Académique Documents

Professionnel Documents

Culture Documents

EP729 Service Manual Ver.2.0

Transféré par

laitangCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

EP729 Service Manual Ver.2.0

Transféré par

laitangDroits d'auteur :

Formats disponibles

Prepared by SI :

________________________________________

Prepared by TSE :

________________________________________

Checked by :

________________________________________

Approved by :

________________________________________

Model Name : EP729

SERVICE MANUAL

Date Revise Version Description

2005/6/14 V1.0 Initial Issue

Copyright June, 2005 . All Rights Reserved

Document #82F-G04-01A . P/N: 36.82F01.001

2006/9/8 V2.0 Revise Chapter 4

EP729 i

Preface

This manual is applied to EP729 0.7 DMD XGA digital projection system. Its the mode of single Panel,

156 Watt Compact P-VIP Lamp and 1024(H) x 768(V) resolution. The manual gives you a brief descrip-

tion of basic technical information to help in service and maintaining the product.

Your customers will appreciate the quick response time when you immediately identify problems that occur

with our products. We expect your customers will appreciate the service that you offer them.

This manual is for technicians and people who have an electronic background. Send the product back to

the distributor for repairing and do not attempt to do anything that is complex or is not mentioned in the

troubleshooting.

NOTICE :

The information found in this manual is subject to change without prior notice. Any subsequent changes

made to the data herein will be incorporated in further edition.

Copyright 2005, June

All Rights Reserved

Manual Version 1.0

Table of Contents

Chapter 1 Introduction 1-1

Product Highlight 1-1

Compatible Modes 1-5

Chapter 2 Disassembly of Procedure 2-1

Equipment Needed 2-1

Remove Lamp and Lamp Cover 2-2

Remove Keypad Board and Top Cover 2-3

Remove Main Board and Fan Module 2-5

Remove DC Power Supply 2-7

Remove Ballast Power Supply 2-8

Remove Color Wheel, Engine and Thermal Sensor Board 2-9

Chapter 3 Troubleshooting 3-1

Equipment Needed 3-1

LED lighting message 3-1

LED Message Indication 3-2

Main Procedure 3-3

Chapter 4 Function Test and Alignment Procedure 4-1

Test Equipment 4-1

Test Condition 4-1

Test Display Modes and Pattern 4-2

Inspection Procedure 4-5

Calibration 4-6

Guide to Entering Engnineering Mode and Factory Reset 4-7

Chapter 5 Firmware Upgrade Procedure 5-1

Equipment Needed 5-1

Hardware Setup Procedure 5-1

Firmware Progarm Installation Procedure 5-2

Firmware Upgrade Procedure 5-9

EP729

Chapter 6 DDC Key-in Procedure 6-1

Equipment Needed 6-1

Setup Procedure 6-2

DDC Key-in Procedure 6-3

Appendix A 7-1

Exploded Overview 7-1

Appendix B 7-18

PCBA Code Definition 7-18

Appendix C 7-19

Serial Number System Definition 7-19

Readers Response 7-20

EP729 ii

1-1 EP729

Chapter 1

Introduction

1-1 Product Highlights

This manual is applied to 0.7 DMD XGA Micro Projector with digital imaging functionality based on Digital

Micromirror Device (DMD) technology. Its the mode of single panel, 156 watt long life lamp.

The manual gives you a brief description of basic technical information to help in service and main taining

the product.

Your customers will appreciate the quick response time when you immediately identify problems that occur

with our products. We expect your customers will appreciate the service that you offer them.

This manual is for technicians and people who have an electronic background. Send the product back to the

distributor for repairing and do not attempt to do anything that is complex or is not mentioned in the

troubleshooting.

- One panel 0.7" XGA/12o DDR DMD projection system

- 156 - Watt Compact P-VIP Lamp (user replaceable)

- High efficiency cooling system with system acoustic noise level typical 38dB(A)

- Light weight Approx. 2.2 ~ 2.3 lbs.

- Manual focus projection, 1:1.15 mechanical zoom lens

- True 1024 x 768 resolution, 16.7M True colors

- Build-in full screen NTSC/PAL/SECAM video capability with S-video / Composite /

component and HDTV terminals

- SXGA/XGA/SVGA/VGA/MAC compatibility with one D-Sub 15 pin VGA connector

input terminal

- Auto image re-sizing to 1024 x 768 full screen

- Auto detection of computer signal input

- Auto Image synchronization (Auto-tracking /frequency /position adjustment)

- Powerful enlarge and freeze function

- Automatically saves adjustments for future use

- IR remote control function

- Adaptive voltage control fan speed

- Digital Vertical Keystone Correction

1-2 EP729

Dimensions (WxHxD) - 62.5 mm x 152.5 mm x 200 mm

Weight - Approx. 2.2 ~ 2.3 lbs.

Cooling System - Advanced air flow

- Two fans with low system acoustic noise level

- Temperature control circuits with adaptive voltage control fan speed

- Max touch temperature follows UL 60950 regulation

Lamp housing - Lamp could be changed by customer, but should follow the user manual

instruction

- Replaceable Lamp should be provided by Coretronic or its authorized

agencies

Tilt Angle - 8 degrees with elevator mechanism

Keystone correction - 8 degrees

Lamp Door Protection - Lamp power supply shut off automatically when door opens

Number of active dots - 1024(H) x 768(V)

Power Supply - Input AC 100240V~ , 2A, 50 - 60 Hz with PFC

- 156 Watt lamp and ballast

- Variance FAN speed control (Depend on temperature variant)

Power consumption -195W +/- 10% @ 110V ac/60 HZ.

Terminals - Computer Input (VGA)

- Composite Video Input (x 1)

- S Video Input (Standard x 1)

- USB Port

1-3 EP729

Input signal spec. - Hsync Frequency 31.5~80 kHz

- Vsync Frequency 56-85 Hz

- Video Signal RGB (PC)

Analog RGB 0.7Vp-p, 75 ohm

Analog RGB 1Vp-p, 75 ohm,

- Sync. Signal

Separate Sync : (H V) TTL level (bi-polarity)

Composite Sync: TTL level (bi-polarity)

Sync-on-green: negative sync. 0.3Vp-p

- Video

Composite video 1Vp-p, 75 ohm

S-video Luminance 0.714Vp-p, 75 ohm

Chrominance 0.286Vp-p, 75 ohm

Projection lens - F# 2.7 ~2.88, f = 28.43 ~ 32.73 mm. 1.15X Mechanical Zoom Lens.

Projection Image Size - Adjustable from 31.7" to 246" (Diagonal) (For Reference Only)

Throw Distance - 1.5m - 10m (mechanical travel)

Throw Ratio - 2.0 ~ 2.30

Brightness (110 degree white segment color wheel)

- 1300 (ANSI Lumens) (Typical)

- 1000 (ANSI Lumens) Minimum

Contrast - 1800:1 Typical 1300:1 Minimum (Full On/Full Off)

Uniformity - 85 % Typical , 70% Minimum (Japan standard)

Temperature - Operating: 5 -- 35

o

C

- Storage: -20 -- 60

o

C

Maximum Humidity - Operating: 5 -- 35

o

C, 80%RH (Max.), non-condensing

- Storage: -20 -- 60

o

C, 80%RH (Max.), non-condensing

Acoustic noise level - Normal mode 38 dB(A) (+/-2

o

C)

- Dim mode 35 dB(A) (+/-2

o

C)

Follow ISO-7779 regulation sound pressure level A weighting measurement

1-4 EP729

Lamp life - 3000 hours typical, morethan 50% of lamp population have light output >50%

of min. initial lumen after the specified lamp life time.

Altitude - Operating 0~2,500 ft 5

o

C~35

o

C

2,500~5,000 ft 5

o

C~30

o

C

5,000~10,000 ft 5

o

C~25

o

C

- Storage 40,000 ft

MTBF - Operating more than 12,000 hours ( 90% Confidence Level )

1-5 EP729

1-2 Compatible Modes

Analog

EP729 2-1

Chapter 2

Disassembly Procedure

The Front Side The Rear Side

Equipment Needed

Appearance

Long Nose Nipper (Left)

Angle Cutting Nipper (Right)

Hex Sleeves 5mm (Top)

Screw Bit (-) 101

Screw Bit (+) : 107, 102, 101

(from top to bottom)

EP729 2-2

2-1 Remove Lamp and Lamp Cover

Lamp

Lamp Cover

Step2

Step1

*Notice:

If you replace Lamp Cover, you must attach Lamp Cover SI foam EP729 "Green" on Lamp Cover manually.

Step1: Turn unit facedown, unscrew two screws to remove Lamp Cover.

Step2: Unscrew two screws to pull out Lamp Module.

EP729 2-3

2-2 Remove Keypad Board and Top Cover

Step1: Unscrew 5 screws.

Step2: Unplug FFC cable to remove Top Cover.

Top Cover

EP729 2-4

Step3: Unscrew 4 screws to remove Key Button and Keypad Board.

Keypad Board Key Button

EP729 2-5

2-3 Remove Main Board and Fan Module

Step1: Unplug 10 connectors and unsrew 3 screws.

Step2: Remove Main Board just like the way shown in Step two.

Step2

Step1

EP729 2-6

Step3: Unscrew 2 screws to remove I/O Panel.

Step4: Remove Fan Module directly.

Fan Module

EP729 2-7

2-4 Remove DC Power Supply

Step1: Unscrew one screw to remove DC Power Supply

Step2: Unplug 1 connector.

EP729 2-8

2-5 Remove Ballast Power Supply

Step1: Unscrew one screw to remove Ballast CNNT holder.

Step2: Unscrew 4 screws to remove Ballast Power Supply.

Step3: Unscrew one screw to remove Ballast CNNT Holder & Outlet Vent Light Cut.

EP729 2-9

2-6 Remove Color Wheel, Engine and Thermal Sensor

Board

Step1: Pull out Focus Ring and loose five tenons to remove Front Cover and IR Sensor Board.

Step2: Unscrew 6 screws to remove Engine.

IR Sensor Board

Engine Module

EP729 2-10

Step3: Unscrew three screws to remove Zoom Ring and Mylar.

Step4: Unscrew one screw to remove Color Wheel and tear the tape to remove FPC.

Step5: Unscrew two screws to remove Thermal Sensor and Fan Module

Unsrew three screws to disassemble Fan Module.

Thermal Sensor

Zoom Ring

Color Wheel

Fan Module

Mylar

EP729 2-11

Step6. Unscrew 2 screws to remove DMD Heatsink and DMD Heatsink Spring Plate.

Step7: Remove 4 screws and remove all the components.

Spring Plate

DMD Heatsink

EP729 2-12

Step8: Unscrew two screws to remove Interrupt Switch and Thermal Sensor Board.

3-1 EP729

Equipment Needed

- PC or pattern generator

- DVD player (Video, S-Video, Audio)

- Quantum Data 802B or CHROMA 2327

- After changing parts, check the below information.

Charge Parts/Update Version Update Color Wheel Index ADC Calibration Video Calibration

Reset Lamp

Use Time

Factory Reset EDID

M/B v v v v v v

FW v v v v v

Color Wheel v

Lamp Module v

Chapter 3

Troubleshooting

LED lighting message

LED Status Work Condition

Power

Solid orange Standby State

(Input power cord)

Solid GreenNormal Mode

Flashing Green Warning

Flashing orange Cooling

Lamp

Solid Red Error (Lamp fail)

Flashing

1 sec -ON

1 sec -OFF

Error (Fan lock fail)

Solid Red Error (Lamp no strike)

Temp

Solid Red Error (Over temp)

Solid Red Error (Thermal fail)

3-2 EP729

Power LED Lamp LED Temp LED I ndi cat i on

Standby State

(Input power cord)

Normal Mode

Warning

Cooling

Error (Lamp fail)

Error (Fan lock fail)

Error (Lamp no strike)

Error (Over temp.)

Error (Thermal fail)

LED Message Indication

1 sec -ON

1 sec -OFF

Solid LED

Light off

Flashing

3-3 EP729

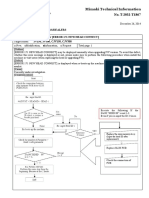

Main Procedure

No Power

- Ensure that the power cord and AC power outlet are securely connected.

- Check Lamp Cover and Interrupt Switch

- Ensure that all connectors are securely connected and arent broken.

- Check DC-DC

- Check Ballast

- Check Main Board

Auto Shut Down

- Check LED Status

a. Lamp LED light

- Check Lamp

- Check Lamp Driver

- Check Main Board

b. Temp LED Light

- Check Thermal Sensor

- Check Thermal Switch

- Check Fan

c. Color Wheel

- Check color wheel

- Photo sensor

d. No Power

- Refer to No Power troubleshooting

No Image

- Ensure that the signal cables and source are work as well. (If you connect

multiple sources at the same time, use the Source button on the control

panel to switch.)

- Ensure that all connectors are securely connected and arent broken.

- Check Main Board

- Check DMD Board

- Check Color Wheel

- Check DMD Chip

- Check Engine Module

3-4 EP729

No Light on

- Ensure that all connectors are securely connected and arent broken.

- Check Lamp Module

- Check DC-DC

- Check Ballast

- Check Main Board

Mechanical Noise

- Check Color Wheel

- Check Fan Module

Line Bar/Line Defect

- Sometimes its because of DMD chip and DMD board did not assemble

properly

- Check DMD Board

- Check DMD Chip

- Check Main Board

Image Flicker

- Do Reset of the OSD Menu.

- Ensure that the signal cables and source are work as well.

- Check Lamp Module

- Check Color Wheel

- Check DMD Board

- Check Main Board

Color Abnormal

- Do Reset of the OSD Menu.

- Adjust Color Wheel Index

- Check Main Board

- Check DMD Board

- Check Color Wheel

Poor Uniformity/Shadow

- Ensure the projection screen without dirt.

- Ensure the projection lens is clean.

- Ensure the Brightness is within spec.

(Replace the Lamp if the Brightness is less than spec.)

- Check Engine Module

3-5 EP729

Dead Pixel/Dust (Out of spec.)

- Ensure the projection screen without dirt

- Ensure the projection lens is clean

- Clean DMD Chip and Engine Module

- Check DMD Chip

- Check Engine Module

Garbage Image

- Ensure that the signal cables and source work as well.

- Check Main Board

- Check DMD Board

Remote Controllor or Control Panel Failed

- Remote Control

a. Check Battery

b. Check Remote Controller

c. IR receiver

- Control Panel

a. Check FPC

b. Check keypad

c. Check Main Board

Function Abnormal

- Do Reset of the OSD menu

- Check Main Board

- Check DMD board

4-1

EP729

Test Equipment

- IBM PC with XGA resolution (Color Video Signal & Pattern Generator)

- DVD player with Multi-system (NTSC/PAL/SECAM)

- HDTV Tuner or Source (480p, 720p, 1080i), equipped with S-Video,

Component, Composite interface.

- Minolta CL-100

- Quantum Data 802B or CHROMA2327

Test Condition

- Circumstance Brightness : Dark room less than 2.5 lux.

- Inspection Distance : 1.5m~3m for functional inspection

- Screen Size : 60 inches diagonal (wide)

- After repairing each EP729, the unit should be burn-in (Refer to the table

below).

Symptom Burn-in Time

Normal Repair 2 Hours

NFF 4 Hours

Auto Shutdown 6 Hours

Chapter 4

Function Test

EP729

4-2

Test Display Modes & Pattern

Function Test Display Pattern

Item Test Content Pattern Specification Remark

1

Frequency &

Tracking

Fine Line Moire

Eliminate visual wavy noise by

Rsync, Frequency or Tracking

selection.

Figure 1

2 Contrast/Brightness 64 RGBW scale

Gray level should be

distinguishable and without color

abnormal.

Figure 2

3

R, G, B and White

Color Performance

R, G, B and

White Color

Each R, G, B color should be

normal without color abnormal

issue.

Figure

3~6

4 Screen Uniformity Full White

Should be compliant with

60%.(Minimum)

Figure 6

5

Dead Pixel (Bright

pixel)

Full Black Cannot accept any bright pixel Figure 7

Dead Pixel (Dark

pixel)

Full White

The numbers of dead pixel should

be smaller or amount to 6 pixel.

Figure 8

6 Blemish (Bright)

Full Black / Gray

30

The bright blemish cannot be

accepted if the problem appear

with Gary 30 pattern.

Figure 7,

8

7 Blemish (Dark)

Full white / Blue

60

The dark blemish cannot be

accepted if the problem appear

with Blue 60 pattern.

Figure

6,9

8 Focus Text Pattern

The text in the corner should be

clear after adjust the focus ring.

Figure

10

9 Boundary Boundary Frame

Horz. And Vert. position of video

should be adjustable to be the

screen frame.

Figure

11

10 Light Leak Gray 10

The unit can't accept the leakage is

brighter than Gray 10 pattern

Figure

12

11 HDTV Color Bar No discolor

Figure

13

4-3

EP729

Figure 6. Full White

Figure 7. Full Black

Figure 1. Fine Line Moire Figure 2. 64 RGBW Scale

Figure 3. Red Pattern Figure 4. Green Pattern

Figure 5. Blue Pattern

Figure 8. Gary 30 Pattern

EP729

4-4

Figure 9. Blue 60 Pattern

Figure 10. Text Pattern

Figure 11. Boundary Frame

Figure 12. Gary 10 Pattern

Figure 13. Color Bar

Figure 14. Calibration Pattern

4-5

EP729

- Frequency and Tracking

Test Signal : 1024x768@60Hz

Test Pattern : Line Moire Pattern

* Check and see if image sharpness and focus are well performed.

* If not, readjust by following steps.

(1) Select Frequency function to adjust the total pixel number of pixel

clock in one line period.

(2) Then select Tracking function and use right or left arrow key to adjust

the value to minimize video flicker.

- Boundary

Test Signal : 1024x768@60Hz

Test Pattern : Boundary Frame

* Adjust Resync or Frequency/Tracking/H. Position/V. Position to the inner of

the screen.

- Focus

Test Signal : 1024x768@60Hz

Test Pattern : Text Pattern

* Adjust the center clearly, meanwhile, one slightly vague corner in the image is

allowed

- HDTV

Equipment : Quantum Data 802B or CHROMA 2327

Test Signal : 480p, 702P, 1080I

Test Pattern : Color Bar

If the test result was discoloration or flickering, please return the unit back to the

repair center.

- Color Performance

Test Signal : 1024x768@60Hz

Test Pattern : 64 RGBW scale Pattern and Gray 16 Pattern

* Please check and ensure if each color is normal and distinguishable

* If not,please adjust color index of the engineering mode.

Inspection Procedure

EP729

4-6

- Screen Uniformity

Test Signal : 1024x768@60Hz

Test Pattern : Full White Pattern

* Please check and ensure the unit is under the spec.

* Please check and see if its in normal condition.

* If not, please return the unit to repair area.* Please check and see if there

are dead pixels on DMD chip

* The total numbers and distance of dead pixels should be complaint with the

spec.

Notice : (1) Bright Pixel :

Test Pattern : Full Black Pattern

-Please check and ensure that the unit cannot accept any

bright pixel.

-If not, please return the unit to repair area.

(2) Dark Pixel :

Test Pattern : Full White Pattern

-Please check and ensure that the pixel number should be smaller

or amount to 6 pixels

-If not, please return the unit to repair area.

- Light Leak

Test Signal : 1024x768@60Hz

Test Pattern : Gray 10 Pattern

* Please check and see if the light leaks*Notice

* The unit cannot accept the leakage is brighter than Gary 10 pattern

Notice : light leak on reflective edge, eyecatcher, bond wires and exposed metal.

Calibration

Once Main Board is changed, firmware upgrade should be done as well.

- Video Calibration

Test Signal : HDTV Signal (480p)

Test Pattern : Calibration Pattern (Figure 13)

- ADC Calibration (PC Calibration)

Test Signal : 1024x768@60Hz

Test Pattern : Calibration Pattern (Figure 14)

* Calibration Pattern should be in full screen mode, white above and black

below.

4-7

EP729

Note: 1. Refer to the above Calibrations test signal.

2. Please refer to the follwoing steps for entering service mode.

3. Choose and access video calibration & ADC calibration for correction in service

mode. Choose Exit to leave the service mode after all.

- Dead Pixel (Bright/Dark pixel)

Test Signal : 1024x768@60Hz

Test Pattern : Full Black Pattern and Full White Pattern

Guide to Entering Service Mode and Factory Reset

- Service Mode

- Please do the following steps to enter service Mode.

Turn on the power and wait for the disappearance of Logo picutre.

- press + buttons at the same time for five seconds to enter

Service Mode Menue

- Factory Reset

After final QC step, we have to erase all saved change again and restore the fac-

tory defaults.

Please enter the service mode, and then choose Factory Reset then choose

YES and press enter to see if it works.

This action will allow you to erase all end-users settings and restore the original

setting.

4 g

EP729 5-1

Chapter 5

Firmware Upgrade Procedure

5-1 Equipment Needed

Software :

- DLP Composer

- EP729 Firmware

Hardware :

- Power Cord

- USB Cable

- PC or Laptop

- EP729 Projector

1. Connect USB Cable of PC to USB port of EP729 Projector.

2. Connect Power Cord to E729 unit.

5-2 Hardware Setup Procedure

USB Cable

EP729 5-2

5-3.1 DLP Composer Lite Setup Procedure

5-3 Firmware Progarm Installation Procedure

1. Choose DLP Composer Lite v3.6 Setup program.

2. Click Next button.

EP729 5-3

3. Reading the License Agreement rules, choose I accept and agree to be bound by all the

terms and conditions of this License Agreement icon, then click Next button.

1

2

3

EP729 5-4

4. Click Next button.

1

2

5. Choose All icon, then click Next button.

EP729 5-5

6. Click Next button.

7. The program is executing Initializing status.

EP729 5-6

3. Type any key to continue. Then wait about a minute.

1. Press Power button for six to seven seconds.

Note : The system fan will be at full speed. Lamp LED will flash green three

times.LED of TEMP, POWER and LAMP will be lit red.

2. Execute the C:\Program files\DLP Composer\usbupdata.cmd.

Note : The DLP Composer program must be closed first.

5-3.2 USB Driver Upgrade Procedure

EP729 5-7

4. Click OK. The USB driver updated successfully.

5. Right click My Computer on the desktop. Select Properties on the popup menu to

launch the System Properties window. Choose Hardware and then click Device

Manager.

EP729 5-8

6. Click Jungo to assure DDP2000 and WinDriver are properly installed. If not, repeat

Step 1 ~ 6.

Device Manager

EP729 5-9

5-4 Firmware Upgrade Procedure

1. Execute the DLP Composer

TM

file.

2. Click Edit and Preferences.

1

2

EP729 5-10

3. Click Library. The library path located to the default installation directory is :

C:\Program Files\DLP Composer. If not then press Browse to select the right path.

4. Select Edit\Preferences\Communications, choose USB, and then click OK.

1

2

1

2

EP729 5-11

5. Choose Flash Loader and click Browse to search the

EP729_RefDesign_Flash.img file.

Select the item Skip Boot Loader Area (load all but the first 16KB).

6. Click Reset Bus to erase the flash memory.

2

1

EP729 5-12

7. If the firmware is ready, then click Start Download to process the firmware upgrade.

8. Click Yes to erase the flash memory.

EP729 5-13

Note : How to into Service Mode:

- Turn on the power and wait for the disappearance of Logo picutre.

- press 5 , 4 , , g buttons at the same time for five seconds to enter

Service Mode Menue

9. After file was download. Please to restart the unit and enter the Service mode to check the

F/W version of EP729 .

Note

6

EP729 6-1

Chapter 6

DDC Key-in Procedure

6-1 Equipment Needed

- PC or Laptop

- EDID Fixture

- Power Adapter

- RS-232 Cable (Female to Male)

- VGA Cable

- Power Cord

- DDC Driver

- EP729 Unit

EDID Fixture

RS-232 Cable (F-M)

VGA Cable

Power Adapter

EP729 6-2

6-2 Setup Procedure

Step1. Connect Power Adapter with the fixture.

Step2. Connect P1 of the fixture with COM1 of PC/Laptop by RS232 cable.

Step3. Connect P2 or P4 of the fixture with VGA in port of EP729 cable.

Step4. Plug Power Adapter to the fixture and connect the EP729 Power Cord.

*Notice : Confirm JP3 is Close status.

P2

P4

Power Adapter P1

marked as Generic

JP3

VGA port

EP729 6-3

6-3 DDC Key-in Procedure

Step 1. Execute EDID program.

Step 2. Check the Com port is COM1, then click the Model item and choose the

source file OPTOMA_EP729_EDID_A.ini and then open it.

1

2

3

EP729 6-4

Step 3. Key in the Serial Number into the blank space, then click Program button.

Step 4. Please change the cable to VGA message is shown on the screen, then click

OK button.

Notice : RUN message will appear on the screen.

1

2

EP729 6-5

Step 5. When the EP729 EDID program is finish, the OK message will appear on the

screen.

Step 6. Make sure to check Analog and Trans in Read item and then press Read

button. EDID Informations will show the result and click Reset to do the next

unit or Exit button to close the EDID program.

1

2

3

4

EP729

7-1

Appendix A

Exploded Overview

I. EP729 Unit

EP729

7-2

Exploded Parts List

Item Description

1 LAMP COVER EP729 NORYL N300X "GREEN"

2 ENGINE LIGHT CUT LT20 FRPP MYLAR "GREEN"

3 LAMP COVER SI FOAM LT20 "GREEN"

4 LAMP HOUSING SHOULDER SCREW SB21 "GREEN"

5 LAMP MODULE LT20 "GREEN"

6 OPTICAL ENGINE MODULE EP729 "GREEN"

7 TOP COVER MODULE EP729 "GREEN"

8 FRONT COVER MODULE EP729 "GREEN"

9 IO COVER MODULE EP729"GREEN"

10 BOTTOM COVER MODULE EP729 "GREEN"

11 SCREW PAN MECH M2.6*30 BLACK NYLOK "GREEN"

12 SCREW PAN MECH M2.6x6 Ni NYLOK "GREEN"

EP729

7-3

II. Optical Engine Module

EP729

7-4

Item Description

1 CNNT F 166P FOR 0.55" SVGA LGA DMD SOCKET;TELEDYNE

2 WT44 ZOOM PROJECTION LENS 115% "GREEN"

3 EMI GASKET W20*H2.5*L25mm "GREEN"

4 EMI TAPE 30*50 "GREEN"

5 EMI GASKET W10-H10.5*L35mm 3400MP "GREEN"

6 DMD 1024*768 PIXEL DDR FTP 0.7"XGA "GREEN"

7 ZOOM RING EP729 PC+ABS "GREEN"

8 ZOOM RING HOLDER LT20 PC+ABS C6200"GREEN"

9 DMD MYLAR LT20 "GREEN"

10 FOCUS RING EP729 PC+ABS "GREEN"

11 DMD ANTIDUST RUBBER 739 SILICONE RUBBER "GREEN"

12 ANTI DUST RING LT20 SILICON RUBBER"GREEN"

13

THERMAL PAD FOR DMD HEAT SINK 17*13*0.3mm, Fujipoly GR-HM

"GREEN"

14 BACKER PLATE LT20 AL ALLOY "GREEN"

15 DMD HEATSINK LT20 AL ALLOY "GREEN"

16 HEATSINK SPRING PLATE2 LT20 SUS301 t0.4mm "GREEN"

17 DMD LIGHT MASK LT20 SUS301 "GREEN"

18 SCREW PAN MECH M2.6*4 BLACK NYLOK "GREEN"

19 DMD SHOULDER SCREW SB21 "GREEN"

20 ENGINE MODULE LT20

21 PCBA DMD BOARD LT20

22 SCREW PAN MECH M2*4 Ni

23 SCREW PAN MECH M2.6*3 Ni "GREEN"

24 SCREW PAN TAP M1.7*5 BLACK "GREEN"

25 WASHER FLA NYLON PINGOOD "GREEN"

Exploded Parts List

EP729

7-5

III. Engine Module

EP729

7-6

Exploded Parts List

Item Description

1 POLYGON MIRROR 1 (t1.1mm) "GREEN"

2 POLYGON MIRROR 2 (t1.1mm) "GREEN"

3 RELAY LENS (Material:Zeonex) "GREEN"

4 HOLLOW ROD 6.25MM*4.40MM*24.7MM(t1.1MM) "GREEN"

5 X16mm CONDENSER B270 SPHERE "GREEN"

6 THERMAL SWITCH 135

7 SUNON 45*45*10mm R TYPE "GREEN"

8 RELAY LIGHT CUT LT20 NORYL "GREEN"

9 RELAY PORON LT20 "GREEN"

10 OFF RAY ISOLATOR LT20 "GREEN"

11 BLOWER 4510 DUCT AIRTIGHT SILICON RUBBER LT20 "GREEN"

12 PORON LENS BLACK XB31 "GREEN"

13 ENGINE TOP LT20 AZ91D "GREEN"

14 ENGINE BOTTOM LT20 AZ91D "GREEN"

15 4510 BLOWER DUCT LT20 AL ALLOY "GREEN"

16 ROD HOLDER SPRING LT20 SUS301 t0.2mm"GREEN"

17 ROD MASK LT20 SUS301 t0.3mm "GREEN"

18 MIRROR 1 SPRING LT20 SUS301 t0.25mm "GREEN"

19 MIRROR 2 SPRING LT20 SUS301 t0.25mm "GREEN"

20 ROD HOLDER LT20 SUS301 t0.2mm "GREEN"

21 OFF RAY HEATSINK PLATE LT20 SUS301 t0.3mm "GREEN"

22 ENGINE DUCT LT20 AL t0.5mm "GREEN"

23 BLOWER 4510 HOLDER LT20 SECC t1.0mm "GREEN"

24 COLOR WHEEL MODULE EP729 "GREEN"

25 SCREW DOUBLE FLAT MECH M2.6*4 BLACK NYLOK

26 SCREW PAN MECH M1.7*3 BLACK "GREEN"

27 SCREW PAN MECH M2.6*4 BLACK NYLOK "GREEN"

28 WASHER FLAT 7*3.1*0.8t PC PINGOOD WS-1M "GREEN"

EP729

7-7

IV. Buttom Cover Module

EP729

7-8

Exploded Parts List

Item Description

1 BOTTOM COVER EMI GASKET LT20 W10H1*L15

2 W.A. 7P #24 UL1007 110mm DC DC/MAIN BOARD "GREEN"

3 W.A. 5P #28 UL1007 65mm BALLAST/MAIN BOARD "GREEN"

4 W.A. 4P #22/#24 90mm DC DC/BALLAST "GREEN"

5 W.A. GROUND #20 UL1007 BLACK 80mm 3.0

6 SUNON GM1255PHV1.AR.B.196.13 55*55*15mm R TYPE "GREEN"

7 NYLON WASHER PG U-3 FOR BALLAST LT20 "GREEN"

8 BALLAST MYLAR FRPP 0.5t LT20 "GREEN"

9 BALLAST CNNT HOLDER PEEK LT20 "GREEN"

10 ADJUST FOOT PC+ABS C6200 CS-ES01A DP725 "GREEN"

11 FUSE COVER (FH-1L-UL) "GREEN"

12 FAN 5515 SILICON RUBBER LT20 "GREEN"

13 RUBBER FOOT REAR DP725 "GREEN"

14 SELF LOCKING RING(SPN 1.5)

15 SPRING FOR BALLAST EMI VULCAN-1

16 BOTTOM COVER AZ91D EP727 "GREEN"

17 DC DC INLET VENT MESH LT20 SPCC t0.6mm "GREEN"

18 OUTLET VENT LIGHT CUT AL 0.4t LT20 "GREEN"

19 DC DC MODULE LT20 "GREEN"

20 INTERLOCK SWITCH MODULE LT20 "GREEN"

21 ASSY OSRAM BALLAST 150W

22 PCBA THERMAL SENSOR BOARD LT20 "GREEN"

23 SCREW PAN MECH PLASTIC M2.6*5 LT20 "GREEN"

24 SCREW PAN MECH M2.6*5 BLACK NYLOK

25 SCREW PAN MECH M4*5 COLOR W/TOOTH WASHER

26 NUT HEX M2.0*0.4P L1.5 Ni

EP729

7-9

V. Lamp Module

EP729

7-10

Exploded Parts List

Item Description

1 17*17BOROFLOAT UV-IR SQUARE t2.75mm "GREEN"

2 OSRAM 150W E18 arc 1.0 Lamp

3 Cable 4/2P 72/61mm FOR 150W LAMP "GREEN"

4 LAMP CNNT HOLDER LT20 PEEK "GREEN"

5 LAMP CONTACT COVER RUBBER SB21 "GREEN"

6 LAMP MESH HOLDER SILIOCNE FOAM "GREEN"

7 UVIR SPRING PLATE SUS303 80L "GREEN"

8 LAMP MESH HOLDER LT20 AZ91D "GREEN"

9 LAMP BOTTOM PLATE LT20 AZ91D "GREEN"

10 LAMP P12 LIGHTCUT LT20 AZ91D "GREEN"

11 LAMP FIX SPRING LT20 SUS301 t0.2mm"GREEN"

12 LAMP P12 MESH REAR LT20 SUS301 t0.2mm "GREEN"

13 LAMP FIX SPRING SUS301 0.2t SB21 "GREEN"

14 LAMP HOUSING SHOULDER SCREW SB21 "GREEN"

15 LAMP CHANGER HANDLE SUS304 1.6d DP725 "GREEN"

16 SCREW PAN MECH M2.6x5 BLACK NYLOK

17 SCREW SOCKET MECH M2.6*5 BLACK NYLOK

EP729

7-11

VI. Front Cover Module

EP729

7-12

Exploded Parts List

Item Description

1 EMI GASKET W3*H3*L20mm "GREEN''

2 IR LENS FRONT PC EP729 "GREEN"

3 FRONT COVER EP729 NORYL N300 "GREEN"

4 ELE BUTTOM EP729 PC+ABS C6200 "GREEN"

5 ELE BUTTOM HOLDER LT20 PC+ABS C6200 "GREEN"

6 ELE FOOT LT20 NORYL + FIBER "GREEN"

7 ELE FOOT STOP PIN LT20 NORYL + FIBER "GREEN"

8 FRONT COVER F12 EP729 "GREEN"

9 FRONT COVER VENT F12 EP729 "GREEN"

10 ELE FOOT SPRING LT20 SUS301 %%1660.4 "GREEN"

11 ELE BUTTOM SPRING LT20 SUS301 %%1660.35 "GREEN"

12 PCBA IR BOARD EP729

13 SCREW PAN MECH M2.6x5 BLACK NYLOK

EP729

7-13

VII. Top Cover Module

Exploded Parts List

Item Description

1 EMI GASKET 3X10X21 mm EP729"GREEN"

2 CABLE FFC 14P 106mm SB21 "GREEN"

3 KEYPAD DECO PC EP729 "GREEN"

4 REAR IR LENS EP729 PC "GREEN"

5 KEYPAD RUBBER EP729 "GREEN"

6 TOP COVER F12+PC EP729 "GREEN"

7 ASSY TOP COVER EP729 "GREEN"

8 PCBA KEYPAD BOARD EP729

9 SCREW CAP PAN D7.0 MECH M2.6x4 Ni "GREEN"

EP729

7-14

VIII. IO Cover Module

Exploded Parts List

Item Description

1 PCBA W HOLDER LT20 SECC t1.0mm "GREEN"

2 PCBA MAIN BOARD EP729

3 ASSY IO COVER EP729 "GREEN"

4 SCREW I/O STEEL #4-40UNCxH4xL5.5 NYLOK

5 SCREW PAN MECH M2.6x6 Ni NYLOK "GREEN"

EP729

7-15

IX. Color Wheel Module

Exploded Parts List

Item Description

1 X35mm R92/G83/W110/B75 SKC COLOR WHEEL "GREEN"; "YO"

2 FFC 4P P=1.0 120mm COLOR WHEEL/MAIN BOARD "GREEN"

3 COLOR WHEEL DISC RUBBER EzPro755 "GREEN"

4 COLOR WHEEL HOLDER SKC LT20 AL ALLOY "GREEN"

5 COLOR WHEEL SHOULDER SCREW EzPro755 "GREEN"

6 PCBA PHOTOSENSOR BOARD LT20

7 SCREW PAN MECH M2.6*4 BLACK NYLOK "GREEN"

EP729

7-16

X. DC DC Module

Exploded Parts List

Item Description

1 PLASTIC RIVET D3.0 SR-3L "PG" "GREEN"

2 DC DC HOLDER LT20 PC+ABS C6200 "GREEN"

3 DC-DC MYLAR LT20 "GREEN"

4 ASSY ISQUASAR DC DC LT20

EP729

7-17

XI. Interlock Switch Module

Exploded Parts List

Item Description

1 INTERLOCK SWITCH SEESAW LT20 NORYL N300X "GREEN"

2 INTERRUPT S/W HOLDER LT20 NORYL N300X "GREEN"

3 ASSY INTERRUPT SWITCH MODULE LT20

EP729

7-18

Appendix B

I. PCBA Code Definition

PCBA Code for Projector

A B XXXXXXXXXX C XXX EEEE

1 2

3 4 5 6

1

2

3

4

5

6

: ID

: Vendor Code

: P/N

: Revision

: Date Code

: S/N

C: M/B

B: DMD/ B

EP729

7-19

Appendix C

Serial Number System Definition

Serial Number Format for Projector

A BBB Y WW C D BEMO EEEE

: A = Optoma, B~Z = OEM

: Product code (ex: 82F = EP729)

: Y = Last number of the year (ex: 2004 - 4)

: Week of year

: Panel vendor code

: Electrical classification (1=110V, 2=220V, 0=universal)

: B = BIOS version, E = PCB board version,

M = Mechanical version, O = Optical version

: Serial code (from 0001~)

EX : A82F429T0AAAA1001

This label A82F429T0AAAA1001 represents the whole serial number for EP729, including Ver.

1st of BIOS and Ver. 1 of PCB Board. Both mechanical and optical version are 1st. In addition,

panel vendor is T0. Its produced on 29s-week of 2004 for universal area and its serial code is 1001.

3

6

1

2

5

4

7

6 1 2 5 4 7 8

8

3

EP729

7-20

*Readers Response*

Dear Readers:

Thank you for your backing our service manual up. In order to refine our content of the

service manual and satisfy your requirement. We expect you can offer us some precious

opinions for reference.

Assessment:

Name: Title:

Company:

Add:

Tel: Fax:

E-mail:

Item Excellent Good Fair Bad

1. Service Manual Content

2. Service Manual Layout

3. The form and listing

Unit Excellent Good Fair Bad

1. Introduction

2. Disassembly Procedure

3. Troubleshooting

4. Function Test & Alignment Procedure

5. Firmware Upgrade Procedure

6. DDC key-in Procedure

7. Appendix

B. Are you satisfied with the EP729 service manual?

C. Do you have any other opinion or suggestion about this service manual?

Readers basic data:

After your finishing this form, please send it back to Coretronic Customer Service

Dept. by fax: 886-3-563-5333.

A. What do you think about the content after reading EP729 Service Manual?

Vous aimerez peut-être aussi

- Manual Datalogic Magellan 9300iDocument464 pagesManual Datalogic Magellan 9300iNuno Matoucas50% (2)

- Lc7.2e LB 312278517172Document107 pagesLc7.2e LB 312278517172Toni Martin SebéPas encore d'évaluation

- Dinse Dix-Sas-100-Dinse-Gmbh-DeDocument42 pagesDinse Dix-Sas-100-Dinse-Gmbh-DeMPas encore d'évaluation

- PIEF0158 a-QB Document Check SheetDocument1 pagePIEF0158 a-QB Document Check SheetĐỗ Thành NhươngPas encore d'évaluation

- Arena TutorialDocument8 pagesArena TutorialCoxa100NocaoPas encore d'évaluation

- Process of EB, QB Samples ShipmentDocument9 pagesProcess of EB, QB Samples ShipmentBự BụngPas encore d'évaluation

- Autocar Ppap Requirements Rev 5Document17 pagesAutocar Ppap Requirements Rev 5man hoPas encore d'évaluation

- A4uv ManualDocument23 pagesA4uv ManualNischit Kunwar Chhetri100% (1)

- Takaya Apt 9400ceDocument210 pagesTakaya Apt 9400ceJack W Pichai100% (1)

- UV Printer (A3L) - 1390 ManualDocument10 pagesUV Printer (A3L) - 1390 ManualSonia NaickerPas encore d'évaluation

- LBP 3500 ManualDocument56 pagesLBP 3500 ManualChathura ChamikaraPas encore d'évaluation

- Production ProblemDocument2 pagesProduction ProblemSaqib RehmanPas encore d'évaluation

- Konica Minolta FTP Setup GuideDocument5 pagesKonica Minolta FTP Setup GuideBryan MillerPas encore d'évaluation

- ESE Printer-Hanwha TechwinDocument20 pagesESE Printer-Hanwha TechwinMuhammad Imran SiddiquiPas encore d'évaluation

- SAi Production Suite 12 Readme PDFDocument22 pagesSAi Production Suite 12 Readme PDFsherub wangdiPas encore d'évaluation

- RoHS Compliant Printed Board Assembly With Guaranteed - Power - Heros ElectronicsDocument3 pagesRoHS Compliant Printed Board Assembly With Guaranteed - Power - Heros ElectronicsHeros ElectronicsPas encore d'évaluation

- Ngaranaing Saha Atuh UdinDocument1 pageNgaranaing Saha Atuh Udinadian herawanPas encore d'évaluation

- Autotronik ManualDocument820 pagesAutotronik ManualFarhan AbdurrafiPas encore d'évaluation

- Lista de Repuestos EASY PRINTDocument90 pagesLista de Repuestos EASY PRINTjcojedar2009Pas encore d'évaluation

- Vp6000-V Brochure enDocument6 pagesVp6000-V Brochure enFarhan AbdurrafiPas encore d'évaluation

- How To Reset Brother DCP 130cDocument2 pagesHow To Reset Brother DCP 130cGilang Boedi PrayogoPas encore d'évaluation

- Colorcalibrationtutorial 2008 v4 enDocument21 pagesColorcalibrationtutorial 2008 v4 enpicolorjPas encore d'évaluation

- 3DQuickPress V5.0.1 Training Manual PDFDocument219 pages3DQuickPress V5.0.1 Training Manual PDFNguyen Tan TaiPas encore d'évaluation

- CS1407003E-008 YSM20 2beam Inst 20180314 Tablet PDFDocument8 pagesCS1407003E-008 YSM20 2beam Inst 20180314 Tablet PDFGanapathy SakthiPas encore d'évaluation

- 701P37410 Synergix Scanner Service ManualDocument218 pages701P37410 Synergix Scanner Service Manualjovan5510% (1)

- PET Preform Troubleshooting Computer Hardware Software Husky Injection Molding Systems LTD S New Molding Troubleshooting Software ProPet 2 PDFDocument2 pagesPET Preform Troubleshooting Computer Hardware Software Husky Injection Molding Systems LTD S New Molding Troubleshooting Software ProPet 2 PDFkmasanPas encore d'évaluation

- Canon PricingDocument14 pagesCanon PricingMark ReinhardtPas encore d'évaluation

- Process Capability Report Form06Document8 pagesProcess Capability Report Form06arunradPas encore d'évaluation

- Keypress Cheat SheetDocument3 pagesKeypress Cheat SheetLalit MangalPas encore d'évaluation

- BASF Injection Molding Defects PDFDocument38 pagesBASF Injection Molding Defects PDFSenthil Kumar100% (1)

- Yamaha Feeder Calibration MachineDocument10 pagesYamaha Feeder Calibration MachineMactech SMTPas encore d'évaluation

- VSPlayer User Manual V6.0.0.4Document17 pagesVSPlayer User Manual V6.0.0.4PalMan SatShopsPas encore d'évaluation

- 2 - Teneth CCD Camera Cutting PlotterDocument2 pages2 - Teneth CCD Camera Cutting PlotterGuillermo RussoPas encore d'évaluation

- Bedienungsanleitung Winter DSP Control SystemDocument57 pagesBedienungsanleitung Winter DSP Control SystemOgnjen BanjacPas encore d'évaluation

- Ai 11Document141 pagesAi 11Juan100% (1)

- Large Format Printer Price List 2020Document4 pagesLarge Format Printer Price List 2020JonasPas encore d'évaluation

- PowerMILL 9 Whats - New PDFDocument186 pagesPowerMILL 9 Whats - New PDFcharan eslatePas encore d'évaluation

- 20110520101701Document27 pages20110520101701Arie Teckno100% (2)

- UJF-3042 - 6042MKII Maintenance Manual D501202 Ver.1.50Document366 pagesUJF-3042 - 6042MKII Maintenance Manual D501202 Ver.1.50Amur ServicePas encore d'évaluation

- CNC - CHANGE Software Install Specifications - EDocument3 pagesCNC - CHANGE Software Install Specifications - EAlejandro Ramírez0% (1)

- DPP 140 Blister Packing MachineDocument31 pagesDPP 140 Blister Packing MachineMuthia ShofiPas encore d'évaluation

- (20210426 HUILI) 75 Injection Blow Moulding MachineDocument11 pages(20210426 HUILI) 75 Injection Blow Moulding MachineEsteban Juan Sejas AlanocaPas encore d'évaluation

- JV33 - CJV Trouble Shooting of ElectricalDocument1 pageJV33 - CJV Trouble Shooting of ElectricalGarner100% (1)

- Digital Plate ControlDocument32 pagesDigital Plate ControlecdtcenterPas encore d'évaluation

- HP2-B82 HP LaserJet FundamentalsDocument2 pagesHP2-B82 HP LaserJet FundamentalsRobinson ArteagaPas encore d'évaluation

- ZKS T2 Software ManualDocument69 pagesZKS T2 Software ManualAngie Di Martino Cid100% (3)

- Tool Design TerminologyDocument5 pagesTool Design Terminologyanmol6237Pas encore d'évaluation

- easyFIXS - About Canon Service Tool v.4720Document9 pageseasyFIXS - About Canon Service Tool v.4720younes bessamPas encore d'évaluation

- SM300 ManualDocument32 pagesSM300 ManualdeivisroseroPas encore d'évaluation

- EPSON Mini PrinterDocument6 pagesEPSON Mini Printer黃政昀Pas encore d'évaluation

- Error 171 New Head Connect For Jv300Document2 pagesError 171 New Head Connect For Jv300MPas encore d'évaluation

- HP Latex 3000 Printer SMDocument1 069 pagesHP Latex 3000 Printer SMMario BraićPas encore d'évaluation

- Powermill Cowling Notes 2010Document14 pagesPowermill Cowling Notes 2010SAMEERBOBALPas encore d'évaluation

- Centroid cnc12 Oak Allin1dc Lathe Operator Manual v4.14Document269 pagesCentroid cnc12 Oak Allin1dc Lathe Operator Manual v4.14Cesar Augusto MontejoPas encore d'évaluation

- Mimaki JV3-160 SP PDFDocument136 pagesMimaki JV3-160 SP PDFAlisson BrighentiPas encore d'évaluation

- AuraJet Series II UserManualDocument48 pagesAuraJet Series II UserManualdarkenelPas encore d'évaluation

- Generic: Process Step Illustration 1.3Document4 pagesGeneric: Process Step Illustration 1.3idenbellePas encore d'évaluation

- Toshiba Tdp-p8 DLP ProjectorDocument55 pagesToshiba Tdp-p8 DLP ProjectorSeema RoyPas encore d'évaluation

- Optoma H76 Service ManualDocument34 pagesOptoma H76 Service ManuallaitangPas encore d'évaluation

- EP719H and EP749 Service ManualDocument88 pagesEP719H and EP749 Service ManualHoàng Lân NguyễnPas encore d'évaluation

- MP-4054 PM PDFDocument216 pagesMP-4054 PM PDFlaitang100% (2)

- Docucentre s2010 PDFDocument202 pagesDocucentre s2010 PDFlaitangPas encore d'évaluation

- SP8200DN MS - v00 PDFDocument682 pagesSP8200DN MS - v00 PDFlaitangPas encore d'évaluation

- Ar-5516 5520 SM S3eDocument95 pagesAr-5516 5520 SM S3elaitangPas encore d'évaluation

- Ar6020 6023 6026 6031 - ImDocument28 pagesAr6020 6023 6026 6031 - ImlaitangPas encore d'évaluation

- SP - MP 2591 - 3391 - 2550 - 3350 PDFDocument200 pagesSP - MP 2591 - 3391 - 2550 - 3350 PDFlaitangPas encore d'évaluation

- SC - MP 2591 - 3391 - 2550 - 3350 PDFDocument53 pagesSC - MP 2591 - 3391 - 2550 - 3350 PDFlaitangPas encore d'évaluation

- Ineo 165 185 PartsDocument44 pagesIneo 165 185 PartslaitangPas encore d'évaluation

- KIP7100 Parts Manual Ver 1 1Document94 pagesKIP7100 Parts Manual Ver 1 1laitangPas encore d'évaluation

- DP-M300 Series - Parts Manual PDFDocument102 pagesDP-M300 Series - Parts Manual PDFlaitangPas encore d'évaluation

- MF3000 PF-P08 Service ManualDocument331 pagesMF3000 PF-P08 Service ManuallaitangPas encore d'évaluation

- DP-440 430 340 330 Service Manual PDFDocument311 pagesDP-440 430 340 330 Service Manual PDFlaitangPas encore d'évaluation

- C552 - 652 Parts For DFDocument24 pagesC552 - 652 Parts For DFlaitangPas encore d'évaluation

- DP-M300 Series - Parts ManualDocument102 pagesDP-M300 Series - Parts Manuallaitang67% (3)

- Optoma H76 Service ManualDocument34 pagesOptoma H76 Service ManuallaitangPas encore d'évaluation

- Ineo 360 PartsDocument151 pagesIneo 360 PartslaitangPas encore d'évaluation

- Optoma EH1020 V1.0 (DDP 3021-USB) Service ManualDocument46 pagesOptoma EH1020 V1.0 (DDP 3021-USB) Service ManualLeonardo Javier ObermeyerPas encore d'évaluation

- C203 C253 C353 Installation ManualDocument18 pagesC203 C253 C353 Installation ManuallaitangPas encore d'évaluation

- Problems: C D y XDocument7 pagesProblems: C D y XBanana QPas encore d'évaluation

- Dpb6013 HRM - Chapter 3 HRM Planning w1Document24 pagesDpb6013 HRM - Chapter 3 HRM Planning w1Renese LeePas encore d'évaluation

- Matsusada DC-DC ConvertersDocument4 pagesMatsusada DC-DC ConvertersAP SinghPas encore d'évaluation

- Group 4 - When Technology and Humanity CrossDocument32 pagesGroup 4 - When Technology and Humanity CrossJaen NajarPas encore d'évaluation

- A Presentation On-: E-Paper TechnologyDocument19 pagesA Presentation On-: E-Paper TechnologyRevanth Kumar TalluruPas encore d'évaluation

- Naca Duct RMDocument47 pagesNaca Duct RMGaurav GuptaPas encore d'évaluation

- Configuring Hyper-V: This Lab Contains The Following Exercises and ActivitiesDocument9 pagesConfiguring Hyper-V: This Lab Contains The Following Exercises and ActivitiesMD4733566Pas encore d'évaluation

- Solutions of Inverse Geodetic Problem in Navigational Applications PDFDocument5 pagesSolutions of Inverse Geodetic Problem in Navigational Applications PDFLacci123Pas encore d'évaluation

- IU IIDC Time Management and Organizational SkillsDocument40 pagesIU IIDC Time Management and Organizational SkillsAsger HamzaPas encore d'évaluation

- Most Dangerous City - Mainstreet/Postmedia PollDocument35 pagesMost Dangerous City - Mainstreet/Postmedia PollTessa VanderhartPas encore d'évaluation

- World English 2ed 1 WorkbookDocument80 pagesWorld English 2ed 1 WorkbookMatheus EdneiPas encore d'évaluation

- Mediator Analysis of Job Embeddedness - Relationship Between Work-Life Balance Practices and Turnover IntentionsDocument15 pagesMediator Analysis of Job Embeddedness - Relationship Between Work-Life Balance Practices and Turnover IntentionsWitty MindsPas encore d'évaluation

- Pascal Die Casting Machine SystemDocument20 pagesPascal Die Casting Machine Systemenascimento32Pas encore d'évaluation

- 1988 Mazda 323 Workshop Manual V1.0 (Turbo Only)Document880 pages1988 Mazda 323 Workshop Manual V1.0 (Turbo Only)Mike Marquez100% (2)

- DAY 3 STRESS Ielts NguyenhuyenDocument1 pageDAY 3 STRESS Ielts NguyenhuyenTĩnh HạPas encore d'évaluation

- Turbine Start-Up SOPDocument17 pagesTurbine Start-Up SOPCo-gen ManagerPas encore d'évaluation

- Fiedler1950 - A Comparison of Therapeutic Relationships in PsychoanalyticDocument10 pagesFiedler1950 - A Comparison of Therapeutic Relationships in PsychoanalyticAnca-Maria CovaciPas encore d'évaluation

- Performance Comparison of VxWorks Linux RTAI and Xenomai in A Hard Real-Time ApplicationDocument5 pagesPerformance Comparison of VxWorks Linux RTAI and Xenomai in A Hard Real-Time ApplicationsatyanaryanakPas encore d'évaluation

- Car Parking DesignDocument6 pagesCar Parking Designcharler kinyuajPas encore d'évaluation

- WSI - Catalogue of O-Ring PDFDocument37 pagesWSI - Catalogue of O-Ring PDFyearetg100% (1)

- Fanii 2Document55 pagesFanii 2Remixer INDONESIAPas encore d'évaluation

- ALTS150-12P Datasheet1Document2 pagesALTS150-12P Datasheet1mamlovePas encore d'évaluation

- The 5 Pivotal Paragraphs in A PaperDocument1 pageThe 5 Pivotal Paragraphs in A PaperFer Rivas NietoPas encore d'évaluation

- Sustainable Development Precautionary PR 2Document12 pagesSustainable Development Precautionary PR 2PramodPas encore d'évaluation

- SAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitDocument61 pagesSAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitARPITA BISWASPas encore d'évaluation

- TransistorDocument3 pagesTransistorAndres Vejar Cerda0% (1)

- SIMPLE PlaybookDocument12 pagesSIMPLE PlaybookMatt LylesPas encore d'évaluation

- Career Orientation QuestionnaireDocument5 pagesCareer Orientation QuestionnaireApple May100% (1)

- Skirmishes Graham Harman PDFDocument383 pagesSkirmishes Graham Harman PDFparaiaPas encore d'évaluation

- Caroline G Babin: Undergraduate Degree at Louisiana State University in Baton Rouge, Louisiana - Currently EnrolledDocument2 pagesCaroline G Babin: Undergraduate Degree at Louisiana State University in Baton Rouge, Louisiana - Currently EnrolledCaroline BabinPas encore d'évaluation