation

- OPM SLA in OPMDocument46 pagesOPM SLA in OPMSAlah MOhammedPas encore d'évaluation

- Controls Lab Manual PDFDocument12 pagesControls Lab Manual PDFedwin dableoPas encore d'évaluation

- Siva QADocument6 pagesSiva QAsivakanth mPas encore d'évaluation

- Joy Global SolutionsDocument18 pagesJoy Global Solutionsjvr001100% (1)

- Mold Design Using Pro/ENGINEER Wildfire 4.0Document6 pagesMold Design Using Pro/ENGINEER Wildfire 4.0arachman297988Pas encore d'évaluation

- Data Warehouse Massively Parallel Processing Design PatternsDocument28 pagesData Warehouse Massively Parallel Processing Design PatternsMatthew LawlerPas encore d'évaluation