Académique Documents

Professionnel Documents

Culture Documents

LTG - VSR Ru MS e - 450 60

Transféré par

Ahsan JavedTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

LTG - VSR Ru MS e - 450 60

Transféré par

Ahsan JavedDroits d'auteur :

Formats disponibles

The Innovation Company

LTG Aktiengesellschaft

High-pressure

Conveying Fans

VSR-5./RU...MS

LTG Aktiengesellschaft

D - 70435 Stuttgart, Grenzstrae 7

+49 (0711) 82 01-180, Fax +49 (0711) 82 01-696

Internet: http://www.LTG-AG.de

E-Mail: info@LTG--AG.de

LTG Incorporated

105 Corporate Drive, Suite E

Spartanburg S.C., 29303 USA

+1 (864) 599--6340, Fax +1 (864) 599--6344

Internet: http://www.LTG-INC.net

E-Mail: info@LTG--INC.net

LTG S.r.l. con socio unico

Via G. Leopardi 10

I--20066 Melzo

+39 (02) 9 55 05 35, Fax +39 (02) 9 55 08 28

Internet: http://www.LTG-SRL.com

E-Mail:ltg@ltgsrl.191.it

VSR--RU--MS-E-TP-01 (05/08) 450--60

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications.

Components for Process Air Technology

Japan

Toho Engineering Co. Ltd.

14-11, Shimizu 3-Chome, Kita Ku

Japan 462 Nagoya

(052) 9 91-10 40, Fax (052) 9 14-98 22

E--Mail: main@tohoeng.com

Axial--flow, centrifugal and tangential fans

LTG Collector System

Coarse and fine particles filration

Separating and compacting

Compressing and humidifying

The Program for Process Air Technology

Components

Engineering services

Technical services for construction engineers and plant designers during develop-

ment and operation of assembly groups, machines and plants.

Components for

Room Air Technology

Germany

Frankfurt Herborn Berlin Chemnitz

Dsseldorf

Europe

Ladendorf/Austria Epne/France Wick-

ford/Great Britain Ermelo/Netherlands

Krakow/Poland Lissabon/Portugal

Ljubljana/Slowenia Istanbul/Turkey

The Program for

Room Air Technology

Components

Air diffusers for walls, floors and

ceilings LTG System clean

R

Coandatrol

R

and Coandavent

R

air diffu-

sers LTG cool wave

R

chilling fans

Klimavent

R

induction units

Raumluft

R

fan coil units

Facade fan coil units

Airflow control units labair

R

system

Engineering services

Technical services for investors, archi-

tects, engineers and plant builders during

design, construction and operation of

buildings. Reliable and precise data rela-

ting to the ventilation of air conditioning

system are given already before realiza-

tion of the project, determined by measu-

rements, calculations, building simula-

tions and experiments.

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 3

High-pressure Conveying Fans Types VSR-5./RU...MS

LTG series RU...MS high--pressure conveying fans are di-

rect--driven, single inlet centrifugal fans.

Range of Products

VSR--51/RU...MS

for static pressure 3000 Pa

VSR--52/RU...MS

for static pressure 4000 Pa

VSR--53/RU...MS

for static pressure 6000 Pa

VSR--54/RU...MS

for static pressure 8000 Pa

VSR--55/RU...MS

for static pressure 10000 Pa

other models available on request

Application

This series of fans is particularly suitable to pneumati-

cally convey dust, fibers and shavings and wherever com-

mon impellers would easily get clogged, e.g. in the tex-

tile, plastics, and paper industry.

Note: This fan type may easily be remodelled to become

a high--quality paper shredder without changing the fan

dimensions or features.

Spezification and Features

Design: reinforced version, welded sheet steel housing,

non--rotating, with opening for cleaning, special 6 mm

steel frame and tongue with increased wear resistance.

Round suction and discharge flange connection.

Welded sheet steel impeller with open blading for direct

material conveyance, special 6mm steel blades made out

of special steel with increased wear resistance, bolted to

cast--iron hub, dynamically balanced according to DIN

ISO1940, grade 6.3, directly mounted to the motor shaft.

Surface finish similar to RAL 5003, accessories similar

to RAL 9006.

Motor

Standard three--phase motors, construction type IMB3,

up to 3 kW 230/400 V, from 4 kW 400/690 V, 50 Hz,

type of protection: IP55 (with PTC resistor sensor).

Advantages

Perfect aerodynamic properties

Flat fan curve

ensuring minimum pressure fluctuation during operation.

Low noise operation

Compact design

High operation safety

due to solid, torsion--resistant steel housing;

welded, bolted, coated.

High production accuracy

ensuring that specifications are always met.

Great variety of models

5 series, each with up to 6 sizes and 6 housing positions

for flow rates up to 3,000 m

3

/h and

static pressures up to 10,000 Pa.

Computer--based design

LTG fans are sized with the help of computer program

for each case individually based on the actual criteria.

Thus ensures to select the best possible fan for each ap-

plication.

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 4

High-pressure Conveying Fans Types VSR-5./RU...MS

Technical Specifications for standard conditions (20 _C, = 1,2 kg/m

3)

Size VSR--

Flow

rate

1)

Total

pressure rise

1)

Power

requirement

Motor--

output

Motor

speed

Sound

pressure

level

2)

Weight

of fan

with motor

[m

3

/h] [Pa] [kW] [kW] [rpm] [dB(A)] [kg]

51/RU 80 MS 360 3040 0,8 2,2 2880 74 61

100 MS 560 3040 1,2 2,2 2880 75 66

125 MS 900 3040 2 3 2890 75 87

140 MS 1100 3380 2,4 3 2890 76 87

160 MS 1450 3730 3,2 4 2905 77 99

52/RU100 MS 560 4220 1,6 3 2890 77 92

125 MS 900 4220 2,6 4 2905 78 104

140 MS 1100 4220 3,4 4 2905 79 109

160 MS 1450 4220 4,2 5,5 2925 79 124

180 MS 1830 4330 5,5 7,5 2930 80 129

53/RU80 MS 430 6380 2,6 4 2905 80 109

100 MS 670 6280 2,7 4 2905 80 109

125 MS 1060 6280 4,2 5,5 2925 81 124

140 MS 1330 6180 5,2 7,5 2930 82 138

160 MS 1450 6470 6,7 7,5 2930 82 148

180 MS 1800 6700 8 11 2940 83 178

54/RU80 MS 430 8100 2,2 7,5 2930 82 153

100 MS 670 8100 3,5 7,5 2930 82 158

125 MS 1060 8100 5,6 11 2940 83 188

140 MS 1330 8100 7 11 2940 84 198

160 MS 1740 8100 9,2 15 2940 84 217

55/RU80 MS 430 10500 3,3 7,5 2930 84 188

100 MS 670 10450 5,3 11 2940 85 213

125 MS 1060 10500 8,3 15 2940 85 227

1)

for fan speed 2900 rpm.

Motor: standard three--phase motor, type IM B3 up tp 3 kW 230/400V, from 4 kW 400/690 V,

50 Hz, type of protection IP 55 (with PTC resistor sensor)

2)

measured at a distance of 1 m with ducts connected and elastic installation according to DIN 45635.

Accessories

Elastic installation:

Base or base frame of U--channel with rubber vibration dampers.

Flex connection to the duct:

Flex suction and discharge socket with inner sleeve of sheet steel to reduce sound emission.

Flanges

The high--pressure conveying fans are equipped with flanges on both the suction and discharge side (details see dimen-

sional sheets).

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 5

High-pressure Conveying Fans Types VSR-51/RU...MS

Dimensions

Houses are non--rotating

Tolerances according to DIN ISO 2768--cL

k

n

m

h

q

c1 w1 w

c

a

D

N

DN

50

50 50

b f

da

14

dl

p

o

Figure:

Housing position R360

Size

VSR--51/RU

80 MS 100 MS 125 MS 140 MS 160 MS 250 MS

a 350 350 400 400 400 458

b 300 300 350 350 350 350

c1 250 250 300 300 300 350

c 310 310 360 360 360 410

w 50 50 50 50 50 54

w1 30 30 30 30 30 30

h 350 350 350 410 410 470

f 103 103 103 103 118 192

k 280 270 256 309 300 314,5

m 330 330 330 315 315 330

n 330 330 330 340 340 370

o 330 330 330 365 365 410

p 330 330 330 390 390 450

q 385 385 385 400 400 575

DN 80 100 125 140 160 250

dl 114 135 161 180 198 --

da 134 155 181 206 224 266

Bolts 4 x M8 4 x M8 8 x M8 8 x M8 8 x M8 --

Housing positions (View onto motor side)

Position R 360 Position R 90 Position R 270 Position L 270 Position L 360 Position L 90

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 6

High-pressure Conveying Fans Types VSR-51/RU...MS

Fan Curves (at 20 _C, = 1.2 kg/m

3

)

0 300 600 900 1200 1500

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

0

1

2

3

4

5

6

7

8

9

10

11

12

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 3 kW

51/RU 125 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0 100 200 300 400 500 600

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

6

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 2.2 kW

51/RU 80 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0 100 200 300 400 500 900

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

6

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 2.2 kW

51/RU 100 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

600 700 800

0 300 600 900 1200 1500 1800

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

0

1

2

3

4

5

6

7

8

9

10

11

12

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 3 kW

51/RU 140 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 7

High-pressure Conveying Fans Types VSR-51/RU...MS

Fan Curves (at 20 _C, = 1.2 kg/m

3

)

0 400 800 1200 1600 2000

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

0

1

2

3

4

5

6

7

8

9

10

11

12

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 4 kW

51/RU 160 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 8

High-pressure Conveying Fans Types VSR-52/RU...MS

Dimensions

k

n

m

h

q

c1 w1 w

c

a

D

N

DN

50

50 50

b f

da

14

dl

p

o

Houses are non--rotating

Tolerances according to DIN ISO 2768--cL

Figure:

Housing position R360

Size VSR--52/RU 100 MS 125 MS 140 MS 160 MS 180 MS

a 400 400 400 450 450

b 350 350 350 400 400

c1 300 300 300 350 350

c 360 360 360 410 410

w 50 50 50 50 50

w1 30 30 30 30 30

h 400 400 450 450 450

f 104 104 104 119 134

k 304 293 350 335 327

m 365 365 360 350 350

n 365 365 380 375 375

o 365 365 410 400 400

p 365 365 430 425 425

q 420 420 430 420 420

DN 100 125 140 160 180

dl 135 161 180 198 217

da 155 181 206 224 243

Bolts 4 x M8 8 x M8 8 x M8 8 x M8 8 x M8

Housing positions (View onto motor side)

Position R 360 Position R 90 Position R 270 Position L 270 Position L 360 Position L 90

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 9

High-pressure Conveying Fans Types VSR-52/RU...MS

Fan Curves (at 20 _C, = 1.2 kg/m

3

)

0 200 400 600 800 1400

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 4 kW

52/RU 125 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

1000 1200

0 400 800 1200 1600 2000

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

0

1

2

3

4

5

6

7

8

9

10

11

12

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 4 kW

52/RU 140 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0 200 400 600 800 1000

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 3 kW

52/RU 100 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

6

0

1

2

3

4

5

6

7

8

9

10

11

12

0 400 800 1200 1600 2000

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

0

1

2

3

4

5

6

7

8

9

10

11

12

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 5.5 kW

52/RU 160 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 10

High-pressure Conveying Fans Types VSR-52/RU...MS

Fan Curves (at 20 _C, = 1.2 kg/m

3

)

0 500 1000 1500 2000 2500 3000

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

0

1

2

3

4

5

6

7

8

9

10

11

12

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 7.5 kW

52/RU 180 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 11

High-pressure Conveying Fans Types VSR-53/RU...MS

Dimensions

k

n

m

h

q

c1 w1 w

c

a

D

N

DN

50

50 50

b f

da

14

dl

p

o

Houses are non--rotating

Tolerances according to DIN ISO 2768--cL

Figure:

Housing position R360

Size

VSR--53/RU

80 MS 100 MS 125 MS 140 MS 160 MS 180 MS

a 400 400 400 450 450 450

b 350 350 350 400 400 450

c1 300 300 300 350 350 350

c 360 360 360 410 410 410

w 50 50 50 50 50 50

w1 30 30 30 30 30 30

h 430 430 430 480 480 480

f 104 104 104 104 119 136

k 358 350 340 387 380 361

m 405 405 405 390 390 390

n 405 405 405 420 420 420

o 405 405 405 440 440 440

p 405 405 405 470 470 470

q 460 460 460 460 460 460

DN 80 100 125 140 160 180

dl 114 135 161 180 198 217

da 134 155 181 206 224 243

Bolts 4 x M8 4 x M8 8 x M8 8 x M8 8 x M8 8 x M8

Housing positions (View onto motor side)

Position R 360 Position R 90 Position R 270 Position L 270 Position L 360 Position L 90

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 12

High-pressure Conveying Fans Types VSR-53/RU...MS

Fan Curves (at 20 _C, = 1.2 kg/m

3

)

0 200 400 600 800 1000

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 4 kW

53/RU 80 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0

2

4

6

8

10

12

14

16

18

0 200 400 600 800 1000

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 4 kW

53/RU 100 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0

1

2

3

4

5

6

7

8

9

0 200 400 600 800 1000

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 5.5 kW

53/RU 125 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0

1

2

3

4

5

6

7

8

9

1400 1200 0 500 1000 1500 2000 2500

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 7.5 kW

53/RU 140 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0

2

4

6

8

10

12

14

16

18

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 13

High-pressure Conveying Fans Types VSR-53/RU...MS

Fan Curves (at 20 _C, = 1.2 kg/m

3

)

0 500 1000 1500 2000 2500

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 11 kW

53/RU 180 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0

2

4

6

8

10

12

14

16

18

3500 3000 0 500 1000 1500 2000 2500

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 7.5 kW

53/RU 160 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0

2

4

6

8

10

12

14

16

18

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 14

High-pressure Conveying Fans Types VSR-54/RU...MS

Dimensions

k

n

m

h

q

c1 w1 w

c

a

D

N

DN

50

50 50

b f

da

14

dl

p

o

Houses are non--rotating

Tolerances according to DIN ISO 2768--cL

Figure:

Housing position R360

Size

VSR--54/RU

80 MS 100 MS 125 MS 140 MS 160 MS

a 450 450 450 500 500

b 400 400 500 520 520

c1 350 350 350 400 400

c 410 410 410 460 460

w 50 50 50 50 50

w1 30 30 30 30 30

h 450 450 480 560 560

f 106 106 106 106 121

k 381 370 357 410 401

m 430 430 430 430 430

n 430 430 430 450 450

o 430 430 430 470 470

p 430 430 430 490 490

q 485 485 485 500 500

DN 80 100 125 140 160

dl 114 135 161 180 198

da 134 155 181 206 224

Bolts 4 x M8 4 x M8 8 x M8 8 x M8 8 x M8

Housing positions (View onto motor side)

Position R 360 Position R 90 Position R 270 Position L 270 Position L 360 Position L 90

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 15

High-pressure Conveying Fans Types VSR-54/RU...MS

Fan curves (at 20 _C, = 1.2 kg/m

3

)

0 200 400 600 800 1000

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 7.5 kW

54 RU 80 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0

1

2

3

4

5

6

7

8

9

0 500 1000 1500 2000 2500

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 11 kW

54/RU 140 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0

2

4

6

8

10

12

14

16

18

3000 0 500 1000 1500 2000 2500

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 11 kW

54/RU 125 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0

2

4

6

8

10

12

14

16

18

0 200 400 600 800 1000

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 7.5 kW

54/RU 100 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0

2

4

6

8

10

12

14

16

18

1400 1200

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 16

High-pressure Conveying Fans Types VSR-54/RU...MS

Fan curves (at 20 _C, = 1.2 kg/m

3

)

0 500 1000 1500 2000 2500

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 15 kW

54/RU 160 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0

3

6

9

12

15

18

21

24

27

3500 3000

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 17

High-pressure Conveying Fans Types VSR-55/RU...MS

Dimensions

k

n

m

h

q

c1 w1 w

c

a

D

N

DN

50

50 50

b f

da

14

dl

p

o

Houses are non--rotating

Tolerances according to DIN ISO 2768--cL

Figure:

Housing position R360

Size

VSR--55/RU

80 MS 100 MS 125 MS 140 MS

a 500 500 500 500

b 520 520 520 520

c1 400 400 400 400

c 460 460 460 460

w 50 50 50 50

w1 30 30 30 30

h 560 560 560 560

f 108 108 108 108

k 431 420 408 462

m 480 480 480 480

n 480 480 480 500

o 480 480 480 520

p 480 480 480 540

q 540 540 540 555

DN 80 100 125 140

dl 114 135 161 180

da 134 155 181 206

Bolts 4 x M8 4 x M8 8 x M8 8 x M8

Housing positions (View onto motor side)

Position R 360 Position R 90 Position R 270 Position L 270 Position L 360 Position L 90

The Innovation Company

LTG Aktiengesellschaft

ELTG Aktiengesellschaft Grenzstrae 7 D-70435 Stuttgart +49 (0711) 8201-180 Fax -696 VSR--RU--MS-E-TP (05/08)

Internet: http://www.LTG-AG.de E-Mail: prozessluft@LTG-AG.de Printed in Germany Ausgaben mit frherem

Datum werden hiermit ungltig Technische nderungen vorbehalten Former editions are invalid Subject to technical modifications. 18

High-pressure Conveying Fans Types VSR-55/RU...MS

Fan Curves (at 20 _C, = 1.2 kg/m

3

)

0 200 400 600 800 1400

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 11 kW

55/RU 100 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

1000 1200

0 400 800 1200 1600 2000

0

2

4

6

8

10

12

14

16

18

20

22

24

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 15 kW

55/RU 125 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0 200 400 600 800 1000

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

11000

12000

P

r

e

s

s

u

r

e

i

n

P

a

Motor: 7.5 kW

55/RU 80 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

Flow rate in m

3

/h

p

tot

p

s

P

w

0

1

2

3

4

5

6

7

8

9

10

11

12

0

1

2

3

4

5

6

7

8

9

10

11

12

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

11000

12000

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

11000

12000

0 500 1000 1500 2000 2500 3000 3500

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

11000

12000

0

4

8

12

16

20

24

28

32

36

40

44

48

P

r

e

s

s

u

r

e

i

n

P

a

Flow rate in m

3

/h

Motor: 15 kW

55/RU 140 MS

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

o

f

f

a

n

i

n

k

W

p

tot

p

s

P

w

Vous aimerez peut-être aussi

- Axial Centrifugal FansDocument15 pagesAxial Centrifugal FansAhsan JavedPas encore d'évaluation

- Manuales Bombas PLUS SV-SL-SLXDocument16 pagesManuales Bombas PLUS SV-SL-SLXLeo XavierPas encore d'évaluation

- Preview 92103Document4 pagesPreview 92103Almir RodriguesPas encore d'évaluation

- Bringing valuable water solutions to various applicationsDocument32 pagesBringing valuable water solutions to various applicationsAhmadMoaazPas encore d'évaluation

- API Drill Pipe Specs-1Document26 pagesAPI Drill Pipe Specs-1SACHIN H. DHAMAPURKARPas encore d'évaluation

- T Ces Series PDFDocument12 pagesT Ces Series PDFDaniel InostrozaPas encore d'évaluation

- SEIFERT Air Conditioners Indoor&Outdoor 1503ENDocument20 pagesSEIFERT Air Conditioners Indoor&Outdoor 1503ENTomPas encore d'évaluation

- Maintenance Arpex enDocument39 pagesMaintenance Arpex enPatrick BaridonPas encore d'évaluation

- B5-25GS. Goulds Water Technology - SUBMERSIBLE PUMPS Residential Water Systems (8 Model 18GS)Document12 pagesB5-25GS. Goulds Water Technology - SUBMERSIBLE PUMPS Residential Water Systems (8 Model 18GS)Andrés OyarzúnPas encore d'évaluation

- SVL606 Stainless Steel Safety Valve: DescriptionDocument4 pagesSVL606 Stainless Steel Safety Valve: DescriptionalejjavierdelgadoPas encore d'évaluation

- DLP enDocument15 pagesDLP enpir8s_xPas encore d'évaluation

- Electrical Price List 2016Document23 pagesElectrical Price List 2016shivamPas encore d'évaluation

- Flow MeterDocument6 pagesFlow MeterYvoSteentjes100% (1)

- TTM Post TensioningDocument103 pagesTTM Post Tensioninghorea67100% (2)

- Catalog Donaldson EngDocument10 pagesCatalog Donaldson EngLatDatPas encore d'évaluation

- CATALOUGEDocument3 pagesCATALOUGEdeepthiPas encore d'évaluation

- Equipo Hot Tap de 42 inDocument5 pagesEquipo Hot Tap de 42 inSerch Villa100% (1)

- Hja-Hjn Leaflet-RbcDocument3 pagesHja-Hjn Leaflet-Rbcapi-97482572Pas encore d'évaluation

- M Catalogue 2008Document9 pagesM Catalogue 2008stan876Pas encore d'évaluation

- 10 SEER air conditioner specsDocument4 pages10 SEER air conditioner specsOscar Sanchez Velasquez0% (1)

- Efficient Modular Cooling Towers for Air Conditioning and Industrial ApplicationsDocument12 pagesEfficient Modular Cooling Towers for Air Conditioning and Industrial ApplicationsnkhhhPas encore d'évaluation

- Centrifugal PumpDocument32 pagesCentrifugal PumpAshok SrivatsanPas encore d'évaluation

- Low Voltage Components Buy LogDocument52 pagesLow Voltage Components Buy LogSharafat AliPas encore d'évaluation

- Vanzetti Cryogenic Pumps & Technology GuideDocument0 pageVanzetti Cryogenic Pumps & Technology GuidekanchanabalajiPas encore d'évaluation

- Shimpo Able EVL BrochureDocument4 pagesShimpo Able EVL BrochureElectromatePas encore d'évaluation

- KSB WKLNDocument2 pagesKSB WKLNgangruka0% (1)

- Shimpo Able EVB BrochureDocument4 pagesShimpo Able EVB BrochureElectromatePas encore d'évaluation

- Three-Phase Multi-Voltage Squirrel Cage Motors FeaturesDocument6 pagesThree-Phase Multi-Voltage Squirrel Cage Motors Featuresmarvin17Pas encore d'évaluation

- Ss 01059 eDocument8 pagesSs 01059 eDavid LapacaPas encore d'évaluation

- pds-500 BILGE PUMP 355-010-00 10Document2 pagespds-500 BILGE PUMP 355-010-00 10Priscila CardosoPas encore d'évaluation

- Diesel Power Plant: Eco-Friendly and Energy-EfficientDocument10 pagesDiesel Power Plant: Eco-Friendly and Energy-EfficientFIDELPULIDO100% (1)

- Three-Phase Squirrel-Cage High Voltage Motors Series: Catalogue Sheet No. 26bDocument5 pagesThree-Phase Squirrel-Cage High Voltage Motors Series: Catalogue Sheet No. 26bPedro GomesPas encore d'évaluation

- Moulded Case Circuit Breakers: New DU Series 20 A To 250 ADocument8 pagesMoulded Case Circuit Breakers: New DU Series 20 A To 250 AtanushagrPas encore d'évaluation

- B3887BHF1Document4 pagesB3887BHF1xianmingPas encore d'évaluation

- Wear-resistant agitator pumps for heavy slurriesDocument4 pagesWear-resistant agitator pumps for heavy slurriesDaniel MocanuPas encore d'évaluation

- Secondary CrusherDocument1 pageSecondary CrusherVivek SakthiPas encore d'évaluation

- Alarko Fcu İngDocument16 pagesAlarko Fcu İngcalavera83Pas encore d'évaluation

- Pukor 11-049e Priced Gsec Pdvsa Gas-Mega-Project 11058a-In-12 (P)Document43 pagesPukor 11-049e Priced Gsec Pdvsa Gas-Mega-Project 11058a-In-12 (P)avaisharmaPas encore d'évaluation

- Coupling PDFDocument7 pagesCoupling PDFAnkur GaurPas encore d'évaluation

- Mep 300 Recommended Spare Parts List 2020Document15 pagesMep 300 Recommended Spare Parts List 2020voPas encore d'évaluation

- Someflu FP ECO-N ENDocument2 pagesSomeflu FP ECO-N ENAnonymous r3MoX2ZMTPas encore d'évaluation

- Ventilator - S&P - Vent (En)Document8 pagesVentilator - S&P - Vent (En)Muhidin KozicaPas encore d'évaluation

- 12 - 10 E Hoists ADocument6 pages12 - 10 E Hoists AHoang Minh HungPas encore d'évaluation

- Catalogue FSDA 60 HZDocument7 pagesCatalogue FSDA 60 HZAndres Fitria FarrelPas encore d'évaluation

- Ventilator - Mixvent-Td (En)Document23 pagesVentilator - Mixvent-Td (En)Muhidin KozicaPas encore d'évaluation

- Tieu Chuan Cac May CatDocument3 pagesTieu Chuan Cac May CatvuongPas encore d'évaluation

- 100 SeriesDocument5 pages100 Seriesfathur2107Pas encore d'évaluation

- Compressed Air Filtration-Product Catalogue 2009Document52 pagesCompressed Air Filtration-Product Catalogue 2009Jose SantosPas encore d'évaluation

- Ventilator Centrifugal de Acoperis Tip Turela CHT CVTDocument6 pagesVentilator Centrifugal de Acoperis Tip Turela CHT CVTIuliana TodoranPas encore d'évaluation

- VFD DocumentsDocument592 pagesVFD DocumentsLe Anh Dang50% (2)

- WWW - Solerpalau.ro Docs Catalogo General en 357 367 CMB CMT Fid5630 PDFDocument11 pagesWWW - Solerpalau.ro Docs Catalogo General en 357 367 CMB CMT Fid5630 PDFEsteban GalarcePas encore d'évaluation

- 1.2 Z.014-A WFDocument6 pages1.2 Z.014-A WFehab8320014413Pas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- British Commercial Computer Digest: Pergamon Computer Data SeriesD'EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesPas encore d'évaluation

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- High-Performance GM LS-Series Cylinder Head GuideD'EverandHigh-Performance GM LS-Series Cylinder Head GuideÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PD'EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PPas encore d'évaluation

- Ansi - Ari 850-2004Document12 pagesAnsi - Ari 850-2004Ahsan JavedPas encore d'évaluation

- Ansi - Ari 680-2004Document12 pagesAnsi - Ari 680-2004Ahsan JavedPas encore d'évaluation

- Ansi - Ari 620-2004Document13 pagesAnsi - Ari 620-2004Ahsan JavedPas encore d'évaluation

- Ansi - Ari 430-99Document19 pagesAnsi - Ari 430-99Ahsan JavedPas encore d'évaluation

- Ansi - Ari 530-2005Document18 pagesAnsi - Ari 530-2005Ahsan JavedPas encore d'évaluation

- Ani - Ari 365-2003Document14 pagesAni - Ari 365-2003Ahsan JavedPas encore d'évaluation

- LTG VSR-M E-Tp 450-61Document15 pagesLTG VSR-M E-Tp 450-61Ahsan JavedPas encore d'évaluation

- Series 2100Document8 pagesSeries 2100Ahsan JavedPas encore d'évaluation

- Combustion Air Centrifugal Fan VRA-eDocument18 pagesCombustion Air Centrifugal Fan VRA-eAhsan JavedPas encore d'évaluation

- MCHDocument17 pagesMCHAhsan JavedPas encore d'évaluation

- Group 20 M191en 05 2015 PDFDocument46 pagesGroup 20 M191en 05 2015 PDFDavid Solis0% (1)

- Data Sheet: Multi-Standard SC 2.1Document1 pageData Sheet: Multi-Standard SC 2.1kar_ind4u5636Pas encore d'évaluation

- Labview Pda Module Release Notes: © 2003 National Instruments Corp. All Rights Reserved. Printed in IrelandDocument14 pagesLabview Pda Module Release Notes: © 2003 National Instruments Corp. All Rights Reserved. Printed in IrelandMaynor JarquinPas encore d'évaluation

- Mid Term Essay Writing RyandikhaDocument5 pagesMid Term Essay Writing RyandikhaRyandikha OktaviandiPas encore d'évaluation

- Iva 55Document9 pagesIva 55Nasir KarwanPas encore d'évaluation

- LMEDocument25 pagesLMEAlvaro FloresPas encore d'évaluation

- Microsoft Office 2004 For Mac Resource KitDocument109 pagesMicrosoft Office 2004 For Mac Resource KitKeith FischerPas encore d'évaluation

- Low Pressure CO2 SystemsDocument4 pagesLow Pressure CO2 SystemsNarinePas encore d'évaluation

- Precios MayoDocument230 pagesPrecios Mayoeuronet_sePas encore d'évaluation

- Assignment 3Document5 pagesAssignment 3kevin0% (2)

- Multi Region DVD Codes Latest EditionDocument282 pagesMulti Region DVD Codes Latest Editionjelenjek83Pas encore d'évaluation

- Project Quality Plan TemplateDocument15 pagesProject Quality Plan TemplateRavi ValiyaPas encore d'évaluation

- Unit 2 ECommerce ApplicationsDocument63 pagesUnit 2 ECommerce ApplicationsSuresh Babu C VPas encore d'évaluation

- Rpa SheetDocument5 pagesRpa SheetGaurav PoddarPas encore d'évaluation

- Boss VE20 Owners ManualDocument20 pagesBoss VE20 Owners ManualJazzWizardPas encore d'évaluation

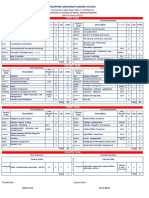

- Philippine Merchant Marine School: First YearDocument5 pagesPhilippine Merchant Marine School: First YearCris Mhar Alejandro100% (1)

- Why Bridges CollapseDocument4 pagesWhy Bridges CollapseNataliaPas encore d'évaluation

- CNS-9101 SM PDFDocument70 pagesCNS-9101 SM PDFhadiiir pal100% (1)

- Santosh KumarDocument4 pagesSantosh KumarNagaraju kPas encore d'évaluation

- DNV Os 101Document80 pagesDNV Os 101preceptiveinquirerPas encore d'évaluation

- Prince2 ThemesDocument3 pagesPrince2 Themesshiva_1912-1Pas encore d'évaluation

- Techagilecoach SampleDocument27 pagesTechagilecoach Sampletrha at hnepiPas encore d'évaluation

- CS01 - Create Material BOMDocument15 pagesCS01 - Create Material BOMshuva007100% (1)

- Manufacturing Process Capability and Specification LimitsDocument8 pagesManufacturing Process Capability and Specification LimitsMitulPas encore d'évaluation

- Model QuestionDocument3 pagesModel QuestionParthasarothi SikderPas encore d'évaluation

- Integrated SafetyDocument39 pagesIntegrated SafetyViorel CroitoruPas encore d'évaluation

- 193 Um015 - en P PDFDocument736 pages193 Um015 - en P PDFAdelson PimentelPas encore d'évaluation

- Electrical SubstationsDocument16 pagesElectrical SubstationsEngr Syed Numan ShahPas encore d'évaluation

- Newlester PhilipsDocument49 pagesNewlester PhilipsCarlos D MauroPas encore d'évaluation

- Case Study II - RoffDocument3 pagesCase Study II - RoffNikhil MaheshwariPas encore d'évaluation