Académique Documents

Professionnel Documents

Culture Documents

Specifications and Schematic of The Expected Microwave Reactor

Transféré par

Chayan BhallaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Specifications and Schematic of The Expected Microwave Reactor

Transféré par

Chayan BhallaDroits d'auteur :

Formats disponibles

A MW pyrolysis reactor setup is envisaged with two numbers of water jacketed condensers, two

liquid product collecting flasks, a pyrolysis gas scrubber and a venting point for the collection of

pyrolysis gas collection. The approimate specifications of the setup are mentioned in table

below.

The reactor is fed with a fied amount of plastic feed material into the quart! cavity of the

microwave system. "eactor internals will be required to be purged with nitrogen gas in order to

maintain an inert atmosphere, a pre#requisite for pyrolysis process. The reactor temperature will

be raised at a pre#determined controlled rate with the help of microwave heating till the

stipulated reaction temperature and will be maintained same till the product sei!es to come out of

reactor. The reaction temperature is monitored and controlled by adjusting the heating rate. The

process is conceived to operate at atmospheric pressure. Adequate care must be taken while

handing of the microwave oven chamber and all other associated internals so as to avoid direct

contact with them. The pyrolysis products leaving the reactor will pass through two water

cooled glass condensers getting collected in the bottom flasks. The incondensable gases, after the

cold traps, pass through a scrubber for collection of any aerosol, if any, before leaving the

system. These can be collected and analy!ed for detailed composition.

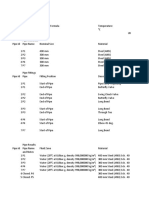

$pecifications of the proposed MW %yrolysis "eactor.

Sr. No. Parameter Specification

& Microwave distribution

system

Multiple magnetron with diffuser for

homogeneous microwave distribution

' Microwave %ower (.)*w, '()+ M,!

-. %yrolysis reactor

$ample holder

') . capacity, made of $$ -+(

) . capacity made of alumina.

(. /ondensers and material of

construction

Water cooled 0lass condensers with &.

capacity vessels for oil collection

). Metal to glass connector Teflon bellow to connect glass

condenser to gas outlet pipe

1. $afety interlock $afety interlocks are provided to

prevent microwave leakage

2. Microwave leakage .ess than ' mW3cm

'

at &' inches

distance from the MW chamber

4. Temperature measurement $pecially designed microwave compatible sensor

for temperature. Measurement. 5igital display of

temp.

6. /ontrol system. $equential control of power 783 799

for magnetrons through %./.

&+. /ooling system for magnetrons Air cooling with ehaust blower

&&. :nput power &) Amp, ((+ ;olt, - phase, )+ ,<

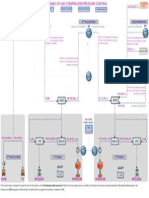

Following shown are two of typical microwave reactor systems as an example.

Typical laboratory scale Micro Wave %yrolysis "eactor $ystems

PYROLYSIS

GASES

WAVE

GUIDE

Nitroge

n

fowmet

er

Vent

gas

scrubbe

r

Liui!

con!ensin

g S"stem

Agitat

or

Nitroge

n #ent

Vent

gas

scrubbi

$icrowa

#e

c%amber

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Coker Heavy Gasoil Hydrotreater Unit (CHTU)Document1 pageCoker Heavy Gasoil Hydrotreater Unit (CHTU)Chayan BhallaPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Distance Running For BeginnersDocument14 pagesDistance Running For BeginnersChayan BhallaPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Indian Institute of Technology KharagpurDocument18 pagesIndian Institute of Technology Kharagpurkushal bosuPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Kra 2014-2015Document3 pagesKra 2014-2015Chayan BhallaPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Incinerators in DisguiseDocument48 pagesIncinerators in DisguiseChayan BhallaPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- CGHT MugcDocument1 pageCGHT MugcChayan BhallaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Case Study of OMC PLTsDocument1 pageCase Study of OMC PLTsChayan BhallaPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Recovery of Aromatics From Pyrolysis Gasoline by Conventional and Energy-Integrated Extractive DistillationDocument6 pagesRecovery of Aromatics From Pyrolysis Gasoline by Conventional and Energy-Integrated Extractive DistillationChayan BhallaPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Advanced Application of Micropasma WeldingDocument12 pagesAdvanced Application of Micropasma WeldingKonstantin MarjanuczPas encore d'évaluation

- L3 Polar and Nonpolar Covalent MoleculesDocument33 pagesL3 Polar and Nonpolar Covalent Molecules1256- FRONDA, RHOVIC D.Pas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Specifications & Properties for Motiva Base OilsDocument1 pageSpecifications & Properties for Motiva Base OilsMassimiliano VolaPas encore d'évaluation

- Laurito-STOICHIOMETRY of Fuel Combustion Etc.Document66 pagesLaurito-STOICHIOMETRY of Fuel Combustion Etc.James Nevin Go73% (11)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- REVIEWDocument14 pagesREVIEWerlifiePas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- 4 - Chemical Bonding StructuredDocument28 pages4 - Chemical Bonding StructuredHayaa KhanPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- What Are Van Der Waals ForcesDocument3 pagesWhat Are Van Der Waals Forcesapi-19918310Pas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- T187400 - Heliosmart Technical SpecificationsDocument4 pagesT187400 - Heliosmart Technical Specificationsrudy repellinPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Why Is The Ocean SaltyDocument2 pagesWhy Is The Ocean SaltyintermazePas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Understanding Gas Laws Through Hands-On ActivitiesDocument5 pagesUnderstanding Gas Laws Through Hands-On ActivitiesKirsten Tiffany TriasPas encore d'évaluation

- 7G Particle Theory: 3 0 Stage DDocument3 pages7G Particle Theory: 3 0 Stage DBen PassmorePas encore d'évaluation

- Axial Magnetic Field Effect On Taylor-Couette Flow: S. A, M. I, M. Moderes and A. GhezalDocument10 pagesAxial Magnetic Field Effect On Taylor-Couette Flow: S. A, M. I, M. Moderes and A. GhezalGhezal AbderrahmanePas encore d'évaluation

- Course Work 2020 Multiphase ThermodynamicsDocument2 pagesCourse Work 2020 Multiphase ThermodynamicsYalchin MammadliPas encore d'évaluation

- (Supercritical Unit) Date: 02.05.2011: 1 X 660 MW TPP For Visa Power Limited at RaigarhDocument4 pages(Supercritical Unit) Date: 02.05.2011: 1 X 660 MW TPP For Visa Power Limited at RaigarhirfanPas encore d'évaluation

- EK 1aDocument16 pagesEK 1azüheyir nuralPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Design and Performance Evaluation of An Ice Block Making MachineDocument9 pagesDesign and Performance Evaluation of An Ice Block Making Machinebasel abduPas encore d'évaluation

- Equation of State of Ideal GasesDocument7 pagesEquation of State of Ideal GasesJose GalvanPas encore d'évaluation

- Cryogenics EngineeringDocument174 pagesCryogenics EngineeringGomathi Sankar100% (1)

- LNG R&D For The Liquefaction and Regasification Processes: 1.theme DescriptionDocument9 pagesLNG R&D For The Liquefaction and Regasification Processes: 1.theme DescriptionVikas PatelPas encore d'évaluation

- Design Considerations For Dry ScrubbersDocument5 pagesDesign Considerations For Dry ScrubbersAntonio LebrunPas encore d'évaluation

- States of MatterDocument8 pagesStates of MatterSumit PatilPas encore d'évaluation

- White1971 - Vapor Dominated Hydrotermal Systems Compared With Hot-Water SystemDocument23 pagesWhite1971 - Vapor Dominated Hydrotermal Systems Compared With Hot-Water SystemNino PumaPas encore d'évaluation

- Sakhalin LNG-Train GenDocument54 pagesSakhalin LNG-Train GenRobert WatersPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Q4 BoylesLawDocument34 pagesQ4 BoylesLawnomen helloomPas encore d'évaluation

- H2o CycleDocument2 pagesH2o CycleHeather ClarchickPas encore d'évaluation

- Calculation of Dew Point of Flue Gas 4x135 MW Jindal, AngulDocument2 pagesCalculation of Dew Point of Flue Gas 4x135 MW Jindal, AngulAshitava SenPas encore d'évaluation

- Vapor-Liquid Miscibility: Equilibria EthylDocument4 pagesVapor-Liquid Miscibility: Equilibria EthylRafael HenriquePas encore d'évaluation

- Refrigeration Cycles ExplainedDocument8 pagesRefrigeration Cycles ExplainedAwais Asghar KhanPas encore d'évaluation

- Molecular Orbital TheoryDocument45 pagesMolecular Orbital TheoryKulsumPas encore d'évaluation

- Interfacial Phenomena in Pharmaceutical FormulationDocument21 pagesInterfacial Phenomena in Pharmaceutical FormulationNickson DrabePas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)