Académique Documents

Professionnel Documents

Culture Documents

Wind Energy

Transféré par

jjeanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Wind Energy

Transféré par

jjeanDroits d'auteur :

Formats disponibles

we-energies.

com

Developing

and Constructing

Wind Energy

we-energies.com

W I N D E N E R G Y

Introduction

We Energies is undertaking several efforts

to generate more energy from renewable

resources. In May 2008, the Blue Sky

Green Field Wind Energy Center began

operating. The site is home to 88 wind

turbines in the towns of Marsheld and

Calumet in northeast Fond du Lac County.

Blue Sky Green Field is designed to

generate 145 megawatts of electricity,

and is capable of powering more than

36,000 residential homes.

We are currently pursuing additional wind

energy to meet customer demand and to

meet the state of Wisconsins Renewable

Portfolio Standard.

Our customers are demanding more

renewable energy through our Energy

for Tomorrow program, which allows

customers residential, commercial and

industrial to purchase all or a portion

of their energy from renewable sources.

Additionally, the states Renewable

Portfolio Standard requires Wisconsin

utilities to generate 10 percent of their

energy from renewable sources by 2015.

Currently, We Energies supply portfolio

includes approximately 3 percent from

renewable energy.

Throughout history, people have connected

with the wind. Wind power was used

to grind grain and pump water before

electrication of farming in the Midwest. In

the early 1970s, oil shortages created more

demand for alternative energy sources,

thus increasing the popularity of wind

turbines to generate electricity.

A wind turbine uses moving air to create

electricity. Steady winds turn the blades,

which drive a generator that produces

electricity. Electricity generated by utility-

scale wind turbines is sent to the electric

distribution network, where it replaces

electricity that would otherwise have been

generated by more traditional sources such

as coal, oil, nuclear and natural gas.

* The contents of this book are a representation of construction activities at our Blue Sky Green Field site.

Some aspects of construction may vary from one development to another. 2

we-energies.com

S I T E P R E P A R A T I O N

Clearing and building a gravel access road

One of the rst steps in the

construction process is site

clearing and building the

gravel access roads. Access

roads are constructed from

existing public roadways to

each turbine site to provide

access for equipment

necessary for construction,

and to facilitate access to the

turbine for ongoing operation

and maintenance. Temporary

access roads are constructed

within a corridor approximately

40 feet wide.

3

we-energies.com

S I T E P R E P A R A T I O N

Clearing and building a gravel access road

Before gravel is installed topsoil is

stockpiled, subsoil is compacted,

and a geotextile matting is placed.

Upon completion of construction,

temporary access roads are con-

verted to smaller, permanent roads

approximately 16 feet wide. The

portion being removed is cleared

of gravel and fabric, decompacted,

and topsoil restored.

4

we-energies.com

S I T E P R E P A R A T I O N

Installing a culvert for drainage

A culvert can range in

length from 150 175 feet.

This is necessary for the

large component deliveries.

5

we-energies.com

S I T E P R E P A R A T I O N

Access road completed for construction

The width of the gravel road is

approximately 16 feet for the

primary travel path, but may be

up to 40 feet wide during the

construction phase to allow for the

large cranes needed for turbine

erection. All access roads are

restored to the 16 foot width after

construction is completed.

6

we-energies.com

Constructing a crane path

S I T E P R E P A R A T I O N

To erect the turbine, two different

cranes are needed. A smaller crane

is used to install the turbines control

system and base and lower mid-

tower sections. It is also used to

assemble the rotor. A larger crane is

used to install the upper mid-tower

and top-tower sections, nacelle

and rotor. Due to the size, weight

and slow speed of this large crane,

it cannot drive along public roads;

therefore, it is necessary to create

cross-country paths. The path used

is determined by several factors

including looking for the shortest

distance between turbines, use of

land already participating in the

project, signicant changes in grade,

and avoiding woodlands, wetlands

and waterways.

7

we-energies.com

A completed crane path

S I T E P R E P A R A T I O N

Topsoil is cleared and

stockpiled, and the subsoils

are compacted. The crane

path area is restored once

the turbines are standing.

Landowners are compensated

for lost crop opportunities in the

area used for the crane path.

8

we-energies.com

Collection system circuit example

C O L L E C T O R S Y S T E M

The collector system is a series of

underground electric cables that run

from each turbine to the electrical

substation. Typically, a series of

turbines will be interconnected to

create a circuit rather than having

a direct cable from each turbine

to the substation. At our Blue Sky

Green Field wind farm there

are a total of eight circuits.

This is a drawing of a circuit

that connects 11 turbines and

sends the electrical output to the

substation via one underground

cable system.

9

we-energies.com

C O L L E C T O R S Y S T E M

Installing cable for the collector system

In this photo, there is a single

circuit being installed in a two-

foot-wide trench. When multiple

circuits are installed in adjacent

trenches, there must be a ve-

foot-wide separation between

each circuit. The minimum

buried depth is four feet.

10

we-energies.com

F O U N D A T I O N S

Removing and stockpiling soils

The rst steps in constructing

the foundation is to remove and

stockpile topsoil and subsoils.

These soils are stockpiled

separately. Upon completion of

foundation construction, the soils

are replaced in the proper strata.

11

we-energies.com

F O U N D A T I O N S

Construction of the turbine foundation

Foundations are constructed

by excavating a hole,

placing reinforcing steel

and pouring approximately

325 yards of concrete into the

excavation. Each foundation

is approximately 55 feet wide

and 8 feet deep in the center.

12

we-energies.com

F O U N D A T I O N S

Backlled foundation

Topsoil and subsoil

from the excavation is

stockpiled in a semicircle

around the foundation.

The next step is to replace

the subsoil and then the

topsoil over the concrete

foundation. Only the very

center of the foundation

remains above the soil

surface when grading is

complete.

13

we-energies.com

F O U N D A T I O N S

Completed foundation base

A backlled foundation prior

to topsoil replacement and

crane pad installation.

14

we-energies.com

Crane pads

F O U N D A T I O N S

After the foundation construction is

complete and the area backlled, a crane

pad is constructed to allow for turbine

erection. The area is approximately 55 x 80

feet and will remain after construction for

routine maintenance activities.

crane pad area

15

Rotor

Nacelle

Foundation

Tower

Rotor Radius

134 feet

Tip Height

397 feet

Hub Height

262 feet

Drive Train

Main Shaft

Blade

Nose Cone

Nacelle

Tower

Gears

Anemometer

Cable carrying electricity

to substation and

transmission towers

Generator

we-energies.com

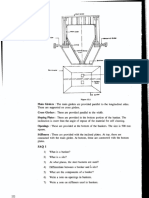

Turbine components

T U R B I N E C O N S T R U C T I O N

There are four main parts of

a wind turbine: the foundation

(base), the tower, the nacelle,

and the rotor (hub and blades

assembly). The rotor converts

the energy of the wind into

rotational motion. The nacelle

contains the electric generator

and other components that

convert the mechanical rotation

of the rotor into electricity. The

tower supports the nacelle and

rotor, and the foundation acts

as an anchor that supports the

entire assembly.

16

we-energies.com

T U R B I N E C O N S T R U C T I O N

Transporting the tower sections

For the Blue Sky Green Field

site, the tower sections were

off-loaded at the Port of Green Bay

and transported by truck to the

site. Each truck transported one

tower section - approximately

74 feet long.

17

we-energies.com

T U R B I N E C O N S T R U C T I O N

Erecting the tower

The rst components

delivered and erected are

the base and mid-section of

the tower. When completed,

each turbine consists of four

tower sections.

18

we-energies.com

T U R B I N E C O N S T R U C T I O N

Setting the base-section on the turbine foundation

It takes approximately

seven hours to set the

rst two tower sections.

Power

Module

19

we-energies.com

T U R B I N E C O N S T R U C T I O N

Base and mid-section of the tower

The base and mid-section, as

seen here, stand approximately

105 feet. The total height of the

turbines at Blue Sky Green Field

from the base to the tip of the

blade is 397 feet.

20

we-energies.com

Looking up inside a turbine

21

we-energies.com

T U R B I N E C O N S T R U C T I O N

Nacelle

The nacelle is the

enclosure at the top of

the tower that contains

the drive shaft, gearbox,

generator, electronic

controls and associated

equipment. The nacelle is

reached by a ladder that

runs inside the tower so

technicians can access

the turbine components for

maintenance and repair.

22

we-energies.com

Inside the nacelle

23

we-energies.com

Yaw deck inside the nacelle

The yaw deck allows

the rotor and nacelle to

align with the wind.

24

we-energies.com

Yaw deck inside the nacelle

The yaw deck is able

to turn three complete

revolutions before

locking to ensure the

cables are not twisted. It

will then reset itself.

25

we-energies.com

T U R B I N E C O N S T R U C T I O N

Turbine hub

The blades are connected

to a central cone called the

hub, which is connected to

a shaft that passes into the

nacelle.

26

we-energies.com

T U R B I N E C O N S T R U C T I O N

Turbine blades

Turbine blades have

aerodynamic wings that

create lift and rotation of

the rotor as the wind blows

across them. Each turbine

blade at Blue Sky Green

Field measures 134 feet.

The rotor assembly weighs

approximately 47 tons.

27

we-energies.com

T U R B I N E C O N S T R U C T I O N

Flying the blade assembly

28

we-energies.com

S I T E R E S T O R A T I O N

Restored site after construction

29

we-energies.com

S I T E R E S T O R A T I O N

Restored site after construction

The area around the turbine is

returned to the landowner for

planting. We ask that a distance

of 15 feet be maintained from the

foundation of the towers to protect

the equipment. Directly under this

area, only 18-24 inches below

the surface, are the concrete

foundations and grounding cables

for the turbines. For safety, gravel is

placed in this area as a reminder of

the underground infrastructure.

30

we-energies.com

Blue Sky Green Field Wind Energy Center

31

we-energies.com

2K8259-JN-IN

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Slash ChordsDocument1 pageSlash Chordsjjean100% (2)

- Legato PlayingDocument3 pagesLegato Playingjjean100% (2)

- Apache Maven BookDocument342 pagesApache Maven BookAbhi SharmaPas encore d'évaluation

- A History of Fingerprints: InterpolDocument19 pagesA History of Fingerprints: InterpoljjeanPas encore d'évaluation

- Improvising With SUS StructuresDocument3 pagesImprovising With SUS Structuresjjean100% (2)

- Legato Playing - Step by Step Technique Vol. IIIDocument4 pagesLegato Playing - Step by Step Technique Vol. IIIjjeanPas encore d'évaluation

- Jazz Comping 3Document4 pagesJazz Comping 3jjean100% (2)

- Jazz Comping 2Document3 pagesJazz Comping 2jjean100% (4)

- Comping With FourthsDocument4 pagesComping With FourthsjjeanPas encore d'évaluation

- Jazz Comping 1Document3 pagesJazz Comping 1jjean80% (5)

- Blues Guitar Lesson - Blues Note RiffsDocument2 pagesBlues Guitar Lesson - Blues Note Riffsjjean100% (2)

- Jazz Guitar Lesson - BB Mixolydian LicksDocument2 pagesJazz Guitar Lesson - BB Mixolydian Licksjjean100% (2)

- Blues Guitar Lesson - F BLues LicksDocument2 pagesBlues Guitar Lesson - F BLues LicksjjeanPas encore d'évaluation

- Jazz Guitar Lesson - F Melodic Minor ScaleDocument1 pageJazz Guitar Lesson - F Melodic Minor Scalejjean100% (1)

- Jazz Guitar Lesson - E Dorian ModeDocument1 pageJazz Guitar Lesson - E Dorian ModejjeanPas encore d'évaluation

- Blues Guitar Lesson - G Shuffle LicksDocument3 pagesBlues Guitar Lesson - G Shuffle Licksjjean100% (4)

- Jazz Guitar Lesson - BB Mixolydian LicksDocument2 pagesJazz Guitar Lesson - BB Mixolydian Licksjjean100% (2)

- Jazz Guitar Lesson - 2-5-1 in C ChordsDocument1 pageJazz Guitar Lesson - 2-5-1 in C Chordsjjean100% (1)

- Jazz Guitar Lesson - 2-5-1 Licks in AbDocument1 pageJazz Guitar Lesson - 2-5-1 Licks in Abjjean100% (2)

- Country Guitar Lesson - Intro To Cross Stringing ScalesDocument2 pagesCountry Guitar Lesson - Intro To Cross Stringing Scalesjjean100% (2)

- Country Guitar Lesson - Snapping and PoppingDocument2 pagesCountry Guitar Lesson - Snapping and Poppingjjean100% (1)

- Country Guitar Lesson - Intro To Chicken PickingDocument3 pagesCountry Guitar Lesson - Intro To Chicken Pickingjjean100% (2)

- Country Guitar Lesson - Chromatic Cross Stringing ScalesDocument1 pageCountry Guitar Lesson - Chromatic Cross Stringing Scalesjjean100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Paediatric Intake Form Modern OT 2018Document6 pagesPaediatric Intake Form Modern OT 2018SefPas encore d'évaluation

- Main Girders: CrossDocument3 pagesMain Girders: Crossmn4webPas encore d'évaluation

- Assignment 1Document3 pagesAssignment 1farhang_tPas encore d'évaluation

- Sustainable Events Guide May 30 2012 FINAL PDFDocument118 pagesSustainable Events Guide May 30 2012 FINAL PDFInter 4DMPas encore d'évaluation

- Worlds Apart: A Story of Three Possible Warmer WorldsDocument1 pageWorlds Apart: A Story of Three Possible Warmer WorldsJuan Jose SossaPas encore d'évaluation

- IV. Network Modeling, Simple SystemDocument16 pagesIV. Network Modeling, Simple SystemJaya BayuPas encore d'évaluation

- Board Replacement CasesDocument41 pagesBoard Replacement CasesNadeeshPas encore d'évaluation

- Structural Analysis and Design of Pressure Hulls - The State of The Art and Future TrendsDocument118 pagesStructural Analysis and Design of Pressure Hulls - The State of The Art and Future TrendsRISHABH JAMBHULKARPas encore d'évaluation

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocument3 pagesDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoPas encore d'évaluation

- Emw 2007 FP 02093Document390 pagesEmw 2007 FP 02093boj87Pas encore d'évaluation

- Kinematics in One DimensionDocument4 pagesKinematics in One DimensionAldrin VillanuevaPas encore d'évaluation

- Twilight PrincessDocument49 pagesTwilight PrincessHikari DiegoPas encore d'évaluation

- Ficha Tecnica-Skyjack SJ3219 8mtDocument2 pagesFicha Tecnica-Skyjack SJ3219 8mtLESLY MILENA MORENO CORALPas encore d'évaluation

- Comparing Exponential NumbersDocument5 pagesComparing Exponential NumbersMaya RahayuPas encore d'évaluation

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcPas encore d'évaluation

- Kindergarten Math Problem of The Day December ActivityDocument5 pagesKindergarten Math Problem of The Day December ActivityiammikemillsPas encore d'évaluation

- Extract From The Painted Door' by Sinclair RossDocument2 pagesExtract From The Painted Door' by Sinclair RosssajifisaPas encore d'évaluation

- Tree Growth CharacteristicsDocument9 pagesTree Growth CharacteristicsMunganPas encore d'évaluation

- Scott 2001Document20 pagesScott 2001Mariana CatiniPas encore d'évaluation

- Ensemble Averaging (Machine Learning)Document3 pagesEnsemble Averaging (Machine Learning)emma698Pas encore d'évaluation

- HCPL 316J 000eDocument34 pagesHCPL 316J 000eElyes MbarekPas encore d'évaluation

- CBSE DetailsDocument6 pagesCBSE DetailsNARESH KUMARPas encore d'évaluation

- Updated Factory Profile of Aleya Apparels LTDDocument25 pagesUpdated Factory Profile of Aleya Apparels LTDJahangir Hosen0% (1)

- User'S Guide: Tm4C Series Tm4C129E Crypto Connected Launchpad Evaluation KitDocument36 pagesUser'S Guide: Tm4C Series Tm4C129E Crypto Connected Launchpad Evaluation KitLương Văn HưởngPas encore d'évaluation

- Straight LineDocument15 pagesStraight LineAyanPas encore d'évaluation

- Hopeless PlacesDocument1 304 pagesHopeless Placesmoreblessingmarvellous659Pas encore d'évaluation

- Worksheet Series 5: Answer Any 3 Questions From 1 To 6. (2 Score Each)Document6 pagesWorksheet Series 5: Answer Any 3 Questions From 1 To 6. (2 Score Each)AswithPas encore d'évaluation

- Liver: Anatomy & FunctionsDocument18 pagesLiver: Anatomy & FunctionsDR NARENDRAPas encore d'évaluation

- Socialized HousingDocument48 pagesSocialized HousingJessieReiVicedoPas encore d'évaluation

- Solutions GoldsteinDocument10 pagesSolutions GoldsteinAnyiPas encore d'évaluation