Académique Documents

Professionnel Documents

Culture Documents

Ardb2 Manual Rev1 2 Rev

Transféré par

mk116d0 évaluation0% ont trouvé ce document utile (0 vote)

61 vues11 pagesPatented 2 nd Generation Auto Recharging Dehydrating Breather is designed to remove moisture from the air of load tap changer tanks, conservators, sealed tanks or control cabinets. Heaters controlled by an adjustable timer and humidity sensor provide automatic regeneration of the silica gel desiccant eliminating the need for manual intervention. Logic controls ensure that regeneration occurs only during transformer exhale, effectively "learning" the best time of day to run.

Description originale:

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentPatented 2 nd Generation Auto Recharging Dehydrating Breather is designed to remove moisture from the air of load tap changer tanks, conservators, sealed tanks or control cabinets. Heaters controlled by an adjustable timer and humidity sensor provide automatic regeneration of the silica gel desiccant eliminating the need for manual intervention. Logic controls ensure that regeneration occurs only during transformer exhale, effectively "learning" the best time of day to run.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

61 vues11 pagesArdb2 Manual Rev1 2 Rev

Transféré par

mk116dPatented 2 nd Generation Auto Recharging Dehydrating Breather is designed to remove moisture from the air of load tap changer tanks, conservators, sealed tanks or control cabinets. Heaters controlled by an adjustable timer and humidity sensor provide automatic regeneration of the silica gel desiccant eliminating the need for manual intervention. Logic controls ensure that regeneration occurs only during transformer exhale, effectively "learning" the best time of day to run.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 11

2

nd

Generation 2 Generation

Auto Recharging Dehydrating Breather Manual

GENERAL DESCRIPTION

The second generation High Voltage Supply

Auto Regenerating Dehydrating Breather Systems

(ARDB2) have been designed to remove moisture from the air of load tap changer tanks,

conservators, sealed tanks or control cabinets. Heaters controlled by an adjustable timer and

humidity sensor provide automatic recharging of the silica gel desiccant eliminating the need for humidity sensor provide automatic recharging of the silica gel desiccant, eliminating the need for

manual intervention. Logic controls ensure that regeneration occurs only during transformer

exhale, effectively learning the best time of day to run. Systems can be configured for various

tank (air volume) sizes:

Small Breather Designed for 8,000 gallons (30,283 liters) or less

Large Breather Designed for 18,000 gallons (68,137 liters) or less

Any combination of breathers can be configured for larger volumes. Each breather includes the

ARDB2-Manual

Rev. 1.2, 12/29/2009

1 of 11

The patented 2

nd

Generation Auto Recharging Dehydrating Breather is manufactured and

distributed by High Voltage Supply, a division of Waukesha Electric Systems, Inc.

U.S. Patent Nos. 5,902,381; 6,797,037; 7,285,150 and 7,332,015.

logic circuits that will operate the breather independently.

2

nd

Generation 2 Generation

Auto Recharging Dehydrating Breather Manual

SYSTEM PRINCIPLE OF OPERATION

See Figure 1. During normal operation, air enters the breather through slots in the upper molding

GENERAL DESCRIPTION (continued)

g g p g pp g

and passes through the desiccant to the center of the assembly. The center tube contains several

holes along the entire length, forcing the airflow to disperse through the maximum surface area of

desiccant. Airflow then travels through the center tube, along a horizontal path to the isolation

solenoid and humidity sensor, and eventually through the top port.

During regeneration, temperature regulating heater elements within the center tube are energized

to heat the desiccant to a specified temperature. Any moisture present in the desiccant is driven

outward to the polycarbonate tube where it condensates and runs to the bottom of the breather p y

assembly. A ball float releases the water to atmosphere and then reseals. Also during

regeneration, the solenoid valve at the top of the breather assembly directs exhaled air from the

tank to a side port open to atmosphere. If the tank attempts to inhale during regeneration, logic

controls suspend regeneration mode and direct the tank to breathe through the desiccant.

CONSTRUCTION

ARDB2 systems are shipped as a single integrated assembly along with accessories necessary to

install. Both sizes of breathers are very similar and are constructed with a molded integrated top

and controls housing, a lower molded housing, integrated heating elements, heat conductive fins,

screen, condenser media and filter vent system. Watertight over-molded power and customer

monitoring harnesses eliminate the need for electrical conduit directly tied to breather.

The housings are molded from a high strength, high temperature, UV-stabilized plastic. The outer

polycarbonate tube is high strength, UV-stabilized and transparent to allow easy visual indication of

the desiccant condition. Sealed lenses on the control cover protect LED lamps that provide easy

visual indication of breather status.

INTELLIGENT CONTROLS

ARDB2 systems feature an integrated PCB microcontroller that constantly monitors the condition

of airflow through the breather. User adjustable, time-based controls regenerate the desiccant

regardless of condition. Humidity sensing capability automatically overrides and regenerates the

desiccant if needed between the set timer frequency. Constant monitoring of airflow direction

ll th l i i it t t ti ll dj t ti t l t l th b t ti f d t allows the logic circuit to automatically adjust timer controls to learn the best time of day to

regenerate.

Internal diagnostics constantly monitor, evaluate and adjust the performance of the components to

ensure breather operation will always provide optimum protection for the airspace. All controls and

components default to a standard desiccant breather in the event of power loss.

ARDB2-Manual

Rev. 1.2, 12/29/2009

2 of 11

The patented 2

nd

Generation Auto Recharging Dehydrating Breather is manufactured and

distributed by High Voltage Supply, a division of Waukesha Electric Systems, Inc.

U.S. Patent Nos. 5,902,381; 6,797,037; 7,285,150 and 7,332,015.

2

nd

Generation 2 Generation

Auto Recharging Dehydrating Breather Manual

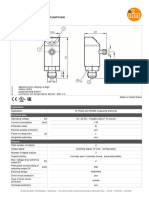

Figure 1 ARDB2 Functional Operation and Component Identification

ARDB2-Manual

Rev. 1.2, 12/29/2009

3 of 11

The patented 2

nd

Generation Auto Recharging Dehydrating Breather is manufactured and

distributed by High Voltage Supply, a division of Waukesha Electric Systems, Inc.

U.S. Patent Nos. 5,902,381; 6,797,037; 7,285,150 and 7,332,015.

2

nd

Generation 2 Generation

Auto Recharging Dehydrating Breather Manual

SAFETY INFORMATION

Correct use of this equipment is important for your personal safety and for trouble-free functioning

of the unit. Incorrect control or attempts to perform adjustments could cause damage or lead to

i t ti B t d d d t d ll i t ti b f tt ti t t incorrect operation. Be sure to read and understand all instructions before attempting to operate

the unit. The unit is designed to produce dry air. Do not operate the unit beyond its limits (see

specifications on page 5). In addition to the warnings and cautions in this manual, use the following

safety guidelines for safe operation of the unit.:

WARNING - This unit is an electrical appliance. Make sure that the main power supply is

disconnected before you perform installation, maintenance or repair work.

WARNING - If you must work on the equipment with the main power supply on, be aware of

electrical hazards.

WARNING - The heaters and globe become very hot when operating. Be careful when you touch

the system if the amber light is on (heater energized).

CAUTION - Do not block the ventilation inlets and outlets, this could cause damage to the unit.

WARNING - In order to prevent injury or damage caused by the sudden release of compressed

air, make sure that the unit and connected systems are fully de-pressurized before you start

uncoupling parts of the system.

IMPORTANT: The following words and symbols appear throughout this manual and designate

important safety instructions:

DANGER - Indicates information important to the proper operation of the equipment. Failure to

observe will result in damage to the equipment and/or severe bodily injury or death.

WARNING - Indicates information important to the proper operation of the equipment. Failure to

observe may result in damage to the equipment and/or severe bodily injury or death.

CAUTION - Indicates information important to the proper operation of the equipment Failure to CAUTION Indicates information important to the proper operation of the equipment. Failure to

observe may result in damage to the equipment.

Read all safety instructions to avoid personal injury or death and to avoid damage to the unit or

property.

ARDB2-Manual

Rev. 1.2, 12/29/2009

4 of 11

The patented 2

nd

Generation Auto Recharging Dehydrating Breather is manufactured and

distributed by High Voltage Supply, a division of Waukesha Electric Systems, Inc.

U.S. Patent Nos. 5,902,381; 6,797,037; 7,285,150 and 7,332,015.

2

nd

Generation 2 Generation

Auto Recharging Dehydrating Breather Manual

Components Electrical

100 240VAC

SPECIFICATIONS

Airflow Solenoid 12VDC non-latching Voltage/Frequency

100-240VAC,

50/60Hz

Humidity Sensor RH 2% to 100%

Power

Consumption*

0 5.5A

Vacuum Switch

Normally open,

0.1 psi vacuum to close

Potential free alarm Normally open, 1A

Indicator Lights LED Inrush Damping

Staged heating 30

seconds apart

Timer Control Dip switch on PCB Ambient Conditions

Operation Temperature Range 40 to 40C

Time Base

5 10 20 40 d tti Ai lit

Normally clean Time Base

Settings

5, 10, 20, 40 day settings Air quality

Normally clean

ambient air

Humidity Sense

Trigger

35% required to activate Relative humidity >90%

Heating

10 seconds staging,

3 hour full power

10 minutes before solenoid

Cooling Time

10 minutes before solenoid

deactivation

Environment

Vacuum

Detection

10 seconds continuous

required

Location

Indoor/Outdoors,

wall-mounted

Failure Detection

Heater, vacuum switch,

humidity sensor * Typical operation is non-regenerating: 20mA y

Diagnostics

Mode

Hours become seconds

Typical operation is non regenerating: 20mA

SmallBreather 5.5Ainrush,1to1.5Anom

LargeBreather 5.5Ainrush,2to3Anom

Table 1 Auto Recharging Dehydrating Breather Specifications

ARDB2-Manual

Rev. 1.2, 12/29/2009

5 of 11

The patented 2

nd

Generation Auto Recharging Dehydrating Breather is manufactured and

distributed by High Voltage Supply, a division of Waukesha Electric Systems, Inc.

U.S. Patent Nos. 5,902,381; 6,797,037; 7,285,150 and 7,332,015.

2

nd

Generation 2 Generation

Auto Recharging Dehydrating Breather Manual

INSTALLATION

CAUTION - The unit must be mounted in an upright position. Do not mount unit on its side

or back.

CAUTION - Do not block the ventilation inlets and outlets as this could cause damage to the

unit and provide inadequate protection for the airspace.

The unit must be mounted level and upright.

The unit and piping must be installed so that oil cannot enter the breather.

Install unit away from heat sources.

Do not install in an enclosed cabinet; proper ventilation is required. p p q

Figure 2 ARDB2 mounting dimensions

1. Measure and mark the mounting holes or studs as shown by the center-to-center distances in

figure 2 above.

2. Place the unit into position and install with 1/4 hardware (not included).

3. Install included hose barb into top of breather casting (see figure 3 on page 7). Use of thread

sealant is recommended

ARDB2-Manual

Rev. 1.2, 12/29/2009

6 of 11

The patented 2

nd

Generation Auto Recharging Dehydrating Breather is manufactured and

distributed by High Voltage Supply, a division of Waukesha Electric Systems, Inc.

U.S. Patent Nos. 5,902,381; 6,797,037; 7,285,150 and 7,332,015.

sealant is recommended.

4. Install included hose barb to tank piping or port. Use of thread sealant is recommended.

INSTALLATION INSTRUCTIONS CONTINUED ON NEXT PAGE

2

nd

Generation 2 Generation

Auto Recharging Dehydrating Breather Manual

CAUTION - The connection to tank port is critical to ensure that no oil can enter the breather.

INSTALLATION (continued)

HOSE BARB

SIDE PORT

FILTER

CAUTION AND

TEMPERATURE

LABELS (PLACE

FOR OPTIMUM

VISIBILITY)

WATER DRAIN

FILTER

Figure 3 ARDB2 fittings and label installation

5. Install included hose between hose barbs.

6. Remove top cap and pour included indicating silica gel into breather. Small breather requires

2.2lbs/1kg of desiccant and large breather requires 4.4lbs/2kg of desiccant. Replace cap and

ensure it is locked in place.

7. Install side port filters and water drain filter (see figure 3 above).

8. Install temperature and caution labels. Locate these labels on the globe in the area best visible

to service personnel (dependent upon the mounting location).

9. Proceed with ELECTRICAL CONNECTIONS on next page.

ARDB2-Manual

Rev. 1.2, 12/29/2009

7 of 11

The patented 2

nd

Generation Auto Recharging Dehydrating Breather is manufactured and

distributed by High Voltage Supply, a division of Waukesha Electric Systems, Inc.

U.S. Patent Nos. 5,902,381; 6,797,037; 7,285,150 and 7,332,015.

2

nd

Generation 2 Generation

Auto Recharging Dehydrating Breather Manual

ELECTRICAL CONNECTIONS

WARNING - Electrical shock hazard. Failure to follow these instructions could result in

serious injury or death.

Electrical ground is required on this appliance.

Do not use an extension cord with this appliance.

The unit should be grounded according to local electrical codes to prevent the possibility

of electrical shock. It requires a grounded receptacle with separate electrical lines,

protected by fuses or circuit breaker of the proper rating.

Check with a qualified electrician if you are in doubt as to whether the appliance is

properly grounded.

Figure 4 Alarm and Power Connections

1. Locate the three wire over-molded harness assembly. Terminate the white and black flying

leads to the power source terminals and the green wire to the ground terminal.

2. Plug the three wire harness into the three wire receptacle on the left side of the breather as

shown in figure 2 on page 6 shown in figure 2 on page 6.

3. Alarm connections are not required for ARDB operation. If used, proceed to step 4 below. If not,

proceed to STARTUP on next page.

4. Locate the five wire over-molded harness assembly. Terminate the required alarm connections

as shown in figure 4 above.

5. Plug the five wire harness into the five pin receptacle on the right side of the breather as shown

in figure 2 on page 6.

6. Proceed to STARTUP on next page.

ARDB2-Manual

Rev. 1.2, 12/29/2009

8 of 11

The patented 2

nd

Generation Auto Recharging Dehydrating Breather is manufactured and

distributed by High Voltage Supply, a division of Waukesha Electric Systems, Inc.

U.S. Patent Nos. 5,902,381; 6,797,037; 7,285,150 and 7,332,015.

2

nd

Generation 2 Generation

Auto Recharging Dehydrating Breather Manual

IMPORTANT: Make sure the unit has been properly installed according to the Installation

Instructions Included in this manual.

STARTUP

CAUTION When the unit becomes energized, the controls will proceed with a regeneration

cycle. The unit will quickly become hot to the touch.

1. Verify all electrical connections are securely fastened and the breather is securely mounted in

an upright position.

2. Energize breather.

3. Verify that green LED is lit. This may immediately turn to amber signifying a heating cycle has

been initiated (assuming transformer is not inhaling).

4. Verify heating occurs within 10 minutes. The globe should be warm to the touch.

5. The unit is ready for operation.

6. Proceed to ALARMS AND TROUBLESHOOTING and MAINTENANCE sections on following

pages.

REGENERATION FREQUENCY

The ARDB2 system is factory set for optimum performance and adjustments are limited to the

preferred timer-based regeneration frequency. The timer-based regeneration cycle is factory set

for a frequency of 10 days, however, the system can be set for 5, 10, 20 or 40 day cycles.

TO CHANGE THE REGENERATION FREQUENCY

1. Ensure that the unit is de-energized from the power source.

2. Remove the four screws from the front access cover and lay off to the side. Be careful with the

wires connecting the LED PCB.

3. Locate the dip switch control and switch all four dip switches to the OFF position.

4. Switch ONLY ONE of the four dip switches to the on position for the desired frequency:

a. Switch 1 : 5 Day Frequency

b. Switch 2 : 10 Day Frequency

c. Switch 3 : 20 Day Frequency

d. Switch 4 : 40 Day Frequency

5. Install front cover and tighten the four screws.

CAUTION - Only one switch can be in the ON position or breather malfunction can occur.

ARDB2-Manual

Rev. 1.2, 12/29/2009

9 of 11

The patented 2

nd

Generation Auto Recharging Dehydrating Breather is manufactured and

distributed by High Voltage Supply, a division of Waukesha Electric Systems, Inc.

U.S. Patent Nos. 5,902,381; 6,797,037; 7,285,150 and 7,332,015.

2

nd

Generation 2 Generation

Auto Recharging Dehydrating Breather Manual

ALARMS AND TROUBLESHOOTING

The ARDB2 system features LED indicator alarm contacts that can be used to monitor the

condition of the system externally. The following table lists each alarm, corresponding condition

LED Indicator Condition

Feedback

Condition

Action

Green

Breather is in normal

standby mode and tank

Local Indication None

and recommended action for the system:

Green

is breathing normally

thru desiccant

Local Indication None

Amber Regeneration Mode

Pins 5 and 6 closed

(1A @ 125VAC,

2A @ 30VDC)

None

Blinking Amber Humidity Sensor Error Local Indication

Decrease breather time

based frequency;

if problem persists

g y

if problem persists,

contact factory

Blinking Red Vacuum Switch Failure Local Indication Contact Factory

Red Heater Element Failure Local Indication Contact Factory

T bl 2 Al Table 2 Alarms

GEL COLOR TABLE

Date of Manufacture

OR Gel Replacement Dry (Unsaturated) Color Wet (Saturated) Color

12/2005 to 2/2010 YELLOW GREEN

After 2/2010 ORANGE CLEAR

NOTE: If the gel has been replaced, the gel color should correspond to the dates above as

applied to the date of gel replacement rather than the date of breather manufacture.

ARDB2-Manual

Rev. 1.2, 12/29/2009

10 of 11

The patented 2

nd

Generation Auto Recharging Dehydrating Breather is manufactured and

distributed by High Voltage Supply, a division of Waukesha Electric Systems, Inc.

U.S. Patent Nos. 5,902,381; 6,797,037; 7,285,150 and 7,332,015.

Table 3 Gel Color

2

nd

Generation 2 Generation

Auto Recharging Dehydrating Breather Manual

INSPECTIONS / MAINTENANCE

The ARDB2 system is a self-monitoring system that requires minimal maintenance. Periodic

inspection is required to ensure that the system is operating at optimum efficiency.

ANNUAL INSPECTION

1. Remove bottom vent drain and inspect for restrictions such as dust or other contaminants.

2. Clean or replace bottom vent drain, as necessary (HVS P/N 1030-385).

3. Remove side vent and inspect for restrictions such as dust or other contaminants.

4. Clean or replace side vent, as necessary (HVS P/N 1030-1291).

5. Visually inspect desiccant for contamination, particularly oil which will show up as a dark or

blackened desiccant color. The desiccant should be an orange/yellow color (see Table 3 on

page 10 to view relevant gel color for your unit based on manufacture or desiccant change page 10 to view relevant gel color for your unit based on manufacture or desiccant change

date). If clear/green, the desiccant is saturated and the timer regeneration frequency should be

decreased (see STARTUP section on page 9).

6. If desiccant is oil contaminated, desiccant must be replaced (HVS P/N 1030-1288).

NOTE: The small breather uses 1 bag of P/N 1030-1288, and the large breather uses two bags

of P/N 1030-1288.

7. Clean breather globe if necessary.

CAUTION - Only mild soap and water should be used to clean the globe. Solvents must not

be used for any reason as they will degrade the performance of the polycarbonate material.

Use of solvents on the unit will immediately void warranty.

EVERY FIVE YEARS INSPECTION

1. Replace bottom and side vents as described in annual inspection section above.

2. Remove bottom vent and inspect ball float operation. Use the rubber end of a pencil to ensure

ball moves freely from sealing surface. This ensures that condensed moisture is properly

draining from the assembly.

3. Ensure all connections are secure and fill cap is properly tightened on assembly.

4. Visually inspect desiccant for contamination, particularly oil which will show up as a dark or

blackened desiccant color. The desiccant should be an orange/yellow color (see Table 3 on

page 10 to view relevant gel color for your unit based on manufacture or desiccant change

date). If clear/green, the desiccant is saturated and the timer regeneration frequency should be

decreased (see STARTUP section on page 9) decreased (see STARTUP section on page 9).

5. If desiccant is oil contaminated, desiccant must be replaced (HVS P/N 1030-1288).

NOTE: The small breather uses one bag of P/N 1030-1288, and the large breather uses two

bags of P/N 1030-1288.

REPLACEMENT PARTS AND SERVICE

Please contact High Voltage Supply 800 338 5526 for parts and service

ARDB2-Manual

Rev. 1.2, 12/29/2009

11 of 11

The patented 2

nd

Generation Auto Recharging Dehydrating Breather is manufactured and

distributed by High Voltage Supply, a division of Waukesha Electric Systems, Inc.

U.S. Patent Nos. 5,902,381; 6,797,037; 7,285,150 and 7,332,015.

Please contact High Voltage Supply 800-338-5526 for parts and service.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Toyota Hilux 1KD y 2KDDocument11 pagesToyota Hilux 1KD y 2KDOtto BrignolePas encore d'évaluation

- Service FORMS FOR GENERATORSDocument78 pagesService FORMS FOR GENERATORSJose MoralesPas encore d'évaluation

- DTSC-200A Product TrainingDocument45 pagesDTSC-200A Product TrainingEliyanto E BudiartoPas encore d'évaluation

- Minisonic Assembly HeadDocument70 pagesMinisonic Assembly Headcesar cabezas rojasPas encore d'évaluation

- Motor Hidrostatico SauerDocument80 pagesMotor Hidrostatico SauerAlexis Peña100% (1)

- PDS Nytro Libra EN PDFDocument2 pagesPDS Nytro Libra EN PDFmk116dPas encore d'évaluation

- Thermal Aging Collection PDFDocument40 pagesThermal Aging Collection PDFmk116dPas encore d'évaluation

- Aislador Epoxi Catalogo 2011 ENGDocument56 pagesAislador Epoxi Catalogo 2011 ENGmk116dPas encore d'évaluation

- HTTP WWW - SpppumpsDocument103 pagesHTTP WWW - Spppumpsmk116dPas encore d'évaluation

- ABB Manual Motor Starters MS116, MS325 and MS4xx PDFDocument35 pagesABB Manual Motor Starters MS116, MS325 and MS4xx PDFgreyllom9791Pas encore d'évaluation

- Lifting Equipment 04 11 2023Document22 pagesLifting Equipment 04 11 2023rome reyesPas encore d'évaluation

- Unor3smbus 2.inoDocument6 pagesUnor3smbus 2.inoM. Randy AswinPas encore d'évaluation

- Holtek Semicon HT7750SA C192571Document17 pagesHoltek Semicon HT7750SA C192571a637888Pas encore d'évaluation

- Supply and Installation of Solar PV and BESS For 7 Government Institutions in Telefomin District HospitalDocument20 pagesSupply and Installation of Solar PV and BESS For 7 Government Institutions in Telefomin District HospitalDe Guzman MappingPas encore d'évaluation

- Aerial RopewaysDocument43 pagesAerial RopewaysAnshul yadavPas encore d'évaluation

- PCBs in VFDDocument11 pagesPCBs in VFDAdrián Darío Nieves LeyvaPas encore d'évaluation

- User ManualDocument1 pageUser ManualAnil ChowdaryPas encore d'évaluation

- F200aet 2006Document88 pagesF200aet 2006Ray Cepeda MenaPas encore d'évaluation

- Terex - Luminarias Repuestos PDFDocument62 pagesTerex - Luminarias Repuestos PDFIliana Georgina RamirezPas encore d'évaluation

- G. Pulla Reddy Engineering College (Autonomous) : Kurnool Department of Electrical & Electronics Engineering Power Electronics (PEP) Laboratory (Scheme-2013)Document87 pagesG. Pulla Reddy Engineering College (Autonomous) : Kurnool Department of Electrical & Electronics Engineering Power Electronics (PEP) Laboratory (Scheme-2013)Sreenath SreenathPas encore d'évaluation

- GTU MechatronicsDocument2 pagesGTU MechatronicspmagrawalPas encore d'évaluation

- Flexi Edge Bts SystemDocument25 pagesFlexi Edge Bts SystemMuty Koma67% (3)

- Belt I.D. Chart 2012 SMDocument1 pageBelt I.D. Chart 2012 SMManuel Eduardo QuezadaPas encore d'évaluation

- AeromechDocument31 pagesAeromechMohd Kamaruddin LiauPas encore d'évaluation

- Pre-Insertion Resistor and Grading Capacitor in Multi Break Circuit Breaker - Electrical ConceptsDocument15 pagesPre-Insertion Resistor and Grading Capacitor in Multi Break Circuit Breaker - Electrical ConceptsSheraz KhanPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document9 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Elie Abisaad100% (1)

- AP9MK3 Rev-H ManualDocument202 pagesAP9MK3 Rev-H ManualRyan PacamarraPas encore d'évaluation

- Lesson 8: Cpus Used in Personal ComputersDocument14 pagesLesson 8: Cpus Used in Personal ComputersahsanloverboyPas encore d'évaluation

- Hytera tc610 User GuideDocument41 pagesHytera tc610 User GuideAriel BecerraPas encore d'évaluation

- 520AOD01 CS enDocument13 pages520AOD01 CS enBhageerathi SahuPas encore d'évaluation

- Cm200dy-24nf eDocument4 pagesCm200dy-24nf eWesamPas encore d'évaluation

- Digital Motor Protection RelayDocument16 pagesDigital Motor Protection RelaySukant Kumar MohantyPas encore d'évaluation

- TMB Switchgear ProductsDocument3 pagesTMB Switchgear Productskazem shakeriPas encore d'évaluation

- BMS System PresentationDocument17 pagesBMS System PresentationBishwajeet GhoshPas encore d'évaluation

- TR7432 00 - en GBDocument3 pagesTR7432 00 - en GBThiago MouttinhoPas encore d'évaluation